Page 1

SERVICE MANUAL

20" COLOR TELEVISION

WF203

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and described in this service manual are effective methods of performing service

operations. Some of these service special tools should be used when and

as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk of

personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Funai

could not possibly know, evaluate and advice the service trade of all conceivable ways in which service might be done or of the possible hazardous

consequences of each way. Consequently, Funai has not undertaken any

such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not recommended by Funai must first use all precautions thoroughly so that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

TABLE OF CONTENTS

Specifications ........................................................ 1-1

Important Safety Precautions................................ 2-1

Standard Notes for Servicing ................................ 3-1

Disassembly Instructions ...................................... 4-1

Electrical Adjustment Instructions ......................... 5-1

Block Diagram....................................................... 6-1

Schematic Diagram / CBA's and Test Points ....... 7-1

Schematic Diagram .............................................. 7-3

CBA Views and Test Points.................................. 7-11

Wave Forms .......................................................... 8-1

Wiring Diagram...................................................... 9-1

IC Pin Function .................................................... 10-1

Cabinet Exploded View ....................................... 11-1

Packing Exploded View ....................................... 11-3

Mechanical Parts List .......................................... 12-1

Electrical Parts List.............................................. 13-1

Page 3

SPECIFICATIONS

<TUNER> ANT. Input ------------------- 75ohm Unbal., F type

Reference Level------------20Vp-p (CRT Green Cathode)

Test Input Signal -----------400Hz 30% modulation

Description Condition Unit Nominal Limit

1. Intermediate Freq. Picture

Sound

2. Peak Picture Sens VHF

CATV

UHF

MHz

MHz

dBµv

dBµv

dBµv

45.75

41.25

15

15

15

-

-

30

30

40

3. AFT Pull In Range

(10mV input)

- MHz ±2.2 ±0.7

<DEFLECTION>

Description Condition Unit Nominal Limit

1. Deflection Freq. Horizontal

Vert ical

2. Linearity Horizontal

Vert ical

3. Over Scan - % 10 -

4. High Voltage - KV 26 -

KHz

Hz

%

%

15.734

60

-

-

<VIDEO & CHROMA>

Description Condition Unit Nominal Limit

1. Misconvergence Center

Side

Corner

2. Brightness APL 100% Ft-L 40 25

mm

mm

mm

-

-

-

-

-

±15

±10

0.4

1.5

2.1

3. Color Temperature - °K 9200°K -

4. Resolution Horizontal

Vert ical

<AUDIO>

Description Condition Unit Nominal Limit

1. Audio Output Power 10% THD W 1 0.8

2. Audio Distortion (w/LPF) 500mW % 2 7

3. Audio Freq. Response

Note:

Nominal specifications represent the design specifications. All units should be able to approximate

these. Some will exceed and some may drop slightly below these specifications. Limit specifications

represent the absolute worst condition that still might be considered acceptable. In no case should

a unit fail to meet limit specifications.

All items are measured across 8Ω load at speaker output terminal.

-

3dB Hz 100~11K -

1-1 L1443SP

Line

Line

250

300

-

-

Page 4

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for TV Circuit

1. Before returning an instrument to the custom-

er, always make a safety check of the entire instru-

ment, including, but not limited to, the following

items:

a. Be sure that no built-in protective devices are de-

fective and have been defeated during servicing.

(1) Protective shields are provided on this chassis

to protect both the technician and the customer.

Correctly replace all missing protective shields, including any removed for servicing convenience.

(2) When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpapers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not oper-

ate this instrument or permit it to be operated

without all protective devices correctly installed and functioning. Servicers who defeat

safety features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to, (1) spacing between the picture tube and the cabinet

mask, (2) excessively wide cabinet ventilation

slots, and (3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug prongs.

Place the instrument AC switch in the on position.

Connect one lead of an ohmmeter to the AC plug

prongs tied together and touch the other ohmmeter lead in turn to each tuner antenna input exposed terminal screw and, if applicable, to the

coaxial connector. If the measured resistance is

less than 1.0 megohm or greater than 5.2 megohm, an abnormality exists that must be corrected

before the instrument is returned to the customer.

Repeat this test with the instrument AC switch in

the off position.

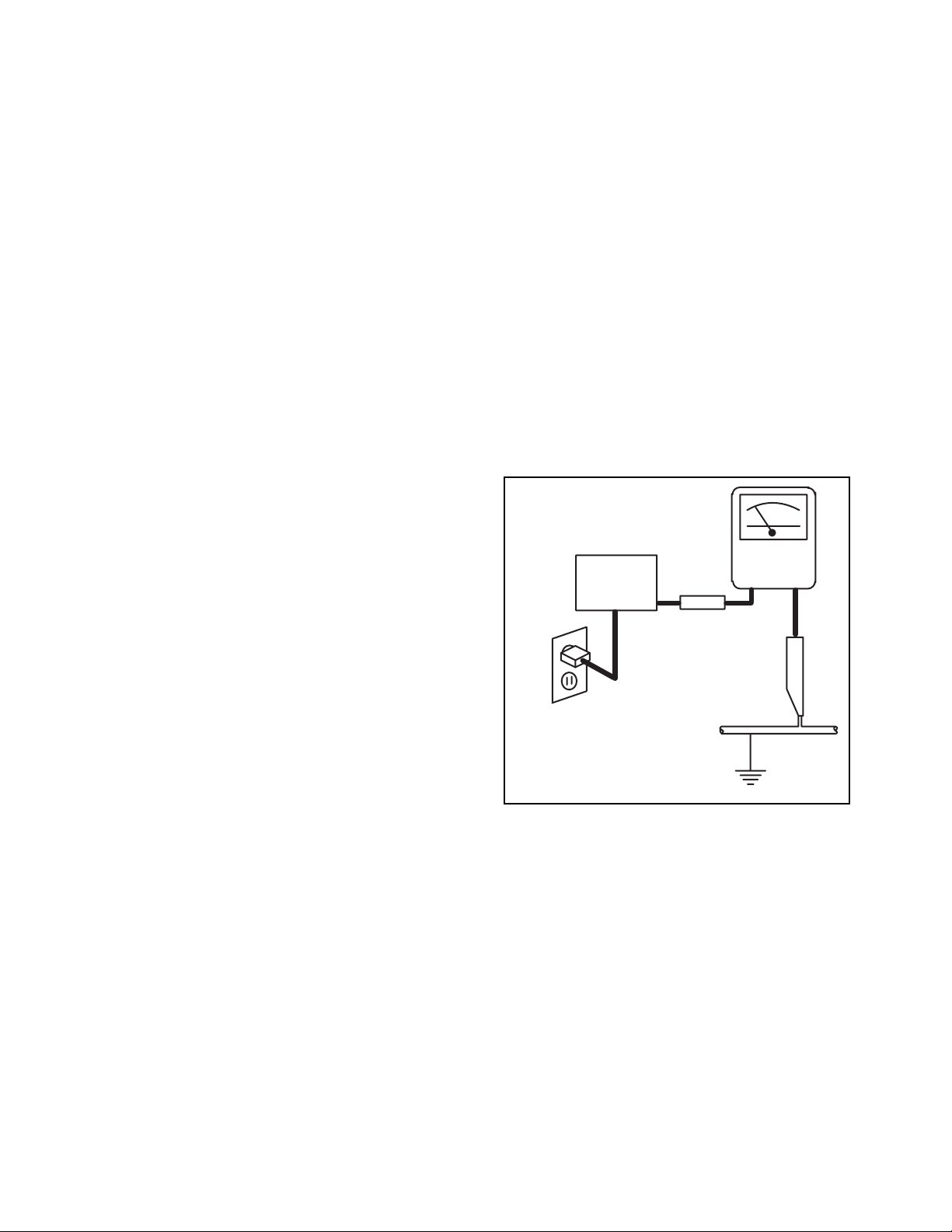

d. Leakage Current Hot Check - With the instru-

ment completely reassembled, plug the AC line

cord directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leak-

age current tester or a metering system that complies with American National Standards Institute

(ANSI) C101.1 Leakage Current for Appliances

and Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on position and then in the off position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinet, screw

heads, metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any current

measured must not exceed 0.5 milli-ampere. Reverse the instrument power cord plug in the outlet

and repeat the test.

READING SHOULD

NOT BE ABOVE 0.5 mA

LEAKAGE

DEVICE

BEING

TESTED

TEST ALL EXPOSED

METAL SURFACES

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO

THE CUSTOMER OR BEFORE CONNECTING

THE ANTENNA OR ACCESSORIES.

e. X-Radiation and High Voltage Limits - Because

the picture tube is the primary potential source of

X-radiation in solid-state TV receivers, it is specially constructed to prohibit X-radiation emissions.

For continued X-radiation protection, the replacement picture tube must be the same type as the

original. Also, because the picture tube shields

and mounting hardware perform an X-radiation

protection function, they must be correctly in place.

High voltage must be measured each time servic-

CURRENT

TESTER

+

EARTH

GROUND

_

2-1 L6115IMP

Page 5

ing is performed that involves B+, horizontal deflection or high voltage. Correct operation of the Xradiation protection circuits also must be reconfirmed each time they are serviced. (X-radiation

protection circuits also may be called "horizontal

disable" or "hold down.") Read and apply the high

voltage limits and, if the chassis is so equipped,

the X-radiation protection circuit specifications given on instrument labels and in the Product Safety

& X-Radiation Warning note on the service data

chassis schematic. High voltage is maintained

within specified limits by close tolerance safety-related components/adjustments in the high-voltage

circuit. If high voltage exceeds specified limits,

check each component specified on the chassis

schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV receiver. Design alterations and additions, including,

but not limited to circuit modifications and the addition of items such as auxiliary audio and/or video

output connections, might alter the safety characteristics of this receiver and create a hazard to the

user. Any design alterations or additions will void

the manufacturer's warranty and may make you,

the servicer, responsible for personal injury or

property damage resulting therefrom.

4. Picture Tube Implosion Protection Warning -

The picture tube in this receiver employs integral

implosion protection. For continued implosion protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles

equipped with side shields. People not so

equipped must be kept safely away while picture

tubes are handled. Keep the picture tube away

from your body. Do not handle the picture tube by

its neck. Some "in-line" picture tubes are equipped

with a permanently attached deflection yoke; because of potential hazard, do not try to remove

such "permanently attached" yokes from the picture tube.

5. Hot Chassis Warning -

a. Some TV receiver chassis are electrically connect-

ed directly to one conductor of the AC power cord

and maybe safety-serviced without an isolation

transformer only if the AC power plug is inserted

so that the chassis is connected to the ground side

of the AC power source. To confirm that the AC

power plug is inserted correctly, with an AC voltmeter, measure between the chassis and a known

earth ground. If a voltage reading in excess of 1.0V

is obtained, remove and reinsert the AC power

plug in the opposite polarity and again measure

the voltage potential between the chassis and a

known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground regardless of the AC plug polarity. This chassis can

be safety-serviced only with an isolation transformer inserted in the power line between the receiver

and the AC power source, for both personnel and

test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not isolated from the AC power line. The two ground systems are electrically separated by insulation

material that must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead dress in the following areas:a.

near sharp edges,b. near thermally hot parts-be

sure that leads and components do not touch thermally hot parts,c. the AC supply,d. high voltage,

and,e. antenna wiring. Always inspect in all areas

for pinched, out of place, or frayed wiring. Check

AC power cord for damage.

7. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or wiring that meet original specifications. Additionally,

determine the cause of overheating and/or damage and, if necessary, take corrective action to remove any potential safety hazard.

8. Product Safety Notice - Some electrical and mechanical parts have special safety-related characteristics which are often not evident from visual

inspection, nor can the protection they give necessarily be obtained by replacing them with components rated for higher voltage, wattage, etc.. Parts

that have special safety characteristics are identified by a ( # ) on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or

other hazards. The product's safety is under review continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are strictly inspected to confirm they comply with the recognized product safety and electrical codes of the countries in which

they are to be sold. However, in order to maintain

such compliance, it is equally important to implement the following precautions when a set is being

serviced.

2-2 L6115IMP

Page 6

Precautions during Servicing

A. Parts identified by the ( # ) symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder drop-

lets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power transformer uses crimp type connec-

tors which connect the power cord and the primary

side of the transformer. When replacing the trans-

former, follow these steps carefully and precisely

to prevent shock hazards.

Replacement procedure

1) Remove the old connector by cutting the wires at

a point close to the connector.

Important: Do not re-use a connector (discard it).

2) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3) Align the lengths of the wires to be connected. Insert the wires fully into the connector.

4) Use the crimping tool to crimp the metal sleeve at

the center position. Be sure to crimp fully to the

complete closure of the tool.

L. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC supply outlet.

2-3 L6115IMP

Page 7

Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts and wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order to verify compliance

with safety standards.

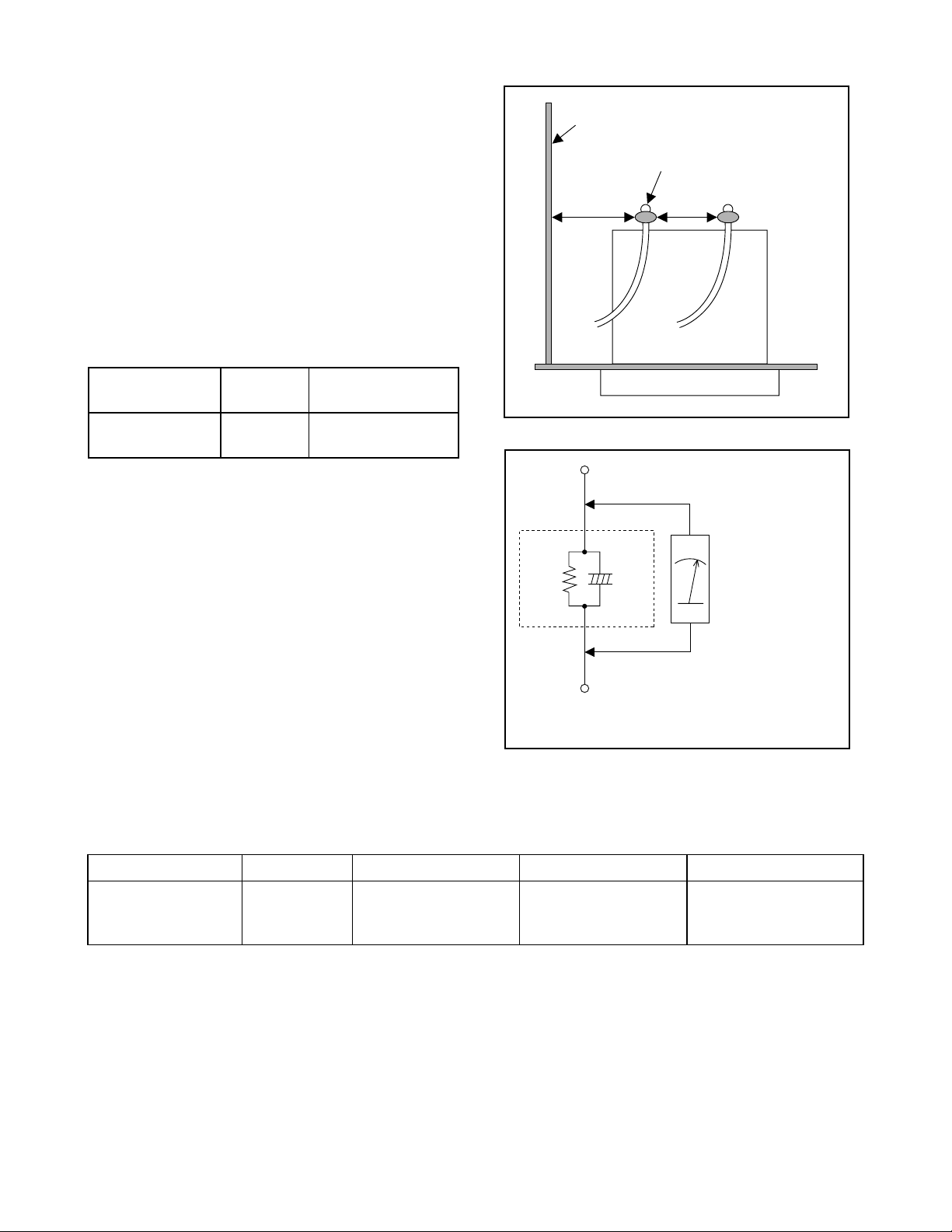

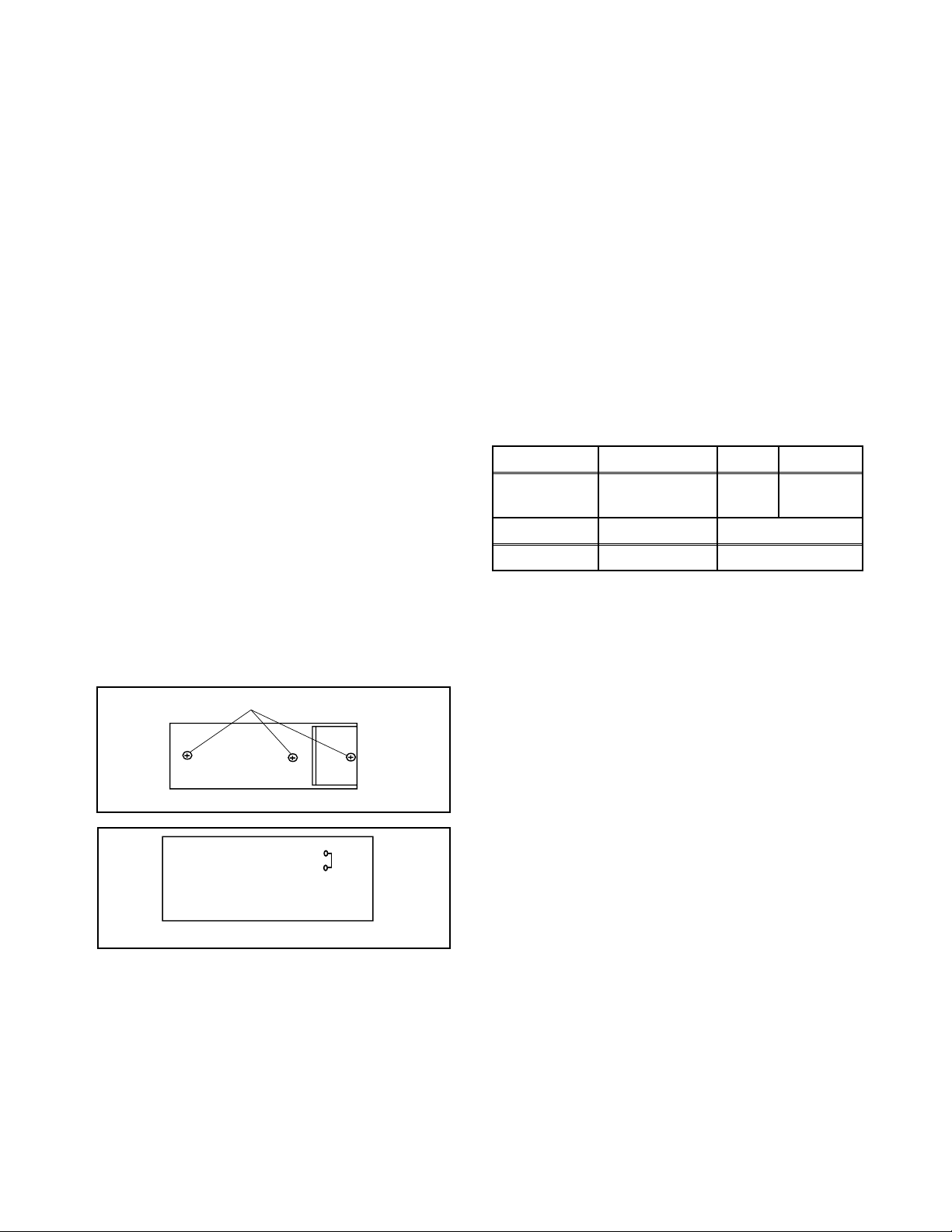

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Region

110 to 130 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

USA or

CANADA

Clearance

Distance (d) (d')

≥ 3.2 mm

(0.126 inches)

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method : (Power ON)

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of

load Z. See Fig. 2 and following table.

Z

1.5kΩ

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

Exposed Accessible Part

AC Voltmeter

0.15µF

Earth Ground

B

Power Cord Plug Prongs

(High Impedance)

Fig. 1

Fig. 2

Table 2 : Leakage current ratings for selected areas

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

0.15µF CAP. & 1.5kΩ

110 to 130 V USA

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

RES. connected in

parallel

2-4 L6115IMP

i≤0.5mA rms

Exposed accessible

parts

Page 8

STANDARD NOTES FOR SERVICING

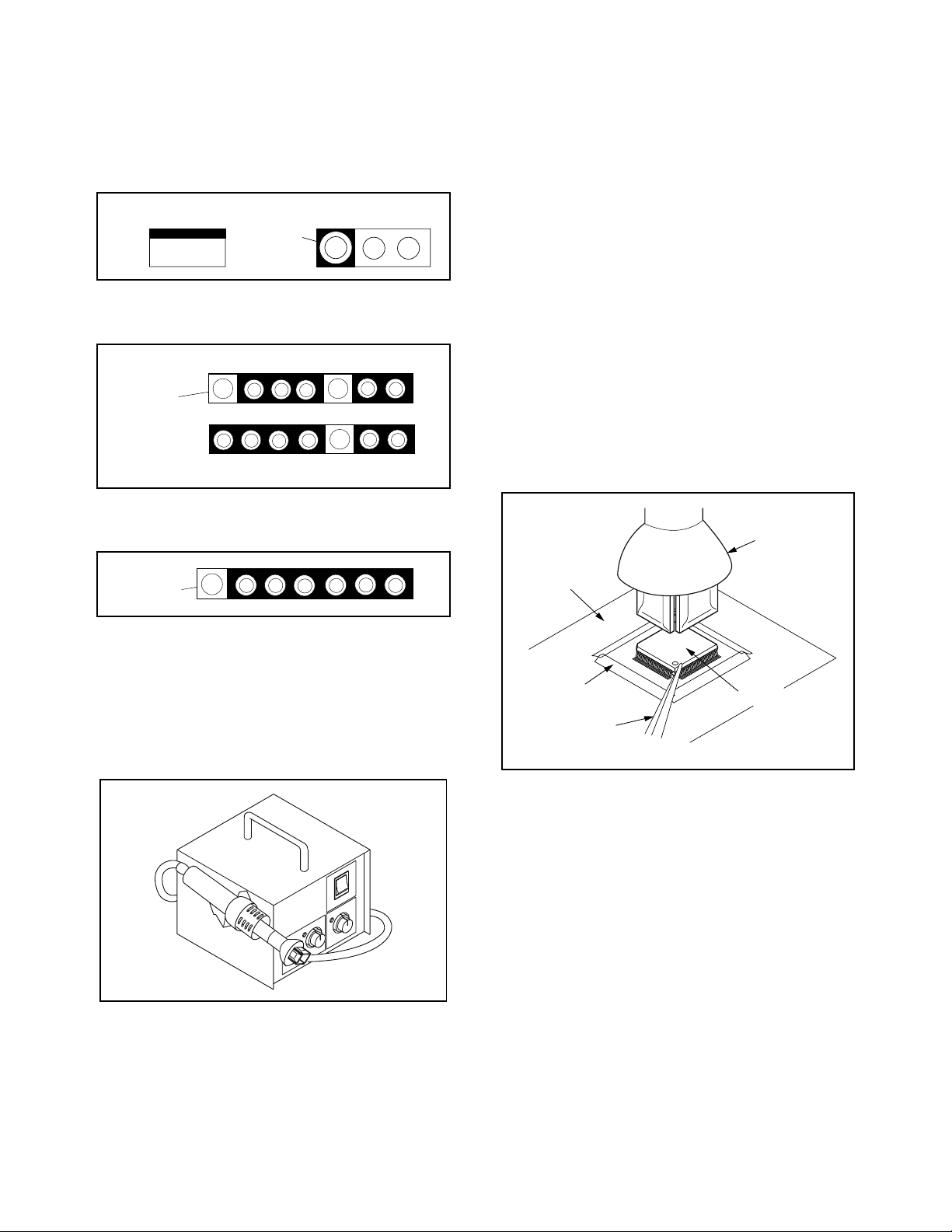

Circuit Board Indications

a. The output pin of the 3 pin Regulator ICs is indicat-

ed as shown.

Top View

Out

b. For other ICs, pin 1 and every fifth pin are indicat-

ed as shown.

Pin 1

c. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

(2) Remove the flat pack-IC with tweezers while ap-

plying the hot air.

(3) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Caution:

1. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

2. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing it.

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

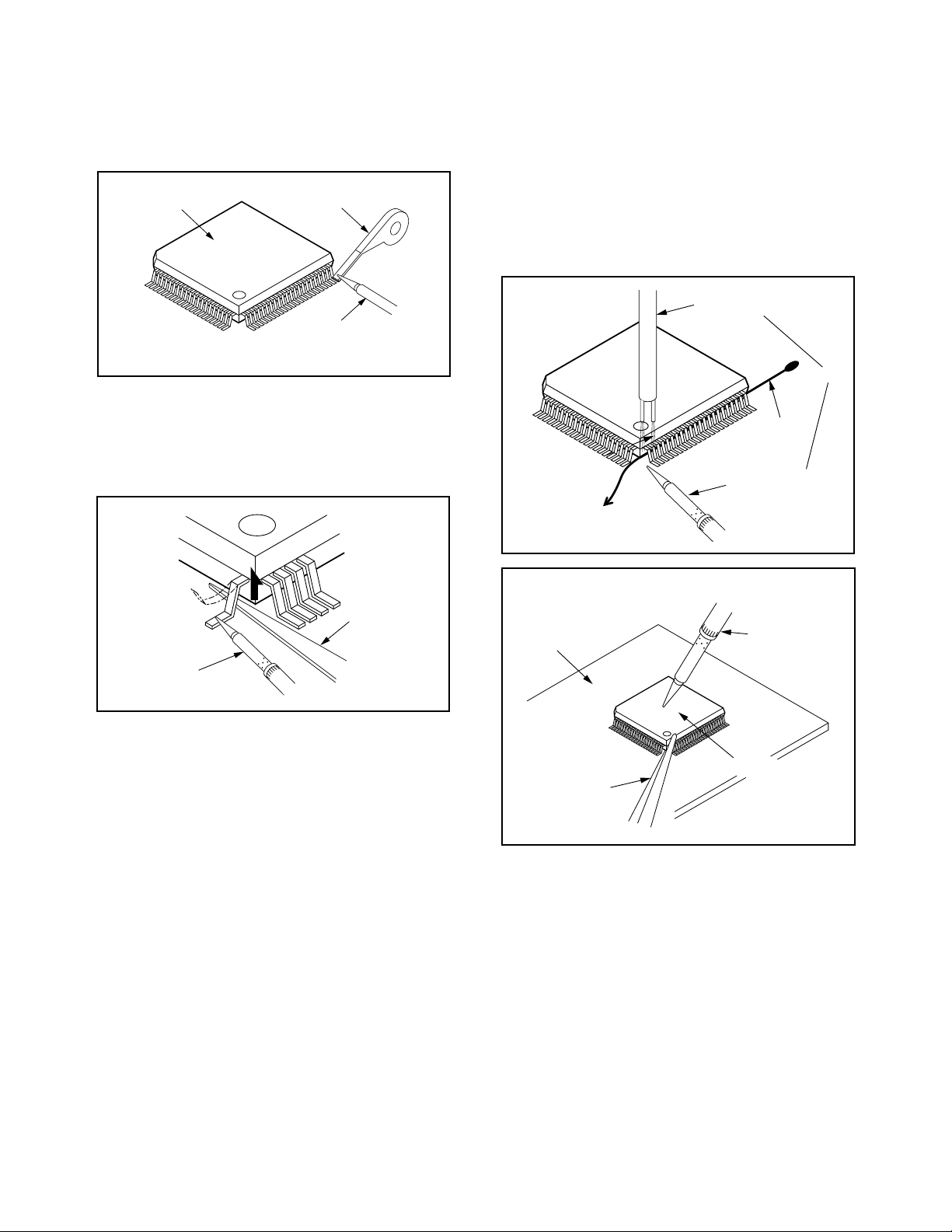

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

(1) Prepare the hot-air flat pack-IC desoldering ma-

chine, then apply hot air to the Flat Pack-IC (about

5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Masking

Tape

Tweezers

Flat Pack-IC

Fig. S-1-2

3-1 L6115STA

Page 9

With Soldering Iron:

(1) Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering machine.(Fig. S-1-4)

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a soldering iron, care must be taken to

ensure that the flat pack-IC is not being held by

glue. When the flat pack-IC is removed from the

CBA, handle it gently because it may be damaged

if force is applied.

Hot Air Blower

or

Iron Wire

Soldering Iron

To Solid

Mounting Point

Fig. S-1-5

Sharp

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

(3) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

With Iron Wire:

(1) Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA contact pads as shown in Fig. S-1-5.

(4) Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

CBA

Tweezers

Fine Tip

Soldering Iron

Flat Pack-IC

Fig. S-1-6

3-2 L6115STA

Page 10

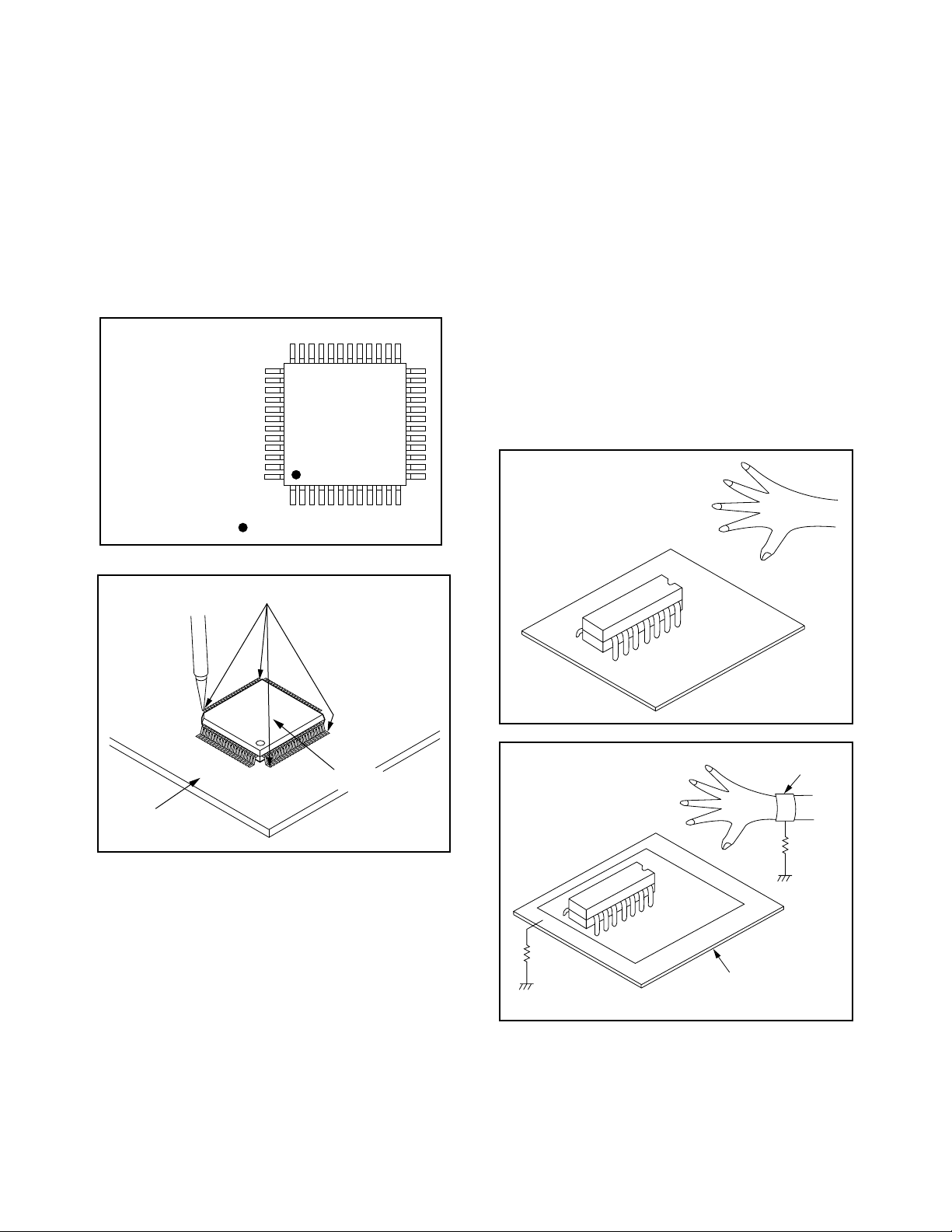

2. Installation

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

(2) The "I" mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

pre- solder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

(3) Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Instructions for Handling

Semiconductors

Electrostatic breakdown of the semiconductors may

occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly grounded to remove any static electricity that may

be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the workbench or

other surface, where the semiconductors are to be

placed. Because the static electricity charge on clothing will not escape through the body grounding band,

be careful to avoid contacting semiconductors with

your clothing.

<Incorrect>

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

3-3 L6115STA

Page 11

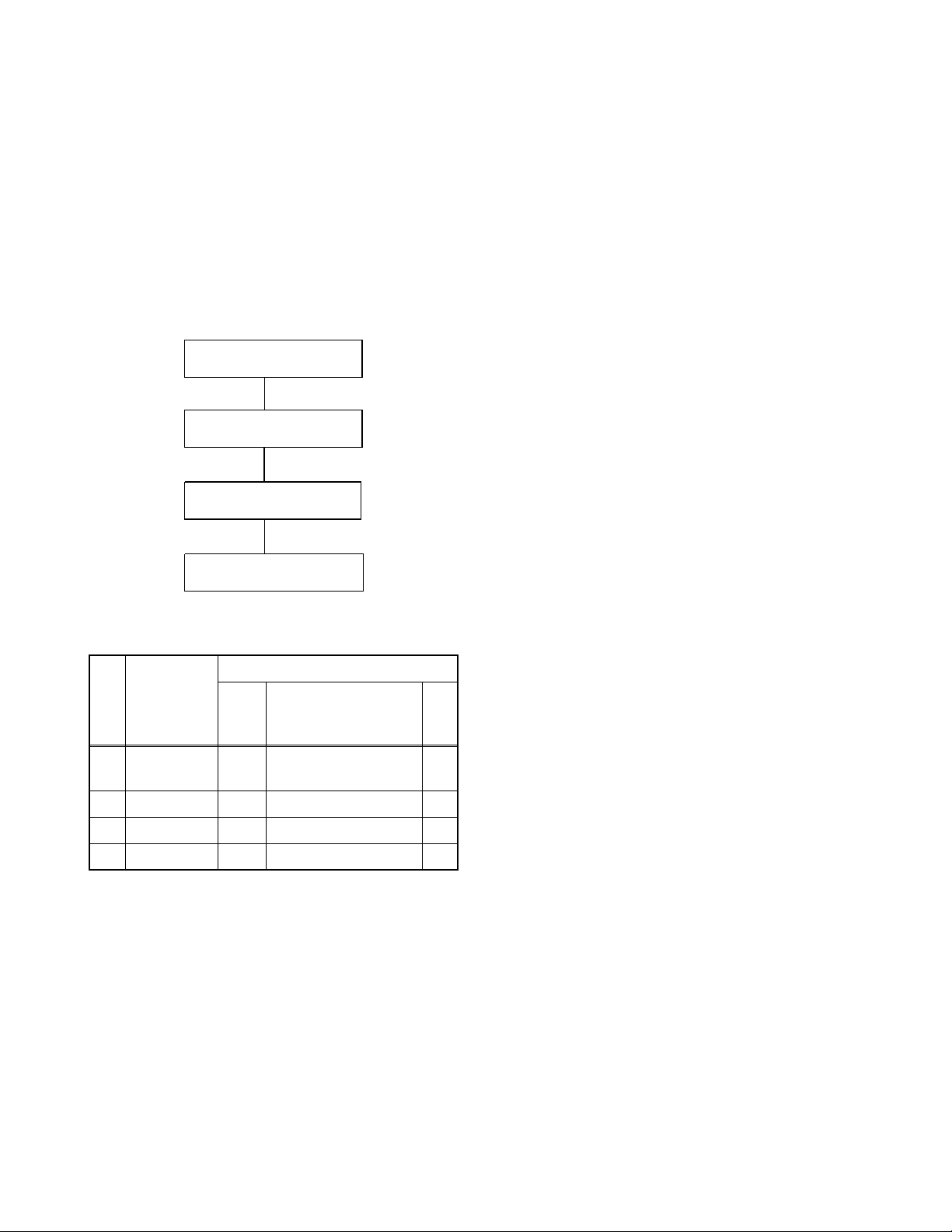

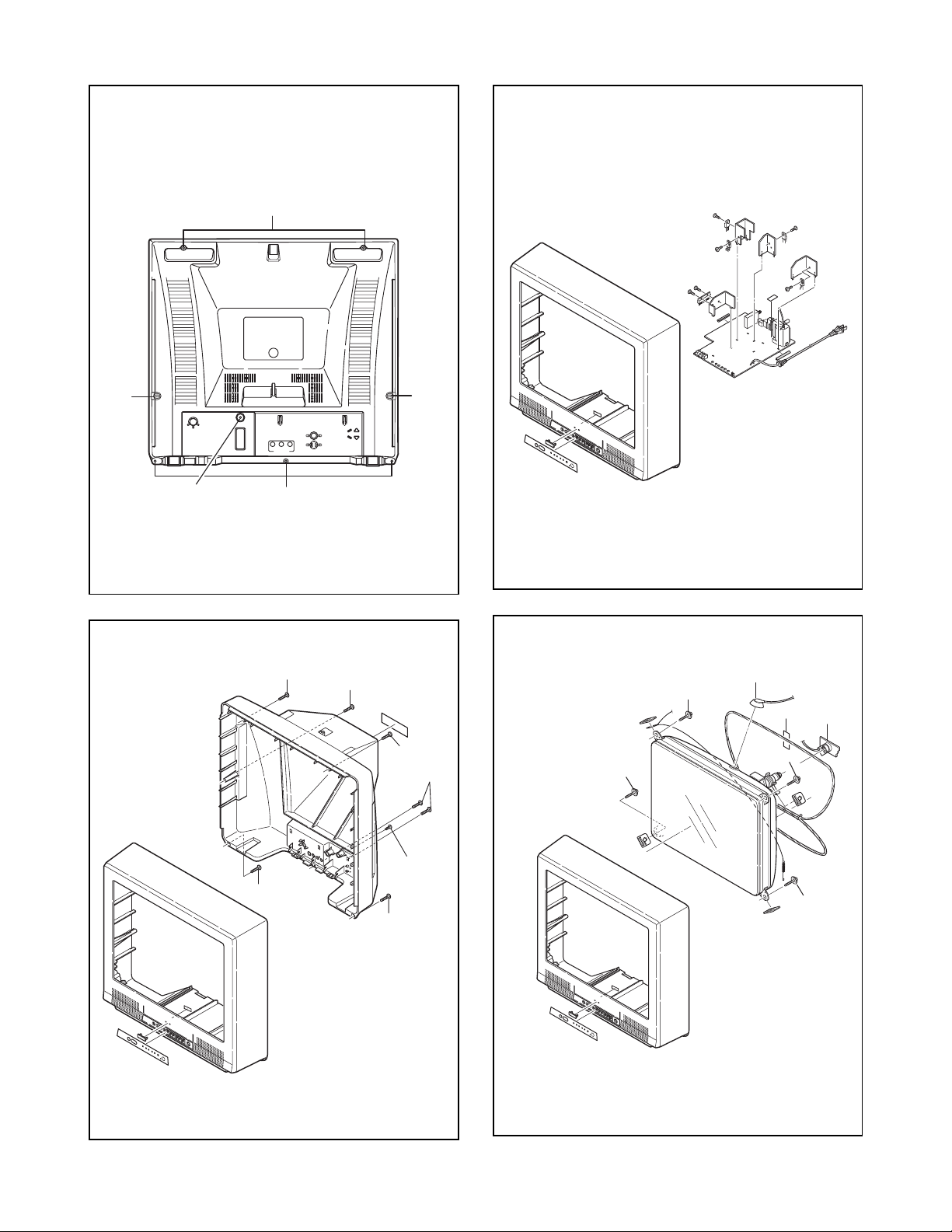

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the CBA in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

Caution !

When removing the CRT, be sure to discharge the

Anode Lead of the CRT with the CRT Ground Wire

before removing the Anode Cap.

[1] Rear Cabinet

[2] CRT CBA

[3] Main CBA

[4] CRT

2. Disassembly Method

Step/

Loc.

No.

[1]

Part

Rear

Cabinet

Fig.

No

1,2

Removal

Remove/*unlock/

release/unplug/

unclamp/desolder

7(S-1), 1(S-4)

Note

1

Note :

(1) Order of steps in procedure. When reassembling,

follow the steps in reverse order.These numbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of part to be removed, unhooked, un-

locked, released, unplugged, unclamped, or

desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connector, *=Unhook, Unlock, Release, Unplug, or

Desolder

2(S-2) = two Screws (S-2)

(5) Refer to the following "Reference Notes in the

Table."

Reference Notes in the Table

1. Removal of the Rear Cabinet. Remove screws

7(S-1) and 1(S-4) then slide the Rear Cabinet

backward.

2. Removal of the CRT CBA. Disconnect CN501 then

pull the CRT CBA backward.

3. Removal of the Main CBA. Disconnect CN571 on

the Main CBA then slide the Main CBA backward.

Caution !

Discharge the Anode Lead of the CRT with the CRT

Ground Wire before removing the Anode Cap.

4. Removal of the CRT. Remove screws 4(S-3) and

Anode Cap. then slide the CRT backward.

[2] CRT CBA 4,5 CN501 2

[3] Main CBA 3,5 CN571 3

[4] CRT 4 4(S-3), CN691 4

↓↓↓↓↓

(1) (2) (3) (4) (5)

4-1 L6509DC

Page 12

S-1

S-1

S-4

S-1

S-1

S-1

S-1

Fig. 1

S-1

S-1

S-3

S-3

[3] Main CBA

ANODE CAP

Scotch Tape

#880

S-3

Fig. 3

CRT

CBA

S-1

[1] Rear Cabinet

S-1

S-4

Fig. 2

[4] CRT

S-3

Fig. 4

4-2 L6509DC

Page 13

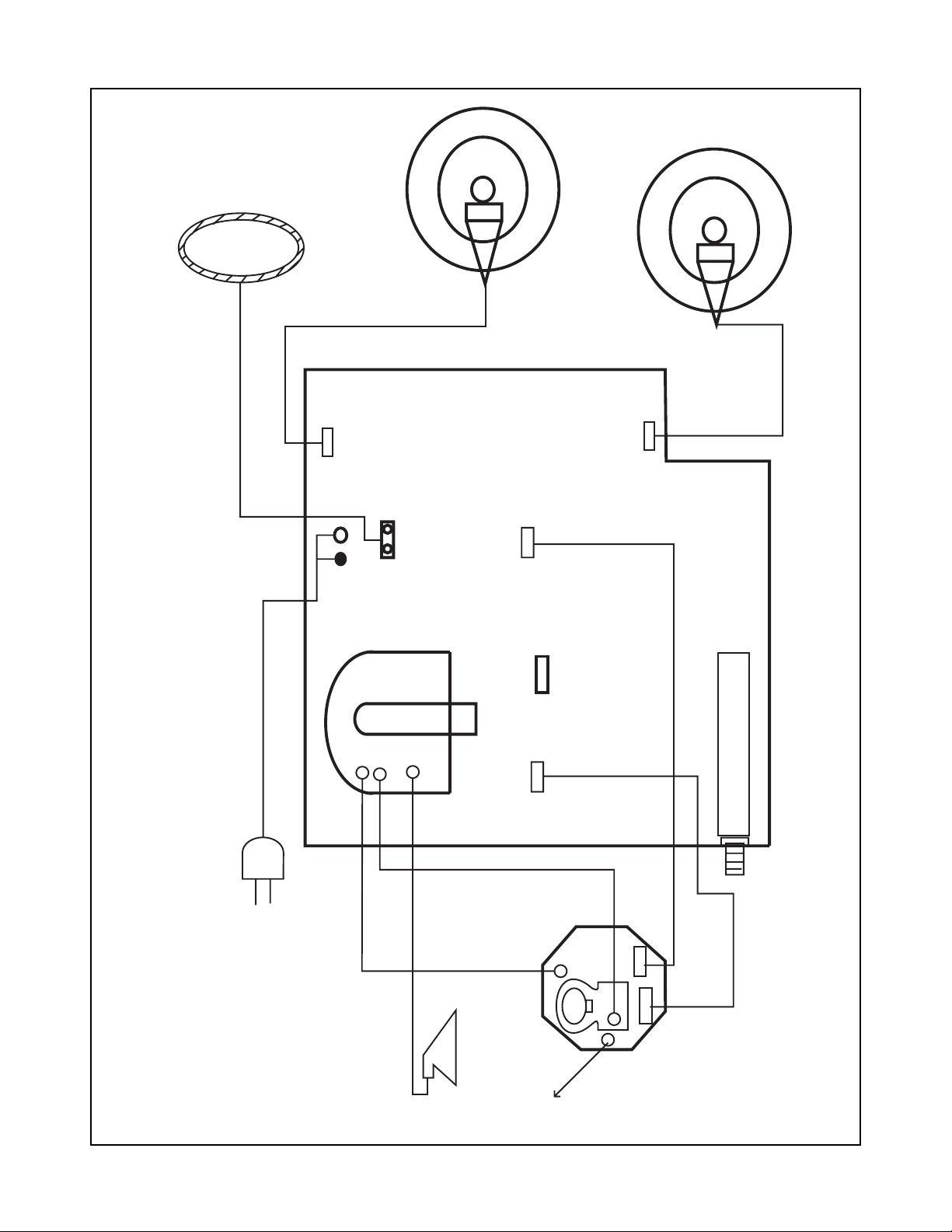

TV Cable Wiring Diagram

L691 DEGAUSSING COIL

SP802

CN802

CN691

FLYBACK

TRANSFORMER

CLN802

MAIN CBA

WH301A

CN571

SP801

CLN801

CN801

TU1

TUNER

AC601

AC CORD

T571

FOCUS

SCREEN

ANODE

WH501A

JK1501

CN1501

TO CRT GROUND

WH301B

WH501B

Fig. 5

4-3 L6509DC

Page 14

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note:

"CBA" is abbreviation for "Circuit Board Assembly."

NOTE:

Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to perform these adjustments only

after all repairs and replacements have been completed.

Also, do not attempt these adjustments unless the

proper equipment is available.

Test Equipment Required

1. NTSC Pattern Generator (Color Bar W/White

Window, Red Color, Dot Pattern, Gray Scale,

Monoscope, Multi-Burst)

2. DC Voltmeter

3. Oscilloscope: Dual-trace with 10:1 probe,

V-Range:0.001~50V/Div,

F-Range: DC~AC-60MHz

4. Plastic Tip Driver

5. Remote control unit: Part No. N0138UD or N0139UD

6. DC power supply 13.2V/5A

How to make Service remote control unit:

1.

Prepare normal remote control unit. (Part No.

N0138UD or N0139UD) Remove 3 Screws from

the back lid. (Fig. 1-1)

2. Added J1 (Jumper Wire) to the remote control CBA.

(Fig. 1-2)

How to set up the service mode:

Service mode:

1. Use the service remote control unit.

2. Turn the power on. (Use main power on the TV

unit.)

3. Press "SLEEP" button on the service remote control unit. Version of micro computer will display on

the CRT. (Ex: 057-0.02)

4. Check the display on the lower left is "2801" and if

it is not "2801," set it at "2801" according to "2. Initial Setting."

1. +B Adjustment

Purpose: To obtain correct operation.

Symptom of Misadjustment: The picture is dark and

the unit does not operate correctly.

Test Point Adj. Point Mode Input

TP601(+B)

TP300(GND)

Tape M. EQ. Spec.

--- DC Voltmeter +112±0.5V DC.

Note:TP601, TP300(GND), VR661 --- Main CBA

1. Connect DC Volt Meter to TP601 and TP300(GND).

2. Adjust VR661 so that the voltage of TP601 becomes

+112±0.5V DC.

VR661 --- ---

SCREWS

REMOTE CONTROL UNIT

J 1

REMOTE CONTROL CBA

Fig. 1-1

Fig. 1-2

5-1 L6509EA

Page 15

2. Initial Setting

General

1. Enter the Service mode. (See page 5-1)

2. Press "VOL p" button on the service remote control

unit. Display changes "C/D," "7F," "LANGUAGE,"

"ACCESS CODE," "SOUND TYPE," "VIDEO

TONE," "FM MODE," "V-OUT," "VIDEO," "AV

MEMO," "STABLE SOUND," "FILTER," "300," and

"YUV MEMORY" cyclically when "VOL p" button is

pressed.

3. To set the following each data value, press "CH o

/ p" buttons on the service remote control unit.

7F --- Set to "FF."

LANGUAGE --- Set to "SPA."

ACCESS CODE --- Set to "OFF."

SOUND TYPE --- Set to "MTS."

3. Setting for BRIGHT, CONTRAST,

COLOR, TINT, and SHARPNESS

data Values

General

1. Enter the Service mode. (See page 5-1)

2. Press "MENU" button on the service remote control

unit. Display changes "BRT," "CNT," "CLR," "SCLR," "TNT," "V-TNT," "S-TNT," "SHARP," and

"S-SRP" cyclically when "MENU" button is

pressed.

Note: BRIGHT data value does not need to be adjust-

ed at this moment.

This model doesn’t have a S-VIDEO input, so

that you don’t have to adjust "S-COLOR"(S-

CLR), "S-TINT"(S-TNT) and "S-SHARPNESS"(S-SRP).

VIDEO TONE --- Set to "ON."

FM-MODE --- Set to "OFF."

V-OUT --- Set to "OFF."

VIDEO --- Set to "V1/V2."

AV MEMO --- Set to "OFF."

STABLE SOUND --- Set to "OFF."

FILTER --- Set to "OFF."

Adjusting the monitoring time --- Set to "500."

YUV MEMORY --- Set to "OFF."

CNT

1. Press "MENU" button on the service remote control

unit. Then select "CONTRAST" (CNT) display.

2. Press "CH o/p" buttons on the service remote

control unit so that the value of "CONTRAS" (CNT)

becomes 84.

CLR

1. Press "MENU" button on the service remote con-

trol unit. Then select "COLOR" (CLR) display.

2. Press "CH o/p" buttons on the service remote

control unit so that the value of "COLOR" (CLR)

becomes 56.

TNT

1. Press "MENU" button on the service remote con-

trol unit. Then select "TINT" (TNT) display.

2. Press "CH o/p" buttons on the service remote

control unit so that the value of "TINT" (TNT) becomes 62.

V-TNT

1. Press "MENU" button on the service remote con-

trol unit. Then select "V-TINT" (V-TNT) display.

2. Press "CH o/p" buttons on the service remote

control unit so that the value of "V-TINT" (V-TNT)

becomes 62.

SHARP

1. Press "MENU" button on the service remote con-

trol unit. Then select "SHARPNESS" (SHARP) display.

2. Press "CH o/p" buttons on the service remote

control unit and select "47."

Note: BRIGHT data value does not need to be adjust-

ed at this moment.

5-2 L6509EA

Page 16

4. Black Stretch Control Adjustment

Purpose: To show the fine black color.

Symptom of Misadjustment: Black color will not

appear correctly.

Note: Use service remote control unit.

1. Enter the Service mode. (See page 5-1)

2. Press "6" button on the service remote control unit.

"B-S" is indicated.

3. Press "CH o / p" buttons on the service remote control unit so that display will change "OFF," "0," and

"1." Then choose "B-S OFF."

4. Press "6" button on the service remote control unit.

"B-S2" is indicated.

5. Press "CH o / p" buttons on the service remote

control unit so that display will change "0" and "1."

Then choose "B-S2 0."

6. Turn the power off and on again, using the main

power button on the TV unit.

5. Purity Check

1. Enter the Service mode. (See page 5-1)

2. Press "7" button on the remote control unit. Each

time pressing 7" button on the remote control unit,

display changes Red mode, Green mode, Blue

mode, and White mode cyclically.

3. Select White mode.

4. Turn the power off and on again. (Main power button on the TV unit.)

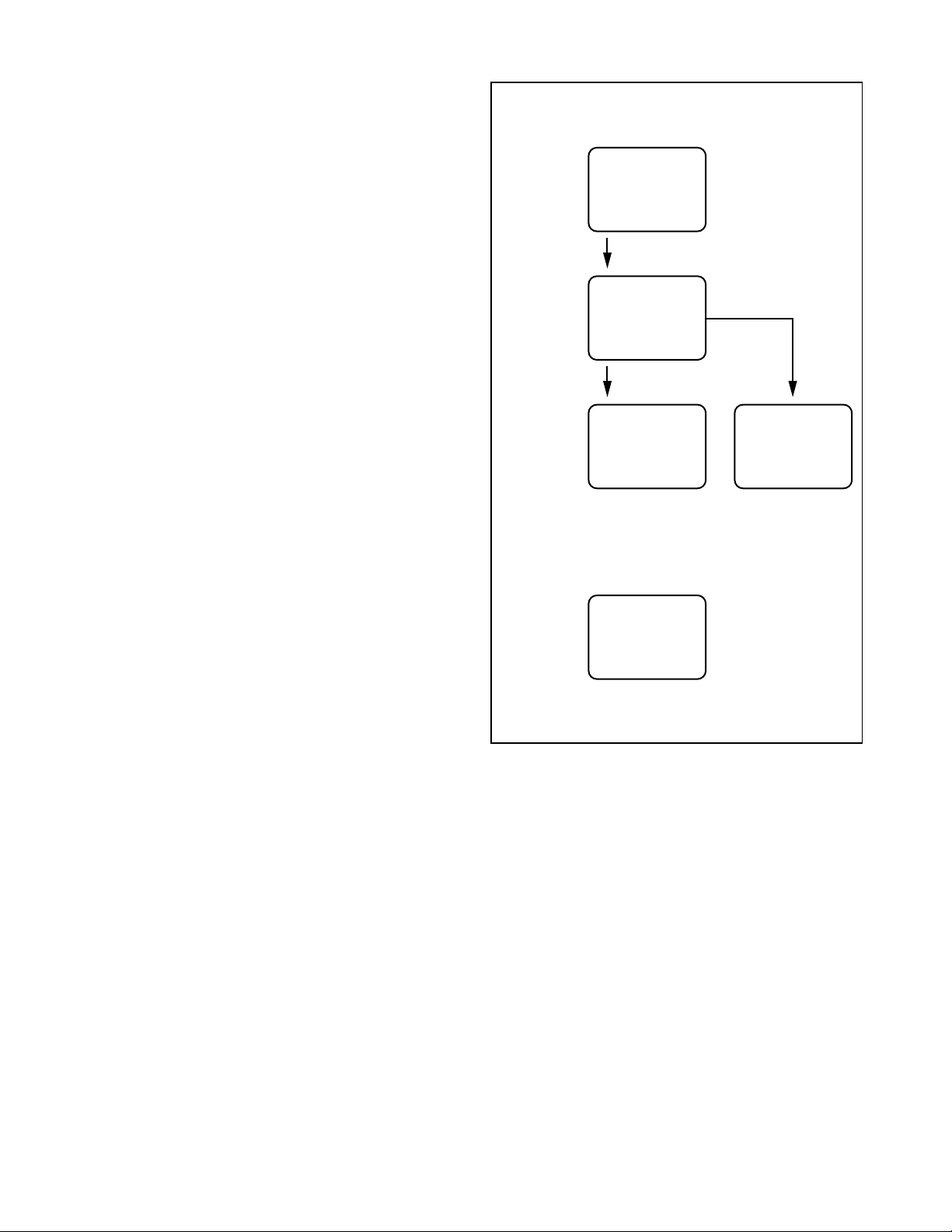

6. SD Check Mode

1. Enter the Service mode. (See page 5-1)

2. Press "1" button on the remote control unit. The

unit enter the SD-Check mode.

3. The unit starts selecting the added channel from

first channel according to the memorized CH ADD/

DELL data and CATV/TV data in RAM.

SD Check mode (Factory mode)

Press "1" buton.

7

Please wait

OSD color:

Magenta

13

Please wait

There are SD

in all channel.

When SD-Check starting,

there is no ADD channel.

OSD color:

Magenta

26

OK

OSD color:

Magenta

ADD nothing

OSD color:

Magenta

There is no SD after

selecting channel.

30

NG

OSD color:

Magenta

5-3 L6509EA

Page 17

7. H. Position Adjustment

Purpose: To obtain correct horizontal position of

screen image.

Symptom of Misadjustment: If H. Position is incor-

rect, horizontal position of image on the screen may

not be properly displayed.

9. V. Position Adjustment

Purpose: To obtain correct vertical width of screen

image.

Symptom of misadjustment: If V. Position is incor-

rect, vertical height of image on the screen may not be

properly displayed.

Test Point Adj. Point Mode Input

---

Tape M. E Q. S p e c.

--- Monoscope 90±5%

Note: Use service remote control unit

1. Operate the unit for at least 20 minutes.

2. Enter the Service mode. (See page 5-1)

3. Receive the monoscope pattern.

4. Press "8" button on the remote control unit.

"H-P" is indicated.

5. Press "CH o/p" buttons on the service remote

control unit so that the monoscope pattern will be

90±5% of display size and the circle is round.

6. Turn the power off and on again. (Main power button on the TV unit.)

CH o / p

buttons

RF

Mono-

scope

8. V. Size Adjustment

Purpose: To obtain correct vertical width of screen image.

Symptom of Misadjustment: If V. Size is incorrect, vertical

size of image on the screen may not be properly displayed.

Test Point Adj. Point Mode Input

---

Tape M. EQ. Spec.

--- Monoscope See below.

Note: Use service remote control unit

1. Operate the unit for at least 20 minutes.

2. Enter the Service Mode. (See page 5-1)

3. Receive the monoscope pattern.

4. Press "9" button on the service remote control unit

and select "V-P" mode. (Display change "V-S" and

"V-P" cyclically when "9" button is pressed).

5. Press "CH o/p" buttons on the service remote

control unit so that the top and bottom of the monoscope pattern will be equal of each other.

6. Turn the power off and on again. (Main power button on the TV unit.)

CH o / p

buttons

RF

Mono-

scope

10. Software Reset

To reset software, press “5” button on the remote control unit for at least 5 seconds after pressing “CH

RETURN” button on the remote control unit.

Test Point Adj. Point Mode Input

---

Tape M . EQ . Spe c .

--- Monoscope 90±5%

Note: Use service remote control unit.

1. Operate the unit for at least 20 minutes.

2. Enter the Service mode. (See page 5-1)

3. Receive the monoscope pattern.

4. Press "9" button on the service remote control unit

and select "V-S" mode. (Display changes "V-S" and

"V-P" cyclically when "9" button is pressed).

5. Press "CH o/p" buttons on the service remote

control unit so that the monoscope pattern will be

90±5% of display size and the circle is round.

6. Turn the power off and on again. (Main power button on the TV unit.)

CH o / p

buttons

RF

Mono-

scope

5-4 L6509EA

Page 18

11. Cut-off Adjustment

Purpose: To adjust the beam current of R, G, B, and

screen voltage.

Symptom of Misadjustment: White color may be

reddish, greenish or bluish.

12. White Balance Adjustment

Purpose: To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

Test Point Adj. Point Mode Input

Screen-Control

---

Tape M . EQ . Spe c .

---

Note: Screen Control FBT --- Main CBA

F.B.T= Fly Back Transformer

Use service remote control unit

1. Degauss the CRT and allow CRT to operate for 20

minutes before starting the alignment.

2. Input the Black Raster Signal from RF Input.

3. Enter the Service mode. (See page 5-1)

4. Press "VOL p" button on the service remote control unit and select "C/D" mode. (Display changes

"C/D," "7F," "LANGUAGE," "ACCESS CODE,"

"SOUND TYPE," "VIDEO TONE," "FM MODE,"

"V-OUT," "VIDEO," "AV MEMO," "STABLE

SOUND," "FILTER," "500," and "YUV MEMORY"

cyclically when "VOL p button is pressed.) then

press "1." The display will momentarily show "CUT

OFF R" (R= Red). Now there should be a horizontal line across the center of the picture tube. If

needed gradually turn the screen control on the flyback, clockwise until the horizontal line appears.

Adjust the Red Cut off by pressing the "CH o/p"

buttons. Proceed to Step 5 when the Red Cut off

adjustment is done.

5. Press the "2" button. The display will momentarily

show "CUT OFF G" (G=Green). Adjust the Green

Cut off by pressing the "CH o/p" buttons. Proceed

to step 6 when the Green Cut off adjustment is done.

6. Press the "3" button. The display will momentarily

show "CUT OFF B" (B=Blue). Adjust the Blue cut

off by pressing the "CH o/p" buttons. When done

with steps 4, 5 and 6 the horizontal line should be

pure white if not, then attempt the Cut off adjustment again.

CH o / p

buttons

Pattern

Generator

Figure

PATTERN GENERATOR

EXT. INPUT

RF

See Reference

Notes below.

Fig. 2

Black

Raster

Test Point Adj. Point Mode Input

White

Screen

Tape M. EQ. Spec.

---

Note: Use service remote control unit

1. Operate the unit more than 20 minutes.

2. Face the unit to east. Degauss the CRT using Degaussing Coil.

3. Input the White Raster (APL 100%).

4. Set the color analyzer to the CHROMA mode and

after zero point calibration, bring the optical receptor to the center on the tube surface (CRT).

5. Enter the Service mode. Press "VOL p" button on the

service remote control unit and select "C/D" mode.

(Display changes "C/D," "7F," "LANGUAGE," "ACCESS CODE," "SOUND TYPE," "VIDEO TONE,"

"FM MODE," "V-OUT," "VIDEO," "AV MEMO,"

"STABLE SOUND," "FILTER," "500," and "YUV

MEMORY" cyclically when "VOL p" button is

pressed.) then Press No. 8 button on the service remote control Unit.

6. Press No. 4 button on the service remote control

unit for Red adjustment. Press N0. 5 button on the

service remote control unit for Blue adjustment.

7. In each color mode, Press "CH o/p" button to adjust

the values of color.

8. Adjusting Red and Blue color so that the temperature

becomes 9200K (x: 286 / y: 294)±3%.

9. At this time, Re-check that Horizontal line is white.

If not, Re-adjust Cut-off Adjustment until the Horizontal Line becomes pure white.

10. Turn off and on again to return to normal mode. Receive APL 100% white signal and Check Chroma

temperatures become 9200K (x: 286 / y: 294)±3%.

Note: Confirm that Cut Off Adj. is correct after this

adjustment, and attempt Cut Off Adj. if needed.

CH o / p

buttons

Pattern

Generator,

Color analyzer

Figure

Color Analyzer

RF

Raster

(APL

100%)

See below

Fig. 3

5-5 L6509EA

Page 19

13. Sub-Brightness Adjustment

Purpose: To get proper brightness.

Symptom of Misadjustment: If Sub-Brightness is

incorrect, proper brightness cannot be obtained by

adjusting the Brightness Control.

4. Adjust the Focus Control on the FBT to obtain

clear picture.

The following adjustments normally are not

attempted in the field. Only when replacing the

CRT then adjust as a preparation.

Test Point Adj. Point Mode Input

---

Tape M. EQ. Spec.

---

White

Note: IQW Setup level --- 7.5 IRE

Use service remote control unit

1. Enter the Service mode. (See page 5-1)

Then input IQW signal from RF Input.

2. Press "MENU" button on the service remote control

unit and Select "BRT" mode. (Display changes

"BRT," "CNT," "CLR," "S-CLR," "TNT," "V-TNT," "STNT," "SHARP," and "S-SRP" cyclically when

"MENU" button is pressed). Press "CH o/p" buttons

so that the bar is just visible (See above figure).

3. Turn the power off and on again. (Main power button on the TV unit.)

CH o / p

buttons

Pattern

Generator

Figure

RF IQW

See below

Black

This bar

just

visible

Fig. 4

14. Focus Adjustment

Purpose: Set the optimum Focus.

Symptom of Misadjustment: If Focus Adjustment is

incorrect, blurred images are shown on the display.

Test Point Adj. Point Mode Input

--- Focus Control ---

Tape M. EQ. Spec.

Mono-

scope

15. Purity Adjustment

Purpose: To obtain pure color.

Symptom of Misadjustment: If Color Purity Adjust-

ment is incorrect, large areas of color may not be

properly displayed.

Test Point Adj. Point Mode Input

Deflection

---

Tape M. EQ. Spec.

---

GREEN RED BLUE

1. Set the unit facing east.

2. Operate the unit for over 30 minutes before adjusting.

3. Fully degauss the unit using an external degaussing coil.

4. Loosen the screw on the Deflection Yoke Clamper

and pull the Deflection Yoke back away from the

screen. (See Fig. 6)

5. Loosen the Ring Lock and adjust the Purity Magnets so that a red field is obtained at the center of

the screen. Tighten Ring Lock. (See Fig. 5,6)

6. Slowly push the Deflection Yoke toward bell of

CRT and set it where a uniform red field is obtained.

7. Tighten the clamp screw on the Deflection Yoke.

Yoke Purity

Magnet

Pattern

Generator

Figure

---

See below.

Red

Color

Fig. 5

---

Note: Focus VR (FBT) - Main CBA,

FBT=Fly Back Transformer

1. Operate the unit more than 30 minutes.

2. Face the unit to the East and Degauss the CRT

using Degaussing Coil.

3. Input the Monoscope Pattern.

Pattern

Generator

See below

5-6 L6509EA

Page 20

16. Convergence Adjustment

Purpose: To obtain proper convergence of red, green

and blue beams.

Symptom of Misadjustment: If Convergence Adjust-

ment is incorrect, the edge of white letters may have

color edges.

Test Point Adj. Point Mode Input

C.P. Magnet

(RB),

---

C.P. Magnet

---

(RB-G),

Deflection Yoke

Tape M. E Q . Spec .

Dot Pattern

or

Crosshatch

1. Loosen the Ring Lock and align red with blue dots

or Crosshatch at the center of the screen by rotating (RB) C.P. Magnets. (See Fig. 7)

2. Align red / blue with green dots at the center of the

screen by rotating (RB-G) C.P. Magnet. (See Fig. 8)

3. Fix the C.P. Magnets by tightening the Ring Lock.

4. Remove the DY Wedges and slightly tilt the Deflection Yoke horizontally and vertically to obtain

the best overall convergence.

5. Fix the Deflection Yoke by carefully inserting the

DY Wedges between CRT and Deflection Yoke.

---

DY WEDGE

Pattern

Generator

CRT

DEFLECTION YOKE

C.B. MAGNET (RB-G)

Figures

COIL

SCREW

COIL CLAMPER

See below.

PURITY

RB-GRB

RING LOCK

SCREW

C.P. MAGNET CLAMPER

C.P. MAGNET

Fig. 6

RB

RB

G

G

Fig. 8

5-7 L6509EA

Page 21

System Control Block Diagram

(NO CONNECTION)

I2C-OPEN 3

SDA 5

SCL 6

CN301 is used for

adjustment at factory

CN301

IC333

TV MICON/VIDEO

/AUDIO/CHROMA

/DEFLECTION

BLOCK DIAGRAMS

RCV-IN

KEY-IN1

KEY-IN2

70

66

69

RCV101

REMOTE

SENSOR

KEY

SWITCH

FROM/TO

AUDIO BLOCK

FROM

IF/VIDEO BLOCK

IC151

(MEMORY)

CS

SCL

SDA 5

SCL

SDA

AFT

AGC

INPUT0

7

6

72 I2C-OPEN

58

SCL

56

SDA

73

AFT

75

AGC

INPUT0

INPUT1

VOLUME

63

80

62

64A-MUTE-H

Q141

Q131

INPUT0

INPUT1

VOLUME

A-MUTE-H

TO

IF/VIDEO BLOCK

TO

AUDIO BLOCK

MAIN CBA

DG-ON-H

+5V CTRL

+5V CTRL2

+8V CTRL

P-ON-H

PROTECT-1

PROTECT-2

PROTECT-3

74

28

18

40

79

68

67

76

6-1 6-2

DG-ON-H

+5V CTRL

+5V CTRL2

+8V CTRL

PROTECT-1

PROTECT-2

P-ON-H

PROTECT-1

PROTECT-2

PROTECT-3

P-ON-H

FROM/TO

POWER

SUPPLY BLOCK

FROM/TO

CRT/H.V. BLOCK

L6509BLS

Page 22

IF/Video Block Diagram

TU1

AGC

EXT.CLK

SCL

SDA

VIDEO SIGNALRF/IF SIGNAL

SF1

IF

11

1

4

5

8

WF16

SAW

FILTER

IC33 (IF SIGNAL PROCESS)

20

VIF

AMP

21

RF

17

AGC

AMP

14

IC333

TV MICON/VIDEO

/AUDIO/CHROMA

/DEFLECTION

AUDIO SIGNAL

VIDEO

DET

VCO

AFT

5

11

14

CF31

4.5MHz

TRAP

CF32

4.5MHz

FILTER

LPF

IF AGC DET

WF2

WF1

MAIN CBA

3

8

EQ

AMP

SIF

AMP

VCO F/B

10

22

16

1

SIF

7

Q21

Q33

INPUT0

AGC

AFT

TO

AUDIO BLOCK

FROM/TO

SYSTEM

CONTROL

BLOCK

JK721

VIDEO-IN

(FRONT)

JK701

VIDEO-IN

(REAR)

58

56

32

26

24

20

SCL

SDA

OSD

LPF

LUMINANCE

PROCESS

CIRCUIT

CHROMINANCE

PROCESS

CIRCUIT

CHROMA COMB

BASEBAND TINT

H-SYNC

PROCESS

CIRCUIT

V-SYNC

PROCESS

CIRCUIT

VCXO

RGB MATRIX

/COLOR CONT

OSD SW

CONTRAST

BRIGHTNESS

RGB DRIVE

/CUT OFF

/H.V. BLK

16

52

51

50

53

46

45

38

37

WH301A

X301

3.58MHz

BLUE5

GREEN4

RED3

ACL

H-DRIVE

FBP

RAMP-OUT

V-RAMP-F/B

TO

CRT/H.V. BLOCK

WH301B

FROM/TO

CRT/H.V. BLOCK

L6509BLIF6-3 6-4

Page 23

Audio Block Diagram

AUDIO SIGNAL

MAIN CBA

FROM

IF/VIDEO BLOCK

JK702

AUDIO-IN(L)

(REAR)

JK703

AUDIO-IN(R)

(REAR)

JK722

AUDIO-IN(L)

(FRONT)

JK723

AUDIO-IN(R)

(FRONT)

SIF

IC431 (MTS/SAP AUDIO SIGNAL PROCESS)

21

24

27

VCA

I2C

DECORDER

11

15

12

4

2

1

STEREO

FILTER

SAP

FILTER

IC771 (INPUT SELECT)

TUNER

REAR

FRONT

(L-CH)

(R-CH)

TUNER

REAR

FRONT

SW CTL

9 10

OFFSET

CANCEL

SAP

DEMOD

13

3

L+R

FILTER

L-R

FILTER

SAP OUT

FILTER

WF6

IC801

5

2

75uS

DE-EMPH

(L-R)/SAP

SW

(AUDIO AMP)

DC

VOL.

DC

VOL.

OFFSET

CANCEL

MATRIX AGC

WIDE BAND

FILTER

dBX

DE-EMPH

SPECTRAL

FILTER

6

WIDE BAND

RMS DET

SPECTRAL

EXPAND

SPECTRAL

RMS DET

7

12

Q825

WIDE BAND

EXPAND

OFFSET

CANCEL

CN801

SP-L 2

SP-GND

CN802

SP-R 2

SP-GND 1

1

L-CH

R-CH

SP801

SPEAKER

L-CH

SP802

SPEAKER

R-CH

30

29

A-MUTE-H

VOLUME

INPUT 0

INPUT 1

SCL

SDA

FROM/TO

SYSTEM CONTROL

BLOCK

6-5 6-6 L6509BLA

Page 24

CRT/H.V. Block Diagram

RAMP-OUT

P-ON-H

V-RAMP-F/B

FROM/TO

IF/VIDEO BLOCK

H-DRIVE

PROTECT-1

PROTECT-2

VIDEO SIGNAL

MAIN CBA

WF7 WF8

Q572 Q571

H.DRIVE

T572

H.OUTPUT

Q531

(SWITCHING)

Q533

SWITCHING

P-ON-ON

WF11

IC551 (V-DEFLECTION CONTROL)

THERMAL

PROTECTION

7

AMP

1

6 3

PULSE

UP

5

4

3

1

DY551 D.Y.

VDRIVE

HDRIVE

WF12

5

WF9

CN571

FROM POWER

SUPPLY BLOCK

FROM/TO

SYSTEM CONTROL

BLOCK

FROM

IF/VIDEO BLOCK

DEF+B

+B

PROTECT-3

FBP

ACL

RED

GREEN 4

BLUE 5

T571 F.B.T. FOCUS VR

HV

F

10

S

11

8

7

9

6

WF15

SCREEN VR

WF4

WF10

Q1521,

Q1522

GREEN AMP

WF14

X-RAY CHECK

TP591 TP592

TP302

15kHz

WH301BTO WH301A

3

TP500

GND

TP501

BLUE

1

3

5

4

WF3

Q1511,

Q1512

RED AMP

ANODE

FOCUS

SCREEN

HEATER3 3

1 1

+200V

WF5 WF13

WH501BWH501A

BLUE AMP

Q1531,

Q1532

JK1501

7

4

8

6

11

10

9

CN1501

ANODE

FOCUS

SCREEN

GND

R

G

B

HEATER

GND

V501

CRT

CRT CBA

6-7 6-8

L6509BLCRT

Page 25

Power Supply Block Diagram

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

HOT CIRCUIT. BE CAREFUL.

HOT COLD

4A/125V

CAUTION:

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE 4 A, 125V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE 4A, 125V.

NOTE :

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

AC601

AC CORD

L691

DEGAUSSING

COIL

CN691

4A/125V

F601

4A/125V

PS691

L601

LINE

FILTER

Q601

SWITCHING

Q602

LIMITER

D605 - D608

BRIDGE

RECTIFIER

T601

6

10

4

2

1 13

11

12

14

DEF +B

TP601

+B

9

Q672

SWITCHING

Q673

SWITCHING

CONTROL

Q851

+9V

REGULATOR

Q961

+5V

REGULATOR

Q681

+8V

SWITCHING

Q682

+5V

SWITCHING

Q111

+5V

SWITCHING

Q321

+9V

SWITCHING

PROTECT-2

(TO PIN 67 OF IC333)

+B

AL+33V

BACK-UP

P-ON+5V

+5V-CTRL2

(FROM PIN 18 OF IC333)

AL+9V

AL+12V

P-ON+5V

P-ON+8V

+8V-CTRL

(FROM PIN40 OF IC333)

P-ON+5V

Q683

+5V

SWITCHING

4

IC601

ERROR

VOLTAGE DET

3

RL601

1

Q831

VR661

2

Q652

FEED

BACK

Q696

SWITCHING

DG-ON-ON

DG-ON-H

(FROM PIN74 OF IC333)

+B ADJ

Q674

SWITCHING

P-ON-ON

SWITCHING

P-ON-ON

Q841

(SWITCHING)

Q191

SWITCHING

P-ON-ON

Q832

SWITCHING

P-ON-ON

6-9 6-10

MAIN CBA

+5V-CTRL

(FROM PIN28 OF IC333)

PROTECT-1

(TO PIN68 OF IC333)

P-ON+12V

P-ON-H

(FROM PIN79 OF IC333)

L6509BLP

Page 26

SCHEMATIC DIAGRAMS / CBA'S AND TEST POINTS

Standard Notes

Many electrical and mechanical parts in this chassis have special characteristics. These characteristics often

pass unnoticed and the protection afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts that have these special safety characteristics are

identified in this manual and its supplements; electrical components having such features are identified by the

mark " # " in the schematic diagram and the parts list. Before replacing any of these components, read the parts

list in this manual carefully. The use of substitute replacement parts that do not have the same safety characteristics as specified in the parts list may create shock, fire, or other hazards.

Note:

1. Do not use the part number shown on these drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since these drawings were prepared.

2. All resistance values are indicated in ohms (K=10

3. Resistor wattages are 1/4W or 1/6W unless otherwise specified.

4. All capacitance values are indicated in µF (P=10

5. All voltages are DC voltages unless otherwise specified.

Note of Capacitors:

ML --- Mylar Cap. PP --- Metallized Film Cap. SC --- Semiconductor Cap. L --- Low Leakage type

3

, M=106).

-6

µF).

Temperature Characteristics of Capacitors are noted with the following:

B --- ±10% CH --- 0±60ppm/°C CSL --- +350~-1000ppm/°C

Tolerance of Capacitors are noted with the following:

Z --- +80~-20%

Note of Resistors:

CEM --- Cement Res. MTL --- Metal Res. F --- Fuse Res.

Capacitors and transistors are represented by the following symbols.

CBA Symbols

(Top View) (Bottom View)

+

(Bottom View)

Transistor or Digital Transistor

E C B

(Top View)

NPN Transistor

Electrolytic Capacitor

(Top View)

PNP Transistor

Schematic Diagram Symbols

Digital Transistor

E C B

(Top View)

E C B

NPN Digital Transistor

E C B

(Top View)

PNP Digital Transistor

E C B

7-1 L13SC

Page 27

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

THE FOLLOWING PAGES:

1. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME

TYPE_A,_V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE_A,_V.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, first check to see that all components in the power supply circuit are not defective

before you connect the AC plug to the AC power supply. Otherwise it may cause some components in the power supply circuit to fail.

3. Note:

(1) Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

(2) To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Wire Connectors

(1) Prefix symbol "CN" means "connector" (can disconnect and reconnect).

(2) Prefix symbol "CL" means "wire-solder holes of the PCB" (wire is soldered directly).

5. Note: Mark "I" is a leadless (chip) component.

6. Voltage indications on the schematics are as shown below:

Plug the TV power cord into a standard AC outlet.:

Voltage

7. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to area "D3".

2. "1-B1" means that line number "1" goes to area "B1".

8. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

5.0

(3.0)

231

5.0

(3.0)

Indicates that the voltage

is not consistent here.

Power on mode

Power off mode

Unit: Volts

3

AREA D3

2

1

ABCD

AREA B1

1-D3

1-B1

: Used to indicate a test point with a test pin.

7-2 L13SC

Page 28

Main 1/4 Schematic Diagram

VIDEO SIGNAL

A4

A3

B4

B3

C4

C3

D4

D3

E4

E3

F4

F3

MAIN 1/4

Ref No. Position

ICS

IC151

IC333

TR ANSIST ORS

Q111 D-1

Q131 A-3

Q141 A-4

Q191 B-4

Q321 E-1

CONNECTO R

CN301 A-3

A-3

C-2

A2

A1

B2

B1

7-3 7-4

C2

C1

D2

D1

E2

E1

F2

F1

L6509SCM1

Page 29

Main 2/4 Schematic Diagram

VIDEO SIGNAL

AUDIO SIGNAL

G4

G3

H4

H3

I4

I3

J4

J3

K4

K3

L4

L3

MAIN 2/4

Ref No. Posit i o n

ICS

IC431

IC771

IC801

TR ANSISTOR S

Q825 J-3

Q831 K-3

Q832 K-3

Q841 K-3

Q851 J-3

Q961

CONNECTO RS

CN801 L-4

CN802 L-4

G-3

H-2

J-4

J-3

G2

G1

7-5

H2

H1

I2

I1

J2

J1

K2

K1

7-6

L2

L1

L6509SCM2

Page 30

Main 3/4 Schematic Diagram

IF SIGNAL

VIDEO SIGNAL

AUDIO SIGNAL

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

NOTE :

The voltage for parts in hot circuit is measured

using hot GND as a common terminal.

4A/125V

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE 4A, 125V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE

MÊME TYPE DE 4A, 125V.

M4

M3

M2

N4

N3

N2

O4

O3

O2

P4

P3

P2

Q4

Q3

Q2

R4

R3

R2

MAIN 3/4

Ref No. Posit i o n

ICS

IC33

IC601 O-1

TR AN SISTO RS

Q21 P-4

Q33

Q601

Q602

Q652

Q672

Q673

Q674

Q681

Q682

Q683

Q696

CONNECTO R

CN691 Q-2

TEST PO INTS

TP300

TP301

VARIABLE R ESISTO R

VR661 O -1

P-3

P-4

P-2

P-1

O-1

N-2

N-1

N-1

M-2

M-1

M-1

O-2

N-4

N-4

M1

N1

7-7

O1

P1

Q1

7-8

R1

L6509SCM3

Page 31

Main 4/4 & CRT Schematic Diagram

MAIN 4/4

Ref No. Position Ref No. Position

IC

IC551

TR AN SISTO RS

Q531

Q533

Q571

Q572

CONNECTO RS

CN571 T-3

S-3 WH301A V-2

S-2

S-2

U-2

T-2 TP592 U-2

CONNECTORS

WH501A V-3

TEST PO INTS

TP302

TP591

TP601 U-3

V-2

U-2

VIDEO SIGNAL

CRT

Ref No. Posit i o n

TR ANSISTOR S

Q1511

Q1512

Q1521

Q1522

Q1531

Q1532

CONNECTO RS

CN1501 X-2

WH301B V-2

WH501B V-3

TEST PO INTS

TP500

TP501 W-2

W-1

W-2

W-1

W-2

W-1

W-2

W-1

S3

S2

T3

T2

U3

U2

V3

V2

W3

W2

X3

X2

S1

7-9

T1

U1

V1

W1

7-10

X1

L6509SCM4

Page 32

Main CBA Top View

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, check to see that all components in the power

supply circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

NOTE :

The voltage for parts in hot circuit is measured

using hot GND as a common terminal.

TP601

+B

FOCUS-VR

(UPPER SIDE)

SCREEN-VR

(LOWER SIDE)

TP300

GND

BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER

SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

ALSO, IN ORDER TO HAVE THE ABILITY TO INCREASE THE INPUT

SLOWL Y , WHEN TROUBLESHOO TING THIS TYPE POWER SUPPL Y

CIRCUIT, A VARIABLE ISOLATION TRANSFORMER IS REQUIRED.

4A/125V

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE 4A, 125V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE

MÊME TYPE DE 4A, 125V.

MAIN CBA

Ref No . Positi o n Ref No. Position

ICS

IC33

IC151

IC333

IC431

IC551

IC601

IC771

IC801 E-2

TR AN SISTO R S

Q21 C-1

Q33

Q111 F -3

Q131 F -4 CN691 D-5

Q141 E-5

Q191 F -5

Q321 E-3 WH301A D-4

Q531 C-2 WH501A A-4

Q533 C-2

Q571

Q572

Q601

Q602

Q652

Q672

Q673

Q674 D-3 VR661 B-2

Q681 D-3

B-2

E-5

F-5

A-1

C-2

C-4

D-1

C-1

B-4

C-2

B-5 TP30 2 A- 4

B-4 TP59 1 A- 3

D-4 TP5 9 2 A- 3

D-3

D-3

TRANSISTORS

Q682

Q683

Q696

Q825

Q831

Q832

Q841

Q851

Q961 C-1

CONNECTORS

CN301

CN571

CN801

CN802

TEST POINTS

TP300

TP301

TP601

VARIABL E R ESISTO R

D-4

D-4

D-4

E-2

E-3

F-3

F-2

E-3

A-1

B-3

E-2

E-5

A-4

A-2

B-5

VR661

+B ADJ

7-11

7-12

BL6509F01012-1

Page 33

Main CBA Bottom View

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

4A/125V

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ONLY WITH SAME TYPE 4A, 125V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE

MÊME TYPE DE 4A, 125V.

NOTE :

The voltage for parts in hot circuit is measured

using hot GND as a common terminal.

BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER

SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

ALSO, IN ORDER TO HAVE THE ABILITY TO INCREASE THE INPUT

SLOWL Y , WHEN TROUBLESHOO TING THIS TYPE POWER SUPPL Y

CIRCUIT, A VARIABLE ISOLATION TRANSFORMER IS REQUIRED.

WF8

Q571

Base

WF2

PIN 14

OF IC333

WF10

PIN 3

OF WH501A

WF9

PIN 1

OF CN571

WF12

PIN 4

OF CN571

WF11

PIN 7

OF IC551

WF7

Q572

Collector

WF16

PIN 8

OF TU1

WF1

PIN 3

OF IC33

WF6

PIN 5

OF IC801

7-13 7-14

BL6509F01012-1

Page 34

CRT CBA Top View CRT CBA Bottom View

CRT CBA

Ref No. Posit i on

TRANSI STORS

Q1511 C-1

Q1512 C-1

Q1521

Q1522

Q1531

Q1532

CONNECTORS

CN1501 A-2

WH301B B-2

WH501B A-2

TEST POINT S

TP500 B-2

TP501 A-2

C-1

B-1

B-1

B-1

WF15

Q1511

Collector

WF3 WF14

Q1511

Base

WF4

Q1521

Base

Q1521

Collector

WF5

Q1531

Base

WF13

Q1531

Collector

7-15

7-16

BL6509F01012-2

Page 35

WF1 ~ WF16 = Waveforms to be observed at

Waveform check points.

(Shown in Schematic Diagram.)

WAVEFORMS

Input: NTSC Color Bar Signal (with 1kHz Audio Signal)

INITIAL POSITION: Unplug unit from AC outlet for at least 5 minutes.

reconnect to AC outlet and then turn power on.

(Brightness---Center Color---Center Tint --- Center Contrast---Approx 70%)

WF1

WF2

1DIV: 0.5V 20µsec

IC 33 Pin 3

1DIV: 0.5V 20µsec

IC 333 Pin 14

GND

WF5

WF6

1DIV: 2V 20µsec

Q 1531 Base

1DIV: 0.2V 20msec

IC 801 Pin 5

GND

WF9

WF10

1DIV: 200V 20µsec

CN 571 Pin 1

1DIV: 5V 20µsec

WH501A Pin 3

GND

GND

WF13

WF14

1DIV: 20V 20µsec

Q 1531 Collector

1DIV: 20V 20µsec

Q 1521 Collector

WF3

WF4

1DIV: 2V 20µsec

Q 1511 Base

1DIV: 2V 20µsec

Q 1521 Base

GND

WF7

1DIV: 10V 20µsec

Q 572 Collector

GND

WF8

1DIV: 5V 20µsec

Q 571 Base

8-1 8-2

GND

WF11

1DIV: 2V 5msec

IC 551 Pin 7

10 V 5 ms

WF12

1DIV: 10V 5msec

CN 571 Pin 4

WF15

WF16

1DIV: 20V 20µsec

Q 1511 Collector

1DIV: 0.2V 20µsec

TU 1 Pin 8

L6650WF

Page 36

WIRING DIAGRAM

V501

CRT

GND

CN1501

ANODE

FOCUS

SP801

SPEAKER

L-CH

SP802

SPEAKER

R-CH

SCREEN

CLN801

CLN802

CN801

SP-L

1

SP-GND

2

CN802

SP-R

1

SP-GND

2

CN691

1

2

TU1 TUNER UNIT

MAIN CBA

BL6509F01012-1

T571

FBT

CRT CBA

BL6509F01012-2

WH301B

BLUE

GREEN

RED

GND

+8V

HEATER 3

GND 2

+200V 1

5

4

3

2

1

CLN301

CLN501

DY551

D.Y.

HD

VD

5

4

3

2

1

WH301A

BLUE

GREEN

RED

GND

+8V

WH501AWH501B

HEATER3

GND2

+200V1

CN571

1

2

3

4

5

(NO CONNECTION)

CN301

1

INT-MONI

AGC2

I2C-OPEN3

4

GND

SDA5

6

SCL

CN301 IS USED FOR

ADJUSTMENT AT

FACTORY.

AC601

9-1 L6509WI

Page 37

IC PIN FUNCTIONS

IC333 (TV Micro Computer)

Pin

Signal Name Function

No.

1GND GND

2 N.U. Not Used

3 N.U. Not Used

4 N.U. Not Used

5GND GND

6VCC AL+5V

7 N.U. Not Used

8 FILT FILT

9 HLF Filter for CCD

10 VHOLD VHOLD

11 CVIN Input for Video Signal

12 RESET RESET

MCU RESET

13

OUT

14 Y-SW OUT Composite Signal Output

15 GND GND

16 3.58 X'TAL 3.58MHz Crystal

17 C-APC CHROMINANCE APC

MCU 5.7REG

18

OUT

19 N.U. Not Used

20 CVBS IN 3 Composite Signal Input 3

21 N.U. Not Used

22 VCC VCC

23 N.U. (GND)

24 CVBS IN2 Composite Signal Input 2

25 N.U. Not Used

26 CVBS IN1 Composite Signal Input 1

27 N.U. Not Used

28 5.7V REG OUT 5.7V Output

29 C(Y/C) IN Chrominance Signal Input

30 Y(Y/C) IN Luminance Signal Input

31 V REG VCC DC 8.7V Input

32 FSC OUT Clock Output 3.58MHz

33 MONITOR OUT Monitor Out

34 N.U. Not Used

RESET Signal Output

Micro controller Control

Voltage Output

Pin

Signal Name Function

No.

35 N.U. Not Used

36 N.U. Not Used

37 V RAMP F/B V Ramp Feed Back

38 V RAMP OUT Vertical Output

39 V RAMP CAP V Ramp OSC Capacitor

40 8.7 VREG OUT DC 8.7V Output

41 N.U. Not Used

42 H VCO F/B H Vco Feed Back

43 AFC FILT Horizontal AFC Filter

44 GND GND

45 FBP IN Flyback Pulse Input

46 H-OUT H Pulse Output

47 VCC Vcc

48 VCC Vcc

49 VCC Vcc

50 R OUT Red Output

51 G OUT Green Output

52 B OUT Blue Output

53 ACL IB-Input

54 N.U. Not Used

55 A-O-MUTE Mute Signal of Audio Output

56 SDA

57 N.U. Not Used

58 SCL

59 N.U. (GND)

60 N.U. Not Used

61 S-SW

62 VOLUME Volume

63 INPUTO Input Select 0

64 A-MUTE-H Audio Mute

65 N.U. Not Used

66 KEY-IN 1 Key Input 1 (Main)

67 PROTECT-2 Power Supply Protection

68 PROTECT-1 Power Supply Protection

69 KEY-IN 2 Key Input 2 (Main)

I2C-BUS Controller Interface

(Data)

I2C-BUS Controller Interface

(Clock)

Detecting S-VIDEO Jack

Connection

10-1 L6650PIN

Page 38

Pin

Signal Name Function

No.

70 RCV-IN Input For Remote Control

71 N.U. Not Used

72 I2C OPEN

73 AFT AFT Voltage Input

74 DG-ON-H Degaussing Coil Control

75 AGC AGC Voltage Input

76 PROTECT 3 Power Supply Protection

77 N.U. Not Used

78 FM-SW Switching IF IC VCO

79 P-ON-H Output for P-ON-H

80 INPUT 1 Input Select 1

White Balance Adjustment

Judgement

10-2 L6650PIN

Page 39

C

EXPLODED VIEWS

Cabinet

SHINWHA

TAPE SGT-730

(BLACK)

SHINWHA

TAPE SGT-730

(WHITE)

V501-2

V501-3

V501-1

DY551

Details for DY551

and surrounding parts

CLN551

B-11

CRT CBA

Scotch

L-8

L-8

A-4

L-8

L-9

Tape #880

LN801

L-13

B-5

B-2

B-4

B-13

L-13

L-8

B-4

SP801

CLN802

B-13

B-2

SP802

DY551

B-2

B-5

Scotch

Tape #880

L-8

B-11

L-8

L691

B-5

B-8

B-7

A-2

L-1

A-7

A-3

L-1

B-1

Scotch

B-6

Tape #880

B-2

L-1

B-9

L-1

V501

B-5

B-12

MAIN CBA

PB6

PB6

AC601

A-1

11-1 11-2 L6509CEX

Page 40

Packing

Some Ref. Numbers are

not in sequence.

S-2

S-2

X-1

X-3

TAPE

X-2

X-4

S-3

S-4

S-6

S-3

PACKING TAPE

S-7

X5

FRONT

S-1

A-5

PACKING TAPE

11-3 L6509PEX

Page 41

MECHANICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a #

have special charac teristics important to safety. Before

replacing any of these components, read caref ully the

product safety notice in this service manual. Don't

degrade the safety of the product through improper servicing.

NOTE:

Parts that are not assign ed part numbers (---------) are

not available.

Ref. No. Description Part No.

A-1 FRONT CABINET L6509UK 0EM000530G

A-2 REAR CABINET L6509UK 0EM000531G

A-3 CONTROL PLATE L6509UK 0EM301921

A-4# RATING LABEL L6509UK ---------A-5 SERIAL NO. LABEL L9750UA ---------A-7 BRAND BADGE L6509UK 0EM408355

B-1 TENSION SPRING B0080B0:EM40808 26WH006

B-2 SCREW L1500UA 0EM406142

B-4 SPEAKER HOLDER L1440JL 0EM301478

B-5# DEGAUSS HOLDER L9800UA 0EM404845

B-11 CLOTH L9800UA:95X15XT:0.5 0EM405041

B-12 CLOTH L1440JL:15X55XT1.0 0EM406793

B-13 CLOTH(B) L5201U0:15X10 X1.0T 0EM400076

CLN551 CRT GND WIRE CRT GND WX1L7820-003

CLN801 WIRE ASSEMBLY SPEAKER WIRE(2 20MM) WX1L7950-001

CLN802 WIRE ASSEMBLY SPEAKER WIRE(1 80MM) WX1L1 131-001

L-8 SCREW, P-TIGHT 4X18 BIND HEAD + GBMP4180

L-9 SCREW TAPPING M4X14 DBU14140

L-13 SCREW, P-TIGHT 3X12 BIND HEAD+ GBMP3120

L691# DEGAUSSING COIL F-044 LLBH00ZTM044

SP801 SPEAKER S08F02B or DSD0808XQ010

SPEAKER J-F097-C5 DSD0808DCP01

SP802 SPEAKER S08F02B or DSD0808XQ010

SPEAKER J-F097-C5 DSD0808DCP01

PACKING

S-1# CART0N L6509UK 0EM408354

S-2 STYROFOAM TOP L6509UK 0EM000796

S-3 STYROFOAM BOTTOM L6509UK 0EM000797

S-4 SET SHEET B7500UA:1000X1700 0EM402178

S-6 HOLD PAD L1440JL 0EM406682

S-7 LABEL, EAS(H3761UD) MAKER NO.ZLLFNSLE1 ----------

ACCESSORIES

X-1 REMOTE CONTROL NE122UD or NE122UD

REMOTE CONTROL NE151UD NE151UD

X-2 DRY BATTERY R6P UM3 or XB0M451GH001

DRY BATTER Y R6P/2S or XB0M451T0001

DRY BATTER Y(SUNRISE) R6SSE/2S or XB0M451MS0 02

DRY BATTER Y R6P(AR)2PX or XB0M451HU002

DRY BATTER Y R6P(AR)2P X ICI XB0M451HU003

X-3# OWNER'S MANUAL(E)/(S) L6509UK:ENGLISH/

X-4 RETURN STOP SHEET L6100UA 0EM407076

X-5 POLYETHYLENE BAG F8626B5 Z325350

SPANISH

0EMN02217

Ref. No. Description Part No.

Note:

1. V501 (CRT) HAS COUPLE OF SUBSTITUTIONAL P ARTS AND EACH P AR TS

ALSO HAS MATCHING COMBINA TION WITH DY551.

PLEASE SEE TABLE 1 FOR DET AI LS OF MA TCHING COMBINA TION.

2. DY551 (DEFLECTION YOKE) HAS MATCHING COMBINATION WITH V501.

PLEASE SEE TABLE 1 FOR DET AI LS OF MA TCHING COMBINA TION.

CRT TYPE A

DY551# DEFLECTION YOKE 6150Z-1223B or LLBY00ZGS005

# DEFLECTION YOKE KDY3NWC90X LLBY00ZMS028

V501# CRT A51QDJ279X(PI) TCRT190GS039

V501-1 C.P.MA GNET JH 8210-SD XM04000BV008

V501-2 WEDGE FT-00110W or XV10000T4001

WEDGE DB25SR XV10000D9001

V501-3 RUBBER MAGNET 20X10X1.2 XM05000BV001

CRT TYPE B

DY551# DEFLECTION YOKE CDY -N2102F or LLBY00ZQS017

# DEFLECTION YOKE CDY-MT2103A LLBY00Z0X001

V501# CRT A51QDX992X( H) TCRT190SM030

V501-1 C.P.MA GNET JH 8210-SD XM04000BV008