Page 1

S1000 All in One

S3000 All in One MAXI

S3000 All in One

NL

Service boek

GB

Service book

Manuel de service / maintenance

F

Page 2

S1000 All in One

S3000 All in One (MAXI)

CONTENT

S1000 All in One

S3000 All in One (MAXI)

PREFACE .....................................................................................................................................44

1. BASIC FUNCTIONING ..........................................................................................................45

1.1 Boiler System ...................................................................................................................46

1.2 Temperature regulation ....................................................................................................46

1.3 Hot water dispensing .......................................................................................................46

1.4 Evaporation extractor system ..........................................................................................46

1.5 Ingredients and mixer system .......................................................................................... 46

1.6 Coffee splitter ...................................................................................................................46

1.7 Solid state relais (SSR) ....................................................................................................47

1.8 Steam thermostat .............................................................................................................47

1.9 Adjustment .......................................................................................................................47

1.9.1 Cup volume ...........................................................................................................47

1.9.2 Strength .................................................................................................................47

1.9.3 Number of shots .................................................................................................... 48

2. MENU STRUCTURE .............................................................................................................49

2.1 The operator/service menu .............................................................................................. 49

2.2 The operator menu ..........................................................................................................50

2.3 The service menu ............................................................................................................50

Quick recipe .....................................................................................................................51

Button setting ...................................................................................................................51

Recipe setting ..................................................................................................................52

Recipe setting (continued) ...............................................................................................53

Settings ............................................................................................................................54

Settings (continued) / Reset countes / Descale/fi lter .......................................................55

Hardware test ..................................................................................................................56

Read log / Clear log / SD menu .......................................................................................57

3. RECIPE SETTINGS ...............................................................................................................58

3.1 Cartridge confi guration ....................................................................................................58

3.2 Button settings .................................................................................................................59

3.2.1 Parameter settings S3000 ......................................................................................60

3.2.2 Parameter settings S3000 MAXI ............................................................................61

3.2.3 Parameter settings S1000 Coffee ...........................................................................62

3.2.4 Parameter settings S1000 Cacao ...........................................................................63

3.2.5 Parameter settings S3000 Milk ...............................................................................64

3.3 Detailed recipe settings ....................................................................................................65

3.4 Timebar recipe settings....................................................................................................65

3.5 Calibrating the hot water valves .......................................................................................66

5. COMPONENT ACCESSIBILITY ............................................................................................71

5.1 Electronics summary .......................................................................................................72

5.1.1 Control unit ...................................................................................................................... 72

5.1.2 Interface / Display .................................................................................................. 73

5.1.3 Power supply .........................................................................................................73

5.2 Main circuit board entrances ............................................................................................74

5.3 Main circuit board exits ....................................................................................................75

5.4 Main circuit board communication ...................................................................................76

6. TROUBLESHOOTING ........................................................................................................... 76

6.1 Read log ..........................................................................................................................76

6.2 Clear log ..........................................................................................................................76

6.3 Troubleshooting ...............................................................................................................77

7. COIN MECHANISM (OPTIONAL) ..........................................................................................79

7.1 Standard con

fi guration .....................................................................................................79

7.2 Rejecting coins ................................................................................................................79

7.3 Activating existing tokens ................................................................................................80

7.4 Programming a new token ............................................................................................... 80

7.5 Accepting Euros and Tokens ...........................................................................................80

7.6 accepting Tokens only .....................................................................................................81

7.7 Cleaning the coin holder ..................................................................................................81

4. SERVICE ..........................................................................................................................67

4.1 Setting a service parameter ............................................................................................. 67

4.2 Preventative maintenance ............................................................................................... 68

4.2.1 Service contracts ...................................................................................................68

4.2.2 Servicing ................................................................................................................68

4.3 Descaling instructions ......................................................................................................69

S1000 / S3000 / S3000 MAXI

42

08/2009 Rev. 0.4

08/2009 Rev. 0.4

43

S1000 / S3000 / S3000 MAXI

Page 3

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

© 2009 Symfoni®

All rights reserved.

No part of this document may be reproduced and/or made public in print, microfi lm, electronic media

or any other form without the manufacturer’s prior consent. This also applies to the corresponding

diagrams and/or charts.

PREFACE

Purpose of this document

This document provides directions for use and serves as a service document for trained, authorised

service staff to safety install, programme and maintain this device.

- Trained, authorised service staff are considered to be those who install, programme and maintain

the device, and are able to carry out repairs.

The majority of settings, including product settings, are protected by a PIN code. This PIN code

ensures that users do not gain access to the service menu. It is recommended not to leave this

document with the user after installation and to change the standard factory PIN code.

All sections and paragraphs are numbered. The various fi gures referred to in the text can be found in

the fi gures section at the beginning of the manual or with the corresponding subjects.

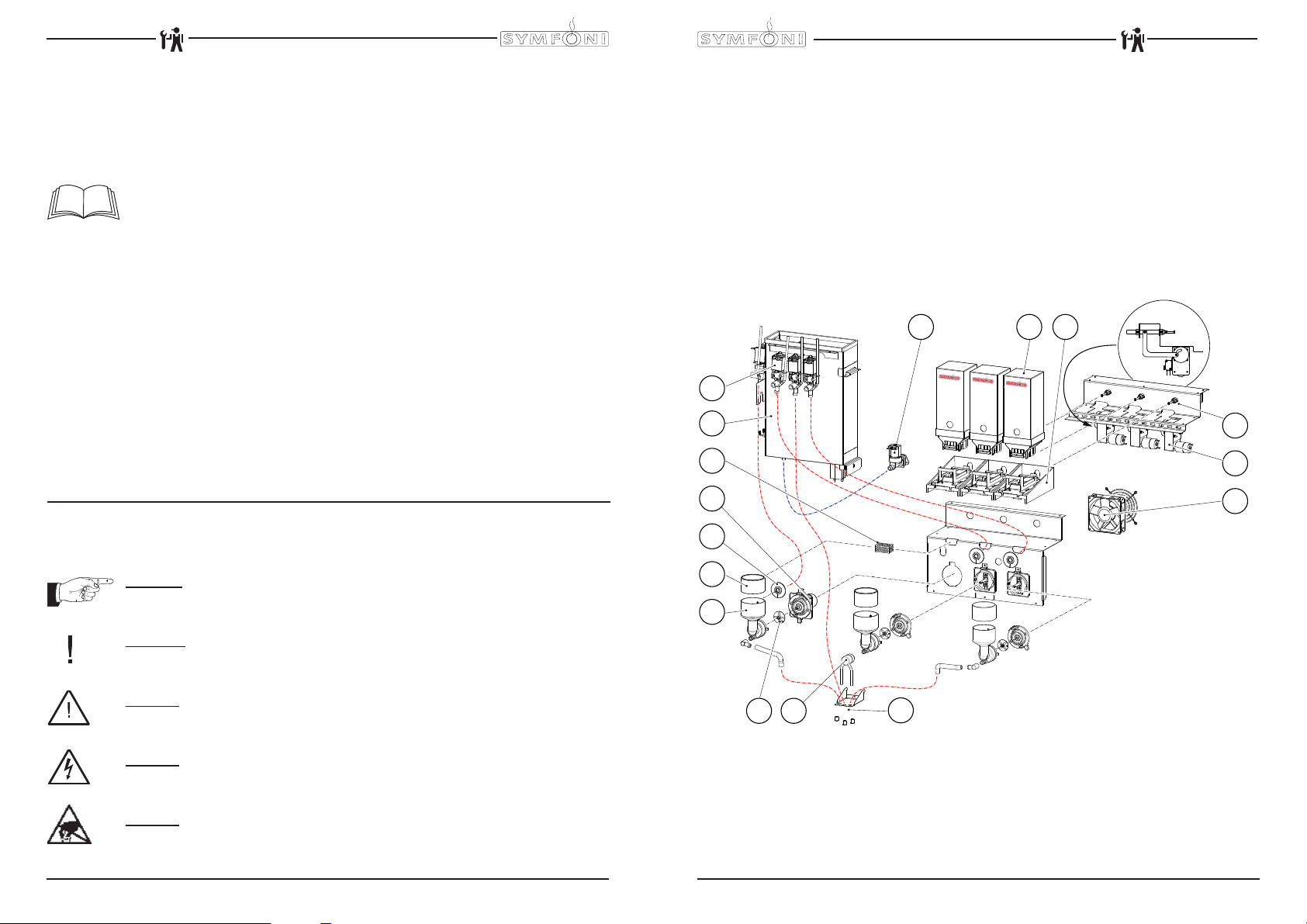

1. BASIC FUNCTIONING

1 Drink outlet/ Hot water outlet 9 Water reservoir

2 Coffee splitter 10 Dispensing valves

3 Mixer impellor 11 Inlet valve

4 Mixer housing 12 Ingredient cartridge

5 Evaporation extractor ring 13 Cartridge holder

6 Hot water connection mixer 14 Push rod

7 Mixer motor 15 Ingredient motor

8 Filter 16 Ventilator

11 12 13

10

Chocolate

Coee

Topping

9

Milk

8

7

14

15

16

Pictograms and symbols.

CAUTION

General indication for: IMPORTANT, CAUTION or REMARK.

WARNING

Warning for possible damage to the device, surroundings or environment.

DANGER

Danger of possible severe damage to the device or physical injury.

DANGER

Danger of electricity and voltage.

DANGER

Danger of electrostatic discharge (ESD) in electronics.

S1000 / S3000 / S3000 MAXI

44

08/2009 Rev. 0.4

6

5

4

08/2009 Rev. 0.4

Fig. 1

23

1

45

S1000 / S3000 / S3000 MAXI

Page 4

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

1.1 Boiler System

Turn on the device using the ON/OFF switch. The display will light up.

The magnetic valve (fi g. 1-11) will open and the hot water reservoir (fi g. 1-9) will be fi lled to the maxi-

mum electrode. The heating element will be switched on. The display shows [ boiler fi lling ] and

[ boiler heating ]. As soon as the NTC sensor measures the set temperature, the heating element will

be switched off.

When a drink is being dispensed the water level drops and the maximum electrode is released;

the inlet valve (2.5 litres/min.) opens and immediately refi lls the reservoir until the maximum level

is reached again. If the water level falls under the minimum electrode level during operation, the

operating panel display will show [refi lling boiler]. If the supply of water is not restored within 90

seconds, the display will show the error message [ E3 level error ] and shut off the inlet valve.

1.2 Temperature regulation

The heating element is turned on when the water temperature falls below the temperature setting and

the minimum electrode registers water. The temperature in the water reservoir is measured using an

NTC precision sensor mounted on the outside wall of the reservoir.

The water temperature also drops when drinks are dispensed. To avoid the temperature regulator from

responding too late, the heating element is switched on as soon as the inlet valve (fi g. 1-11) opens

and cold water is added. The heating element switches off again as soon as the inlet valve shuts

off. The software can also be used to delay when the heating element switches off. See menu item

2.4 Settings / Temperature in the service menu. The heating element always switches off when the

maximum boiler temperature of 97˚C is reached.

1.3 Hot water dispensing

When dispensing drinks one of the dispensing valve (fi g. 1-10) opens and hot water fl ows to the brew-

er or mixer system. The fl ow velocity for each valve is set using the adjustment screw on the valve.

The amount of outfl ow is determined by the length of time that the valve stays open. In order to rinse

the brewer unit and mixer system, a small amount of rinsing water is released shortly after dispensing

to rinse away any ingredient residue.

1.5 Evaporation extractor system

Evaporation released during mixing is largely absorbed by the evaporation extractor ring (fi g. 1-5) and

sucked into the machine via the fi lter (fi g. 1-8). The evaporation and ingredient residue are absorbed

by the fi lter. The fi lter (fi g. 1-8) can be easily reached (for cleaning purposes) by dismantling the mixer

unit (fi g. 1-4). To a large extent, this prevents evaporation from entering the canister outlet and making

ingredients damp.

1.5 Ingredients and mixer system

The ingredients cartridges (fi g. 1-12) are fi tted in a holder (fi g. 1-13). The ingredient slide inside the

holder is driven via a special mechanism by a gear motor (fi g. 1-15). The instant product (ingredient)

is dispensed by a drawer in the bottom of the cartridge and directly dispensed into the mixer unit (fi g.

1-15). At the same time, the dispensing valves (fi g. 1-10) dispense hot water into the mixer unit. The

mixer motor (fi g. 1-7) blends the instant product with water at a speed of 10,700 RPM using the mixer

rotor (fi g. 1-3). The drink fl ows into the cup via the drink outlet (fi g. 1-1). All individual parts mentioned

in this section can be sequentially coordinated using adjustable

parameters (timers) in the control unit.

1.6 Coffee Splitter

The coffee splitter (fi g. 1-2) is specially designed for dispensing two cups of coffee at the Same time.

The build-in fi lter creates the perfect creme layer on top of the coffee.

1.7 Solid State Relay (SSR)

The heating element is controlled by a solid state

relay (fi g. 2C), which supersedes the magnetic

switch that was formerly used for this purpose.

1.8 Steam thermostat

The solid state relay (fi g. 2C) is secured by a steam

thermostat (fi g. 2D) which is build in line with the

overfl ow tube (fi g. 2A). The steam thermostat

contact is in series with the solid state. This thermostat prevents the boiler from boiling empty when

the solid state breaks down in a operating condition.

The thermostat switches the heating element OFF

(fi g. 2B) when steam escapes from the boiler. The

A

B

C

D

SSR

N

L1

C

24Vdc

SSR

D

B

thermostat must be manually reset.

* Modifi ed in the Symfoni models from machine

number 1S06945 (March 2009)

Fig. 2

1.9 Adjustment

1.9.1 Cup volume

First of all we would like to remind you that the cup volume (ml) can easily be set in the service menu

2.1 Quick recipe (page 49 of this document).

The operator of the device (end user) also has access to this quick recipe, which is found under

section 1.4 Quick recipe (see user manual).

As supplier of the device, you can remove the quick recipe from the operator menu if desired. Go to

2.4 Settings / 2.4.9 I/0 Quick recipe via the service menu and change Yes into No.

1.9.2 Drink strength

The amount of product dispensed, and therefore the strength of the drink, is determined by the

number of the times (shots) the cartridge drawer is opened whilst the drink is being made, and how

far the drawer opens each time.

Fig. 3

A. Cartridge holder

B. Ingredient slide

B

C. Push rod

D. Lock nuts

E. Adjustment screw

A

To Fine adjust the ingredient pull please follow below written instructions:

1. Remove the relevant cartridge holder (fi g. 3A).

2. Loosen the adjustment screw lock nuts (fi g. 3D).

3. Adjust the screw (fi g. 3E) as required. Anti-clockwise increases the strength and clockwise

decreases the strength.

4. Replace the cartridge holder and cartridge.

5. Taste the drink and re-adjust as necessary.

6. When the adjustment is correct tighten both the lock nuts (fi g. 3D) against the push rod (fi g. 3C).

7. Replace the cartridge holder and cartridge. Important: After replacing check that the push rod is

free To move back and forwards pushing the slide out as it moves forwards.

+

-

C

D

E

Fig. 3

S1000 / S3000 / S3000 MAXI

46

08/2009 Rev. 0.4

08/2009 Rev. 0.4

47

S1000 / S3000 / S3000 MAXI

Page 5

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

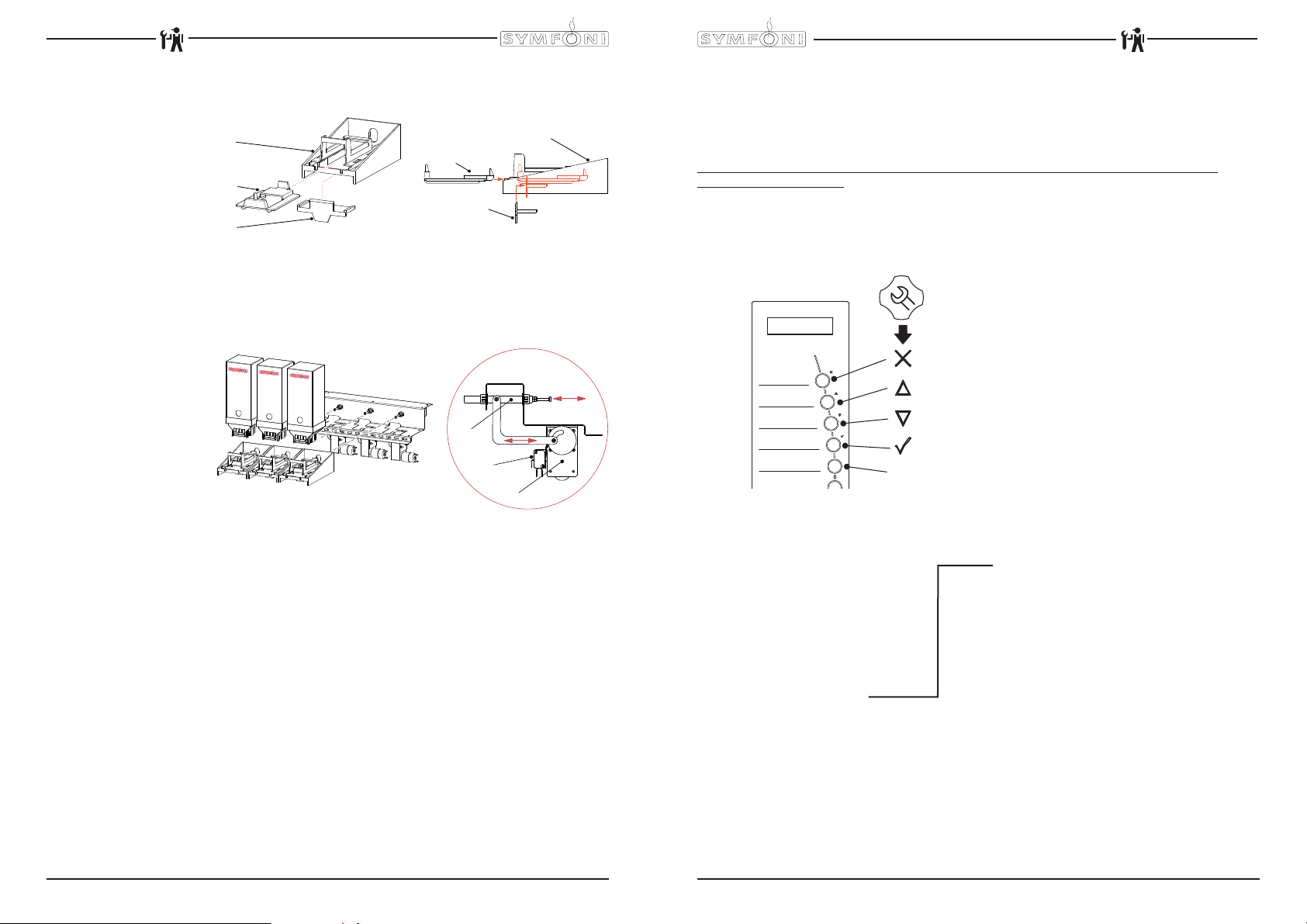

Check also if the mechanism is assembled as shown below.

Fig. 4

A. Cartridge holder

B. Ingredient slide

C. Ingredient shield

a

b

a

b

c

c

1.7.3 Number of shots

If a greater adjustment is needed, the number of times the cartridges drawer is opened For each drink

can be changed.

Fig. 5

A. Ingredient motor

B. Micro switch

C. Push rod

Chocolate

Coee

Topping

Milk

Fig. 4

C

B

A

Fig. 5

The push rod (fi g. 5C) is driven by the ingredient motor (fi g. 5A). Every rotation is being detected by a

micro switch (fi g. 5C). One rotation is one shot.

To set the shot amount go to the service menu 2.3 Recipe setting (page 50 of this document).

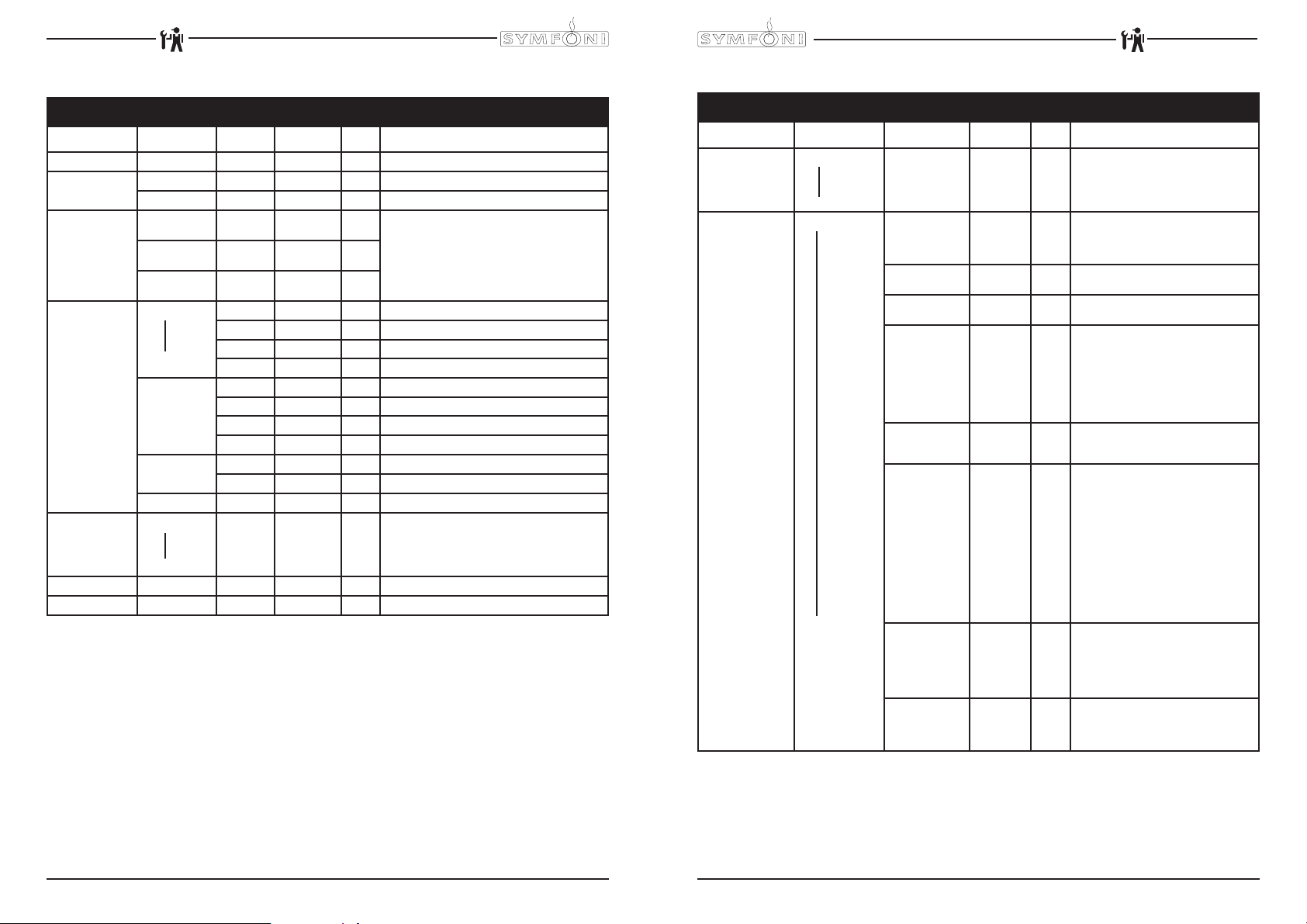

2. MENU STRUCTURE

2.1 The operator/service menu

The majority of settings, including product settings, are protected by a PIN code. This PIN code

ensures that users do not gain access to the service menu.

It is recommended not to leave this document with the user after installation and to change the

standard factory PIN code.

This section describes how the various settings can be changed by trained, authorized service staff.

You can read about how to gain access to the service menu below. On access to the service menu

the control panel has the following functions:

Escape (back without confi rming any changes)

Previous (menu item / increase value)

Next (menu item / decrease value)

Enter (confi rm menu choice)

TEST

Test (press for 1 sec.)

Summary:

Operator menu Service menu

1.0 Free dispensing 2.1 Quick recipe

1.1 Clock 2.2 Button settings

1.2 Timer settings 2.3 Recipe settings

1.3 Recipe counters 2.4 Settings

1.4 Quick recipe 2.5 Reset counters

1.6 Software 2.6 Descale / fi lter

1.7 PIN-code 2.7 Hardware test

2.8 Read log

2.9 Clear log

2.10 Load defaults

2.11 SD menu

2.12 Change PIN code

2.13 Additional settings

S1000 / S3000 / S3000 MAXI

48

08/2009 Rev. 0.4

08/2009 Rev. 0.4

49

S1000 / S3000 / S3000 MAXI

Page 6

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

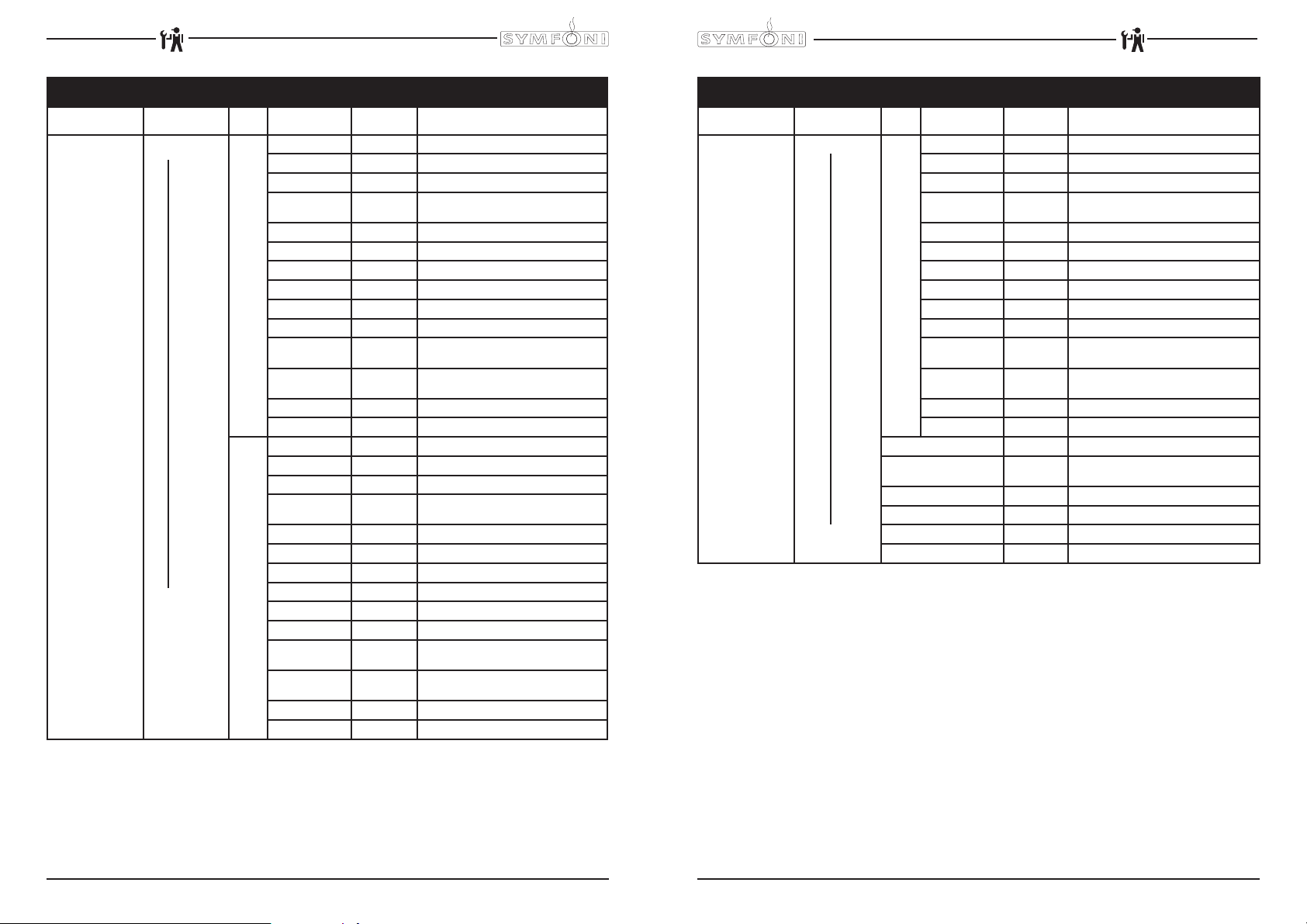

2.2 The operator menu

Operator menu

Main item Sub item Item Range Set Description

1.0 Free dispensing

1.1 Clock Time HH:MM Set the clock to the correct local time here.

Date DD-MM-JJJJ Set the clock to the correct local time here.

1.2 Timer Mon-Fri On 00:00

Sat On 00:00

Sun On 00:00

1.3 Recipe counters

1.4 Quick recipe Recipe name 1

1.6 Software Software version is readable here.

1.7 PIN-code 2-2-2-2-2 PIN code = press the number 2 key fi ve times.

Recipe 1

Recipe 10

Recipes total Total Cups Total counter for all dispensed recipes

Rinse counters Brewer Number of brewer rinses

Reset counters Total rest of all counters

Recipe name 10

Total Off 00:00 Total counter for recipe 1 (free-paid-jugs)

Free Cups Number of free dispensed drinks (recipe 1)

Paid Cups Number of paid dispensed drinks (recipe 1)

Jug Cups Number of dispensed jugs (recipe 1)

Free Cups Total counter for all free dispensed recipes

Paid Cups Total counter for all paid dispensed recipes

Jug Cups Total counter for all dispensed jugs

Mixer(s) Number of mixer rinses

Cup volume

Yes/no Yes Set the device to free or paid dispensing here.

Off 00:00

Off 00:00

Off 00:00

50-300 ml 125ml Use this for setting the volume easily per recipe

Set the time when the device should operate here. If

the timer switches off the device it will automatically

revert to standby mode.

(drink button).

2.3 The service menu

Service menu

Main item Sub item Item Range Set Description

2.1 Quick recipe Recipe name 1

Recipe name 10

2.2 Button setting Button 1

Button 10

Cup volume

<Recipe name> Recipe list

Recipe active Yes/no Yes Use this to place the product concerned

Price 0,05-2,00 0,10 For paid dispensing a price can be set

Cup volume 50-300ml * 125ml Set the desired cup volume here. All other

Multicup 0-20 0 Set the number of cups that should be

Key switch 0-1-2-3 0 / 1 Recipe button concerned works as follows:

Push & Hold Yes-No No If set to yes: pressing this button starts the

Drip time 0-10 sec. 2 sec. The length of time that the product

50-300 ml 125ml Use this for setting the volume per recipe

See section

3.2

(drink key).

Change any recipe buttons here that

standard factory settings. All settings

that correspond to selected recipes are

automatically loaded.

out of service.

here for each product button.

parameters (e.g. coffee dosage) can be

adjusted automatically. This parameter is

coupled to the quick recipe cup volume!

Advice: deactivate Quick recipe in the

Operator menu; 2.4 Settings / I/O Quick

recipe.

dispensed when the key switch is in the

jug setting.

0= key switch setting n/a

CUP (paid) or JUG* (paid)

1= key switch |: CUP (paid)

key switch –: JUG* (paid)

2= key switch |: no dispensing

key switch –: JUG* (paid)

3= key switch |: CUP (paid)

key switch –: JUG* (free)

(*when multicup is set to >1)

hot/cold water dispensing and releasing it

stops the hot water dispensing.

Only use this option for Water 4 and Water

6 in combination with a hot/cold water

recipe button.

continues to run from the brewer or mixer.

After this time has elapsed a new drink

selection can be made.

S1000 / S3000 / S3000 MAXI

50

08/2009 Rev. 0.4

08/2009 Rev. 0.4

51

S1000 / S3000 / S3000 MAXI

Page 7

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

Service menu continued ….

Main item Sub item Sub Item Range Description

2.3 Recipe setting Recipe name 1

Recipe name 10

Unit 1 DV 1 WT 0,0-30,0 s Waiting time Water 1

DV 1 0,0-100,0 ml Dispensing amount Water 1 (Brewer)

Rinse 1 WT 0,0-20,0 s Waiting time Rinsing Water 1

Rinse 1 0,0-15,0 ml

Ingredient 1 WT 0,0-30,0 s Waiting time Cacao (left cartridge)

Ingredient 1 0 - 6 x Number of shots Cacao (left cartridge)

Ingredient 2 WT 0,0-30,0 s Not used

Ingredient 2 0 - 6 x Not used

Mixer 1 WT 0,0-30,0 s Waiting time Mixer 1

Mixer 1 0,0-50,0 s Mixing time Mixer 1

Pause open IM1 0,0-10,0 s

Pause rest IM1 0,0-10,0 s

S3000 (MAXI) Cacao unit /

S1000 coffee unit

Pause open IM2 0,0-10,0 s Not used

Pause rest IM2 0,0-10,0 s Not used

Unit 2 DV 2 WT 0,0-30,0 s Waiting time Water 2

DV 2 0,0-100,0 ml Dispensing amount Water 2

Rinse 2 WT 0,0-20,0 s Waiting time Rinsing Water 2

Rinse 2 0,0-15,0 ml

Coffee WT 0,0-30,0 s Waiting time Coffee (middle cartridge)

Coffee 0 - 6 x Number of shots Coffee (middle cartridge)

Ingredient 4 WT 0,0-30,0 s Not used

Ingredient 4 0 - 6 x Not used

Coffee unit

Mixer 2 WT 0,0-30,0 s Waiting time Mixer 2

Mixer 2 0,0-50,0 s Mixing time Mixer 2

Pause open IM3 0,0-10,0 s

Pause rest IM3 0,0-10,0 s

Pause open IM4 0,0-10,0 s Not used

Pause rest IM4 0,0-10,0 s Not used

Dispensing amount Rinsing Water 1 Automatically deducted from Water 1

Pause time IM 1 when dosing slide is

totally open.

Pause time IM 1 in between 2 shots (motor

pauses in home position)

Dispensing amount Rinsing Water 2 Automatically deducted from Water 2

Pause time IM 3 when dosing slide is

totally open.

Pause time IM 3 in between 2 shots (motor

pauses in home position)

Service menu continued ….

Main item Sub item Sub Item Range Description

2.3 Recipe setting

(continued…)

Recipe name 1

Recipe name 10

Unit 3 DV 3 WT 0,0-30,0 s Waiting time Water 3

DV 3 0-100 ml Dispensing amount Water 3

Rinse 3 WT 0,0-20,0 s Waiting time Rinsing Water 3

Rinse 3 0,0-15,0 ml

Topping WT 0,0-30,0 s Waiting time Topping (right cartridge)

Topping 0 - 6 x Number of shots Topping (right cartridge)

Ingredient 6 WT 0,0-30,0 s Not used

Ingredient 6 0 - 6 x Not used

Mixer 3 WT 0,0-30,0 s Waiting time Mixer 3

Mixer 3 0,0-50,0 s Mixing time Mixer 3

Topping unit

Pause open IM5 0,0-10,0 s

Pause rest IM5 0,0-10,0 s

Pause open IM6 0,0-10,0 s Not used

Pause rest IM6 0,0-10,0 s Not used

DV 4 WT 0,0-30,0 s Waiting time Water 4

DV 4

DV 5 WT 0,0-30,0 s Not used

DV 5 0,0-100,0 ml Not used

DV 6 WT 0,0-30,0 s Not used

DV 6 0,0-100,0 ml Not used

0,0-100,0 ml

Dispensing time Rinsing Water 3

Automatically deducted from Water 3

Pause time IM 5 when dosing slide is

totally open.

Pause time IM 5 in between 2 shots (motor

pauses in home position)

Dispensing amount Water 4

(Hot water dispensed)

S1000 / S3000 / S3000 MAXI

52

08/2009 Rev. 0.4

08/2009 Rev. 0.4

53

S1000 / S3000 / S3000 MAXI

Page 8

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

Service menu continued…

Main item Sub item Item Range

2.4 Settings Language English Language choice display.

Dutch

German

French

Temperature Temp. boiler 70-95°C 95°C Boiler temperature

Hysteresis 2-10°C 2°C

Output block 70-90°C 78°C

Output release 70-90°C 85°C

Stand-by 60-80°C 60°C Boiler temperature during stand-by

Extended Heating 0-5 sec 1 sec

Display Show clock Yes/no No Show clock in display

Show date Yes/no No Show date in display

Message text Yes/no No

Use bleeper Yes/no Yes Sound signal on or off

Fan time 0-300 sec. 60 s.

Fan speed 1 40-100% 60% Fan speed when resting

Fan speed 2 40-100% 100% Fan speed during dispensing

Set-

Description

ting

Ex factory setting English.

Temperature drop, after which boiler

must reheat

Boiler temperature disables dispensing. Display: [Out of order, boiler

heating]

Boiler temperature allows

dispensing again

To maintain the optimum boiler temperature the heating element and

inlet valve switch on simultaneously.

Set the waste delay of the element

here after the inlet valve is closed.

Inlet valve

Heating

Inlet valve

Heating

Show message text (running text) in

display. Only shown if Display Date,

Clock or both are set to no. Message text only programmable using

a future PC programme.

Duration of Fan speed 1 after

dispensing

Service menu continued …..

Main item Sub item Item Range

2.4 Settings

(continued…)

2.5 Reset counters Rinse counters Brewer counter? Reset brewer spoelteller

2.6 Descale/fi lter Service moment 0-50000 12500 After the Service Due setting has

Coin system G13

I/0 Reset counter

I/0 Quick recipe

Drip tray sign.

Recipe counters Recipe counter 1

Reset all counters Reset alle tellers ineens

Service counter ????? The number of beverages dis-

Reset serv. coun After periodic maintenance has

Coin channel 1

0-100,00 +

Token

Coin channel 6

Single vend ja-nee ja

Max coin accep.

Point position 0-2 2 Decimal position in amount

Show credit Yes/no Yes Show credit on the display

MDB No MDB software available yet

Mixer counter? Reset mixer spoelteller

Recipe counter 10

Reset counter total Reset totaal tellers

€ 0,05100,00

Yes/no No

Yes/no Yes

Yes/no Yes Turns off drip tray sensor software.

Set-

Description

ting

€ 0,05

Coin value setting for each channel.

€ 0,10

€0.05-€2 respectively.

€ 0,20

0.00=free

€ 0,50

TOKEN=coffee token

€ 1,00

€ 2,00

Yes: any excess credit is not

retained for next drink. No: credit

retained for next drink.

Coins larger than € 1.00 are rejected

and ejected through the return slot

€ 1,00

of the coin mechanism. Adjust to the

highest recipe product price.

Add Reset counters menu item to

the operator menu

Add Quick recipe menu item to the

operator menu

Reset recepttellers per recept.

been reached the Descale/fi lter

indicator will be displayed. See sec-

tion 5. Service

pensed is counted here. Check here

to see how far the machine is from

periodic maintenance (descaling

boiler or replacing water fi lter).

been carried out (boiler descaled or

fi lter replaced) the service counter

should be set to nil.

S1000 / S3000 / S3000 MAXI

54

08/2009 Rev. 0.4

08/2009 Rev. 0.4

55

S1000 / S3000 / S3000 MAXI

Page 9

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

Service menu continued….

Main item Sub item Sub Range Description

2.7 Hardware test Inputs Temperature Boiler temp

Outputs

Test by holding

in recipe button 5.

# During test the

display shows

the Nominal

current (mA)

When the

Nominal current

of a output rises

above the set

current *

mentioned output

will be shut off.

Calib. valves

Test by holding

in recipe button

5 (for 1 sec.)

to open the relevant valve for

10 seconds.

Level sensors High Yes/no

Drip tray sensor Yes/no

Shot 1 Yes/no

Shot 2 Yes/no

Shot 3 Yes/no

Key switch Yes/no

KW1

DV1 Dispenser valve 1 (Mixer 1)

DV2 Dispenser valve 2 (Mixer 2)

DV3 Dispenser valve 3 (Mixer 3)

DV4 Dispenser valve 4 (Hot water)

DV5 Not used

DV6 Not used

IM1 #

IM2 # Not used

IM3 # Ingredients motor 3 (Coffee cartridge)

IM4 # Not used

IM5 # Ingredients motor 5 (Topping cartridge)

IM6 # Not used

MM1 #

MM2 # Mixer motor 2

MM3 # Mixer motor 3

Ventilator * 200 mA Ventilator

LED’s Not used

DV1 15 ml / sec Calibrate to 150 ml (10 sec x 15 ml)

DV2 15 ml / sec Calibrate to 150 ml (10 sec x 15 ml)

DV3 15 ml / sec Calibrate to 150 ml (10 sec x 15 ml)

DV4 20 ml / sec Calibrate to 200 ml (10 sec x 20 ml)

DV5 Not used

DV6 Not used

Low Yes/no

* 400 mA

* 400 mA

* 800 mA

Shows the status of the sensors/switches

indicated

Inlet valve (Boiler)

Ingredients motor 1 (Cacao cartridge)

Mixer motor 1

Service menu continued….

Main item Sub item Item Description

2.8 Read log Saves last 20 error messages, including date and time

2.9 Clear log Are you sure? Clears log

Are you sure?

2.10 Load defaults

* From software

V3.08 sept 2009

2.11 SD menu

Before saving

or loading data,

insert an empty SD

memory card into

the card reader .

This is located

behind the stainless

steel panel on the

inside of the door.

SD card

specifi cations:

- 16MB or greater

- FAT16 format

2.12 Change PIN New PIN code Repeat PIN code This menu item is for changing the PIN code using buttons 1-4 only.

Model #

S3000

S3000 MAXI

S1000 *

S1000 *

S1000 *

Load data Pers. settings

Memory Card

Save data Pers. settings

Memory Card

Type code

SY1A xx

SY2A xx

SY3A xx

SY4A xx

SY5A xx

Language

Recipe

Recipes

When a new circuit board is introduced it is necessary to load defaults. When loading defaults it must be stated on the Symfoni model

plate. The correct model settings are not loaded until the question

‘Are you sure?’ has been confi rmed.

Attention:

● Before you start changing the button- and/or receipt- settings, first

close the service menu, only after re-entering the service menu the

new model settings will be activated.

● When you confi rm this setting all loaded factory settings and

changed programmed values will be lost.

● After loading defaults the PIN code reverts to 2-2-2-2-2 and the

language reverts to English. Change if necessary.

This menu item is for loading personal settings to the device using

an SD memory card. This fi le contains the (amended) personal set-

tings for menus: 2.4 Settings / 2/6 Descale-fi lter / 2.13 Additional

settings. The data fi le (Ofxxxx00.mdu) should be on the SD card.

This menu item is for loading a different language set to the

device. The data fi le (xxxxxx.tlf) should be on the SD card.

This menu item is for loading personal recipes to the device using

an SD memory card. This fi le contains the (amended) personal reci-

pes for menus: 2.1 Quick recipe / 2.2 Button settings / 2.3 Recipe

settings. The data fi le (OFxxxx00.rcu) should be on the SD card.

This menu item is for saving personal settings to an SD memory

card and copying them to another device.

All settings amended in menus: 2.4 Settings / 2.6 Descale-fi lter /

2.13 Additional settings are loaded to the SD card in one data fi le

(OFxxxx00.mdu).

This menu item is for saving personal recipes to an SD memory

card and copying them to another device.

All settings amended in menus: 2.1 Quick recipe / 2.2 Button

settings/ 2.3 Recipe settings are loaded to the SD card in one data

fi le (OFxxxx00.rcu).

The entire service menu is accessed with this PIN code, which

prevents unintentional changes from being made to the machine

settings by untrained staff.

• The ex-factory PIN code is 2-2-2-2-2

PIN code forgotten or needs to be deactivated?

The PIN code input display (operator menu item 1.7) shows a

number on the right. Enter the corresponding PIN code (see list on

p.56) to access the service menu.

S1000 / S3000 / S3000 MAXI

56

08/2009 Rev. 0.4

08/2009 Rev. 0.4

57

S1000 / S3000 / S3000 MAXI

Page 10

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

PIN Code Table

Table 1

Water Hardness Table

No. Pincode No. Pincode

1 34242 11 13332

2 31434 12 12413

3 41343 13 43121

4 43232 14 11142

5 23341 15 21211

6 42131 16 12233

7 24244 17 34144

8 23241 18 41433

9 24323 19 31241

10 31332 20 22324

Water

Quality

°D °F mmol/l mgCaCo3/l

Hardness Limescale

Very hard 18-30 32-55 3,2-5,3 321- 536 5000

Hard 12-18 22-32 2,2-3,2 214-321 8500

Average 8-12 15-22 1,4-2,2 268-214 12.500*

Soft 4-8 7-15 0,7-1,4 72-268 20.500

Table 2

Very soft 0-4 0-7 0- 0,7 0-72 0 = off

3. RECIPE SETTINGS

3.1 Cartridge confi guration

The Symfoni models have the following standard cartridge confi gurations (fi g. 6):

Chocolate

Coee

Symfoni S1000 [ Coffee ]

Symfoni S3000 [ Cacao / Coffee / Topping ]

Symfoni S3000 MAXI [ Cacao / Coffee / Topping ]

Coee

Topping

Milk

Fig. 6

Indicator ...cups

3.2 Button settings

The standard of programmed recipes (table 3) can easily be transferred over the 10 recipe buttons.

See service menu 2.2 Button settings (page 49).

The optional recipes table are already contained in the software and can easily be programmed under

one recipe button. See service menu 2.2 Button settings (page 49).

Table 3

S3000 S3000 MAXI S1000

Coffee

S1000

Choco

S1000

Milk

Model 1A Model 2A Model 3A Model 4A Model 5A

1 Cacao Cacao Coffee Cacao Topping

2 Coffee Coffee - - -

3 Topping Topping - - -

Unit 2 Unit 3

Unit 1

Cartridge

135

Coee

Cacao

DV 1

Button

1

2

3

4

5

6

7

8

Standard recipes

9

10

Coffee Coffee Coffee

Coffee Coffee Coffee

Espresso Espresso Espresso Hot water -

Coffee Milk Coffee Milk Hot water - Hot Chocolate Hot Chocolate - - Chocolate Milk Chocolate Milk

Cappuccino Cappuccino

Moccacino Moccacino

Espresso Choc Jug of Coffee

Hot water Hot water

Jug of Coffee Espresso Choc Jug of Coffee Jug of Hot Water Jug of Hot Water

Jug of Hot Water Jug of Hot Water Jug of Hot Water

Latte Macchiato Latte Macchiato Decaf

Hot Milk Hot Milk

Decaf Decaf

Topping

DV 2 DV 3

Unit 2 Unit 3

Unit 1

135

Cacao

Topping

Coee

DV 2 DV 3

DV 1

Unit 1

Unit 1

1

Coee

DV 1

1

Coee

DV 1

Hot Chocolate small

Hot Chocolate large

Unit 1

1

Coee

DV 1

Hot Milk

Hot water

Optional recipes

* = only if the necessary ingredient (s) are

available in the catridges

S1000 / S3000 / S3000 MAXI

58

08/2009 Rev. 0.4

08/2009 Rev. 0.4

59

S1000 / S3000 / S3000 MAXI

Page 11

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

3.3.1 Parameter settings S3000

SY1abb00.RCD Buttons Optional recipe

12345678910 1112131415

Symfoni 1A

Standard

Coffee

Double Coffee

Espresso

Coffee Milk

Chocolate

Chocolate Milk

Cappuccino

Moccacino

Espresso Choc

Hot Water

Jug Coffee

Jug Hot Water

Latte Macchiato

Recipe 1 22 527179101511 2021131838

Recipe Active 1111111111 1 1 111

Brewer 0000000000 0 0 00 0

Price 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10

Cup volume ml 125 250 70 125 125 125 150 120 125 125 125 125 150 125 125

Multicup 0000000000 1212000

Key switch 3333333333 0 0 333

Push & Hold 0000000000 0 00 00

Leak out time sec. 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0

DV 1 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 4,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 1 ml 0,0 0,0 0,0 0,0 100,0 66,0 0,0 30,0 66,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 1 WT sec. 0,0 0,0 0,0 0,0 0,5 0,5 0,0 0,5 0,5 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 1 ml 0,0 0,0 0,0 0,0 7,5 7,5 0,0 7,5 7,5 0,0 0,0 0,0 0,0 0,0 0,0

Cacao 1 WT sec. 0,0 0,0 0,0 0,0 0,5 0,5 0,0 0,5 0,5 0,0 0,0 0,0 0,0 0,0 0,0

Cacao 1 Shots 0000330130 0 0 0 0 0

Ingredient 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 2 Shots 0000000000 0 0 0 00

Mixer 1 WT sec. 0,0 0,0 0,0 0,0 0,5 0,5 0,0 0,5 0,5 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 1 sec. 0,0 0,0 0,0 0,0 7,1 4,9 0,0 2,5 4,9 0,0 0,0 0,0 0,0 0,0 0,0

DV 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 9,0 2,0 6,0 0,0 0,0 0,0 20,0 0,0 0,0

DV 2 ml 100,0 100,0 100,0 66,0 0,0 0,0 34,0 30,0 34,0 0,0 100,0 0,0 34,0 0,0 0,0

Rinse 2 WT sec. 0,5 0,5 0,5 0,5 0,0 0,0 0,5 1,0 0,5 0,0 0,5 0,0 0,5 0,0 0,0

Rinse 2 ml 7,5 7,5 7,5 7,5 0,0 0,0 7,5 7,5 7,5 0,0 7,5 0,0 7,5 0,0 0,0

Coffee 3 WT sec. 0,5 0,5 0,5 0,5 0,0 0,0 0,5 0,0 0,5 0,0 0,5 0,0 0,5 0,0 0,0

Coffee 3 Shots 2422002210 2 0 2 00

Ingredient 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 4 Shots 0000000000 0 0 0 00

Mixer 2 WT sec. 0,5 0,5 0,5 0,5 0,0 0,0 0,5 0,5 0,5 0,0 0,5 0,0 0,5 0,0 0,0

Mixer 2 sec. 7,1 7,1 6,1 4,9 0,0 0,0 3,0 3,0 2,7 0,0 7,1 0,0 2,7 0,0 0,0

DV 3 WT sec. 0,0 0,0 0,0 5,0 0,0 6,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 ml 0,0 0,0 0,0 34,0 0,0 34,0 66,0 40,0 0,0 0,0 0,0 0,0 66,0 100,0 100,0

Rinse 3 WT sec. 0,0 0,0 0,0 0,5 0,0 0,5 0,5 0,5 0,0 0,0 0,0 0,0 0,5 0,5 0,5

Rinse 3 ml 0,0 0,0 0,0 7,5 0,0 7,5 7,5 7,5 0,0 0,0 0,0 0,0 7,5 7,5 7,5

Topping 5 WT sec. 0,0 0,0 0,0 0,5 0,0 0,5 0,5 0,5 0,0 0,0 0,0 0,0 0,5 0,5 0,5

Topping 5 Shots 0001013200 0 03 32

Ingredient 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 6 Shots 0000000000 0 0 0 00

Mixer 3 WT sec. 0,0 0,0 0,0 0,5 0,0 0,5 0,5 0,5 0,0 0,0 0,0 0,0 0,5 0,5 0,5

Mixer 3 sec. 0,0 0,0 0,0 2,7 0,0 2,7 4,9 3,1 0,0 0,0 0,0 0,0 4,9 7,1 7,1

DV 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 100,0 0,0 100,0 0,0 0,0 0,0

DV 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 5 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 1 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 1 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 3 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 3 sec. 1,0 2,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 1,0 0,0 0,0 0,0 0,0

Pause Open IM 4 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 4 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 5 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 5 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 6 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 6 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Hot Milk

Decaf

3.3.2 Parameter settings S3000 MAXI

SY2abb00.RCD Buttons Optional recipe

12345678910 1112131415

Symfoni 2A

Standard

Coffee

Double Coffee

Espresso

Coffee Milk

Chocolate

Chocolate Milk

Cappuccino

Moccacino

Jug Coffee

Hot Water

Espresso Choc

Jug Hot Water

Latte Macchiato

Recipe 1 22 5 2 7 17 9 10 20 11 15 21 13 18 38

Recipe Active 1 1 1 1111111 1 1 1 1 1

Brewer 0 0 0 0000000 0 0 0 0 0

Price 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,10

Cup volume ml 125 250 70 125 125 125 150 120 125 125 125 125 150 125 125

Multicup 0 0 0 00000120 0 120 0 0

Key switch 3 3 3 3333303 3 0 3 3 3

Push & Hold 0 0 0 0000000 0 0 0 0 0

Leak out time sec. 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0

DV 1 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 4,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 1 ml 0,0 0,0 0,0 0,0 100,0 66,0 0,0 30,0 0,0 0,0 66,0 0,0 0,0 0,0 0,0

Rinse 1 WT sec. 0,0 0,0 0,0 0,0 0,5 0,5 0,0 0,5 0,0 0,0 0,5 0,0 0,0 0,0 0,0

Rinse 1 ml 0,0 0,0 0,0 0,0 7,5 7,5 0,0 7,5 0,0 0,0 7,5 0,0 0,0 0,0 0,0

Cacao 1 WT sec. 0,0 0,0 0,0 0,0 0,5 0,5 0,0 0,5 0,0 0,0 0,5 0,0 0,0 0,0 0,0

Cacao 1 Shots 0 0 0 0330100 3 0 0 0 0

Ingredient 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 2 Shots 0 0 0 0000000 0 0 0 0 0

Mixer 1 WT sec. 0,0 0,0 0,0 0,0 0,5 0,5 0,0 0,5 0,0 0,0 0,5 0,0 0,0 0,0 0,0

Mixer 1 sec. 0,0 0,0 0,0 0,0 7,1 4,9 0,0 2,5 0,0 0,0 4,9 0,0 0,0 0,0 0,0

DV 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 9,0 2,0 0,0 0,0 6,0 0,0 20,0 0,0 0,0

DV 2 ml 100,0 100,0 100,0 66,0 0,0 0,0 34,0 30,0 100,0 0,0 34,0 0,0 34,0 0,0 0,0

Rinse 2 WT sec. 0,5 0,5 0,5 0,5 0,0 0,0 0,5 1,0 0,5 0,0 0,5 0,0 0,5 0,0 0,0

Rinse 2 ml 7,5 7,5 7,5 7,5 0,0 0,0 7,5 7,5 7,5 0,0 7,5 0,0 7,5 0,0 0,0

Coffee 3 WT sec. 0,5 0,5 0,5 0,5 0,0 0,0 0,5 0,0 0,5 0,0 0,5 0,0 0,5 0,0 0,0

Coffee 3 Shots 2 4 2 2002220 1 0 2 0 0

Ingredient 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 4 Shots 0 0 0 0000000 0 0 0 0 0

Mixer 2 WT sec. 0,5 0,5 0,5 0,5 0,0 0,0 0,5 0,5 0,5 0,0 0,5 0,0 0,5 0,0 0,0

Mixer 2 sec. 7,1 7,1 6,1 4,9 0,0 0,0 3,0 3,0 7,1 0,0 2,7 0,0 2,7 0,0 0,0

DV 3 WT sec. 0,0 0,0 0,0 5,0 0,0 6,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 ml 0,0 0,0 0,0 34,0 0,0 34,0 66,0 40,0 0,0 0,0 0,0 0,0 66,0 100,0 100,0

Rinse 3 WT sec. 0,0 0,0 0,0 0,5 0,0 0,5 0,5 0,5 0,0 0,0 0,0 0,0 0,5 0,5 0,5

Rinse 3 ml 0,0 0,0 0,0 7,5 0,0 7,5 7,5 7,5 0,0 0,0 0,0 0,0 7,5 7,5 7,5

Topping 5 WT sec. 0,0 0,0 0,0 0,5 0,0 0,5 0,5 0,5 0,0 0,0 0,0 0,0 0,5 0,5 0,5

Topping 5 Shots 0 0 0 1013200 0 0 3 3 2

Ingredient 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 6 Shots 0 0 0 0000000 0 0 0 00

Mixer 3 WT sec. 0,0 0,0 0,0 0,5 0,0 0,5 0,5 0,5 0,0 0,0 0,0 0,0 0,5 0,5 0,5

Mixer 3 sec. 0,0 0,0 0,0 2,7 0,0 2,7 4,9 3,1 0,0 0,0 0,0 0,0 4,9 7,1 7,1

DV 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 100,0 0,0 100,0 0,0 0,0 0,0

DV 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 5 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 1 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 1 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 3 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 3 sec. 1,0 2,0 0,0 0,0 0,0 0,0 0,0 0,0 1,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 4 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 4 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 5 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 5 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 6 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Rest IM 6 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Hot Milk

Decaf

S1000 / S3000 / S3000 MAXI

60

Table 4

08/2009 Rev. 0.4

08/2009 Rev. 0.4

61

Table 5

S1000 / S3000 / S3000 MAXI

Page 12

S1000 All in One

S3000 All in One (MAXI)

3.2.3 Parameter settings S1000 Coffee 3.2.4 Parameter settings S1000 Cacao

S1000 All in One

S3000 All in One (MAXI)

SY3Age00.RCD Buttons Optional recipe

12345 1112131415

Symfoni 3A

Standard

Coffee

Double Coffee

Espresso

Hot Water

Recipe 1 22 5 11 0 20 21 38 0 0

Recipe Active 11110 11100

Brewer 00000 00000

Price 0,10 0,10 0,10 0,10 0,00 0,10 0,10 0,10 0,00 0,00

Cup volume ml 125 250 70 125 0 125 125 125 0 0

Multicup 00000 1212000

Key switch 33330 00300

Push & Hold 00000 00000

Leak out time sec. 2,0 2,0 2,0 2,0 0,0 2,0 2,0 2,0 0,0 0,0

DV 1 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 1 ml 100,0 100,0 100,0 0,0 0,0 100,0 0,0 100,0 0,0 0,0

Rinse 1 WT sec. 0,5 0,5 0,5 0,0 0,0 0,5 0,0 0,5 0,0 0,0

Rinse 1 ml 7,5 7,5 7,5 0,0 0,0 7,5 0,0 7,5 0,0 0,0

Ingredient 1 WT sec. 0,5 0,5 0,5 0,0 0,0 0,5 0,0 0,5 0,0 0,0

Ingredient 1 shots 24200 20200

Ingredient 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 2 shots 00000 00000

Mixer 1 WT sec. 0,5 0,5 0,5 0,0 0,0 0,5 0,0 0,5 0,0 0,0

Mixer 1 sec. 7,1 7,1 6,1 0,0 0,0 7,1 0,0 7,1 0,0 0,0

DV 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 2 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 2 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 3 shots 00000 00000

Ingredient 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 4 shots 00000 00000

Mixer 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 3 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 5 shots 00000 00000

Ingredient 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 6 shots 00000 00000

Mixer 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 3 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 ml 0,0 0,0 0,0 100,0 0,0 0,0 100,0 0,0 0,0 0,0

DV 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 5 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 1 sec.

Pause Rest IM 1 sec.

Pause Open IM 2 sec.

Pause Rest IM 2 sec.

Pause Open IM 3 sec.

Pause Rest IM 3 sec.

Pause Open IM 4 sec.

Pause Rest IM 4 sec.

Pause Open IM 5 sec.

Pause Rest IM 5 sec.

Pause Open IM 6 sec.

Pause Rest IM 6 sec.

00000 00000

1020000 100000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

>none<

Jug Coffee

Jug Hot Water

Decaf

>none<

>none<

Tabel 6

SY4Age00.RCD Buttons Optional recipe

12345 1112131415

Symfoni 4A

Standard

Chocolate

Small

Chocolate

Large

Hot Water

>none<

Recipe 62 63 11 0 0 21 0 0 0 0

Recipe Active 1 1 1 0 0 1 0 0 0 0

Brewer 0 0 0 0 0 0 0 0 0 0

Price 0,10 0,10 0,10 0,00 0,00 0,10 0,00 0,00 0,00 0,00

Cup volume ml 125 200 125 0 0 125 0 0 0 0

Multicup 0 0 0 0 0 12 0 0 0 0

Key switch 3 3 3 0 0 0 0 0 0 0

Push & Hold 0 0 0 0 0 0 0 0 0 0

Leak out time sec. 2,0 2,0 2,0 0,0 0,0 2,0 0,0 0,0 0,0 0,0

DV 1 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 1 ml 100,0 100,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 1 WT sec. 0,5 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 1 ml 7,5 7,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 1 WT sec. 0,5 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 1 shots 3 4 0 0 0 0 0 0 0 0

Ingredient 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 2 shots 0 0 0 0 0 0 0 0 0 0

Mixer 1 WT sec. 0,5 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 1 sec. 7,1 7,1 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 2 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 2 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 3 shots 0 0 0 0 0 0 0 0 0 0

Ingredient 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 4 shots 0 0 0 0 0 0 0 0 0 0

Mixer 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 3 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 5 shots 0 0 0 0 0 0 0 0 0 0

Ingredient 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 6 shots 0 0 0 0 0 0 0 0 0 0

Mixer 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 3 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 ml 0,0 0,0 100,0 0,0 0,0 100,0 0,0 0,0 0,0 0,0

DV 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 5 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 1

Pause Rust IM 1

Pause Open IM 2

Pause Rust IM 2

Pause Open IM 3

Pause Rust IM 3

Pause Open IM 4

Pause Rust IM 4

Pause Open IM 5

Pause Rust IM 5

Pause Open IM 6

Pause Rust IM 6

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

00000 00000

sec.

>none<

Jug Hot Water

>none<

>none<

>none<

>none<

Tabel 7

S1000 / S3000 / S3000 MAXI

62

08/2009 Rev. 0.4

08/2009 Rev. 0.4

63

S1000 / S3000 / S3000 MAXI

Page 13

S1000 All in One

S3000 All in One (MAXI)

3.2.5 Parameter settings S1000 Milk 3.3 Detailed recipe settings

SY5Age00.RCD Buttons Optional recipe

12345 1112131415

Symfoni 5A

Standard

Recipe 18 11 0 0 0 21 0000

Recipe Active 11000 10000

Brewer 00000 00000

Price 0,10 0,10 0,00 0,00 0,00 0,10 0,00 0,00 0,00 0,00

Cup volume ml 125 125 0 0 0 125 0000

Multicup 00000 120000

Key switch 33000 00000

Push & Hold 00000 00000

Leak out time sec. 2,0 2,0 0,0 0,0 0,0 2,0 0,0 0,0 0,0 0,0

DV 1 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 1 ml 100,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 1 WT sec. 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 1 ml 7,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 1 WT sec. 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 1 shots 30000 00000

Ingredient 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 2 shots 00000 00000

Mixer 1 WT sec. 0,5 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 1 sec. 7,1 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 2 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 2 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 3 shots

Ingredient 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 4 shots 00000 00000

Mixer 2 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 2 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 3 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Rinse 3 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 5 shots 00000

Ingredient 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Ingredient 6 shots 00000 00000

Mixer 3 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Mixer 3 sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 4 ml 0,0 100,0 0,0 0,0 0,0 100,0 0,0 0,0 0,0 0,0

DV 5 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 5 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 WT sec. 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

DV 6 ml 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Pause Open IM 1

Pause Rust IM 1

Pause Open IM 2

Pause Rust IM 2

Pause Open IM 3

Pause Rust IM 3

Pause Open IM 4

Pause Rust IM 4

Pause Open IM 5

Pause Rust IM 5

Pause Open IM 6

Pause Rust IM 6

sec.

sec.

sec.

sec.

sec.

sec.

sec.

sec.

sec.

sec.

sec.

sec.

Hot Milk

Hot Water

00000 0 0000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

00000 00000

>none<

>none<

Jug Hot

>none<

Water

>none<

>none<

0 0000

>none<

>none<

Tabel 8

To change detailed recipe settings (service menu 2.3) you fi rst need to be aware of the various parts

such as valves, brewer motor, ingredients motor and mixers that work together.

See section 3.4 Timebar recipe settings.

The following rules should be taken into consideration:

● Water (valves) are easily set in millilitres.

● Motor running times of the Mixers are set in seconds (0.1 second steps)

● Motor running times of the ingredients are set in shots

● All parameters (Water and Ingredients) are based on a 100 ml drink and the programme

automatically converts them to the cup volume as set in 1.4 / 2.1 Quick recipe and

2.2 Button settings.

● If a drink contains DV1 and DV2, the total amount of water should always be 100 ml when

combined. For DV1, DV2, DV3 and DV4, this amount = > 100 ml.

● A Rinse parameter is used to ensure that the brewer unit and mixers are properly rinsed after

making a drink. After the mixers are almost empty a small amount of hot water is dispensed to the

mixer so that it is as clean as possible on completion.

A realistic rinse value is 7.5 ml. Caution: this does not need to be deducted from the amount of

water as the programme does this automatically!

Example: Set parameter for DV1 = 100 ml, Rinse 1 = 7.5 ml -->

Programme carries out the following action: DV1 = 92.5 ml, Rinse 1 = 7.5

3.4 Timebar recipe settings

DV 1WT DV 1 R inse 1 WT Rinse 1

Unit 1

DV 2 WT DV 2 Rinse 2 WT Rinse 2

Unit 2

DV 3 WT DV 3 Rinse 3 WT Rinse 3

Unit 3

DV 4 WT DV 4

Ingr. WT

Ingr. WT

Mixer WT M ixer 1

Ingr. WT

Ingr. WT Ingredient 4

Mixer WT M ixer 2

Ingr. WT

Ingr. WT Ingredient 6

Mixer WT Mixer 3

Cacao 1

Ingredient 2

Coee 3

Topping 5

Shot

Shot

Shot

20ml/sec. (Hot water)

15ml/sec.

15ml/sec.

15ml/sec.

S1000 All in One

S3000 All in One (MAXI)

S1000

Unit 1

1

Coee

DV 1

DV 4

Heetwater

S3000 (MAXI)

Unit 2 Unit 3

Unit 1

135

Cacao

DV 1

Mixer 1

Coee

DV 2 DV 3

Mixer 2 M ixer 3

Topping

DV 4

Heetwater

S1000 / S3000 / S3000 MAXI

64

08/2009 Rev. 0.4

08/2009 Rev. 0.4

65

Fig. 7

Fig. 8

S1000 / S3000 / S3000 MAXI

Page 14

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

3.5 Calibrating the hot water valves

The Brewer and Mixers are supplied with water by the

Dispensing Valves (DV).

In the unlikely event that one of the valves needs replacing, it should be calibrated to one of the

dispensing speeds given in fi gure 9 after it has been

fi tted.

When calibrating valves, use the special Valve Calibra-

tion menu by opening the Service Menu and going to

2.7 Hardware Test / 2.7.2 Calibrating Valves.

The hot water dispensing valves are accessible by

dismantling the canister plateau behind the

cartridges.

S1000

DV 1 = 15ml/sec. (Mixer1)

DV 4 = 20ml/sec. (Hot water)

S3000

S3000 MAXI

DV 1 = 15ml/sec. (Mixer1)

DV 2 = 15ml/sec. (Mixer 2)

DV 4 = 20ml/sec. (Hot water)

DV 3 = 15ml/sec. (Mixer 3)

Fig. 9

4.0 SERVICE

WARNING

• In order to descale the water reservoir, the device must be opened. This will expose live parts of

the machine, which can be touched easily. This may lead to highly dangerous situations!

WARNING

• The device must not be submerged or hosed down.

• Always stay with the device during maintenance work.

4.1 Setting a service parameter

During installation, set a parameter for the device to be serviced.

See Service Menu item 2.8 Descale / fi lter. Use the table below to

set the correct service parameter.

Service parameter reached?

The dispensed drinks are counted during use. If the service

parameter is reached the display shows the following message:

Descale / fi lter (fi g. 12).

The message indicates that the device must be descaled. If a water

fi lter is fi tted (recommended), this is also an indication that the fi lter

must be replaced.

Water hardness table

Water

Quality

°D °F mmol/l mgCaCo3/l

Hardness Service Indicator (cups)

Very hard 18-30 32-55 3,2-5,3 321- 536 5000

Hard 12-18 22-32 2,2-3,2 214-321 8500

Average 8-12 15-22 1,4-2,2 268-214 12.500*

Soft 4-8 7-15 0,7-1,4 72-268 20.500

Very soft 0-4 0-7 0- 0,7 0-72 0 = uit

Fig. 10

Table 9

S1000 / S3000 / S3000 MAXI

66

08/2009 Rev. 0.4

08/2009 Rev. 0.4

67

S1000 / S3000 / S3000 MAXI

Page 15

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

4.2 Preventative maintenance

4.2.1 Service contracts

PREFACE

Preventative maintenance will lengthen the life cycle of the device and reduce the chance of

malfunction. Before carrying out maintenance, read the safety instructions in the user manual, service

manual, and recommended cleaning agents.

Water fi lter

We strongly advise you to use a water softener and/or water fi lter if the mains water is heavily

chlorinated or is too hard. This increases the quality of the drink and will ensure that you do not have

to descale the device too often.

4.2.2 Servicing

For an estimated total of < 25000 cups a year we recommend one service a year.

For an estimated total of > 25000 cups a year we recommend two services a year.

Service activity

Time

Descale 45 min.

Descale boiler system (see service manual).

Use valve seal set if necessary.

Mixers 10 min.

Check Motor axis for dirt and wear and tear.

Replace green mounting ring.

Replace mixer rotor.

Clean mixer parts.

Grease water connection using silicone grease).

Inspection (general)

Check that the entire machine is working.

Check parts for damage/wear and tear and/

or leaks.

Cleaning (general)

Brewer and mixer unit as for weekly cleaning.

The entire interior and exterior of the machine.

Product

Art. No.:

Symfoni

S1000

S3000

(MAXI)

descaler

Valve seal set 99673 2x 4x

Mixer fan

03254 1x 3x

Mounting ring (incl.

seals).

03253 1x 3x

WARNING

• Do not leave the device during maintenance work.

• When descaling always follow the instructions for

the descaler used.

• It is advisable to wear safety goggles and protective

gloves when descaling.

• After descaling, allow the device to run a minimum

of three times.

• Wash hands thoroughly after descaling.

• The device must not be submerged or hosed down.

4.3 Descaling instructions

Time required, products and tools:

• Time: approximately 45 minutes

• Animo Descaler x 2 sachets or 8-10 dessert spoons

• Drip tray of approximately 1.5 litres

• Bucket or basin at hand

1. Switch on the device and let it warm up.

The advantage of this is that the reservoir is properly

warmed in advance, which achieves a better result

during descaling.

2. Switch off the device and pull the plug out of the

socket.

3. Dispense one litre of hot water from the water

reservoir using the tap at the backside of the device

(fi g. 11-1).

4. Remove the rear plate (fi g. 11-2) and unscrew the

reservoir lid (fi g. 11-3). Take care: HOT!

5. Before going any further, read the warnings and

instructions for use on the Descaler sachets

before dissolving two 50g sachets in the measuring

jug (8-10 dessert spoons).

1

2

3

S1000 / S3000 / S3000 MAXI

68

Table 10

08/2009 Rev. 0.4

08/2009 Rev. 0.4

69

Fig. 11

S1000 / S3000 / S3000 MAXI

Page 16

S1000 All in One

S3000 All in One (MAXI)

6. Pour the acid solution into the reservoir (fi g. 12-1).

The acid solution will now react with the lime scale.

7. Leave the solution to soak for a minimum of 10

minutes, until the foaming has stopped.

8. Use a brush to spread the acid over the level

electrodes during the soaking time (fi g. 12-2).

9. Put the plug in the socket again and turn on the

device so that the reservoir warms up.

10. Activate the MIXER cleaning programme (fi g. 12-3),

so that the acid solution leaves the water reservoir

via the MIXER VALVES. Place a drip tray under

both outlets (fi g. 12-4) and follow the instructions on

the display.

11. Turn off the device and allow the reservoir to empty

completely using the tap (fi g. 12-1).

12. Turn on the device again; the reservoir will refi ll with

clean water. Repeat instruction 10 one more time to

rinse the reservoir completely free of acid.

13. Turn on the device again; the reservoir will refi ll with

clean water. Allow the water reservoir to heat up.

14. Activate the MIXER programme (fi g. 12-3), so that

valves and pipe systems are rinsed clean. Place the

measuring jug under the outlet (fi g. 12-4).

15. Repeat the above descaling procedure if lime scale

is still present in the reservoir.

16. Screw the lid back onto the reservoir and replace

the rear plate.

17. Clear the service parameter counter in the Service

Menu 2.6 Descale / fi lter /2.6.2 Reset service

counter.

18. The device is now ready for use again.

S1000 All in One

S3000 All in One (MAXI)

5. COMPONENT ACCESSIBILITY

1

2

3

Cartridges

Cartridge holders

Mixers

Splitter

Dispensing valves

Ingredient motors

Display

Interface

Service panel

24V Supply

Power relais

Drip tray full sensor

Inlet valve

S1000 / S3000 / S3000 MAXI

70

4

Fig. 12

08/2009 Rev. 0.4

Water reservoir

Level / NTC

Dry boil safety

Ventilator

Main PC board

Main switch

08/2009 Rev. 0.4

71

Fig. 13

S1000 / S3000 / S3000 MAXI

Page 17

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

5.1 Electronics summary

WARNING

During repairs or maintenance work, avoid electrostatic

discharge (ESD) on the control unit.

● Control unit ........................................ 5.1.1

● Power supply 230Vac:24V 65W ........ 5.1.2

● Circuit board ...................................... 5.1.3

5.1.1 Control unit

This control unit is the device’s main control unit and

is accessible by removing the left side panel (fi g. 14a).

The following important parts can be found in the main

control unit (fi g. 14):

● Fuse (6, 3A t): to safeguard the power supply to the

control unit.

● Battery: to maintain the clock and counter function

when there is no power supply to the device.

1

J12

2

3

GND

+24Vdc

KEY / DISPLAY

4

5

6

7

8

9

10

11

12

+5V

1

GND

2

LB

3

GND

4

LSL

5

GND

6

SENSORS

LSH

7

GND

8

AS

9

BS

10

INPUTS

DS

11

12

13

14

15

16

17

18

J7

TEMP1

1

2

J16

BATT

USB

COMMUNICATION

MICROCONTROLLER

CSI

+

F1

F6,3AT

24V DC

1

2

3

4

J1

POWER SUPPLY

RS232

OUTPUTS

INGREDIENT MOTORSMIXERS

INLET

DOSING VALVESVALVES

FAN

HEATER

RELAIS

G13MDB

MIX/BR

MIX2

MIX3

IM1

IM2

IM3

IM4

IM5

IM6

KW1

KW2

KW3

DV1

DV2

DV3

DV4

DV5

DV6

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J2

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J4

2

1

J15

4

3

2

1

J6

Fig. 14

Fig. 14a

5.1.2 Interface / Display

The interface (fi g. 15) connects all components found

inside and on the door with the main control unit via a

fl at cable.

Animo OptiFresh

Option

JP3

DISPLAY

KEYSWITCH

JP2

SERVICE KEYBOARD

J1

KEYBOARD

SD-READER

J4

J14

MAIN BOARD

J3

J2

JP4

TO MAIN PC BOARD

SD Memory Card

Fig. 15

5.1.3 Power supply

The 24 V DC power supply (fi g. 16) consists of a

24V DC 65W switch mode power supply and can be

accessed by removing the rear plate. The power supply

is located under the main circuit (fi g. 16a).

During an overload the power supply automatically

switches off. Reset the power supply by turning the

main switch off and on.

+24V GND

1

Fig. 16

84-265 Vac

Fig. 15a

Fig. 16a

S1000 / S3000 / S3000 MAXI

72

08/2009 Rev. 0.4

08/2009 Rev. 0.4

73

S1000 / S3000 / S3000 MAXI

Page 18

S1000 All in One

S3000 All in One (MAXI)

S1000 All in One

S3000 All in One (MAXI)

5.2 Main circuit board entrances

Connector J12

Connector cable between the main circuit and door circuit

Connector J7

Pin Sensor Colour Comments

1-2 -

3 Drip tray sensor Yellow

4 Drip tray sensor Mass Black

5 Level sensor Low Brown

6 Level sensor Mass Green

7 Level sensor High White

8-13 Not used -

14 Waste bin switch Grey Ingr. motor in position;

15 Brewer switch Pink Ingr. motor in position;

16 Door switch Orange Ingr. motor in position;

17-18 Not used -

Connector J16

Pin Sensor Colour Comments

1 NTC sensor Violet

2 NTC sensor Violet

Battery

Lithium 3V Type CR2025 Art. No. 02816

Fuse

6,3A slow Art. No. 03391

Connector J1

Pin Colour Comments

1 Mass (GND) Black

2 Mass (GND) Black

3 +24V DC Red

4 +24V DC Red

contact closed

contact closed

contact closed

F1

J7

J16

J1

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

F6,3AT

1

2

3

4

J12

+5V

GND

LB

GND

LSL

GND

LSH

GND

AS

BS

DS

KEY / DISPLAY

SENSORS

TEMP1

BATT

+

24V DC

INPUTS

Fig. 17

5.3 Main circuit board exits

Connector J2

Pin Motor Colour Comments

17-18 Mixer 1

15-16 Mixer 2 Violet

13-14 Mixer 3 Pink

11-12 Ingredient Motor 1 Brown

9-10 Not used -

7-8 Ingredient Motor 3 White

5-6 Not used -

3-4 Ingredient Motor 5 Grey

1-2 Not used -

Connector J4

Pin Valve Colour Comments

17-18 KW 1 (inlet valve) Violet

15-16 KW 2 -

13-14 KW 3 -

11-12 DV 1 (mixer 1 valve) Brown

9-10 DV 2 (mixer 2 valve) White

7-8 DV 3 (mixer 3 valve) Green

5-6 DV 4 (hot water tap) Yellow

3-4 Not used -

1-2 Not used -

Connector J15

Pin Motor Colour Comments

2

Ventilator

1

Connector J6

Pin Relay Colour Comments

4

Power relay (element)

3 White

2

Power relay

1

Black

Take care to rotate in

the right direction!

Shared +24 DC (red wire)

on red spot on Mixer and

Ingredients Motor.

Red wire is a shared

(24VDC) connection

Red

Orange

Red

-

-

INGREDIENT MOTORSMIXERS

INLET

OUTPUTS

DOSING VALVESVALVES

FAN

HEATER

RELAIS

MIX/BR

MIX2

MIX3

IM1

IM2

IM3

IM4

IM5

IM6

KW1

KW2

KW3

DV1

DV2

DV3

DV4

DV5

DV6

H1

H2/3

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J2

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J4

2

1

J15

4

3

2

1

J6

Fig. 18

S1000 / S3000 / S3000 MAXI

74

08/2009 Rev. 0.4

08/2009 Rev. 0.4

75

S1000 / S3000 / S3000 MAXI

Page 19

S1000 All in One

S3000 All in One (MAXI)

5.4 Main circuit board communication

S1000 All in One

S3000 All in One (MAXI)

6.3 Troubleshooting

Communication

Conn Comments

G13 Coin tester NRI G13

MDB Coin changer

CSI Future port

RS232 Future port

USB Future port

OPTIONAL

USB

MDBCSI

RS232

COMMUNICATION

G13

Fig. 19

6. TROUBLESHOOTING

WARNING

● When carrying out repairs and cleaning the device, the plug should always be removed from the

wall socket before the device is opened.

Preface

Before searching for the defect, check that all parts are in their correct position. To do this, remove

the device’s rear plate and check that all printed circuit boards, connectors, wire beams and pipes are

mounted correctly.

After carrying out a general parts inspection, use section 6.3 Troubleshooting analysis to verify the

probable cause of the problem.