Page 1

5.0" HOLE

127mm

PLASTER

SHIELD

FINISH WALL

FLUSH WITH

FINISH WALL

2 3/8"

60mm

min.

2 7/8"

73mm

max.

3/4" PIPE

TTC-295

Water Dance®

High-Flo™ Mixing Valve for Custom Shower or Tub/Shower Application

Installation, Operation & Service Instructions

Model Numbers

Rough-in dimensions are included for the

following models. See separate drawings

enclosed with numbered models for

applicable rough-in dimensions.

■ 1-6320-X ■ 1-7520-X ■ 1-7470-X

■ 1-7460-X ■ 1-1560-X ■ 1-2560-X

■ 1-2550-X ■ 1-2540-X

Tools required

Phillips screw driver, tubing cutter, teflon

tape, soldering equipment, adjustable wrench,

adjustable pliers and 1/8” hex key.

Caution Please review the following water

and drain system requirements prior to

installation of any High-Flo valve or Water

Dance Custom Showering System. This

information serves as a general guide only,

as every installation contains its own unique

conditions and should not replace sound,

professional plumbing judgment.

Water Heater

Determine that you have a sufficient supply

of hot water for the Water Dance system

selected and for the intended user’s personal

preference. With four flow-restricted outlets

flowing simultaneously and continuously, a

Water Dance system can deplete a standard 40

gallon hot water heater in less than 8 minutes.

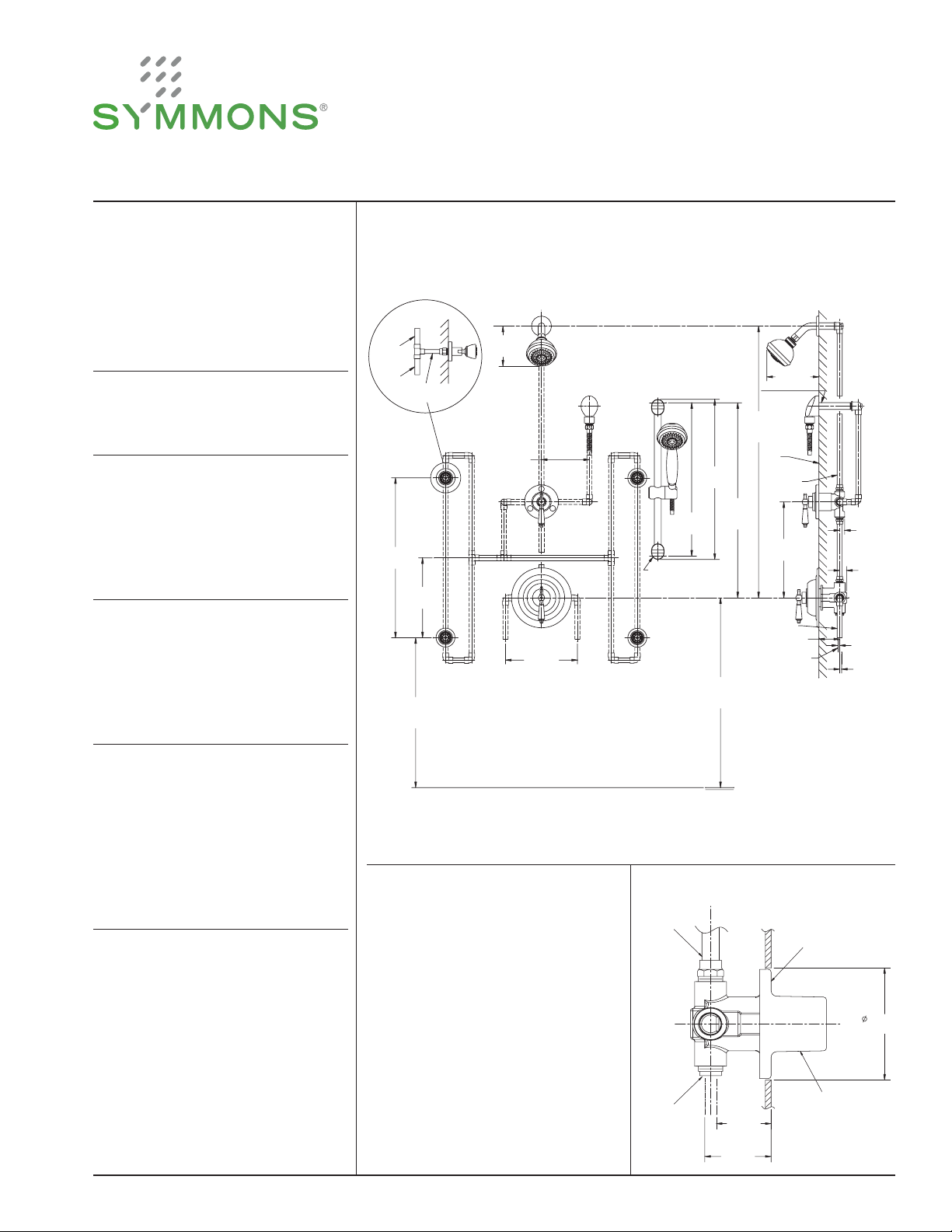

FIGURE 2: WATER DANCE Model 1-7470-X

Dimensions Water Dance Two Wall Shower System, 1-7470-X

Female 1/2'' I.P.S. thread must be recessed 3/8'' (10mm) ± 3/8” (10mm)

from nished wall for proper installation of body spray.

3/4"

3/4"

20"

508mm

1/2"

10"

254mm

approx.

36"

914mm

5"

127mm

approx.

6"-152mm

right or left

381mm

All piping including valve inlets and outlets

3/4" except where noted otherwise.

Male 1/2'' I.P.S. thread must be recessed

1/4'' (6mm) from nished wall for proper

installation of street ell and ange.

15"

25 1/2"

648mm

24 5/8"

625mm

screw bar support

into stud or install

proper backing

approx.

41"

1041mm

1016mm

approx.

30"

762mm

approx.

40"

nished

wall

shower

discharge

hot and

cold inlets

adjustment

6 1/2''

165mm

12''

305mm

2 5/8"

67mm

5/8"

16mm

22mm

1/4''

6mm

1/4"

6mm

7/8"

Pressure Required

Verify that you have adequate flowing (not

static) water pressure before installing a

Water Dance system or High-Flo valve.

For optimum performance we recommend

a minimum of 60 psi flowing pressure to

the High-Flo pressure balancing valve. Also

reducing or eliminating long piping runs and

sharp turns will result in a more satisfactory

performance from the system.

Drain Size

Determine that there is adequate drain size

and capacity to handle the selected Water

Dance system water volume.

The High-Flo valve is capable of delivering

12 gpm at 45 psi. If two valves are to be used

water volumes of up to 24 gpm are possible

depending on available water pressure.

Confirm that the shower drainage system can

handle the anticipated water volume.

oor line

Note: Dimensions subject to

change without notice.

All floor to center dimensions optional. Concealed piping and fittings not furnished by manufacturer.

Install HOT on left and COLD on right

according to valve markings.

FIGURE 1

1) Install piping and fittings with valve body

as shown in Figure 2.

IMPORTANT: Valve rough-in is 2 3/8”

(60mm) min. — 2 7/8” (73mm) max.

from centerline of supplies to face of finish

wall. Install so that surface indicated on

plaster shield on valve is flush with finish

wall as shown in Figure 1.

2) IMPORTANT: Install plug (TTC-295) in

either tub port for shower application or

shower port for tub application.

NOTE: Valve will not work properly with

both ports unplugged.

3) When finishing tile wall remove (pull off;

Page 2

don’t turn) protective plastic shield and

fill area around valve body with grout or

plaster. Do not plaster over SC-2 cap or

service stops.

4) For installation of diverter see installation

instructions included with diverter.

5) Install body spray to the water supply

pipe fitting in the wall; use plumber tape

to seal the connection. Push flange until

flush against finished wall.

NOTE: Any configuration with two or

more body sprays requires that they be

plumbed with a balancing loop as shown

in Figures 2 and 3. This technique insures

that each body spray delivers the same

volume.

6) Turn on hot and cold supplies. Valve will

not operate unless both hot and cold

water are turned on.

7) Adusting Stops - Valve is equipped with a

limit stop screw to be used to limit valve

handle from being turned to excessively

hot water discharge temperatures.

Adjust by removing dome cover, place

handle on stem, open valve to maximum

desired temperature and turn in limit stop

screw until it seats.

WARNING: Failure to adjust the limit

stop screw properly may result in serious

scalding. Shower system may not protect

the user from scalding when there is a

failure of other temperature controlling

devices elsewhere in the plumbing system.

8) Check packing nut (SC-7) for positive

frictional resistance to handle turn

throughout adjustment cycle and at shutoff position, tighten if necessary.

Check valve cap, packing nut and all

valve, pipe and fitting connections for

leaks. Reattach dome cover back onto

packing nut.

9) Push escutcheon (HF-120 or HF-112),

with slot facing downward, and gasket

(HF-129 or HF-130) against wall and

secure to valve with escutcheon screws

(T3-28 or DF-9).

Secure dial (HF-119) to escutcheon (HF-

120).

Mount temperature control handle (T331L or HF-28-LAM) on valve spindle

spline, secure with screw and button.

Install shower arm, flange and shower

head. See Figures 2 and 3.

Install tub spout on stub. Use putty or

sealant on back edge of spout to make

proper seal with finished wall.

10) Allow valve to run in warm position for a

few minutes to flush system. If system is

quite dirty, remove valve spindle or stop

spindles to ensure proper flushing. See

service instructions.

11) Do not install positive shut-off devices

on the outlet of this valve or devices that

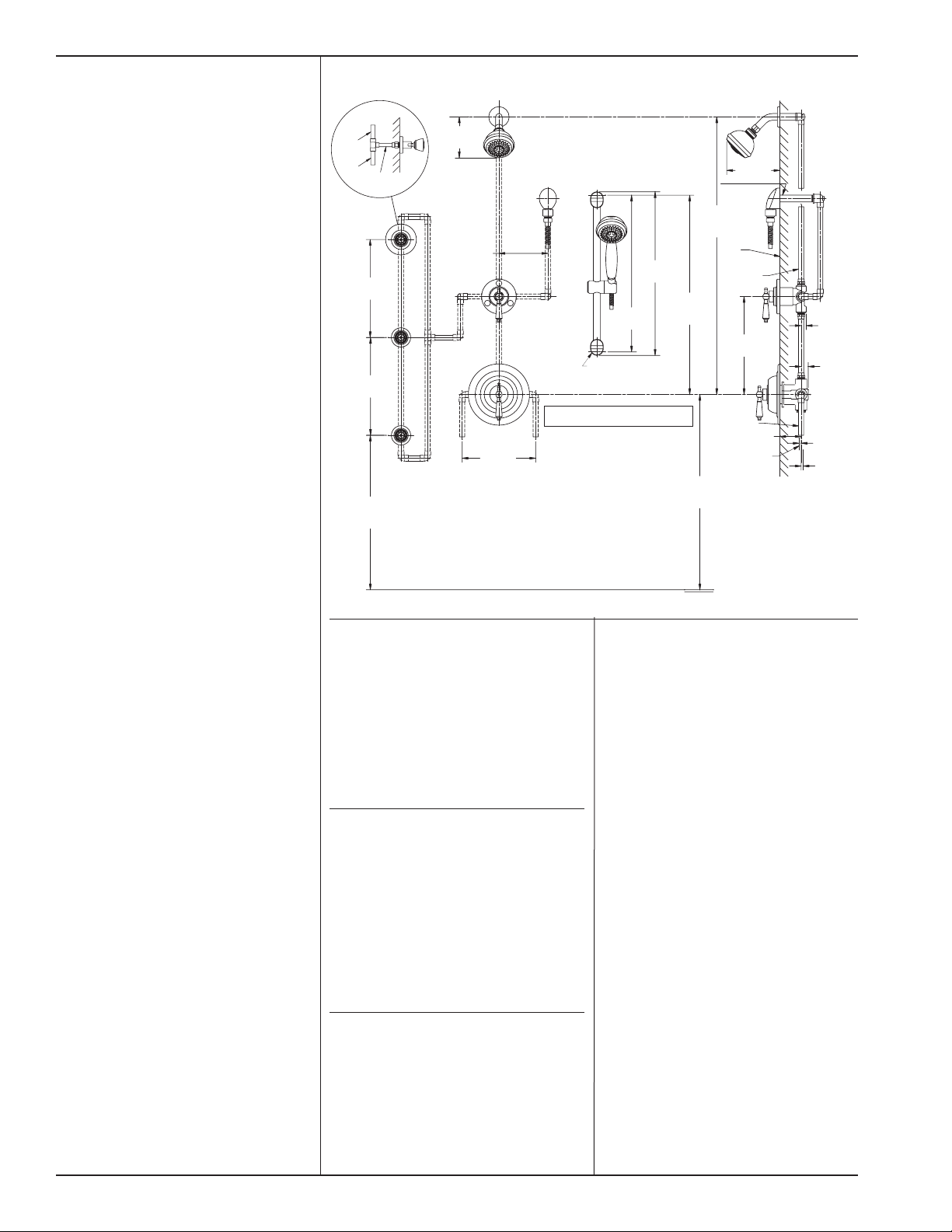

FIGURE 3: WATER DANCE Model 1-7460-X

3/4"

3/4"

1/2"

12"

305mm

12"

305mm

Female 1/2'' I.P.S. thread must be recessed 3/8'' (10mm) ± 3/8” (10mm)

from nished wall for proper installation of body spray.

approx.

36"

914mm

All floor to center dimensions optional. Concealed piping and fittings not furnished by manufacturer.

do not allow the valve to flow at least 1

GPM at 50 psi inlet pressure unless the

inlet supplies of the valve are equipped

with check stops (Suffix: X-CHKS) to

eliminate hot to cold by-pass in the event

the valve’s handle is not turned to off after

use.

Contact your factory representative or

Symmons directly for information on

available checks.

Fiberglass wall installation

When installing the High Flo valve in

fiberglass or panel walls and it is desired

to sandwich wall between valve body and

escutcheon, cut hole in wall as shown in

Figure 4 and mount valve from rear.

Note: It is always recommended to secure

valve piping to rough construction and not

depend on fiberglass wall for valve mounting

security. On panel walls over 1” thick, install

in conventional manner. (See figure 1).

Valve Operation

The main handle of the valve is for control of

temperature only. From the OFF position, the

handle is turned counter-clockwise through

a minimum cold position, through a warm

and hot position for a maximum turn of

approximately one revolution. This allows for

infinite temperature adjustments to suit the

requirements of any user.

5"

127mm

approx.

6"-152mm

right or left

15"

381mm

Male 1/2'' I.P.S. thread must be recessed 1/4''

(6mm) from nished wall for proper

installation of street ell and ange.

25 1/2"

648mm

24 5/8"

625mm

screw bar support

into stud or install

proper backing

All piping including valve inlets and outlets

3/4" except where noted otherwise.

Care and Cleaning

The lustrous finish on your High-Flo valve or

Water Dance system should be treated with

care. It can be readily damaged by improper

handling or abusive treatment.

To clean the finish wipe gently with a soft

damp cloth and lot dry with a soft towel. Use

only a mild soap solution if required.

Do not use abrasive cleaners. Use of polish

abrasive cleaners, solvents or acid cleaners can

damage finish and void Symmons warranty

approx.

30"

762mm

approx.

41"

1041mm

oor line

approx.

40"

1016mm

hot and

cold inlets

6 1/2''

165mm

nished

wall

shower

discharge

12''

305mm

adjustment

2 5/8"

67mm

1/4''

6mm

1/4"

6mm

5/8"

16mm

7/8"

22mm

Page 3

INDIVIDUAL PARTS INDIVIDUAL PARTS COMPOSITE PARTS

C-31 Plaster shield

C-32 Stop spindle assembly

DF-9 Escutcheon screws

DF-10 Handle screw

DF-25 O-ring

HF-106 Cold washer retainer

HF-107 Hot water washer

HF-108 Cold water washer

HF-109 Renewable seat

HF-112 Escutcheon

HF-113 Dome

HF-114 Top seat o-ring

HF-117 Dial

HF-118 Handle flange

HF-119 Dial assembly

HF-120 Escutcheon

HP-17A O-ring

SC-2 Cap

SC-7 Packing nut

SC-10A Hot washer screw

SC-13B Dome cover

SC-17B Packing

SC-18 Lock nut, dome

SC-19 Cap gasket

SC-26 Limit stop with o-ring

T-2 Bottom seat o-ring

T3-28 Escutcheon screws

T-32 Handle screw

T-33 Plug button

T3-31 INS Handle insert

HF-28-LAM Metal finish insert handle:

Handle screw (DF-10)

HF-28-LCF Clear faceted insert handle:

Handle screw (DF-10)

HF-28-LPO White insert handle:

Handle screw (DF-10)

T3-31L Loop style lever handle:

Insert (T3-31 INS)

Handle screw (T-32)

Plug button (T-33)

T3-31S Solid style lever handle:

Insert (T3-31 INS)

Handle screw (T-32)

Plug button (T-33)

Washer & Gasket KIT-HF

HF-106 Cold washer retainer

SC-10A Hot washer screw

HF-107/108 Hot/cold washer

SC-17B Packing

SC-19 Cap gasket

Repair Units

HF-109 Renewable seat unit

complete

HF-103 Spindle

C-31 Plaster shield

FIGURE 5: Parts Breakdown

HF-119

HF-113

T3-31-INS

T3-31L

T-32

T-33

DF-28

DF-10

T3-2 8

HF-120

HF-118

DF-25

SC-1 8

SC-7

HF-117

SC-17B

SC-13B

DF-9

SC-2

HP-17A

T-2

C-32

C-31

HF-106

SC-10A

HF-107

HF-108

SC-1 9

SC-2 6

HF-112

HF-103

FIGURE 4: Fiberglass Wall Installation

HF-114

HF-109

Page 4

SERVICE

1) Shut off water supply to valve.

2) Loosen set screw and remove handle,

dome cover, dial and escutcheon in that

order.

3) Open valve to about warm position and

unscrew cap (SC-2). Warning: Failure

to OPEN VALVE will damage cap and

spindle. Spindle assembly (HF-103) will

be removed with cap. Leave packing nut

(SC-7) in place while unscrewing cap to

avoid distortion.

4) Ordinary service to eliminate dripping

or not shutting off requires only the

replacement of parts supplied in washer

and gasket kit (KIT-HF). Hold spindle

with handle while removing hot washer

screw and cold washer retainer (remove

retainer with channel lock pliers).

5) Inspect surfaces of renewable seat (HF-

109). If seat surfaces are worn or wire

drawn or if NEW SPINDLE IS VERY

LOOSE IN SEAT, replace renewable seat

(HF-109). Use 1/2” hex key. Clean seat

surfaces for proper sealing of top seat

o-ring (HF-114). Tighten seat to 15 foot

pounds of torque.

6) The perforated end of the (HF-109)

spindle assembly houses the balancing

piston which is the heart of this pressure

balancing valve. The piston should be free

to move back and forth and should click

when the spindle assembly is shaken. If

deposits block this action, tap the handle

end of the spindle against a solid object

to free the piston. Soaking in household

vinegar will help free foreign matter. If

this does not free piston, replace (HF-103)

spindle assembly. DO NOT TAMPER

WITH PERFORATED CYLINDER

ON THE SPINDLE ASSEMBLY OR

ATTEMPT REMOVAL OF THE

PISTON.

7) Reassemble, reversing above procedure.

Be sure spindle assembly is drawn close

to the cap before screwing cap back into

valve. Warning: Failure to do this will

damage cap and spindle.

8) USE ONLY SYMMONS SAFETYMIX

GENUINE REPAIR PARTS. FAILURE

TO DO SO WILL VOID ALL

WARRANTIES AND IMPAIR PROPER

OPERATION OF YOUR VALVE.

TROUBLE SHOOTING CHART

Problem Cause Solution (Follow service instructions)

Turn on both supplies. Valve will not

Valve will not pass water Hot and cold water not turned on

Hot and cold washers are worn or foreign

Valve leaks when shut off.

Temperature control handle is turned

from cold to hot (or hot back to cold) and

volume from spout or head is not constant.

Valve delivers sufficient quantity of cold, but

little hot, or the reverse.

Temperature varies without moving handle. Same as above Same as above

Valve delivery temperature reduces gradually

during use; handle must be turned on

to hotter positions to maintain constant

temperature.

matter (solder, chips, etc.) are between

washers and seat surfaces.

Pressure-balancing piston housed in spindle

assembly is blocked from free movement by

foreign matter.

Same as above Same as above

Overdraw on hot water supply, i.e. running

out of hot water.

Symmons Industries, Inc. ■ 31 Brooks Drive ■ Braintree, MA 02184

(800) 796-6667, (781) 848-2250

Website: www.symmons.com

■ Fax (800) 961-9621, (781) 664-1300

■ Email: customerservice@symmons.com

operate unless both HOT and COLD water

pressure is turned on.

Replace HOT and COLD washers. Inspect

top surface on hot and cold seats and

replace if necessary.

With valve open half way, remove handle

and tap spindle with plastic hammer.

If problem not solved, remove spindle

assembly completely and tap handle end

against solid object to free piston. Soaking

in household vinegar will help free foreign

matter.

See note regarding Hot Water Heater on

page 1.

©2007-2014 Symmons Industries, Inc. Printed in U.S.A.

■ ZV-432 ■ Rev A ■ 061114

Loading...

Loading...