Page 1

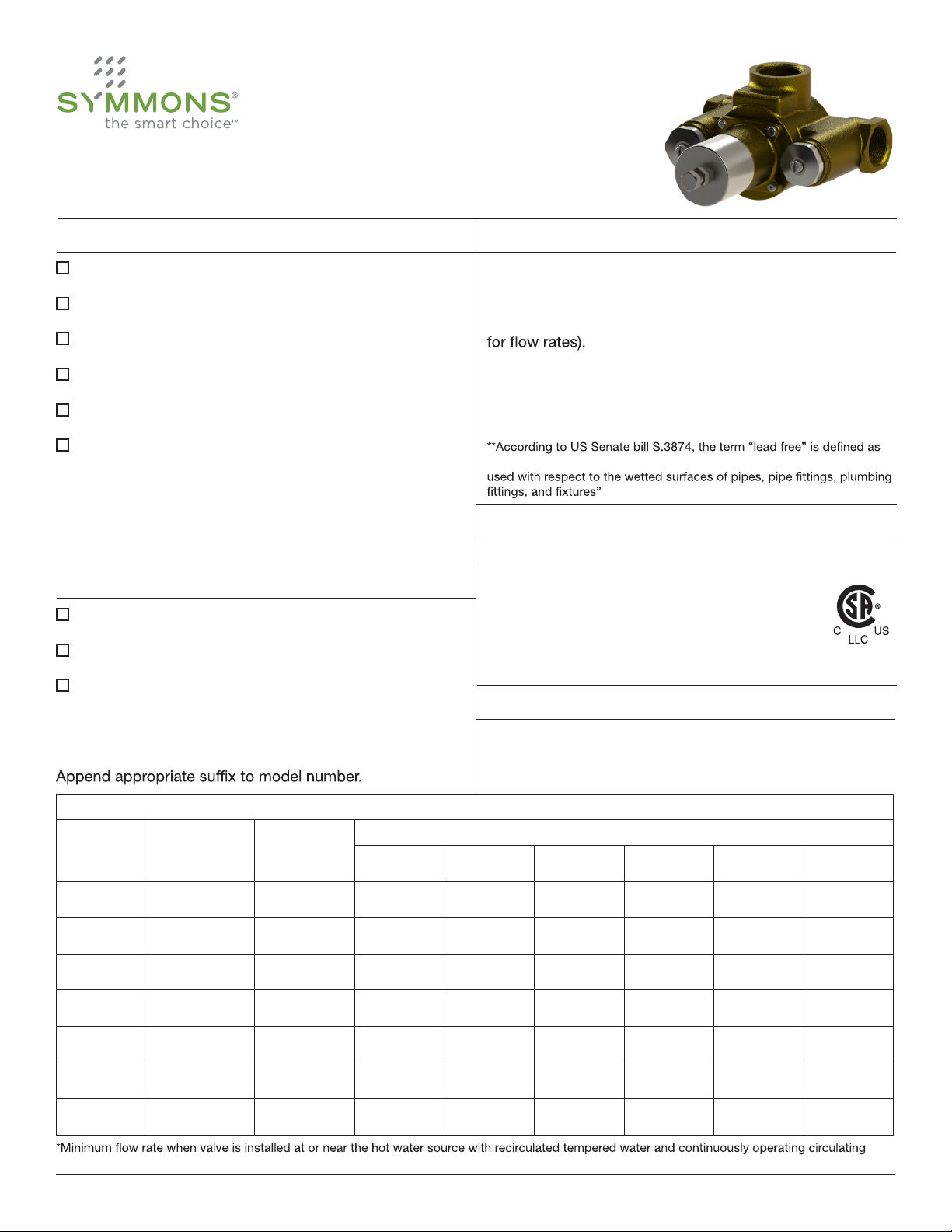

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

Coordinating Model Numbers Specification

HTA-100

T-425-( )

BV-( )

SV-( )

TF-( )

WHA-1

High temp audio/visual alarm system

3” bimetal dial thermometer

Volume control shut off valves

Solenoid valve

Tee fittings

Water hammer arrestor

Note:

Insert proper model number in parenthesis.

Configurations (Components Certified Separately)

A

B

BW

Valve and piping assembly

Valve and piping in cabinet

Valve and piping in cabinet with cold

water bypass

TempControl thermostatic mixing valve made from lead

free** metal components. Models 102-700 feature

serviceable integral check stops. Models 900 & 1000

feature removable check stops with union ells (see table 1

Temperature control range:

70°F - 150°F (21.1°C - 65.6°C)

Approach temperature: 5°F (2.8°C)

follows: “not more than a weighted average of 0.25 percent lead when

Compliance

-ASME A112.18.1/CSA B125.1

-CSA B125.3

-ASSE 1017

-CA 116875 (AB 1953)

-NSF 372

-US S.3874

Warranty

Note:

Valve Model Min. Flow Rate* Min. Flow Rate

pump.

7-102

7-200

7-400

7-500

7-700

7-900

7-1000

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

0.5 gpm

(1.9 L/min)

5 gpm

(19 L/min)

9 gpm

(34 L/min)

13 gpm

(49 L/min)

13 gpm

(49 L/min)

13 gpm

(49 L/min)

13 gpm

(49 L/min)

5 Years - for commercial installations.

Refer to www.symmons.com/warranty for complete

warranty information.

Table 1: Flow Rate - gpm (L/min)

5 psi

(34 kPa)

1 gpm

(4 L/min)

7 gpm

(27 L/min)

18 gpm

(68 L/min)

22 gpm

(83 L/min)

25 gpm

(95 L/min)

30 gpm

(114 L/min)

38 gpm

(144 L/min)

10 psi

(69 kPa)

3 gpm

(11 L/min)

12 gpm

(46 L/min)

27 gpm

(102 L/min)

38 gpm

(144 L/min)

43 gpm

(163 L/min)

55 gpm

(209 L/min)

67 gpm

(254 L/min)

Pressure Differential - psi (kPa)

20 psi

(138 kPa)

6 gpm

(23 L/min)

18 gpm

(68 L/min)

37 gpm

(140 L/min)

50 gpm

(190 L/min)

57 gpm

(216 L/min)

76 gpm

(288 L/min)

100 gpm

(379 L/min)

25 psi

(172 kPa)

7 gpm

27 L/min)

21 gpm

(80 L/min)

41 gpm

(155 L/min)

55 gpm

(209 L/min)

62 gpm

(235 L/min)

84 gpm

(318 L/min)

111 gpm

(421 L/min)

30 psi

(207 kPa)

8 gpm

(30 L/min)

23 gpm

(87 L/min)

44 gpm

(167 L/min)

59 gpm

(224 L/min)

66 gpm

(250 L/min)

89 gpm

(337 L/min)

120 gpm

(455 L/min)

45 psi

(310 kPa)

11 gpm

(42 L/min)

27 gpm

(102 L/min)

53 gpm

(201 L/min)

70 gpm

(265 L/min)

77 gpm

(292 L/min)

104 gpm

(394 L/min)

140 gpm

(531 L/min)

1

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 2

A

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

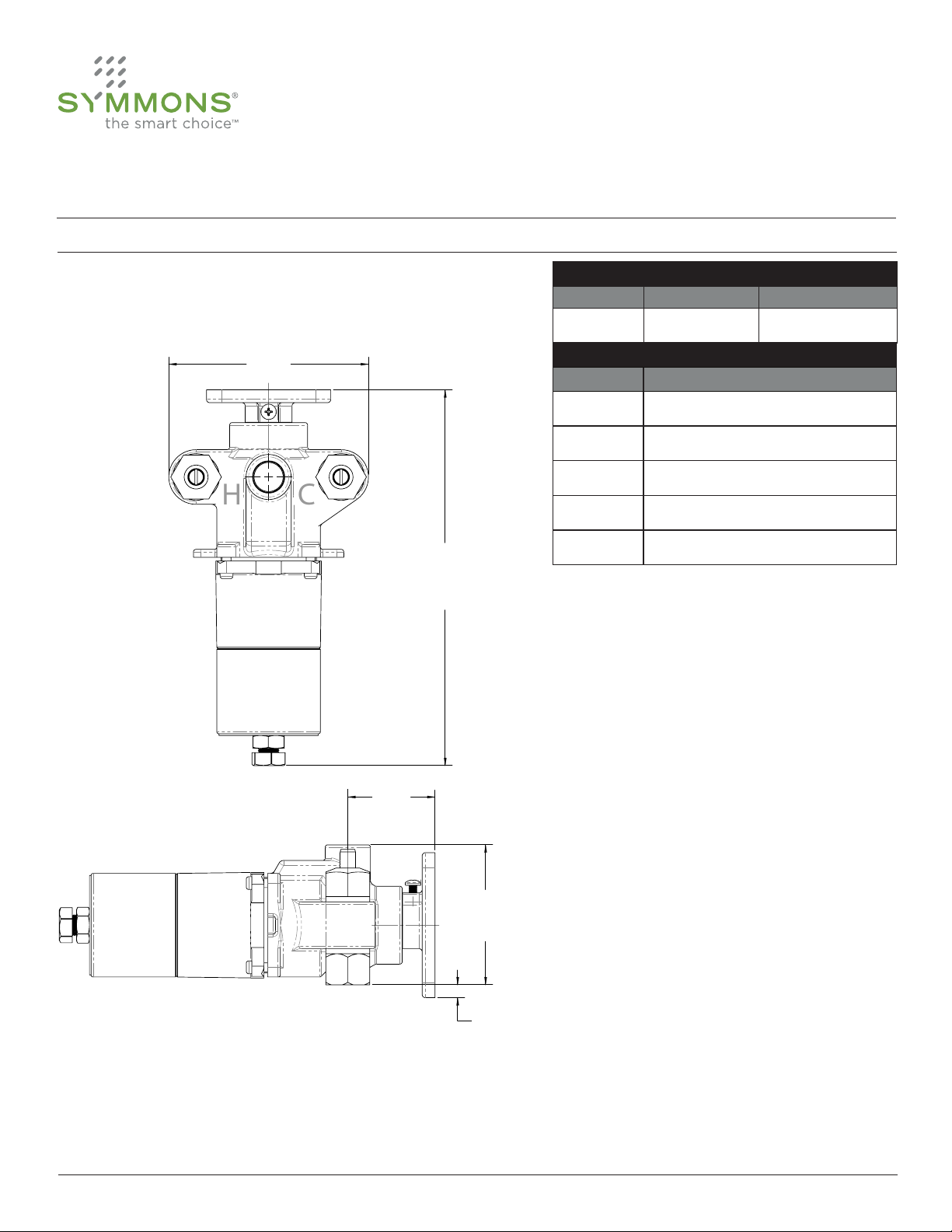

Dimensions (7-102)

Model No. Inlet Outlet

Dimension 7-102

TempControl Valve Sizes

7-102 1/2” 1/2”

Measurements

A 4 13/16”, 122 mm

B 9 1/4”, 235 mm

C 2 1/8”, 53 mm

D 3 3/8”, 86 mm

E 5/16”, 8 mm

B

C

D

Note:

1) Dimensions are subject to change without notice.

2

E

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 3

A

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

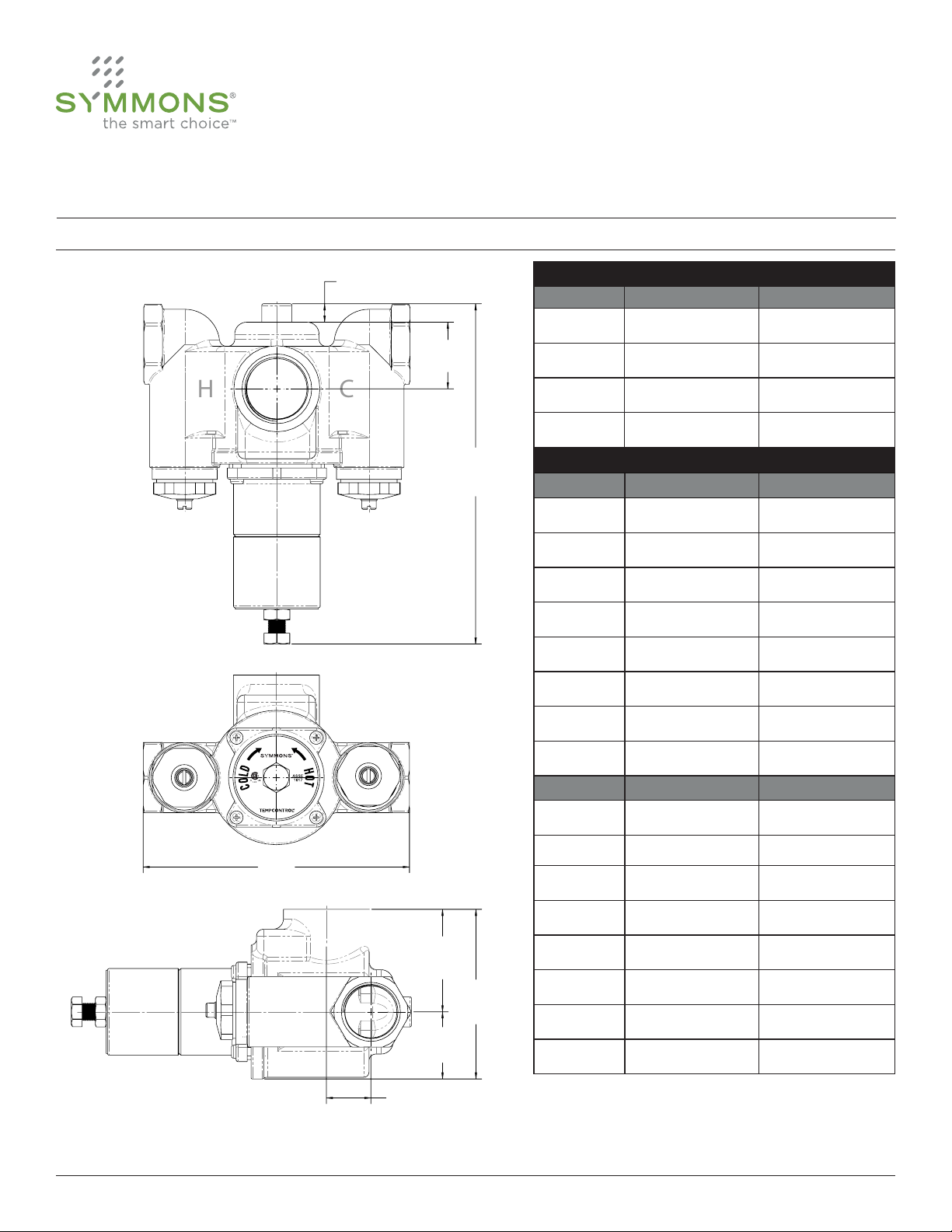

Dimensions (7-200, 7-400, 7-500, 7-700)

Model No. Inlet Outlet

7-200 3/4” 3/4”

TempControl Valve Sizes

B

C

7-400 3/4” 1”

7-500 1” 1 1/4”

7-700 1 1/4” 1 1/2”

Measurements

Dimension 7-200 7-400

A 1/2”, 13 mm 1/2”, 13 mm

B 1 7/8”, 46 mm 1 1/2”, 39 mm

C 8 15/16”, 226 mm 9 3/4”, 251 mm

D 5 15/16”, 150 mm 6 1/2”, 165 mm

E 2”, 51 mm 2 5/8”, 67 mm

F 3 5/16”, 84 mm 4 1/8”, 105 mm

G 1 5/16”, 33 mm 1 1/2”, 38 mm

H 11/16”, 17 mm 3/4”, 19 mm

Dimension 7-500 7-700

Note:

1) Dimensions are subject to change without notice.

3

A 1/2”, 13 mm 1/2”, 13 mm

B 1 15/16”, 49 mm 1 15/16 ”, 49 mm

D

E

C 9 5/8”, 248 mm 9 13/16”, 243 mm

D 7 11/16”, 195 mm 7 11/16”, 195 mm

E 2 15/16”, 75 mm 2 15/16”, 75 mm

F 4 7/8”, 124 mm 4 7/8”, 124 mm

F

G 1 15/16”, 49 mm 1 15/16”, 49 mm

G

H 1 5/16”, 33 mm 1 5/16”, 33 mm

H

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 4

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

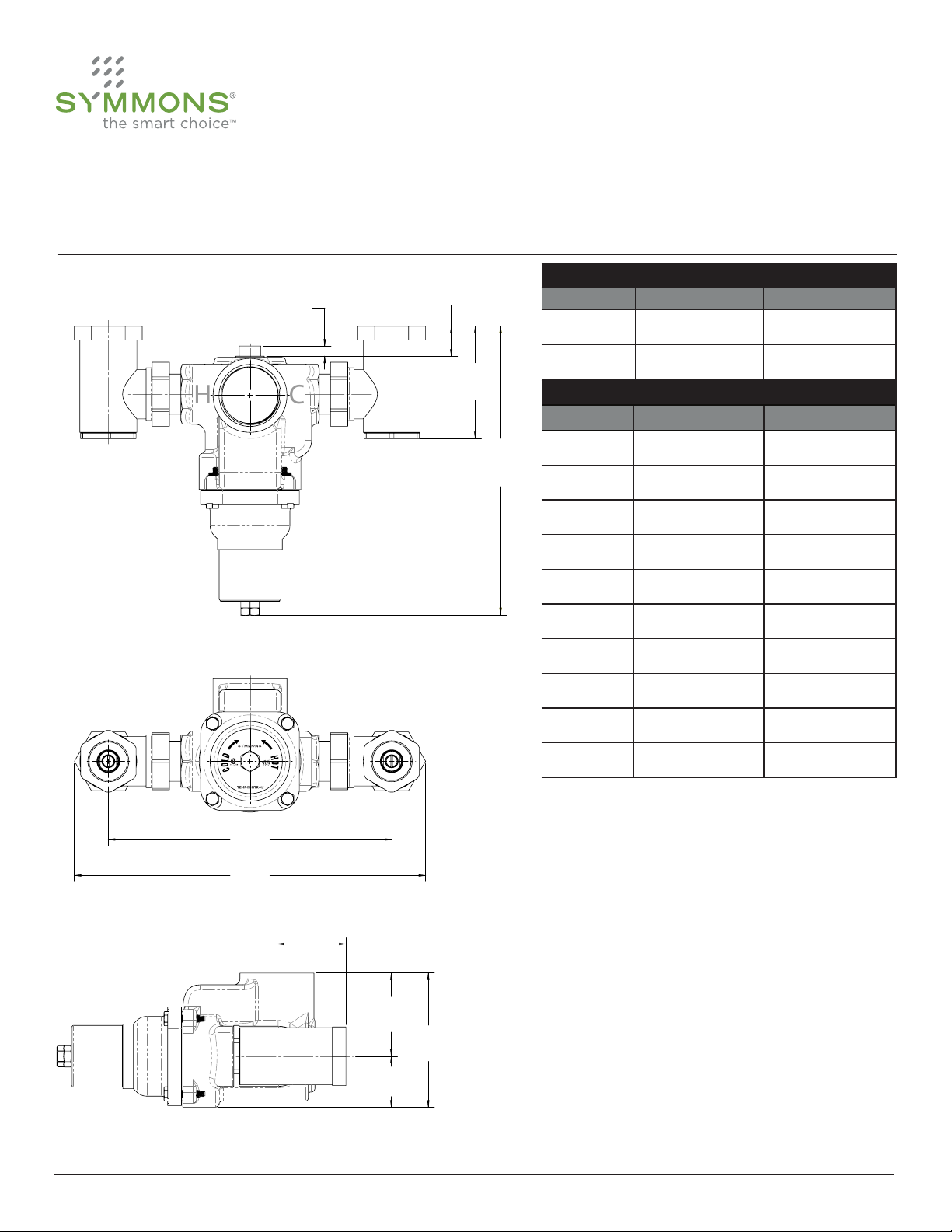

Dimensions (7-900, 7-1000)

Model No. Inlet Outlet

A B

C

Dimension 7-900 7-1000

D

TempControl Valve Sizes

7-900 1 1/2” 1 1/2”

7-1000 1 1/2” 2”

Measurements

A 7/16”, 11 mm 7/16”, 11 mm

B 1 3/16”, 31 mm 1 3/16”, 31 mm

C 4 9/16”, 116 mm 4 9/16”, 116 mm

D 11 1/6”, 280 mm 11 3/8”, 289 mm

E 11 1/2”, 296 mm 11 1/2”, 296 mm

E

F

F 14 1/4”, 365 mm 14 1/4”, 365 mm

G 2 13/16”, 71 mm 2 13/16”, 71 mm

H 3 3/8”, 86 mm 3 3/8”, 86 mm

I 5 7/16”, 138 mm 5 7/16”, 138 mm

J 2 1/16”, 52 mm 2 1/16”, 52 mm

G

H

I

Note:

1) Dimensions are subject to change without notice.

4

J

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 5

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

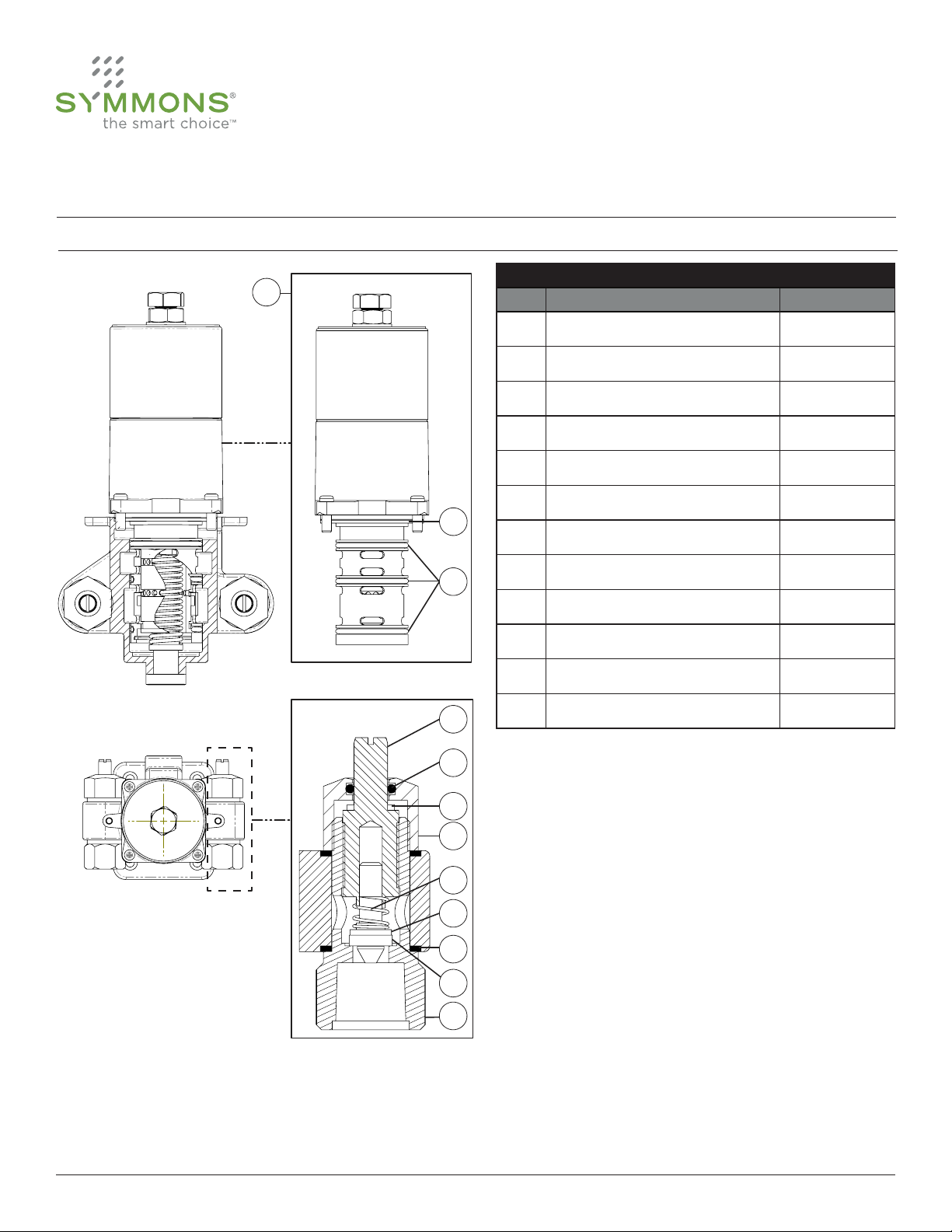

Parts Breakdown (7-102)

A

Item Description Part No.

A Valve replacement cartridge 7-102NW

B Check stop spindle CSE-35

C O-ring CE-29

D Washer CSE-31

E Check stop cap CSE-26

F Check spring CSE-34

K

G Check assembly CSE-33

Replacement Parts for Model 102

L

B

C

D

E

F

G

H

J

H Gasket (x2) CE-30

I Check stop washer CSE-32

J Check stop body with stop seat CSE-25

K Casing Gasket TT-11-100

L Sleeve o-rings (x3) TT-15-100

I

5

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 6

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

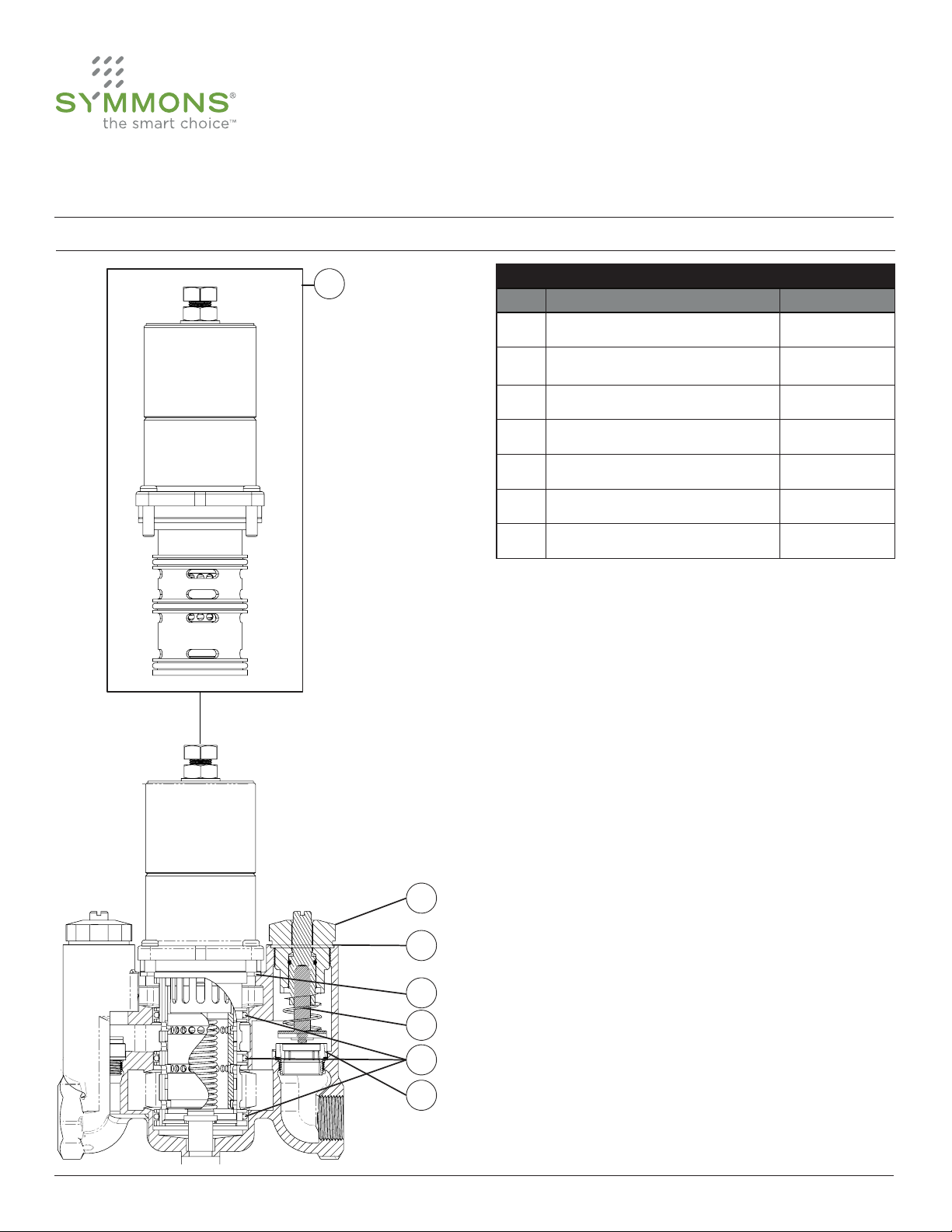

Parts Breakdown (7-200, 7-400, 7-500, 7-700)

A

Replacement Parts for Models 200-700

Item Description Part No.

A Valve replacement cartridge 7-( )NW

B

C Cap gasket TT-21-( )

D Casing gasket TT-11-( )

E Check spindle and spring TT-181-( )

F Sleeve o-rings (x3) TT-15-( )

G Check seat TT-26-( )

Notes:

1) Insert proper model number in parenthesis.

2) Item B contains cap gasket, check spring, bonnet

assembly and check assembly.

Complete replacement stop

assembly

TT-50AN-( )

B

C

D

E

F

G

6

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 7

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

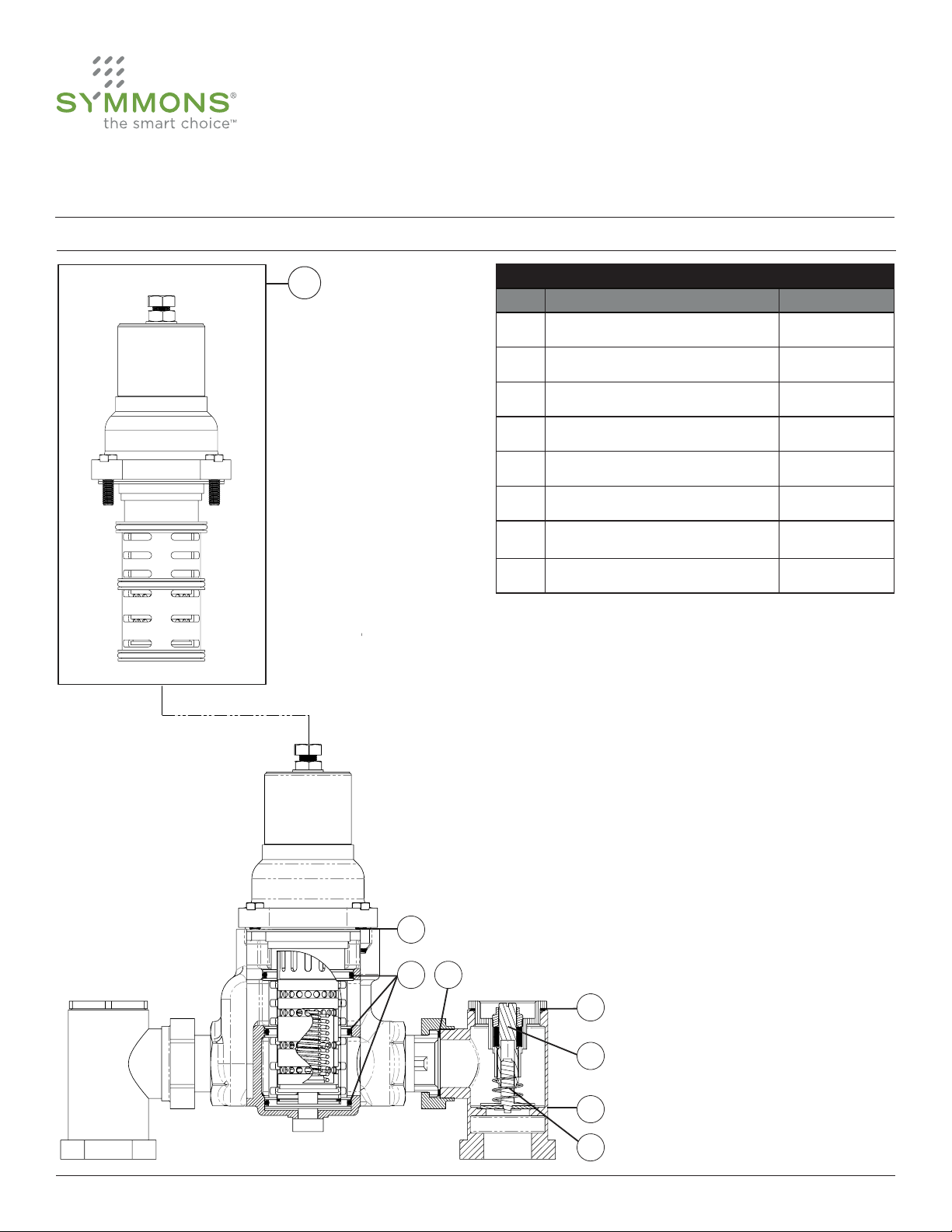

Parts Breakdown (7-900, 7-1000)

A

Replacement Parts for Model 900 & 1000

Item Description Part No.

A Valve replacement cartridge 7-( )NW

B Casing gasket TT-11-( )

C Sleeve o-rings (x3) TT-15-( )

D Gasket between stops TT-32A

E Cap gasket TT-21-( )

F Stop spindle TT-22-( )

G

H Check spindle and spring TT-200-( )

Notes:

1) Insert proper model number in parenthesis.

2) Item G contains check body, cap, check spring

and check assembly.

Complete replacement stop

body assembly

TT-27-( )

B

C

D

E

F

G

H

7

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 8

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

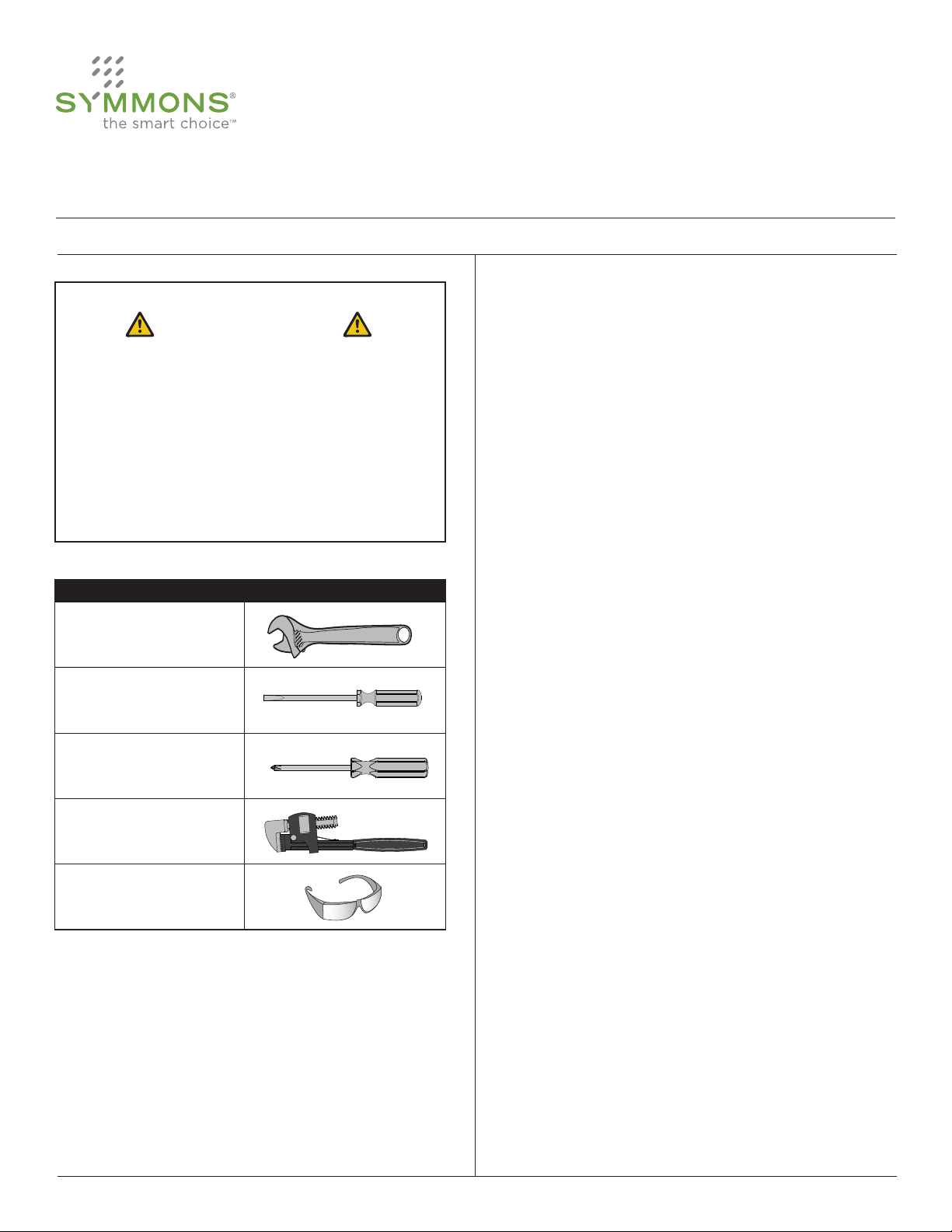

Installation

Technical Assistance and Sizing

CAUTION

When these installation, operation and service

instructions are not followed, TempControl functionality

and service life will be greatly impaired.

All TempControl installations must have a

thermometer and shut off valve in the tempered water

outlet (as shown in diagrams) for proper trouble

shooting service.

Tools Required for Installation

Adjustable wrench

Flat head screwdriver

Phillips head screwdriver

Pipe wrench

For assistance and technical support in sizing and

selection of the proper TempControl valve or system,

consult the Symmons TempSize™ computer sizing software, your local representative or Symmons

Customer Service Department at 1-800-SYMMONS.

TempControl Location

An underlying premise of thermostatic water controller

installations is an acknowledgement that thermostatic

mixing valves will not operate properly when the hot and

cold supplies serving such valves are subjected to pressure disturbances when owing less than full capacity. In

a correctly designed mechanical room, the supply pressures are stable and not subject to pressure disturbances. As a result, when a TempControl valve is indicated as

being located in the mechanical room, a Hi-Low system

will not be recommended.

When the valve’s location is indicated as being outside

of the mechanical room, it is assumed that there is a

potential for pressure uctuations in the hot and cold

supply lines servicing a TempControl valve and a HiLow system will automatically be recommended.

Note: If the system is designed so that the TempControl

valve is not subjected to high-low ow demand, even

though it is located outside the mechanical room, a

single TempControl valve will operate properly.

Safety goggles

8

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Installation Tips

All piping should be thoroughly ushed before TempControl is installed. The TempControl can be installed in any

position as long as Hot Water is connected to “H” port

and Cold Water is connected to “C” port. Close service

stops on TempControl, remove cartridge, (see page 11

for Cartridge Removal & Replacement section), turn on

water supply and open stops wide to thoroughly ush

piping before putting valve in service. TempControl is set

at factory to deliver approximately 100° F.

Page 9

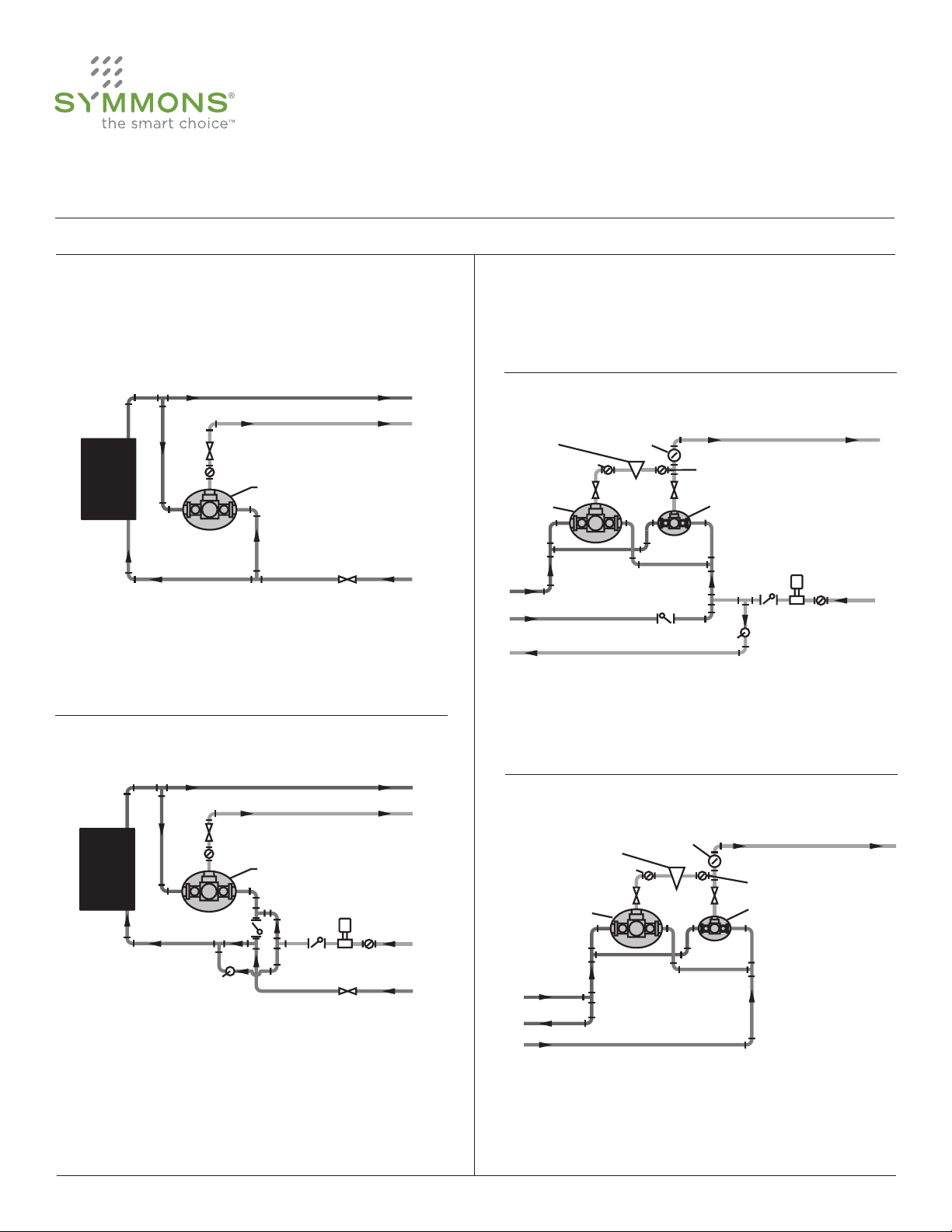

Diagram 1

Single Valve Installation at or near Hot Water Source

tempered water main hot supply to system

high temperature hot (if required for laundry, etc.)

cold supply

valve

valve

thermometer

TempControl thermostatic

water controller

hot

water

tank,

heater,

etc.

valve

Diagram 2

Single Valve Installation with Recirculating

Tempered Water at Hot Water Source

tempered water main hot supply to system

high temperature hot (if required for laundry, etc.)

tempered water return

valve

thermometer

TempControl thermostatic

water controller

hot

water

tank,

heater,

etc.

check

thermometer

circulating pump

ball valve

cold supply

check

Diagram 3

Remote HI-LOW System Installation with

Recirculating Tempered Water

tempered water to showers, lavatories, etc.

V1 valve

TMV1

V2 valve

TMV2

check

thermometer

circulating pump

ball valve

hot supply

cold supply

tempered water return to cold inlet of heater

thermometer

check

PRV valve

P1 pressure gauge

P2 pressure gauge

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

Installation

Piping Diagrams

Diagram 1 INSTALLATION AT OR NEAR THE HOT

WATER SOURCE: TempControl must be positioned

below the hot water tank or heater, well below the high

temperature water line. This procedure creates a heat

trap and protects against hot water migrating through

the controller.

plumbing system, no water can be added to the system;

therefore, the “cold” and “hot” supplies to the TempControl must come from within the system as described

below using the ball valve for ne tuning the operation

as outlined in (a) and (b).

Diagram 3 REMOTE HI-LOW INSTALLATION WITH

RECIRCULATING TEMPERED WATER OR HOT WATER

RETURN: TempControl Hi-Low system must have the

return line connected exactly as shown (See Diagram 2

notes).

Diagram 2 INSTALLATION WITH RECIRCULATING

TEMPERED WATER AT HOT WATER SOURCE: TempControl must have the return line connected exactly as

shown. This procedure allows the controller to maintain

the set temperature during periods of no draw by (a)

allowing the major volume of return water to supply the

cold inlet of the TempControl and (b) the minor volume

of return water to be reheated and supply the hot inlet of

the TempControl. When there is no water draw on the

9

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

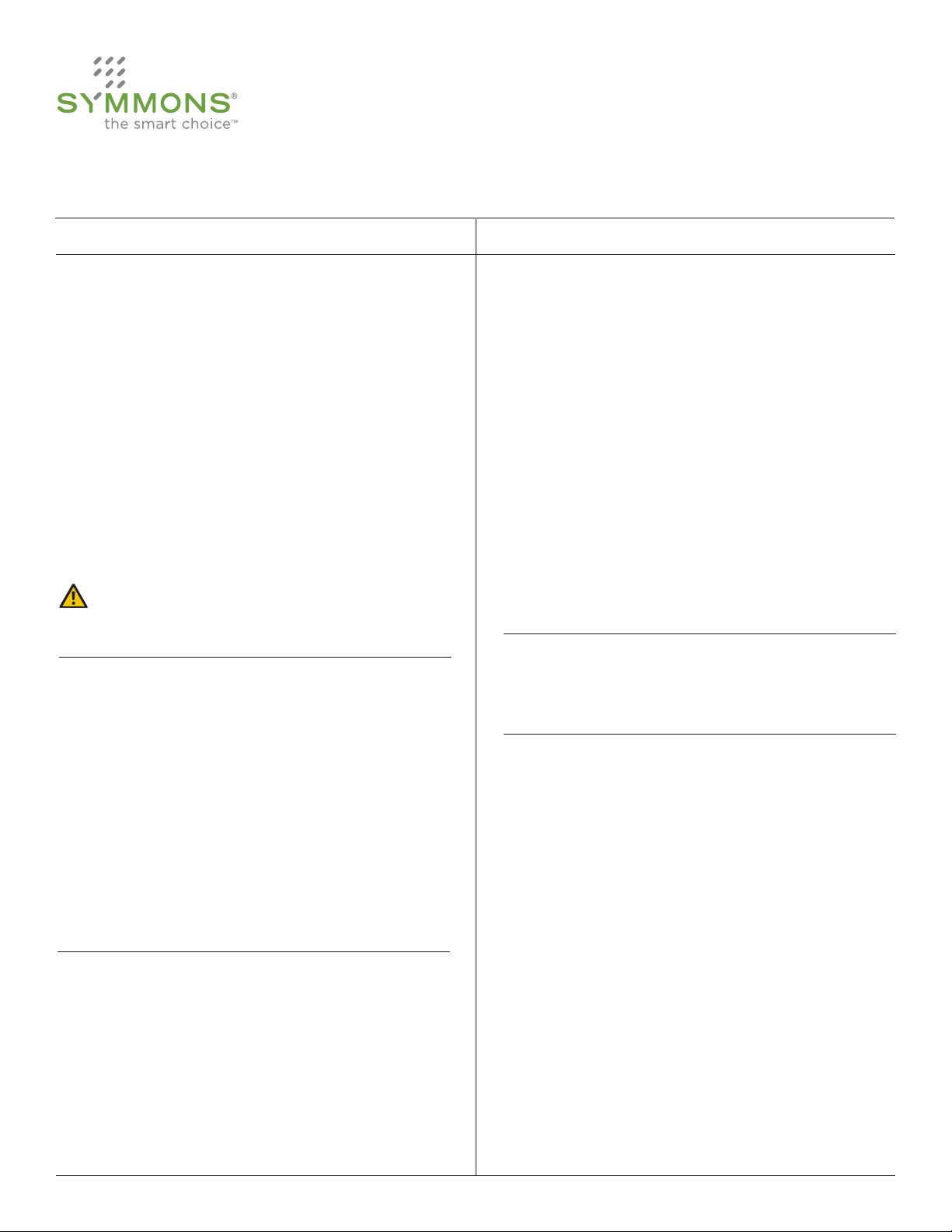

Remote HI-LOW System Installation with

Recirculating Hot Water

PRV valve

P1 pressure gauge

TMV1

hot supply

hot water return

cold supply

thermometer

V1 valve V2 valve

tempered water to showers,

lavatories, etc.

P2 pressure gauge

TMV2

Diagram 4 REMOTE HI-LOW INSTALLATION WITH

RECIRCULATING HOT WATER SUPPLY ONLY:

TempControl Hi-Low system must be piped as shown.

Diagram 4

Page 10

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

Operation & Maintenance

Operation & Adjustment

Cycle valve to full hot (counterclockwise) then cold

(clockwise) 3 full times allowing valve to reach full

temperature. With approximately 80% of the design

intent owing water, turn adjustment bolt to obtain

desired setting and lock nut in place. Thermostatic

water controllers should be sized according to the ow

capacity required from the valve, NOT the pipe size supplied to the valve. For assistance and technical support

in sizing and selection of the proper TEMPCONTROL

Thermostatic Water Controller, consult the Symmons

TEMPSIZE™ computer sizing software, your local representative or Symmons Customer Service Department at

1-800-SYMMONS.

CAUTION: Turning adjustment bolt fully counterclockwise will remove bolt from TempControl. If

this occurs simply replace bolt.

For systems piped to Diagram 2:

1. With ball valve closed, set TempControl to desired

temperature with water owing from tempered water

line.

2. After obtaining desired temperature, stop the water

ow.

3. Crack the ball valve open so that a small amount of

water is returned to the hot water source. This allows

the TempControl to maintain the set temperature

during periods of no draw on the system.

4. During no draw, observe the thermometer on the

discharge of the TempControl. If the temperature

increases above the setting in Step 1, close the ball

valve slightly or if temperature decreases, open it

slightly.

For systems piped to Diagram 3:

1. Turn off recirculating pump and close ball valve.

2. Shut off (V1).

3. Open 5 showers or equivalent to the full hot position.

4. Set small TempControl valve (TMV2) to the full cold

position and note the temperature on thermometer.

5. Shut off valve (V2) and open valve (V1). Set large

TempControl valve (TMV1) to desired system

temperature (make sure adjustment screw on PRV

valve is in the full clockwise position).

6. Shut off 2 showers or equivalent (leaving 3 still on) and open

valve (V2).

7. Turn PRV adjustment screw counter-clockwise until

temperature (T) equals that obtained in step #4.

8. Adjust TempControl valve (TMV2) to desired system

temperature and system will be in operational mode.

9. Stop the water ow, after obtaining desired temperature and turn on the recirculating pump.

Crack the ball valve open so that a small amount of

10.

water is returned to the hot water source. This allows

the TempControl to maintain the set temperature

during periods of no draw on the system.

11.

During no draw, observe the thermometer on the

discharge on the TempControl. If the temperature

increases above the setting in step #8, close the ball

valve slightly or open it if the temperature decreases.

For systems piped to Diagram 4:

Follow steps 2 through 9 for systems piped to

Diagram 3. Ignore reference to recirculating pump in

step 9 (not applicable to this installation).

Maintenance

The cartridge unit contains the entire valve control

mechanism. For non-interrupted service, keep a spare

cartridge on hand.

TempControl valve control mechanism must be kept

clean and free from deposits and any foreign matter

build-up that will be present in many water systems.

Inspect within 30 days of initial installation or operation. If inspection determines that your water system

causes deposits and foreign matter build-up monthly, then valve should be cleaned monthly as follows:

Remove cartridge (see page 11 for Cartridge Removal

& Replacement section) and soak in any acceptable

de-liming agent (or regular household vinegar). Wash off

deposits, be sure piston is moving freely in its sleeve,

and replace cartridge. Clean more frequently if your

system so demands (do not completely remove piston

from cartridge).

The Check Valves in the TempControl are highly important

10

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 11

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

Operation & Maintenance

factors in its proper operation. If chips, dirt or other foreign

materials lodge on the seats and prevent the checks from

fully seating, there may be a bypass of water into the

opposing line, and the TempControl will not operate to its

set delivery temperature. A bypass may be detected by

feeling the supply line while the TempControl is not operating. If, for example, the cold line feels hot, the cold water

check is not seating properly. It should be removed and

the check and its seat cleaned.

Cartridge Removal & Replacement

Before removing a used cartridge for cleaning, have

new casing gasket and sleeve o-rings on hand.

Shut off supplies at stop checks by turning clockwise.

Remove 4 bolts on cartridge bolt ange.

With 2 large bladed screwdrivers, pry evenly on two

opposite sides of bolt ange until cartridge is free to be

removed by hand. Pull out cartridge with a twisting and

turning action, always keeping cartridge on center line.

Leave compensating spring in position at bottom center

of valve body.

Clean cartridge as described in maintenance instructions.

Replace sleeve O-rings and grease same.

With a twisting and pushing action, replace cartridge

in valve body until bolt ange is rmly against housing

gasket.

While holding cartridge in place, replace bolts and tighten. Do not attempt to pull cartridge into position with

bolts—it will damage the valve control mechanism.

Open stops and adjust temperature.

Seasonal Use

When a TempControl is used seasonally (schools, campgrounds, golf clubs, etc.) the cartridge must be removed

and thoroughly drained of all water to prevent freeze

damage. The check stops should also be removed to

drain all water from the supply lines and valve body (see

“Cartridge Removal & Replacement”). This will prohibit

damage caused by freezing water.

11

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 12

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl 7 Series

Operation & Maintenance Manual

Trouble Shooting Chart

For Tempered Water Recirculated Systems

Problem Cause Solution

Thermometer in TempControl outlet

rises to temperature of the heater at

start of no draw (i.e. sink or

showers not running, etc.).

Hot water temperature at sink or

shower is below set point of

TempControl.

Temperature rises.

Cannot elevate or decrease

tempered water by turning

adjustment bolt.

Temperature drops during draw (sink,

shower running, etc.).

No circulation of tempered water

because return line is piped to the hot

water source only.

Sufcient circulation of tempered

water is not reaching the hot water

source.

Not piped to Diagrams 2 or 3. Ball

valve too far open.

Piston stuck with foreign matter.

Valve was set in no draw mode.

Repipe system to diagram 2 or 3

(pg. 9) which allows the discharge of

the pump (tempered water return) to

go back to the hot water source and

the cold inlet of the TempControl.

Repipe system to diagram 2 or 3

(pg. 9) which allows the discharge of

the pump (tempered water return) to

go back to the hot water source and

the cold inlet of the TempControl.

Check valve must be installed on cold

supply to controller or adjust ball valve

(see diagram 2 or 3 on page 9).

Remove cartridge and soak in

household vinegar for an hour. If

piston does not free after soaking

replace cartridge.

Run showers and sinks and then set

valve.

For Tempered Water Non-Recirculated Systems

Problem Cause Solution

Bypass, cold to hot or hot to cold. Checks not properly seating.

12

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Clean fouled checks, or if damged,

replace damaged parts.

Page 13

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Coordinación de números de modelo Especificación

HTA-100

Sistema de alarma sonora/visual de

alta temperatura

T-425-( )

BV-( )

SV-( )

TF-( )

WHA-1

Termómetro de aguja bimetálico de 3"

Válvulas de cierre para control de volumen

Válvula de solenoide

Accesorios en T

Silenciador de martillo hidráulico

Nota:

Introduzca el número de modelo adecuado entre paréntesis.

Configuraciones (Componentes certificados

por separado)

A

B

BW

Conjunto de válvula y tuberías

Válvula y tuberías en gabinete

Válvula y tuberías en gabinete

con derivación de agua fría

Válvula mezcladora termostática TempControl fabricada con

componentes metálicos libres de plomo**. Los modelos 102700 ofrecen válvulas antirretorno integrales con capacidad

de mantenimiento. Los modelos 900 y 1000 cuentan con

válvulas antirretorno extraíble con celdas de unión

Rango de control de temperatura:

70 °F - 150 °F (21,1 °C - 65,6 °C)

Temperatura de enfoque: 5 °F (2,8 °C)

que un promedio ponderado de 0,25 por ciento de plomo cuando se

de tubería, accesorios de fontanería y artefactos”

Cumplimiento

-ASME A112.18.1/CSA B125.1

-CSA B125.3

-ASSE 1017

-CA 116875 (AB 1953)

-NSF 372

-US S.3874

Garantía

Nota:

Modelo de

válvula

7-102

7-200

7-400

7-500

7-700

7-900

7-1000

circulación de funcionamiento continuo.

13

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

0.5 gpm

(1,9 L/min)

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

0.5 gpm

(1,9 L/min)

5 gpm

(19 L/min)

9 gpm

(34 L/min)

13 gpm

(49 L/min)

13 gpm

(49 L/min)

13 gpm

(49 L/min)

13 gpm

(49 L/min)

5 psi

(34 kPa)

1 gpm

(4 L/min)

7 gpm

(27 L/min)

18 gpm

(68 L/min)

22 gpm

(83 L/min)

25 gpm

(95 L/min)

30 gpm

(114 L/min)

38 gpm

(144 L/min)

5 años - para instalaciones comerciales.

Consulte www.symmons.com/warranty para obtener

información completa sobre la garantía.

Diferencial de presión - psi (kPa)

10 psi

(69 kPa)

3 gpm

(11 L/min)

12 gpm

(46 L/min)

27 gpm

(102 L/min)

38 gpm

(144 L/min)

43 gpm

(163 L/min)

55 gpm

(209 L/min)

67 gpm

(254 L/min)

20 psi

(138 kPa)

6 gpm

(23 L/min)

18 gpm

(68 L/min)

37 gpm

(140 L/min)

50 gpm

(190 L/min)

57 gpm

(216 L/min)

76 gpm

(288 L/min)

100 gpm

(379 L/min)

25 psi

(172 kPa)

7 gpm

27 L/min)

21 gpm

(80 L/min)

41 gpm

(155 L/min)

55 gpm

(209 L/min)

62 gpm

(235 L/min)

84 gpm

(318 L/min)

111 gpm

(421 L/min)

30 psi

(207 kPa)

8 gpm

(30 L/min)

23 gpm

(87 L/min)

44 gpm

(167 L/min)

59 gpm

(224 L/min)

66 gpm

(250 L/min)

89 gpm

(337 L/min)

120 gpm

(455 L/min)

45 psi

(310 kPa)

11 gpm

(42 L/min)

27 gpm

(102 L/min)

53 gpm

(201 L/min)

70 gpm

(265 L/min)

77 gpm

(292 L/min)

104 gpm

(394 L/min)

140 gpm

(531 L/min)

Page 14

A

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Dimensiones (7-102)

Dimensión 7-102

B

Tamaños de la válvula TempControl

N.° de

modelo

7-102 1/2” 1/2”

A 4 13/16”, 122 mm

B 9 1/4”, 235 mm

C 2 1/8”, 53 mm

D 3 3/8”, 86 mm

E 5/16”, 8 mm

Entrada Salida

Medidas

Nota:

1) Las dimensiones pueden cambiar sin previo aviso.

14

C

D

E

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 15

A

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Dimensiones (7-200, 7-400, 7-500, 7-700)

N.° de

modelo

7-200 3/4” 3/4”

B

7-400 3/4” 1”

7-500 1” 1 1/4”

7-700 1 1/4” 1 1/2”

Tamaños de la válvula TempControl

Entrada Salida

D

C

Medidas

Dimensión 7-200 7-400

A 1/2”, 13 mm 1/2”, 13 mm

B 1 7/8”, 46 mm 1 1/2”, 39 mm

C 8 15/16”, 226 mm 9 3/4”, 251 mm

D 5 15/16”, 150 mm 6 1/2”, 165 mm

E 2”, 51 mm 2 5/8”, 67 mm

F 3 5/16”, 84 mm 4 1/8”, 105 mm

G 1 5/16”, 33 mm 1 1/2”, 38 mm

H 11/16”, 17 mm 3/4”, 19 mm

Dimensión 7-500 7-700

A 1/2”, 13 mm 1/2”, 13 mm

B 1 15/16”, 49 mm 1 15/16”, 49 mm

C 9 5/8”, 248 mm 9 13/16”, 243 mm

Nota:

1) Las dimensiones pueden cambiar sin previo aviso.

15

D 7 11/16”, 195 mm 7 11/16”, 195 mm

E

F

G

E 2 15/16”, 75 mm 2 15/16”, 75 mm

F 4 7/8”, 124 mm 4 7/8”, 124 mm

G 1 15/16”, 49 mm 1 15/16”, 49 mm

H 1 5/16”, 33 mm 1 5/16”, 33 mm

H

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 16

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Dimensiones (7-900, 7-1000)

A B

Tamaños de la válvula TempControl

N.° de

modelo

7-900 1 1/2” 1 1/2”

Entrada Salida

C

D

7-1000 1 1/2” 2”

Medidas

Dimensión 7-900 7-1000

A 7/16”, 11 mm 7/16”, 11 mm

B 1 3/16”, 31 mm 1 3/16”, 31 mm

C 4 9/16”, 116 mm 4 9/16”, 116 mm

D 11 1/6”, 280 mm 11 3/8”, 289 mm

E 11 1/2”, 296 mm 11 1/2”, 296 mm

F 14 1/4”, 365 mm 14 1/4”, 365 mm

G 2 13/16”, 71 mm 2 13/16”, 71 mm

H 3 3/8”, 86 mm 3 3/8”, 86 mm

I 5 7/16”, 138 mm 5 7/16”, 138 mm

J 2 1/16”, 52 mm 2 1/16”, 52 mm

Nota:

1) Las dimensiones pueden cambiar sin previo aviso.

16

E

F

G

H

I

J

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 17

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Desglose de partes (7-102)

A

Artículo Descripción N.° de parte

A

B Eje de la válvula antirretorno CSE-35

C Anillo de goma CE-29

D Arandela CSE-31

Repuestos para el modelo 102

Reemplazo del cartucho

de la válvula

7-102NW

K

L

B

C

D

E

E

F Resorte antirretorno CSE-34

G Ensamblaje antirretorno CSE-33

H Junta de estanqueidad (x2) CE-30

I

J

K

L

Tapa de la válvula

antirretorno

Arandela de la válvula

antirretorno

Cuerpo de la válvula

antirretorno con asiento

de retención

Junta de estanqueidad

de la carcasa

Anillos de goma de

manguito (x3)

CSE-26

CSE-32

CSE-25

TT-11-100

TT-15-100

F

17

G

H

I

J

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 18

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Desglose de partes (7-200, 7-400, 7-500, 7-700)

A

Repuestos para modelos 200-700

Artículo Descripción N.° de parte

A

B

C

D

E Eje y resorte antirretorno TT-181-( )

F

G Asiento antirretorno TT-26-( )

Notas:

1) Introduzca el número de modelo adecuado

entre paréntesis.

2) El Artículo B contiene la junta de estanqueidad de la

tapa, el resorte antirretorno, ensamblaje de bonete

y ensamblaje antirretorno.

Reemplazo del cartucho

de la válvula

Repuesto del ensamblaje

de retención completo

Junta de estanqueidad

de la tapa

Junta de estanqueidad

de la carcasa

Anillos de goma de

manguito (x3)

7-( )NW

TT-50AN-( )

TT-21-( )

TT-11-( )

TT-15-( )

18

B

C

D

E

F

G

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 19

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Desglose de partes (7-900, 7-1000)

A

Repuestos para los modelos 900 y 1000

Artículo Descripción N.° de parte

A

B

C

D

E

F Eje de retención TT-22-( )

G

H Eje y resorte antirretorno TT-200-( )

Notas:

1) I ntroduzca el número de modelo adecuado

entre paréntesis.

2) El Artículo G contiene cuerpo antirretorno, tapa, resorte

antirretorno y ensamblaje antirretorno.

Reemplazo del cartucho

de la válvula

Junta de estanqueidad

de la carcasa

Anillos de goma de

manguito (x3)

Junta de estanqueidad

entre retenciones

Junta de estanqueidad

de la tapa

Repuesto del ensamblaje

de cuerpo de retención

completo

7-( )NW

TT-11-( )

TT-15-( )

TT-32A

TT-21-( )

TT-27-( )

19

B

C

D

E

F

G

H

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 20

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Instalación

Asistencia técnica y dimensionamiento

PRECAUCIÓN

Si no se siguen estas instrucciones de instalación,

operación y servicio, la funcionalidad y la vida útil de

TempControl se deteriorarán considerablemente.

Todas las instalaciones de TempControl deben tener

un termómetro y válvula de cierre en la salida de agua

templada (como se muestra en los diagramas) para el

servicio adecuado de resolución de problemas.

Herramientas necesarias para la instalación

Llave regulable

Destornillador plano

Destornillador Phillips

Para obtener ayuda y soporte técnico en el

dimensionamiento y selección de la válvula o sistema

TempControl adecuado, consulte el software de

dimensionamiento informático TempSize™, a su

representante local o al departamento de Atención al

cliente de Symmons al 1-800-SYMMONS.

Ubicación de TempControl

Un principio fundamental de las instalaciones de controlador

de agua termostático es un reconocimiento de que las

válvulas mezcladoras termostáticas no funcionarán

correctamente cuando los suministros de agua caliente y

fría que sirven a estas válvulas se someten a perturbaciones

de presión cuando cuentan con tasas de ujo menores

a su capacidad total. En una sala de máquinas diseñada

correctamente, las presiones de suministro son estables y no

están sujetas a perturbaciones de presión. Como resultado,

cuando se indica la ubicación de una válvula TempControl en

el cuarto de máquinas, no se recomienda un sistema Hi-Low.

Cuando la ubicación de la válvula se indica fuera de la

sala de máquinas, se supone que existe una posibilidad

de uctuaciones de presión en las líneas de suministro

de agua caliente y fría que prestan servicio a una válvula

TempControl y se recomienda automáticamente un

sistema Hi-Low.

20

Llave de tubo

Gafas de seguridad

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Nota: Si el sistema está diseñado de manera que la

válvula TempControl no está sometida a una demanda

alta-baja de ujo, a pesar de que se encuentre

ubicada fuera de la sala de máquinas, una sola válvula

TempControl funcionará correctamente.

Consejos para la instalación

Todas las tuberías deben limpiarse a fondo antes de instalar

TempControl. La TempControl se puede instalar en cualquier

posición, siempre y cuando el agua caliente está conectado

al puerto “H” y el agua fría esté conectada al puerto “C”.

Cierre las válvulas antirretorno en TempControl, extraiga

el cartucho, (ver página 11 para consultar la sección

Extracción y reemplazo de cartucho), active el suministro

de agua y abra las válvulas antirretorno completamente

para limpiar a fondo las tuberías antes de poner la válvula en

servicio. TempControl cuenta con conguración de fábrica

para entregar aproximadamente 100° F (38 °C).

Page 21

Diagrama 1

Instalación de una sola válvula en

o cerca de la fuente de agua caliente

suministro principal de agua caliente

templada al sistema

agua caliente a alta temperatura

(si fuese necesaria para lavaderos, etc.)

suministro

de agua fría

válvula

válvula

termómetro

Controlador de agua

termostático TempControl

tanque

de agua

caliente,

calentador,

etc.

válvula

Diagrama 2

Instalación de una sola válvula con recirculación

de agua templada en la fuente de agua caliente

suministro principal de agua caliente

templada al sistema

agua caliente a alta temperatura

(si fuese necesaria para lavaderos, etc.)

retorno de agua templada

válvula

termómetro

Controlador de agua

termostático TempControl

tanque

de agua

caliente,

calentador,

etc.

válvula

de

retención

termómetro

bomba de circulación

válvula esférica

suministro

de agua fría

válvula de retención

Diagrama 3

Instalación de sistema HI-LOW remoto

con recirculación de agua templada

agua templada para duchas, lavatorios, etc.

Válvula V1

TMV1

Válvula V2

TMV2

termómetro

bomba de circulación

válvula esférica

suministro de

agua caliente

suministro de

agua fría

retorno de agua templada a la entrada de agua fría del calentador

termómetro

válvula

de retención

válvula

de retención

válvula PRV

manómetro P1

manómetro P2

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Instalación

para el suministro de la entrada de agua caliente de

Diagramas de tuberías

Diagrama 1 INSTALACIÓN EN O CERCA DE LA FUENTE

DE AGUA CALIENTE: TempControl debe colocarse

debajo del tanque de agua caliente o calentador, muy

por debajo de la línea de agua de alta temperatura. Este

procedimiento crea una trampa de calor y protege contra

la migración de agua caliente a través del controlador.

la TempControl. Cuando no hay drenaje de agua en

el sistema de tuberías, no se puede añadir agua al

sistema, por lo tanto, los suministros de agua “fría”

y “caliente” a la TempControl deben provenir desde

adentro del sistema como se describe a continuación,

utilizando la válvula esférica para un ajuste no de la

operación como se indica en (a) y (b).

Diagrama 2 INSTALACIÓN CON RECIRCULACION DE

AGUA TEMPLADA EN LA FUENTE DE AGUA CALIENTE:

TempControl debe tener la línea de retorno conectada

exactamente como se muestra. Este procedimiento

permite que el controlador mantenga la temperatura

de consigna durante períodos sin drenaje permitiendo

ya sea (a) el mayor volumen de agua de retorno para el

suministro de la entrada de agua fría de la TempControl y

(b) que el volumen menor de agua de retorno se recaliente

21

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Diagrama 3 INSTALACIÓN DE HI-LOW REMOTO CON

RECIRCULACION DE AGUA TEMPLADA O RETORNO

DE AGUA CALIENTE: El sistema Hi-Low de TempControl

debe tener la línea de retorno conectada exactamente

como se muestra (Ver las notas del Diagrama 2).

termómetro

Diagrama 4

agua templada para duchas,

lavatorios, etc

manómetro P2

TMV2

Instalación de sistema HI-LOW remoto

con recirculación de agua caliente

válvula PRV

manómetro P1

Válvula V1 Válvula V2

TMV1

suministro de

agua caliente

retorno de agua caliente

suministro de agua fría

Diagrama 4 INSTALACIÓN DE HI-LOW REMOTO

CON RECIRCULACION DE AGUA CALIENTE

ÚNICAMENTE: Las tuberías del sistema Hi-Low de

TempControl debe estar conectadas como se muestra.

Page 22

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Funcionamiento y mantenimiento

Funcionamiento y ajuste

Aplique un ciclo de válvula de caliente (sinistrórsum)

completo y luego frío (dextrorso) 3 veces permitiendo

que la válvula alcance la temperatura completa. Con

aproximadamente el 80% del agua uyendo de la intención

del diseño, gire el perno de regulación para obtener el ajuste

deseado y bloquee la tuerca en su lugar. Los controladores

de agua termostáticos deben tener un tamaño acorde a la

capacidad de ujo requerida de la válvula, NO el tamaño

de la tubería suministrada a la válvula. Para obtener ayuda

y soporte técnico en el dimensionamiento y selección

del controlador de agua termostático TEMPCONTROL

adecuado, consulte el software de dimensionamiento

informático TEMPSIZE™ de Symmons, a su representante

local o al departamento de Atención al cliente de Symmons

al 1-800-SYMMONS.

PRECAUCIÓN: Girar el perno de regulación totalmente

a la izquierda extraerá el perno de la TempControl.

Si esto ocurre, simplemente reemplace perno.

En el caso de sistemas conectados mediante tuberías al

Diagrama 2:

1. Con la válvula esférica cerrada, regule la TempControl

a la temperatura deseada con agua uyendo desde la

línea de agua templada.

2. Después de obtener la temperatura deseada, detenga

el ujo de agua.

3. Abra la válvula esférica completamente de modo que

una pequeña cantidad de agua retorne a la fuente

de agua caliente. Esto permite que la TempControl

mantenga la temperatura de consigna durante períodos

sin drenaje en el sistema.

4. Durante los períodos sin drenaje, observe el

termómetro en la descarga de la TempControl. Si la

temperatura aumenta por encima de la conguración

en el paso 1, cierre la válvula esférica ligeramente o si

la temperatura disminuye, ábrala levemente.

En el caso de sistemas conectados mediante tuberías al

Diagrama 3:

1. Apague la bomba de recirculación y cierre la

válvula esférica.

2. Cierre (V1).

3. Abra 5 duchas o equivalente a la posición de calor máximo.

4. Coloque la válvula TempControl pequeña (TMV2) a la

posición de frío máximo y anote la temperatura en

el termómetro.

5. Cierre la válvula (V2) y abra la válvula (V1). Regule la

válvula TempControl grande (TMV1) a la temperatura

deseada del sistema (asegúrese que el tornillo de

ajuste en la válvula PRV se encuentra en la posición

hacia la derecha por completo).

6. Apague 2 duchas o el equivalente (dejando 3 encendidas)

y la válvula abierta (V2).

7. Gire el tornillo de ajuste del PRV hacia la izquierda hasta

que la temperatura (T) sea igual a la obtenida en el paso 4.

8. Ajuste la válvula TempControl (TMV2) a la temperatura

deseada del sistema y el sistema estará en modo

de funcionamiento.

9. Detenga el ujo de agua, después de obtener

la temperatura deseada y encienda la bomba

de recirculación.

10. Abra la válvula esférica completamente de modo que

una pequeña cantidad de agua retorne a la fuente

de agua caliente. Esto permite que la TempControl

mantenga la temperatura de consigna durante

períodos sin drenaje en el sistema.

11. Durante los períodos sin drenaje, observe el

termómetro en la descarga de la TempControl. Si la

temperatura aumenta por encima de la conguración

en el paso 8, cierre la válvula esférica ligeramente o

ábrala si la temperatura disminuye.

En el caso de sistemas conectados mediante tuberías

al Diagrama 4:

Siga los pasos 2 a 9 para los sistemas conectados

mediante tuberías al Diagrama 3. Ignore la referencia

a la bomba de recirculación en el paso 9 (no aplicable

a esta instalación).

Mantenimiento

La unidad de cartucho contiene todo el mecanismo

de control de la válvula. En el caso de servicio sin

interrupción, tenga un cartucho de repuesto a mano.

El mecanismo de control de la válvula TempControl

debe mantenerse limpio y libre de depósitos y cualquier

acumulación de material extraño que estará presente

en muchos sistemas de agua. Inspeccione dentro

de los 30 días de la instalación o el funcionamiento

inicial. Si la inspección determina que el sistema de

agua causa depósitos y acumulación mensual de

materiales extraños, entonces la válvula se debe limpiar

mensualmente de la siguiente manera: Quite el cartucho

(ver la página 11 para consultar la sección de Extracción

y reemplazo del cartucho) y remoje en cualquier agente

de-encalado aceptable (o vinagre de cocina común).

Lave los depósitos, asegúrese de que el pistón se mueve

libremente en el manguito y reemplace el cartucho.

Limpie con mayor frecuencia si el sistema así lo exige (no

extraiga completamente el pistón del cartucho).

Las válvulas de retención en la TempControl son

muy importantes

22

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 23

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Funcionamiento y mantenimiento

factores que inuyen en su correcto funcionamiento. Si se

alojan virutas, suciedad u otros materiales extraños sobre los

asientos y evitan que las válvulas de retención se asienten

totalmente, puede ser una derivación de agua en la línea

opuesta, y la TempControl no funcionará a su temperatura

de suministro establecida. Una derivación se puede detectar

mediante el tacto sobre la línea de suministro, mientras que

la TempControl no está funcionando. Si, por ejemplo, la línea

fría se siente caliente, la válvula de retención del agua fría

no se está asentando correctamente. Se debe extraer y la

válvula de retención y su asiento se deben limpiarse.

Extracción y reemplazo del cartucho

Antes de extraer un cartucho usado para su limpieza,

tenga una junta de estanqueidad de la carcasa y anillos

de goma del manguito nuevos a la mano.

Cierre los suministros en las válvulas antirretorno

girándolas hacia la derecha.

Retire los 4 pernos de la brida del cartucho.

Con 2 destornilladores de puntas grandes, levante

uniformemente dos lados opuestos de la brida de pernos

hasta que se libere el cartucho para extraerlo a mano.

Tire del cartucho con una acción de torsión y giro,

manteniendo siempre cartucho en la línea central.

Deje un resorte de compensación en el lugar en la parte

central inferior del cuerpo de la válvula.

Limpie el cartucho como se describe en las instrucciones

de mantenimiento.

Reemplace los anillos de goma del manguito y engráselos.

Con una acción de torsión y empuje, vuelva a colocar el

cartucho en el cuerpo de la válvula hasta que la brida de

pernos se encuentre rmemente sobre la junta de la carcasa.

Mientras mantiene el cartucho en su lugar, vuelva a

colocar los pernos y apriete. No intente colocar el

cartucho en su posición con pernos, ya que esto puede

dañar el mecanismo de control de la válvula.

Abra las válvulas antirretorno y regule la temperatura.

Uso estacional

Cuando una TempControl se utiliza estacionalmente

(escuelas, campamentos, campos de golf, etc.), el cartucho

se debe extraer y drenar bien de cualquier volumen de

agua para evitar daños por congelación. Las válvulas

antirretorno también se deben extraer para drenar toda el

agua de las tuberías de suministro y el cuerpo de la válvula

(ver la sección “Extracción y reemplazo del cartucho”). Así,

se evitará el daño causado por la congelación del agua.

23

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 24

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Serie 7

Manual de funcionamiento y mantenimiento

Tabla de solución de problemas

Para sistemas de recirculación de agua templada

Problema Causa Solución

El termómetro en la salida de

TempControl se eleva a la temperatura

del calentador al comienzo de sin

drenaje (es decir, ni el lavabo ni las

duchas están funcionando, etc.).

La temperatura del agua caliente en el

lavabo o la ducha está por debajo del

punto de TempControl establecido.

La temperatura se eleva.

No se puede elevar o disminuir el

agua templada girando el perno de

regulación.

La temperatura baja durante el

drenaje (lavabo, ducha corriendo, etc.)

No hay circulación de agua templada

porque la línea de retorno se

conecta únicamente a la fuente

de agua caliente.

La circulación suciente de agua

templada no llega a la fuente de

agua caliente.

No está conectado mediante tuberías

al diagrama 2 o 3. La válvula esférica

está demasiado abierta.

Pistón atascado con material extraño.

La válvula se conguró en modo

sin drenaje.

Vuelva a conectar el sistema mediante

tuberías al diagrama 2 o 3 (pág. 9),

lo que permite que la descarga de la

bomba (retorno del agua templada)

vuelva a la fuente de agua caliente y la

entrada de agua fría de la TempControl.

Vuelva a conectar el sistema mediante

tuberías al diagrama 2 o 3 (pág. 9),

lo que permite que la descarga de la

bomba (retorno del agua templada)

vuelva a la fuente de agua caliente y la

entrada de agua fría de la TempControl.

La válvula de retención debe instalarse

en el suministro de agua fría al

controlador o regular la válvula esférica

(ver el diagrama 2 o 3 en la página 9).

Extraiga el cartucho y remoje en

vinagre de cocina durante una hora.

Si el pistón no se libera después de la

inmersión, reemplace el cartucho.

Haga funcionar duchas y lavabos,

y luego congure la válvula.

Para sistemas sin recirculación de agua templada

Problema Causa Solución

24

Derivación, fría a caliente

o caliente a fría.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Las válvulas de retención no se

asientan correctamente.

Limpie las válvulas de retención

sucias o, si están averiadas,

reemplace las piezas dañadas.

Page 25

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Numéros de modèle Spécification

HTA-100

Système d’alarme audio/vidéo

à température élevée

T-425-( )

BV-( )

SV-( )

TF-( )

WHA-1

Thermomètre à numérotation bimé-

Vannes d’arrêt du contrôle du volume

Vanne solénoïde

Raccords en T

Dispositifs antibélier

Insérez le numéro de modèle approprié entre parenthèse.

Configurations (Composants certifiés séparément)

A

B

BW

Vanne et assemblage de raccords

Vanne et raccord dans le cabinet

Vanne et raccord dans le cabinet avec

système de déviation pour l’eau froide

Vanne mixte en thermoplastique TempControl faite à partir

de composants en métal sans plomb. Modèles 102-700

avec arrêts de retenue intégraux utilisables. Les modèles

900 et 1000 sont dotés de dispositifs d’arrêt anti-retour

amovibles avec des

-

lorsqu’utilisé avec des surfaces de tuyaux, raccords de tuyau, raccords

Conformité

-ASME A112.18.1/CSA B125.1

-CSA B125.3

-ASSE 1017

-CA 116875 (AB 1953)

-NSF 372

-US S.3874

Garantie

- pour les installations commerciales.

Se référer au www.symmons.com/warranty pour les

renseignements complets relatifs à la garantie.

Modèle de la

vanne

7-102

7-200

7-400

7-500

7-700

7-900

7-1000

*Débit minimal lorsque la vanne est installée à la source d’eau chaude ou à proximité de celle-ci avec de l’eau modérée recirculé et faisant fonctionner

en continu la pompe de circulation.

Débit min.* Débit min.*

Différentiel de pression - psi (kPa)

104 gpm

25

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 26

A

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Dimensions (7-102)

N° de mo-

Dimension 7-102

Dimensions des vannes TempControl

dèle

7-102 1/2po 1/2po

A 413/16po, 122mm

B 91/4po, 235mm

C 21/8po, 53mm

Entrée Sortie

Mesures

C

B

D 33/8po, 86mm

E 5/16po, 8mm

D

Remarque:

1) Les dimensions sont sujettes à changer sans préavis.

26

E

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 27

A

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Dimensions (7-200, 7-400, 7-500, 7-700)

N° de mo-

7-200 3/4po 3/4po

B

7-400 3/4po 1po

7-500 1po 11/4po

7-700 11/4po 11/2po

Dimensions des vannes TempControl

dèle

Entrée Sortie

D

H

Remarque:

1) Les dimensions sont sujettes à changer sans préavis.

E

G

C

F

Mesures

Dimension 7-200 7-400

A

B

C

D

E

F

G

H

Dimension 7-500 7-700

A

B

C

D

E

F

G

H

1/2po,

13mm

17/8po,

46mm

815/16po,

226mm

515/16po,

150mm

2po,

51mm

35/16po,

84mm

15/16po,

33mm

11/16po,

17mm

1/2po,

13mm

115/16po,

49mm

95/8po,

248mm

711/16po,

195mm

215/16po,

75mm

47/8po,

124mm

115/16po,

49mm

15/16po,

33mm

1/2po,

13mm

11/2po,

39mm

93/4po,

251mm

61/2po,

165mm

25/8po,

67mm

41/8po,

105mm

11/2po,

38mm

3/4po,

19mm

1/2po,

13mm

115/16po,

49mm

913/16po,

243mm

711/16po,

195mm

215/16po,

75mm

47/8po,

124mm

115/16po,

49mm

15/16po,

33mm

27

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 28

H C

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Dimensions (7-900, 7-1000)

N° de mo-

A B

Dimensions des vannes TempControl

dèle

7-900 11/2po 11/2po

Entrée Sortie

E

C

D

7-1000 11/2po 2po

Mesures

Dimension 7-900 7-1000

A

B

C

D

E

F

G

H

I

J

7/16po,

11mm

13/16po,

31mm

49/16po,

116mm

111/6po,

280mm

111/2po,

296mm

141/4po,

365mm

213/16po,

71mm

33/8po,

86mm

57/16po,

138mm

21/16po,

52mm

7/16po,

11mm

13/16po,

31mm

49/16po,

116mm

113/8po,

289mm

111/2po,

296mm

141/4po,

365mm

213/16po,

71mm

33/8po,

86mm

57/16po,

138mm

21/16po,

52mm

Remarque:

1) Les dimensions sont sujettes à changer sans préavis.

28

F

G

H

I

J

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 29

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Nomenclature des pièces (7-102)

Pièces de remplacement pour modèle 102

A

Article Description

A

B Tige anti-retour CSE-35

C Anneau CE-29

D Rondelle CSE-31

E Capuchon anti-retour CSE-26

Cartouche de remplacement

de vanne

Numéro de

pièce

7-102NW

K

L

B

C

D

E

G

H

F Ressort anti-retour CSE-34

G Assemblage anti-retour CSE-33

H Joint (x2) CE-30

I Rondelle anti-retour CSE-32

J

K Joint de boîtier TT-11-100

L Anneaux à bague (x3) TT-15-100

Corps anti-retour avec

dispositif d’arrêt

CSE-25

F

29

I

J

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 30

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Nomenclature des pièces (7-200, 7-400, 7-500, 7-700)

A

Pièces de remplacement pour modèle 200-700

Article Description

A

B

C Joint de capuchon TT-21-( )

D Joint de boîtier TT-11-( )

E Tige et ressort anti-retour TT-181-( )

F Anneaux à bague (x3) TT-15-( )

G Siège anti-retour TT-26-( )

Notes:

1) Insérez le numéro de modèle approprié

entre parenthèse.

2) L’article B contient un joint de bouchon, un ressort antiretour, un chapeau de robinet et un chapeau anti-retour.

Cartouche de remplacement

de vanne

Assemblage de remplacement

d’arrêt complet

Numéro de

pièce

7-( )NW

TT-50AN-( )

30

B

C

D

E

F

G

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 31

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Nomenclature des pièces (7-900, 7-1000)

A

Pièces de remplacement pour modèle 900 et 1000

Article Description

A

B Joint de boîtier TT-11-( )

C Anneaux à bague (x3) TT-15-( )

D

E Joint de capuchon TT-21-( )

F Tige d’arrêt TT-22-( )

G

H Tige et ressort anti-retour TT-200-( )

Notes:

1) Insérez le numéro de modèle approprié

entre parenthèse.

2) L’article G comprends une partie anti-retour, un bouchon,

un ressort anti-retour et un assemblage anti-retour.

Cartouche de remplacement

de vanne

Joints entre les

dispositifs d’arrêt

Assemblage de remplacement

du corps d’arrêt complet

Numéro de

pièce

7-( )NW

TT-32A

TT-27-( )

31

B

C

D

E

F

G

H

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 32

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Installation

Assistance technique et taille

MISE EN GARDE

Lorsque des directives d’installation, d’opération

et de service ne sont pas respectées, la fonction

TempControl et la durée de vie du service seront

grandement affectées.

Toutes les installations TempControl doivent

être munies d’un thermomètre et d’une vanne

d’arrêt au niveau de l’entrée d’eau modérée (comme

montré dans les diagrammes) pour un service de

dépannage approprié.

Outils requis pour l’installation

Clé ajustable

Tournevis à tête plate

Tournevis Phillips

Pour obtenir de l’aide et un soutien technique au niveau

de la dimension et de la sélection de la vanne ou du

système TempControl approprié, consultez le logiciel de

taille informatisé TempSize™, votre représentant local ou

le service à la clientèle Symmons au 1-800-SYMMONS.

Emplacement TempControl

Un principe fondamental des installations du contrôleur

d’eau thermostatique est une reconnaissance que les

vannes mixtes thermostatiques ne fonctionneront pas

adéquatement lorsque les approvisionnements en eau

chaude et froide desservant de telles vannes sont sujettes

à des perturbations de pression lorsque le débit est

inférieur à la capacité entière. Dans une salle mécanique

adéquatement conçue, les pressions d’approvisionnement

sont stables et non sujettes à des perturbations de

pression. Ainsi, lorsqu’une vanne TempControl est

indiquée comme étant située dans la salle mécanique, un

système Hi-Low ne sera pas recommandé.

Lorsque l’emplacement de la vanne est indiquée comme

étant située à l’extérieur de la salle mécanique, on

présume qu’il existe une possibilité de uctuations de

pression dans les conduites d’approvisionnement d’eau

chaude et froide desservant une vanne TempControl et

un système Hi-Low sera automatiquement recommandé.

32

Clé serre-tube

Lunettes de sécurité

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Remarque: Si le système est conçu de manière

à ce que la vanne TempControl n’est pas sujet à

une demande de débit high-low, même si elle est

située à l’extérieur de la salle mécanique, une vanne

TempControl unique fonctionnera adéquatement.

Conseils d’installation

Tous les raccords doivent être bien rincés avant

l’installation du TempControl. Le TempControl peut être

installé à toute position tant que l’eau chaude est connecté

dans le port «H» et l’eau froide dans le port «C». Fermez

les dispositifs d’arrêt de service sur le TempControl,

retirez la cartouche, (consultez la page11 pour la section

Retrait et remplacement de la cartouche), allumez

l’approvisionnement en eau et ouvrez les dispositifs d’arrêt

pour bien rincer les tuyaux avant de mettre en service la

vanne. TempControl est réglé aux réglages d’usine pour

offrir environ 100° F (38 °C).

Page 33

Diagramme 1

Installation vanne unique à la source

d'eau chaude ou à proximité de celle-ci

eau tiède, principale alimentation en

eau chaude vers le système

eau chaude à haute température

(si nécessaire pour la lessive, etc.)

alimentation en eau froide

vanne

vanne

thermomètre

Contrôleur thermostatique

à eau TempControl

réservoir

d'eauchaude,

fournaise,

etc.

vanne

Diagramme 2

Installation vanne unique avec recirculation

d'eau tiède à la source d'eau chaude

eau tiède, principale alimentation

en eau chaude vers le système

eau chaude à haute température

(si nécessaire pour la lessive, etc.)

retour d’eau tiède

vanne

thermomètre

Contrôleur thermostatique

à eau TempControl

réservoir

d'eau

chaude,

fournaise,

etc.

anti-retour

thermomètre

pompe de circulation

clapet à bille

alimentation en eau froide

anti-retour

Diagramme 3

Installation du système HI-LOW à distance avec recirculation

d'eau tiède à la source d'eau chaude

eau tiède pour les douches, lavabos, etc.

Vanne V1

V1 TM

Vanne V2

V2 TM

anti-retour

thermomètre

pompe de circulation

clapet à bille

alimentation en

eau chaude

alimentation en

eau froide

retour d’eau tiède à eau froide à l'entrée de la fournaise

thermomètre

anti-retour

Vanne PRV

Jauge de pression P1

Jauge de pression P2

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

.

TempControl Série 7

Manuel d’opération et d’entretien

Installation

Diagrammes de raccords

Diagramme1 INSTALLATION À LA SOURCE D’EAU

CHAUDE OU À PROXIMITÉ DE CELLE-CI: TempControl

doit être placé sous la cuve d’eau chaude ou le chauffeeau, bien inférieur à la ligne d’eau de température élevée.

Cette procédure créé une trappe de chaleur et protège

contre la migration de l’eau chaude dans le contrôleur.

aucune vidange d’eau sur le système de plomberie,

aucune eau ne peut être ajoutée au système; ainsi, les

approvisionnements en eau «froide» et «chaude» vers

le TempControl doit provenir du système, comme décrit

ci-dessous à l’aide de la vanne à bille pour le réglage n

de l’opération, comme mentionné dans (a) et (b).

Diagramme3 INSTALLATION AVEC RECIRCULATION

D’EAU TIÈDE À LA SOURCE D’EAU CHAUDE: Le

système Hi-Low TempControl doit avoir un raccord de

retour connecté exactement comme démontré

(consultez les notes du Diagramme2).

33

Diagramme2 INSTALLATION AVEC RECIRCULATION

D’EAU TIÈDE À LA SOURCE D’EAU CHAUDE:

TempControl doit avoir un raccord de retour connecté

exactement comme démontré. Cette procédure permet

au contrôleur de maintenir la température pendant les

périodes de non vidange en (a) allouant la volume de

retour d’eau important pour approvisionner l’entrée d’eau

froide du TempControl et (b) le volume de retour d’eau

moins important pour être réchauffé et approvisionner

l’entrée d’eau chaude du TempControl. Lorsqu’il n’y a

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Installation du système HI-LOW à distance

avec recirculation d'eau chaude

Vanne PRV

Jauge de pression P1

V1 TM

alimentation

en eau chaude

retour d'eau chaude

alimentation en eau froide

thermomètre

Vanne V1 Vanne V2

eau tiède pour les douches, lavabos, etc

Jauge de pression P2

V2 TM

Diagramme4 INSTALLATION HI-LOW A DISTANCE

AVEC RECIRCULATION D’EAU TIÈDE À LA SOURCE

D’EAU CHAUDE SEULEMENT: Le système Hi-Low

TempControl doit être raccordé comme montré.

Diagramme 4

Page 34

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Opération et entretien

Opération et ajustement

Déterminez le cycle de la vanne à entièrement chaud

(dans le sens antihoraire), puis froid (dans le sens des

aiguilles) trois fois, permettant à la vanne d’atteindre

une température complète. Grâce à environ 80% de

l’eau de source pour lequel il a été conçu, tournez le

boulon d’ajustement pour obtenir le réglage désiré

et verrouillez l’écrou en place. Les contrôleurs d’eau

thermostatiques doivent être de taille appropriée selon

la capacité du débit requis de la vanne, et NON selon

la taille du raccord fourni à la vanne. Pour obtenir de

l’aide et un soutien technique au niveau de la dimension

et de la sélection du contrôleur d’eau thermostatique

TEMPCONTROL approprié, consultez le logiciel de taille

informatisé TEMPSIZE™, votre représentant local ou le

service à la clientèle Symmons au 1-800-SYMMONS.

MISE EN GARDE: Tourner entièrement le boulon

d’ajustement dans le sens horaire retirera le

boulon du TempControl. Si cela survient, replacez

simplement le boulon.

Pour les systèmes raccordés à Diagramme2:

1. Avec la vanne à bille fermée, réglez TempControl à la

température désirée avec de l’eau provenant d’une

canalisation d’eau modérée.

2. Après avoir obtenu la température désirée, arrêtez le

débit de l’eau.

3. Ouvrez la vanne à bille an qu’une petite quantité

d’eau retourne à la source d’eau chaude. Ceci permet

à TempControl de maintenir la température réglée

pendant les périodes de non vidange du système.

4. Pendant la non vidange, observez le thermomètre

sur la décharge du TempControl. Si la température

augmente au-delà du réglage à l’étape 1, fermez la

vanne à bille légèrement ou si la température baisse,

ouvrez-la légèrement.

Pour les systèmes raccordés à Diagramme3:

1. Fermez la pompe de recirculation et fermez la vanne

à bille.

2. Fermez la vanne (V1).

3. Ouvrez 5douches ou l’équivalent à la position

d’eau chaude.

4. Réglez la petite vanne TempControl (TMV2) à la

position d’eau froide et remarquez la température sur

le thermomètre.

5. Fermez la vanne (V2) et ouvrez la vanne (V1). Réglez

la grande vanne TempControl (TMV1) à la température

désirée (assurez-vous que la vis d’ajustement sur la

vanne PRV est à la position horaire).

6. Fermez 2 douches ou l’équivalent (laissant la 3e ouverte)

et ouvrez la vanne (V2).

7. Tournez l’ajustement PRV dans le sens antihoraire

jusqu’à ce que la température (T) soit égale à celle

obtenue à l’étape n4.

8. Ajustez la vanne TempControl (TMV2) à la

température du système désirée et le système sera

en mode opérationnel.

9. Arrêtez le débit d’eau, après avoir obtenu la

température désirée et ouvrez la pompe

de recirculation.

Ouvrez la vanne à bille an qu’une petite quantité

10.

d’eau retourne à la source d’eau chaude. Ceci permet

à TempControl de maintenir la température réglée

pendant les périodes de non vidange du système.

Pendant la non vidange, observez le thermomètre

11.

sur la décharge du TempControl. Si la température

augmente au-delà du réglage à l’étape 8, fermez

la vanne à bille légèrement ou ouvrez-la si la

température baisse.

Pour les systèmes raccordés à Diagramme4:

Suivez les étapes 2 à 9 pour les systèmes raccordés à

Diagramme3: Ignorez la référence pour la pompe de

recirculation à l’étape9 (non applicable à cette installation).

Entretien

La cartouche contient le mécanisme entier de contrôle

de la vanne. Pour un service non interrompu, gardez

une cartouche de remplacement à portée de main.

Le mécanisme de contrôle de la vanne du TempControl

doit être propre et sans dépôts et toute matière

étrangère qui seront présent dans plusieurs systèmes

d’eau. Inspectez dans les 30jours suivant l’installation

ou l’opération initiale. Si l’inspection détermine que

votre système d’eau cause des dépôts et qu’une

matière étrangère se forme mensuellement, la vanne

doit alors être nettoyée mensuellement comme suit:

Retirez la cartouche (consultez la page11 pour la

section Retrait et remplacement de la cartouche) et

trempez-la dans tout agent déchaulant acceptable

(ou vinaigre maison régulier). Lavez les dépôts,

assurez-vous que le piston bouge librement dans son

manchon, et remplacez la cartouche. Nettoyez plus

souvent si votre système le requiert (ne retirez pas

complètement le piston de la cartouche).

34

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184 ■ (800)796-6667 ■ Télécopieur: (800)961-9621

©2014 Symmons Industries, Inc.■ www.symmons.com ■ gethelp@symmons.com ■ ZV-3008 REV D 01/06/14

Page 35

7-102, 7-200, 7-400, 7-500, 7-700, 7-900, 7-1000

TempControl Série 7

Manuel d’opération et d’entretien

Opération et entretien

les vannes anti-retour du système TempControl sont

grandement importantes facteurs dans son opération

appropriée. Si des copeaux, saleté ou autres matériaux

étrangers se logent sur les supports et empêchent

les anti-retours d’être bien installés, il peut y avoir une

dérivation de l’eau dans la canalisation opposée, et le

TempControl ne fonctionnera pas à température de

prestation réglée. Une dérivation peut être détectée

en touchant la canalisation, tandis que le système

TempControl ne fonctionne pas. Si, par exemple, la

canalisation d’eau froide est chaude, l’anti-retour d’eau

froide n’est pas installé correctement. Elle doit être retirée

et l’anti-retour et son support nettoyés.

Retrait et remplacement

de la cartouche

Avant de retirer une cartouche usagée pour la

nettoyer, ayant un nouveau joint de boîtier et des

anneaux à bague à portée de main.

Fermez les approvisionnements aux anti-retours d’arrêt

en tournant dans le sens horaire.

Retirez les 4boulons sur la bride du boulon de

la cartouche.

Grâce à deux tournevis à bout large, forcez de

manière uniforme sur les deux côtés opposés de la

bride du boulon jusqu’à ce que la cartouche puisse