Page 1

Identity

CG

6703, 6704

Operation & Maintenance Manual

™

Model Numbers

6703

Identity Hand Shower System

6704

Identity Tub/Hand Shower System

Modifications

-1.5 1.5 gpm (5.7 L/min) flow restrictor

-2.0 2.0 gpm (7.6 L/min) flow restrictor

-72

-B30

-B48

-CHKS Integral check stops - for use in

-IPS

-L/HS

-LP Loop handle

-LR Lever handle

-OP 13" oval plate

-QD

-R

-REB-TRM

-REV Reverse coring, hot on right, cold on

-SS Slip spout on any tub/hand shower unit

-STN Satin Nickel finish

-T724 24" slide / grab bar with ADA hand

-T736 36" slide / grab bar with ADA hand

-TRM Trim only, valve not included

-X Integral service stops - allows water

6' metal hose in place of 5' standard

metal hose

30" slide bar in place of wall cradle

48" slide bar in place of wall cradle

installations where a positive shut-off

device is used downstream of mixing valve

1/2" female IPS connections

Less hand shower

Quick disconnect on hand shower units

White vinyl hose in place of metal hose

Rebuild trim kit

left, for back to back installations

shower in place of standard hand shower unit

shower in place of standard hand shower unit

shutoff at valve for service

Specification

6703

Hand shower system powered by the Temptrol® pressurebalancing valve. Features adjustable stop screw to limit

handle turn, wall ell, in-line vacuum breaker, 60" exible

metal hose, hand shower cradle, 1 mode hand shower and

standard 2.5 gpm (9.5 L/min) ow restrictor. Components

made from metal and nonmetallic materials, plated in

standard polished chrome nish.

6704

Tub/hand shower system powered by the Temptrol®

pressure-balancing valve. Features adjustable stop screw

to limit handle turn, diverter tub spout, wall ell, in-line

vacuum breaker, 60" exible metal hose, hand shower

cradle, 1 mode hand shower and standard 2.5 gpm

(9.5 L/min) ow restrictor. Components made from metal

and nonmetallic materials, plated in standard polished

chrome nish.

Compliance

-ASME A112.18.1/CSA B125.1

-WaterSense 1.5 gpm (5.7 L/min)

2.0 gpm (7.6 L/min)

For California Residents

WARNING: This product contains chemicals known to the

State of California to cause cancer, birth defects, or other

reproductive harm.

Certied by

CSA Group

Warranty

Limited Lifetime - to the original end purchaser in

consumer/residential installations.

5 Years - for industrial/commercial installations.

Refer to www.symmons.com/warranty for complete

warranty information.

Note: Append appropriate -sufx to model number.

Page 2

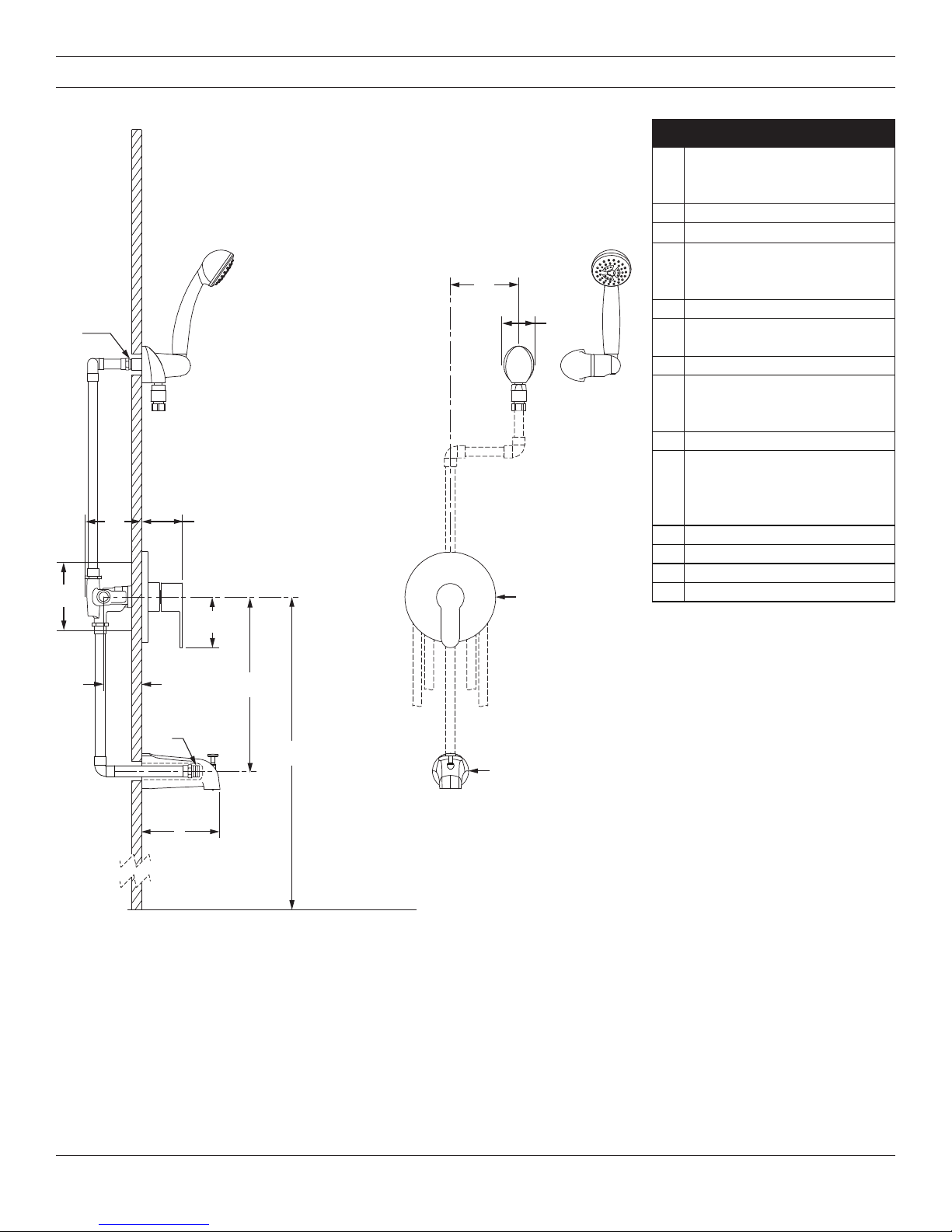

Dimensions

DD

AA

BB

CC

EE

KK

MM

Measurements

Male 1/2" NPT tting must

A

be recessed 1/4" (6 mm)

from nished wall

B 3-1/2", 89 mm

C 2-7/8", 73 mm

Shower Valve Hole Size

D

E 3-1/2", 89 mm

LL

F

G 12", 305 mm

H

I 5-1/4", 133 mm

J

K 6", 152 mm

L 2-1/8", 54 mm

M Ø 6-3/8", 162 mm

N Ø 2-5/8", 67 mm

Min. Ø 3", 76 mm

Max. Ø 4", 102 mm

Rough-in

2-3/8" ± 1/2", 60 mm ± 13 mm

Male 1/2" NPT tting must

protrude 4" (102 mm)

from nished wall

6703

Ref. 42", 1067 mm

6704

Ref. 32", 813 mm

FF

GG

HH

JJ

NN

II

FLOORFLOOR

Notes:

1) All dimensions measured from nominal rough-in (see F as reference).

2) Dimensions subject to change without notice.

2

Page 3

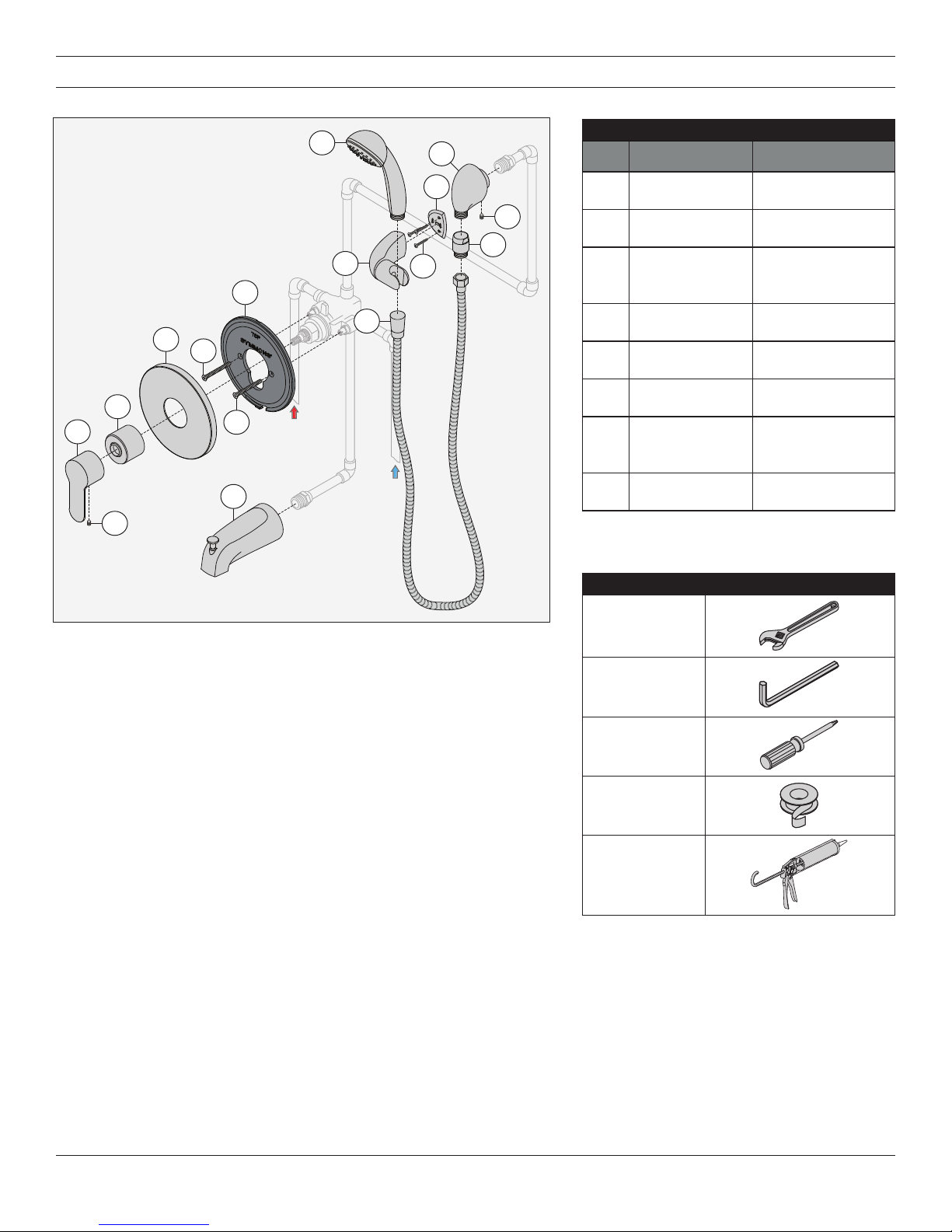

Parts Breakdown

A

E

N

H

L

M

B

C

D

G

F

Item Description Part Number

A Hand Shower EF-100*

B

D

C

E

F

GHVacuum Breaker

I

J

K

I

M

HOT

Water Supply

K Dome Cover T-19*

L

M

N

O

COLD

Water Supply

J

O Tub Spout 054*

*Note: Append -STN to part number for

Replacement Parts

Wall Ell

Set Screw

Mounting Plate

Wall Cradle

Screws

60" Hose

Handle

Set Screw

Escutcheon

Screws

Mounting Plate

EF-105*

EF-106*

EF-104*

RTS-084*

6700-ESC*

Satin Nickel nish.

Notes:

1) Apply a bead of silicone around the perimeter of all shower trim installed

ush to the nished wall (less mounting plates and brackets).

Leave opening on bottom of escutcheons for weep hole.

2) Apply plumber tape to all threaded connections.

Tools Required for Installation

Adjustable

Wrench

Allen Wrench

3/32"

Phillips Head

Screwdriver

Plumber Tape

Silicone

3

Page 4

2

2

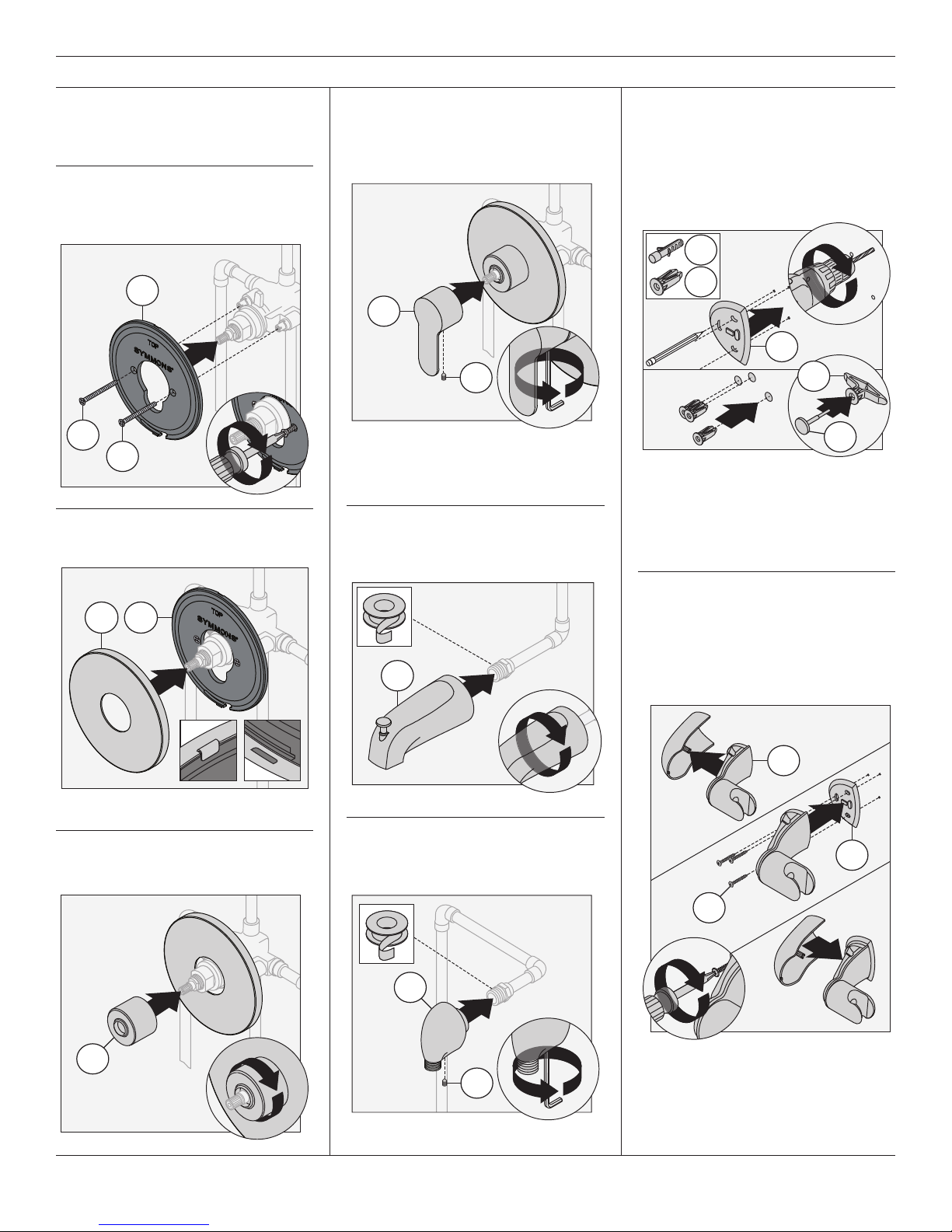

Installation

2

2

3

2

2

Note:

For valve body installation, please

see valve body manual.

1) Install shower mounting plate (N)

to shower valve. Secure with two

screws (M).

N

1

M

M

2) Attach shower escutcheon (L) to

shower mounting plate (N).

4) Install shower handle (I) to shower

valve. Secure shower handle with

set screw (J).

1

I

J

Note: Handle should be facing the 6

o’clock position.

5) Install tub spout (O) to pipe tting

Turn clockwise to tighten.

7) Place mounting plate

position, mark and drill 3/16" holes

for tile anchors (P1), 5/16" holes

for drywall anchors (P2). Install

anchors.

(C)

in

P1

P2

1

C

P2

3

4

P3

Note: For dry wall 1/2" thick or less,

insert anchor tool (P3) into drywall

anchor (P2) to secure behind wall

prior to installing wall cradle.

L N

Note: Tabs should snap into place.

3) Install dome cover (K) to shower

valve by turning clockwise.

1

O

6) Install wall ell

Tighten set screw (D) to secure.

1

(B)

to pipe tting.

B

1

1

8) Remove cover of hand shower

cradle

(E)

. Install cradle and

mounting plate

three screws

hand shower cradle.

1

(C)

. Secure with

(F)

. Replace cover on

E

2

C

F

4

K

D

4

Page 5

Installation

5

3

4

9) Attach vacuum breaker (G) to wall ell (B). Attach hose (H) to vacuum breaker. Attach hand shower (A) to hose (H). Turn

clockwise to tighten.

B

1

A

G

2

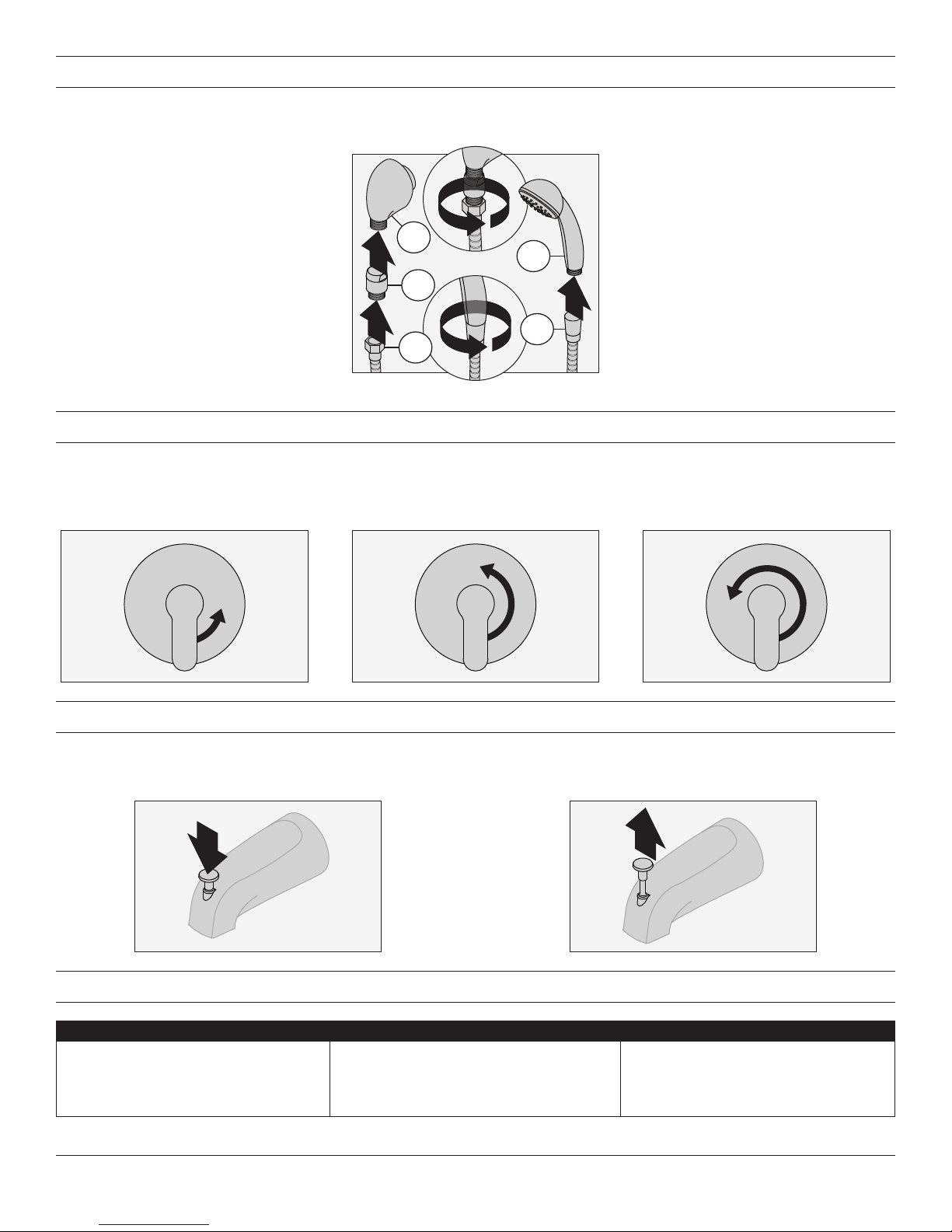

Operation (Temperature Control)

1) Turn shower handle counterclockwise approximately 1/4 turn

to put valve in cold position.

Operation (Diverter Control for 6704 only)

1) Diverter lever in down position for

tub spout operation.

2) Turn shower handle counterclockwise approximately 1/2 turn

to put valve in warm position.

H

H

3) Turn shower handle counterclockwise approximately 3/4 turn

to put valve in hot position.

2) Diverter lever in up position for

shower operation.

Troubleshooting Chart

Problem Cause Solution

Finish is spotting.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ Phone: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright © 2017 Symmons Industries, Inc. ■ symmons.com ■ gethelp@symmons.com ■ ZV-3197 REV B ■ 021617

Elements in water supply may cause

water staining on nish.

Clean nished trim area with a soft

cloth using mild soap and water or a

non-abrasive cleaner and then quickly

rinse with water.

Page 6

Identity

CG

6703, 6704

Manual de funcionamiento y mantenimiento

™

Números de modelo

6703

Sistema de ducha de mano Identity

6704

Sistema de bañera/ducha de mano Identity

Modificaciones

-1.5

-2.0

-72

-B30

-B48

-CHKS

-IPS

-L/HS

-LP

-LR

-OP

-QD

-R

-REB-TRM

-REV

-SS

-STN

-T724

-T736

-TRM

-X

Reductor de caudal de 1.5 gpm (5.7 L/min)

Reductor de caudal de 2.0 gpm (7.6 L/min)

Manguera de metal de 6 pies en vez de la

estándar de 5 pies

Barra deslizante de 30” en lugar del soporte

de pared

Barra deslizante de 48” en lugar del soporte

de pared

Válvulas de retención integradas - para usar en

instalaciones donde se usa un dispositivo de cierre

positivo aguas abajo de la válvula mezcladora

Salida de unión hembra de 1/2” I.P.S.

Sin ducha de mano

Manija en bucle

Manija de la palanca

Placa ovalada de 13"

Desconexión rápida en unidades de ducha

de mano

Manguera de vinilo blanco en lugar de la

manguera de metal

Juego del acabado de reconstrucción

Conexión inversa para instalaciones encontradas,

caliente a la derecha, frío a la izquierda.

Surtidor de deslizamiento en cualquier unidad

de bañera/ducha de mano

Acabado de níquel satinado

Barra agarradera/deslizante de 24” con

ducha de mano ADA en lugar de la unidad de

ducha de mano estándar

Barra agarradera/deslizante de 36” con

ducha de mano ADA en lugar de la unidad de

ducha de mano estándar

Borde solamente, válvula no incluida

Llaves de paso integradas - permiten el cierre

del agua en la válvula para el servicio

Especificación

6703

Sistema para ducha de mano con válvula compensadora

de presión Temptrol®. Incluye un tornillo con tope ajustable

para limitar el giro de la manija, codo de pared, igualador de

presión integrado, manguera metálica exible de 60", base de

ducha de mano, ducha de mano de 1 función y un restrictor

de caudal estándar de 2.5 gpm (9.5 L/min). Las piezas

están fabricadas con materiales metálicos y no metálicos

recubiertos con el acabado estándar de cromo pulido.

6704

Sistema para bañera y ducha de mano con válvula

compensadora de presión Temptrol®. Incluye un tornillo

con tope ajustable para limitar el giro de la manija,

desviador de surtidor de bañera, codo de pared, igualador

de presión integrado, manguera metálica exible de 60",

base de ducha de mano, ducha de mano de 1 función y

un restrictor de caudal estándar de 2.5 gpm (9.5 L/min).

Las piezas están fabricadas con materiales metálicos y no

metálicos recubiertos con el acabado estándar de cromo

pulido.

Cumplimiento

-ASME A112.18.1/CSA B125.1

-WaterSense 1.5 gpm (5.7 L/min)

2.0 gpm (7.6 L/min)

Certied by

CSA Group

Garantía

Limitada de por vida - para el comprador original

del producto en establecimientos del consumidor/

residenciales.

5 años - para instalaciones industriales y comerciales.

Consulte www.symmons.com/warranty para obtener

información más completa sobre la garantía.

Nota: Anexar el -complemento apropiado al número de modelo.

Page 7

Dimensiones

DD

AA

BB

FF

CC

EE

GG

KK

MM

Medidas

La rosca macho

NPT de 1/2” debe

A

B 3-1/2”, 89 mm

C 2-7/8", 73 mm

LL

D

E 3-1/2”, 89 mm

F

G 12", 305 mm

H

I 5-1/4", 133 mm

J

K 6", 152 mm

L 2-1/8", 54 mm

M Ø 6-3/8", 162 mm

N Ø 2-5/8", 67 mm

estar empotrada a

1/4” (6 mm)

de la pared terminada

Tamaño de los oricios

de la válvula para ducha

Mín. Ø 3”, 76 mm

Máx. Ø 4", 102 mm

Empotrado

2 3/8” ± 1/2”,

60 mm ± 13 mm

La rosca macho

NPT de 1/2” debe

sobresalir 4” (102 mm)

de la pared terminada

6703

Ref. 42", 1067 mm

6704

Ref. 32", 813 mm

HH

JJ

NN

II

PISOPISO

Notas:

1) Todas las dimensiones tomadas desde el empotrado (ver F para referencia).

2) Las dimensiones están sujetas a cambios sin previo aviso.

7

Page 8

Desglose de piezas

A

B

C

D

G

E

F

N

H

L

M

K

M

I

Suministro

de agua

CALIENTE

Suministro

O

de agua

FRÍA

J

Notas:

1) Aplique una gota de silicona alrededor del perímetro del borde de la

ducha a nivel de la pared terminada (salvo en las placas y soportes de

montaje). Deje un oricio en la parte inferior del escudete para drenar

la humedad.

2) Coloque cinta de teón en todas las salidas de unión roscadas.

Repuestos

Artículo Descripción

A

B

D

C

E

F

G

H

I

J

K

L

M

N

O

*Nota: Anexar -STN al número de pieza para

acabado de níquel satinado.

Ducha

de mano

Codo de pared

Tornillo de

presión

Placa de

montaje

Soporte de

pared

Tornillos

Igualador

de presión

Manguera

de 60”

Manija

Tornillo de

presión

Cubierta del

domo

Escudete

Tornillos

Placa de

montaje

Surtidor para

bañera

Número

de la pieza

EF-100*

EF-105*

EF-106*

EF-104*

RTS-084*

T-19*

6700-ESC*

054*

Herramientas necesarias

para la instalación

Llave inglesa

Llave Allen

3/32"

Destornillador

de cruz

Cinta de teón

Silicona

8

Page 9

2

2

Instalación

2

2

3

2

2

Nota:

Para instalar el cuerpo de la válvula,

vea el manual de la válvula.

1) Instale la placa de montaje (N) a la

válvula de la ducha. Sujétela con

dos tornillos (M).

N

1

M

M

2) Una el escudete de la ducha (L) a la

placa de montaje de la ducha (N).

4) Instale la manija de la ducha (I) en

la válvula de la ducha. Sujete la

manija de la ducha con el tornillo

de presión (J).

1

I

J

Nota: La manija debe situarse en la

posición de las 6 en punto.

5) Instale el surtidor para la bañera

(O) a la conexión de la tubería

girándolo en el sentido de las

manecillas del reloj para apretar.

7) Coloque la placa de montaje (C)

en su posición, marque y taladre

agujeros de 3/16" para las anclas

para mosaico (P1), agujeros de

5/16" para las anclas para yeso

(P2). Instale las anclas.

P1

P2

1

C

P2

3

4

P3

Nota:Para paredes de yeso de

1/2" de grosor o menos inserte la

herramienta para anclas (P3) en la

ancla para yeso (P2) para sujetarla

detrás de la pared antes de instalar

el soporte de pared.

L N

Nota: Las lengüetas deben

encajar en sus sitios.

3) Instale la cubierta del domo (K) a la

válvula de la ducha girándola en el

sentido de las manecillas del reloj.

1

O

6) Instale el codo de pared (B)

en el conector de la tubería.

Apriete el tornillo de presión

(D) para sujetarlo.

1

B

1

1

8) Retire la cubierta del soporte de

la ducha de mano (E). Instale el

soporte y la placa de montaje (C).

Sujete con tres tornillos (F). Vuelva

a colocar la cubierta del soporte

de la ducha de mano.

1

E

2

C

F

4

K

D

9

Page 10

Instalación

5

3

4

9) Una el igualador de presión (G) al codo de pared (B). Una la manguera (H) al igualador de presión. Una la ducha de

mano (A) a la manguera (H). Gire en el sentido de las manecillas del reloj para apretar.

B

1

A

G

2

H

Funcionamiento (Control de temperatura)

1) Gire el mango de la ducha 1/4 de

vuelta en sentido contrario a las

manecillas del reloj para colocar la

válvula en la posición de agua fría.

Funcionamiento (Control de desviador solo para 6704)

1) Palanca del desviador hacia

abajo para utilizar el surtidor

para bañera.

2) Gire el mango de la ducha 1/2

de vuelta en sentido contrario

a las manecillas del reloj para

colocar la válvula en la posición

de agua tibia.

H

3) Gire el mango de la ducha 3/4

de vuelta en sentido contrario

a las manecillas del reloj para

colocar la válvula en la posición

de agua caliente.

2) Palanca del desviador hacia arriba

para utilizar la ducha.

Tabla de resolución de problemas

Problema Causa Solución

El acabado se está manchando.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ Teléfono: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright © 2017 Symmons Industries, Inc. ■ symmons.com ■ gethelp@symmons.com ■ ZV-3197 REV B ■ 021617

Las partículas en el suministro

de agua pueden provocar que

el agua manche el acabado.

Limpie el área del acabado utilizando

un paño suave, jabón neutro y agua, o

con un limpiador no abrasivo y luego

enjuague rápidamente con agua.

Page 11

Identity

CG

6703, 6704

Manuel d'utilisation et d'entretien

™

Numéros de modèle

6703

Système de douche à main Identity

6704

Système de douche à main/baignoire Identity

Modifications

-1.5

-2.0

-72

-B30

-B48

-CHKS

-IPS

-L/HS

-LP

-LR

-OP

-QD

-R

-REB-TRM

-REV

-SS

-STN

-T724

-T736

-TRM

-X

Remarque: Juxtaposer le -sufxe approprié au numéro de modèle.

Réducteur de débit de 1,5gpm (5,7L/min)

Réducteur de débit de 2,0gpm (7,6L/min)

Boyau de 6 pieds au lieu du boyau en métal

standard de 5 pieds

Barre coulissante de 30 pouces au lieu du

support mural

Barre coulissante de 48 pouces au lieu du

support mural

Valve d'arrêt intégrée - pour une utilisation

dans les installations où un dispositif de

coupure intégrale est utilisé en aval de la

vanne de mélange.

Raccords IPS femelles de 1/2po

Moins la douche à main

Poignée en boucle

Poignée en levier

Plaque ovale de 13po

Débranchement rapide des accessoires de la

douche à main

Tuyau de vinyle blanc au lieu du tuyau de métal

Restaurez la trousse de finition

Corps central inversé, l'eau chaude à

la droite, l'eau froide à la gauche, pour

installations dos à dos

Bec de baignoire à enfiler sur toute unité de

baignoire/douche à main

Fini nickel satiné

Barre coulissante / d'appui de 24 pouces

avec douche à main ADA au lieu de l'unité de

douche à main standard

Barre coulissante / d'appui de 36 pouces

avec douche à main ADA au lieu de l'unité de

douche à main standard

Garniture seulement, vanne non incluse

Robinet d’interruption du service - permet la

coupure de l'eau à la vanne pour le service

Spécifications

6703

Système de douche à main alimenté par la vanne à

pression autorégularisée Temptrol®. Comprend une vis

d'arrêt réglable pour limiter la rotation de la poignée, un

coude mural, un brise-vide en ligne, un tuyau de métal

exible de 60po, un support mural de la douche à main,

une douche à main à mode unique et un réducteur de

débit standard de 2,5gpm (9,5L/min). Les composants

sont faits de matériaux métalliques et non métalliques au

ni chrome poli standard.

6704

Système de douche à main/baignoire alimenté par la

vanne à pression autorégularisée Temptrol®. Comprend

une vis d'arrêt réglable pour limiter le tournage de la

poignée, un bec de baignoire déviateur, un coude mural,

un brise-vide en ligne, un tuyau de métal exible de 60po,

un support mural de la douche à main, une douche à

main à mode unique et un réducteur de débit standard

de 2,5gpm (9,5L/min). Les composants sont faits de

matériaux métalliques et non métalliques au ni chrome

poli standard.

Conformité

-ASME A112.18.1/CSA B125.1

-WaterSense 1,5 gpm (5,7 L/min)

2,0 gpm (7,6 L/min)

Certied by

CSA Group

Garantie

À vie limitée–à l'acheteur original dans les installations

résidentielles/à l'usage du consommateur.

5 ans–pour des installations commerciales et

industrielles. Se reporter au site www.symmons.com/

warranty pour des informations complètes concernant

la garantie.

Page 12

Dimensions

DD

AA

BB

FF

CC

EE

GG

KK

MM

Mesures

Raccord NPT

1/2po mâle doit

A

B 3-1/2 po, 89mm

C 2-7/8 po, 73 mm

LL

D

E 3-1/2 po, 89mm

F

G 12 po, 305 mm

H

faire saillie de 4po (102 mm)

I 5-1/4 po, 133mm

J

K 6 po, 152 mm

L 2-1/8 po, 54mm

M Ø 6-3/8 po, 162 mm

N Ø 2-5/8 po, 67 mm

être encastré à

1/4po (6mm)

du mur ni

Taille du trou pour

la vanne de douche

Min. Ø3po, 76mm

Max. Ø 4po, 102mm

Robinetterie brute

2-3/8 po ± 1/2po,

60 mm ± 13 mm

Raccord NPT

1/2po mâle doit

du mur ni

6703

Réf.42po, 1067mm

6704

Réf.32po, 813mm

HH

JJ

NN

II

PLANCHERPLANCHER

Remarques:

1) Toutes les dimensions sont mesurées à partir de la robinetterie brute nominale (voir F en référence).

2) Les dimensions sont sujettes à modication sans préavis.

12

Page 13

Liste des pièces

A

B

Article Description

Pièces de rechange

Numéro

de pièce

C

A Douche à main EF-100*

D

G

E

F

N

D

C

E

F

B

H

L

M

G

H

I

J

K

M

I

Alimentation

en eau

CHAUDE

K Couvercle en dôme T-19*

L

M

N

O

Alimentation

en eau

FROIDE

O Bec de baignoire 054*

Coude mural

Vis de pression

Plaque de montage

Support mural

Vis

Brise-vide

Tuyau de 60po

Assemblage

Vis de pression

Rosace

Vis

Plaque de montage

EF-105*

EF-106*

EF-104*

RTS-084*

6700-ESC*

J

*Remarque: Juxtaposer le -STN au numéro

de pièce pour le ni nickel satiné.

Remarques:

1) Appliquez un joint de silicone autour du périmètre de la garniture de

la douche installée à égalité avec le mur ni (moins les plaques et les

supports de xation). Laissez une ouverture au fond de la rosace pour

l'évacuation.

2) Appliquez du ruban de plombier à toutes les connections letées.

Outils requis pour l'installation

Clef ajustable

Clef Allen

3/32 po

Tournevis à

tête cruciforme

Ruban de

plombier

Silicone

13

Page 14

2

2

Installation

2

2

3

2

2

Remarque: Pour l'installation du

corps de vanne, veuillez consulter le

manuel du corps de vanne.

1) Installez la plaque de montage

de la douche (N) à la vanne de

douche. Fixez avec deux vis (H).

N

1

M

M

2) Attachez la rosace de douche (L) à la

plaque de xation de la douche (N).

L N

4) Installez la poignée de douche

(I) à la vanne de douche. Fixez la

poignée de douche avec les vis de

pression (J).

1

I

J

Remarque: La poignée doit être

orientée vers la position 6h sur

une horloge.

5) Installez le bec de baignoire (O) au

raccord de tuyauterie en tournant

dans le sens horaire pour serrer.

7) Placez la plaque de montage

(C) en position, marquez et

percez des trous de 3/16po

pour l'ancrage pour céramique

(P1) et des trous de 5/16po pour

l'ancrage pour cloison sèche (P2).

Installez les dispositifs d'ancrage.

P1

P2

1

C

P2

3

4

P3

Remarque: Pour une cloison sèche

de 1/2po d'épaisseur ou moins,

insérer l'outil d'ancrage (P3) dans

le dispositif d'ancrage (P2) de la

cloison pour le xer derrière le mur

avant d'installer le support mural.

Remarque: Les languettes devraient

s'enclencher dans la bonne position.

3) Installez le couvercle en dôme (K)

à la vanne de douche en tournant

dans le sens des aiguilles d'une

montre.

1

K

O

6) Installez le coude mural (B) au

raccord de tuyauterie. Serrez les

vis de pression (D) pour xer en

place.

1

B

1

1

D

8) Enlevez le couvercle du support

de la douche à main (E). Installez

le support mural et la plaque de

montage (C). Fixez avec trois vis

(F). Remettre le couvercle sur le

support mural de la douche à

main.

1

E

2

C

F

4

14

Page 15

Installation

5

3

4

9) Fixez le brise-vide (G) au coude mural (B). Attachez le boyau (H) au brise-vide. Attachez la douche à main (A) au boyau

(H). Tournez dans le sens des aiguilles d'une montre pour serrer.

B

1

A

G

2

H

H

Fonctionnement (Contrôle de la température)

1) Tournez la poignée de douche dans

le sens contraire des aiguilles d'une

montre approximativement 1/4 de

tour pour mettre la vanne dans la

position d'eau froide.

Fonctionnement (Contrôle de dérivation 6704 seulement)

1) Le levier de dérivation dans

la position vers le bas pour le

fonctionnement du bec de baignoire.

2) Tournez la poignée de douche dans

le sens contraire des aiguilles d'une

montre approximativement 1/2 de

tour pour mettre la vanne dans la

position d'eau tiède.

3) Tournez la poignée de douche dans

le sens contraire des aiguilles d'une

montre approximativement 3/4 de

tour pour mettre la vanne dans la

position d'eau chaude.

2) Le levier de dérivation dans la

position vers le haut pour le

fonctionnement de la douche.

Tableau de résolution des problèmes

Symptôme Cause Solution

Le ni est tâché.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ Téléphone: (800)796-6667 ■ Télécopieur: (800) 961-9621

Copyright © 2017 Symmons Industries, Inc. ■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3197 REV B ■ 021617

Les éléments présents dans l'eau

peuvent causer des tâches sur le ni.

Nettoyer la zone avec un chiffon doux

en employant de l'eau et du détergent

doux ou un nettoyant non abrasif et

rincer rapidement à l'eau.

Loading...

Loading...