Page 1

Instruction

Harmony Series

Bridge Controller and Processor Bus Adapter

BRC-100 and PBA-100

Page 2

Preface

The BRC-100 Harmony Bridge Controller is a high-performance, high-capacity process controller. It is a rack controller

designed to interface with both Harmony I/O blocks and Harmony rack I/O in the Symphony Enterprise Management and

Control System. The Harmony bridge controller is fully compatible with the INFI 90

munication and packaging. The Harmony bridge controller

collects process I/O, performs control algorithms and outputs

control signals to process level devices. It also imports and

exports process data of other controllers and system nodes,

and accepts control commands from operators and computers

connected to the network.

This instruction provides information about how the Harmony

bridge controller works, and how to install, configure, operate

and troubleshoot the module.

®

OPEN system in functionality, com-

The Harmony bridge controller is designed for redundancy.

This can be achieved while remaining connected to the Hnet, or

without, using an optional BRC redundancy kit.

WBPEEUI230017B1

Page 3

List of Effective Pages

Total number of pages in this instruction is 99, consisting of the following:

Page No. Change Date

Preface 04 December 2000

List of Effective Pages 04 December 2000

iii through x 04 December 2000

1-1 through 1-8 04 December 2000

2-1 through 2-8 04 December 2000

3-1 through 3-19 04 December 2000

4-1 through 4-5 04 December 2000

5-1 through 5-23 04 December 2000

6-1 through 6-4 04 December 2000

7-1 through 7-3 Original

8-1 04 December 2000

A-1 through A-8 Original

B-1 through B-7 04 December 2000

Index-1 through Index-3 04 December 2000

When an update is received, insert the latest changed pages and dispose of the superseded

pages.

NOTE: Changed text or tables are indicated by a vertical bar adjacent to the changed area. Changed figures are indicated by a vertical bar next to the figure caption. The date appears beside the page number.

WBPEEUI230017B1

Page 4

Table of Contents

Section 1 Introduction ..................................................................................................1-1

Overview .................................................................................................................. 1-1

Intended User .......................................................................................................... 1-2

Hardware Description .............................................................................................. 1-2

Faceplate ............................................................................................................. 1-3

Circuit Board ....................................................................................................... 1-3

Hardware Application............................................................................................... 1-3

Features .................................................................................................................. 1-3

Instruction Content.................................................................................................. 1-4

How to Use this Instruction...................................................................................... 1-4

Glossary of Terms and Abbreviations........................................................................ 1-5

Reference Documents............................................................................................... 1-6

Related Nomenclatures ............................................................................................ 1-6

Specifications........................................................................................................... 1-6

Section 2 Description and Operation .........................................................................2-1

Introduction............................................................................................................. 2-1

Operation................................................................................................................. 2-1

Circuitry .................................................................................................................. 2-2

Microprocessor..................................................................................................... 2-2

Clock and Real-Time Clock ................................................................................... 2-2

Memory................................................................................................................ 2-2

Direct Memory Access .......................................................................................... 2-3

Controlway........................................................................................................... 2-4

Redundancy Link ................................................................................................. 2-4

Hnet Communication ........................................................................................... 2-5

I/O Expander Bus ................................................................................................ 2-5

I/O Section .......................................................................................................... 2-6

Serial Channels.................................................................................................... 2-6

Station Link ......................................................................................................... 2-6

Power................................................................................................................... 2-7

Section 3 Installation ....................................................................................................3-1

Introduction............................................................................................................. 3-1

Special Handling ...................................................................................................... 3-2

Unpacking and Inspection........................................................................................ 3-2

Dipswitches and Jumpers ........................................................................................ 3-3

Dipswitch SW5 - Module Address ......................................................................... 3-4

Dipswitch SW2 - Normal Operating Options.......................................................... 3-5

Dipswitch SW2 - Special Operations ..................................................................... 3-5

Dipswitch SW3 - Module Options ......................................................................... 3-8

WBPEEUI230017B1 iii

Page 5

Table of Contents (continued)

Section 3 Installation (continued) ..........................................................................................

Dipswitch SW4 - Module Options ..........................................................................3-8

Jumpers ...............................................................................................................3-8

Module Mounting Unit Preparation ...........................................................................3-9

Module Slot Assignments ......................................................................................3-9

Dipshunts ..........................................................................................................3-10

Controlway Cable................................................................................................3-10

PBA Board Installation........................................................................................3-11

Mounting Bracket ...........................................................................................3-11

Cable and Terminator .....................................................................................3-12

Mounting ........................................................................................................3-13

BRC Redundancy Kit Installation ........................................................................3-16

Module Installation.................................................................................................3-18

Pre-Installation Check ........................................................................................3-18

Installation .........................................................................................................3-19

Section 4 Operating Procedures .................................................................................4-1

Introduction .............................................................................................................4-1

Startup.....................................................................................................................4-1

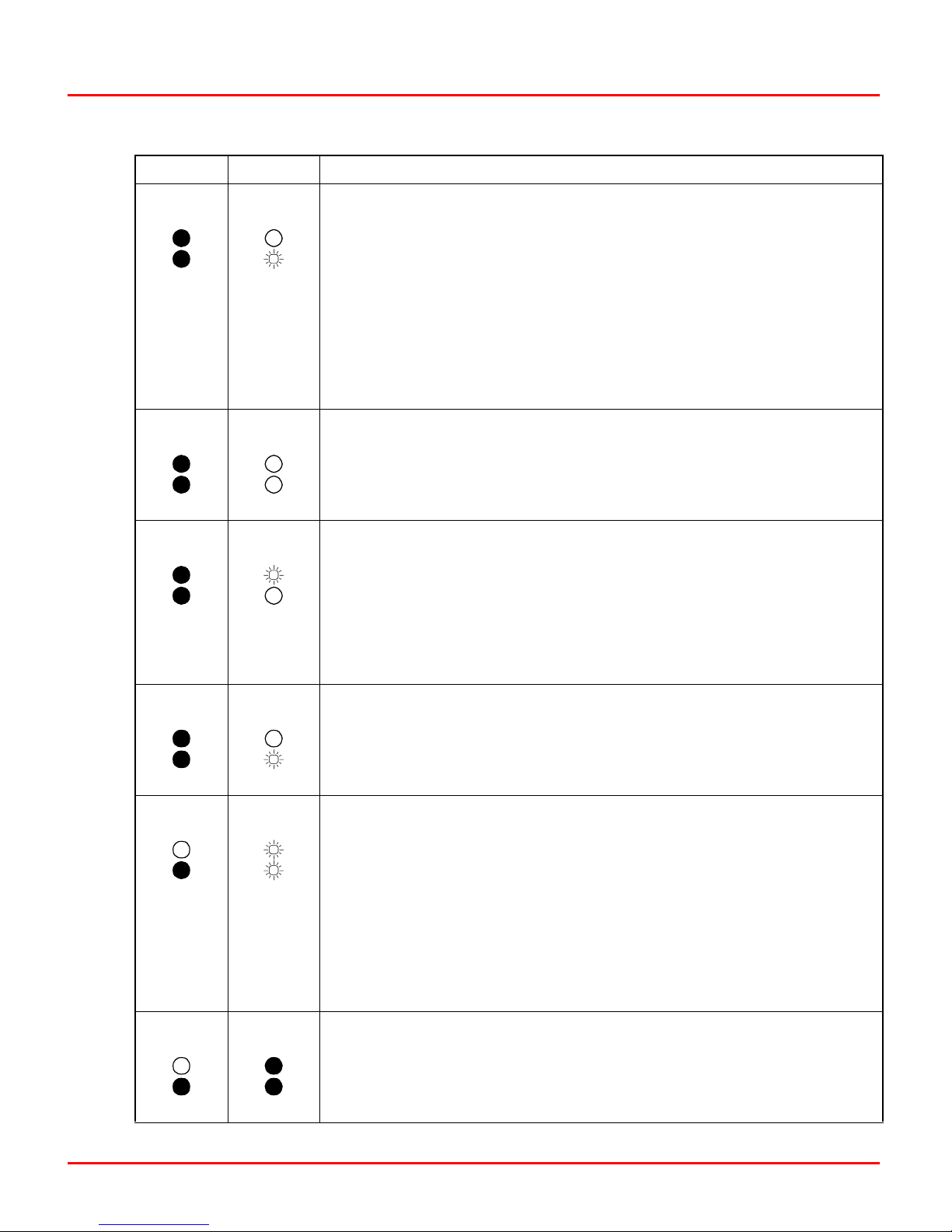

Module LEDs ............................................................................................................4-2

Front Panel LEDs..................................................................................................4-2

Red/Green Status LED .........................................................................................4-3

Stop/Reset Switch ....................................................................................................4-3

Modes of Operation...................................................................................................4-4

Section 5 Troubleshooting ..........................................................................................5-1

Introduction .............................................................................................................5-1

Error Codes ..............................................................................................................5-1

Flowcharts ...............................................................................................................5-5

Diagnostics ..............................................................................................................5-5

Overview...............................................................................................................5-5

Diagnostic Test Selection ......................................................................................5-8

LED Display .......................................................................................................5-11

Module Status Summary ........................................................................................5-12

Card Edge Connectors ............................................................................................5-17

Section 6 Maintenance .................................................................................................6-1

Introduction .............................................................................................................6-1

Preventive Maintenance Schedule .............................................................................6-1

Equipment and Tools Required .................................................................................6-1

Preventive Maintenance Procedures ..........................................................................6-2

iv WBPEEUI230017B1

Page 6

Table of Contents (continued)

Section 6 Maintenance (continued) .......................................................................................

Printed Circuit Board Cleaning ............................................................................. 6-2

General Cleaning and Washing ......................................................................... 6-3

Edge Connector Cleaning.................................................................................. 6-3

Checking Connections .......................................................................................... 6-4

Section 7 Repair and Replacement .............................................................................7-1

Introduction............................................................................................................. 7-1

Module Replacement ................................................................................................ 7-1

PBA Board Replacement........................................................................................... 7-2

Section 8 Replacement and Spare Parts ....................................................................8-1

Parts........................................................................................................................ 8-1

Appendix A Online Configuration ..............................................................................A-1

Introduction.............................................................................................................A-1

Setup.......................................................................................................................A-1

Operation.................................................................................................................A-2

Backup Cycle ....................................................................................................... A-3

Primary Cycle.......................................................................................................A-6

Appendix B NTMP01 Termination Unit ...................................................................... B-1

Description ..............................................................................................................B-1

List of Figures

No. Title Page

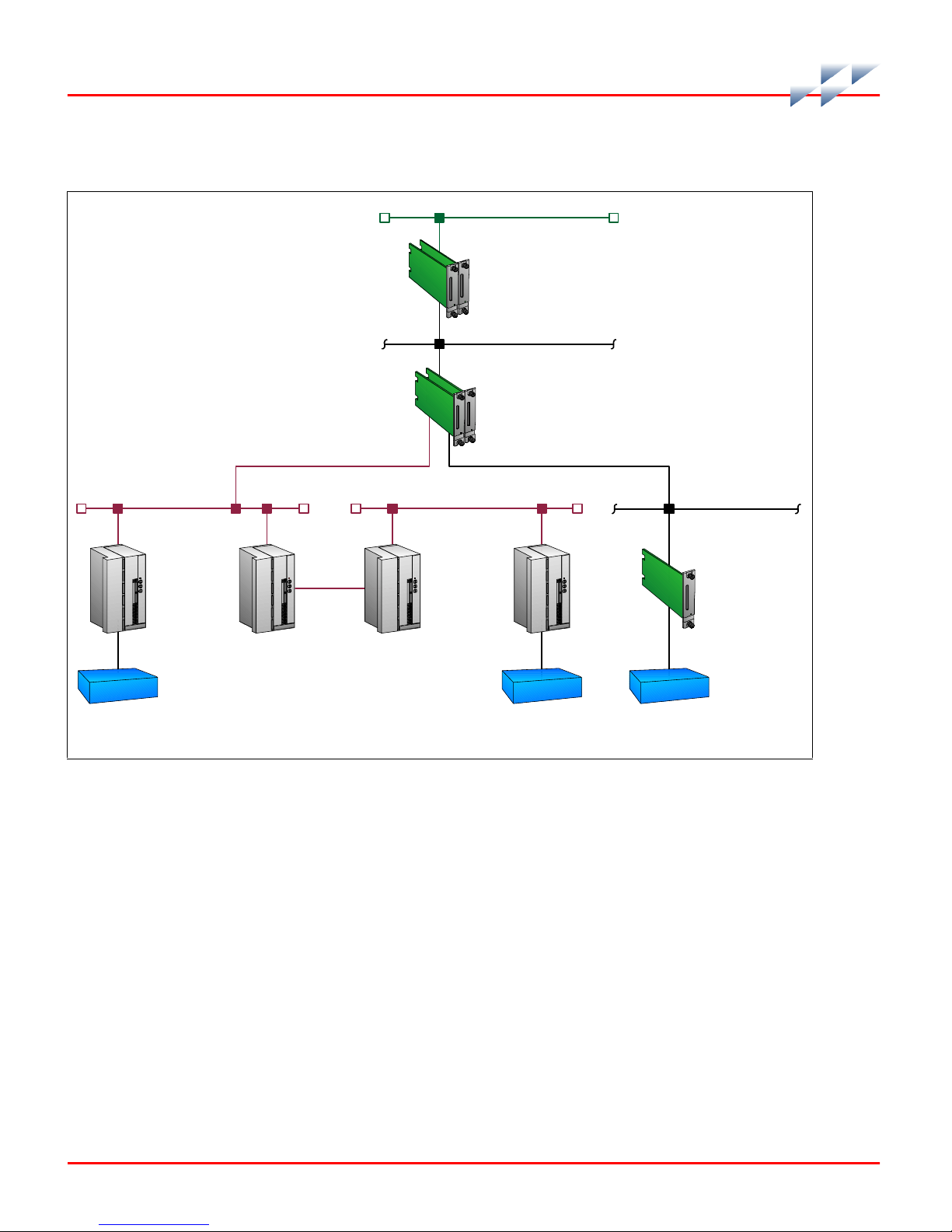

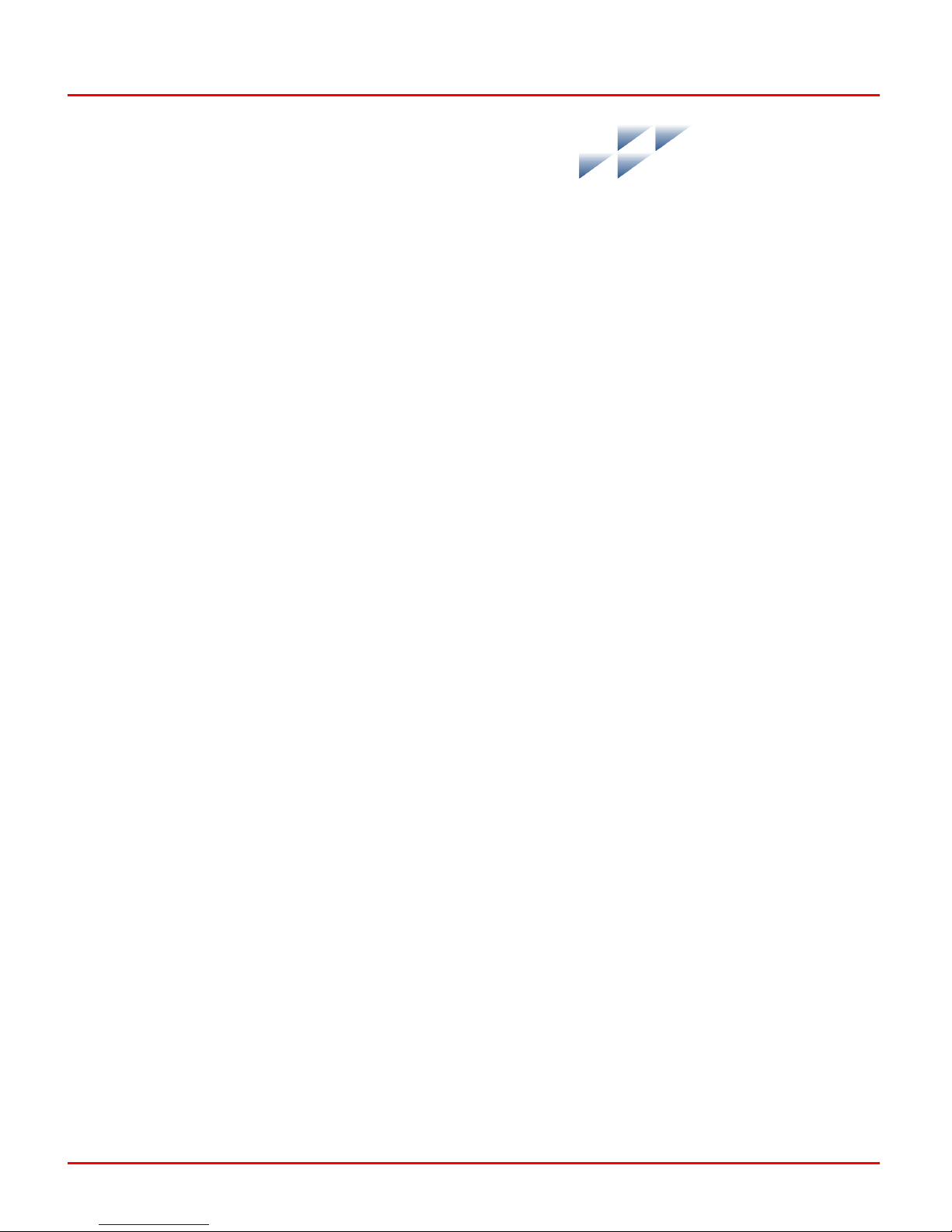

1-1. Harmony Bridge Controller Architecture.................................................... 1-2

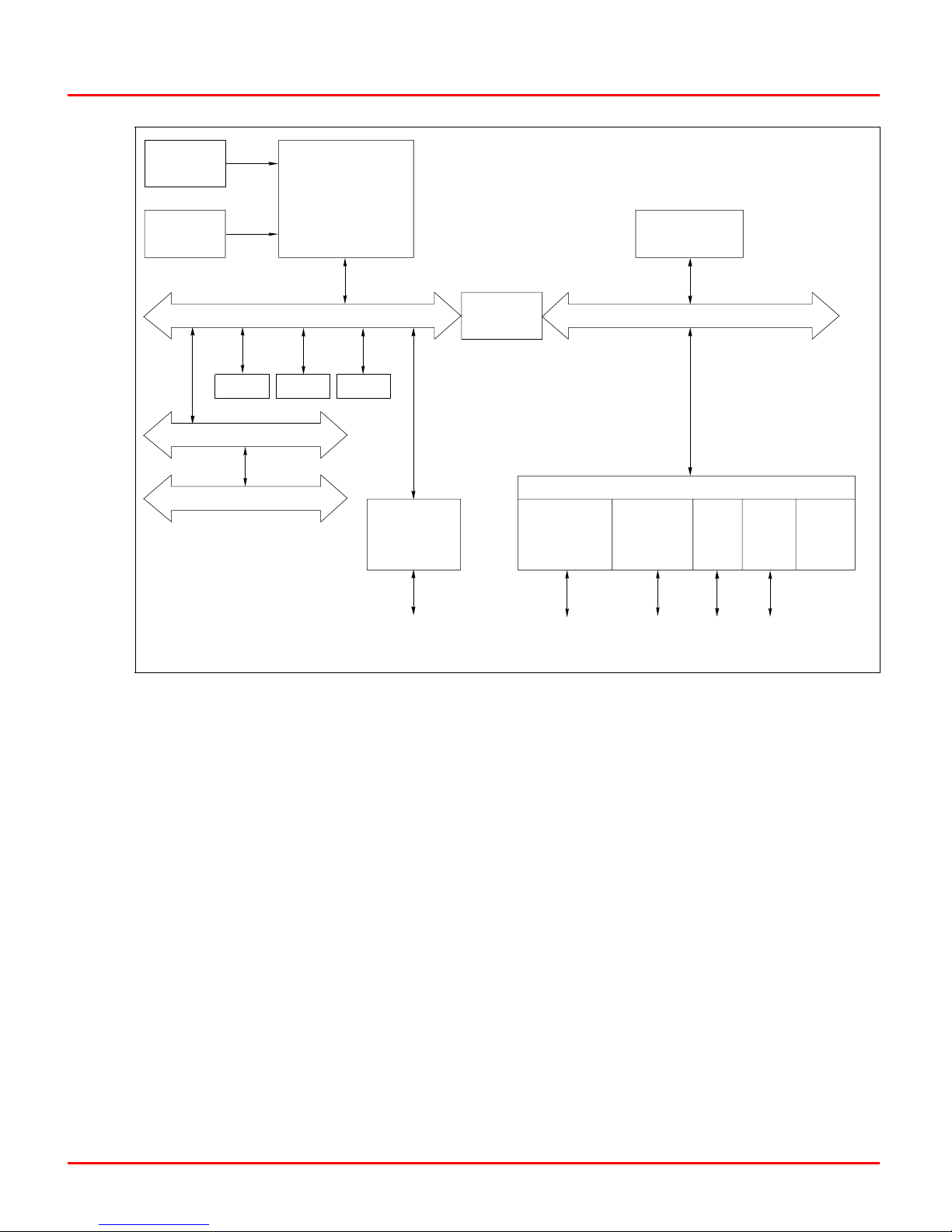

2-1. Functional Block Diagram ......................................................................... 2-3

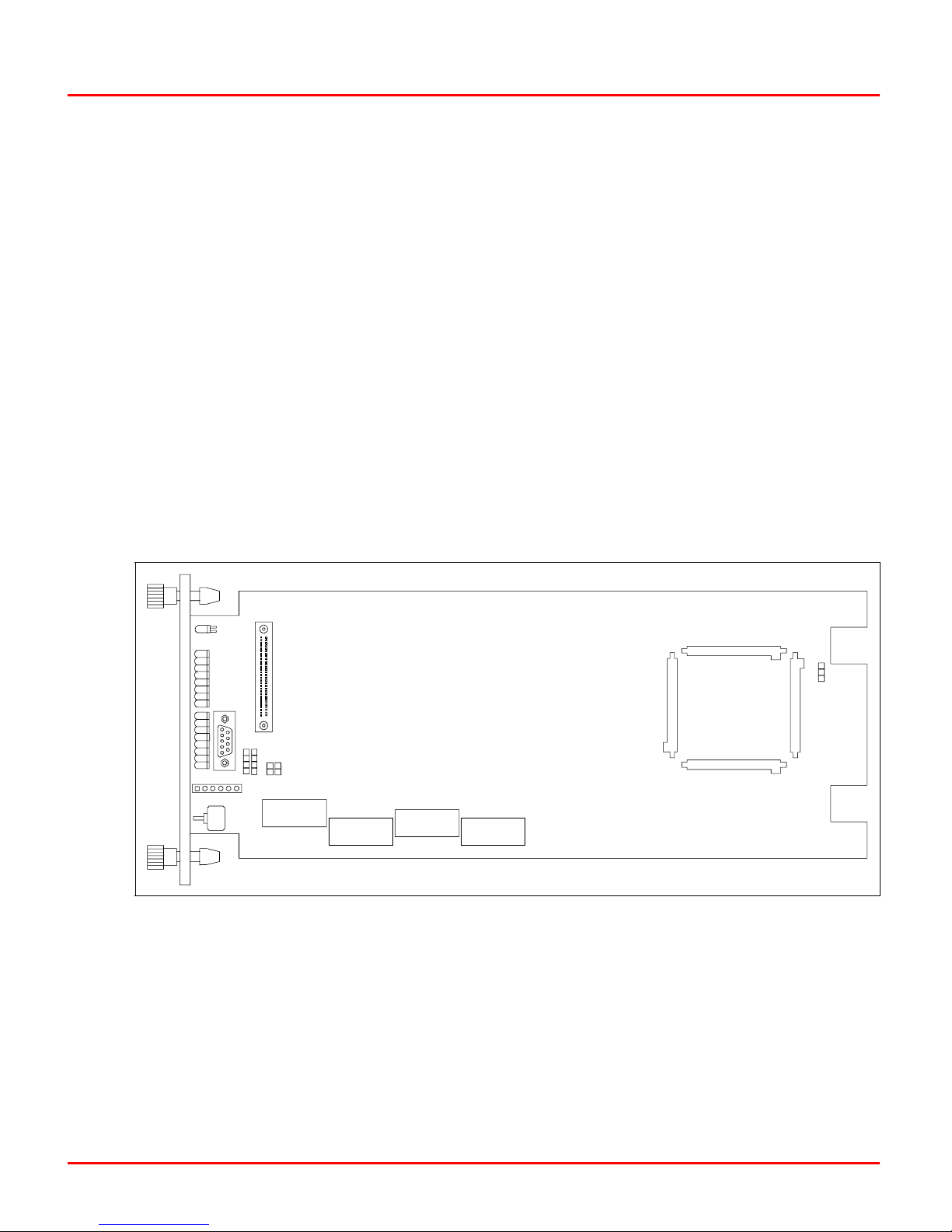

3-1. BRC Module Layout ................................................................................. 3-3

3-2. Controlway Cable Installation ................................................................. 3-11

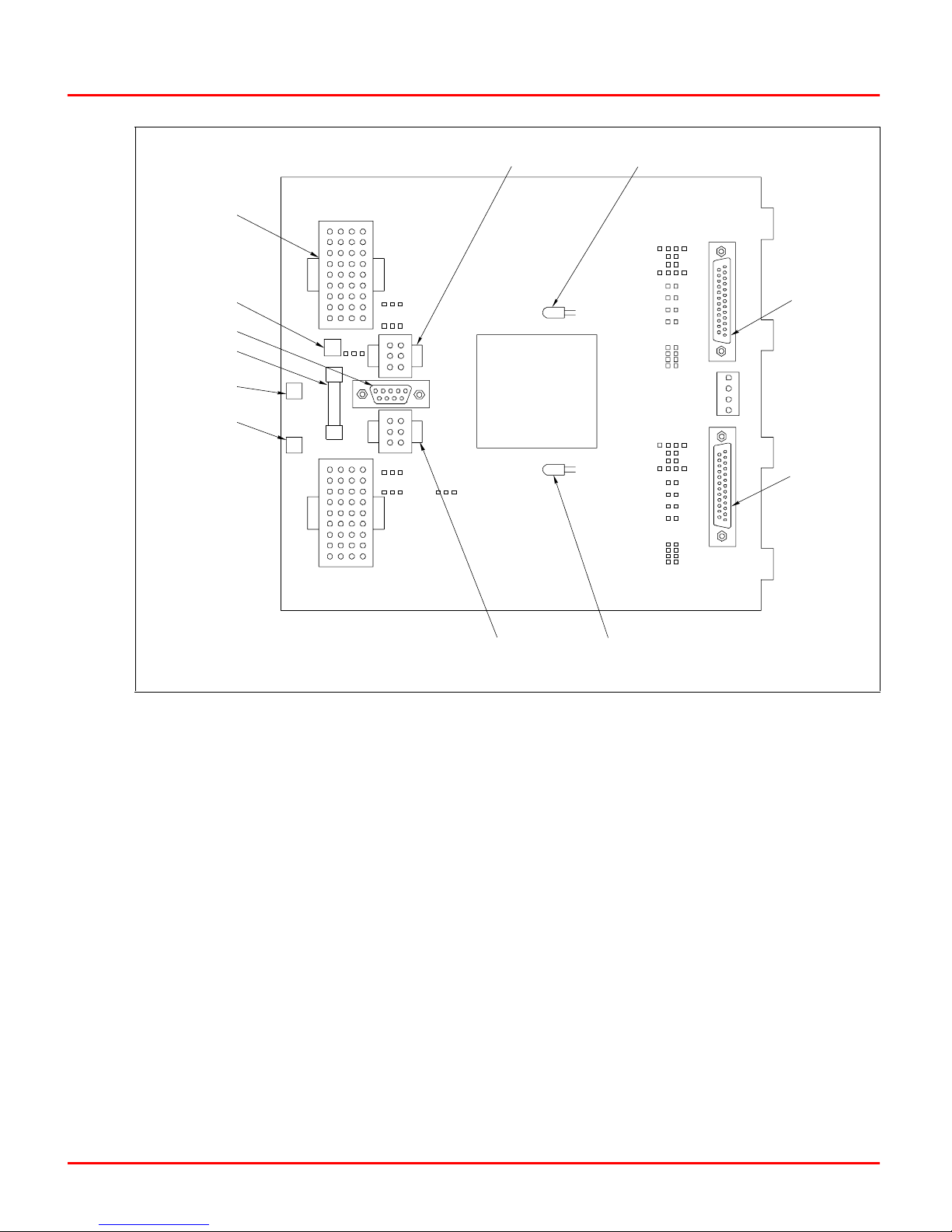

3-3. PBA Installation ...................................................................................... 3-14

3-4. PBA Connector Identification................................................................... 3-15

3-5. BRC Redundancy Kit Installation ............................................................ 3-17

3-6. Hood Connector Assembly Connector Identification ................................. 3-18

4-1. Front Panel ............................................................................................... 4-2

WBPEEUI230017B1 v

Page 7

List of Figures (continued)

No. Title Page

5-1. Troubleshooting Flowchart (Serial Port) .....................................................5-6

5-2. Troubleshooting Flowchart (Status LED) ....................................................5-7

5-3. LEDs - Pass/Fail .....................................................................................5-12

A-1. Backup Cycle ........................................................................................... A-6

A-2. Primary Cycle ........................................................................................... A-8

B-1. DTE Jumper Configuration (NTMP01) ....................................................... B-2

B-2. DCE Jumper Configuration (NTMP01)....................................................... B-2

B-3. Nonhandshake Jumper Configuration (NTMP01)....................................... B-3

B-4. Loopback Jumper Configuration (NTMP01) ............................................... B-3

B-5. Jumpers J3 through J10 Configuration (NTMP01) .................................... B-4

B-6. NTMP01 Board Layout.............................................................................. B-5

B-7. NTMP01 Cable Connections (Redundant BRC Modules/PBA Boards) ........ B-6

B-8. Cable Connections (Redundant BRC Modules Using BRC Redundancy Kit) B-7

List of Tables

No. Title Page

1-1. Glossary of Terms and Abbreviations .........................................................1-5

1-2. Reference Documents ................................................................................1-6

1-3. Related Nomenclatures ..............................................................................1-6

1-4. Specifications ............................................................................................1-7

3-1. Dipswitch SW5 Settings (Operation)...........................................................3-4

3-2. Dipswitch SW5 Settings (Address)..............................................................3-5

3-3. Dipswitch SW2 Settings (Operating Options) ..............................................3-6

3-4. Dipswitch SW2 Settings (Special Operations) .............................................3-7

3-5. Dipswitch SW4 Settings (Module Options)..................................................3-8

3-6. Jumpers Settings (J1 through J4) ..............................................................3-9

5-1. Error Codes ...............................................................................................5-1

5-2. Status LED and Other Conditions..............................................................5-4

5-3. DSO and BRC Setup for I/O Expander Bus Test ........................................5-8

5-4. Diagnostic Dipswitch Settings....................................................................5-8

5-5. Diagnostic Tests ........................................................................................5-9

5-6. Status Report ..........................................................................................5-13

5-7. Status Report Field Descriptions..............................................................5-13

5-8. P1 Pin Assignments (BRC) .......................................................................5-17

5-9. P2 Pin Assignments (BRC) .......................................................................5-18

5-10. P3 Pin Assignments (BRC)1,2 ..................................................................5-18

5-11. P4 Pin Assignments (BRC) .......................................................................5-19

5-12. P1 Pin Assignments (PBA) ........................................................................5-19

vi WBPEEUI230017B1

Page 8

List of Tables (continued)

No. Title Page

5-13. P3 Pin Assignments (PBA) ....................................................................... 5-20

5-14. P4 Pin Assignments (PBA) ....................................................................... 5-20

5-15. P5 Pin Assignments (PBA) ....................................................................... 5-21

5-16. P5 Pin Assignments (Hood Connection Assembly) .................................... 5-22

6-1. Preventive Maintenance Schedule.............................................................. 6-2

8-1. Miscellaneous Nomenclatures ................................................................... 8-1

8-2. Cable Nomenclatures ................................................................................ 8-1

8-3. Miscellaneous Parts .................................................................................. 8-1

A-1. Legend of Symbols ....................................................................................A-3

A-2. Backup Cycle ............................................................................................ A-3

A-3. Primary Cycle............................................................................................A-7

WBPEEUI230017B1 vii

Page 9

Safety Summary

GENERAL

WARNINGS

SPECIFIC

WARNINGS

Equipment Environment

All components, whether in transportation, operation or storage,

must be in a noncorrosive environment.

Electrical Shock Hazard During Maintenance

Disconnect power or take precautions to insure that contact with

energized parts is avoided when servicing.

Special Handling

This module uses electrostatic sensitive devices.

Disconnect power before installing dipshunts on the module mounting unit backplane. Failure to do so will result in contact with cabinet

areas that could cause severe or fatal shock. (p. 3-9)

Disconnect power before installing the processor bus adapter

mounting bracket on the module mounting unit backplane. Failure to

do so will result in contact with cabinet areas that could cause

severe or fatal shock. (p. 3-11)

Wear eye protection whenever working with cleaning solvents.

When removing solvents from printed circuit boards using compressed air, injury to the eyes could result from splashing solvent as

it is removed from the printed circuit board. (p. 6-1)

SPECIFIC

CAUTIONS

viii WBPEEUI230017B1

Never operate the BRC module with the machine fault timer circuit

disabled (jumper pins connected). Unpredictable module outputs

and configuration corruption may result. The unpredictable module

outputs may damage control equipment connected to the BRC

module.

To avoid potential module damage, evaluate your system for compatibility prior to module installation. This module uses connections

to the module mounting unit backplane that served other functions

in early Network 90 systems. (p. 3-16)

Page 10

Support Services

ABB will provide assistance in the operation and repair of its

products. Requests for sales or application services should be

made to your nearest sales or service office. ABB can also provide installation, repair and maintenance contract services.

When ordering parts, use nomenclature or part numbers and

part descriptions from equipment manuals. Parts without a

description must be ordered from the nearest sales or service

office. Recommended spare parts lists, including prices are

available though the nearest sales or service office.

ABB has modern training facilities available for training your

personnel. On-site training is also available. Contact your

nearest ABB sales office for specific information and scheduling.

Additional copies of this instruction, or other instructions, can

be obtained from the nearest ABB sales office at a reasonable

charge.

WBPEEUI230017B1 ix

Page 11

Trademarks and Registrations

Registrations and trademarks used in this document include:

® INFI 90 Registered trademark of ABB Process Automation.

® INFI-NET Registered trademark of ABB Process Automation.

® Network 90 Registered trademark of ABB Process Automation.

x WBPEEUI230017B1

Page 12

Introduction

Overview

Section 1

The BRC-100 Harmony Bridge Controller is a high-performance, high-capacity process controller. It is a rack controller

designed to interface with both Harmony I/O blocks and Harmony rack I/O in the Symphony Enterprise Management and

Control System. The Harmony bridge controller (BRC) is fully

compatible with the INFI 90 OPEN system in functionality,

communication, and packaging.

The Harmony bridge controller is a stand-alone controller that

can handle specific control and information processing applications in addition to multiple-loop analog, sequential, and

batch control. It has the power to execute demanding process

control applications that are data intensive, program intensive

or both. The Harmony bridge controller supports multiple control languages which include function codes, C, Basic,

Batch 90, and Ladder.

The Symphony system uses a variety of analog, control, and

digital I/O devices to interface with the process. Control input/

output is available from I/O blocks using the Harmony communication network (Hnet) or from Harmony rack I/O modules

using the I/O expander bus.

For added reliability, the BRC module has circuitry that supports redundancy. A backup BRC module waits in a standby

mode while the primary module executes. If the primary goes

offline for any reason, there is a bumpless transfer of control to

the backup module. A processor bus adapter (PBA) board is

required to support redundant BRC modules and redundant

Hnet buses. When no Hnet and termination unit connection is

needed, a BRC redundancy kit may be used to support redundant BRC modules.

IISAC01 Analog Control Stations can connect directly to the

BRC module via a PBA board and termination unit. The BRC

module also supports IISAC01 stations that are connected to a

Harmony control I/O block (CIO-100/110) on the Hnet bus or

a Harmony control I/O module (IMCIS12, IMQRS12) on the I/

O expander bus. The BRC module supports up to 128 SAC sta-

WBPEEUI230017B1 1 - 1

Page 13

Intended User

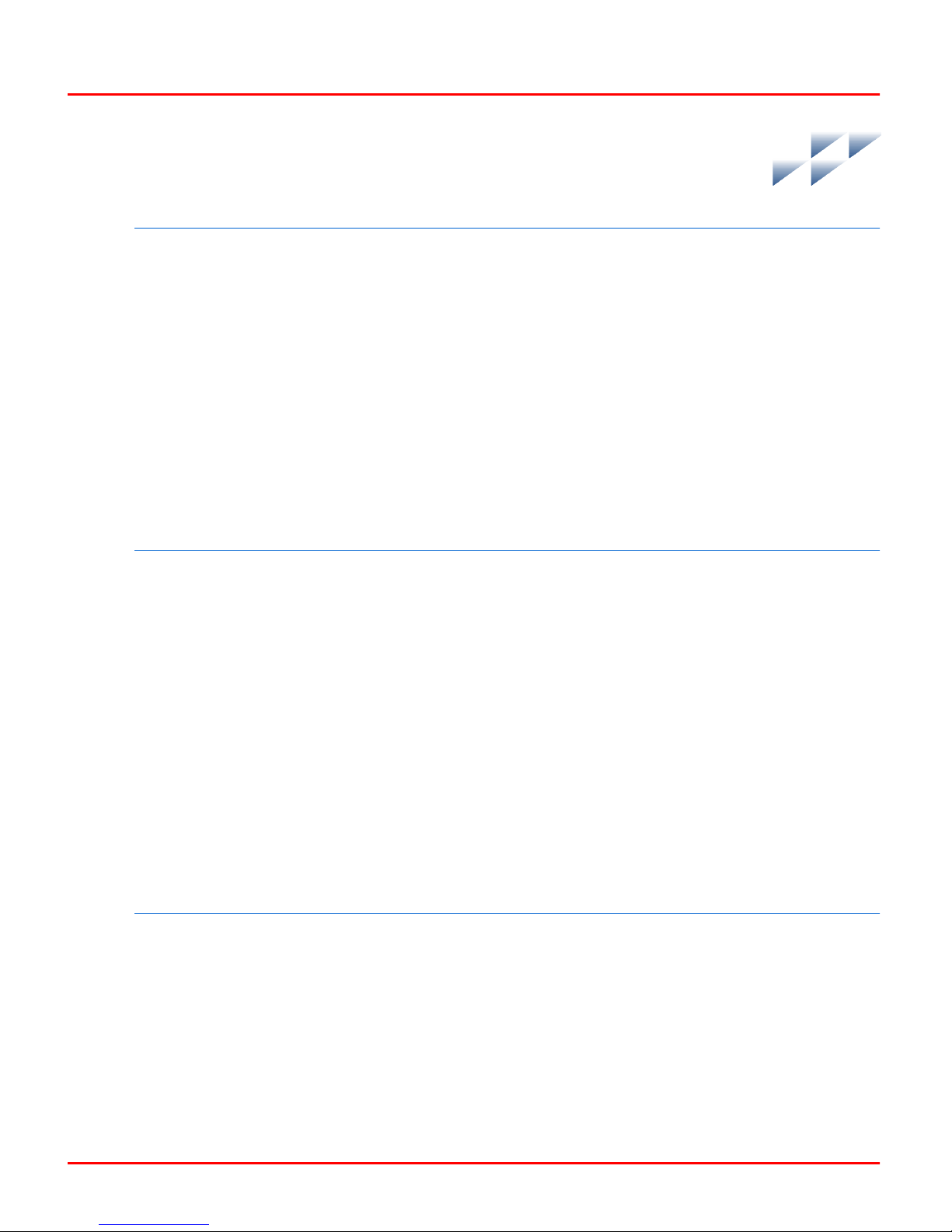

tions communication at a 40-kbaud rate. Figure 1-1 shows the

Harmony bridge controller architecture.

CNET

HARMONY RACK

COMMUNICATION

MODULES

CONTROLWAY

HARMO NY

BRIDGE

CONTROLLER

HNET

HARMONY

I/O BLOCKS

REPEATER

MOUNTING

UN IT (R M U )

HNET

RMU

Figure 1-1. Harmony Bridge Controller Architecture

Intended User

Personnel installing, operating or maintaining the BRC module

should read this instruction before performing any installation, operation, or maintenance procedures. Installation

requires an engineer or technician with experience handling

electronic circuitry. Formal training in Symphony system configuration (especially function codes) is helpful when configuring the BRC module.

HNET

HARMONY

I/O BLOCKS

REMOTE LOCATION

I/O EXPAN DER BUS

HARMONY RACK

I/O M O D U L E S

PROCESS I/OPROCESS I/O PROCESS I/O

T0246 7A

1 - 2 WBPEEUI230017B1

Page 14

Hardware Description

The Harmony bridge controller consists of a circuit board and

a faceplate.

Faceplate

The BRC faceplate measures 35.56-millimeters wide by

177.80-millimeters high (1.4-inches wide by 7.0-inches high).

Two latching screws, one at the top, the other at the bottom,

lock the module assembly in a module mounting unit (MMU). A

transparent window on the faceplate enables viewing the 16

CPU LEDs and the status LED. These LEDs display operating

information. A small hole directly below the window provides

access to the combination stop/reset pushbutton. Besides

locking the module in place, the faceplate also protects the circuit components and promotes proper air flow within the

enclosure.

Hardware Description

Circuit Board

The circuit board features state-of-the-art surface mount technology. On the board are nonvolatile random access memory

(NVRAM), static random access memory (SRAM), flash memory

(ROM), a microprocessor running at 32 megahertz, direct

memory access (DMA) circuits, ABB Process Automation custom bus circuits, and various support circuitry. The board

attaches to the faceplate with two screws. The module assembly occupies one slot in a module mounting unit.

A processor bus adapter board is required for connection to the

Harmony I/O subsystem via Hnet. It also connects to a termination unit for two auxiliary serial I/O ports and IISAC01 stations. Redundant BRC modules and Hnet buses connect

through redundant PBA boards.

Hardware Application

Because of the superior performance of the BRC module, applications that formerly required an external mainframe or minicomputer can now be handled in the Harmony control unit.

The large memory space and on-board communication ports of

the BRC module enable it to meet the sophisticated control

WBPEEUI230017B1 1 - 3

Page 15

Features

Features

application requirements of supervisory control, optimization

routines, performance assessment, and process modeling.

The Harmony bridge controller retains all of the features of the

INFI 90 OPEN multifunction processor modules. Additional

features of the Harmony bridge controller include:

• Simultaneous Hnet bus and I/O expander bus communi-

cation supports both Harmony I/O blocks and Harmony

rack I/O modules.

• Redundant Hnet bus.

• Online Hnet communication bus diagnostics and fault

isolation.

• Automatic downloading of Harmony I/O block

configurations.

• NVRAM battery power monitoring.

• Status output alarm monitoring.

• Two megabytes of on-board SRAM memory.

• Compatible with existing INFI 90 OPEN systems.

Instruction Content

This instruction consists of the following sections:

Introduction

Description and

Operation

Installation

Operating Procedures

Provides an overview of the module, a description of the hardware, a glossary of unique terms, and a table of physical, electrical and environmental specifications.

Uses block diagrams to explain the function of the key circuits.

Explains the handling, inspection, hardware configuration,

and installation aspects of the module.

Discusses the front panel indicators and controls, and everyday operation.

Troubleshooting

1 - 4 WBPEEUI230017B1

Features detailed flowcharts and tables that enable quick diagnosis of error conditions and provides corrective actions.

Page 16

How to Use this Instruction

Maintenance

Repair and

Replacement

Replacement and Spare

Parts

Appendices

Covers scheduled module maintenance.

Describes how to repair and replace the module.

Provides a list of part numbers and nomenclatures.

Provide quick reference information for NTMP01 hardware

configuration and step-by-step instructions for performing

online configuration.

How to Use this Instruction

Read this instruction in sequence. To get the best use out of

this instruction, read it from cover to cover, then go back to

specific sections as required. ABB strongly advises against

putting the module into operation until the installation section

has been read and performed.

1. Read and perform all steps in the installation section.

2. Thoroughly read the operating procedures section before

applying power to the module.

3. Refer to the troubleshooting section if a problem occurs.

This section will help to diagnose and correct a problem.

4. Go to the repair and replacement section for replacement

part numbers and nomenclatures, and for instructions on how

to replace the module.

Glossary of Terms and Abbreviations

Table 1-1 contains those terms and abbreviations that are

unique to ABB or have a definition that is different from standard industry usage.

Table 1-1. Glossary of Terms and Abbreviations

Term Definition

Controlway High speed, redundant, peer-to-peer communication link. Used to transfer infor-

mation between intelligent modules within a Harmony control unit.

Hnet Communications path between Harmony controller and I/O blocks.

Executive block Fixed function block that determines overall module operating characteristics.

WBPEEUI230017B1 1 - 5

Page 17

Reference Documents

Table 1-1. Glossary of Terms and Abbreviations

Term Definition

Function block The occurrence of a function code at a block address of a module.

Function code An algorithm which manipulates specific functions. These functions are linked

together to form the control strategy.

I/O block Generic name for a processor based Harmony input/output device: AIN-120,

AOT-150, CIO-100, DIO-400, etc.; comprised of an I/O module and a base.

I/O module Houses the I/O block circuitry; part of I/O block.

I/O expander

bus

MFT Machine fault timer. Reset by the processor during normal operation. If not reset

MMU Module mounting unit. A card cage that provides electrical and communication

PBA Processor bus adapter.

Termination unit Provides input/output connection between plant equipment and the Harmony

Parallel communication bus between the Harmony rack controller and Harmony

rack I/O modules.

regularly, the MFT times out and the module stops.

support for Harmony rack modules.

rack modules.

(continue d)

Reference Documents

Table 1-2 contains a list of documents referenced in this

instruction that provide information on BRC firmware and

related hardware.

Table 1-2. Reference Documents

Number Title

WBPEEUI200502?? Module Mounting Unit (IEMMU11, IEMMU12,

WBPEEUI210504?? Function Code Application Manual, Symphony

WBPEEUI230022?? Analog Control Station (IISAC01)

WBPEEUI240751?? Harmony Input/Output System

WBPEEUI240762?? IMDSO14 Digital Output Module

WBPEEUI260039?? NTMP01 Multifunction Processor Termination Unit

WBPEEUI270002?? Primary Interface, Composer

WBPEEUI270003?? Automation Architect, Composer

IEMMU21, IEMMU22)

1 - 6 WBPEEUI230017B1

Page 18

Related Nomenclatures

Table 1-3 lists nomenclatures related to the BRC module.

Table 1-3. Related Nomenclatures

Nomenclature Description

Related Nomenclatures

IEMMU11, IEMMU12,

IEMMU21, IEMMU22

IISAC01 Analog control station

NTMP01 Field termination panel

Module mounting unit

Specifications

Table 1-4 lists the specifications for the BRC module, process

bus adapter board and BRC redundancy kit.

Table 1-4. Specifications

Property Characteristic/Value

Microprocessor 32-bit processor running at 32 MHz

Memory All memory has 32-bit data path

SRAM NVRAM

Total Available Total Available

2 Mb 1.57 Mb 512 kb 441 kb 1 Mb

Power requirements 5 VDC at 2 A; 10 W typical (BRC)

Flash ROM

Tot al

Station support 128 40-kbaud serial stations (IISAC01) or eight 5-kbaud serial stations

Redundant controller

communication link

Programmability Function codes, C, Basic, Batch, Ladder, user-defined functions

Dimensions

BRC

PBA

Weight

BRC

PBA

WBPEEUI230017B1 1 - 7

5 VDC at 100 mA; 0.5 W typical (PBA)

4 MHz per byte per second (normal operation)

35.56 mm wide, 177.80 mm high, 298.45 mm long

(1.40 in. wide, 7.00 in.high, 11.75 in. long)

31.60 mm wide, 166.12 mm high, 102.62 mm long

(1.24 in. wide, 6.54 in. high, 4.04 in. long)

0.70 kg (24.69 oz)

0.30 kg (10.6 oz)

Page 19

Specifications

Table 1-4. Specifications (continued)

Property Characteristic/Value

Communication ports 2 RS-232-C or 1 RS-232-C and 1 RS-485,

1 SAC channel (128 SACs maximum

Ambient temperature 0° to 70°C (32° to 158°F)

Relative humidity 0% to 95% relative humidity up to 55°C (131°F) noncondensing

0% to 45% relative humidity at 70°C (158°F) noncondensing

Atmospheric pressure Sea level to 3 km (1.86 mi)

Certification CSA certified for use as process control equipment in ordinary

(nonhazardous) locations.

CE mark compliant for EMC directive and LV directive.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

)

1 - 8 WBPEEUI230017B1

Page 20

Description and Operation

Introduction

This section explains the functionality of the Harmony bridge

controller (BRC) using block diagrams and text. Block diagrams divide the operation of the Harmony bridge controller.

Operation

The BRC module incorporates the power of a second generation 32-bit microprocessor operating at 32 megahertz. This is

coupled with 32-bit wide memory design with an optimized

interface. The microprocessor supplies superior performance

capable of supplanting the need for external mainframes or

minicomputers.

Control input/output is available from I/O blocks using Hnet

or from Harmony rack I/O modules using the I/O expander

bus. The data within the BRC module may be exported to the

Cnet communication network and to existing INFI-NET

Plant Loop communication systems.

Section 2

®

and

In some processes, the effects of a control failure in the system

can create dangerous situations or cause economic loss. To

reduce the possibility of these problems occurring, redundant

modules provide fail-safe control. Redundant BRC modules

link directly to each other via the processor bus adapter (PBA)

board or the BRC redundancy kit to keep the database in the

backup module current. Each module uses a redundant high

speed communication channel to accomplish this function. If

the primary module fails, the backup module is waiting in

standby mode and immediately takes over. The backup module

has the same control strategy loaded in its memory as the primary BRC module and is ready to assume control. When operating in Hnet communication mode, the redundant

communication channel insures that single point failures will

not prevent the backup module from being in a state of readiness to take over.

While the BRC module is controlling a process, it also executes

diagnostic routines. It is constantly checking the integrity of its

WBPEEUI230017B1 2 - 1

Page 21

Circuitry

hardware and firmware during normal operation. If the

diagnostic routines discover a module hardware or software

problem, it makes that information available to the operator.

The operator has access to this information through status

LEDs on the module faceplate and through reports received on

the human system interface (HSI) in module status bytes.

The BRC module uses a control I/O block (CIO) on Hnet to

support a station link that can handle up to 128 IISAC01

stations and is compatible with the Symphony system.

Two auxiliary RS-232-C ports and a serial station link are

available through a cable connection via the PBA board to an

NTMP01 Multifunction Processor Termination Unit. This station link can handle up to 64 IISAC01 stations at a 40-kilobaud rate or eight stations at a five-kilobaud rate. Various

handshake options are available via jumper configurations on

the termination unit.

Circuitry

Microprocessor

The BRC module has all the needed circuitry to operate as a

stand-alone controller. Direct memory access (DMA) operation

is supported for the station link. Figure 2-1 shows a block diagram of the BRC circuitry.

The microprocessor is responsible for module operation and

control. The BRC microprocessor is a 32-bit processor that

runs from a 32-megahertz clock. The microprocessor executes

synchronous access to long word memories and an asynchronous access to all byte ports. Since the microprocessor is

responsible for module operation, it communicates with all

blocks of the BRC circuitry. The microprocessor operating system instructions and the function code library reside in the

read only memory (flash ROM). The microprocessor carries out

all control responsibilities as it executes the control strategy

set up in its function block configuration.

The microprocessor constantly triggers the machine fault timer

(MFT) circuit. If the microprocessor or software fails, the MFT

circuit times out, issues a board wide reset, and the status

LED turns red. This condition is a fatal module error.

2 - 2 WBPEEUI230017B1

Page 22

CLOCK

MACHINE

FA U LT

TIME R

MICROPROCESSOR

LEDs,

SWITCHES,

DATA BUFFERS

Circuitry

32 -B IT D ATA PAT H

ROM NVRAM SRAM

16 -B IT D ATA PAT H

REDUNDANT HNET BUS

REDUNDANCY

Figure 2-1. Functional Block Diagram

Clock and Real-Time Clock

DUAL

LINK

STEERING

DATA

LOGIC

DMA /PERIPHERAL CONTROL I/O

CONTROLWAY/

MODULE BUS

8-BIT DATA PATH

I/O

EXPANDER

BUS

SAC/

DCS

TO

PROCESSOR

BUS ADAPTER

DUART RTC

T01272A

The clock section provides the clock signals to drive the microprocessor and associated peripheral devices. The clock/timer

section also includes a real-time clock (RTC).

Memory

The BRC memory is made up of one megabyte of flash ROM

memory, two megabytes of SRAM memory, and 512 kilobytes

of NVRAM memory.

The flash ROM memory holds the operating system instructions for the microprocessor. The SRAM memory provides temporary storage and a copy of the system configuration. The

NVRAM memory holds the system configuration (control strategy designed with function codes) and files for Batch, Basic, C,

WBPEEUI230017B1 2 - 3

Page 23

Circuitry

and UDF applications. NVRAM memory retains whatever information it has, even when it loses power.

Direct Memory Access

The DMA section enables the various communication links to

do direct data transfers to and from RAM memory without processor intervention. Communication links that support direct

memory access are the I/O expander bus, the dual redundancy link, the station serial link, and Controlway.

ABB-designed chips control DMA activity.

The DMA process greatly reduces the amount of work the

microprocessor needs to do when making data moves. This

greatly increases the speed of the BRC module by not

overloading the microprocessor with the work associated with

data moves. The microprocessor does not have to execute data

moves and is free to do other tasks.

Controlway

The Controlway is a high speed communication bus between

Harmony rack controllers. The BRC module uses this bus to

communicate with other control modules within a Harmony

control unit. It provides a one-megabaud, peer-to-peer communication link that can support up to 32 devices. The Controlway interface is provided by a custom integrated circuit

that links the BRC module to the Controlway. It has full DMA

capabilities (allowing for quicker operation), and two independent, redundant channels.

The redundant Controlway channels run through two paths on

the module mounting unit backplane circuit. The BRC module

transmits and receives data over both channels simultaneously. By receiving data through two channels, the BRC

module can check its integrity. In this way, the Controlway

minimizes the potential that a failure on a circuit board or

backplane will cause loss of module communication.

The Controlway interface also allows the BRC module to run

on module bus by operating in an 83.3-kilobaud mode (switch

selectable). The module bus operation option is provided to

support existing INFI 90 OPEN and Network 90

jumper allows the BRC module to be installed in systems using

early Network 90 modules that require -30 VDC. The jumper

®

systems. A

2 - 4 WBPEEUI230017B1

Page 24

Redundancy Link

Circuitry

disconnects -30 VDC from pin four of connector P2 on the BRC

module.

The redundancy link is a dual parallel link between a primary

and backup BRC module in redundant configurations. As the

primary module executes, the backup module waits in standby

mode and receives a copy of block outputs over this link. If for

any reason the primary module fails, the backup takes over

without any process interruption.

NOTE: Firmware revision levels must be the same in both primary and second-

ary BRC modules. If the firmware revision level is different and a failover

occurs, the redundant BRC module may operate erratically.

Two parallel channels of data and control signals connect by

way of a processor bus adapter board. Each BRC module in a

redundant configuration connect through PBA boards connected by redundant PBA cables. Both channels have parity

protection.

If no Hnet or termination unit communication is needed, the

primary and backup BRC modules connect by a BRC redundancy kit. The BRC redundancy kit contains two Harmony I/O

hood connection assemblies and a redundant PBA cable. The

connection assemblies replace the redundant PBA boards and

connect to each other through the redundant PBA cable.

Hnet Communication

An Hnet interface enables communication with Harmony I/O

blocks. All communication functions are handled by the Hnet

application-specific integrated circuit (ASIC). Hnet is a 16-bit

interface that operates via control registers in the I/O section

of BRC module memory and a one-megabyte memory space for

shared SRAM.

Hnet and I/O expander bus communication can be active

simultaneously if enabled, allowing the BRC module to utilize

both Harmony I/O blocks and Harmony rack I/O modules to

control a process. Function code 90 (S3) controls what combination of I/O interfaces are active. Three selections are

available: enable Hnet only, enable Hnet and I/O expander

bus, and enable I/O expander bus only.

WBPEEUI230017B1 2 - 5

Page 25

Circuitry

I/O Expander Bus

Physical connection is provided by a direct connection from the

BRC module P3 connector to the processor bus adapter board

P5 connector. The processor adapter board mounts on the rear

of a module mounting unit with the proper adapter brackets

installed. It uses cables to connect to the Harmony block

mounting columns. The PBA board provides Hnet physical

layer functions, termination, isolation relays, and BRC module

redundancy link.

The I/O expander bus interface is implemented using an

ABB-designed integrated circuit. The microprocessor can

select one of two modes of operation: DMA or auto mode. The

BRC software selects the mode of operation. Mode selection is

based on optimizing the number of bytes to be transferred. In

either mode of operation, the microprocessor does not need to

wait for each byte to transfer (as in previous controllers).

I/O Section

Serial Channels

The BRC module connects to the I/O expander bus through

the P2 connector on the module mounting unit backplane. It is

an eight-bit parallel bus that provides the communication path

for I/O data from Harmony rack I/O modules. The I/O

expander bus supports 64 low power I/O modules.

The I/O section interface allows the microprocessor to read the

switches that tell it how to operate and set the module address.

This section also contains latches whose outputs connect to

the status and error LEDs. This section monitors redundant

modules and outputs a signal to the LEDs of the primary module. Upon failover, this output de-energizes and the output of

the backup module energizes as it takes over. Additionally, the

I/O section monitors the stop/reset pushbutton. When the

pushbutton is pressed, the I/O section insures that the module completes any I/O functions before it stops the module.

Two independent serial channels (RS-485) are available on the

BRC module. Both serial channels are dedicated for language

support (C or Basic) or sequence of events recording. Clear to

send (CTS) and request to send (RTS) handshake signals are

supported. A DUART circuit on the processor bus adapter

2 - 6 WBPEEUI230017B1

Page 26

Circuitry

board supplies the serial channels with handshaking signals.

Clock signals for the baud rate generator are derived from an

on-board, 7.3728-megahertz oscillator.

The PBA board connects to an NTMP01 Multifunction Processor Termination Unit. Input/output signals enter or leave the

PBA board through a cable connection to the termination unit.

An NKTU01 or NKTU11 cable connects an NTMP01 termination unit. Standard D-type connectors are available on the termination unit.

To provide better noise immunity, both channels transmit and

receive differential serial signals based on the RS-485 standard. These signals are converted to normal RS-232-C voltage

levels by the termination unit. Each channel is capable of supporting standard RS-232-C baud rates up to 38.4 kilobaud.

The termination unit also provides optical isolation to eliminate the possibility of introducing ground loops into the system

from improper cable shield grounding. Channel A (the terminal

channel) can be selected to operate without the RS-485/

RS-232-C conversion allowing it to be used with differential

terminals or programmable logic controllers (PLC).

Station Link

Station communication originates from a DUART circuit on the

BRC module. This link controls the serial communication

between the BRC module and the control stations. It has two

modes of operation: Hnet transactions to a Harmony control I/

O block, or direct operation by the BRC module via a termination unit.

The Hnet-to-CIO block mode of operation allows stations to be

placed at greater distances from the BRC module because the

CIO block contains the physical interface to the station. The

BRC module is capable of communicating with a total of 128

IISAC01 stations attached to a total of 64 CIO-100/110 blocks.

NOTES: The system station maximum of 128 stations assumes that only Hnet-

to-CIO block communication mode is used.

The BRC module can also directly connect to local IISAC01 stations. Eight stations can be supported at the five-kilobaud rate

and up to 64 stations can be supported at the 40-kilobaud

rate. The BRC module makes this direct local connection

through the PBA board and appropriate termination hardware.

WBPEEUI230017B1 2 - 7

Page 27

Circuitry

Power

Support for bypass stations requires a Harmony control I/O

module (IMCIS12, IMQRS12) configured on the I/O expander

bus.

Power requirements are 5 VDC for logic power and for line drivers/receivers. The Hnet interface derives all other power

requirements from the 5 VDC logic power. Power for the module is supplied via the module mounting unit connection to the

BRC module P1 connector. The PBA board receives 5 VDC logic

power via its connection to the BRC module. The PBA board

uses this power for Hnet termination, and to power the isolation relays.

2 - 8 WBPEEUI230017B1

Page 28

Installation

Introduction

Section 3

This section explains how to set up and install the Harmony

bridge controller (BRC). Read, understand, and complete the

steps in the order they appear before operating the BRC

module.

The Harmony bridge controller requires a P-H-BRC-PBA1000

Processor Bus Adapter (PBA) board to support Hnet communication and BRC module redundancy. If no Hnet communication and termination unit is needed, a BRC redundancy kit

may be used to support redundancy instead of the PBA boards.

This section includes instructions for PBA board, BRC redundancy kit, and related cable installations.

NOTE: This module uses connections to the module mounting unit backplane

that served other functions in earlier Network 90 systems. To avoid potential

module damage, evaluate your system for compatibility prior to module instal-

lation. Earlier Network 90 systems applied -30 VDC to pins three and four of

the module connector P1. This voltage is not required for Symphony and

INFI 90 OPEN modules. In Symphony and INFI 90 OPEN systems, pin four is

used for the Controlway bus.

If the system contains modules that require -30 VDC, set jumper J3 to the

30 VDC position (jumper pins one and two). Doing so allows the installation of

the BRC module in a module mounting unit that uses -30 VDC and limits com-

munication to module bus. Refer to Table 3-6 for more information about setting

jumper J3.

WBPEEUI230017B1 3 - 1

Page 29

Special Handling

Special Handling

Observe these steps when handling electronic circuitry:

1. Use Static Shielding Bag.

shielding bag until you are ready to install them in the system.

Save the bag for future use.

2. Ground Bag Before Opening.

ing an assembly with semiconductors, touch it to the equipment housing or a ground to equalize charges.

3. Avoid Touching Circuitry.

avoid touching the circuitry.

NOTE: Always use ABB's field static kit (part number 1948385?1 - consisting

of two wrist straps, ground cord assembly, alligator clip and static dissipative

work surface) when working with the modules. The kit grounds a technician

and the static dissipative work surface to the same ground point to prevent

damage to the modules by electrostatic discharge.

Use Static Shielding Bag. Keep the modules in the static

Use Static Shielding Bag. Use Static Shielding Bag.

Ground Bag Before Opening. Before opening a bag contain-

Ground Bag Before Opening.Ground Bag Before Opening.

Avoid Touching Circuitry. Handle assemblies by the edges;

Avoid Touching Circuitry.Avoid Touching Circuitry.

4. Avoid Partial Connection of Semiconductors.

Avoid Partial Connection of Semiconductors. Verify that all

Avoid Partial Connection of Semiconductors. Avoid Partial Connection of Semiconductors.

devices connected to the modules are properly grounded before

using them.

5. Ground Test

Ground Test Equipment.

Ground TestGround Test

6. Use an Antistatic Field Service Vacuum.

Use an Antistatic Field Service Vacuum. Remove dust from

Use an Antistatic Field Service Vacuum.Use an Antistatic Field Service Vacuum.

the module if necessary.

7. Use a Grounded Wrist Strap.

Use a Grounded Wrist Strap. Connect the wrist strap to the

Use a Grounded Wrist Strap. Use a Grounded Wrist Strap.

appropriate grounding plug on the power entry panel. The

grounding plug must be effectively connected to the earth

grounding electrode system through the AC safety ground.

8. Do Not Use Lead Pencils to Set Dipswitches.

Do Not Use Lead Pencils to Set Dipswitches. To avoid con-

Do Not Use Lead Pencils to Set Dipswitches. Do Not Use Lead Pencils to Set Dipswitches.

tamination of dipswitch contacts that can result in unnecessary circuit board malfunction, do not use a lead pencil to set a

dipswitch.

Unpacking and Inspection

Equipment.

Equipment.Equipment.

1. Examine the hardware immediately to verify that it has not

been damaged in transit.

2. Notify the nearest ABB sales office of any damage.

3 - 2 WBPEEUI230017B1

Page 30

3. File a claim for any damage with the transportation company that handled the shipment.

4. Use the original packing material and container to store the

hardware.

5. Store the hardware in an environment of good air quality,

free from temperature and moisture extremes.

Dipswitches and Jumpers

This section explains how to configure and install the BRC

module. After installing the module, a function block

configuration must be created to define the functions the module will perform.

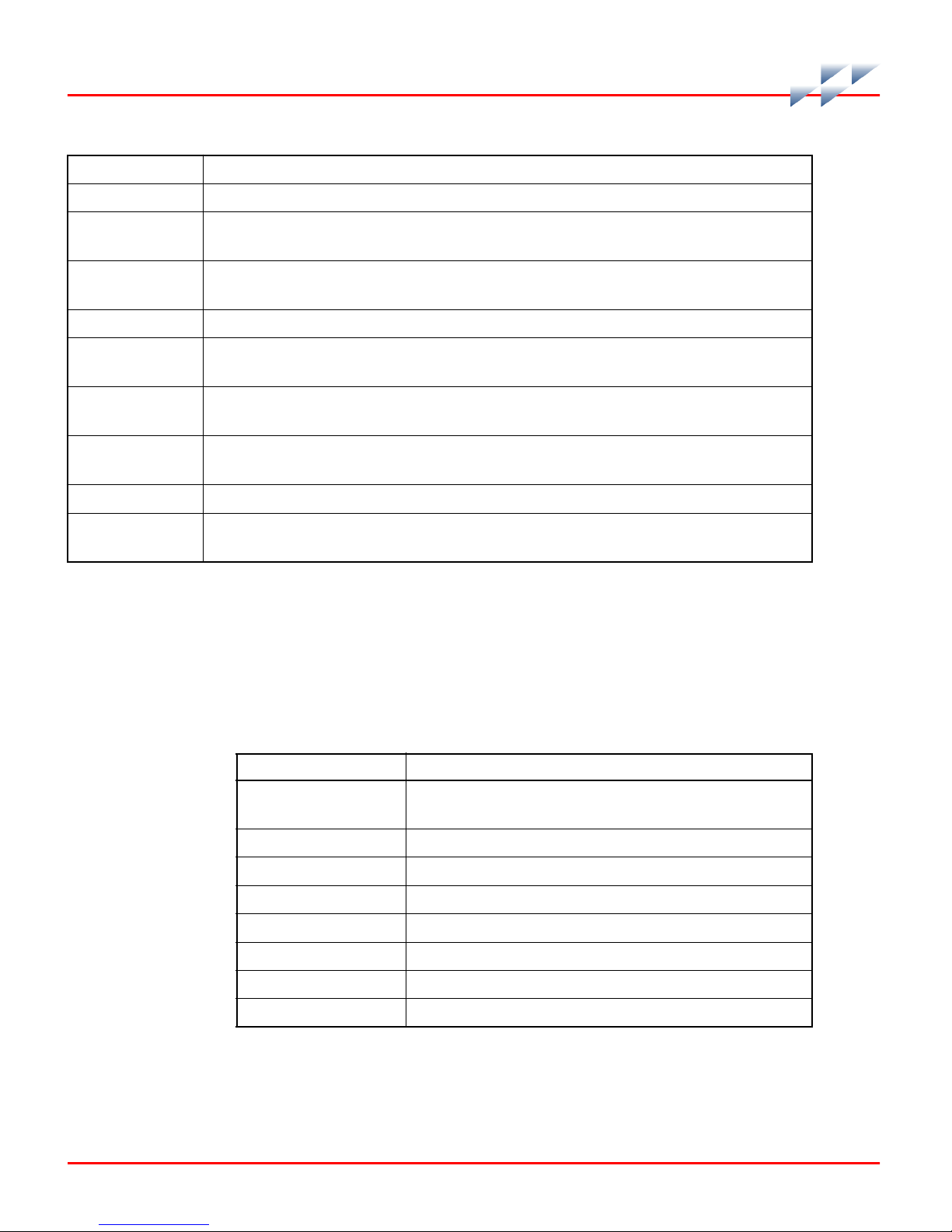

The BRC module has four configurable dipswitches, and four

jumpers. Each dipswitch has eight poles. Figure 3-1 shows the

location of the dipswitches and jumpers on the circuit board.

Dipswitches and Jumpers

CR21

P5

15

J4

26

37

48

P4

J2

J1

P6

SW1

SW5

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Figure 3-1. BRC Module Layout

Dipswitch SW5 sets the module address, bus speed, and operation mode (normal/diagnostic). Dipswitch SW2 sets module

options, enables special operations, and enables diagnostic

operations. Dipswitch SW4 sets module mounting unit and

memory options. Dipswitch SW3 is not used.

SW2

SW 3

1 2 3 4 5 6 7 8

SW4

1 2 3 4 5 6 7 8

P1

P10

J3

P11 P9

P3

P8

P2

T01274B

WBPEEUI230017B1 3 - 3

Page 31

Dipswitches and Jumpers

Jumpers J1, J2, J3, and J4 define module functions and operation. Jumper J1 enables or disables the machine fault timer

(MFT). Jumper J2 sets the diagnostic RS-232-C port for operation as data communication equipment (DCE) or data terminal

equipment (DTE). Jumper J3 disengages -30 VDC from the

module when installing it in a module mounting unit that supplies -30 VDC to other modules. Jumper J4 is reserved for use

by ABB engineering.

Dipswitch poles marked not used must be set to the default

settings listed in the appropriate table. The BRC module may

not operate properly if these dipswitches are improperly set.

Since factory settings do not reflect default settings, it is

imperative that all dipswitch settings be checked before putting the module into operation.

Dipswitch SW5 - Module Address

Dipswitch SW5 sets the module address, enables module diagnostics, and sets the bus mode. The BRC module can have an

address from zero through 31. Table 3-1 explains the functions

set by dipswitch poles one through three. Dipswitch poles four

through eight set the module address. Table 3-2 shows examples of how to set the address. Record the module address setting in the user setting portion of the table.

NOTES:

1. SW5 provides a module bus option to support existing INFI 90 OPEN and

early Network 90 systems. All modules within a process control unit must be

set to communicate on the same type of communication bus, either Controlway

or module bus.

2. Module addresses of redundant BRC modules must be identical.

Table 3-1. Dipswitch SW5 Settings (Operation)

Pole Setting Function

1 0 Normal run

1 Enable diagnostics using dipswitch SW2

2 0 Not used - do not change setting

Setting

User

3 - 4 WBPEEUI230017B1

Page 32

Table 3-1. Dipswitch SW5 Settings (Operation) (continued)

Dipswitches and Jumpers

Pole Setting Function

1

3

NOTE: 0 = closed or on, 1 = open or off.

1. The module bus setting is for support of existing INFI 90 OPEN and Network 90 systems.

0 Controlway (1 Mbaud)

1 Module bus (83.3 kbaud) or -30 VDC

operation

Dipswitch SW2 - Normal Operating Options

Dipswitch SW2 sets module options that are available when

the BRC module is in normal operation. Refer to Table 3-3 for

option setting information. The options listed in this table

Table 3-2. Dipswitch SW5 Settings (Address)

Dipswitch Pole

Address

Example

4

(16)5(8)

(Binary Value)

6

(4)

7

(2)

User

Setting

8

(1)

7 00111

15 01111

User s ettin g

NOTE: 0 = closed or on, 1 = open or off.

apply to normal operation. Normal operation options are

enabled when dipswitch SW2 pole one is set to closed (on). If

dipswitch SW2 pole one is set to open (off), special operations

are enabled. Refer to Dipswitch SW2 - Special Operations

for a description.

NOTE: Poles one through seven must have the same setting for both modules

when using redundant BRC modules.

Dipswitch SW2 - Special Operations

The special operations feature provides a means to configure

the BRC module to perform a one-time special operation rather

than entering its normal mode of operation. Setting dipswitch

SW2 pole one to open (off) enables the special operation mode.

WBPEEUI230017B1 3 - 5

Page 33

Dipswitches and Jumpers

Table 3-3. Dipswitch SW2 Settings (Operating Options)

Pole Setting Function

1 0 Disable special operations.

1 Enable special operations. Refer to Dipswitch SW2 - Special Opera-

tions.

2 0 Disable online configuration.

1 Enable online configuration.

3 0 Perform NVRAM checksum routine.

1 Inhibit NVRAM checksum routine.

4 0 Perform flash ROM checksum routine and file system check.

1 Inhibit flash ROM checksum routine and file system check.

5 0 Enable file system check.

1 Disable file system check.

6 0 Normal operation.

1 Compact configuration. The compact configuration function moves

configured function blocks to the top of the NVRAM while moving free

space to the bottom. To enable this function, open the pole and insert

the module into the module mounting unit. After a short time (directly

proportional to the configuration size), the module will return to the

mode it was in prior to being reset for the compact operation.

1

User

Setting

2

7 0 Normal operation.

1 Initialize. This operation destroys (erases) the module function block

configuration. Initialize NVRAM (erase configuration). Leave pole

open; insert module into module mounting unit. When group A LEDs

1, 2 and 4 are on, remove the module, put the pole in the closed position, and insert the module. The module is now ready to be configured. Use special operation two to initialize all NVRAM.

NOTE: This pole must remain closed for normal operation.

8 0 Primary BRC module.

1 Redundant BRC module.

NOTES: 0 = closed or on, 1 = open or off.

1. This setting is used by development personnel and should never be used for normal operation. The checksum provides additional module integrity and should be used whenever the module is controlling a process.

2. Leaving this option enabled causes the configuration to be compacted every time the module is reset, thereby increasing the

startup time. This increase becomes more substantial as the size of the configuration increases. Therefore, do not leave this

option enabled longer than necessary. Disabling this option stops any further compacting operations. It does not uncompact any

previously compacted configuration.

3. When redundancy is used, poles one through seven on the redundant BRC module are set the same as the primary BRC

module. Pole eight is set to closed (on) for the primary module and to open (off) for the secondary module.

3

3 - 6 WBPEEUI230017B1

Page 34

Poles two through eight select the special operation. The following steps explain how to set the BRC module for special

operations and reset it for normal operation. Table 3-4 shows

the dipswitch settings and explains each special operation.

To use special operations:

1. Set dipswitch SW2 pole one to open (off).

2. Set poles two through eight per Table 3-4. Begin with special operation two.

Table 3-4. Dipswitch SW2 Settings (Special Operations)

Dipswitches and Jumpers

Special

Operation

0 10000000 Force the BRC module into configure mode.

1

2

4 10000100 Cnet or INFI

5 10000101 Permit segment modification (allows change to segment scheme

Dipswitch Pole

Description

12345678

10000010 Initialize and format all NVRAM configuration space for Plant Loop

protocol.

-NET protocol enable. This allows the BRC module to

use the Cnet or INFI-NET capabilities.

configured with function code 82, specification S1).

6 10000110 Enable time-stamping. This operation instructs the BRC module to

generate time information with point data. It is applicable only to

Cnet or INFI-NET systems.

9 10001001 Enable simulation mode.

NOTE: 0 = closed or on, 1 = open or off.

1. Special operation two is for support of existing INFI 90 OPEN and Network 90 systems.

3. Insert the BRC module in its slot in the module mounting

unit (refer to Module Installation).

4. When the special operation is complete, the status LED

turns red and LEDs one through six illuminate.

5. Remove the BRC module.

6. Repeat Steps 2 through 8 for any other special operation

desired.

WBPEEUI230017B1 3 - 7

NOTE: Do special operation two as the first step of the module installation. If

installing the BRC module in a Cnet or INFI-NET environment, do special oper-

ation four next. For time-stamping, do special operation six next. To reverse

Cnet or INFI-NET protocol or time-stamping, do operation two again.

Page 35

Dipswitches and Jumpers

7. When all special operations are complete, reset pole one on

dipswitch SW2 to the closed (on) position.

8. Poles two through eight (module options) should be set for

the desired BRC operation per Table 3-4.

9. Insert the BRC module in its slot. It will begin normal

operation.

Dipswitch SW3 - Module Options

Dipswitch SW3 is not used. All poles should be set to closed

(on).

Dipswitch SW4 - Module Options

Dipswitch SW4 sets additional module options. This dipswitch

should be set to the user settings shown in Table 3-5.

Jumpers

Table 3-5. Dipswitch SW4 Settings (Module Options)

Pole Setting Function User Setting

1 - 4 — Not used 1

5 0 Disable SRAM multiple transfer 1

1 Enable SRAM multiple transfer

6 — Not used 0

7 0 Disable data cache 1

1 Enable data cache

8 0 Disable instruction cache 1

1 Enable instruction cache

NOTE: 0 = closed or on, 1 = open or off.

There are four jumpers (J1 through J4) on the BRC board.

These jumpers are for special hardware applications. They

define the RS-232-C diagnostic terminal as data terminal

equipment (DTE) or data communication equipment (DCE),

enable the machine fault timer and enable the module to oper-

3 - 8 WBPEEUI230017B1

Page 36

ate in a module mounting unit that uses -30 VDC. Refer to

Table 3-6 for an explanation of the functions set by jumpers.

NOTE: Jumper J1 is for ABB development personnel usage only. It is used to

disable the machine fault timer circuit. If this function is disabled (jumper pins

connected) and a problem develops in the BRC module, the module will not

halt, which may result in configuration corruption and unpredictable module

outputs.

Table 3-6. Jumpers Settings (J1 through J4)

Module Mounting Unit Preparation

Jumper Setting Function

J1 Open Not used. Must remain open for normal operation.

1

J2 Vertical

Horizontal Sets the RS-232-C diagnostic port to operate as DTE.

J3 30V Disconnects Controlway for operation in module mounting units that

MODB Allows operation in module mounting units that have Controlway

J4 Open Not used. Must remain open for normal operation.

NOTE:

1. Used by ABB service personnel. The J2 setting does not affect the module during normal operation.

Sets the RS-232-C diagnostic port to operate as DCE.

have -30 VDC (early Network 90).

communication. This setting must be used if dipswitch SW5 selects

Controlway.

Module Mounting Unit Preparation

Preparing the module mounting unit (MMU) consists of identifying the mounting slot, installing the required dipshunts, verifying the Controlway cable is installed, installing the processor

bus adaptor (PBA) board, PBA board cables, and Hnet

terminator.

User

Setting

Module Slot Assignments

Module placement within the module mounting unit is important. The BRC module requires a processor bus adaptor board

to use Hnet and BRC redundancy, or a BRC redundancy kit

when no Hnet and termination unit connection is needed. The

BRC module connects to the PBA board or the BRC redundancy kit at the rear of the module mounting unit. Redundant

BRC modules require mounting in adjacent MMU slots.

WBPEEUI230017B1 3 - 9

Page 37

Module Mounting Unit Preparation

Dipshunts

Disconnect power before installing dipshunts on the module

WARNING

mounting unit backplane. Failure to do so will result in contact

with cabinet areas that could cause severe or fatal shock.

No dipshunts are required if only Hnet is being used. If Hnet

and the I/O expander bus are being used or only the I/O

expander bus is being used, dipshunts are required to maintain bus continuity between all BRC modules associated with

one I/O expander bus segment. Check to see that dipshunts

are in place between all BRC module slots associated with one

I/O expander bus. One dipshunt goes between each module

slot to maintain bus continuity.

To check a particular BRC module configuration, read specification S3 of Extended Executive (function code 90). Specification S3 indicates if the BRC module is configured to operate in

Hnet mode only, Hnet and I/O expander bus mode, or I/O

expander bus mode only. Refer to the Function Code Applica-

tion Manual

tion Manual for details on function code 90.

tion Manualtion Manual

Function Code Applica-

Function Code Applica-Function Code Applica-

Controlway Cable

Install the Controlway cable in module mounting units as

follows:

1. Attach one end of the cable (twisted three-wire) to the bottom three tabs on the lower left of the module mounting unit

backplane (facing from behind). Refer to Figure 3-2.

2. Attach (in the same sequence) the other end of the cable to

the bottom three tabs on the lower left of the next module

mounting unit backplane.

NOTE: Because of high speed transaction constraints, a maximum of eight

related module mounting units (Controlways linked by cable) can be installed in

one enclosure. The number of interconnected module mounting units should

be kept to a minimum to avoid crosstalk and interference. Controlways cannot

be cable linked from enclosure to enclosure.

3 - 10 WBPEEUI230017B1

Page 38

Module Mounting Unit Preparation

T00063A

Figure 3-2. Controlway Cable Installation

PBA Board Installation

Hnet is the communication path between a BRC module and

Harmony I/O blocks. A PBA board is required to connect a

BRC module to Hnet, connect redundant Hnet to redundant

BRC modules, and provide a connection point for the NTMP01

termination unit (TU). The termination unit provides a connection for the two auxiliary serial ports and a direct five-kilobaud

or 40-kilobaud station link.

Mounting Bracket

A processor bus adapter mounting bracket is required to

install the PBA board. The processor bus adapter mounting

bracket consists of two mounting brackets and ten 5-40 ×

½-inch long, self threading screws, ten spacers, and ten flat

washers. Refer to the Module Mounting Unit (IEMMU11,

IEMMU12, IEMMU21, IEMMU22)

IEMMU12, IEMMU21, IEMMU22) instruction for more informa-

IEMMU12, IEMMU21, IEMMU22)IEMMU12, IEMMU21, IEMMU22)

tion on the module mounting unit.

Module Mounting Unit (IEMMU11,

Module Mounting Unit (IEMMU11, Module Mounting Unit (IEMMU11,

Disconnect power before installing the processor bus adapter

WARNING

WBPEEUI230017B1 3 - 11

mounting bracket on the module mounting unit backplane. Failure to do so will result in contact with cabinet areas that could

cause severe or fatal shock.

Page 39

Module Mounting Unit Preparation

To install the PBA mounting bracket:

1. Turn off power to the cabinet.

2. Install one PBA mounting bracket to the top of the module

mounting unit backplane assembly using five screws, flat

washers, and spacers. Refer to Figure 3-3.

3. Install the remaining mounting bracket to the bottom of the

backplane assembly using five screws, flat washers, and

spacers.

Cable and Terminator

There are two cable and terminator installation procedures

presented. The first procedure covers redundant installations

(two PBA boards), the second procedure covers nonredundant

(single PBA board) installations. Refer to Figure 3-4 for PBA

board cable connector assignments.

Redundant PBA Boards. To install the PBA board cables for a

redundant configuration (two PBA boards):

1. Install the redundant bridge controller link cable

(P-MK-HRM-PBA2000A) to both boards. Insert one of the keyed

connectors into the P4 connector on each PBA board.

2. Install the redundant processor bus adapter cable

(P-MK-HRM-PBA1?00?).

a. Position the end socket connector on the PBA assembly

bracket M3 studs. Install the two M3 nuts to maintain the

position of the connector.

b. Install a terminator (P-HA-MSC-TER10000) to the male

socket connector on the redundant bridge controller link

cable.

NOTE: The male socket connector is keyed, but the terminator is not. The ter-

minator can be installed in any direction.

c. Insert the next keyed connector on the cable into the P1

connector on the PBA board with the terminator mounted

to it.

d. Insert the next keyed connector on the cable into the P1

connector on the other PBA board.

3 - 12 WBPEEUI230017B1

Page 40

Module Mounting Unit Preparation

e. Attach the final cable connector to the I/O column after

the PBA boards have been mounted. Continue to Mounting

in this section to mount the redundant PBA boards.

NOTE: Termination unit cables for the direct station link can be installed at any

time after the PBA boards are installed. Refer to Appendix B for more

information.

Single PBA Board. For a single PBA board (nonredundant configu-

ration), install the redundant processor bus adapter cable

(P-MK-HRM-PBA1?00?):

1. Position the end socket connector on the PBA assembly

bracket M3 studs. Install the two M3 nuts to maintain the

position of the connector.

2. Install a terminator (P-HA-MSC-TER10000) to the male

socket connector on the redundant bridge controller link cable.

NOTE: The male socket connector is keyed, but the terminator is not. The ter-

minator can be installed in any direction.

Mounting

3. Insert the next keyed connector on the cable into the P1

connector on the PBA board.

4. The next keyed connector on the cable is used only for

redundant installations and has no purpose in single PBA

board installations. It can be left hanging.

5. Attach the final cable connector to the I/O column after the

PBA boards have been mounted. Continue to Mounting in this

section to mount the PBA board.

NOTE: The termination unit cable for the direct station link can be installed at

any time after the PBA board is installed. Refer to Appendix B for more

information.

There are two PBA board mounting procedures presented. The

first procedure covers redundant installations (two PBA

boards), the second procedure covers nonredundant (single

PBA board) installations. Figure 3-3 shows an example of how

the PBA board mounts to the PBA mounting bracket.

WBPEEUI230017B1 3 - 13

Page 41

Module Mounting Unit Preparation

5-40 x 0.50 IN.

SCREW S (10)

NOTE: MMU CARDCAGE

NOT SHOWN.

MMU

BACKPLANE

PBA MOUNTING BRACKET

(PART O F PBA MOUNTING KIT)

M3 x 8 mM

SCREWS (2)

ASSEMBLY

PBA

ASSEMBLY

HNET

TERMINATOR

PBA

PBA MOUNTING

BRACKET

BRC

MODULE

HNET

TERMINATOR

MM U BACKPLANE

ASSEMBLY

BRACKET

Figure 3-3. PBA Installation

3 - 14 WBPEEUI230017B1

BRC MODULEPBA MOUNTING

T01283A

Page 42

Module Mounting Unit Preparation

TO P3 OF

BRC-100

MODULE

TO REDUNDANT PBA

P4

TERMINATOR

(ON LAST PBA)

P-H-A-MSC-TER10000

P1

REDUNDANT BRIDGE

CONTROLLER LINK CABLE

PART NO. P-MK-HRM-PBA2000A

CONNECTION TO

TU CABLE FOR

P3P5

STATION LINK

REDUNDANT PROCESSOR BUS

ADAPTER CABLE

PART NO. P-MK-HRM-PBA1?00?

Figure 3-4. PBA Connector Identification

Redundant PBA Boards. To mount redundant PBA boards:

1. Locate and verify the adjacent MMU slots assigned to the

redundant BRC modules. Refer to Module Slot Assignments

in this section for more information.

2. For systems using both Hnet and I/O expander bus, or

only I/O expander bus, verify there is a dipshunt installed

between the adjacent MMU slots of each BRC module using a

particular I/O expander bus. Do not

dipshunts in systems using only Hnet. Refer to Dipshunts in

this section for information on how to verify a BRC module

communication bus configuration.

TO HARMONY