Page 1

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

Model Numbers

7-225-CK-MS

7-225-CK-F

7-225-CK-PEX

7-230-CK-M

7-230-CK-FS

Modifications

-B

-NI

-T

-W

-X

Wall cabinet in white enamel finish

including wall mounting bracket

Nickel plated

Stainless steel cabinet in place of

standard white cabinet

Wall mounting bracket

Separate Stops (7-225-CK-MS only)

Connections: 1/2” male NPT

1/2” female sweat

Connections: 1/2” female NPT

Connections: 1/2” PEX

Connections: 3/4” male NPT

Connections: 3/4” female sweat

Specification

Water temperature limiting valve including integral

checks and dual stainless steel strainers for double

protection against suspended particles in supply

lines. Valve made from lead free* metal components

(see table 1 for ow rates).

Temperature control range:

60°F - 140°F (15.6°C - 60°C)

Minimum supply pressure: 20 psi (138 kPa)

Maximum supply pressure: 125 psi (862 kPa)

Inlet to outlet temperature differential: 10°F (5.55°C)

*According to US Senate bill S.3874, the term “lead free” is dened as

follows: “not more than a weighted average of 0.25 percent lead when

used with respect to the wetted surfaces of pipes, pipe ttings, plumbing

ttings, and xtures”

Compliance

-ASME A112.18.1; CSA B125.1

Note: Append appropriate -sufx to model number.

Warranty

5 Years - for commercial installations.

Refer to www.symmons.com/warranty for complete

warranty information.

Valve Model

7-225-CK-MS

7-225-CK-F

7-225-CK-

PEX

7-230-CK-M

7-230-CK-FS

1

Size

Connection

1/2” Male NPT

1/2” Female Sweat

(13 mm)

1/2” Female NPT

(13 mm)

1/2” PEX

(13 mm)

3/4” Male NPT

(19 mm)

3/4” Female Sweat

(19 mm)

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Min. Flow Rate

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

-ASSE 1017; CSA B125.3

-ASSE 1070; CSA B125.3

-CA 116875 (AB 1953)

-NSF/ANSI 61.9; NSF/ANSI 372

-US S.3874

Table 1: Flow Rate - gpm (L/min)

Pressure Differential - psi (kPa)

5 psi

(34 kPa)

4.5 gpm

(17.1 L/min)

4.5 gpm

(17.1 L/min)

3.5 gpm

(13.3 L/min)

5.0 gpm

(19.0 L/min)

5.0 gpm

(19.0 L/min)

10 psi

(69 kPa)

7.0 gpm

(26.6 L/min)

7.0 gpm

(26.6 L/min)

5.5 gpm

(20.9 L/min)

7.0 gpm

(26.6 L/min)

7.0 gpm

(26.6 L/min)

(138 kPa)

9.5 gpm

(36.1 L/min)

9.5 gpm

(36.1 L/min)

8.0 gpm

(30.4 L/min)

10.0 gpm

(38.0 L/min)

10.0 gpm

(38.0 L/min)

20 psi

25 psi

(172 kPa)

10.5 gpm

(39.9 L/min)

10.5 gpm

(39.9 L/min)

8.5 gpm

(32.3 L/min)

11.0 gpm

(41.8 L/min)

11.0 gpm

(41.8 L/min)

30 psi

(207 kPa)

12.0 gpm

(45.6 L/min)

12.0 gpm

(45.6 L/min)

9.5 gpm

(36.1 L/min)

12.0 gpm

(45.6 L/min)

12.0 gpm

(45.6 L/min)

c

45 psi

(310 kPa)

14.0 gpm

(53.2 L/min)

14.0 gpm

(53.2 L/min)

12.0 gpm

(45.6 L/min)

14.0 gpm

(53.2 L/min)

14.0 gpm

(53.2 L/min)

Page 2

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

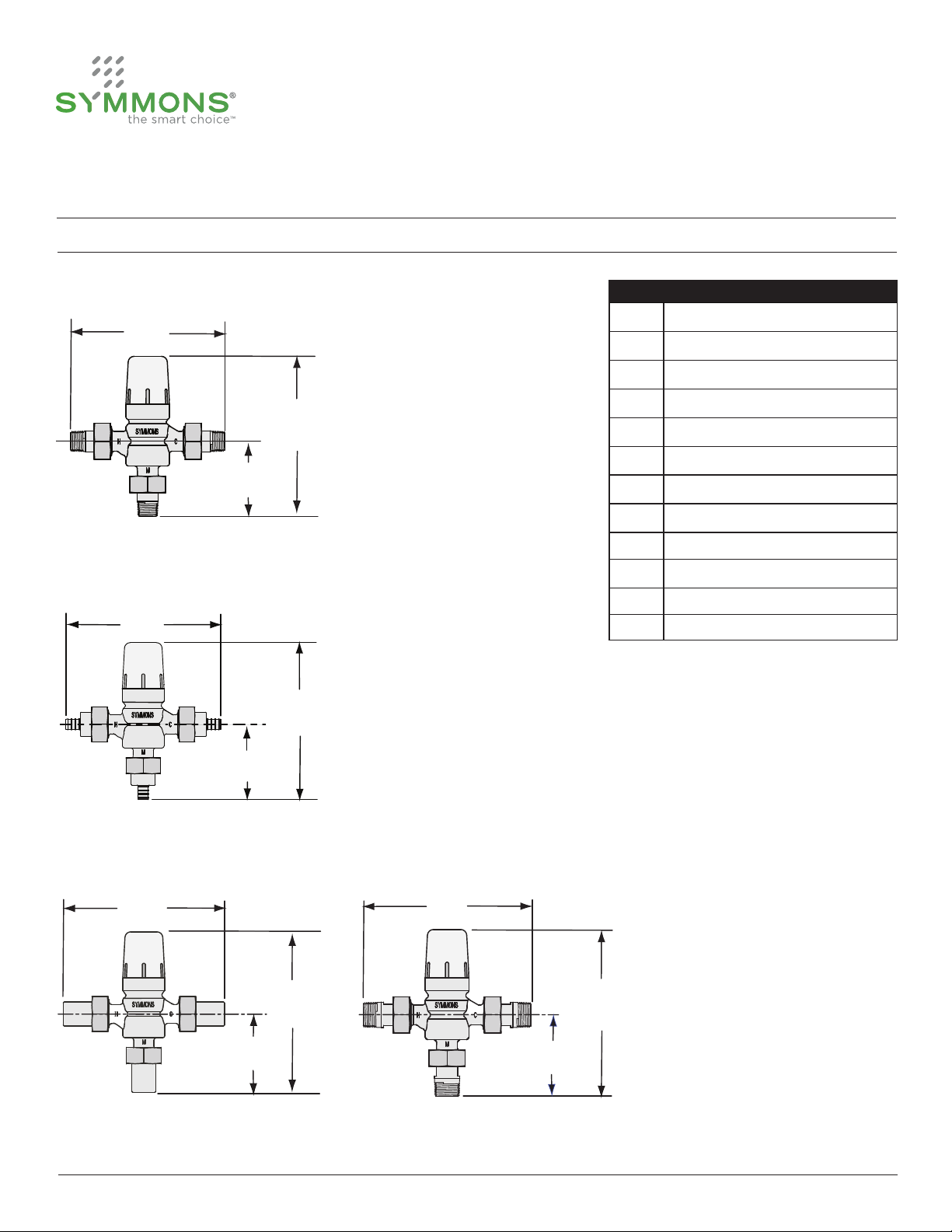

Dimensions

7-225-CK-MS

A

7-225-CK-PEX

D

C

B

E

Measurements

A 6 7/16”, 164 mm

B 6 9/16”, 167 mm

C 3 1/8”, 79 mm

D 6 3/4”, 171 mm

E 6 11/16”, 170 mm

F 3 1/4”, 83 mm

G 7”, 178 mm

H 6 13/16”, 173 mm

I 3 3/8”, 86 mm

J 7”, 178 mm

K 6 13/16”, 173 mm

L 3 3/8”, 86 mm

F

7-225-CK-F, 7-230-CK-FS 7-230-CK-M

G

H

I

Note: Dimensions are subject to change without notice.

2

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

J

K

L

Page 3

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

Parts Breakdown

7-225 Series 7-230 Series

Safety cap

in temperature

adjust position

G

H

D

E

F

E F G

A

B

C

D

E

F

G

Safety cap

in temperature

adjust position

E

F

G

D

A

B

C

D

E F

E

F

Replacement Parts 7-225 Series

Item Description Part No.

A Safety cap TMX-277

B Cap retainer TMX-269

C Cartridge TMX-267-KIT

D Check valve TMX-274-KIT

E

F

G

H Wall hanger TMX-290-KIT

3

1/2” PEX union

tting kit

1/2” female

union tting kit

1/2” male union

tting kit

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

TMX-289-LL-KIT

TMX-293-LL-KIT

TMX-286-LL-KIT

Replacement Parts 7-230 Series

Item Description Part No.

A Safety cap TMX-277

B Cap retainer TMX-269

C Cartridge TMX-267-KIT

D Check valve TMX-274-KIT

E

F

G Wall hanger TMX-290-KIT

3/4” female

union tting kit

3/4” male

union tting kit

TMX-288-LL-KIT

TMX-287-LL-KIT

Page 4

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

Installation

Sizing Valve

For assistance in sizing and selection of the proper

valve, consult your local representative or Symmons

Customer Service.

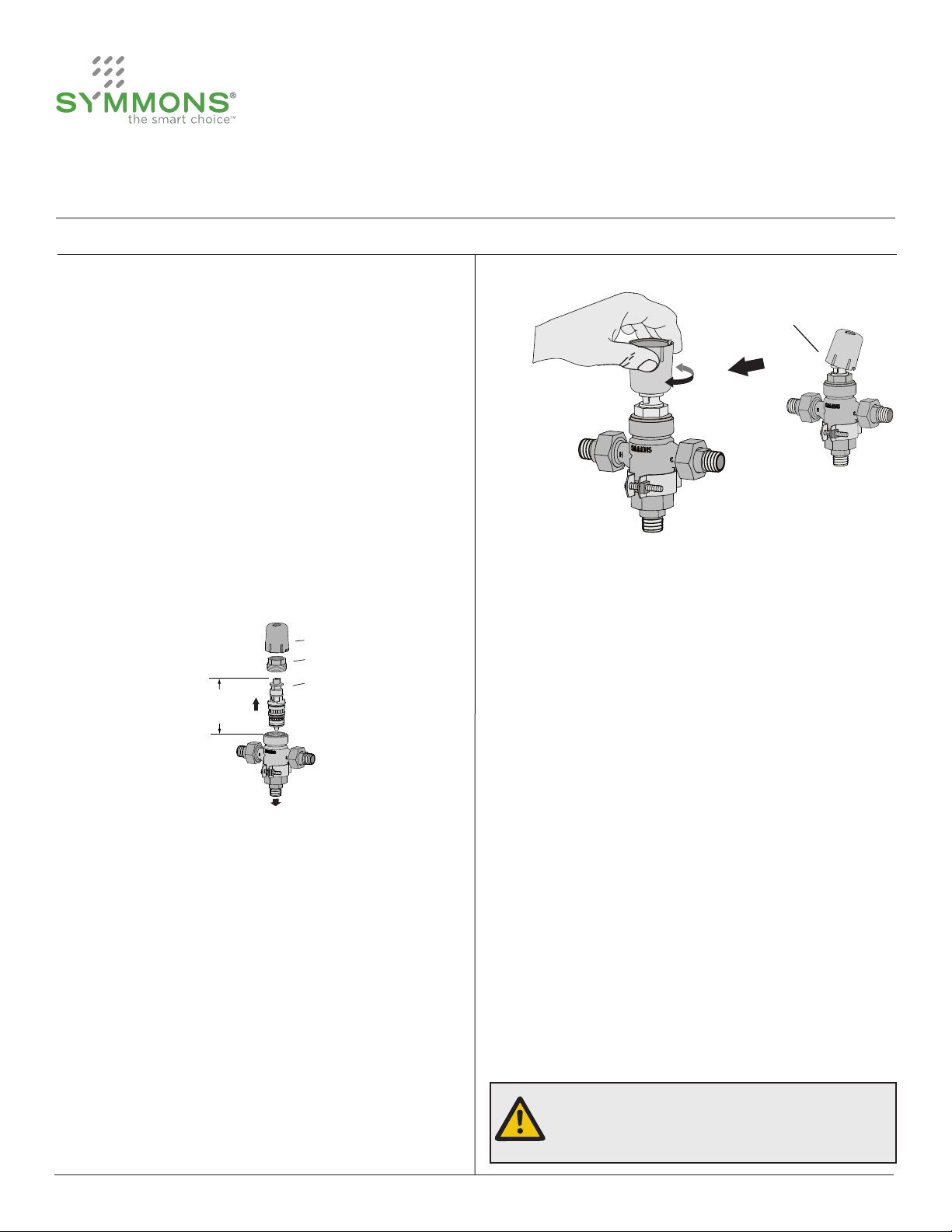

Installing Valve

1) Flush piping thoroughly prior to installing.

2) Install valve so as to allow clearance for replacing

cartridge. Valve can be installed in any orientation.

3) Connect valve input/ouput to supply ports.

a. Hot port marked (H)

b. Cold port marked (C)

c. Mixed output port marked (M)

protective cap

retaining nut

cartridge

Valve

clearance

4"

102 mm

Protective Cap

Temperature

Adjust

4) Place thermometer in the outlet stream. Measure

and accurately set temperature. Inlet temperature

must be ± 10°F (5.55°C) of desired output.

5) To increase temperature turn safety cap

counter-clockwise. To decrease temperature turn

safety cap clockwise.

(H) HOT

supply port

(M) MIXED

output port

(C) COLD

supply port

Setting Valve Temperature

1) Turn hot and cold water supply on.

2) Open faucet to allow hot water to ow for a

minimum of one minute. For two handle faucets

turn on hot water only. For single handle faucets

turn on to the hot position.

3) Remove the safety cap by inserting a small at

tip screw driver into the wide slot at the base of

the cap and pry upward, then ip the safety cap

over 180 degrees and t onto the end of valve

spindle.

4

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

For single temperature applications adjust valve

outlet temperature with full ow of tempered

water from tting.

For dual temperature applications open

approximately 50% of all faucets to their full hot

position to ensure proper operating temperature

at peak demand.

6) Remove safety cap from end of valve spindle and

ip over 180 degrees, then press cap down and

snap back onto valve body to replace.

Note: Once the safety cap is snapped onto the

valve body the outlet temperature cannot be

changed without repeating steps 2-6.

Warning: Water temperatures in excess of

110°F (43°C) may cause scalding or

severe injury!

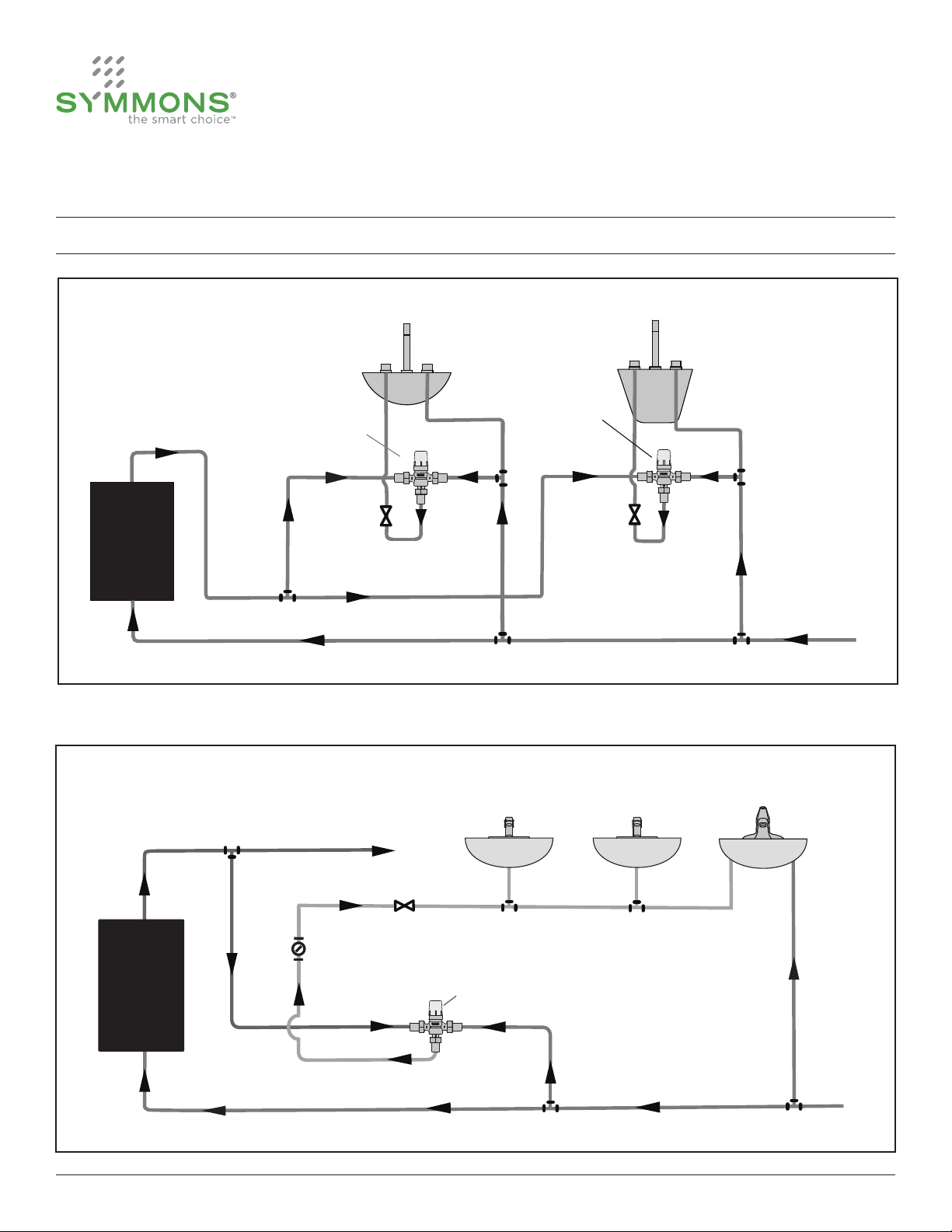

Page 5

HOT

WATER

TANK,

HEATER,

ETC.

Main hot supply

Cold supply

Lavatory

faucet

Tub

valve

(V1)

valve

(V2)

MAXLINE

valve

MAXLINE

valve

Tempered

hot supply

Tempered

hot supply

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

Installation

Point of Use Diagram

Multiple Fixtures Diagram

5

High temperature hot supply

(if required for laundry, etc.)

HOT

WATER

TANK,

HEATER,

ETC.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Thermometer

recommended

valve

Single supply faucets

Tempered hot supply

MAXLINE

valve

Two supply faucet

Cold supply

Page 6

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

Operation & Maintenance

Initial 30 Day Inspection

Inspect cartridge within 30 days of initial operation.

If inspection determines that your water system is

causing deposits and foreign matter to build-up,

then adjust cartridge maintenance accordingly.

Cartridge Replacement

1) Shut off hot and cold water supplies to valve.

2) Remove safety cap by inserting a small

screwdriver into the widest opening at the base

of the cap and pry upward. This will expose the

cartridge stem and cartridge retaining unit.

3) Remove retaining nut by turning counter-clockwise

with adjustable wrench. Grasp cartridge with

pliers and remove from body by pulling straight

out. A slight rocking rotation may be required to

loosen while removing.

on front of valve casting as shown below to the

left. Install retaining nut back onto valve body.

5) Refer to “Setting Valve Temperature” section (pg.4)

to properly set valve to desired temperature.

Service Instructions

Cleaning or replacing lter washer and check valve:

1) Remove union adapter nut from valve body and

then valve tting from union adapter.

2) Clean lter washer seated in valve tting by

soaking both in household vinegar and rinse under

running water. Ensure not to damage screen in

lter washer.

3) Replace lter washer into center of valve tting.

4) Replace check valve by removing from center of

valve body port connection.

4) Lubricate cartridge o-rings with a small amount of

lubricant prior to reinstalling. Insert replacement

cartridge into valve body, applying enough force to

ensure cartridge is fully seated. Install cartridge

with keyway inline with Symmons logo located

retaining nut

Torque to 132 inch lbs. (15Nm)

6

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

5) Fasten and tighten union adapter nut over valve

tting to valve body.

Seasonal Use

If valve is used seasonally, such as in schools or

campgrounds, then perform the following steps to

avoid damage caused by freezing water when valves

are not in use:

1) Shut off hot and cold water supplies.

2) Remove valve cartridge and drain all water.

3) Drain water from the supply lines and valve body.

Page 7

7-225, 7-230 Series

Maxline

Operation & Maintenance Manual

Care and Cleaning

Remove cartridge and clean valve body in household vinegar to remove corrosive mineral build up. Rinse

under running hot water to ensure valve is free of foreign debris.

Trouble Shooting Chart

Problem Cause Solution

1) Remove lter washer and clean

under running water or replace by

ordering check valve/union tting

Water ow is less than normal.

Screen in valve is dirty or cartridge

is dirty or clogged.

2) Remove cartridge and clean in

household vinegar or replace by

ordering cartridge replacement kit.

replacement kit.

Valve is leaking around the cap

retaining nut area.

Tempered hot water temperature

is not hot enough.

Water leaking from o-ring seal.

Hot water supply into valve is not

10°F (5.55°C) above desired set

point temperature.

Replace o-ring by ordering

cartridge replacement kit.

Increase hot water supply

temperature into valve.

7

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 8

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Números de modelo

7-225-CK-MS

7-225-CK-F

7-225-CK-PEX

7-230-CK-M

7-230-CK-FS

Conexiones: NPT macho de 1/2”

hembra de 1/2” de cobre

Conexiones: NPT hembra de 1/2”

Conexiones: PEX de 1/2”

Conexiones: NPT macho de 3/4”

Conexiones: Hembra de 3/4”

de cobre

Modificaciones

-B

-NI

-T

-W

-X

Gabinete de pared en acabado de

esmalte blanco que incluye soporte

de montaje en pared

Chapado en níquel

Gabinete de acero inoxidable

Soporte de montaje en pared

De servicio independiente detiene

(7-225-CK-MS)

Especificación

La válvula limitadora de temperatura del agua que

incluye válvulas antirretorno integrales y dos tamices

de acero inoxidable para una doble protección contra

partículas en suspensión en las líneas de suministro.

Válvula fabricada con componentes metálicos libres

de plomo* (ver la tabla 1 para informarse sobre las

tasas de ujo).

Rango de control de temperatura:

60 °F - 140 °F (15,6 °C - 60 °C)

Presión mínima de suministro: 20 psi (138 kPa)

Presión máxima de suministro: 125 psi (862 kPa)

Diferencial de temperatura entre

entrada y salida: 10 °F (5,55 °C)

*De acuerdo con el proyecto de ley del Senado de los EE.UU. S.3874,

el término “libre de plomo” se dene de la siguiente manera: “no más

que un promedio ponderado de 0,25 por ciento de plomo cuando se

utiliza con respecto a las supercies húmedas de tuberías, accesorios de

tubería, accesorios de fontanería y artefactos”

Cumplimiento

-ASME A112.18.1; CSA B125.1

Nota: Anexe el sujo apropiado al número del modelo.

Garantía

5 años - para instalaciones comerciales.

Consulte www.symmons.com/warranty para obtener

información completa sobre la garantía.

Tabla 1: Tasa de ujo - gpm (L/min)

Modelo de

válvula

7-225-CK-MS

7-225-CK-F

7-225-CK-

PEX

7-230-CK-M

7-230-CK-FS

8

Tamaño

Conexión

NPT macho de 1/2”

Hembra de 1/2” de

cobre (13 mm)

NPT hembra de 1/2”

(13 mm)

PEX de 1/2”

(13 mm)

NPT macho de 3/4”

(19 mm)

Hembra de 3/4” de

cobre (19 mm)

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Tasa de ujo

mín.

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

(17,1 L/min)

(17,1 L/min)

(13,3 L/min)

(19,0 L/min)

(19,0 L/min)

5 psi

(34 kPa)

4.5 gpm

4.5 gpm

3.5 gpm

5.0 gpm

5.0 gpm

-ASSE 1017; CSA B125.3

-ASSE 1070; CSA B125.3

-CA 116875 (AB 1953)

-NSF/ANSI 61.9; NSF/ANSI 372

-US S.3874

Diferencial de presión - psi (kPa)

10 psi

(69 kPa)

7.0 gpm

(26,6 L/min)

7.0 gpm

(26,6 L/min)

5.5 gpm

(20,9 L/min)

7.0 gpm

(26,6 L/min)

7.0 gpm

(26,6 L/min)

20 psi

(138 kPa)

9.5 gpm

(36,1 L/min)

9.5 gpm

(36,1 L/min)

8.0 gpm

(30,4 L/min)

10.0 gpm

(38,0 L/min)

10.0 gpm

(38,0 L/min)

(39,9 L/min)

(39,9 L/min)

(32,3 L/min)

(41,8 L/min)

(41,8 L/min)

25 psi

(172 kPa)

10.5 gpm

10.5 gpm

8.5 gpm

11.0 gpm

11.0 gpm

30 psi

(207 kPa)

12.0 gpm

(45,6 L/min)

12.0 gpm

(45,6 L/min)

9.5 gpm

(36,1 L/min)

12.0 gpm

(45,6 L/min)

12.0 gpm

(45,6 L/min)

c

45 psi

(310 kPa)

14.0 gpm

(53,2 L/min)

14.0 gpm

(53,2 L/min)

12.0 gpm

(45,6 L/min)

14.0 gpm

(53,2 L/min)

14.0 gpm

(53,2 L/min)

Page 9

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Dimensiones

7-225-CK-MS

A

7-225-CK-PEX

D

C

B

E

Mediciones

A 6 7/16”, 164 mm

B 6 9/16”, 167 mm

C 3 1/8”, 79 mm

D 6 3/4”, 171 mm

E 6 11/16”, 170 mm

F 3 1/4”, 83 mm

G 7”, 178 mm

H 6 13/16”, 173 mm

I 3 3/8”, 86 mm

J 7”, 178 mm

K 6 13/16”, 173 mm

L 3 3/8”, 86 mm

F

7-225-CK-F, 7-230-CK-FS 7-230-CK-M

G

H

I

Nota: Las dimensiones pueden cambiar sin previo aviso.

9

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

J

K

L

Page 10

Tapa de

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Desglose de partes

Serie 7-225 Serie 7-230

Tapa de

seguridad

en posición de

regulación de

temperatura

G

seguridad en

posición de

A

regulación de

temperatura

B

H

C

E

D

E

E

F

G

F

A

B

C

D

E

F

G

D

F

D

E F G

Repuestos de la Serie 7-225

Artículo Descripción N.° de parte

A Tapa de seguridad TMX-277

B Retén de la tapa TMX-269

C Cartucho TMX-267-KIT

D Válvula de retención TMX-274-KIT

E

F

G

H Colgador para pared TMX-290-KIT

10

Kit de calce de la

unión PEX de 1/2”

Kit de calce de la

unión hembra de 1/2”

Kit de calce de la

unión macho de 1/2”

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

TMX-289-LL-KIT

TMX-293-LL-KIT

TMX-286-LL-KIT

E F

Repuestos de la Serie 7-230

Artículo Descripción N.° de parte

A Tapa de seguridad TMX-277

B Retén de la tapa TMX-269

C Cartucho TMX-267-KIT

D Válvula de retención TMX-274-KIT

E

F

G Colgador para pared TMX-290-KIT

Kit de calce de la

unión hembra de 3/4”

Kit de calce de la

unión macho de 3/4”

TMX-288-LL-KIT

TMX-287-LL-KIT

Page 11

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Instalación

Dimensionamiento de la válvula

Para obtener ayuda para el dimensionamiento y

selección de la válvula adecuada, consulte a su

representante local o al departamento de Atención

al cliente de Symmons.

Instalación de la válvula

1) Lave a fondo las tuberías antes de instalarla.

2) Instale la válvula con el n de dejar distancia para

la sustitución de cartucho. La válvula se puede

instalar en cualquier orientación.

3) Conecte la entrada/salida de la válvula a los puertos

de suministro.

a. Puerto de agua caliente marcado, (H)

b. Puerto de agua fría marcada, (C)

c. Puerto de salida mixta marcado (M)

Tapa de seguridad

Regulación de

temperatura

4) Coloque el termómetro en el ujo de salida. Mida y

regule la temperatura con precisión. La temperatura

de entrada debe ser de ± 10 °F (5,55 ºC) de la

salida deseada.

Tapa de seguridad

Tuerca de retención

Cartucho

Distancia

de la válvula

Puerto de agua

CALIENTE “C” (H)

4"

102 mm

Puerto de salida

mixta (M)

Puerto de

suministro de

agua FRÍA “F” (C)

Ajuste de temperatura de la válvula

1) Abra el suministro de agua caliente y fría.

2) Abra el grifo para que el agua caliente uya

durante al menos un minuto. En los grifos de

dos canillas abra el agua caliente solamente. En

el caso de grifos mono comando, gírelos a la

posición de caliente.

3) Extraiga la tapa de seguridad mediante la

inserción de un destornillador plano pequeño

en la ranura ancha en la base de la tapa y haga

palanca hacia arriba, luego voltee la tapa de

seguridad 180 grados y colóquela en el extremo

del eje de la válvula.

5) A n de aumentar la temperatura gire la tapa

de seguridad a la izquierda. Para disminuir la

temperatura gire la tapa de seguridad a la derecha.

Para aplicaciones de temperatura única regule

la temperatura de salida de la válvula con el ujo

máximo de agua templada del accesorio.

Para aplicaciones de temperatura doble abra

aproximadamente el 50% de todos los grifos a

su posición de calor máximo para garantizar la

temperatura de funcionamiento adecuada a la

demanda pico.

6) Extraiga la tapa de seguridad de extremo del eje

de la válvula y voltéela 180 grados, a continuación,

presione la tapa hacia abajo y encájela a presión de

nuevo sobre el cuerpo de la válvula para reemplazar.

Nota: Una vez que la tapa de seguridad está

encajada a presión sobre el cuerpo de la

válvula, la temperatura de salida no se puede

cambiar sin repetir los pasos 2 a 6.

Advertencia: ¡Las temperaturas del agua

superiores a 110 °F (43 °C) pueden causar

quemaduras o lesiones graves!

11

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 12

TANQUE DE

AGUA

CALIENTE,

CALENTADOR,

ETC.

Suministro

de agua fría

Grifo de

lavatorio

Aplicaciones de temperatura única

Válvula

MAXLINE

Válvula

MAXLINE

Suministro de agua

caliente templada

Suministro de agua

caliente templada

Llenado

de bañera

válvula

(V1)

válvula

(V2)

Suministro principal de agua caliente

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Instalación

Diagrama de punto de uso

Diagrama de varios artefactos

Suministro de agua caliente

a alta temperatura

(si fuese necesaria para lavaderos, etc.)

válvula

TANQUE DE

AGUA

CALIENTE,

CALENTADO,

ETC.

12

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Termómetro

recomendado

Grifo de suministro individual

Suministro de agua caliente templada

Válvula

MAXLINE

Suministro de agua fría

Grifos de dos suministros

Page 13

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Funcionamiento y mantenimiento

Inspección dentro los 30 días del inicio

del funcionamiento

Inspeccione el cartucho dentro de los 30 días del inicio

del funcionamiento. Si la inspección determina que el

sistema de agua causa depósitos y acumulación de

materiales extraños, entonces ajuste el mantenimiento

del cartucho de manera acorde a tal hecho.

Reemplazo del cartucho

1) Cierre los suministros de agua caliente y fría a

la válvula.

2) Extraiga la tapa de seguridad mediante la

inserción de un destornillador plano pequeño

en la ranura más ancha en la base de la tapa

y haga palanca hacia arriba. Esto expondrá el

vástago del cartucho y la unidad de retención

de dicho cartucho.

3) Quite la tuerca de retención girándola hacia

la izquierda con una llave regulable. Sujete el

cartucho con pinzas y extraiga del cuerpo tirando

hacia fuera. Una ligera rotación oscilante puede

ser necesaria para aojarlo mientras lo extrae.

4) Lubrique los anillos de goma del cartucho con

una pequeña cantidad de lubricante antes de su

reinstalación. Inserte el cartucho de repuesto en

el cuerpo de la válvula mediante la aplicación

de la fuerza suciente para garantizar que el

cartucho está completamente asentado. Instale el

cartucho con el chavetero en línea con el logotipo

de Symmons situado en la parte delantera de la

fundición de la válvula como se muestra abajo a la

izquierda. Instale la tuerca de retención de nuevo

en el cuerpo de la válvula.

5) Consulte la sección “Conguración de la

temperatura de la válvula” (pág. 4) para congurar

correctamente la válvula a la temperatura deseada.

Instrucciones de servicio

Limpieza o reemplazo de la lavadora del ltro y la

válvula de retención:

1) Quite la tuerca adaptadora de unión del cuerpo

de la válvula y luego el accesorio de la válvula del

adaptador de unión.

2) Limpie la lavadora del ltro asentada en el

accesorio de la válvula mediante la inmersión de

ambos en vinagre de cocina y enjuague con agua

corriente. Asegúrese de no dañar la malla de la

lavadora del ltro.

3) Vuelva a colocar la lavadora del ltro en el centro

del accesorio de la válvula.

4) Coloque nuevamente la válvula de retención

mediante la extracción del centro de la conexión

del puerto del cuerpo de la válvula.

5) Fije y apriete la tuerca adaptadora de unión sobre el

accesorio de la válvula al cuerpo de la dicha válvula.

13

Tuerca de retención

Aplique torsión a

132 pulgadas-libras (15 Nm)

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Uso estacional

Si se utiliza la válvula estacionalmente, como por

ejemplo en escuelas o lugares para acampar,

entonces, lleve a cabo los siguientes pasos para

evitar daños causados por la congelación del agua

cuando las válvulas no están en uso:

1) Cierre los suministros de agua caliente y fría.

2) Extraiga el cartucho de la válvula y drene toda

el agua.

3) Realice el drenaje del agua de las tuberías de

suministro y el cuerpo de la válvula.

Page 14

Serie 7-225, 7-230

Maxline

Manual de funcionamiento y mantenimiento

Cuidado y limpieza

Extraiga el cartucho y limpie el cuerpo de la válvula en vinagre de cocina para eliminar la acumulación

de minerales corrosivos. Enjuague bajo un chorro de agua caliente para asegurar la válvula esté libre de

materiales extraños.

Tabla de solución de problemas

Problema Causa Solución

1) Extraiga la lavadora del ltro

y límpielo con agua corriente o

reemplace mediante el pedido del

kit de sustitución de válvula de

El ujo de agua es menor de

lo normal.

La malla de la válvula está sucia o

el cartucho está sucio u obstruido.

retención/accesorio de unión.

2) Retire el cartucho y limpie con

vinagre de cocina o sustitúyalo

mediante el pedido del kit de

sustitución del cartucho.

La válvula tiene una fuga en la

zona de la tuerca de retención de

la tapa.

La temperatura del agua

caliente templada no está lo

sucientemente caliente.

Fuga de agua en el sello del anillo

de goma.

El suministro de agua caliente a

la válvula no está 10 °F (5,55 °C)

por encima de la temperatura de

consigna deseada.

Reemplace el anillo de goma

mediante el pedido del kit de

sustitución de cartucho.

Aumente la temperatura del

suministro de agua caliente

a la válvula.

14

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 15

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Numéros de modèle

7-225-CK-MS

7-225-CK-F

7-225-CK-PEX

7-230-CK-M

7-230-CK-FS

Raccords: 1/2po mâle NPT

1/2po femelle sweat

Raccords: 1/2po femelle NPT

Raccords: 1/2poPEX

Raccords: 3/4pomâle NPT

Raccords: 3/4po femelle sweat

Modifications

-B

-NI

-T

-W

-X

Remarque: Joindre le sufxe approprié au numéro

de modèle.

Cabinet mural au fini émail blanc, incluant un support de montage mura

Plaqué en nickel

Boîtier en acier inoxydable

Support mural

Service distinct s’arrête

(7-225-CK-MS)

Spécification

Vanne limitant la température de l’eau, incluant des

contrôles intégraux et des pommelles doubles en

acier inoxydable pour offrir une protection double

contre les particules suspendues dans les conduites

d’alimentation. Vanne faite à partir de composants

en métal sans plomb* (consultez le tableau1 pour

les débits)

Portée du contrôle de la température:

60°F - 140°F (15,6°C - 60°C)

Pression d’approvisionnement minimale: 20 psi (138 kPa)

Pression d’approvisionnement maximale: 125 psi (862 kPa)

Écart de température d’entrée et de sortie: 10°F (5,55°C)

*Selon la loi du Sénat américain S.3874, le terme «sans plomb» se

dénit comme suit: «au maximum une moyenne 0,25pour cent de

plomb lorsqu’utilisé avec des surfaces de tuyaux, raccords de tuyau,

raccords de plomberie et appareils humides»

Conformité

-ASME A112.18.1; CSA B125.1

-ASSE 1017; CSA B125.3

Garantie

5ans - pour les installations commerciales.

Se référer au www.symmons.com/warranty pour les

renseignements complets relatifs à la garantie.

Tableau1: Débit - gpm (L/min)

Modèle de la

vanne

7-225-CK-MS

7-225-CK-F

7-225-CK-

PEX

7-230-CK-M

7-230-CK-FS

Dimension

Connexion

1/2pomâle NPT

1/2po femelle sweat

(13mm)

1/2po femelle NPT

(13mm)

1/2poPEX

(13mm)

3/4pomâle NPT

(19mm)

3/4po femelle sweat

(19mm)

Débit min.

0,5gpm

(1,9L/min)

0,5gpm

(1,9L/min)

0,5gpm

(1,9L/min)

0,5gpm

(1,9L/min)

0,5gpm

(1,9L/min)

5psi

(34kPa)

4,5gpm

(17,1L/min)

4,5gpm

(17,1L/min)

3,5gpm

(13,3L/min)

5,0gpm

(19,0L/min)

5,0gpm

(19,0L/min)

-ASSE 1070; CSA B125.3

-CA 116875 (AB 1953)

-NSF/ANSI 61.9; NSF/ANSI 372

-US S.3874

Différentiel de pression - psi (kPa)

10psi

(69kPa)

7,0gpm

(26,6L/min)

7,0gpm

(26,6L/min)

5,5gpm

(20,9L/min)

7,0gpm

(26,6L/min)

7,0gpm

(26,6L/min)

20psi

(138kPa)

9,5gpm

(36,1L/min)

9,5gpm

(36,1L/min)

8,0gpm

(30,4L/min)

10,0gpm

(38,0L/min)

10,0gpm

(38,0L/min)

25psi

(172kPa)

10,5gpm

(39,9L/min)

10,5gpm

(39,9L/min)

8,5gpm

(32,3L/min)

11,0gpm

(41,8L/min)

11,0gpm

(41,8L/min)

30psi

(207kPa)

12,0gpm

(45,6L/min)

12,0gpm

(45,6L/min)

9,5gpm

(36,1L/min)

12,0gpm

(45,6L/min)

12,0gpm

(45,6L/min)

c

45psi

(310kPa)

14,0gpm

(53,2L/min)

14,0gpm

(53,2L/min)

12,0gpm

(45,6L/min)

14,0gpm

(53,2L/min)

14,0gpm

(53,2L/min)

15

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 16

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Dimensions

7-225-CK-MS

A

7-225-CK-PEX

D

C

B

E

Mesures

A 67/16po, 164mm

B 69/16po, 167mm

C 31/8po, 79mm

D 63/4po, 171mm

E 611/16po, 170mm

F 31/4po, 83mm

G 7po, 178mm

H 613/16po, 173mm

I 33/8po, 86mm

J 7po, 178mm

K 613/16po, 173mm

L 33/8po, 86mm

F

7-225-CK-F, 7-230-CK-FS 7-230-CK-M

G

J

H

I

Remarque: Les dimensions sont sujettes à changer sans préavis.

16

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

K

L

Page 17

Bouchon de

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Nomenclature des pièces

Série 7-225 Série 7-230

Bouchon de

sécurité en

position

d'ajustement de

la température

A

B

sécurité en position

d'ajustement

de la température

A

B

H

E

C

D

F

D

G

E F G

Pièces de remplacement série 7-225

Article Description Numéro de pièce

A Bouchon de sécurité TMX-277

B Capuchon de maintien TMX-269

C Cartouche TMX-267-KIT

D Vanne anti-retour TMX-274-KIT

E

F

G

H Support mural TMX-290-KIT

Trousse d’installation

1/2po PEX union

Trousse d’installation

1/2po femelle PEX

union

Trousse d’installation

1/2po mâle PEX union

TMX-289-LL-KIT

TMX-293-LL-KIT

TMX-286-LL-KIT

G

E

G

C

E

D

E

F

F

D

F

E F

Pièces de remplacement série 7-230

Article Description Numéro de pièce

A Bouchon de sécurité TMX-277

B Capuchon de maintien TMX-269

C Cartouche TMX-267-KIT

D Vanne anti-retour TMX-274-KIT

Trousse d’installation

E

F

G Support mural TMX-290-KIT

3/4po femelle PEX

union

Trousse d’installation

3/4po mâle PEX union

TMX-288-LL-KIT

TMX-287-LL-KIT

17

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 18

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Installation

Dimension de la vanne

Pour obtenir de l’aide au niveau de la dimension et de

la sélection de la vanne appropriée, consultez votre

représentant local ou le service à la clientèle Symmons.

Installation de la vanne

1) Rincez bien le tuyau avant l’installation.

2) Installez la vanne de sorte à permettre une

distance pour remplacer la cartouche. La vanne

peut être installée dans tous les sens.

3) Connectez l’entrée/la sortie de la vanne pour

approvisionner les ports.

a. Entrée d’eau chaude marquée (H)

b. Entrée d’eau froide marquée (C)

c. Entrée de sortie mixte marquée (M)

bouchon de sécurité

écrou de retenue

cartouche

Dégagement

de la vanne

(H) alimentation

en eau CHAUDE

4 po

102 mm

(C) alimentation

en eau FROIDE

(M) alimentation

mixte

Réglage de la température de la vanne

1) Ouvrez l’approvisionnement en eau chaude et froide.

2) Ouvrez le robinet pour permettre à l’eau chaude

de couler pendant une ou deux minutes. Pour

les robinets à deux poignées, ouvrez uniquement

l’eau chaude. Pour les robinets à poignée simple,

ouvrez à la position d’eau chaude.

3) Retirez le bouchon de sécurité en insérant un

petit tournevis plat dans la large fente à la base

du bouchon et forcez vers le haut, puis retournez

le bouchon de sécurité à 180degrés et ajustez à

l’extrémité de la tige de la vanne.

Bouchon

de protection

Ajustement de

la température

4) Placez le thermomètre dans la décharge.

Mesurez et réglez de manière appropriée la

température. La température d’entrée doit être ±

10°F (5,55°C) de la température de sortie désirée.

5) Pour augmenter la température, tournez le

capuchon de sécurité dans le sens antihoraire.

Pour diminuer la température, tournez le

capuchon de sécurité dans le sens horaire.

Pour les applications de température simple,

ajustez la température de sortie de la vanne avec

un débit complet d’eau modéré sur raccord.

Pour les applications de températures doubles,

ouvrez environ 50% de tous les robinets à

leur position d’eau chaude pour assurer une

température appropriée lors d’une forte demande.

6) Retirez le bouchon de sécurité depuis l’extrémité de

la tige de la vanne et le retourner à 180degrés, puis

appuyez une pression sur le bouchon et le remettre

sur le corps de la vanne pour le remplacer.

Remarque: Une fois le bouchon de sécurité xé sur

le corps de la vanne, la température de

sortie ne peut être modiée sans répéter

les étapes 2 à 6.

Avertissement: Les températures d’eau

supérieures à 110°F (43°C) peuvent causer

des brûlures ou des blessures graves!

18

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 19

RÉSERVOIR

D'EAU

CHAUDE,

FOURNAISE,

ETC.

Alimentation en eau chaude principale

Alimentation

en eau

froide

Robinet

de lavabo

Remplissage

de baignoire

vanne

(V1)

vanne

(V2)

MAXLINE

vanne

MAXLINE

vanne

Alimentation

en eau tiède

Alimentation en

eau tiède

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Installation

Diagramme du point d’utilisation

Diagramme d’appareils multiples

19

Robinets

simples

Alimentation en eau chaude à température élevée

(si nécessaire pour la lessive, etc.)

RÉSERVOIR

D'EAU

thermomètre

recommandé

CHAUDE,

FOURNAISE,

ETC.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

vanne

Alimentation en eau tiède

MAXLINE

vanne

température double

Alimentation

en eau froide

Robinet de

Page 20

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Opération et entretien

Inspection initiale dans les 30jours

Inspectez la cartouche dans les 30jours suivant

l’opération initiale. Si l’inspection détermine que votre

système d’eau cause des dépôts et qu’une matière

étrangère se forme, ajustez l’entretien de la cartouche en conséquence.

Remplacement de la cartouche

1) Éteignez les approvisionnements d’eau chaude et

froide à la vanne.

2) Retirez le bouchon de sécurité en insérant un petit

tournevis dans la fente la plus large, à la base du

bouchon et forcez vers le haut. Ceci exposera

la tige de la cartouche et l’unité retenant la

cartouche.

3) Retirez l’écrou de serrage en tournant dans le sens

antihoraire, à l’aide d’une clé ajustable. Agrippez

la cartouche avec des pinces et retirez du corps

en tirant directement. Une légère rotation peut être

requise pour la desserrer, tout en la retirant.

4) Lubriez les anneaux de la cartouche avec une petite

quantité de lubriant avant la réinstallation. Insérez

une cartouche de remplacement dans le corps de

la vanne, en appliquant sufsamment de force pour

s’assurer que la cartouche est bien enclenchée.

Insérez la cartouche avec une rainure en ligne avec le

logo Symmons situé sur l’avant du boîtier de la vanne,

comme montré plus bas à la gauche. Réinstallez

l’écran de maintien sur le corps de la vanne.

écrou de retenue

Couple jusqu'à 132 pouce lb (15Nm)

5) Se référer à la section «Régler la température de la

vanne» (p. 4) pour régler de manière appropriée la

vanne à la température désirée.

Instructions de service

Nettoyage ou remplacement de la rondelle du ltre

et de la vanne de retenue:

1) Retirez l’écrou d’adaptateur de la vanne, puis le

raccord de la vanne de l’adaptateur.

2) Nettoyez la rondelle du ltre situé dans le raccord

de la vanne en le faisant tremper dans le vinaigre

maison et rincez à l’eau courante. Veillez à ne pas

endommager le ltre de la rondelle du ltre.

3) Remplacez la rondelle du ltre au centre du

raccord de la vanne.

4) Remplacez la vanne de retenue en la retirant du

centre de la connexion du port du corps de la

vanne.

5) Fixez et serrez l’écrou d’adaptateur sur le raccord

de la vanne à la vanne.

Utilisation saisonnière

Si la vanne est utilisée saisonnièrement, comme

dans les écoles et les campings, effectuez les

étapes suivantes pour éviter les dommages

causées par l’eau surgelée lorsque les vannes

ne sont pas utilisées.

1) Éteignez les approvisionnements d’eau chaude

et froide.

20

2) Retirez la cartouche de la vanne et drainez

toute l’eau.

3) Drainez l’eau depuis les conduites d’alimentation

et le corps de la vanne.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Page 21

Séries 7-225, 7-230

Maxline

Manuel d’opération et d’entretien

Entretien et nettoyage

Retirez la cartouche et nettoyez le corps de la vanne dans le vinaigre maison pour retirer l’accumulation

de minéral corrosif. Rincez sous l’eau chaude courante pour s’assurer que la vanne ne contient aucun

débris étranger.

Tableau de problèmes

Problème Cause Solution

1) Retirer la rondelle du filtre

et nettoyez sous l’eau courante,

ou remplacez en commandant

une trousse de remplacement

de vanne de retenue ou de

Le débit de l’eau est inférieur

à la normale.

Le ltre de la vanne est sale ou la

cartouche est sale ou obstruée.

raccord union.

2) Retirer la cartouche et la

nettoyer dans le vinaigre maison

ou la remplacer en commandant

une trousse de remplacement de

la cartouche.

La vanne fuit autour du bouchon

qui retient l’écrou.

La température de l’eau

chaude modérée n’est pas

suffisamment chaude.

L’eau fuit depuis l’anneau.

L’approvisionnement d’eau

chaude dans la vanne n’est pas

10°F (5,55°C) supérieure

à la température désirée.

Remplacer l’anneau en comman-

dant une trousse de remplacement

de cartouche.

Augmenter la température de

l’eau chaude dans la vanne.

21

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3009 REV D 05/27/14

Loading...

Loading...