Page 1

SERVICE MANUAL

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

19" COLOR TV/DVD/VCR

6719DC/

SSC719C

Sec. 2: Deck Mechanism Section

I Standard Maintenance

I Alignment for Mechanism

I Disassembly/Assembly of Mechanism

EWC19T2

Sec. 3: Exploded views

and Parts List Section

I Exploded views

I Parts List

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and

described in this service manual are effective methods of performing service

operations. Some of these service special tools should be used when and as

recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk of

personal injury to service personnel. The possibility exists that improper service methods may damage the equipment. It also is important to understand

that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Funai could not

possibly know, evaluate and advice the service trade of all conceivable ways

in which service might be done or of the possible hazardous consequences of

each way. Consequently, Funai has not undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by Funai must first use all precautions thoroughly so that neither his safety nor the safe operation of the equipment will be jeopardized by

the service method selected.

Manufactured under license from Dolby Laboratories. "Dolby" and

the double-D symbol are trademarks of Dolby Laboratories.

"DTS" and "DTS Digital Out" are trademarks of Digital Theater Systems Inc.

Page 3

MAIN SECTION

19" COLOR TV/DVD/VCR

6719DC/SSC719C/EWC19T2

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Preparation for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

Operating Controls and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

FIRMWARE Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Schematic Diagrams / CBA’s and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

System Control Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

IC Pin Function Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

Lead Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16-1

Page 4

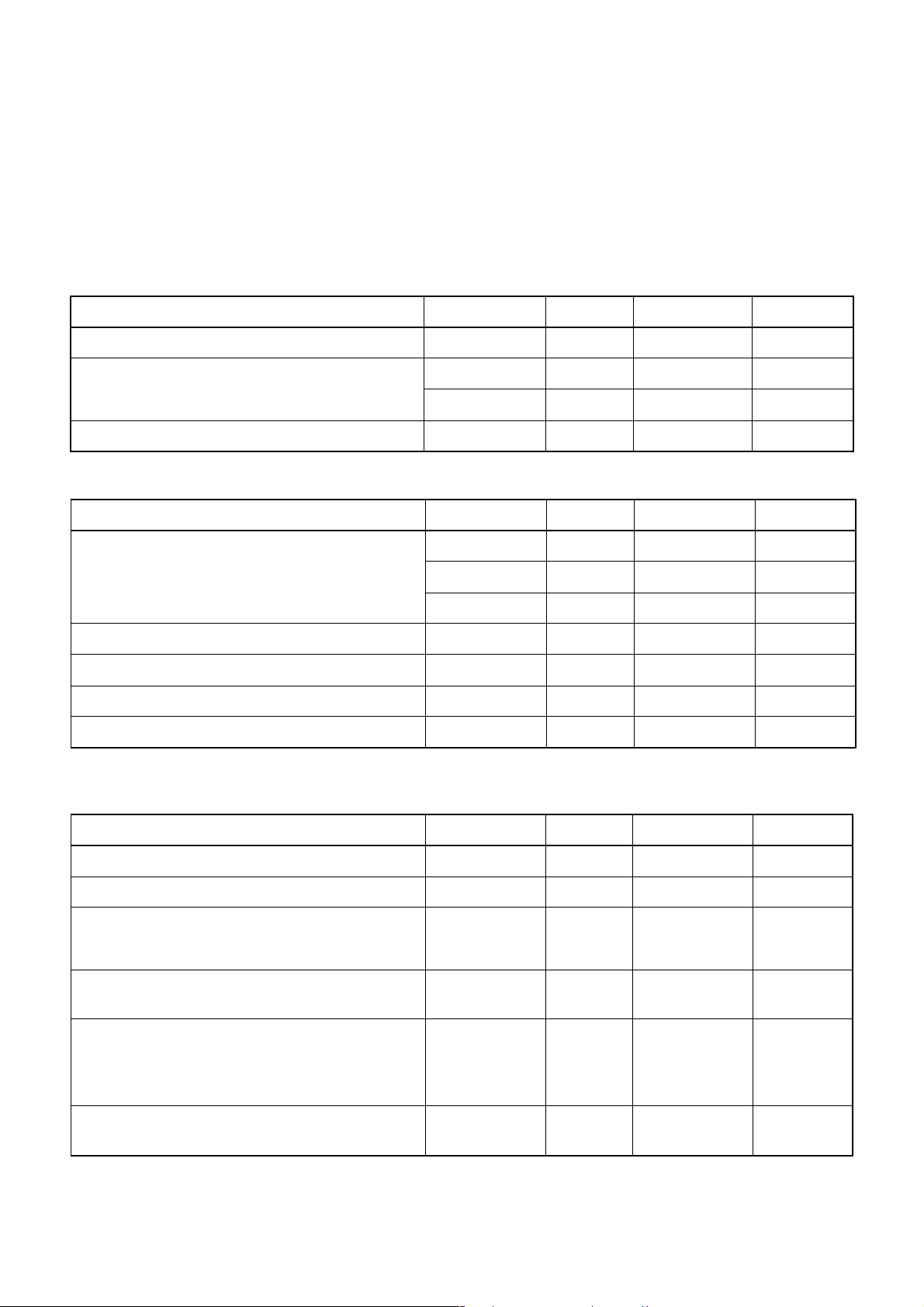

SPECIFICATIONS

*ˆMode---------SP mode unless otherwise specified

*Test input terminal

<Except Tuner>-------------Video input (1Vp-p)

Audio input (-10dB)

<Tuner>-----------------------Ant. input (80dBµV) Video: 87.5%

Audio: 25kHz dev (1kHz Sin)

<DEFLECTION>

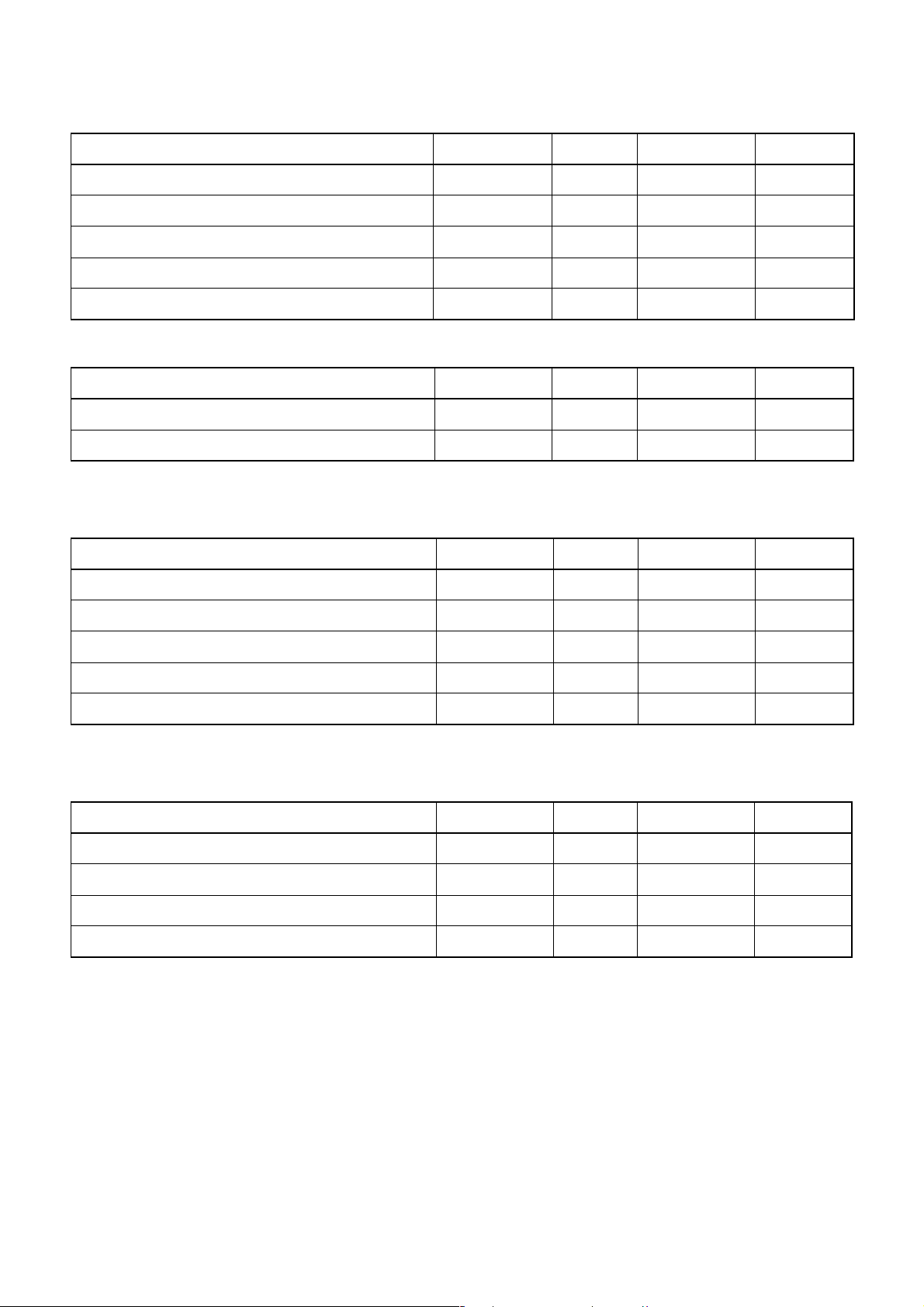

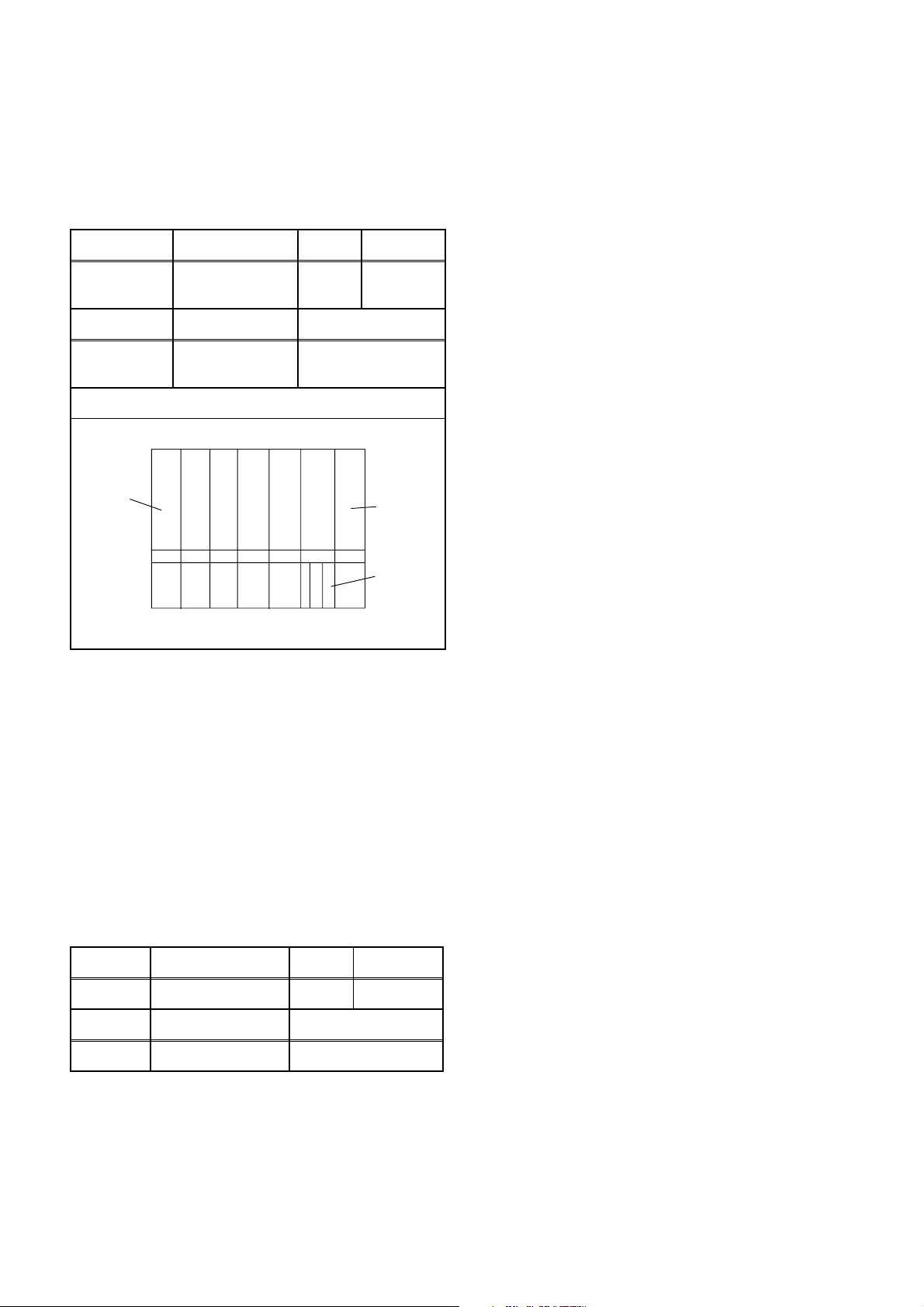

Description Condition Unit Nominal Limit

1. Over Scan — % 90 —

2. Linearity

3. High Voltage — kV 25 —

Horizontal % — 15

Vertical % — 10

<VIDEO & CHROMA>

Description Condition Unit Nominal Limit

Center m/m — 0.4

1. Misconvergence

2. Tint Control Range — deg ±30 —

3. Contrast Control Range — dB 6 2

4. Brightness (100% White Full Field) Contrast: Max ft-L 35 24

5. Color Temperature — K 9200 —

Corner m/m — 2.5

Side m/m — 1.5

<DVD>

Measurement at TP

Description Condition Unit Nominal Limit

1. Horizontal Resolution (TDV-540 TIT.2 CHP.16) — Line 330 320

2. Video S/N at CN3400 (TDV-540 TIT.2 CHP.6) — dB 60 55

3. S/N Chroma at CN3400 AM — dB 58 53

(TDV-540 TIT.2 CHP.17) PM — dB 58 53

4. Audio Distortion (LPCM 48 kHz, W/LPF)

(PTD 1-NOR TIT.1 CHP.1)

5. Audio freq. response (LPCM 48kHz)

(PTD 1-NOR TIT.1 CHP.5 -- 10)

6. Audio S/N (LPCM 48KHz,W/LPF,A-WTD)

(PTD 1-NOR TIT.1 CHP.1 -- 2)

L

R

L, 20 Hz

R, 20 Hz

L, 20 kHz

R, 20 kHz

L

R

1-1-1 T500SP

%

dB 0 +4/-5

dB 100 85

0.03

0.03

0.07

0.07

Page 5

<VCR>

Description Condition Unit Nominal Limit

1. Horizontal Resolution (R/P, SP) Line 230 200

2. Jitter (Low) (R/P, SP) µS0.1 0.2

3. S/N Chroma AM(SP) (R/P, SP) dB 38 33

PM(SP) (R/P, SP) dB 38 33

4. Wow & Flutter (JIS, UNWTD) (R/P, SP) % 0.25 0.5

<TUNER>

Description Condition Unit Nominal Limit

1. Video S/N (80dBµV, TV4ch) — dB 45 40

2. Audio S/N (W/LPF) — dB 45 40

<NORMAL AUDIO>

All items are measured across 8Ω resistor at speaker output terminal.

Description Condition Unit Nominal Limit

1. Audio Output Power (R/P, SP) W 1.0 0.8

2. Audio S/N (W/LPF) (R/P, SP) dB 40 36

3. Audio distortion (W/LPF,-10dB 1kHz IN) (R/P, SP) % 3.0 5.0

4. Audio Freq. Response (-10dB 1kHz IN) 200 Hz (R/P, SP) dB -2.0 -2.0±5.0

8 kHz (R/P, SP) dB 0 0±6.0

<Hi-Fi AUDIO>

* All items are measured at TP1701 and TP1702.

Description Condition Unit Nominal Limit

1. Output Level (-10dB 1kHz IN) (R/P, SP) dB -8.0 -8±4

2. Audio Distortion (-10dB 1kHz IN) (R/P, SP) % 0.5 1.0

3. Freq. Response (-15dB 1kHz IN) 20 Hz (R/P, SP) dB 0 ±4

20 kHz (R/P, SP) dB 0 ±4

Note: Nominal specifications represent the design specifications. All units should be able to approximate these.

Some will exceed and some may drop slightly below these specifications. Limit specifications represent the absolute worst condition that still might be considered acceptable. In no case should a unit fail to meet limit specifications.

1-1-2 T500SP

Page 6

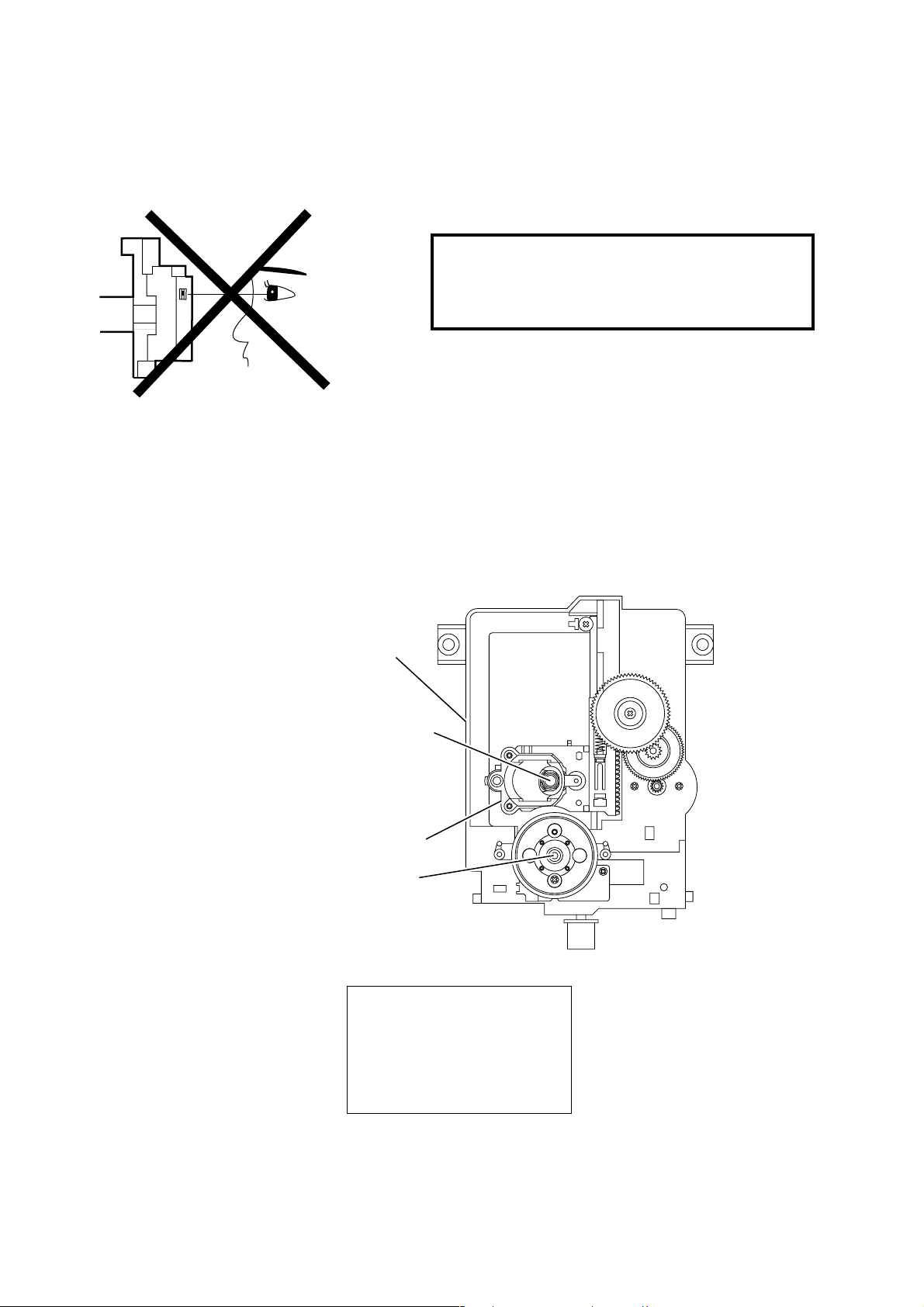

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

Caution: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

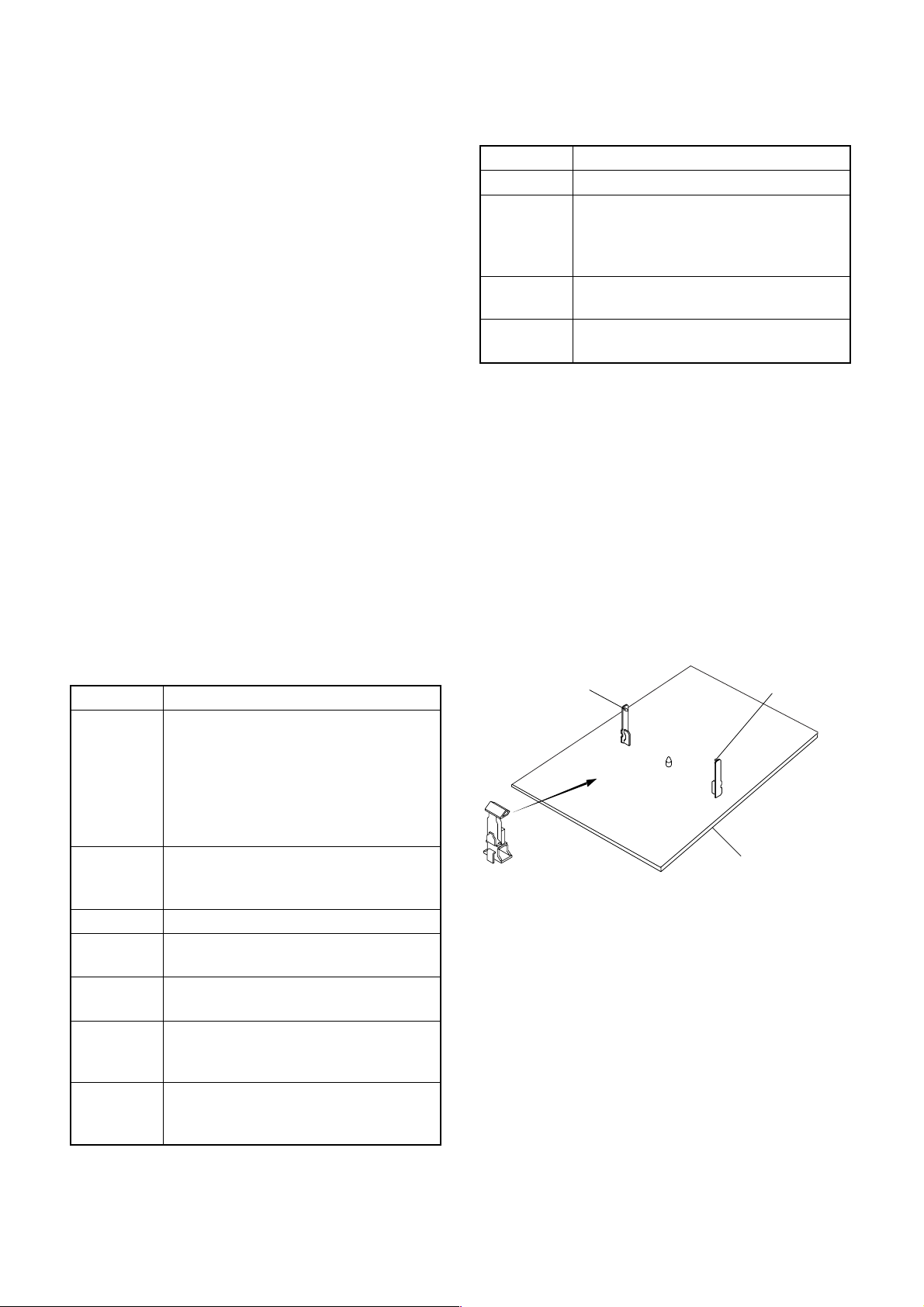

Drive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

CAUTION

Location: Inside Top of DVD mechanism.

1-2-1 DVD_LASER

Page 7

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for TV Circuit

1. Before returning an instrument to the customer, always make a safety check of the entire instru-

ment, including, but not limited to, the following

items:

a. Be sure that no built-in protective devices are de-

fective and have been defeated during servicing.

(1) Protective shields are provided on this chassis

to protect both the technician and the customer.

Correctly replace all missing protective shields, including any removed for servicing convenience.

(2) When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpapers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not oper-

ate this instrument or permit it to be operated

without all protective devices correctly installed and functioning. Servicers who defeat

safety features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to, (1) spacing between the picture tube and the cabinet

mask, (2) excessively wide cabinet ventilation

slots, and (3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug prongs.

Place the instrument AC switch in the on position.

Connect one lead of an ohmmeter to the AC plug

prongs tied together and touch the other ohmmeter lead in turn to each tuner antenna input exposed terminal screw and, if applicable, to the

coaxial connector. If the measured resistance is

less than 1.0 megohm or greater than 5.2 megohm, an abnormality exists that must be corrected

before the instrument is returned to the customer.

Repeat this test with the instrument AC switch in

the off position.

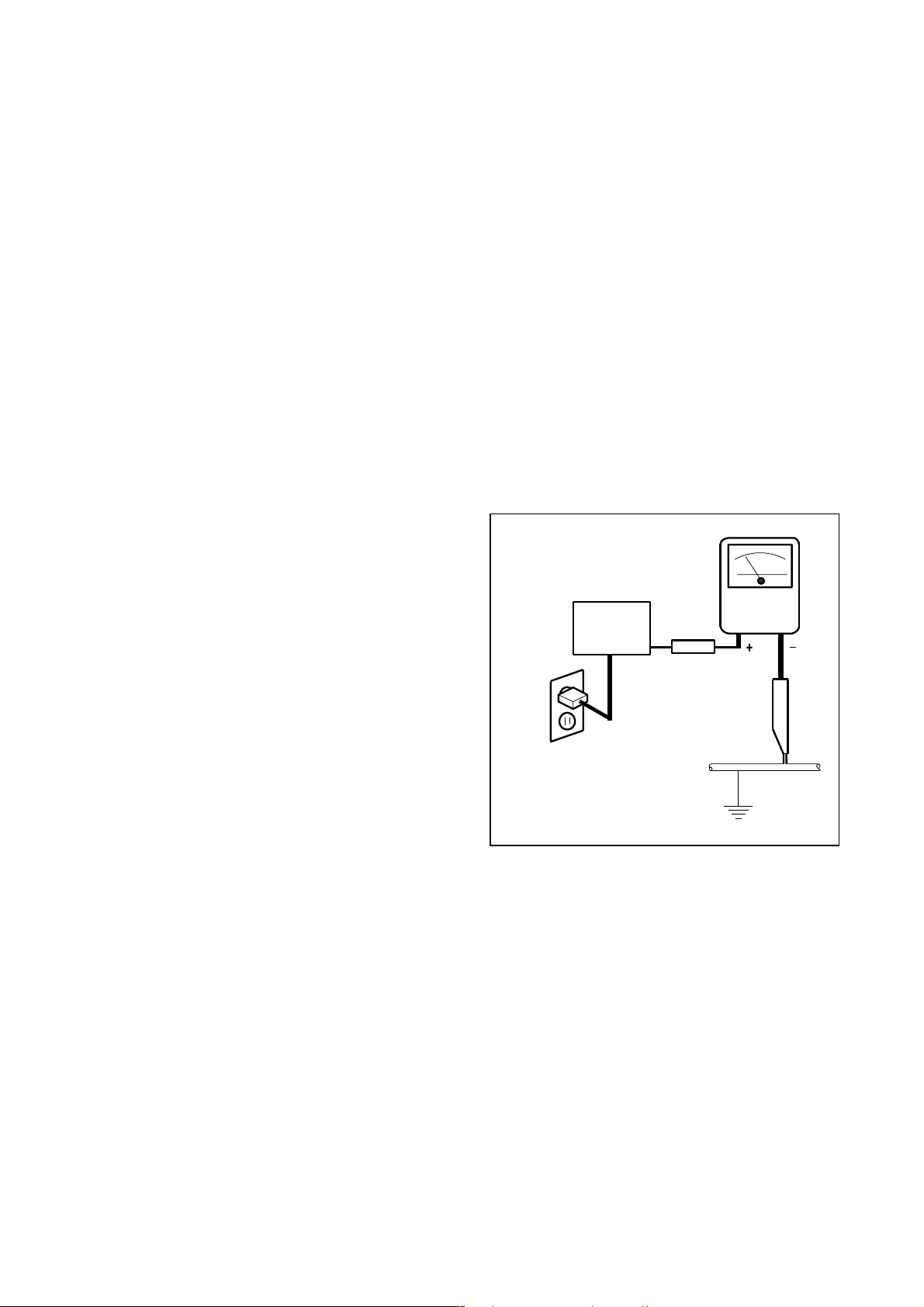

d. Leakage Current Hot Check - With the instru-

ment completely reassembled, plug the AC line

cord directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leak-

age current tester or a metering system that complies with American National Standards Institute

(ANSI) C101.1 Leakage Current for Appliances

and Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on position and then in the off position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinet, screw

heads, metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any current

measured must not exceed 0.5 milli-ampere. Reverse the instrument power cord plug in the outlet

and repeat the test.

READING SHOULD

NOT BE ABOVE 0.5 mA

LEAKAGE

DEVICE

BEING

TESTED

TEST ALL EXPOSED

METAL SURFACES

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

CURRENT

TESTER

EARTH

GROUND

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO

THE CUSTOMER OR BEFORE CONNECTING

THE ANTENNA OR ACCESSORIES.

e. X-Radiation and High Voltage Limits - Because

the picture tube is the primary potential source of

X-radiation in solid-state TV receivers, it is specially constructed to prohibit X-radiation emissions.

For continued X-radiation protection, the replacement picture tube must be the same type as the

original. Also, because the picture tube shields

and mounting hardware perform an X-radiation

protection function, they must be correctly in place.

High voltage must be measured each time servic-

1-3-1 TD204IMP

Page 8

ing is performed that involves B+, horizontal deflection or high voltage. Correct operation of the

X-radiation protection circuits also must be reconfirmed each time they are serviced. (X-radiation

protection circuits also may be called "horizontal

disable" or "hold down.") Read and apply the high

voltage limits and, if the chassis is so equipped,

the X-radiation protection circuit specifications given on instrument labels and in the Product Safety

& X-Radiation Warning note on the service data

chassis schematic. High voltage is maintained

within specified limits by close tolerance safety-related components/adjustments in the high-voltage

circuit. If high voltage exceeds specified limits,

check each component specified on the chassis

schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV receiver. Design alterations and additions, including,

but not limited to circuit modifications and the addition of items such as auxiliary audio and/or video

output connections, might alter the safety characteristics of this receiver and create a hazard to the

user. Any design alterations or additions will void

the manufacturer's warranty and may make you,

the servicer, responsible for personal injury or

property damage resulting therefrom.

4. Picture Tube Implosion Protection Warning -

The picture tube in this receiver employs integral

implosion protection. For continued implosion protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles

equipped with side shields. People not so

equipped must be kept safely away while picture

tubes are handled. Keep the picture tube away

from your body. Do not handle the picture tube by

its neck. Some "in-line" picture tubes are equipped

with a permanently attached deflection yoke; because of potential hazard, do not try to remove

such "permanently attached" yokes from the picture tube.

5. Hot Chassis Warning -

a. Some TV receiver chassis are electrically connect-

ed directly to one conductor of the AC power cord

and may be safety-serviced without an isolation

transformer only if the AC power plug is inserted

so that the chassis is connected to the ground side

of the AC power source. To confirm that the AC

power plug is inserted correctly, with an AC voltmeter, measure between the chassis and a known

earth ground. If a voltage reading in excess of 1.0V

is obtained, remove and reinsert the AC power

plug in the opposite polarity and again measure

the voltage potential between the chassis and a

known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground regardless of the AC plug polarity. This chassis can

be safety-serviced only with an isolation transformer inserted in the power line between the receiver

and the AC power source, for both personnel and

test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not isolated from the AC power line. The two ground systems are electrically separated by insulation

material that must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch thermally hot parts, c. the AC supply, d. high voltage,

and e. antenna wiring. Always inspect in all areas

for pinched, out of place, or frayed wiring. Check

AC power cord for damage.

7. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or wiring that meet original specifications. Additionally,

determine the cause of overheating and/or damage and, if necessary, take corrective action to remove any potential safety hazard.

8. Product Safety Notice - Some electrical and mechanical parts have special safety-related characteristics which are often not evident from visual

inspection, nor can the protection they give necessarily be obtained by replacing them with components rated for higher voltage, wattage, etc.. Parts

that have special safety characteristics are identified by a ( # ) on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or

other hazards. The Product's Safety is under review continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are strictly inspected to confirm with the recognized product safety and electrical codes of the countries in which they are to be

sold. However, in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced.

1-3-2 TD204IMP

Page 9

Precautions during Servicing

A. Parts identified by the ( # ) symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not contact heat produc-

ing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

When replacing the power transformer in sets

where the connections between the power cord

and power transformer primary lead wires are performed using crimp type connectors, in order to

prevent shock hazards, perform carefully and precisely the following steps.

Replacement procedure

1) Remove the old connector by cutting the wires at

a point close to the connector.

Important: Do not re-use a connector (discard it).

2) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3) Align the lengths of the wires to be connected. Insert the wires fully into the connector.

4) Use the crimping tool to crimp the metal sleeve at

the center position. Be sure to crimp fully to the

complete closure of the tool.

L. When connecting or disconnecting the TV/DVD

connectors, first, disconnect the AC plug from AC

supply socket.

1-3-3 TD204IMP

Page 10

Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts and wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order to verify compliance

with safety standards.

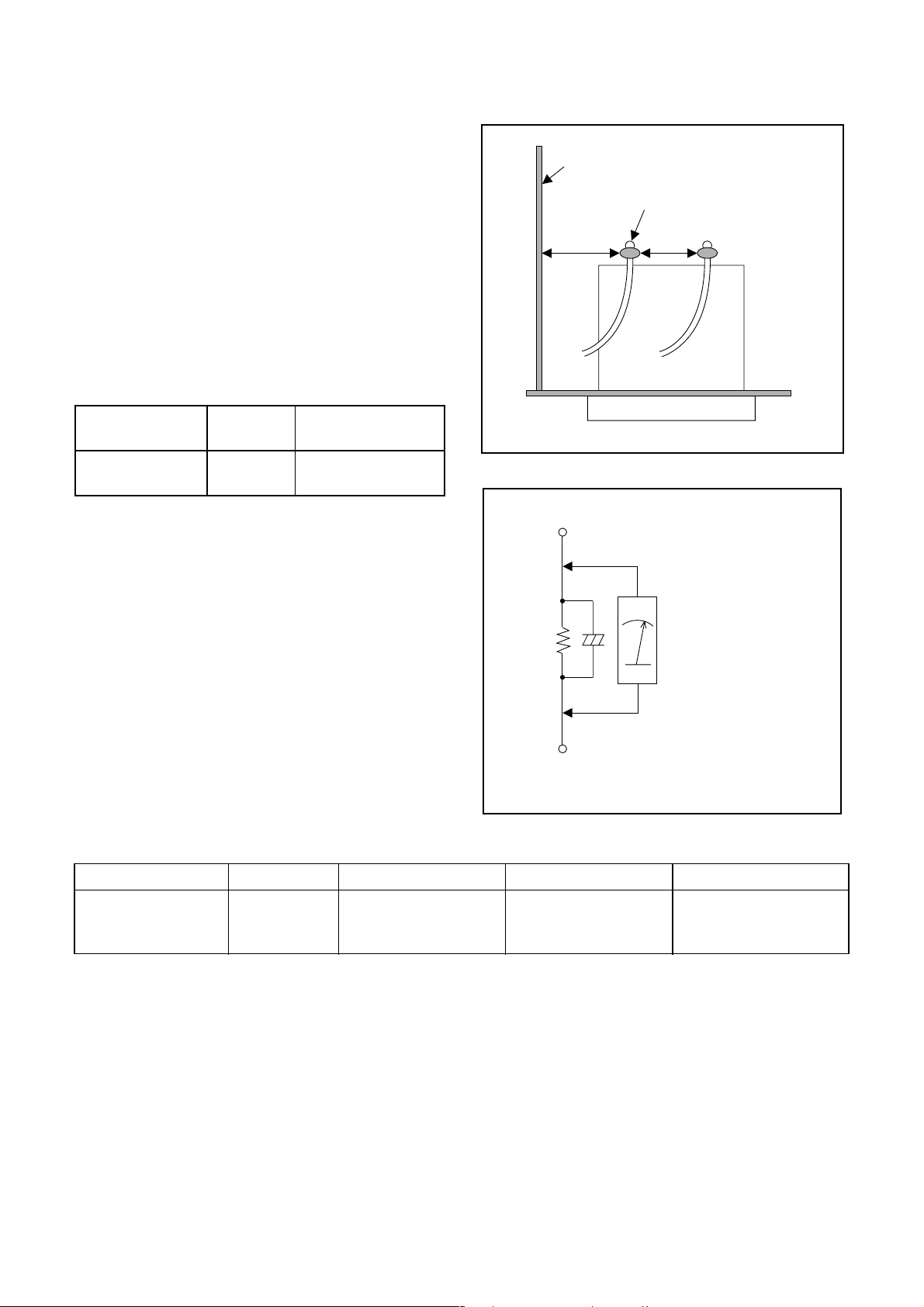

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit Terminals

dd’

AC Line Voltage Region

110 to 130 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

USA or

CANADA

Clearance

Distance (d) (d')

≥ 3.2 mm

(0.126 inches)

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of

load Z. See Fig. 2 and following table.

Table 2 : Leakage current ratings for selected areas

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

Fig. 1

AC Voltmeter

(High Impedance)

Fig. 2

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

110 to 130 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

USA or

CANADA

0.15µF CAP. & 1.5kΩ

RES. connected in

parallel

1-3-4 TD204IMP

i≤0.5mA rms

Exposed accessible

parts

Page 11

STANDARD NOTES FOR SERVICING

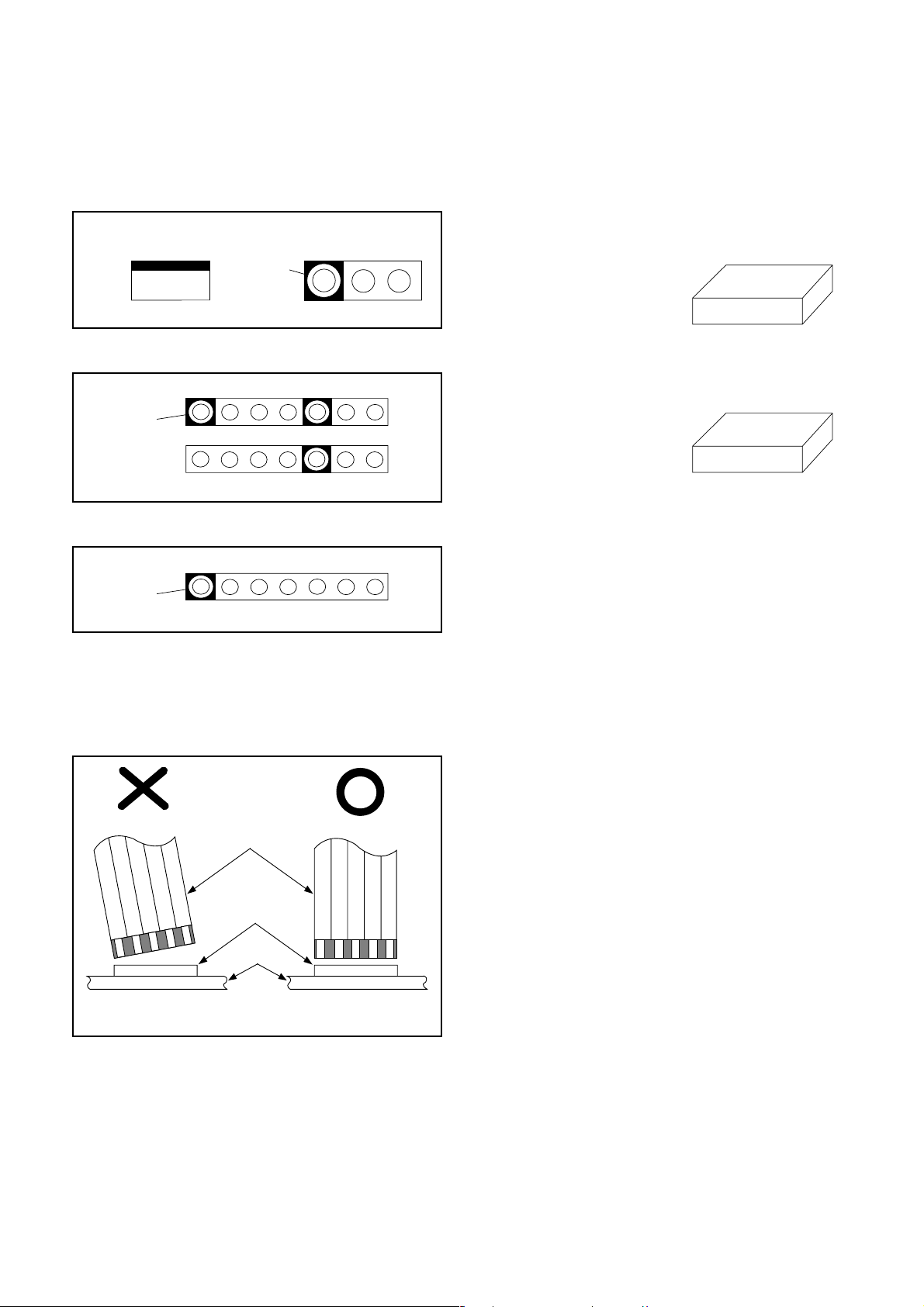

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown:

Top View

Out

2. For other ICs, pin 1 and every 5th pin is indicated

as shown:

Pin 1

3. The 1st pin of every pin connector are indicated as

shown:

Pin 1

Input

In

Bottom View

5

10

How to Read the Values of the Rectangular Type Chip Components

Example:

(a) Resistor

473

= 473 = 47 [kΩ]

(b) Capacitor

= Not Shown

Caution:

Once chip parts (Resistors, Capacitors, Transistors,

etc.) are removed, they must not be reused. Always

use a new part.

Replacement Procedures for

(Top View)

(Top View)

Instructions for Connectors

1. When you connect or disconnect FFC cable (connector), be sure to disconnect the AC cord.

2. FFC cable (connector) should be inserted parallel

into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

[ CBA= Circuit Board Assembly ]

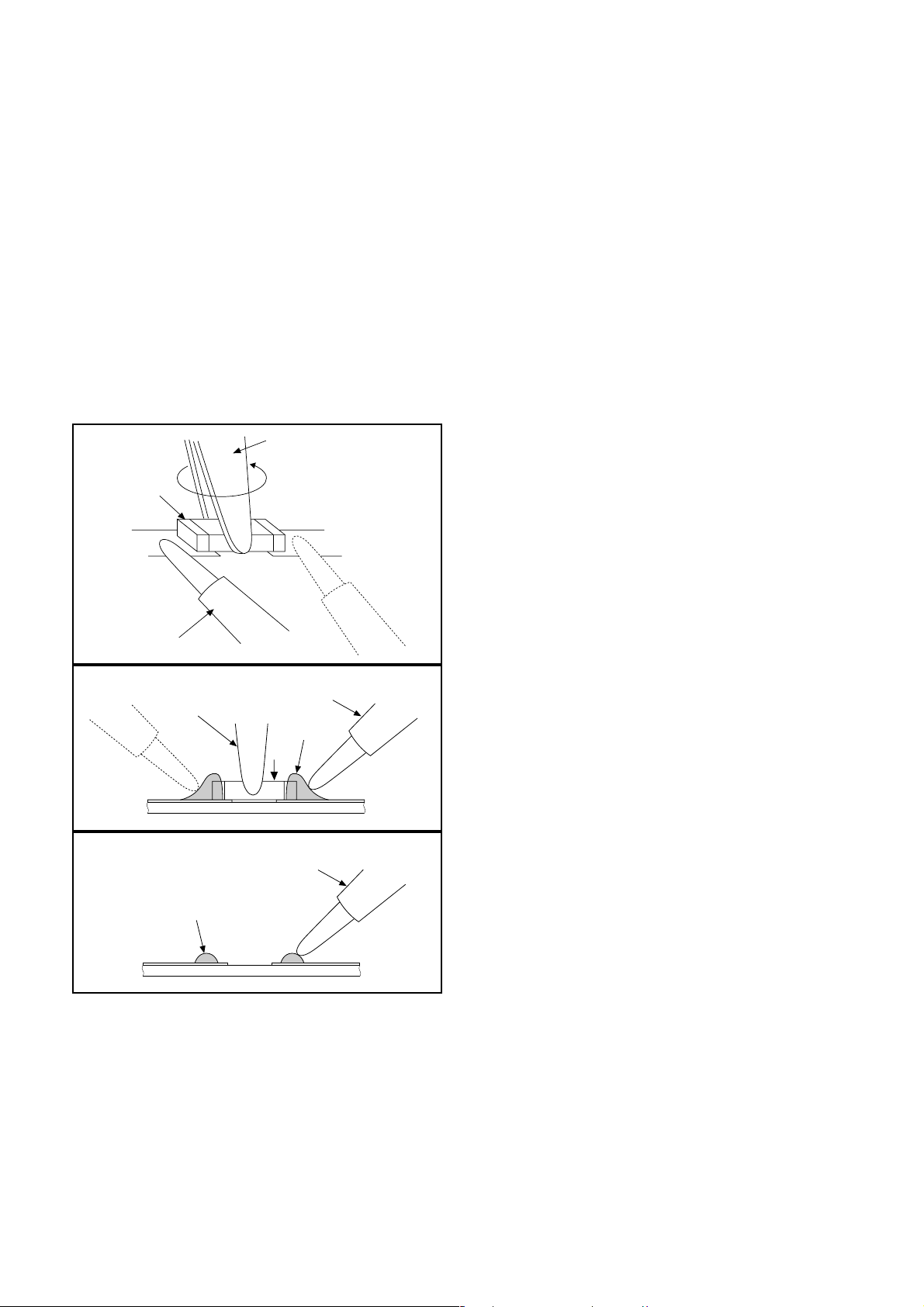

Leadless (Chip) Components

The Following Procedures are Recommended for the Replacement of the

Leadless Components Used in this Unit.

1. Preparation for replacement

a. Soldering Iron

Use a pencil-type soldering iron (less than 30

watts).

b. Solder

Eutectic solder (Tin 63%, Lead 37%) is recommended.

c. Soldering time

Do not apply heat for more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before

installation. (130°C~150°C, for about two minutes.)

Notes:

a. Leadless components must not be reused after

removal.

b. Excessive mechanical stress and rubbing for the

component electrode must be avoided.

2. Removing the leadless component

Grasp the leadless component body with tweezers

and alternately apply heat to both electrodes. When

the solder on both electrodes has melted, remove

leadless component with a twisting motion.

1-4-1 SFTY_5

Page 12

Notes:

a. Do not attempt to lift the component off the board

until the component is completely disconnected

from the board by the twisting action.

b. Take care not to break the copper foil on the

printed board

3. Installing the leadless component

a. Presolder the contact points of the circuit board.

b. Press the part downward with tweezers and solder

both electrodes as shown below.

Note:

Do not glue the replacement leadless component to

the circuit board.

Tweezers

Chip

Soldering Iron

Tweezers

Soldering Iron

Solder

Soldering Iron

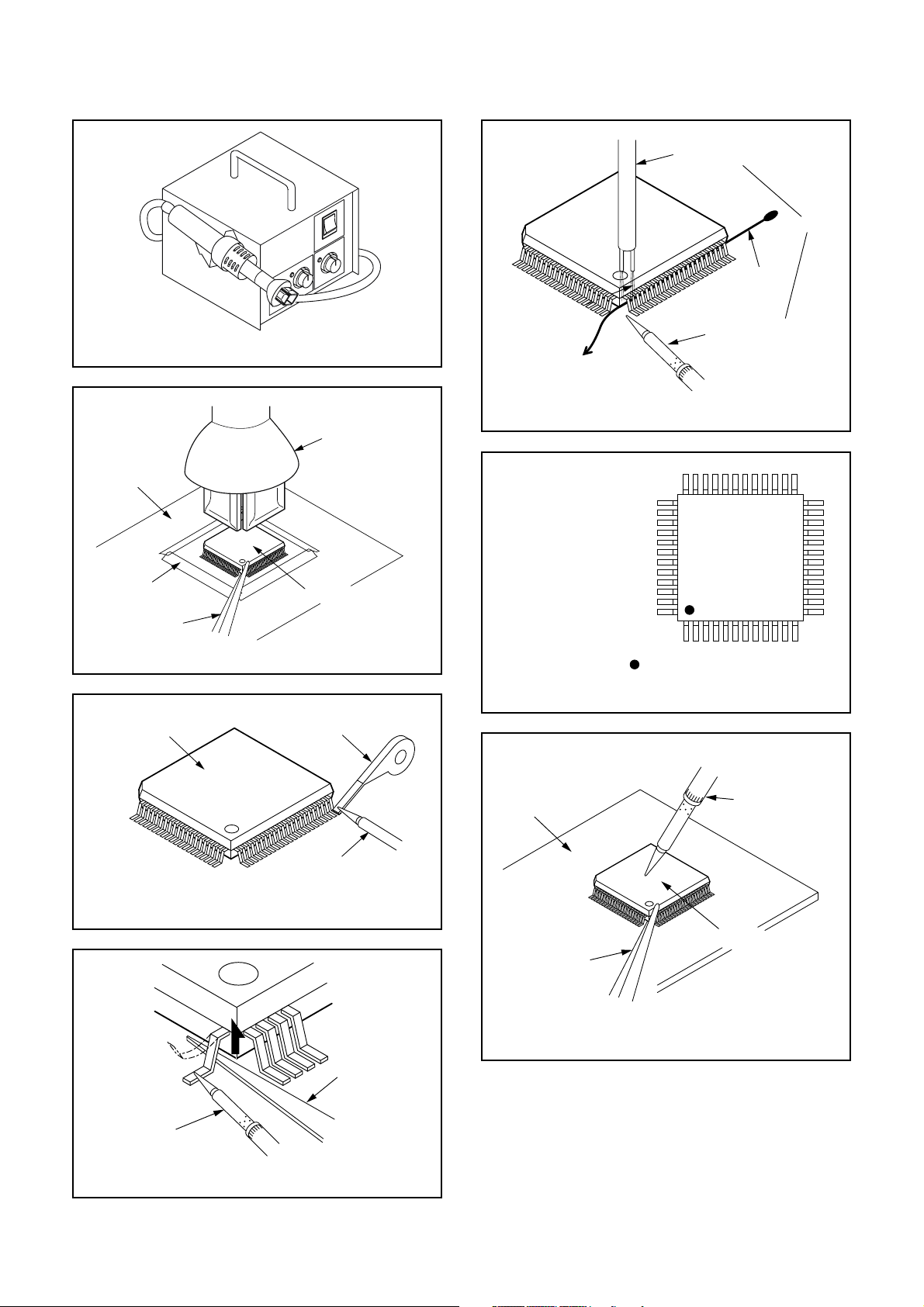

2. The Flat Pack-IC on the CBA is affixed with glue,

so be careful not to break or damage the foil of

each pin or solder lands under the IC when removing it.

1. Removal

With Hot - Air Flat Pack - IC Desoldering Machine:

a. Prepare the Hot - Air Flat Pack - IC Desoldering

Machine, then apply hot air to Flat Pack - IC (about

5~6 seconds). (Fig. S-1-1)

b. Remove the Flat Pack- IC with tweezers while

applying the hot air.

With Soldering Iron:

a. Using desoldering braid, remove the solder from all

pins of the Flat Pack - IC. When you use solder flux

which is applied to all pins of the Flat Pack - IC, you

can remove it easily. (Fig. S-1-3)

b. Lift each lead of the Flat Pack - IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air Desoldering

Machine. (Fig. S-1-4)

With Iron Wire:

a. Using desoldering braid, remove the solder from all

pins of the Flat Pack - IC. When you use solder flux

which is applied to all pins of the Flat Pack - IC, you

can remove it easily. (Fig. S-1-3)

b. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

c. Pull up on the wire as the solder melts so as to lift

the IC leads from the CBA contact pads, while

heating the pins using a fine tip soldering iron or

hot air blower.

Note:

When using a soldering iron, care must be taken

to ensure that the Flat Pack - IC is not being held

by glue, or when it is removed from the CBA, it

may be damaged if force is used.

Presolder

How to Remove / Install Flat Pack IC

Caution:

1. Do not apply the hot air to the chip parts around the

Flat Pack-IC for over 6 seconds as damage may

occur to the chip parts. Put Masking Tape around

the Flat Pack-IC to protect other parts from damage. (Fig. S-1-2)

2. Installation

a. Using desoldering braid, remove the solder from

the foil of each pin of the Flat Pack - IC on the CBA,

so you can install a replacement Flat Pack - IC

more easily.

b. The "I" mark on the Flat Pack - IC indicates pin 1

(See Fig. S-1-6). Make sure this mark matches the

1 on the CBA when positioning for installation.

Then pre - solder the four corners of the Flat PackIC (See Fig. S-1-7).

c. Solder all pins of the Flat Pack - IC. Make sure that

none of the pins have solder bridges.

1-4-2 SFTY_5

Page 13

Fig. S-1-1

Hot Air Blower

or

Iron Wire

Soldering Iron

To Solid

Mounting Point

CBA

Masking

Tape

Tweezers

Flat Pack-IC

Fig. S-1-2

Desoldering Braid

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-5

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-6

CBA

Fine Tip

Soldering Iron

Fine Tip

Soldering Iron

Soldering Iron

Fig. S-1-3

Flat Pack-IC

Tweezers

Fig. S-1-7

Sharp

Pin

Fig. S-1-4

1-4-3 SFTY_5

Page 14

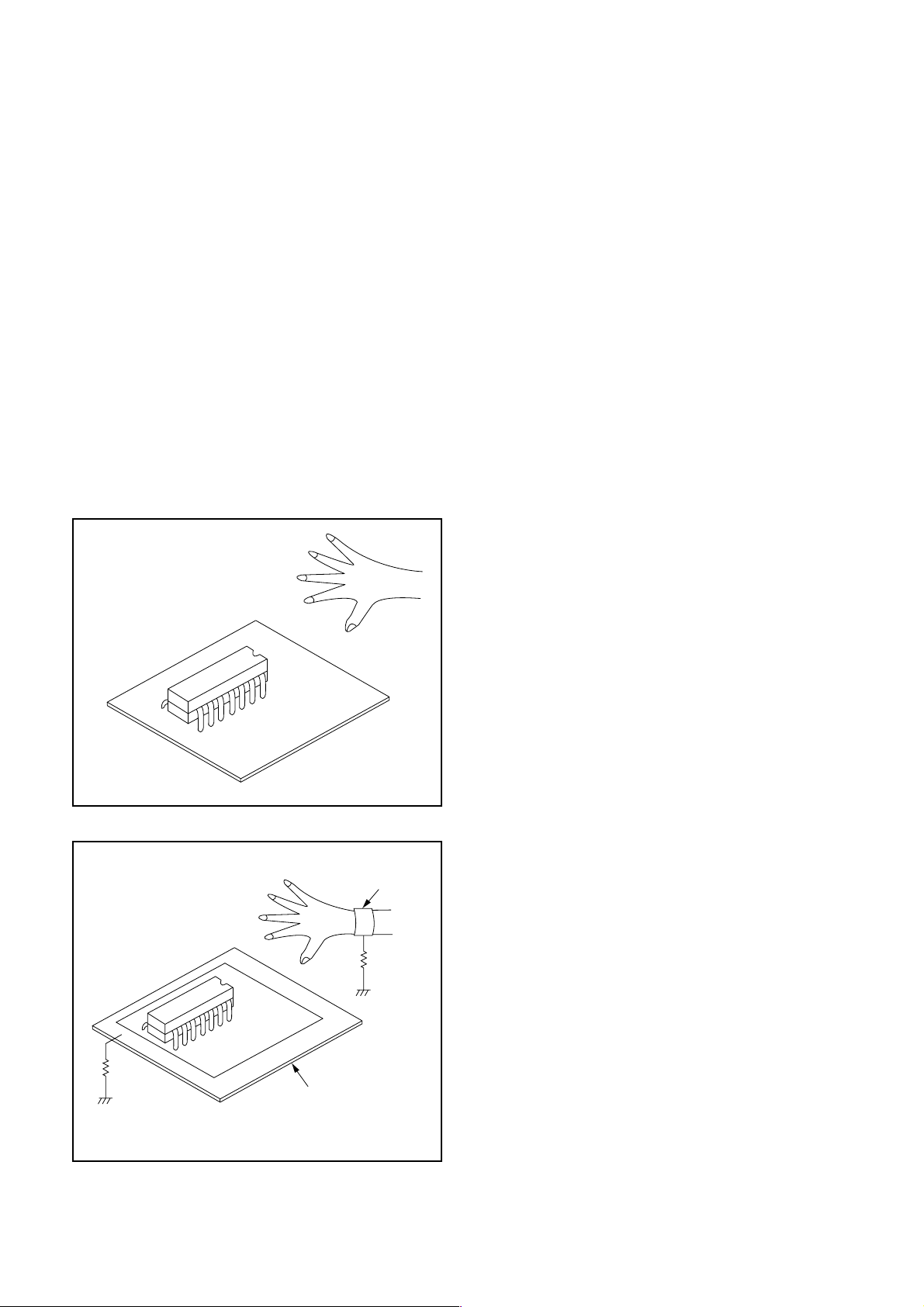

Instructions for Handling

Semiconductors

Electrostatic breakdown of the semiconductors may

occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly grounded to remove any static electricity that may

be charged on the body.

Ground for Work Bench

Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the work bench or

other surface, where the semiconductors are to be

placed. Because the static electricity charge on the

clothing will not escape through the body grounding

band, be careful to avoid contacting semiconductors to

clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 SFTY_5

Page 15

PREPARATION FOR SERVICING

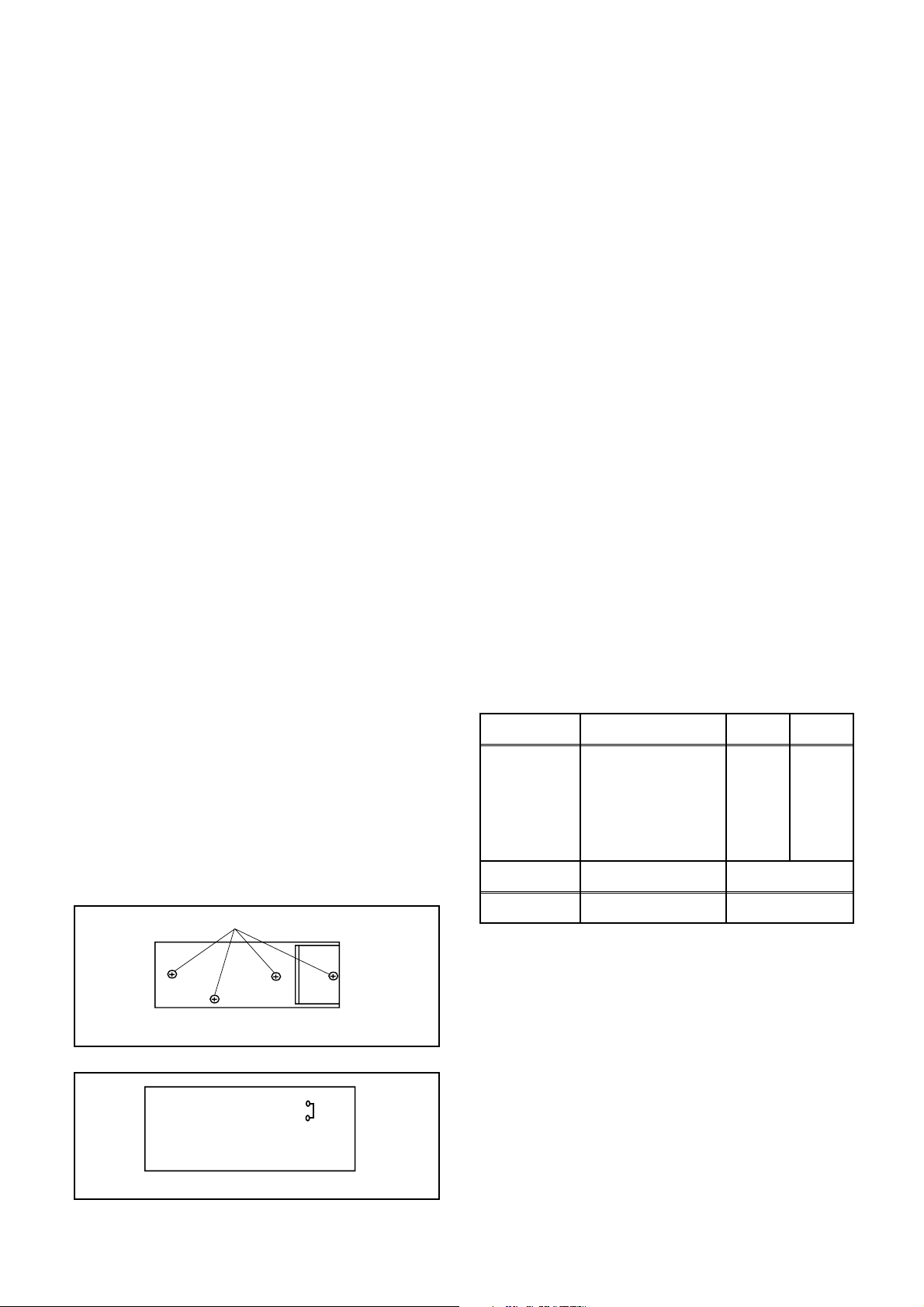

How to Enter the Service Mode

Caution: 1

1. Optical sensors system are used for Tape Start

and End Sensor on this equipment. Read this page

carefully and prepare as described on this page

before starting to service; otherwise, the unit may

operate unexpectedly.

Preparing: 1

1. Cover Q202 (START SENSOR) and Q201 (END

SENSOR) with Insulation Tape or enter the service

mode to activate Sensor Inhibition automatically.

Note: Avoid playing, rewinding or fast forwarding the

tape to its beginning or end, because both Tape End

Sensors are not active.

How to Enter the Service Mode

1. Turn power on.

2. Use service remote control unit and press WAKEUP/SLEEP key. (See page 1-8-1)

3. When entering the service mode, one of the number (1, 2 or 4) will display at corners of the screen.

4. During the service mode, electrical adjustment

mode can be selected by remote control key. (Service remote control unit).

Details are as follows.

Key Adjustment Mode

Picture adjustment mode: Press the

MENU button to change from BRT

(Bright), *CNT (Contrast), *CLR

MENU

0

1 No need to use.

2

3

4

5

(Color), *TNT(Tint) and *V-T. Press

CH UP/DOWN key to display Initial

Value. *Marked items are not necessary to adjust normally.

C-Trap and Y DL Time adjustment

mode: See adjustment instructions

page 1-8-3.

AGC/H adjustment mode: See adjustment instructions page 1-8-2.

Auto AFT adjustment mode: See

adjustment instructions page 1-8-2.

Auto record mode: Perform recording

(15 Sec.)-->Stop-->Rewind (Zero

return) automatically.

Head switching point adjustment

mode: See adjustment instructions

page 1-8-5.

Key Adjustment Mode

6 No need to use.

Purity check mode: Shows Red,

7

8

9

Caution: 2

1. The deck mechanism assembly is mounted on the

Main CBA directly, and SW1211 (REC-SAFETY

SW) is mounted on the Main CBA. When deck

mechanism assembly is removed from the Main

CBA due to servicing, this switch can not be operated automatically.

Green, Blue or White cyclically on the

screen each time the “7” key is

pressed.

H. Shift adjustment mode: See adjustment instructions page 1-8-4.

V.size/V. shift adjustment: See adjustment instructions page 1-8-3.

Preparing: 2

1. To eject the tape, press the STOP/EJECT button

on the unit (or Remote Control).

2. When you want to record during the Service mode,

press the Rec button while depressing SW1211

(REC-SAFETY SW) on the Main CBA.

Q201

(END SENSOR)

SW1211

(REC-SAFETY SW)

Q202

(START SENSOR)

MAIN CBA

1-5-1 TD500PFS

Page 16

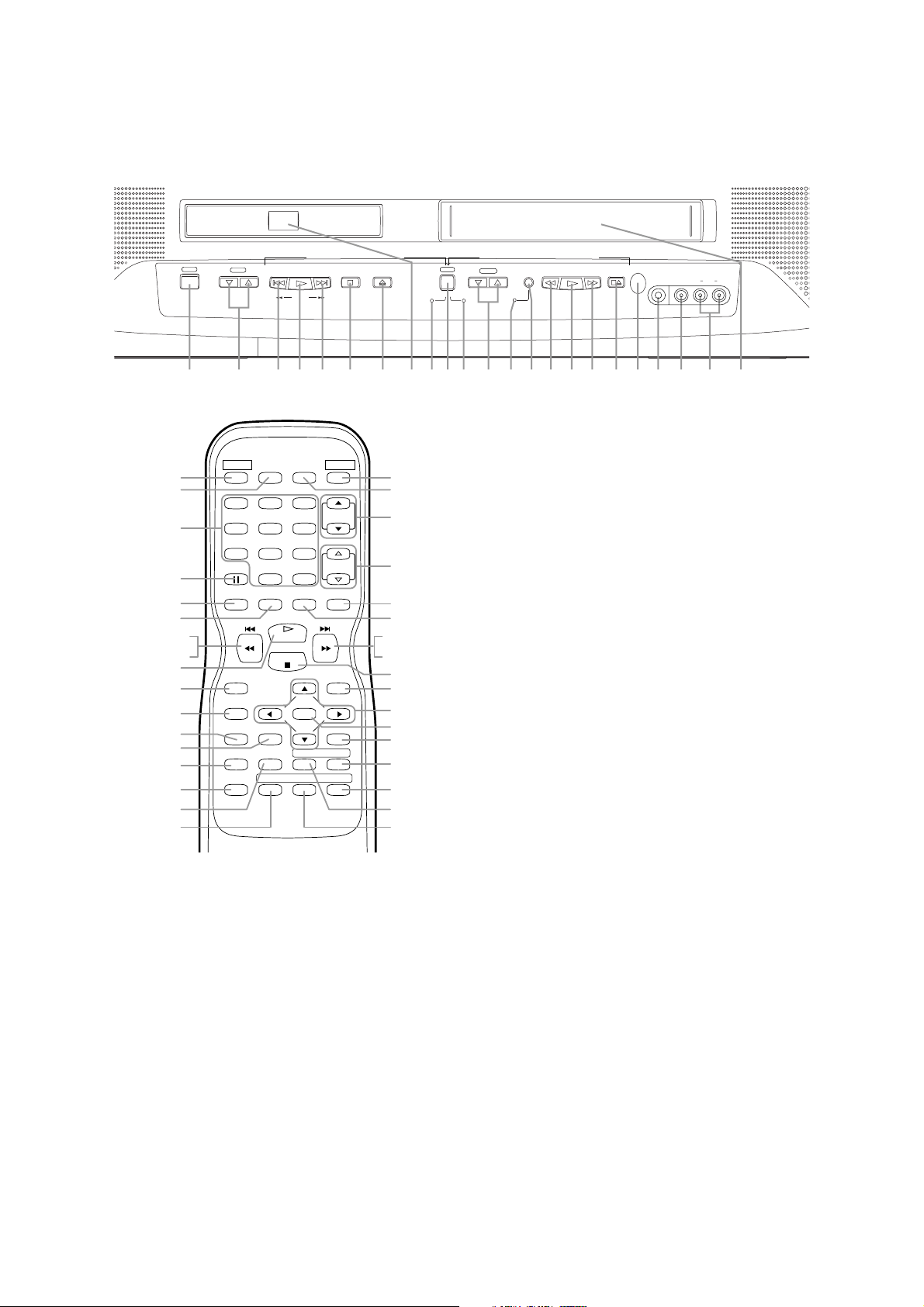

OPERATING CONTROLS AND FUNCTIONS

- TV/DVD/VCR FRONT PANEL -

POWER

VOLUME

DVD buttons TV/VCR buttons

PLAY

SKIP

SKIP

SEARCH

OPEN/CLOSE

STOP

12 4 5 6 107 1514983 3 411 12 13 212019181716

- REMOTE CONTROL -

POWER PICTURE SELECTSLEEP

1

22

23

24

25

26

(DVD) 3

(TV/VCR) 14

4

13

27

28

29

30

31

32

33

1.

POWER button

123

456

789

PAUSE

SPEED C.RESET

RECORD

DISPLAY

CLEAR

MODE

+100

0 +10

PLAY

STOP

ENTER

REPEATSEARCH MODE

RETURNTITLESETUP

CH.

VOL.

MUTEZOOM

DISC

MENU

A

ANGLESUBTITLEAUDIO

-

B

45

44

11

2

43

42

3 (DVD)

15 (TV/VCR)

5

41

40

39

38

37

36

35

34

Press to turn the power on and off.

2. VOLUME X/Y buttons

Press to control the volume level for the DVD and TV.

3. SKIP buttons (for DVD)

Skip chapters or tracks to a desired point.

PLAY button

4.

Starts playback of the disc or tape contents.

5.

STOP button

Stops operation of the disc.

OPEN/CLOSE button

6.

Press to insert discs into or remove them from the

tray.

7.

Disc loading tray

8. DVD indicator

Lights on during DVD mode.

SELECT

CHANNEL

TV/VCR

DVD

9. SELECT button

Press to change to TV/VCR mode or DVD

mode.

NOTE: For about 4 seconds just after the DVD

mode has switched to the TV mode, the button

does not work to switch back to the DVD mode.

10.

TV/VCR indicator

Lights on during TV/VCR mode.

CHANNEL K/L buttons

11.

Press to select memorized channel.

12.

Recording indicator

Flashes during recording. Lights up in the Standby mode for Timer Recording.

REC/OTR (RECORD) button

13.

Press for manual recording. Activates One

Touch Recording. (OTR is only during

TV/VCR mode.)

REW button (for TV/VCR)

14.

Press to rewind the tape, or to view the picture

rapidly in reverse during playback mode.

(Rewind Search)

15.

FWD button (for TV/VCR)

Press to rapidly advance the tape, or to view the

picture rapidly in forward during playback

mode. (Forward Search)

STOP/EJECT button

16.

Press to stop the tape motion. Press in the Stop

mode to remove tape from the unit.

Remote sensor window

17.

18. HEADPHONE jack

To connect headphone (not supplied) for personal listening.

VIDEO input jack

19.

Connect to the video output jack of a video

camera or VCR.

20.

AUDIO L/R input jacks

Connect to the audio output jacks of a video

camera or VCR.

Cassette compartment

21.

22. PICTURE button

Press to adjust the picture.

REC/OTR

REW

HEADPHONE

RL

AUDIO

VIDEO

STOP/EJECT

F.F W D

PLAY

1-6-1 TD500IB

Page 17

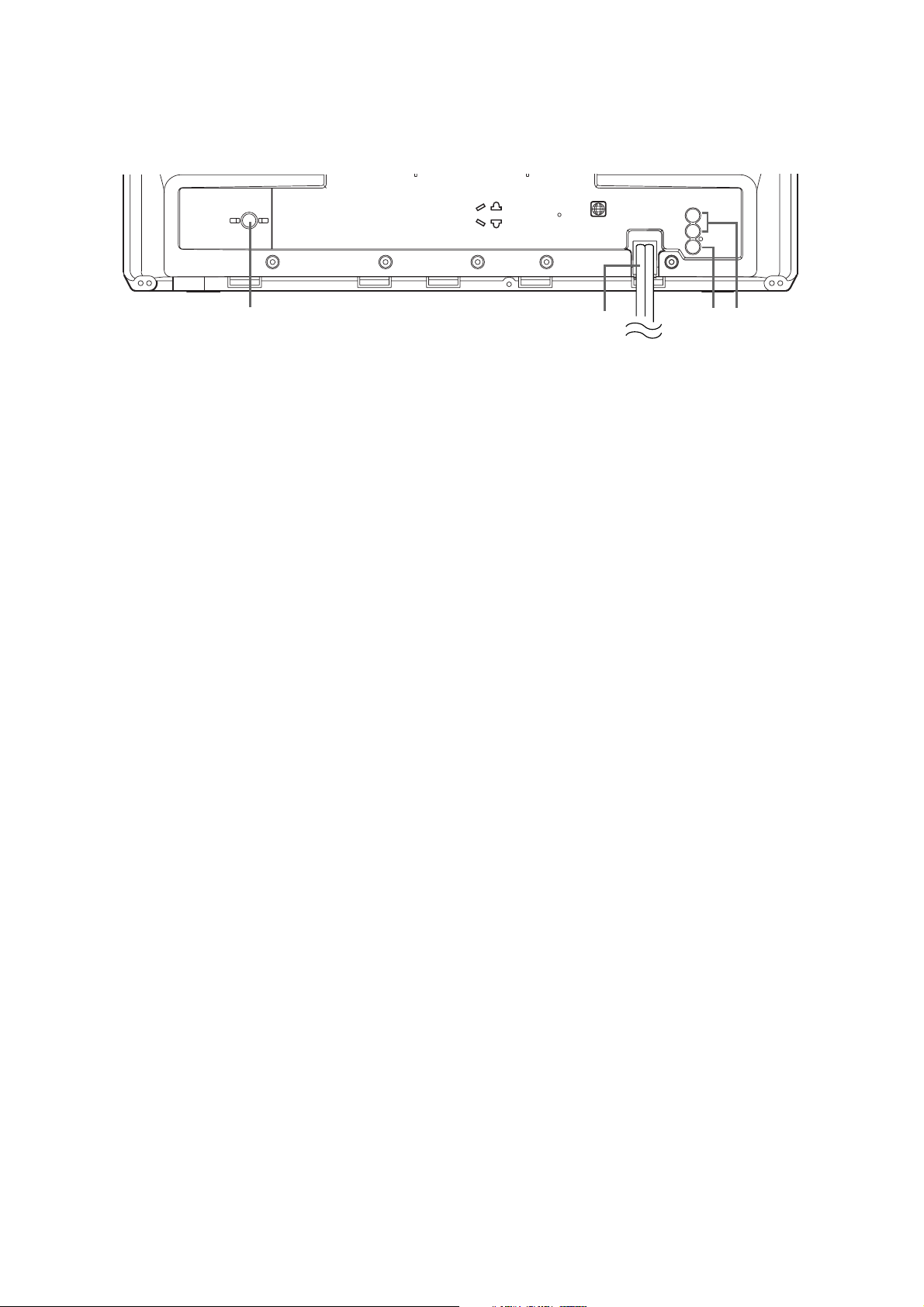

- TV/DVD/VCR REAR PANEL -

ANT.

23. Number buttons

TV Mode:

Press two digits to directly access the desired

channel.

Remember to press a "0" before a single digit

channel.

+100 buttonÐ

Press to select cable channels which are equal or

greater than number 100.

DVD Mode:

Press to enter the desired number.

+10 buttonÐ

Press to enter the desired numbers which are

equal or greater than number 10.

PAUSE button

24.

Pauses the current disc or tape operation.

25.

SPEED button

Press to choose the desired recording speed:

SP/SLP.

C.RESET button

26.

Press to reset counter to 0:00:00.

Press to cancel a setting of timer program.

27.

DISPLAY button

TV/VCR Mode:

Display the counter or the current channel number and current time on the TV screen.

DVD Mode:

Displays the current status on the TV screen for

checking purposes.

SETUP button

28.

Press to enter or exit the TV menu or DVD setup

mode.

29.

TITLE button

Displays the title menu.

CLEAR button

30.

Resets a setting.

MODE button

31.

Activates program playback or random playback

mode.

32. SEARCH MODE button

Press to locate a desired point.

AUDIO button

33.

Press to select a desired audio language or sound

mode.

SUBTITLE button

34.

Press to select a desired subtitle language.

1

AUDIO OUT

COAXIAL

L

R

4746 48 49

35.

REPEAT button

Repeats playback of the current disc, title, chapter

or track.

ANGLE button (DVD mode)

36.

Press to change the camera angle to see the

sequence being played back from a different angle.

37. A-B REPEAT button

Repeats playback of a selected section.

RETURN button

38.

Returns to the previous operation.

39.

ENTER button

Press to accept a setting.

40.

Arrow buttons

TV/VCR Mode:

Press to select a setting mode from the menu on

the TV screen.

Press to select or adjust from a particular menu.

DVD Mode:

Use when making settings while watching the

display on a TV screen.

41.

DISC MENU button

Displays the menus in the DVD.

ZOOM Button

42.

Enlarges part of a DVD-reproduced image.

MUTE button

43.

Mutes the sound. Press it again to resume sound.

44.

SLEEP button

Sets the Sleep Timer.

SELECT button

45.

Press to switch TV/VCR and DVD mode. You can

see the mode (TV/VCR or DVD) on the front

panel indicator.

ANT. in jack

46.

Connect to an antenna, cable system, or satellite

system.

Power cord

47.

Connect to a standard AC outlet (120V/60Hz).

NOTE: Remove the power cord from the hook to

avoid breaking a wire before you connect

to a standard AC outlet.

48.

COAXIAL digital audio out jack

Connect to the digital input of an external

amplifier or decoder.

AUDIO L/R output jack

49.

Connect to the analog audio input of an external

amplifier or decoder.

1-6-2 TD500IB

Page 18

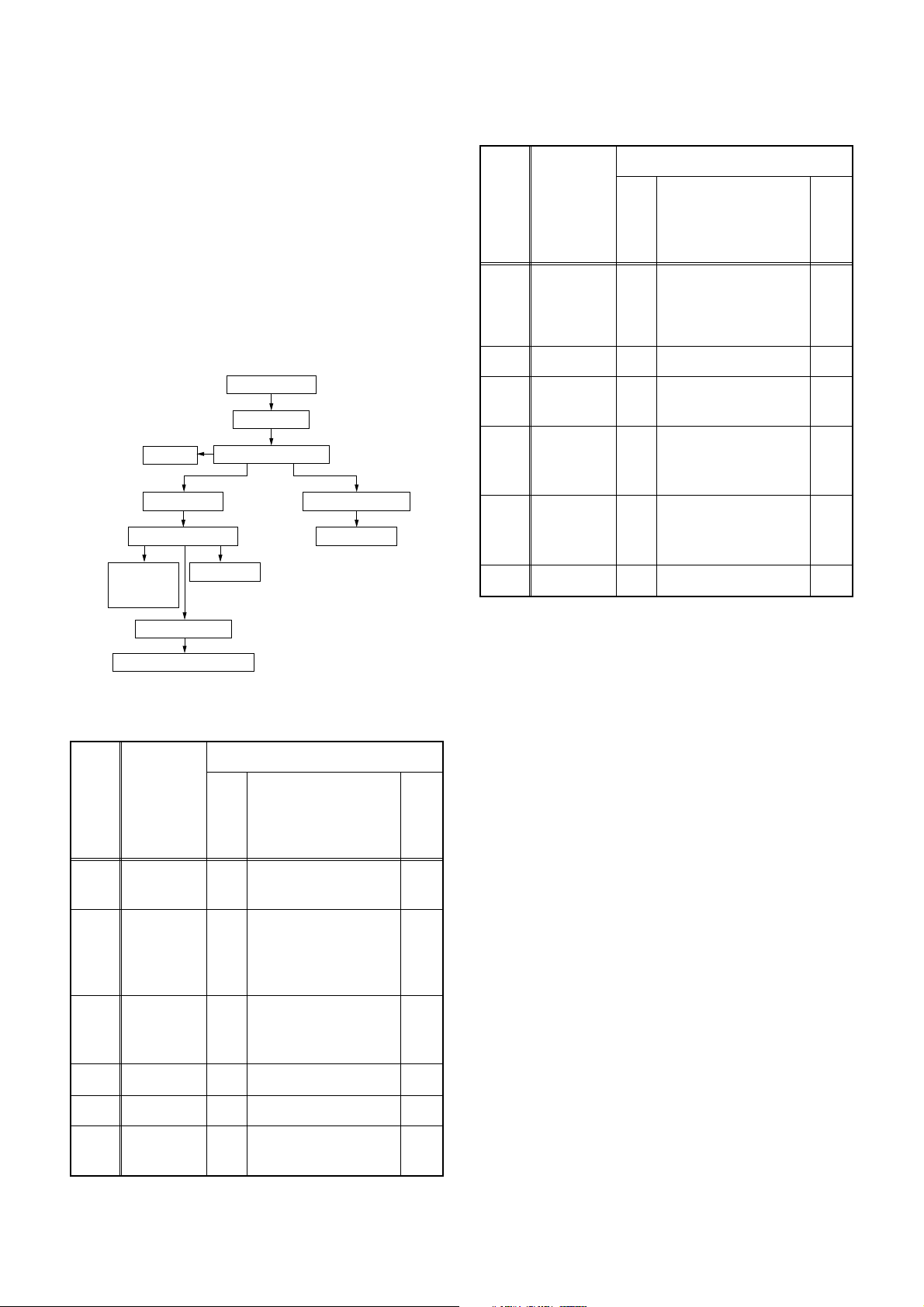

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the CBA in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

Caution !!

When removing the CRT, be sure to discharge the

Anode Lead of the CRT with the CRT Ground Wire

before removing the Anode Cap.

[1] Rear Cabinet

[2] H.V. CBA

[4] CRT

[5] Shield Box

[6] DVD Mechanism

MAIN

CBA UNIT

[9] Bottom Plate

[3] Tray Chassis Unit

[11] Deck Assembly

[12] Main CBA

[8] Filter CBA[7] DVD

REMOVAL

ID/

LOC.

No.

PART

REMOVE/

*UNHOOK/UNLOCK/

Fig.

No.

RELEASE/UNPLUG/

DESOLDER

[7]

DVD Main

CBA Unit

3(S-7), CN101,

5

CN401

[8] Filter CBA 3, 6 CN401, CN402 -

Bottom

[9]

[10]

[11]

Plate

Power

Supply/AV

CBA

Deck

Assembly

3 6(S-8) -

3(S-9), CN2802,

3, 6

CN2803, CN2804

7(S-10), 2(S-11),

CL1201, CL1401,

3, 6

CL1402, CL1403

[12] Main CBA 3 3(S-12) -

↓

(1)

↓

(2)

↓

(3)

↓

(4)

Note

2-1

2-2

2-3

3

-

4

↓

(5)

[10] Power Supply/AV CBA

2. Disassembly Method

REMOVAL

ID/

LOC.

PART

No.

Rear

[1]

Cabinet

H.V. CBA

[2]

(With

Holder)

Tray

[3]

Chassis

Unit

[4] CRT 4 4(S-4) -

[5] Shield Box 3 5(S-5) -

REMOVE/

*UNHOOK/UNLOCK/

Fig.

No.

RELEASE/UNPLUG/

DESOLDER

1, 2 6(S-1), 1(S-2), 1(S-3) -

Anode Cap, CN501,

3, 4,

CRT CBA, CN571,

6

CN1301, CN1302,

CN2602

CN1802, CN2801,

3, 6

CN2601

Note

1

-

(1): Order of steps in Procedure. When reassembling,

follow the steps in reverse order.These numbers

are also used as the identification (location) No. of

parts in Figures.

(2): Parts to be removed or installed.

(3): Fig. No. showing Procedure of Part Location.

(4): Identification of part to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connec-

tor, *=Unhook, Unlock, Release, Unplug, or

Desolder

2(S-2) = two Screw (S-2)

(5): Refer to the following "Reference Notes in the

Table."

[6]

DVD

Mechanism

CN501, CN701,

3, 6

4(S-6)

-

1-7-1 TD500DC

Page 19

Reference Notes in the Table

Caution !

When removing the CRT, be sure to discharge the

Anode Lead of the CRT with the CRT Ground Wire

before removing the Anode Cap.

Reference Notes in the Table

CAUTION 1: Discharge the Anode Lead of the CRT

with the CRT Ground Wire before removing the Anode

Cap.

1. Disconnect the following: Anode Cap, CN501, CRT

CBA, CN571, CN2602, CN1301 and CN1302.

Then remove H.V. CBA (with Holder).

CAUTION 2: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body etc., during

unpacking or repair work.

To avoid damage of pickup follow next procedures.

2-1. Slide the pickup unit as shown in Fig. 5.

2-2. Short the three short lands of FPC cable with sol-

der before removing the FFC cable (CN101) from

it. If you disconnect the FFC cable (CN101), the

laser diode of pickup will be destroyed. (Fig. 5)

2-3. Disconnect Connector (CN401). Remove three

Screws (S-5) and lift the DVD Main CBA Unit.

(Fig. 5)

CAUTION 3: When reassembling, confirm the FFC

cable (CN101) is connected completely. Then remove

the solder from the three short lands of FPC cable.

(Fig. 5)

4. Remove Screws 7(S-10) and 2(S-11). Then, desolder connectors (CL1201, C1401, CL1402, CL1403)

and lift up the Deck Assembly.

1-7-2 TD500DC

Page 20

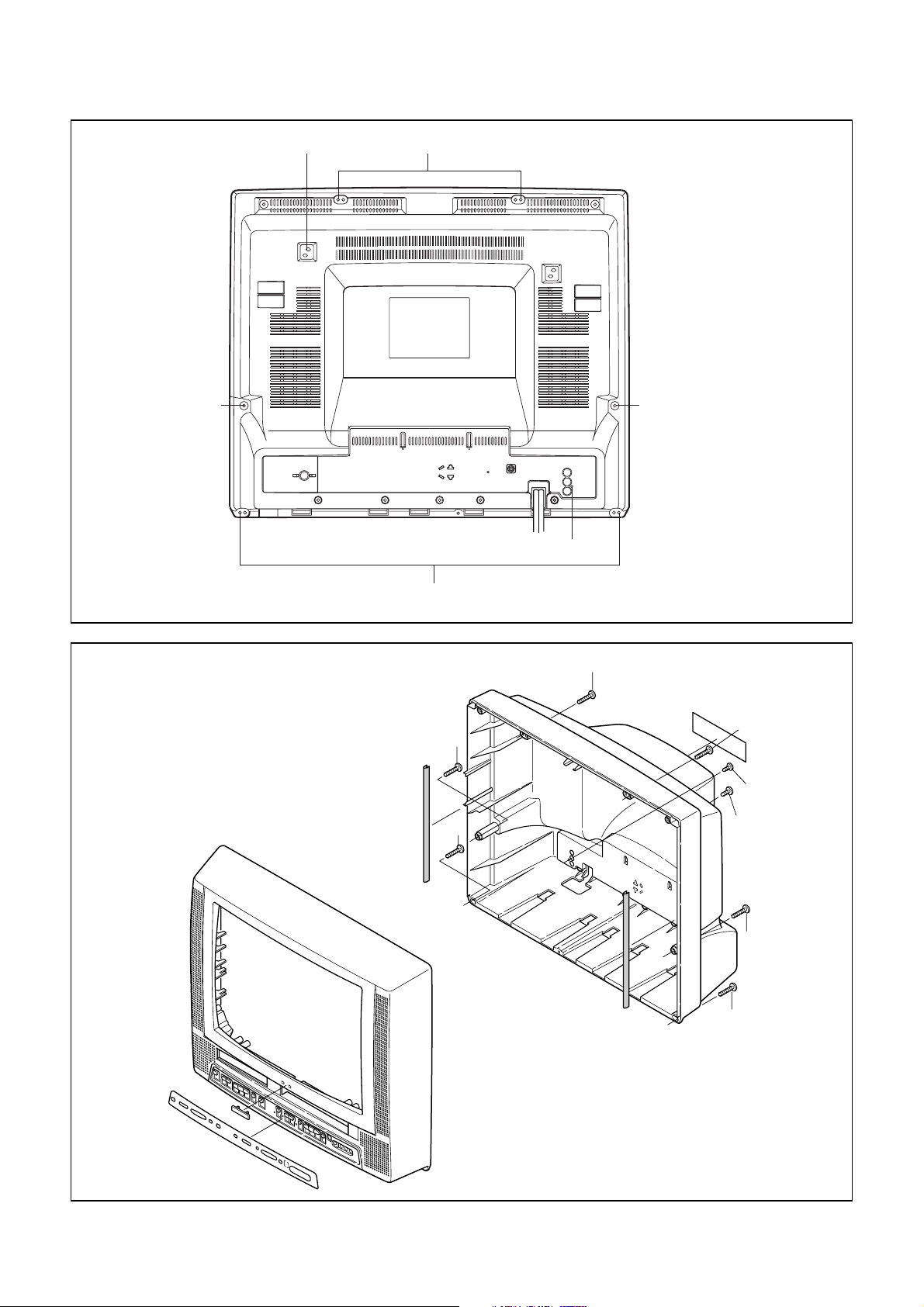

S-2

S-1

[1] REAR CABINET

S-1 S-1

ANT.

1

S-3

S-1

S-1

S-1

S-1

Fig. 1

S-1

S-3

S-2

S-1

S-1

[1] REAR CABINET

Fig. 2

1-7-3 TD500DC

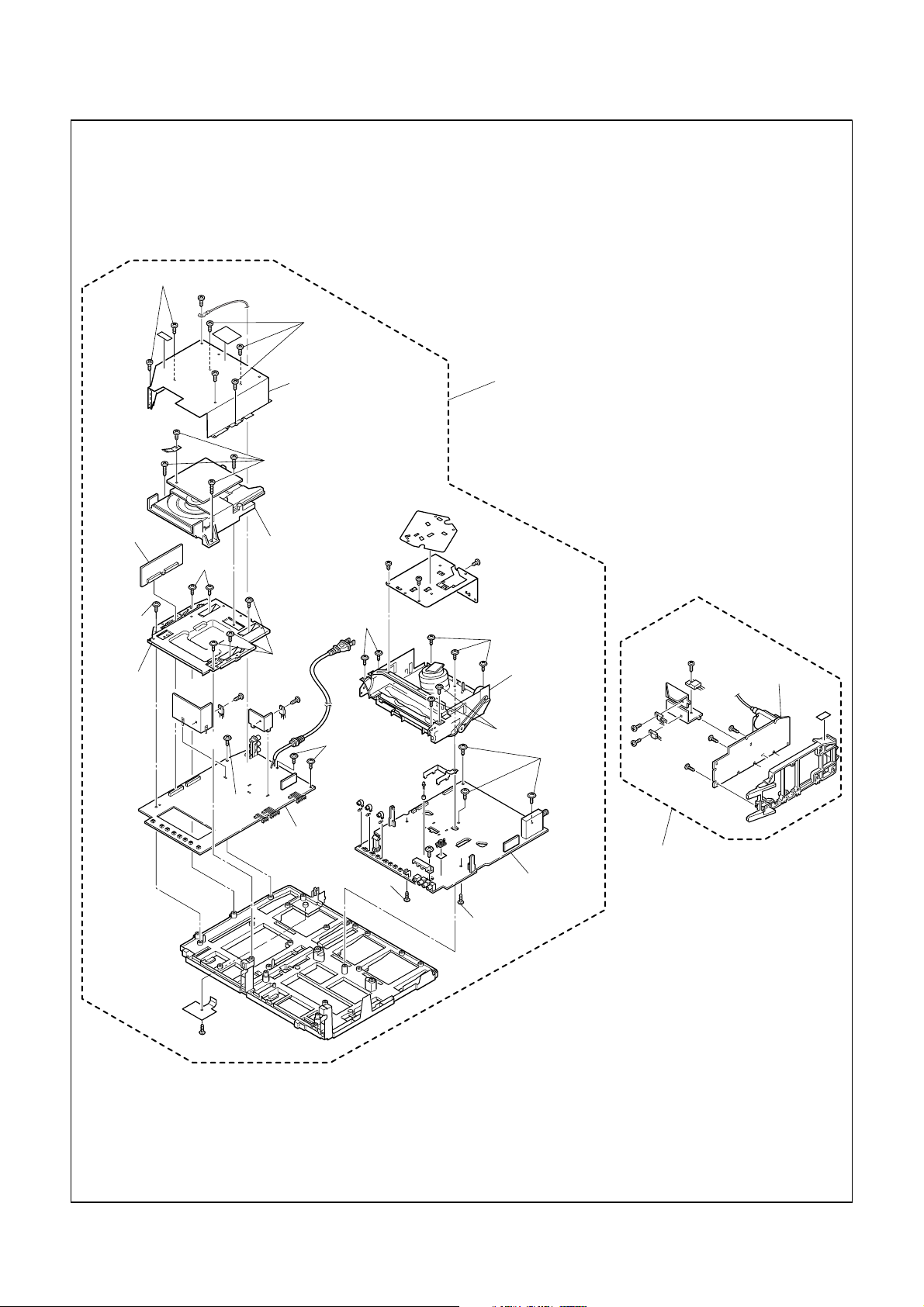

Page 21

S-5

S-5

[8] Filter

CBA

S-8

[9] Bottom

Plate

S-8

S-9

[5] Shield Box

S-6

[6] DVD

Mechanism

S-8

S-9

S-10

[3] Tray Chassis

S-10

[11] Deck

Assembly

S-10

S-12

H.V. CBA

[10] Power

Supply/

AV CBA

S-11

[2] H.V. CBA

[12] Main CBA

S-11

(wih Holder)

Fig. 3

1-7-4 TD500DC

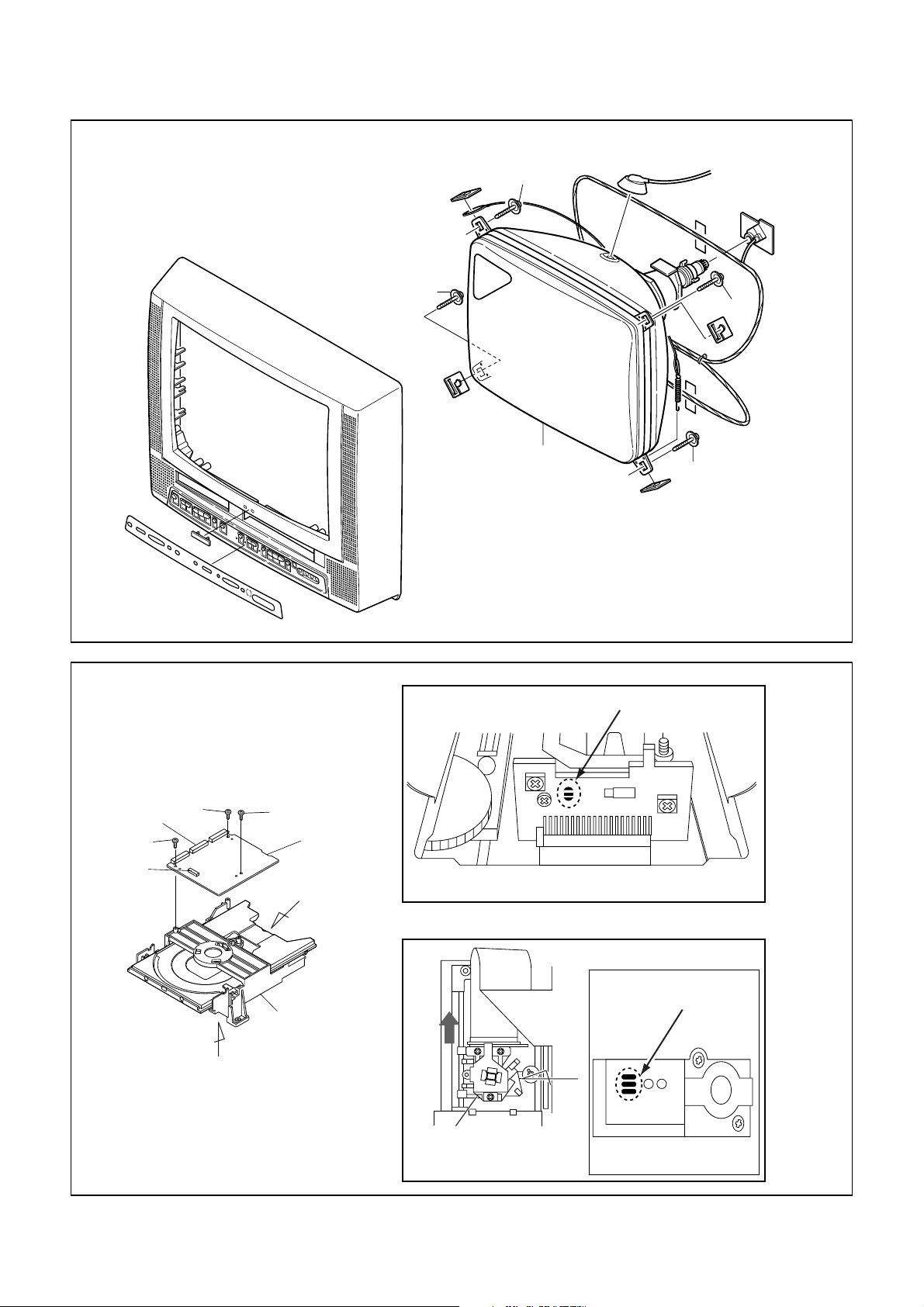

Page 22

S-4

Anode Cap

S-4

CRT CBA

S-4

CN101

S-7

CN401

S-7

S-7

[7] DVD Main

CBA Unit

A

[4] CRT

S-4

Fig. 4

Short the three short lands by soldering

View for A

OR

Short the three short

lands by soldering

DVD Mechanism

Slide

B

C

Pickup Unit

View for B

View for C

Fig. 5

1-7-5 TD500DC

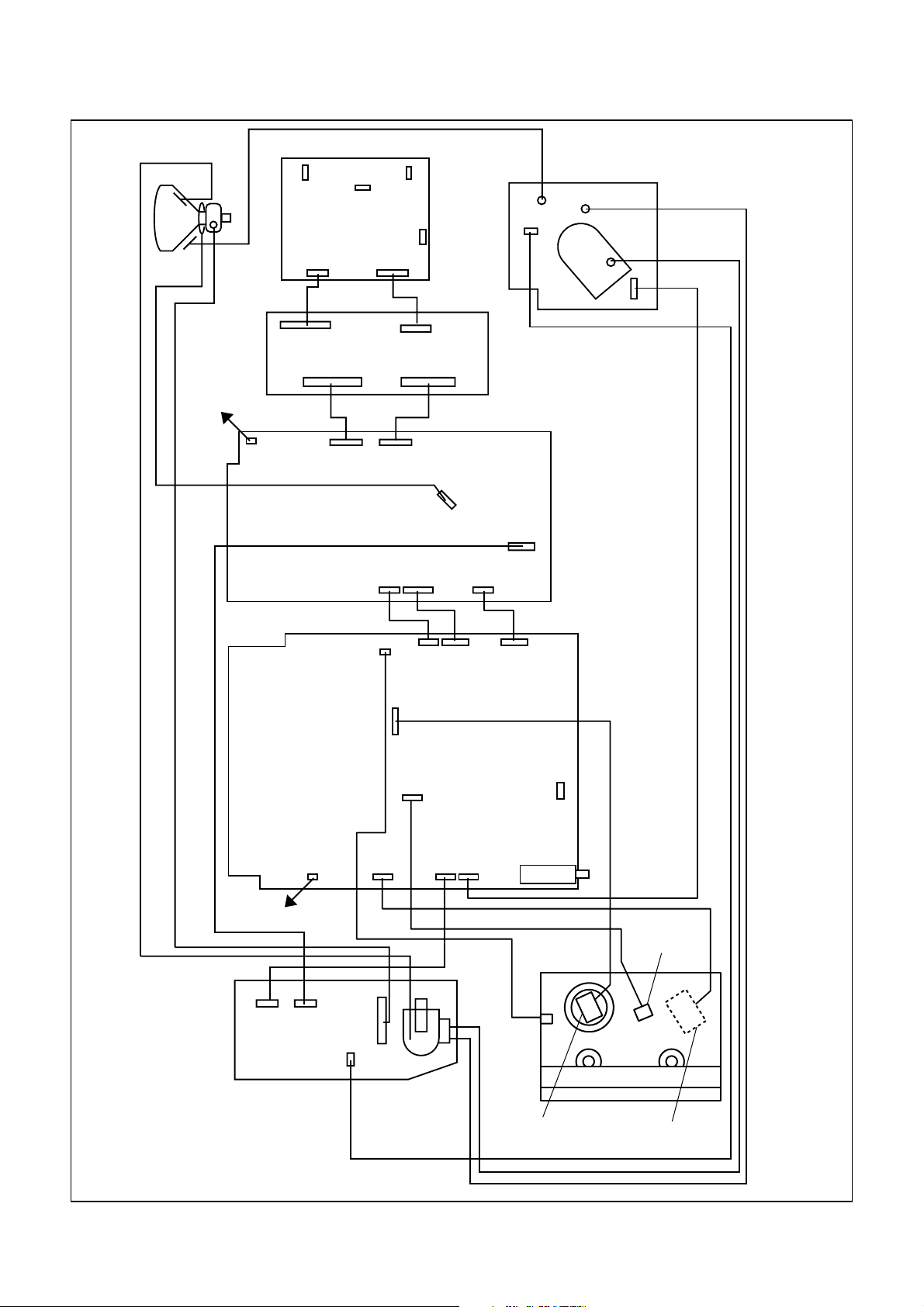

Page 23

ANODE

CRT

DVD MAIN CBA

FACTORY USE

ONLY

CL501

CRT CBA

CN501

SCREEN

GND

TO

SPEAKER

CN2801

POWER SUPPLY/

AV CBA

CN501

CN403

CN401

CN2401 CN2402

CN2802

CL1403

CN701

CN404

CN1805

CN402

CN2803

CN2601

CN2804

CN1804

FOCUS

CL504A

FILTER CBA

CN2602

CN1803

H.V. CBA

MAIN CBA

CN1802

TO SPEAKER

CL503A

CL501A

CL502A

CN571

CL1201

CL1401

CL1402

CN1302

INT MON

FACTORY USE

ONLY

CN1301

CN1303

TUNER

FE HEAD

CYLINDER

ASSEMBLY

AC HEAD

ASSEMBLY

DECK ASSEMBLY

CAPSTAN

MOTOR

Fig. 6

1-7-6 TD500DC

Page 24

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note:

"CBA" is abbreviation for "Circuit Board

Assembly."

NOTE:

Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to perform these adjustments only

after all repairs and replacements have been completed.

Also, do not attempt these adjustments unless the

proper equipment is available.

Test Equipment Required

1. NTSC Pattern Generator (Color Bar W/White Window, Red Color, Dot Pattern, Gray Scale,

Monoscope, Multi-Burst)

2. AC Milli Voltmeter (RMS)

3. Alignment Tape (FL8A, FL8N), Blank Tape

4. DC Voltmeter

5. Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div,

F-Range: DC~AC-60MHz

6. Frequency Counter

7. Plastic Tip Driver

How to Set up the Service mode:

Service Mode:

1. Use the service remote control unit.

2. Turn the power on. (Use main power on the TV

unit.)

3. To enter the TV mode, press CH UP or CH DOWN

button on the TV unit.

4. Press "DISC MENU" button on the service remote

control unit. (Version of micro computer will display

on the CRT. (Ex: 057-001)

X-Ray Protection Test

X-Ray protection test should be done when replacing

any parts of this chassis.

1. Short test points J551 and J552 (on H.V. CBA).

2. Confirm that the main power turns off.

3. If the main power does not turn off, then replace

the following parts (D591, Q591, R592, R593,

R594 and IC1201).

4. Perform steps 1 to 3 again.

1. DC 114V (+B) Adjustment

Purpose: To obtain correct operation.

Symptom of Misadjustment: The picture is dark and

unit does not operate correctly.

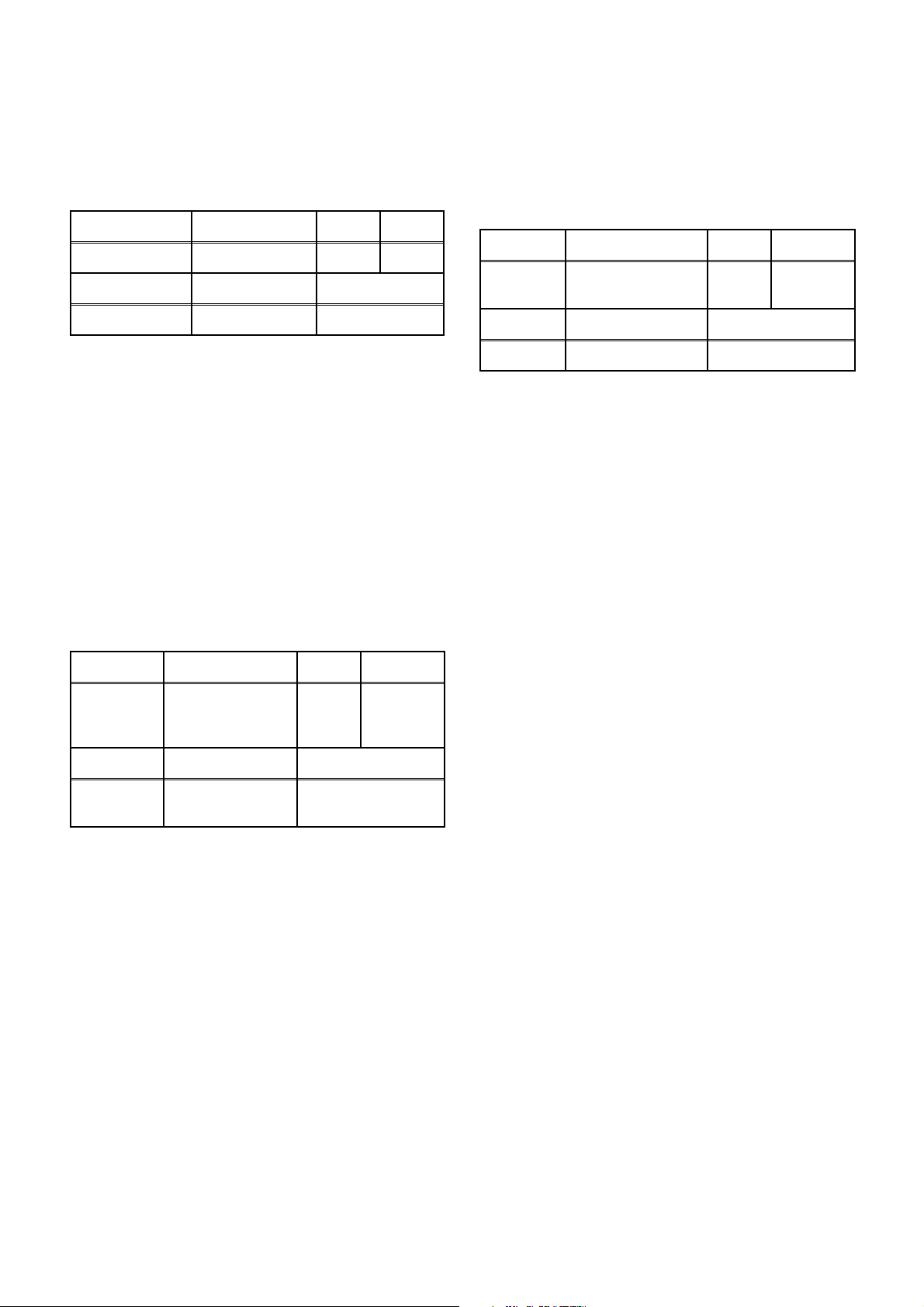

How to make service remote control

unit:

1. Prepare normal remote control unit. (Part No.

NE200UD) Remove 4 screws from the back lid.

(Fig. 1-1)

2. Add J1 (Jumper Wire) to the remote control CBA.

(Fig. 1-2)

SCREW

Remote control unit (Bottom)

J 1

Fig. 1-1

Test point Adj. Point Mode Input

J533

(+B)

HEAT SINK

(on H.V.

CBA)

(GND)

Tape M. EQ. Spec.

--- DC Voltmeter +114±0.5V DC

Note: J533(+B), HEAT SINK --- H.V. CBA

,VR2601 --- Power Supply/AV CBA

1. Connect the unit to AC Power Outlet.

2. Connect DC Volt Meter to J533(+B) and HEAT

SINK (on H.V. CBA)(GND).

3. Adjust VR2601 so that the voltage of J533(+B)

becomes +114±0.5V DC.

VR2601 --- -----

Remote control CBA

Fig. 1-2

1-8-1 TD500EA

Page 25

2. Auto AFT (VCO) Adjustment

4-1. H Adjustment

Purpose: To operate AFT correctly.

Symptom of Misadjustment: AFT does not work cor-

rectly and/or synchronization is faulty.

Test point Adj. Point Mode Input

--- --- Video -----

Tape M. EQ. Spec.

--- --- ---

1. Set the unit to the Video mode with no signal input.

2. Enter the Service mode. (See page 1-8-1.) Then

press number "3" button on the remote control unit.

3. If the screen color changes to "Green" then this

adjustment is finished.

4. If the screen color changes to "Red" then this

adjustment is failed. Repeat steps 1 and 2 or check

relative circuit or parts (IC).

3. TV AGC Adjustment

Purpose: Set AGC (Auto Gain Control) Level.

Symptom of Misadjustment: AGC does not synchro-

nize correctly when RF input level is too weak and picture distortion may occur if it is too strong.

Test point Adj. Point Mode Input

Purpose: To get correct horizontal position and size

of screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

Test point Adj. Point Mode Input

R583

Tape M. EQ. Spec.

--- Frequency Counter 15.734kHz±300Hz

Note: R583 --- H.V. CBA

1. Connect Frequency Counter to R583.

2. Operate the unit for at least 20 mintes.

3. Enter the Service mode. (See page 1-8-1.) Press

"2" button on the remote control unit and select HADJ Mode. (Press "2" button then display will

change H-ADJ and AGC.)

4. Press CH o / p buttons on the remote control unit

so that the display will change "0" to "7."

5. At this moment, choose display "0" to "7" when the

Frequency counter display is closest to

15.734kHz±300Hz.

6. Turn the power off and on again.

CH o / p

buttons

Video ---

TP1001

Tape M. EQ. Spec.

---

Note: TP1001--- Main CBA

1. Enter the Service mode. (See page 1-8-1.) Then

press number 2 button on the remote control unit.

2. Receive the Color Bar signal for channel 4

(67.25MHz). (RF Input Level: 60dBµV)

3. Press CH. o / p buttons so that the voltage of

TP1001 (AGC) becomes +2.8V±0.3V DC.

4. Turn the power off and on again.

CH. o / p

buttons

Pattern Generator

DC Voltmeter

---

+2.8±0.3V DC

Color Bar

67.25MHz

60dBµV

1-8-2 TD500EA

Page 26

4-2. C-Trap Adjustment

5. V. Size Adjustment

Purpose: To get minimum leakage of the color signal

carrier.

Symptom of Misadjustment: If C-Trap Adjustment is

incorrect, stripes will appear on the screen.

Test point Adj. Point Mode Input

D1304

(Cathode)

(B-OUT)

Tape M. EQ. Spec.

---

minimum

CH o / p

buttons

Oscilloscope

Pattern Generator

Figure

--- Color Bar

---

Fig. 2

Purpose: To obtain correct vertical height of screen

image.

Symptom of Misadjustment: If V. Size is incorrect,

vertical height of image on the screen may not be

properly displayed.

Test point Adj. Point Mode Input

---

Tape M. EQ. Spec.

--- Pattern Generator 90±5%

1. Enter the Service mode. (See page 1-8-1.)

Press "9" button on the remote control unit and

select V-S Mode. (Press "9" button then display will

change to V-P and V-S).

2. Input monoscope pattern.

3. Press CH o / p buttons on the remote control unit

so that the monoscope pattern is 90±5% of display

size and the circle is round.

CH o / p

buttons

--- Monoscope

6. V. Shift Adjustment

Note: D1304 (Cathode) (B-Out)--- Main CBA

1. Connect Oscilloscope to D1304 (Cathode).

2. Input a color bar signal from RF input.

Enter the Service mode. (See page 1-8-1.)

3. Press "0" button on the remote control unit and

select C-TRAP Mode.

4. Press CH o / p buttons on the remote control unit

so that the carrier leakage B-Out (3.58MHz) value

becomes minimum on the oscilloscope.

5. Turn the power off and on again.

Purpose: To obtain correct vertical position of screen

image.

Symptom of Misadjustment: If V. position is incorrect, vertical position of image on the screen may not

be properly displayed.

Test point Adj. Point Mode Input

---

Tape M. EQ. Spec.

--- Pattern Generator ---

1. Enter the Service mode. (See page 1-8-1.)

Press "9" button on the remote control unit and

select V-P Mode. (Press "9" button then display will

change to V-P and V-S).

2. Input monoscope pattern.

3. Press CH o / p buttons on the remote control unit

so that the top and bottom of the monoscope pattern are equal to each other.

CH o / p

buttons

--- Monoscope

1-8-3 TD500EA

Page 27

7. H. Shift Adjustment

Purpose: To obtain correct horizontal position and

size of screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

Test point Adj. Point Mode Input

---

Tape M. EQ. Spec.

--- Pattern Generator ---

1. Enter the Service mode. (See page 1-8-1.)

Press "8" button on the remote control unit and

select H-P Mode.

2. Input monoscope pattern.

3. Press CH o / p buttons on the remote control unit

so that the left and right side of the monoscope pattern are equal to each other.

4. Turn the power off and on again.

CH o / p

buttons

--- Monoscope

8. Cut-off Adjustment

Purpose: To adjust the beam current of R, G, B, and

screen voltage.

Symptom of Misadjustment: White color may be

reddish, greenish or bluish.

Test point Adj. Point Mode Input

Black

--- Screen-Control Ext.

Raster /

White

Raster

Notes: Screen Control FBT --- H.V. CBA

FBT= Fly Back Transformer

Use the Remote Control Unit

1. Degauss the CRT and allow CRT to operate for 20

minutes before starting the alignment.

2. Set the screen control to minimum position. Input

the Black raster signal from RF input.

3. Enter the Service Mode. (See page 1-8-1.)

Dimmed horizontal line appears on the CRT.

4. Press the "VOL p" button.

(Press "VOL p" then display will change CUT OFF/

DRIVE, VCO adjustment, 7Fh adjustment).

5. Choose CUT OFF/DRIVE Mode then press "1" button. This adjustment mode is CUT OFF (R).

6. Press the "CH o / p" button until the horizontal line

becomes white.

7. Choose CUT OFF/DRIVE mode then press "2" button. This adjustment mode is CUT OFF (G). Press

"CH o / p" until the horizontal line becomes white.

8. Choose CUT OFF/DRIVE mode then press "3" button. This adjustment mode is CUT OFF (B). Press

"CH o / p" until the horizontal line becomes white.

9. Input the White Raster Signal from Video In.

10.Choose CUT OFF/DRIVE mode then press "4."

Adjust the RED DRIVE as needed with the CH o /

p buttons to get the following value, X= 286, Y=

294.

11.Choose CUT OFF/DRIVE mode then press "5."

Adjust the BLUE DRIVE as needed with the CH o /

p buttons to get the following value, X= 286.

12.Turn the power off and on again.

Tape M. EQ. Spec.

--- Pattern Generator

Figure

PATTERN GENERATOR

RF INPUT

See Reference

Notes below

Fig. 3

1-8-4 TD500EA

Page 28

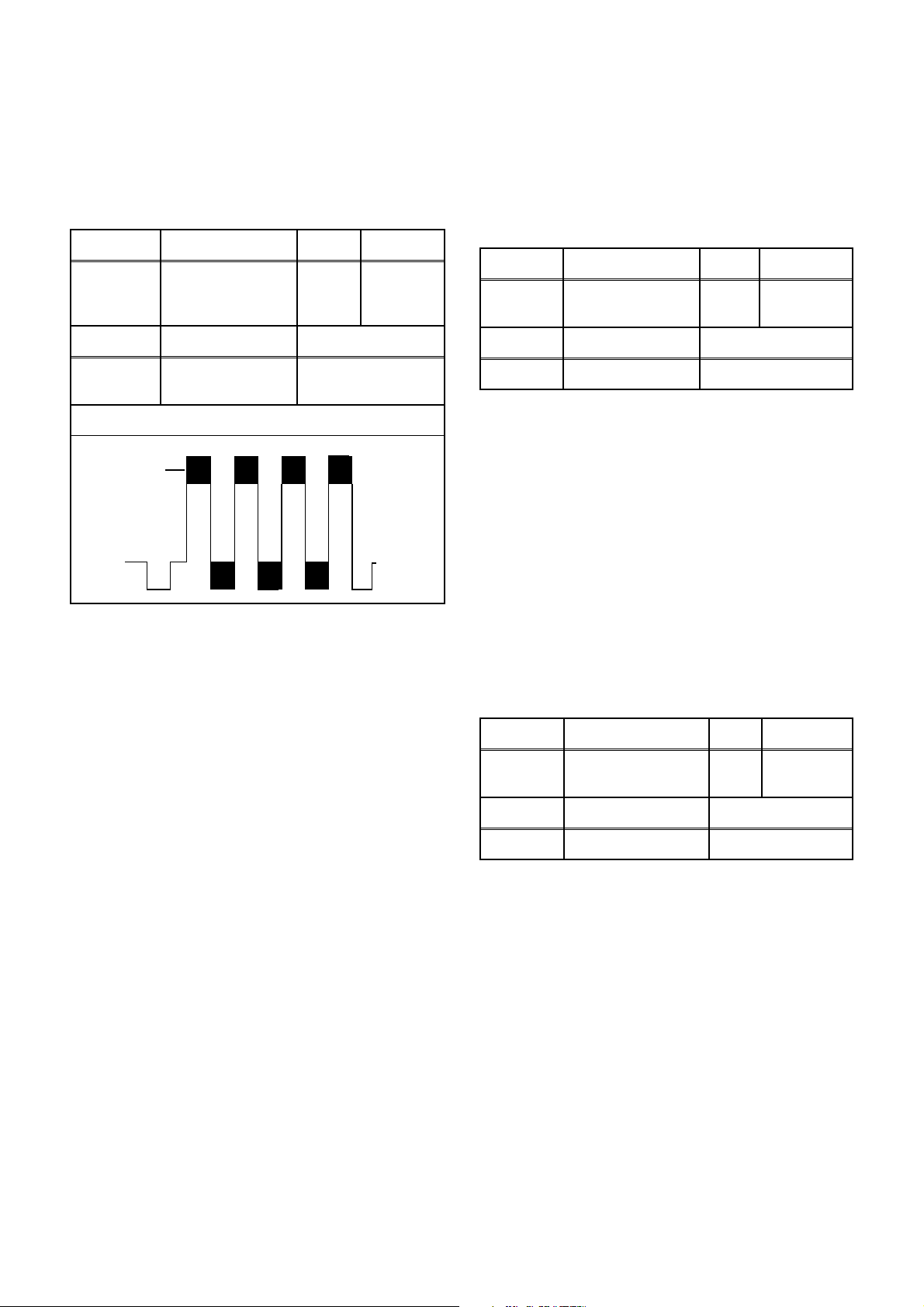

9. Sub-Brightness Adjustment

Purpose: To get proper brightness.

Symptom of Misadjustment: If Sub-Brightness is

incorrect, proper brightness cannot be obtained by

adjusting the Brightness Control.

Test point Adj. Point Mode Input

---

Tape M. EQ. Spec.

CH o / p

buttons

---

SYMPTE

7.5IRE

3. Input the monoscope pattern.

4. Adjust the Focus Control on the FBT to obtain clear

picture.

11. SIF Adjustment

Purpose: To set the SIF (Sound Intermediate Fre-

quency).

Symptom of Misadjustment: Audio may not sound

correctly.

Note: This adjustment automatically done by the

chrominance IC (IC1301).

---

White

Note: SYMPTE Setup level --- 7.5 IRE

1. Enter the Service Mode. (See page 1-8-1.)

Then input SYMPTE signal from RF input.

2. Press MENU button. (Press MENU button then display will change B R T, C N T, T N T, V-T and

SHP). Select BRT and press CH o / p buttons so

that the bar is just visible (See above figure).

3. Turn the power off and on again.

Pattern

Generator

Figure

See below

Black

This bar

just

visible

Fig. 4

10. Focus Adjustment

Purpose: Set the optimum Focus.

Symptom of Misadjustment: If Focus Adjustment is

incorrect, blurred images are shown on the display.

12. CCS Text Box Location

When replacing the CRT, the CCS Box might not stay

in appropriate position. Then, replace micro computer.

Note: This adjustment automatically done by the

microcomputer.

13. Head Switching Position Adjustment

Purpose: Determine the Head Switching Point during

Playback.

Symptom of Misadjustment: May cause Head

Switching Noise or Vertical Jitter in the picture.

Note: Unit reads Head Switching Position automatically and displays it on the screen (Upper Left Corner).

1. Playback test tape (FL8A, FL8N).

2. Enter the Service Mode. (See page 1-8-1.)

Then press the number 5 button on the remote

control unit.

3. The Head Switching position will display on the

screen; if adjustment is necessary follow step 4.

6.5H(412.7µs) is preferable.

4. Press "CH o" or "CH p" button on the remote control unit if necessary. The value will be changed in

0.5H steps up or down. Adjustable range is up to

9.5H. If the value is beyond adjustable range, the

display will change as:

Lower out of range: 0.0H

Upper out of range: -.-H

5. Turn the power off and on again.

Test point Adj. Point Mode Input

--- Focus Control --- Monoscope

Tape M. EQ. Spec.

--- Pattern Generator See below.

Note: Focus VR (FBT) --- H.V. CBA

FBT= Fly Back Transformer

1. Operate the unit more than 30 minutes.

2. Face the unit to the East and degauss the CRT

using a Degaussing Coil.

1-8-5 TD500EA

Page 29

The following 2 adjustments normally are not

attempted in the field. They should be done

only when replacing the CRT then adjust as a

preparation.

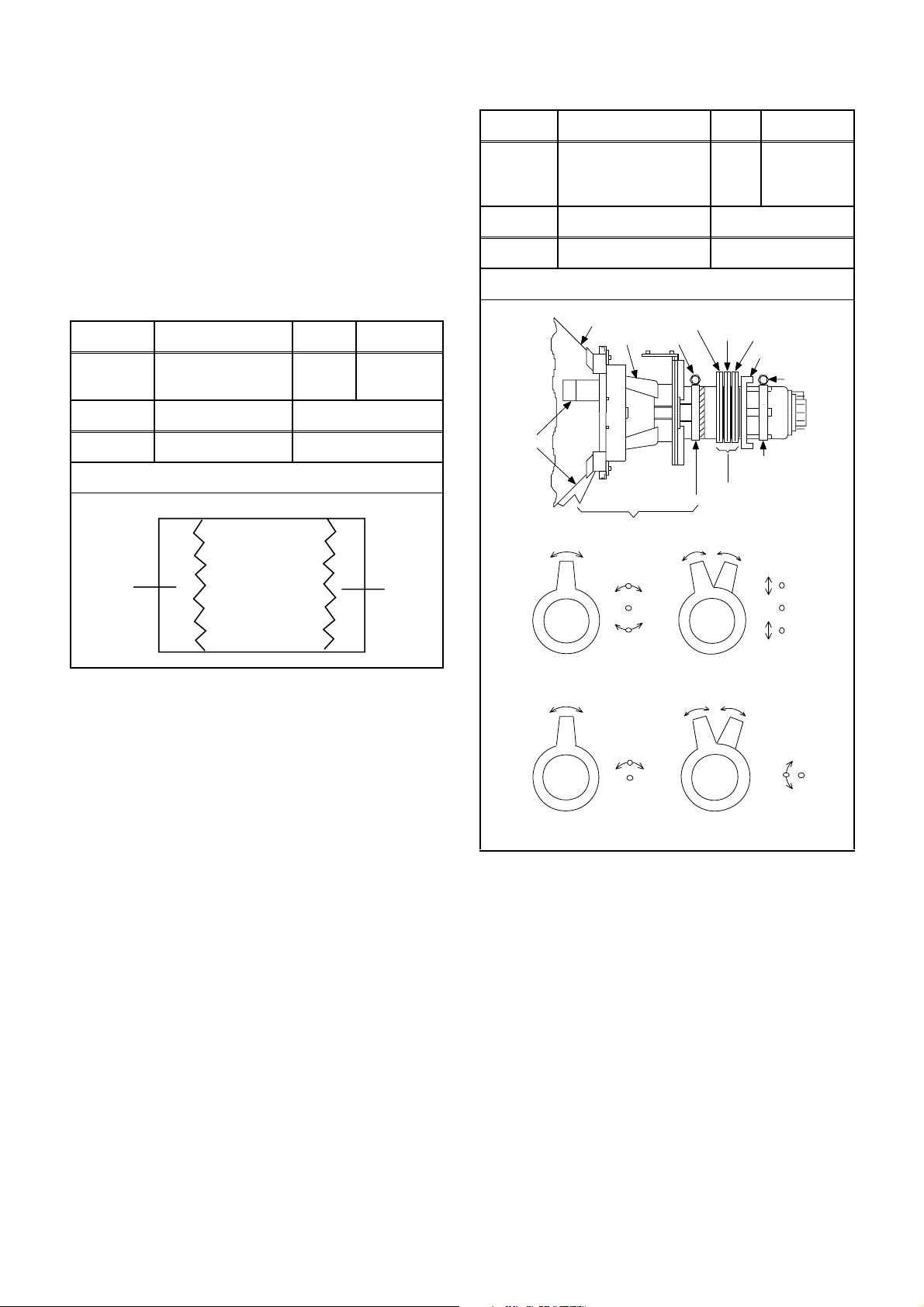

14. Purity Adjustment

Purpose: To obtain pure color.

Symptom of Misadjustment: If Color Purity Adjust-

ment is incorrect, large areas of color may not be

properly displayed.

Test point Adj. Point Mode Input

---

C.P. Magnet (RB),

C.P. Magnet (RB-G),

Deflection Yoke

---

Dot Pattern

or

Crosshatch

Tape M. EQ. Spec.

--- Pattern Generator See below.

Figure

Test point Adj. Point Mode Input

---

Deflection Yoke

Purity Magnet

--- Red Color

Tape M. EQ. Spec.

--- Pattern Generator See below.

Figure

GREEN

RED

BLUE

Fig. 5

1. Set the unit facing east.

2. Operate the unit for over 30 minutes before adjusting.

3. Fully degauss the unit using an external degaussing coil.

4. Set the unit to the AUX Mode which is located

before CH2 then input a red raster from video in.

5. Loosen the screw on the Deflection Yoke Clamper

and pull the Deflection Yoke back away from the

screen. (See Fig. 6.)

6. Loosen the Ring Lock and adjust the Purity Magnets so that a red field is obtained at the center of

the screen. Tighten Ring Lock. (See Fig. 5,6.)

7. Slowly push the Deflection Yoke toward the bell of

the CRT and set it where a uniform red field is

obtained.

8. Tighten the clamp screw on the Deflection Yoke.

15. Convergence Adjustment

Purpose: To obtain proper convergence of red, green

and blue beams.

Symptom of Misadjustment: If Convergence Adjustment is incorrect, the edge of white letters may have

color edges.

CRT

COIL

DY WEDGE

COIL CLAMPER

DEFLECTION YOKE

PURITY

SCREW

RB

RB-G

RING LOCK

C.P. MAGNET

CLAMPER

C.P. MAGNET

SCREW

Fig. 6

C.P. MAGNET (RB)

R

G

B

R

G

B

Fig. 7

C.P. MAGNET (RB-G)

RB

RB

G

G

Fig. 8

1. Set the unit to the AUX Mode which is located

before CH2 then input a Dot or crosshatch pattern.

2. Loosen the Ring Lock and align red with blue dots

or Crosshatch at the center of the screen by rotating (RB) C.P. Magnets. (See Fig. 7.)

3. Align red / blue with green dots at the center of the

screen by rotating (RB-G) C.P. Magnet.

(See Fig. 8.)

4. Fix the C.P. Magnets by tightening the Ring Lock.

5. Remove the DY Wedges and slightly tilt the Deflection Yoke horizontally and vertically to obtain the

best overall convergence.

6. Fix the Deflection Yoke by carefully inserting the

DY Wedges between CRT and Deflection Yoke.

1-8-6 TD500EA

Page 30

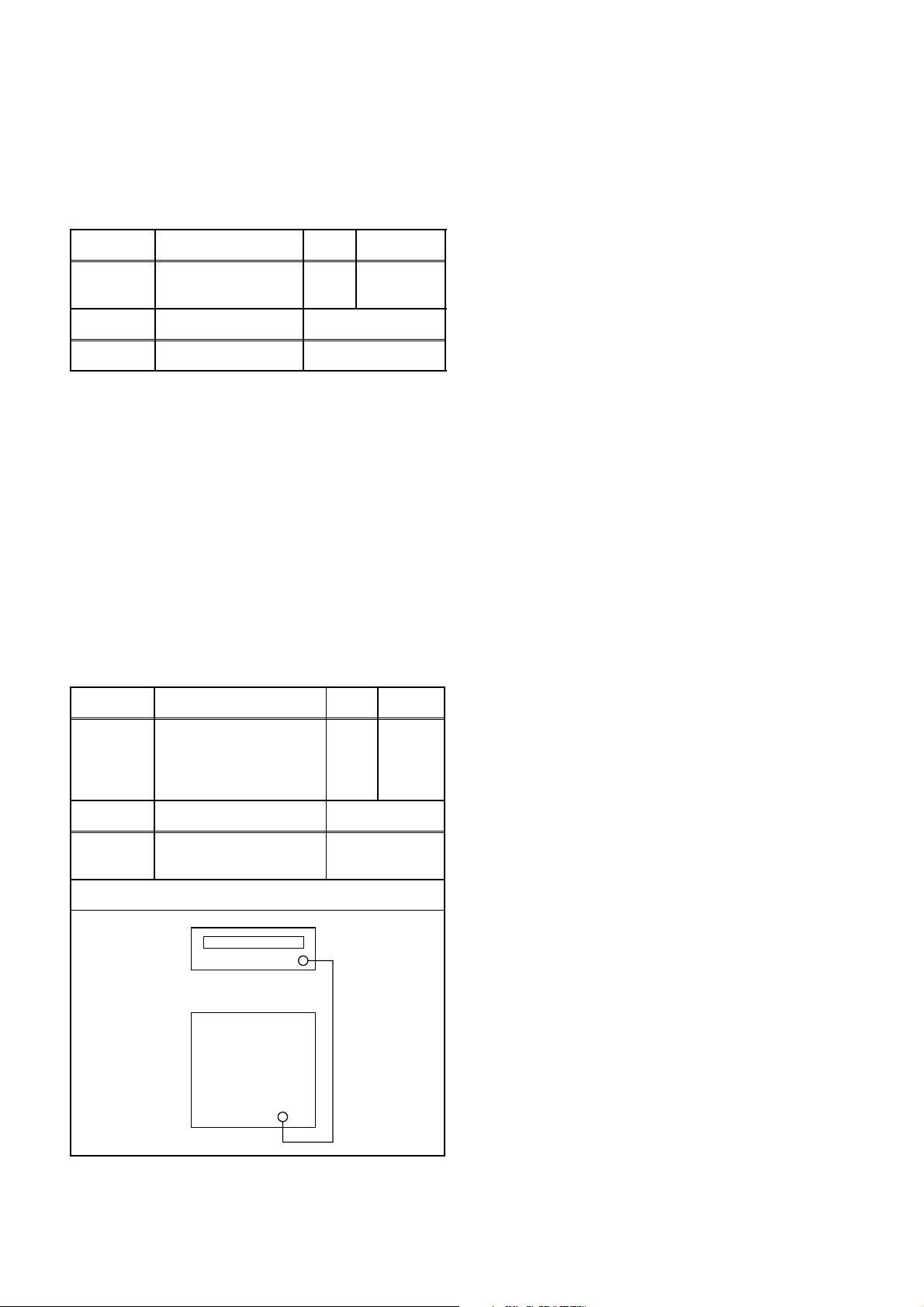

FIRMWARE RENEWAL MODE

HOW TO UPDATE THE FIRMWARE

VERSION

1. Turn the power on and remove the disc on the tray.

2. To enter the DVD mode, press [SELECT] button on

the remote control unit. (DVD indicator lights on.)

3. To open the tray, press [OPEN/CLOSE] button on

the remote control unit.

4. To put the unit into version up mode, press [9], [8],

[7], [6], and [SEARCH MODE] buttons on the

remote control unit in that order. The tray will open

automatically.

Fig. A appears on the screen .

BE F/W VERSION UP MODE

PLEASE INSERT A DISC

FOR BE F/W VERSION UP.

The appearance shown in (*2) of Fig. B is

described as follows:

AppearanceNo. State

Reading... Sending files into the memory

1

Erasing... Erasing previous version data

2

Programming...

3 Writing new version data

7. After programming is finished, the tray opens automatically. Fig. C appears on the screen

BE F/W VERSION UP MODE

VERSION: ********

COMPLETED SUM:7abc(*3)

SELECT

EXIT:

Fig. A Version Up Mode Screen

The unit can also enter the version up mode with

the tray open. In this case, Fig. A will be shown on

the screen while the tray is open.

5. Load the disc for version up. (For closing the tray,

only the [OPEN/CLOSE] button is available.)

6. The unit enters the F/W version up mode automatically. Fig. B appears on the screen.

BE F/W VERSION UP MODE

VERSION: ********

Reading...(*2)

Fig. C Completed Program Mode Screen

At this time, no buttons are available.

8. For tray opening, plug the AC cord into the AC outlet.

9. To close the tray, press [POWER] and [SELECT]

buttons on the remote control unit or [SELECT] button on the unit.

HOW TO VERIFY THE FIRMWARE

VERSION

1. After making sure that no disc is in unit, turn the

power on.

2. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order. The F/E and

B/E versions appear on the screen.

Fig. B Programming Mode Screen

1-9-1 TD601ROM

Page 31

Servo/System Control Block Diagram

SW2406 SW2408

SW2401 SW2405

FROM/TO

DVD

SYSTEM

CONTROL

BLOCK

DIAGRAM

CN401

CN2401

3 SCLK

4 CS

5 REMOTE

POWER SUPPLY / AV CBA

(DECK ASSEMBLY)

KEY SWITCH

KEY SWITCH

CN2802

6 6KEY1

5 5KEY2

CN2803

112 SDATA

12

13

15

CN1805

CN1804

11SDATA

12SCLK

13CS

15REMOTE

BLOCK DIAGRAMS <TV/VCR Section>

IC1201

(SERVO/SYSTEM CONTROL)

MAIN CBA

SW1201 SW1203,

SW1206 SW1210

KEY SWITCH

AL+5V

P-ON+5V

D1224 S-LED

D1204 REC

Q1207

D1216 DVD

D1217

TV/VCR

Q1211

AL+5V

KEY0

5

KEY1

6

KYE2

8

SDATA

52

51

SCLK

50

CS

25

REM-OUT

REC-LED

21

DVD-H

48

TV/VCR-LED

26

REMOTE

SCL

SDA

I2C-OPEN

REC-SAFETY

C-SYNC

14

71

72

45

33

74

RS1201

REMOTE

SENSOR

SW1211

REC

SAFETY

IC1202

SCL

6

5

SDA

CS

7

I2C-OPEN

C-SYNC

(MEMORY)

SCL

SDA

EXT-H

DVD-H

FROM/TO

CHROMA

/TUNER

BLOCK

DIAGRAM

AC HEAD ASSEMBLY

CONTROL

HEAD

CYLINDER ASSEMBLY

PG

SENSOR

DRUM

MOTOR

M

LOADING

MOTOR

M

CL1402

5CTL(+)

6CTL(-)

Q202

ST-SENS.

SENSOR CBA

(ST-SENSOR)

CAPSTAN MOTOR

CAPSTAN

MOTOR

M

Q201

END-SENS.

SENSOR CBA

(END-SENSOR)

P-ON+5V

C-FG

CL1201

1C-F/R

2AL+12V

3D/L+12V

4

5FG-GND

6

7C-CONT

8M-GND

9D-FG

10LD-CONT

11D-CONT

12D-PG

Q1206

T-REEL

AL+12V

D/L+12V

P-ON+5V

Q1210

WF3

TP1201

CTL-AMP-OUT

SW1212

LD-SW

Q1205

RESETT+5V

AL+5V

CTL(+)

95

94

CTL(-)

CTL AMP-OUT

97

LD-SW1

9

ST-SENS.

7

END-SENS.

T-REEL

80

RESET

34

66

C-F/R

87

C-FG

76

C-CONT

89

D-FG

82

LD-CONT

77

D-CONT

90

D-PG

DVD-MAIN-PWR

P-ON-H

P-DOWN-L

Hi-Fi-CS

Hi-Fi-DATA

Hi-Fi-CLK

ST/SAP-IN

NORMAL-H

Hi-Fi-SW

DVD-MUTE

JACK-MUTE-H

A-MUTE-H

D-REC-H

VOL-CONT

V-H-SW

ENV-DET

REC/EE/PB

DV-SYNC

V-ENV

ROTA

RF-SW

TAPE-SPEED

EXT-H

RENTAL

SPL-PLAY

42

31

84

69

68

70

22

19

73

67

65

44

11

16

17

27

13

10

15

18

28

29

30

32

DVD-MAIN-PWR

P-ON-H

P-DOWN-L

Hi-Fi-CS

Hi-Fi-DATA

Hi-Fi-CLK

4

ST/SAP-IN

NORMAL-H

Hi-Fi-SW

A-MUTE-H

DVD-MUTE

JACK-MUTE-H

A-MUTE-H

D-REC-H

VOL-CONT

EXT-H

DVD-H

V-H-SW

ENV-DET

REC/EE/PB

DV-SYNC

V-ENV

ROTA

RF-SW

TAPE-SPEED

EXT-H

RENTAL

SPL-PLAY

FROM/TO

POWER

SUPPLY BLOCK

DIAGRAM

FROM/TO

Hi-Fi AUDIO

BLOCK

DIAGRAM

FROM/TO

AUDIO BLOCK

DIAGRAM

FROM/TO

VIDEO BLOCK

DIAGRAM

1-10-1 1-10-2 TD500BLS

Page 32

Video Block Diagram

REC VIDEO SIGNAL PB VIDEO SIGNAL MODE: SP/REC

FROM/TO

CHROMA/

TUNER BLOCK

DIAGRAM

VCR-VIDEO

VIDEO

WF5

TP1402

V-OUT

WF4

IC1401

VIDEO/AUDIO

SIGNAL PROCESS

42

42

38

Q1401

BUFFER

V-AGC

35

6dB

AMP

CHARA

MIX

FBC

R P

X1401

3.58MHz

62 61

VXO

WF2

Y/C

MIX

MAIN CBA

45 47 49 44

CCD 1H

DELAY

DOC YNR Y/C COMB

Q1402

BUFFER

LUMINANCE

SIGNAL PROCESS

FROM

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

(DECK ASSEMBLY)

EXT-H

RENTAL

REC/EE/PB

SPL-PLAY

ROTA

DV-SYNC

TAPE-SPEED

CYLINDER ASSEMBLY

VIDEO (R)-1 HEAD

VIDEO (L)-1 HEAD

VIDEO (L)-2 HEAD

VIDEO (R)-2 HEAD

71

36

RENTAL

REC/EE/PB

16

SPL-PLAY

73

ROTA

14

DV-SYNC

39

TAPE-SPEED

59

CL1401

V(R)-1

9

V-COM

8

V(L)-1

7

V(L)-2

6

V-COM

5

V(R)-2

4

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

WF1

RF-SW

V-ENV

V-H-SW

ENV-DET

TP1401

RF-SW

91

90

89

88

85

84

83

82

13

93

15

94

ENV-DET

CHROMINANCE

SIGNAL PROCESS

R

L

L

R

SP

EP

HPF

AGC

AMP

R

P

ENV

DET

74

TP1403

ENV

WF6

1-10-3 1-10-4 TD500BLV

Page 33

Audio Block Diagram

REC-AUDIO SIGNAL

PB-AUDIO SIGNAL

DVD AUDIO SIGNAL DATA(AUDIO) SIGNAL

Mode : SP/REC

FROM DVD AUDIO

BLOCK DIAGRAM

CN402

FROM

Hi-Fi AUDIO

BLOCK

DIAGRAM

FROM

SERVO/

SYSTEM

CONTROL

BLOCK DIAGRAM

CN1804

7

5

A-OUT(R)5 5

A-OUT(L)3 3

DVD-H19 19

CN2402

SPDIF11

DVD-AUDIO(R)

DVD-AUDIO(L)

DVD-MUTE13

CN2803

CN2803CN1804

POWER SUPPLY / AV CBA

Q2205

BUFFER

IC2203

(OP AMP)

5

3 1

Q2207

7

2

1

12

13

Q2203

IC2202

(OUTPUT SELECT)

15

14

SW CTL.

1110

Q2209

P-ON+5V

IC2801

(AUDIO AMP)

5

2 12

DC VOL.

6

Q2204

Q2202

Q2208

VOLUME

JACK-MUTE-H

DVD-MUTE

7

JK2201

DIGITAL

A-OUT

A-OUT(R)

A-OUT(L)

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

CN2801

SP-L

SP-GND 2

CN1805CN2802

A-OUT(R)10 10

A-OUT(L)9 9

SP-L11 11

1

SP2801

SPEAKER

L-CH

CN1802

SP-R

SP-GND 2

1

SP1801

SPEAKER

R-CH

JK1801

HEADPHONE

JACK

FROM/TO

Hi-Fi AUDIO

BLOCK

DIAGRAM

N-A-IN

N-A-OUT

BLOCK DIAGRAM FOR SECTION 2 (DECK MECHANISM)

AC HEAD ASSEMBLY

AUDIO

HEAD

AUDIO

ERASE

HEAD

FE HEAD UNIT

FULL

ERASE

HEAD

CL1402

A-PB/REC

4

A-COM

3

AE-H

1

AE-H/FE-H

2

CN1403

FE-H

1

FE-H GND

2

Q1873

Q1874

Q1872

BIAS

OSC

Q1875

Q1871

P-ON+5V

P-ON+5V

76

78

80

4

99

IC1401

(AUDIO PROCESS)

EQ

AMP

3

AUTO

BIAS

SP/LP-ON

ALC

REC

AMP

LINE

AMP

11

EXT-H

96

98

FROM SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

MUTE

D-REC-H

EXT-H

7112

A-MUTE-H

D-REC-H

R

1

2

6

100

P

7

WF8

WF7

TP1802

NA-IN-YCA

1-10-5

MAIN CBA

TD500BLA1-10-6

Page 34

Hi-Fi Audio Block Diagram

FROM

CHROM/TUNER

BLOCK DIAGRAM

SIF

IC1751(MTS/ SAP/ Hi-Fi AUDIO PROCESS/ Hi-Fi HEAD AMP)

NOISE

DET

57

SIF

DEMOD

SAP

FILTER

STEREO

FILTER

PILOT

DET

SAP

DEMOD

PILOT

CANCEL

L-R

DEMOD

MAIN CBA

ST/SAP

SW

DC

dBX

DEC

MATRIX

SERIAL

DATA

DECODER

RIPPLE

FILTER

37

38

39

54

REC-AUDIO SIGNALPB-AUDIO SIGNAL Mode : SP/REC

Hi-Fi-CS

Hi-Fi-DATA

Hi-Fi-CLK

P-ON+9V

FROM SERVO/ SYSTEM

CONTROL BLOCK

DIAGRAM

JK1703

A-IN(R)

JK1702

A-IN(L)

TO AUDIO

BLOCK

DIAGRAM

N-A-OUT

69

STEREO

PLL

R-CH

INSEL

6

NOR

SW

48 47

R-CH

PNR

P

R

SW

NOISE

LIM DEV

COMP

VCO

HOLD

PULSE

NOISE

DET

LPF

MATRIX

R-CH BPF

OUTPUT

SELECT

BO

DET

COMP

ENV

DET

MODE OUT

51

23

80

78

77

40

49

26

ST/SAP-IN

NORMAL-H

4

TP1701

Hi-Fi-OUT-L

TP1702

Hi-Fi-OUT-R

1

N-A-IN

A-OUT(L)

A-OUT(R)

Hi-Fi-SW

A-MUTE-H

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

FROM/TO

AUDIO BLOCK

DIAGRAM

FROM

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

CYLINDER

LIM DEV

7

L-CH

INSEL

13 14

L-CH

PNR

R

SW

P

NOISE

VCO

COMP

LPF

L-CH BPF

AGC

AGC

DET

31 30

R

L

24

27

CL1701A CL1701B

1

2

3

CL1701

1

2

3

CL1401

Hi-Fi-A(R) 3

Hi-Fi-COM 2

Hi-Fi-A(L) 1

ASSEMBLY

Hi-Fi

AUDIO

(R) HEAD

Hi-Fi

AUDIO

(L) HEAD

TD500BLH1-10-7 1-10-8

Page 35

Chroma/Tuner Block Diagram

MAIN CBA

TU1001

AGC

1

IF

11

SDA

5

SCL

4

FSC

8

INT.MONITOR

I2C-OPEN

SDA 4

SCL 5

CN1303 is used for

adjustment at factory

FROM/TO

SERVO/SYSTEM

CONTROL

BLOCK DIAGRAM

TP1001

AGC

CN1303(NO CONNECTION)

1

2

SCL

SDA

I2C-OPEN

C-SYNC

SF1001

SAW

FILTER

REC VIDEO SIGNAL PB VIDEO SIGNAL

IC1301(VIDEO/AUDIO/CHROMA/DEFLECTION/IF)

59

63

64

43

26

27

18

SERIAL

I/F

INTELLIGENT

MONITORING

SYNC

SEPARATION

IF SIGNAL

CONTROL

CIRCUIT

CHROMA

TRAP

CHROMA

BPF

VCR/DVD-Y

VCR

DVD-C

DVD VIDEO SIGNAL

58

41

38

X1301

CLOCK

CONTROL

CIRCUIT

3.58MHz

34

REC-AUDIO SIGNAL

IC1601

(INPUT SELECT)

4

14

15

Q1601

TUNER

LINE

SW CTL

VCR

DVD

11109

DVD

13

12

3

5

1

2

CN1803

14 14

CF1302

4.5MHz

BPF

CF1301

4.5MHz

TRAP

DVD-Y

DVD-C13 13

Q1603

BUFFER

CN2804

BUFFER

BUFFER

BUFFER

BUFFER

Q2210

Q2211

Mode : SP/REC

VCR-VIDEO

Q1302

Q1301

CN2402

TP2201

DVD-V

VIDEO

SIF

DVD-Y14

DVD-C18

DVD-VIDEO16

FROM/TO VIDEO

BLOCK DIAGRAM

TO Hi-Fi AUDIO

BLOCK DIAGRAM

JK1701

V-IN

FROM

DVD VIDEO

BLOCK

DIAGRAM

CN402

IC1201

(SYSTEM CONTROL/OSD)

OSD-R

OSD-G

OSD-B

OSD-BLK

WF18

V-SYNC

WF17

H-SYNC

64

63

62

60

59

58

WF9

23

22

21

24

20

19

V-SYNC

PROCESS

CIRCUIT

H-SYNC

PROCESS

CIRCUIT

LUMA

SIGNAL

PROCESS

CIRCUIT

OSD MIX/RBG MATRIX/

BLANKING

CHROMA

SIGNAL

PROCESS

CIRCUIT

14

15

16

11

10

33

5

6