Page 1

Unity

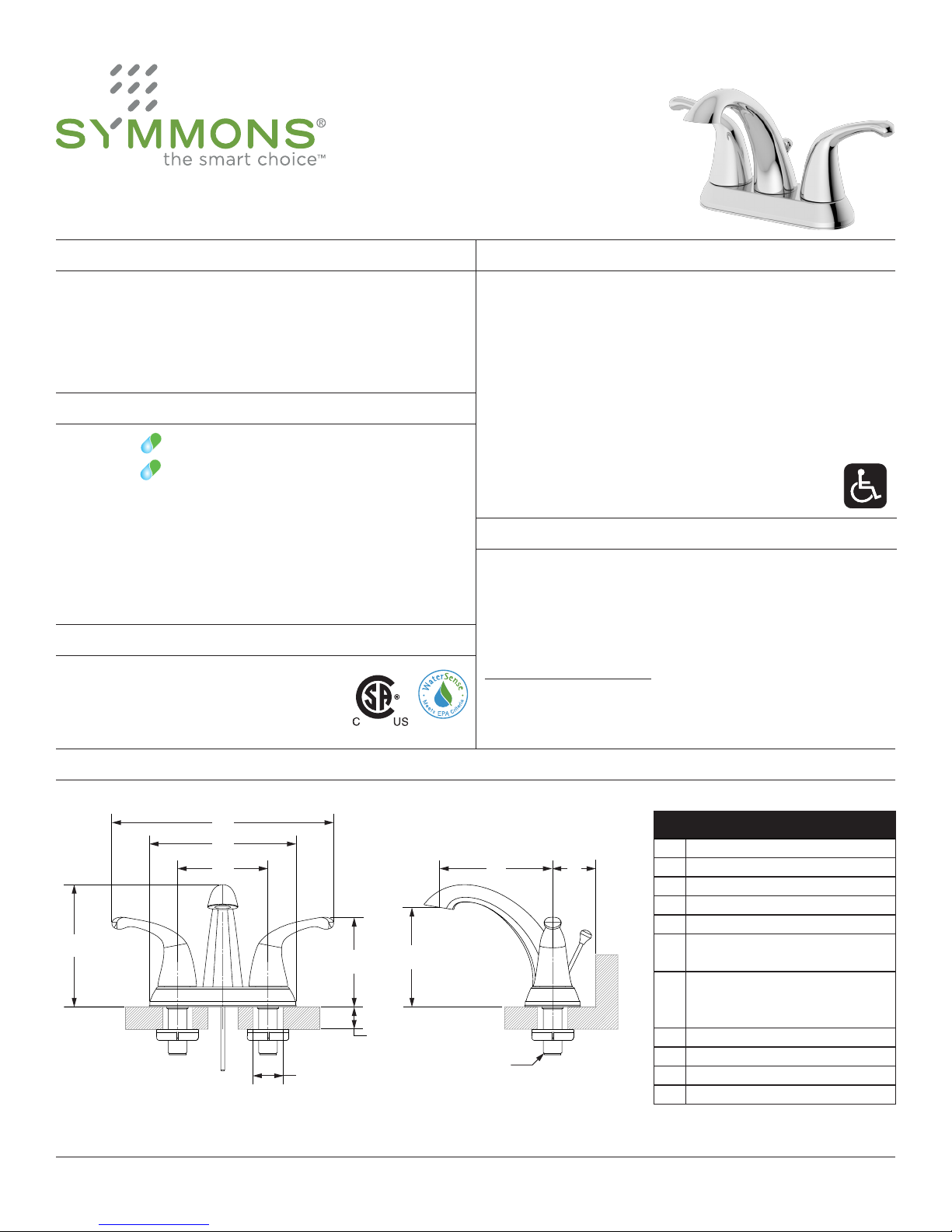

SLC-6610-1.5, SLC-6612-1.5

Two Handle Centerset Lavatory Faucet

Operation & Maintenance Manual

™

Model Numbers

SLC-6610-1.5

Unity Two Handle Centerset Lavatory Faucet

Less Rod

SLC-6612-1.5

Unity Two Handle Centerset Lavatory Faucet

Modifications

-0.5 0.5 gpm (1.9 L/min) aerator

-1.0 1.0 gpm (3.8 L/min) aerator

-G Grid drain

-Delete

Suffix

1.5

-STN Satin Nickel finish

Note: Append appropriate -sufx to model number.

2.2 gpm (8.3 L/min) aerator

Compliance

-NSF/ANSI 372, NSF/ANSI 61.9

-ASME A112.18.1/CSA B125.1

-WaterSense 1.5 gpm (5.7 L/min)

Certied by

CSA Group

Specification

Two handle centerset lavatory faucet featuring a

4” mounting conguration. Includes ceramic cartridges,

1/2” IPS inlet connections, 50/50 drain assembly and

standard 1.5 gpm (5.7 L/min) aerator. Components made

from brass and nonmetallic materials plated in standard

polished chrome nish.

Warranty

Limited Lifetime - to the original end purchaser in

consumer/residential installations.

5 Years - for industrial/commercial installations.

Refer to www.symmons.com/warranty for complete

warranty information.

For California Residents

WARNING: This product contains chemicals known to

the State of California to cause cancer, birth defects, or

other reproductive harm.

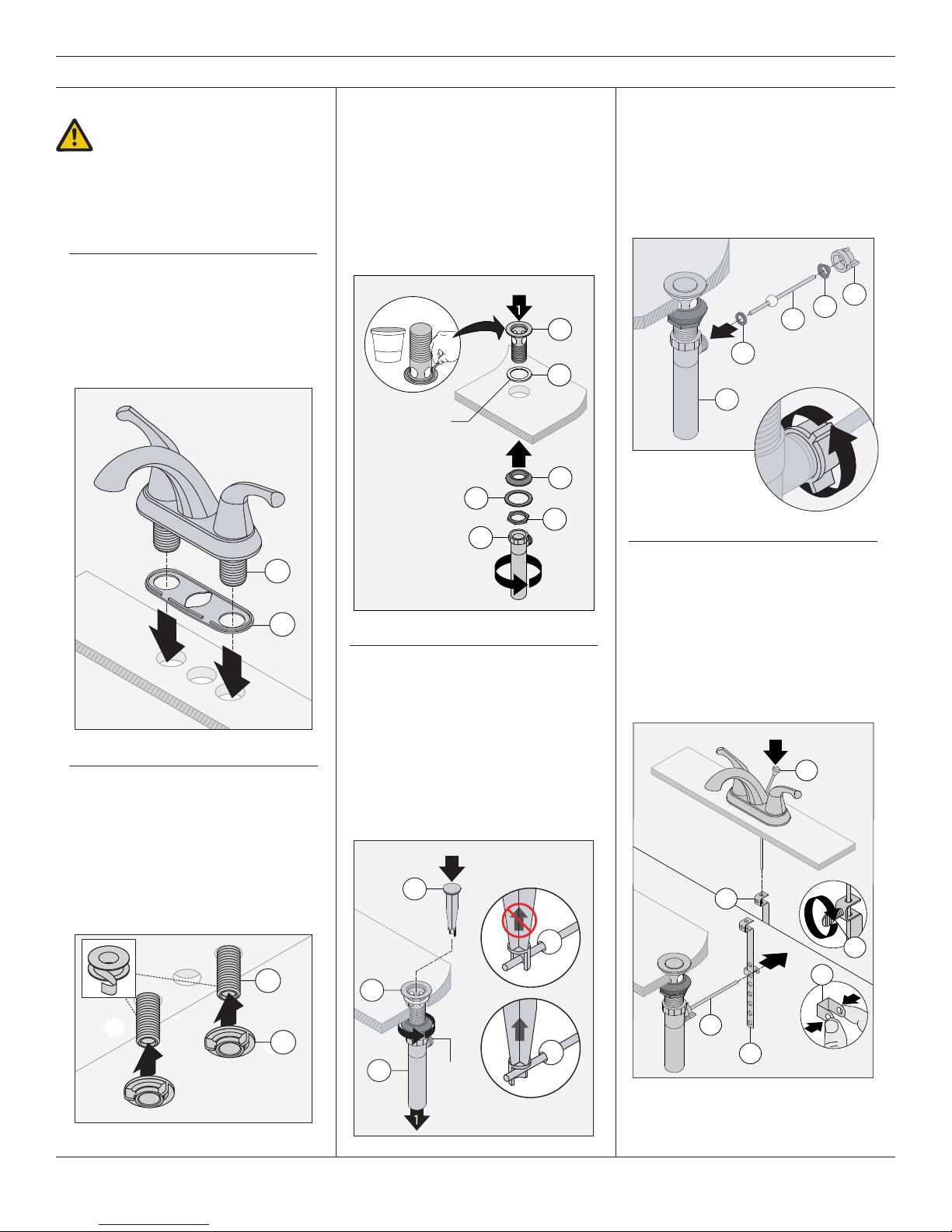

Dimensions

AA

BB

CC

DD

EE

HH

FF

GG

Note: Dimensions subject to change without notice.

II

KK

Measurements

A 9 3/4”, 248 mm

JJ

B 6 1/2”, 165 mm

C 4”, 102 mm

D 5 3/8”, 137 mm

E 3 7/8”, 98 mm

F

G

H 4 3/8”, 111 mm

I 4 7/8”, 124 mm

J Min. 2”, 51 mm

K 1/2-14 NPSM

Deck Thickness Ref.

Max. 1 1/2”, 38 mm

(3x) Hole Size

Min. Ø 1 1/4”, 32 mm

Max. Ø 1 1/2”, 38 mm

Page 2

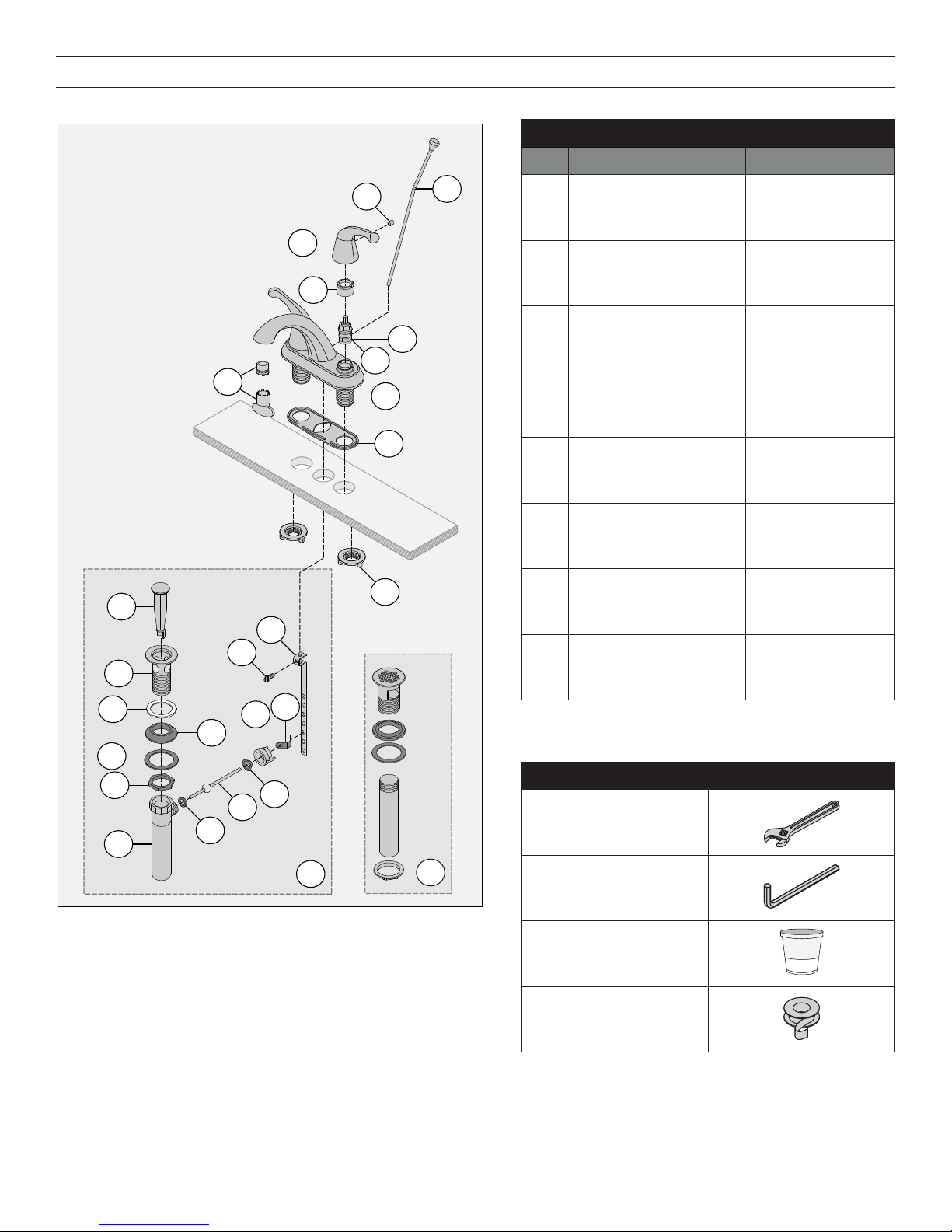

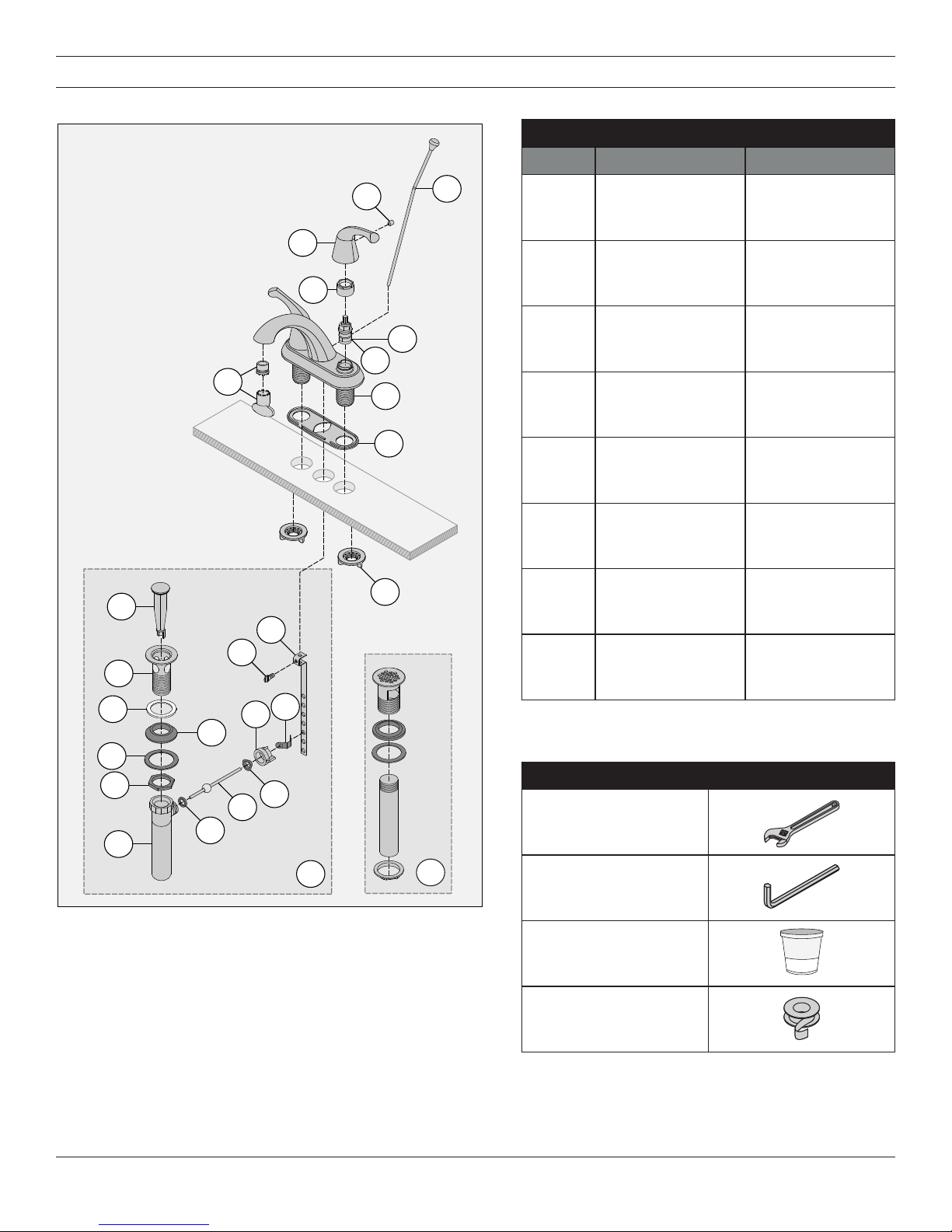

Parts Breakdown

Replacement Parts

Item Description Part Number

K1

K2

G

K14

K13

C

D

A

B

E

A

C

B Lift Rod RL-207*

E Hot Cartridge RL-075

(2x) Handle Kit RL-206*

F

H

I

J

F Cold Cartridge RL-076

LN-333-KIT (2.2)

G Aerator

I

J

K 50/50 Drain Assembly

L Grid Drain

Mounting Hardware RL-208

FLR-102-1.5-KIT (1.5)

LN-742-KIT (1.0)

FLR-102-0.5 (0.5)

RL-223*

(SLC-6612-1.5)

P-26*

(SLC-6610-1.5)

K3

K5

K6

K7

K4

K8

K9

K11

K12

K10

K

*Note: Append -STN to part number for Satin Nickel

nish.

Tools Required

Adjustable wrench

L

Allen wrench (3/32”)

PLUMBER

Plumber putty

Plumber tape

PUTTY

2

Page 3

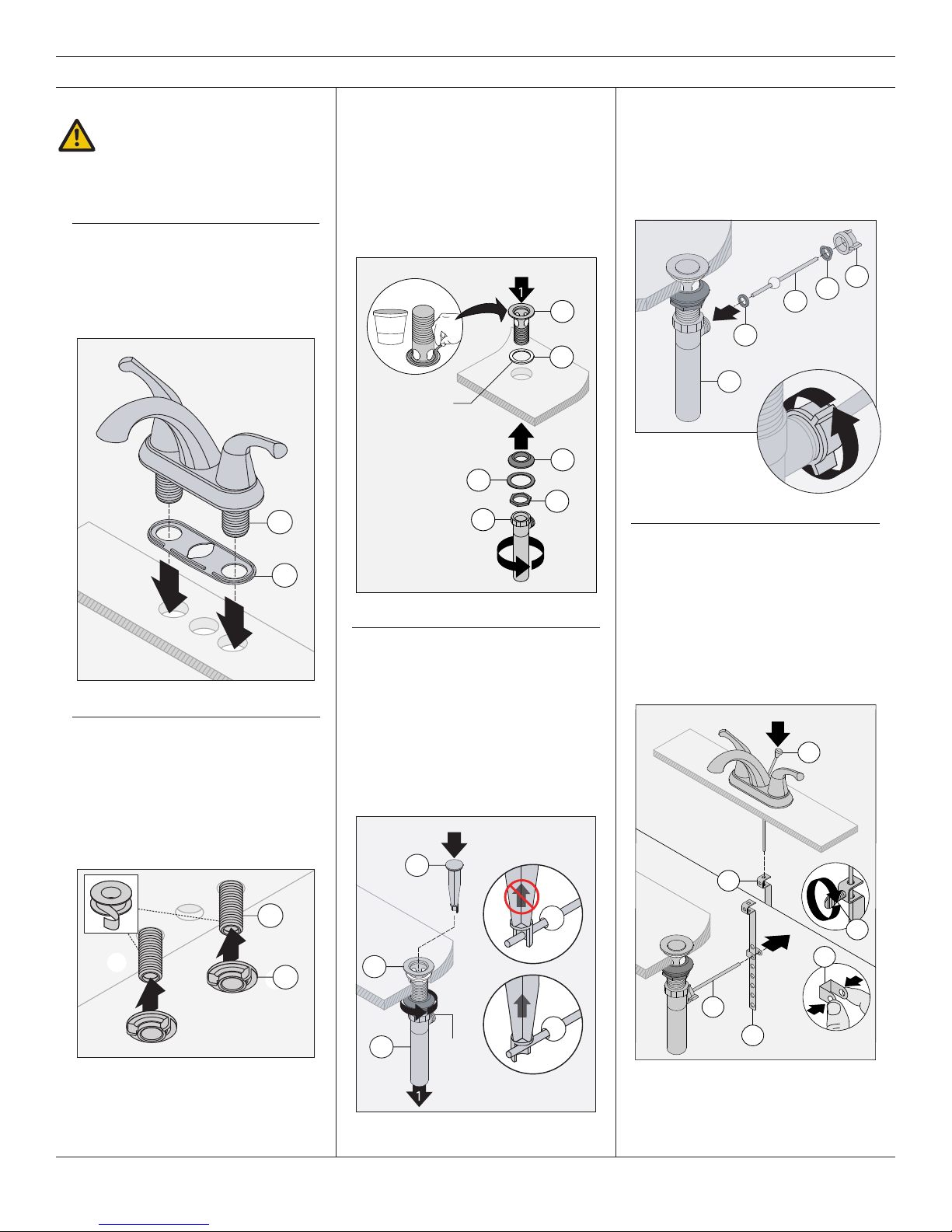

2

3

4

4

K12

K9

K13

2

K14

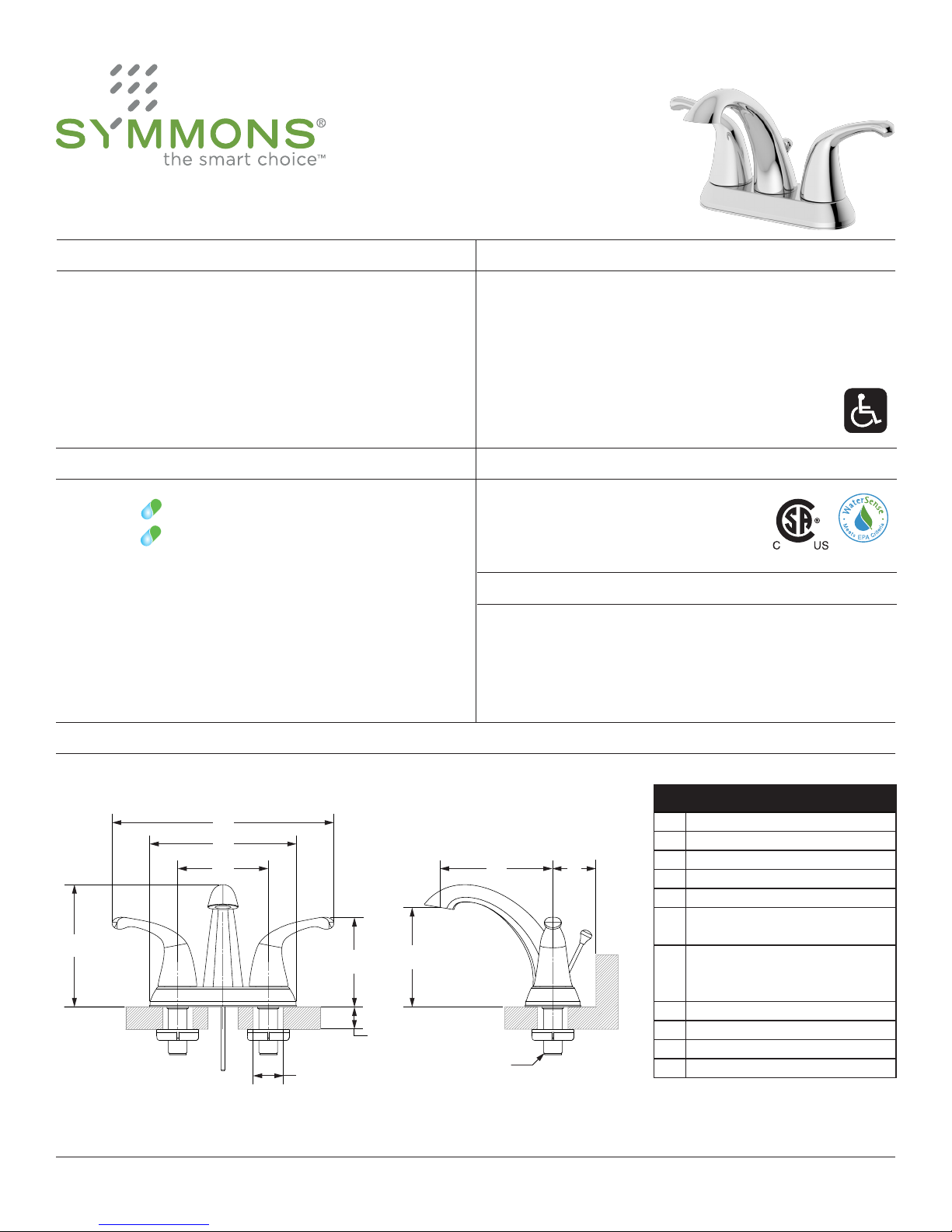

Installation

If replacing an older faucet

ensure water supply is turned

OFF before removing, then

turn faucet control valve ON to

relieve water pressure.

1) Insert faucet body (H) through

mounting gasket (I) and sink

holes.

H

I

2) Install mounting nuts (J) onto 1/2”

IPS inlet connections on faucet

body (H). Using a wrench, nish

with one-half turn. DO NOT overtighten.

3) Seat ange (K2) into sink (K3 gasket optional). Install gasket (K4),

washer (K5) and nut (K6) onto

ange (K2) from below sink, but

do not secure nut. Screw on tail

piece (K7) and hand tighten.

PLUMBER

PUTTY

K2

K3

OPTIONAL

2

K4

K5

K6

K7

3

4) Turn tail piece (K7) and ange

(K2) so pivot is facing toward

faucet. Pull assembly down into

drain hole. Secure hardware from

below sink. Install stopper (K1) in

the removable or non-removable

position.

3

K1

5) Attach inner washer (K8), pivot rod

(K9) and outer washer (K10) to tailpiece (K7). Hand tighten nut (K11)

to secure pivot rod (K9).

K11

K10

1

K8

K7

K9

6) Connect lift rod (B) to clevis strap

(K13) and secure with thumb

screw (K14). Insert pivot rod

(K9) through spring clip (K12)

and clevis strap (K13). Secure

with spring clip (K12) and adjust

linkage if necessary.

1

B

H

1

J

1

1

1

K2

K7

2

PIVOT

K13

3

Page 4

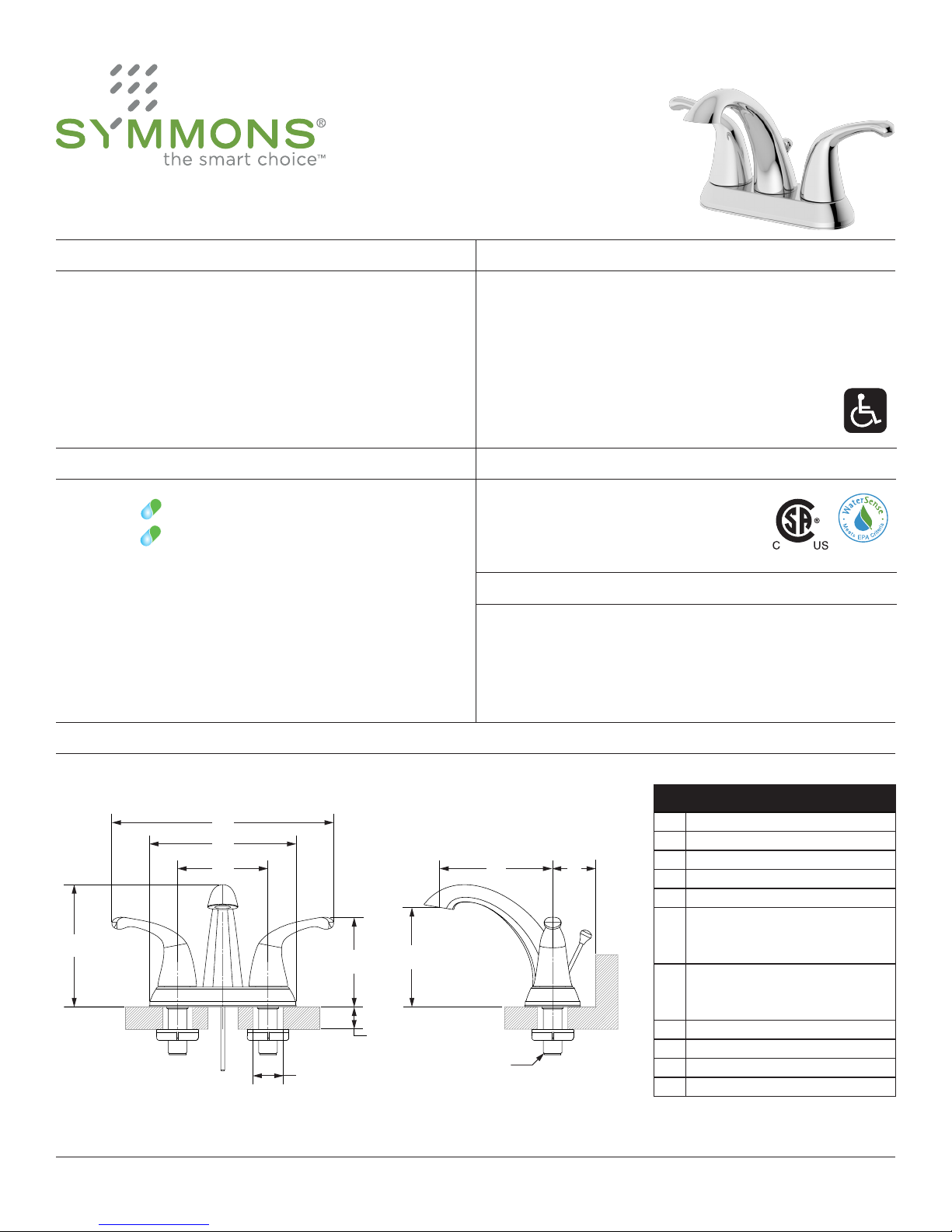

1

Installation

7) Attach supply lines to 1/2” IPS inlet

connections on faucet body (H).

Using a wrench, nish with one half

turn. DO NOT overtighten.

H

Maintenance

1) Remove set screw (A). Turning

counterclockwise, disassemble

handle (C) and nut (D) from cartridge (E or F).

8) Attach supply lines to shut-off

valves and hand tighten. Using a

wrench, nish with one-half turn.

DO NOT overtighten.

1

1

2

2) Remove cartridge (E or F) from

faucet body (H). Inspect for

debris.

necessary.

Replace cartridge if

9) Remove aerator (G) and ush

lines free of debris. Check for

leaks.

2

G

3) Install cartridge and handle assembly

following steps 1 and 2 in reverse.

C

E

F

Finish is spotting.

A

E

F

D

H

Troubleshooting Chart

Clean nished trim area with a soft

Elements in water supply may cause

water staining on nish.

cloth using mild soap and water or a

non-abrasive cleaner and then quickly

rinse with water.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ Phone: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright © 2015 Symmons Industries, Inc. ■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3116 REV B ■ 112515

Page 5

Unity

CSA Group

SLC-6610-1.5, SLC-6612-1.5

Dos manijas del grifo

Manual de Operación y Mantenimiento

™

Números de modelo

SLC-6610-1.5

Dos manijas del grifo Unity sin biela de elevación

SLC-6612-1.5

Dos manijas del grifo Unity

Modificaciones

-0.5 Aireador de 0.5 gpm (1.9 L/min)

-1.0 Aireador de 1.0 gpm (3.8 L/min)

-G Desagüe de rejilla

-Delete

Suffix

1.5

-STN Acabado en níquel satinado

Nota: Anexar el -complemento apropiado al número

Aireador de 2.2 gpm (8.3 L/min)

de modelo.

Especificación

Dos grifo de la manija que ofrecen una conguración de

4 “de montaje. Incluye cartuchos cerámicos, conexiones

1/2” IPS de entrada, 50/50 conjunto de drenaje y 1.5 gpm

(5,7 l / min) aireador estándar. Componentes hechos de

latón y materiales no metálicos chapados en acabado

cromo brillo estándar.

Cumplimiento

-NSF/ANSI 372, NSF/ANSI 61.9

-ASME A112.18.1/CSA B125.1

-WaterSense 1.5 gpm (5.7 L/min)

Garantía

Limitada de por vida - para el comprador original en

instalaciones para el consumidor/residenciales.

5 años - para instalaciones industriales/comerciales.

Consulte www.symmons.com/warranty para obtener

información completa sobre la garantía.

Certied by

Dimensiones

AA

BB

CC

DD

EE

HH

FF

GG

Nota: Las dimensiones pueden cambiar sin previo aviso.

II

KK

Medidas

A 9 3/4”, 248 mm

B 6 1/2”, 165 mm

JJ

C 4”, 102 mm

D 5 3/8”, 137 mm

E 3 7/8”, 98 mm

Referencia del grosor de la

F

Tamaño del oricio (3x)

G

Máx. Ø 1 1/2”, 38 mm

H 4 3/8”, 111 mm

I 4 7/8”, 124 mm

J Mín. 2”, 51 mm

K 1/2-14 NPSM

cubierta

Máx. 1 1/2”, 38 mm

Mín. Ø 1 1/4”, 32 mm

Page 6

Desglose de piezas

Repuestos

Artículo Descripción Número de pieza

K1

K2

G

K14

K13

C

D

A

B

E

A

C

B

E

Juego de manijas

(2x)

Varilla de

levantamiento

Cartucho para agua

caliente

RL-206*

RL-207*

RL-075

F

H

J

F

I

G Aireador

J

K

L Desagüe de rejilla

Cartucho para agua

I

Hardware de

Ensamble del

desagüe

fría

montaje

50/50

RL-076

LN-333-KIT (2.2)

FLR-102-1.5-KIT (1.5)

LN-742-KIT (1.0)

FLR-102-0.5 (0.5)

RL-208

RL-223*

(SLC-6612-1.5)

P-26*

(SLC-6610-1.5)

K3

K5

K6

K7

K4

K8

K9

K11

K12

K10

K

*Nota: Anexar -STN al número de pieza para el

acabado en níquel satinado.

Herramientas requeridas

Llave inglesa

L

Llave Allen (3/32”)

PLUMBER

Masilla de plomero

Cinta de plomero

PUTTY

6

Page 7

2

3

4

4

K12

K9

K13

2

K14

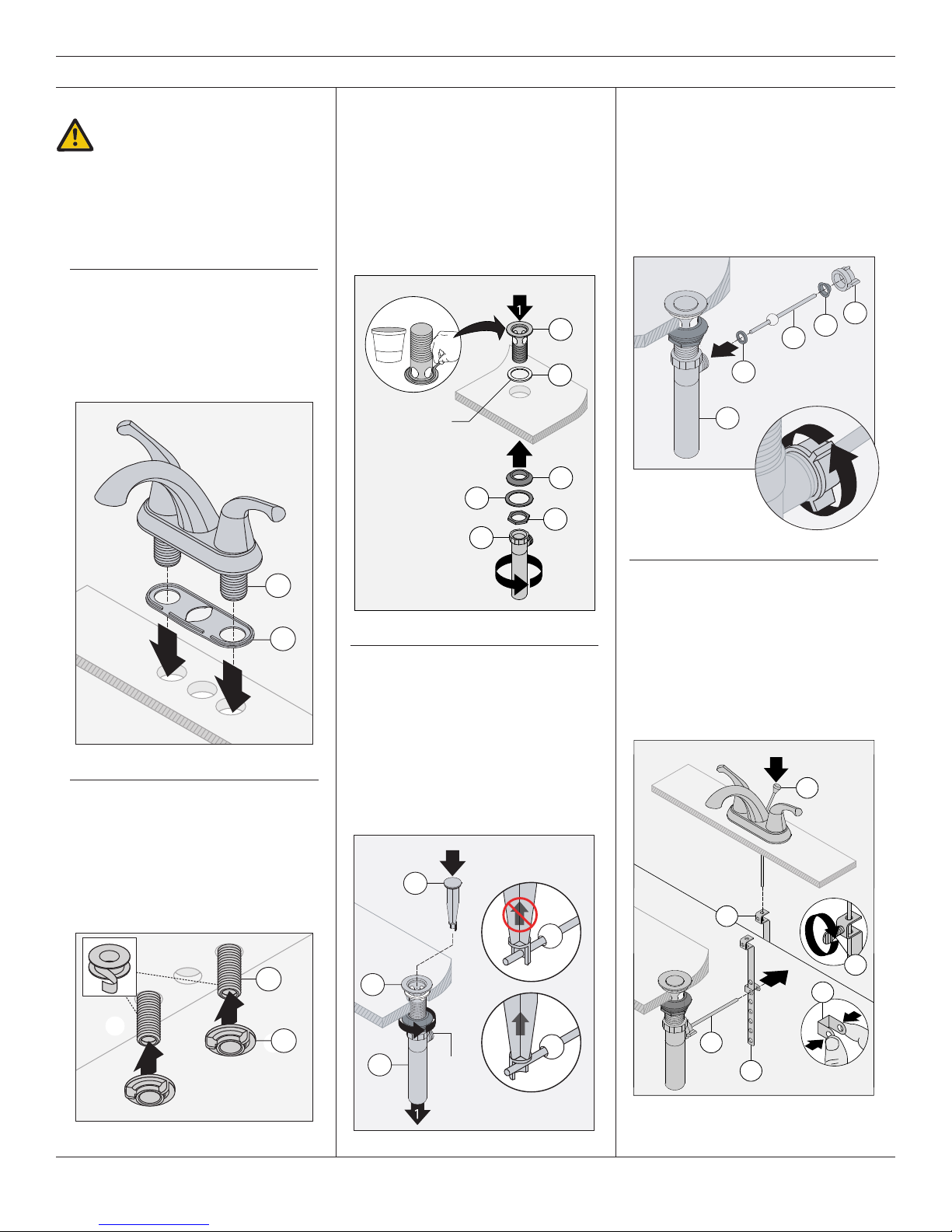

Instalación

Si está reemplazando otro

grifo, asegúrese de que el

suministro de agua esté CERRADO antes de quitarlo, luego

ABRA la válvula de control del

grifo para liberar la presión de

agua.

1) Inserte los conectores roscados

del cuerpo del grifo (H) a través

de la placa de masilla (I) y de la

placa de la plataforma.

H

I

2) Coloque las tuercas de los

conectores roscados (J) en

los conectores roscados (H) y

apriételas. Utilizando una llave,

termine con media vuelta. NO

apriete demasiado.

3) Ajuste la brida (K2) al lavabo (K3,

junta opcional). Instale la junta

(K4), la arandela (K5) y la tuerca

(K6) en la brida (K2) desde debajo

del lavabo, pero no ajuste la tuerca. Atornille la rejilla (K7) y ajuste

con la mano.

PLUMBER

PUTTY

K2

K3

OPTIONAL

2

K4

K5

K6

K7

3

4) Gire la rejilla (K7) y la brida (K2)

para que el pivote mire hacia el

grifo. Jale el ensamble hacia abajo

dentro del oricio de desagüe.

Asegure el hardware al ensamble

desde abajo del lavabo. Instale

el obturador (K1) en la posición

extraíble o no extraíble.

3

K1

5) Sujete la barra de pivote (K9) a la

rejilla (K7). Ajuste la tuerca (K11) a

mano en el sentido de las agujas

del reloj para asegurar la barra de

pivote (K9).

K11

K10

1

K8

K7

K9

6) Conecte la varilla de levantamiento

(B) a la barra con horquilla (K13) y

asegure con una tuerca de orejas

(K14). Inserte la barra de pivote (K9)

en la barra con horquilla (K13). Asegure con una grapa de resorte (K12)

y ajuste la conexión si es necesario.

1

B

H

1

1

1

1

J

K2

K7

2

K13

PIVOT

7

Page 8

1

Instalación

7) Conecte las líneas de suministro

a los conectores roscados del

grifo (H) y apriételas a mano.

Utilizando una llave, termine con

media vuelta. NO apriete demasiado.

H

Mantenimiento

1) Retire el tornillo de jación (A).

Volviendo hacia la izquierda, desmontar la manija (C) y la tuerca

(D) desde el cartucho (E/F).

8) Aplique cinta de plomero para

válvula de cierre. Utilizando una

llave, termine con media vuelta.

NO apriete demasiado.

1

1

2

2) Extraiga el cartucho (E/F) del cuerpo de válvula (H). Inspeccione

si hay desechos. Reemplace el

cartucho si es necesario.

9) Extraiga el aireador (G) y enjuague las líneas para que

queden libres de desechos. Verique que si hay pérdidas.

2

G

3) Reemplace el cartucho siguiendo

las instrucciones del paso 1 y 2 en

sentido inverso.

C

D

E

F

El acabado mancha.

A

E

F

H

Gráfi co de resolución de problemas

Los elementos del suministro de agua

pueden provocar que el agua manche

el acabado.

Limpie el área de reborde terminada

con un paño y jabón suaves y agua, o

un limpiador no abrasivo y luego en-

juague rápidamente con agua.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ Phone: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright © 2015 Symmons Industries, Inc. ■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3116 REV B ■ 112515

Page 9

Unity

CSA Group

™

SLC-6610-1.5, SLC-6612-1.5

Robinet de salle de bain monopièce à deux poignées

Manuel d’Opération et de Maintenance

Numéro de modèle

SLC-6610-1.5

Robinet de salle de bain monopièce à deux

poignées aucune tige de levage Unity

SLC-6612-1.5

Robinet de salle de bain monopièce à deux

poignées Unity

Modifications

-0.5 Aérateur de 0,5 gpm (1,9 L/min)

-1.0 Aérateur de 1,0 gpm (3,8 L/min)

-G Drain de la grille

-Delete

Suffix

1.5

-STN Fini nickel satiné

Remarque: Juxtaposer le -sufxe approprié au numéro

Aérateur de 2,2 gpm (8,3 L/min)

demodèle.

Spécification

Le robinet de salle de bain monopièce à deux poignées

présente une conguration de xation de 4 po et

comprend des cartouches en céramique, des conduits

d’alimentation en eau IPS de 1/2 po, un ensemble pour

drain 50/50 et un aérateur standard de 1,5 gpm (5,7 L/

min). Composants faits de laiton et de matériaux

non métalliques au ni chrome poli standard.

Conforme

-NSF/ANSI 372, NSF/ANSI 61.9

-ASME A112.18.1/CSA B125.1

-WaterSense 1.5 gpm (5.7 L/min)

Certied by

Garantie

À vie limitée -à l’acheteur original dans les installations du

consommateur ou résidentielles.

5 ans - pour des installations commerciales et industrielles.

Se reporter au site www.symmons.com/warranty (en anglais) pour l’information complète concernant la garantie.

Dimensions

AA

BB

DD

CC

EE

HH

II

FF

GG

Remarque: Les dimensions sont sujettes à changer sans préavis.

KK

Mesures

A 9 3/4 po, 248 mm

B 6 1/2 po, 165 mm

JJ

C 4 po, 102 mm

D 5 3/8 po, 137 mm

E 3 7/8”, 98 mm

F

G

H 4 3/8 po, 111 mm

K 1/2-14 NPSM

Épaisseur du comptoir

Max. 1 1/2 po, 38 mm

(3x) Taille du trou

Min. Ø 1 1/4 po, 32 mm

Max. Ø 1 1/2 po, 38 mm

I 4 7/8 po, 124 mm

J Min. 2 po, 51 mm

Page 10

Pièces de remplacement

Pièces de remplacement

Article Description Numéro de pièce

K1

K2

G

K14

K13

C

D

A

B

E

A

C

B Tige de levage RL-207*

E

(2x) Ensemble de

poignée

Cartouche d’eau

chaude

RL-206*

RL-075

F

H

J

F

I

G Aérateur

I

J

K

L Drain de la grille

Cartouche d’eau

froide

Matériel de xation RL-208

Ensemble pour drain

50/50

RL-076

LN-333-KIT (2.2)

FLR-102-1.5-KIT (1.5)

LN-742-KIT (1.0)

FLR-102-0.5 (0.5)

RL-223*

(SLC-6612-1.5)

P-26*

(SLC-6610-1.5)

K3

K5

K6

K7

K4

K8

K9

K11

K12

K10

K

*Remarque: Juxtaposer le -STN au numéro de pièce

pour le ni nickel satiné.

Outils requis

Clef ajustable

L

Clef Allen (3/32 po)

PLUMBER

Mastic de plombier

Ruban de plombier

PUTTY

10

Page 11

2

3

4

4

K12

K9

K13

2

K14

Installation

Si vous remplacez un vieux

robinet, assurez-vous que

l’approvisionnement en eau

soit ÉTEINT (OFF) avant de

l’enlever, tournez ensuite la

vanne de contrôle du robinet

à ON pour alléger la pression

de l’eau.

1) Insérer les queues de xation du

corps de robinet (H) à travers la

plaque de mastic (I) et la plaque

de montage.

3) Bride à siège (K2) dans le vidoir

(K3 joint en option). Installez le

joint (K4), la rondelle (K5) et l’écrou

(K6) sur la bride (K2) en dessous

du vidoir, mais ne serrez pas

l’écrou. Vissez la pièce de raccordement (K7) et serrez à la main.

PLUMBER

PUTTY

K2

K3

OPTIONAL

2

K4

K5

K6

K7

5) Attachez la tige de pivotement (K9)

à la pièce de raccordement (K7).

Serrez l’écrou (K11) à la main dans

le sens des aiguilles d’une montre

pour xer la tige de pivotement

(K9).

K11

K10

1

K8

K7

K9

H

2) Installer les écrous de queue

de xation (J) sur les queues de

xation du robinet (H) et serrer. A

l’aide d’une clé, terminer avec un

demi-tour. NE PAS trop visser.

H

1

1

1

1

3

6) Connectez la tige de levage (B) à

la sangle de manille (K13) et xez

I

avec la vis à tête (K14). Insérez

la tige de pivotement (K9) dans

la sangle de manille (K13). Fixez

4) Tournez la pièce de raccordement

(K7) et la bride (K2) an que le pivot

avec la pince à ressort (K12) et

ajustez le couplage au besoin.

soit face au robinet. Tirez l’ensemble

dans le trou de drainage. Fixez le

matériel à l’ensemble en dessous du

vidoir. Installez le bouchon (K1) dans

la position amovible ou xe.

3

K1

K2

2

1

B

J

K7

PIVOT

K13

11

Page 12

1

Installation

7) Fixer les conduites d’alimentation

aux queues (H) de xation du

robinet et serrer à la main. A l’aide

d’une clé, terminer avec un demitour. NE PAS trop visser.

H

Coût d’entretien

8) Appliquer du ruban de plombier

pour la vanne d’entrée. A l’aide

d’une clé, terminer avec un demitour. NE PAS trop visser.

1

1

2

9) Enlevez l’aérateur (G) et rincez les

conduites de tout débris. Vérier

pour déceler les fuites.

2

G

1) Retirer la vis de réglage (A).

Tourner dans le sens inverse, de

démonter la poignée (C) et l’écrou

(D) de la cartouche (E/F).

C

A

D

E

F

Le ni est tâché.

2) Retirez la cartouche (E/F) du

corps de vanne (M). Inspectez

pour voir s’il y a des débris. Remplacez la cartouche au besoin.

E

F

H

Tableau de résolution des problèmes

Les éléments dans l’alimentation en

eau peuvent causer des tâches sur le

ni.

3) Remplacez la cartouche en suivant

les instructions à l’étape 1 et 2, mais

à l’envers.

Nettoyez la boiserie avec un chiffon

doux en utilisant un savon doux et de

l’eau ou un nettoyant non abrasif et

rincez rapidement avec de l’eau.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ Phone: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright © 2015 Symmons Industries, Inc. ■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3116 REV B ■ 112515

Loading...

Loading...