Page 1

INSTALLATION

INSTRUCTIONS

Rapid City, SD, USA, 10/2009

MODELS PC-100-LLC-CZ

PC-200-LLC-CZ

Revision A1

II_PC-XXX-LLC--CZ_A1

2880 North Plaza Drive, Rapid City, South Dakota 57702

(800) 843-8848 · (605) 348-5580 · fax (605) 348-5685

Page 2

BE SURE POWER IS DISCONNECTED PRIOR TO INSTALLATION!

FOLLOW NATIONAL, STATE AND LOCAL CODES.

SymCom’s PumpSaver

READ THESE INSTRUCTIONS ENTIRELY BEFORE INSTALLATION.

®

Model PC-XXX-LLC-CZ liquid level controllers are used to detect the

presence of conductive liquids and control the operation of a single pump. The line voltage must be

specified in the part number.

These devices use two probe inputs (a High Probe and a Low Probe, with a tank or probe common)

to determine whether to start or stop a pump. The inputs to the PumpSaver

®

are usually liquid level

sensors that sense a decrease in resistance between the probes when liquid contacts the sensors.

Pump-up or pump-down operation may be selected by turning the adjustment knob to the left or

right side of center on the sensitivity range. See Figure 3. The probe sensitivity may be selected by

turning the adjustment knob to the desired resistance threshold. This sets the level at which the

PumpSaver

®

determines whether liquid is present at the probes. If the resistance of the probe drops

below the threshold, then liquid is detected. If the resistance of the probe rises above the threshold,

then liquid is not detected.

These devices may also be used in a single-probe application (with a tank or probe common).

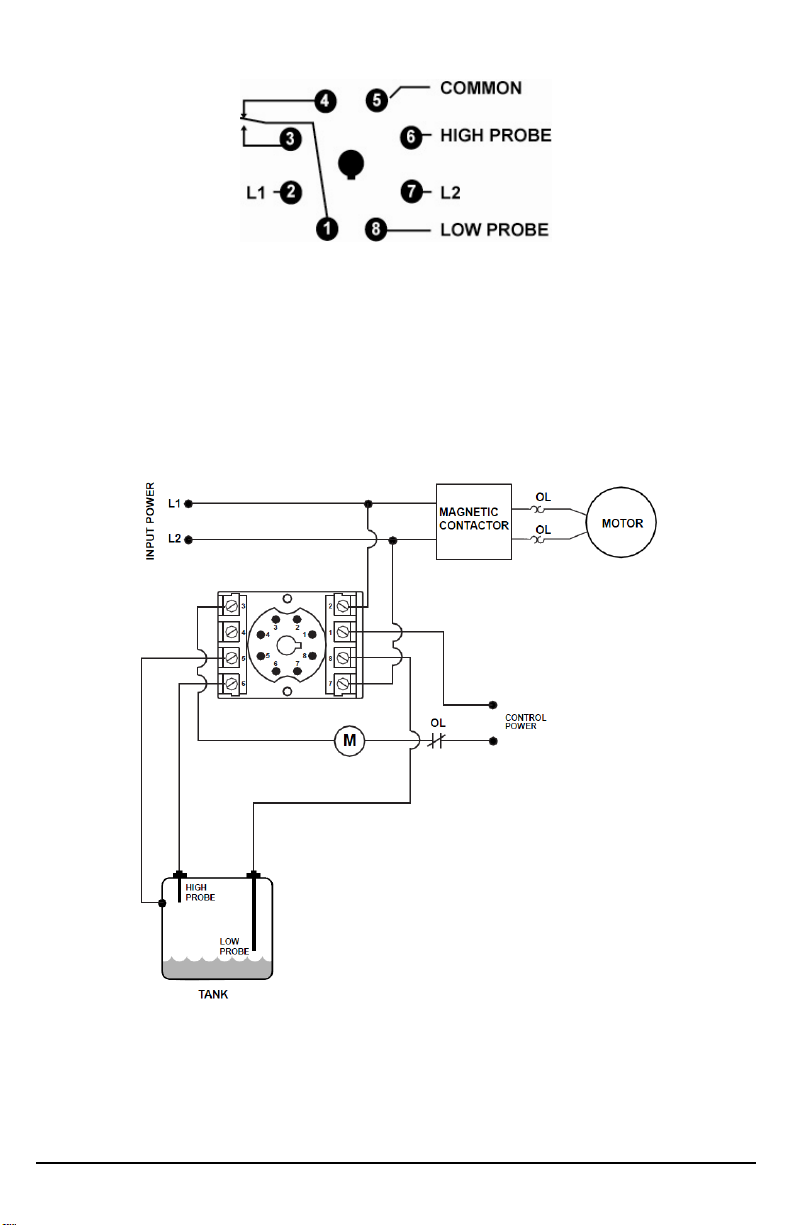

CONNECTIONS for PC-XXX-LLC-CZ Products

1. The PC-XXX-LLC-CZ requires an 8-pin socket, part number OT08-PC (sold separately).

2. Mount the PumpSaver

If the location is wet or dusty, it should be mounted in a NEMA 4 or 12 enclosure.

3. For pump motor control, connect the normally open contact, socket terminal 3, and

common, socket terminal 1, in series with the motor’s magnetic contactor coil (M) as shown

in Figure 2.

4. Connect the power supply L1 to socket terminal 2 and power supply L2 to socket terminal

7.

5. Connect high level probe to socket terminal 6.

6. Connect low level probe to socket terminal 8.

7. If the tank is conductive, connect a probe common wire between the tank and socket

terminal 5. If the tank is not conductive, a wire must be connected between a reference, or

common, probe and socket terminal 5.

8. Plug the PumpSaver

Note: The PC-XXX-LLC-CZ uses a 5vdc pulse to check the resistance of each probe, so the

probes must be isolated from other voltage sources.

®

socket in a convenient location in or near the pump control panel.

1

®

into the socket.

1

For single probe applications, connect a wire between socket terminals 6 and 5. Connect the single

probe between socket terminals 8 and 5. The single probe must be connected to the low probe and

the high probe input must be connected directly to common.

© 2009 SymCom, Inc. All Rights Reserved 2

Page 3

Figure 1: Pin-Out Diagram

Figure 2: Typical Pump Control Wiring Diagram

© 2009 SymCom, Inc. All Rights Reserved 3

Page 4

SETTINGS

Figure 3: Selectivity and Mode Selection

Use the adjustment knob shown in Figure 3 to set the mode of operation and the sensitivity threshold

for the probes. Set the sensitivity from 4.7k to 100k on the left half of the dial for pump-down

applications. Set the sensitivity from 4.7k to 100k on the right half of the dial for pump-up

applications

2

.

OPERATION

Apply power to the system. The green run light will come on if the relay has been energized.

The PumpSaver

®

is equipped with a debounce time delay. The PumpSaver® will wait for the time

delay to complete before energizing/de-energizing the relay.

Pump-Up

3

The relay is energized when liquid is not detected at the low probe, regardless of the state of the

high probe. When the liquid level rises and liquid is detected at the low and high probes, the relay is

de-energized.

4

Pump-Down

The relay is energized when the liquid level rises and is detected at the low and high probes. When

the liquid level drops and no liquid is detected at the low probe, the relay is de-energized, regardless

of the state of the high probe.

2

Reducing the resistance setting will provide increased sensitivity to the presence of liquid.

3

When used with a single probe in a pump-up setting, the relay will energize the pump when no liquid

is detected by the probe and de-energize when liquid is detected by the probe.

4

When used with a single probe in pump-down setting, the relay will energize the pump when liquid is

detected by the probe and de-energize when liquid is not detected by the probe.

© 2009 SymCom, Inc. All Rights Reserved 4

Page 5

TROUBLESHOOTING

SYMPTOM

Device is not functional

LIGHT

PATTERN

N/A

SOLUTION

Verify that the product is wired properly. If

wiring is correct, then measure the line voltage

at terminals 2 and 7 on the octal base. If the

voltage is below the minimum listed in the

Specification Table for the model in use, the

PumpSaver

operate its internal electronics. Also check for

a valid input to the unit from the appropriate

probe. If the voltages and probe inputs are

correct but unit fails to function, call SymCom

at (800) 843-8848 or (605) 348-5580.

®

does not have enough power to

Green LED turns on, but

the pump does not run.

GREEN LED ON

The PumpSaver

®

has energized the internal

relay. Check the wiring to the motor’s magnetic

contactor coil. Verify all safeties and controls

are operating correctly.

© 2009 SymCom, Inc. All Rights Reserved 5

Page 6

DIMENSIONS

2.375”

(60.331)

BOTTOM

WITH OT08* SOCKET

SIDE

*The OT08 octal socket is 35mm DIN rail compatible. The use of an OT08 octal socket is required for

Model PC-XXX-LLC-CZ to qualify as a UL Listed device.

1.75”

(44.55)

4.125”

(104.65)

© 2009 SymCom, Inc. All Rights Reserved 6

Page 7

PUMPSAVER® PC-XXX-LLC-CZ SPECIFICATIONS

Functional Characteristics Debounce Time Delay 2 seconds Input Characteristics Line Supply Voltage

PC-100-LLC-CZ 95-120VAC PC-200-LLC-CZ 190-240VAC

Frequency 505/60Hz Probe Sense Voltage 5vdc Pulsed

Probe Sensitivity 4.7k to 100k Adjustable Output Characteristics Output Contact Rating

Pilot Duty 480VA @ 240VAC General Purpose 10A @ 240VAC

General Characteristics Environmental

Ambient Operating Temperature6 Relative Humidity 10-95%, non-condensing per IEC 68-2-3

Maximum Input Power 5 W Standards Passed

Electrostatic Discharge (ESD) IEC 61000-4-2, Level 3, 6kV contact, 8kV air Radio Frequency Immunity, Radiated 150 MHz, 10V/m Fast Transient Burst IEC 61000-4-4, Level 3, 2kV input power and controls Surge Immunity IEC IEC 61000-4-5, Level 4, 4kV line-to-line; Level 4, 4kV

ANSI/IEEE C62.41 Surge and Ring Wave Compliance to a level

Hi-Potential Test

Safety Marks UL listed (OT08 octal socket

required)

CE IEC 60947-6-2

Dimensions 1.750” H x 2.375” W x 4.125” D (with socket) Weight 9 oz. Enclosure Polycarbonate Mounting Method Plugs into OT08 Socket; DIN Rail or Surface Mount Wire Gauge 12-22 AWG Solid or Stranded Terminal Torque for P/N OT08 Socket 12 in. – lb

-40° to 70°C (-40° to 158°F)

line-to-ground; Level 2, 1kV probe inputs-toground

of 6kV line-to-line

Meets UL508

(2 x rated V +1000 V for 1 minute)

UL508 (File #E68520)

5

50 Hz will increase all delay timers by 20%

6

The ambient air temperature is the air temperature directly surrounding the product.

© 2009 SymCom, Inc. All Rights Reserved 7

Page 8

For warranty information, please see Terms and Conditions at

www.symcom.com

Visit us at www.symcom.com to see

our complete product listing!

Need something special?

Contact SymCom today

for your custom solution!

800-843-8848

© 2009 SymCom, Inc. All Rights Reserved 8

Loading...

Loading...