Symmons Temptrol 262BODY, Temptrol 261XBODY, Temptrol RTS-076, Temptrol 262XBODY Installation Instructions Manual

Temptrol® Pressure Balancing Valve

Installation Instructions

262BODY

(4 PORT)

262XBODY

(4 PORT, SERVICE STOPS)

261XBODY

(3 PORT, SERVICE STOPS)

RTS-076

(BRACKET)

COMPLIANCE

-ASME A112.18.1/CSA B125.1

-ASSE 1016

-Buy American Act Compliant

IMPORTANT / FOR INSTALLER

WARNING:

As the installer of this valve, you must first carefully read and understand the material covered in this manual before

installing and adjusting this valve per instructions. Failure to do so may compromise the installation, operation and/or

serviceability of this valve.

Do not install positive shut-o devices on the outlet of this valve, or devices that do not allow the valve to flow at

least 1.5 GPM at 45 psi inlet pressure. Exception: If a self-closing or slow-closing valve is installed on the outlet, the

supplies of the valve must be equipped with checks to eliminate hot to cold bypass in the event the valve’s handle is

not turned o after use.

When installing this valve, failure to adjust limit stop screw properly may result in serious scalding.

LIFETIME LIMITED WARRANTY

All warranty claims MUST be pre-approved by Symmons.

All parts and finishes of the Symmons products are

warranted to the original consumer purchaser to be free

from manufacturing defects in material and workmanship

for 5 years Non-Residential or Commercial Applications.

Symmons warrants to the original consumer purchaser/

end-user that any Symmons product will be free of

defects in material and workmanship during normal

domestic use for the life of your home.

Symmons recommends using a professional plumber

for all installation and repair. During the warranty

period, Symmons at its sole option, will provide

replacement part(s) or product (or, if no longer available,

a comparable product) to replace those which have

proven defective in materials or workmanship under

normal installation, use and service, FREE OF CHARGE

for the time period of 5 years from the date of purchase.

(BATTERIES NOT INCLUDED)

This warranty is extensive in that it covers replacement of

all defective parts and even finish, but these are the only

two things that are covered. Damage due to installation

error, product abuse, product misuse, or use of cleaners

containing abrasives, alcohols, or other organic solvents,

whether performed by a contractor, Service Company

or yourself are excluded from this warranty. Symmons

will not be responsible for labor charges and/or damage

incurred in installation or repair or replacement, nor for

any indirect, incidental or consequential damages, losses,

injury or costs of any nature relating to the bathing

products. Except provided by law, this warranty is in

lieu of and excluded all other warranties, conditions and

guarantees, whether expressed or otherwise, including

without restriction those of merchantability or of fitness

for use.

Some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above

limitation of exclusion may not apply to you. This

warranty gives you specific legal rights, and you also may

have other rights which vary from state to state. This

warranty is not transferable. This warranty does not cover

damage or defects relating to misuse, abuse, negligence,

normal wear and tear, accident, acts of God, repairs or

alterations not authorized in writing by Symmons, or

improper installation, storage or handling.

The above mentioned warranty information includes each

product that falls under the following: Symmons Bathing

Products Warranty- Non-Residential or Commercial

Applications; Symmons Non-Electronic Lifetime

Faucet and Finish Limited Warranty Non-Residential or

Commercial Applications; Symmons Electronic Faucet

Limited Warranty - Non-Residential, Commercial and

Residential Applications; Symmons Bathing Products

Warranty- Residential Application Symmons NonElectronic Lifetime Faucet and Finish Limited Warranty

Residential Application

If you have any questions regarding technical support,

installation or concerns regarding our warranty plan,

please email us at GetHelp@symmons.com or call us at:

1-800-796-6667.

ZV-3247 REV B

1. RECOMMENDED TOOLS

FIGURE 1

Phillips Screwdriver Flathead Screwdriver

Adjustable Wrench

Safety Glasses Thread Seal Tape Measuring Tape

Torch

Solder

Pipe Cutter

Drywall Saw

(IPS Only)

Pipe Wrench

(CPVC Only)

CPVC Cement

(PEX Only)

PEX Crimping Tool

(PEX Only)

PEX Cold Expansion Tool

Level

Drill

(ProPress Only)

ProPress Tool

Copper, IPS, CPVC, PEX (Crimp) & PEX (Cold Expansion)

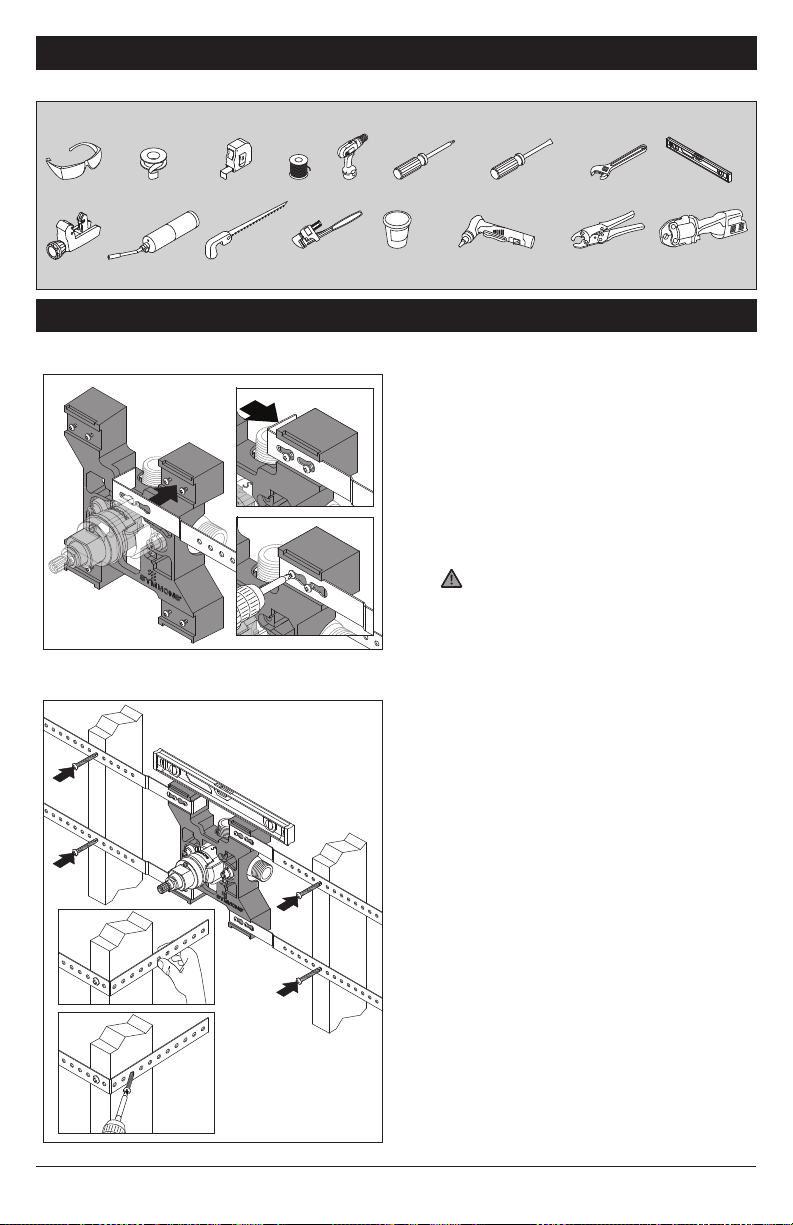

2. MOUNTING BRACKET INSTALLATION

2.1 Metal Straps

Mounting bracket is used to secure valve

between wall studs up to 24 inches, center to

center.

1. Place metal straps (x4) over screws. Screws

will come preassembled to bracket.

2. Pull metal straps tight against bracket ears.

Screws will protrude through small screw

hole in metal straps.

3. Drive screws into bracket to secure straps.

Use caution not to strip screws.

FIGURE 2.1

2.2 Install Bracket

FIGURE 2.3

FIGURE 2.4

ZV-3247 REV B

NOTE: Valve will come preassembled to

mounting bracket unless specified otherwise.

FIGURE 2.2

Mounting bracket will locate valve body in wall

cavity at appropriate depth (valve body rough-in

is not required).

1. Confirm valve body and mounting

2. Bend excess strap around wood studs.

3. Drive (4x) wood screws, at inward angle,

NOTE: If not using mounting bracket, see

STEP 5.1 for stringer mounts installation.

2

bracket are level. Drive (x4) wood screws

through metal straps into wood studs (see

FIGURE 2.2)

(see FIGURE 2.3)

through metal straps into sides of wood

studs (see FIGURE 2.4). Installing wood

screws at inward angle will pull metal straps

tight against wood studs.

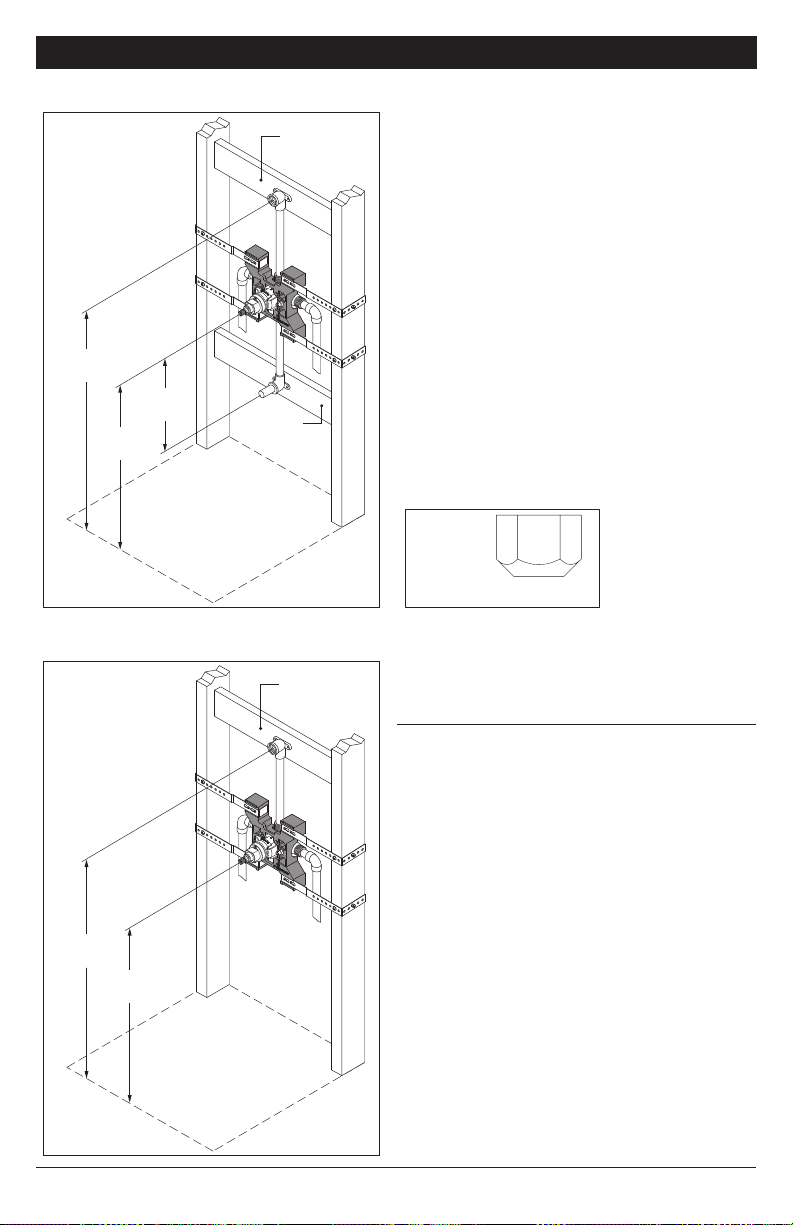

3.1 Tub/Shower Systems

FIGURE 3.1

77"

(1956mm)

12"

32"

(813mm)

(305mm)

INSTALL

BRACING

INSTALL

BRACING

3. DIMENSIONS AND MEASUREMENTS

Valve should be positioned 32 inches above the

tub basin floor. Shower arm should be 77 inches

above the tub basin floor. Tub spout should be

positioned approximately 12 inches below the

valve.

IMPORTANT: The design of this valve requires a

rigid copper tubing connection between the tub

port and the tub spout with no more than one (1)

90 degree bend allowed. Failure to do so, or to

substitute PEX, CPVC, or any other connection

type or outlet accessory such as a hand or

body-spray, other than the Symmons tub spout

provided, may result in excessive backpressure

through the system, and compromise operation.

When valve is used in shower only or tub spout

only installation, apply plumber tape to outlet

that will not be used and install the enclosed cap

to that outlet (see FIGURE 3.2).

FIGURE 3.2

FLOOR

3.2 Shower Systems

FIGURE 3.3

77"

(1956mm)

42"

(1067mm)

FLOOR

INSTALL

BRACING

CAP

1/2-14 NPT

Valve should be positioned 42 inches above the

tub basin floor. Shower arm should be 77 inches

above the tub basin floor.

NOTE: For ADA compliance (Americans with

Disabilities Act) consult your local municipality

for proper product choice and mounting

locations.

3

ZV-3247 REV B

4. DETERMINE WALL TYPE

4.1 T-176 Protective Shield 4.2 T-177 Valve Mounting Plate

FIGURE 4.1

-

F

I

N

T

I

N

S

A

H

T

E

R

D

O

P

M

I

E

C

A

F

R

U

S

S

I

H

T

W

A

L

L

M

U

S

T

B

E

F

L

U

F

S

O

H

M

W

O

I

T

T

H

T

O

B

FIGURE 4.2

Without service stops

With service stops

4.3 Drywall or Other Type Wall

FIGURE 4.3

1/2" (13 mm) or greater

protective shield

Wall Cutout Hole Size

3-1/2" (89 mm) min

4" (102 mm) max

finished wall

shower supply

Rough-in

± 1/2"

2-3/8"

(60 mm ± 13 mm)

pipe centerline

to front of

finished wall

hot & cold

supply inlets

tub spout

supply

Protective shield (T-176) is required for drywall,

plaster or other type walls with:

• 1/2 inch (13 mm) or greater wall thickness

1. Attach protective shield by snap fitting over

end of valve spindle to protect valve during

wall construction.

2. Finished wall must be flush with back side

of protective shield surface.

4.4 Thin Wall Installation

FIGURE 4.4

1/16" (2 mm) min

1/2" (13 mm) max

valve mounting plate

Wall Cutout Hole Size

3-1/2" (89 mm) min

4" (102 mm) max

finished wall

shower supply

Rough-in

± 1/2"

2-3/8"

(60 mm ± 13 mm)

pipe centerline

to front of

finished wall

hot & cold

supply inlets

tub spout

supply

Valve mounting plate (T-177) is required for

fiberglass or acrylic walls, and optional for

plaster or other type walls with:

• Minimum 1/16 inch (2 mm) wall thickness

• Maximum 1/2 inch (13 mm) wall thickness

1. Seat mounting plate against valve (see

FIGURE 4.2 for orientation).

2. Valve mounting plate must be flush with

inner wall.

4.5 Alternative Rough-ins

FIGURE 4.5

2" (51 mm)

Trim Series ± Tolerance

Oxford

Canterbury

Carrington

Temp Com

± 1/4" (± 6 mm)

± 1/2" (± 13 mm)

± 1/2" (± 13 mm)

± 1/2" (± 13 mm)

ZV-3247 REV B

Rough-in

± see table

pipe centerline

to finished wall

finished wall

When installing valve used with any of the

shower or tub/shower trims shown below,

reference rough-in dimensions as shown in

FIGURE 4.5 instead of standard valve rough-in:

Oxford

Canterbury

Temptrol

Carrington

Commercial

4

Loading...

Loading...