Page 1

MP8000

MOTOR PROTECTION RELAY

Instruction Manual

REVISION 0-A-030818

Copyright © 2018 Littelfuse. All rights reserved.

Page 2

Page A

MP8000 Motor Protection Relay

REV. 0-A-030818

All brand or product names appearing in this document are the trademark or registered

trademark of their respective holders. No Littelfuse trademarks may be used without written

permission. Littelfuse products appearing in this document may be covered by U.S. and

Foreign patents.

Littelfuse, Inc. reserves all rights and benefits afforded under federal and international

copyright and patent laws in its products, including without limitation software, firmware, and

documentation.

The information in this document is provided for informational use only and is subject to

change without notice. Littelfuse, Inc. has approved only the English language document.

Page 3

MP8000 Motor Protection Relay

TABLE OF CONTENTS

Page 1

REV. 0-A-030818

SECTION PAGE

1 Preface .......................................................................................3

1.1 Manual Overview .................................................................3

1.2 Safety Information ...............................................................3

1.2.1 Dangers, Warnings, and Cautions ...........................3

1.2.2 Safety Symbols ........................................................3

1.2.3 Warnings, Cautions, and Notes ..............................4

1.2.4 Compliance Approvals .............................................4

1.3 General Information .............................................................4

1.3.1 Typographic Conventions .........................................4

1.3.2 Examples ..................................................................4

1.3.3 Product Labels .........................................................4

1.3.4 Instructions for Cleaning and Decontamination ......4

2 Introduction and Specifications ...........................................5

2.1 Overview ..............................................................................5

2.2 Features ................................................................................5

2.2.1 Standard Protection Features ..................................5

2.2.2 Monitoring Features ................................................5

2.2.3 Communications and Control ..................................5

2.2.4 Connectivity .............................................................5

2.2.5 Security ....................................................................5

2.2.6 Power Supply ...........................................................5

2.3 Models, Options, and Accessories ......................................5

2.3.1 Models .....................................................................5

2.3.2 Accessories ..............................................................5

2.4 Applications .........................................................................6

2.5 Getting Started .....................................................................7

2.5.1 Powering the Relay ..................................................7

2.5.2 Establishing Communication ...................................7

2.6 Specifications .......................................................................7

2.6.1 Compliance ..............................................................7

2.6.2 General ....................................................................7

2.6.3 Type Tests ................................................................8

2.6.4 Current Transformers (CTs) ......................................9

2.6.5 Relay Elements ........................................................9

2.6.6 Metering ................................................................11

3 Installation ..............................................................................12

3.1 Overview ............................................................................12

3.2 Phone Application ..............................................................12

3.3 Relay Placement .................................................................12

3.3.1 Physical Location ...................................................12

3.4 Relay Features and Connections ........................................12

3.4.1 Relay Mounted on DIN Rail ...................................13

3.4.2 Relay Mounted on Solid Surface or Panel ............14

3.5 Relay Connections ..............................................................14

3.5.1 Terminal Block Connections ..................................14

3.5.2 Wire Sizes ..............................................................14

3.5.3 Voltage Connections (L1, L2, L3)............................14

3.5.4 Power Supply Connections (A1, A2) ......................15

3.5.5 Relay Contacts (1 Form C and 1 Form A)

Connections ...........................................................15

SECTION PAGE

3.5.6 Current Connections .............................................15

3.5.7 Power Supply Connections (A1, A2) ......................15

3.5.8 Inputs, PTC, ZSCT Connections .............................15

3.5.9 Input Connections (I.1) ...........................................15

3.5.10 PTC Connections (T1, T2) .......................................16

3.5.11 Zero-Sequence Current Transformer (ZSCT)

(Z1, Z2) (for Ground Fault detection) ......................16

3.5.12 Connecting to a PC ................................................16

3.5.13 Connecting to the Littelfuse MP8000 App ............16

3.6 AC/DC Control Connection Diagrams ................................16

3.6.1 Three-Phase Motor under 100 FLA with

optional ZSCT and PTC connected ........................16

3.6.2 Three-Phase Motor over 100 FLA ..........................17

3.6.3 Single-Phase Applications .....................................18

4 Littelfuse MP8000 Smartphone and Tablet App ...............19

4.1 Overview ............................................................................19

4.2 Installing the Android App .................................................19

4.3 Installing the iPhone App ...................................................19

4.4 Running the Littelfuse MP8000 App ..................................19

4.5 Advertising Page ................................................................19

4.6 Configuration Pages ...........................................................20

4.7 Configuration Basic Page (Protective Features) .................21

4.7.1 Low Voltage (LV) ....................................................21

4.7.2 High Voltage (HV)...................................................22

4.7.3 Voltage Unbalance (VUB).......................................22

4.7.4 Overcurrent (OC) ....................................................22

4.7.5 Undercurrent (UC) ..................................................22

4.7.6 Current Unbalance (CUB) .......................................22

4.7.7 Trip Class (TC) ........................................................22

4.7.8 Restart Delay Zero (RD0) .......................................22

4.7.9 Restart Delay One (RD1) ........................................23

4.7.10 Restart Delay Two (RD2) ........................................23

4.7.11 Restart Delay Three (RD3) .....................................23

4.7.12 Undercurrent Restart Attempts (RU) .....................23

4.7.13 Other Faults Restart Attempts (RF) ........................23

4.7.14 Basic Settings Default Values ...............................23

4.8 Configuration Advanced Page (Protective Features) ..........23

4.8.1 Current Transformer Ratio (CT) ..............................23

4.8.2 Potential Transformer Ratio (PT) ............................24

4.8.3 Undercurrent Trip Delay (UCTD) ............................24

4.8.4 Linear OC Trip Delay (LINTD) .................................24

4.8.5 Ground Fault Trip Current (GFTC) ...........................24

4.8.6 Ground Fault Trip Delay (GFTD) .............................24

4.8.7 Low Power Trip Limit (LKW) ..................................24

4.8.8 High Power Trip Limit (HKW) .................................24

4.8.9 High Power Trip Delay (HPTD) ...............................25

4.8.10 Stall Percentage (STLP) .........................................25

4.8.11 Stall Trip Delay (STTD) ...........................................25

4.8.12 Stall Inhibit Delay (STID) .......................................25

4.8.13 Advanced Settings Default Values ........................25

Page 4

MP8000 Motor Protection Relay

Page 2

REV. 0-A-030818

SECTION PAGE

4.8.14 Hardware Configuration Fields

Single-Phase Motor (SPM) ....................................25

4.8.15 Communication Settings ........................................26

4.8.16 RTD Module ...........................................................26

4.8.17 Change Device Name ............................................26

4.8.18 Change Password ..................................................26

4.8.19 Reset Password .....................................................26

4.9 Real-Time Page (Measurements & Monitoring) ................26

4.9.1 Device ID ................................................................26

4.9.2 Reset Relay ............................................................26

4.9.3 System Status ........................................................26

4.9.4 Active Timer ...........................................................26

4.9.5 Line-to-Line Voltage...............................................27

4.9.6 Voltage Unbalance.................................................27

SECTION PAGE

4.9.7 Line Current ...........................................................27

4.9.8 Current Unbalance .................................................27

4.9.9 Power .....................................................................27

4.9.10 Power Factor ..........................................................27

4.9.11 Run-Time ................................................................27

4.9.12 Start Count .............................................................27

4.9.13 Thermal Capacity ...................................................27

4.9.14 Fault Page ..............................................................27

4.10 Time Settings ...................................................................28

4.11 Real-Time Page (Measurements & Monitoring) ..............28

4.11.1 DHCP Assigned IPv4 Address ................................28

4.11.2 Point to Point IP Address Assignment (no

DHCP) .....................................................................28

4.11.3 Setting a Static IP Address ....................................28

5 PC Interface ............................................................................31

6 Troubleshooting .....................................................................32

6.1 Overview ............................................................................32

7 Ground Fault Testing Procedure .........................................33

Page 5

MP8000 Motor Protection Relay

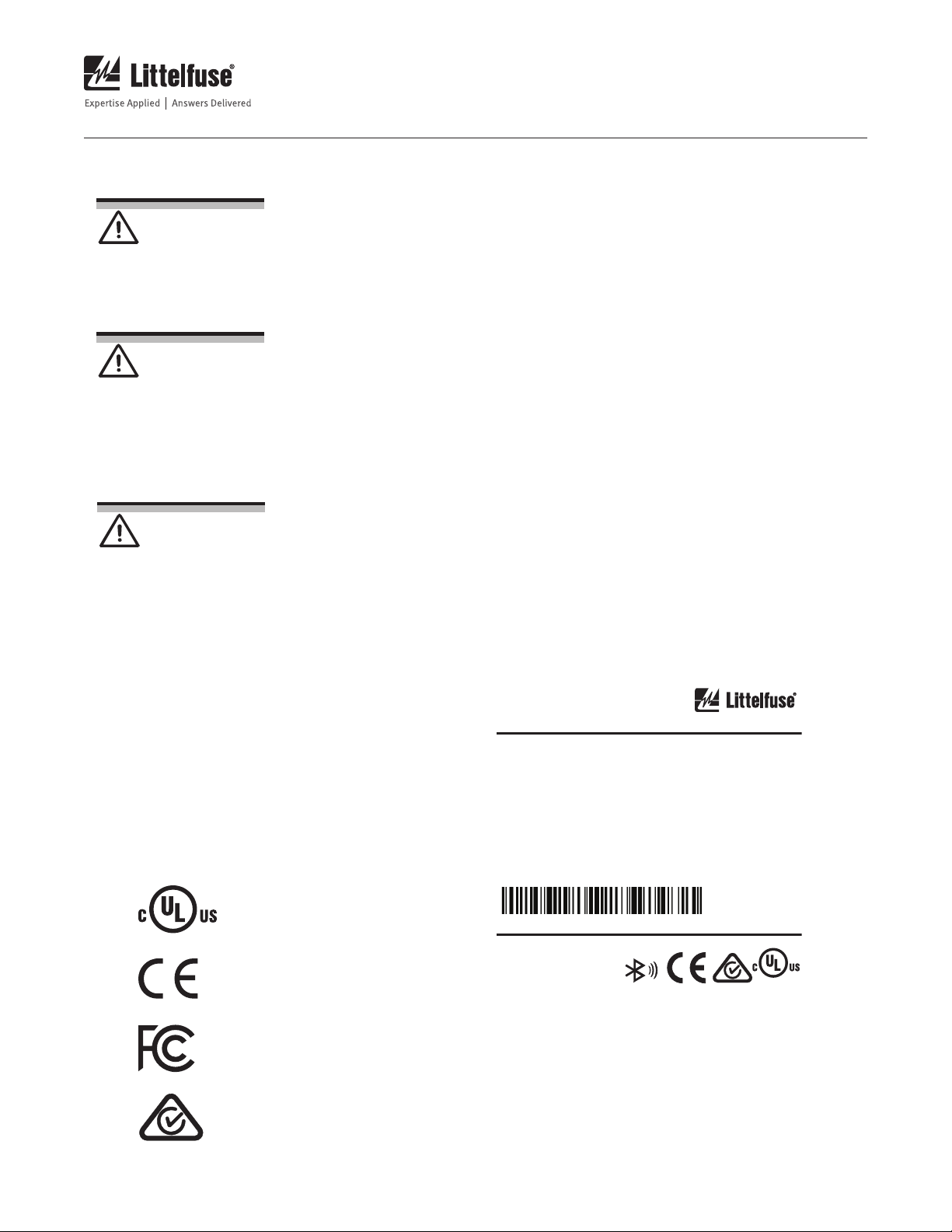

DANGER

DANGER

WARNING

CAUTION NOTE:

DANGER

WARNING

1. PREFACE

Page 3

REV. 0-A-030818

1.1 Manual Overview

The MP8000 Motor Management Relay Instruction

Manual describes common aspects of motor relay

application and use. It includes the necessary

information to install, set, test, and operate the relay.

An overview of each manual section and topics follows:

1. PREFACE

Describes the manual organization and conventions

used to present information.

2. INTRODUCTION AND SPECIFICATIONS

Describes the basic features and functions of the

MP8000; lists the relay specifications.

3. INSTALLATION

Describes how to mount and wire the MP8000;

illustrates wiring connections for various applications.

4. SMARTPHONE/TABLET APPLICATION

Describes the features, installation methods, and

types of help available with the Littelfuse MP8000

App, including setting the relay, meter and monitoring,

control, and fault retrieving.

5. PC INTERFACE

Describes the features, installation methods, and

types of help available with the Littelfuse MP8000

Software, including setting the relay, meter and

monitoring, control, and events retrieving.

6. TROUBLESHOOTING

Describes common causes for various trip/fault

conditions.

7. GROUND FAULT TESTING

1.2 Safety Information

1.2.1 Dangers, Warnings, and Cautions

This manual uses three kinds of hazard statements,

defined as follows:

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation that, if not

avoided, may result in minor or moderate injury or

equipment damage.

1.2.2 Safety Symbols

The following symbols are often marked on Littelfuse

products.

CAUTION

Refer to accompanying documents.

Earth (ground)

Protective earth (ground)

Direct current

Alternating current

Both direct and alternating current

Instruction manual

Page 6

MP8000 Motor Protection Relay

DANGER

WARNING

DANGER

WARNING

CAUTION NOTE:

MP8000

Control Power Input: 90-265VAC

Advanced Motor Protection Overload Relay

Voltage Input (L-to-L): 90-690VAC 50/60Hz 1Ø/3Ø

Input Current: 0.5-100A Direct; 100-1000A*

Contact Rating: 5A @ 240VAC, B300

Pair Code Password: 966352

Setpoint Default Password: admin

MAC Address: 00:21:6F:00:41:F5

*With External CT’s Date Code: 2018/06

Contains FCC ID: TFB-1002

Contains IC: 5969A-1002

Patent Pending

IND. CONT. EQ.

LISTED

®

Page 4

REV. 0-A-030818

1.2.3 Warnings, Cautions, and Notes

Use of this equipment in a manner other than specified

in this manual can impair operator safety safeguards

provided by this equipment.

Installation should be done by qualified personnel

following all national, state and local electrical codes.

Have only qualified personnel service this equipment.

If you are not qualified to service this equipment, you

can injure yourself or others, or cause equipment damage.

Equipment components are sensitive to electrostatic

discharge (ESD). Undetectable permanent damage

can result if you do not use proper ESD procedures.

Ground yourself, your work surface, and this equipment

before installing this equipment. If your facility is not

equipped to work with these components, contact

Littelfuse about returning this device and related

Littelfuse equipment for service.

1.3 General Information

1.3.1 Typographic Conventions

You can communicate with the MP8000 in three ways.

• Use the Littelfuse MP8000 app, iPhone/iPad

or Android. The MP8000 uses Bluetooth 4.0

(Bluetooth Low Energy - BLE). The smartphone or

tablet must have BLE to connect to the MP8000.

• Use the Ethernet port connected to a PC (via

network) with Littelfuse MP8000 Software installed.

• Use the Ethernet port connected to a network

and create a Modbus TCP or Ethernet/IP program

using the MP8000 memory map.

1.3.2 Examples

This instruction manual uses several example

illustrations and instructions to explain how to

effectively operate the MP8000. These examples

are for demonstration purposes only; the firmware

identification information or settings values included

in these examples may not necessarily match those in

the current version of your MP8000.

1.3.3 Product Labels

The MP8000 label is shown below. The label is located

on the right side panel of the product.

Product Compliance Label for the MP8000

NOTE: This device is shipped with default passwords.

Default passwords should be changed to private

passwords at installation. Failure to change each

default password to a private password may allow

unauthorized access. Littelfuse shall not be responsible

for any damage resulting from unauthorized access.

1.2.4 Compliance Approvals

1.3.4 Instructions for Cleaning and

Decontamination

Use a mild soap or detergent solution and a damp

cloth to carefully clean the MP8000 chassis when

necessary. Avoid using abrasive materials, polishing

compounds, and harsh chemical solvents (such as

xylene or acetone) on any surface of the relay.

Page 7

MP8000 Motor Protection Relay

2. INTRODUCTION AND SPECIFICATIONS

Page 5

REV. 0-A-030818

2.1 Overview

The MP8000 Motor Protection Relay is designed

to protect three-phase or single-phase motors. The

basic relay provides locked rotor, overload, overtemperature, and unbalance protection. Voltage-based

protection elements are standard. Additionally, the

relay includes inverse time-over current elements

suitable for overload protection. All relay models

provide monitoring functions.

The relay operates as a fail-safe device. This means

when the voltage is within the programmed limits,

the relay will energize—the NO contact will close.

When the unit loses power or senses a fault condition,

the relay will de-energize and contacts will return to

their original state. Once the unit has been installed

and programmed, the unit is ready to operate. Once

acceptable voltage is applied and the RD0 timer

expires, the relay will energize—the NO contact

will close.

This manual contains the information needed to install,

set, test, operate, and maintain any MP8000. You need

not review the entire manual to perform specific tasks.

2.2 Features

2.2.1 Standard Protection Features

• Overload (Overpower) (49)

• Underload (Underpower) (37P)

• Undercurrent (Load Loss) (37)

• Current Unbalance/Phase Loss (46)

• Overcurrent (Load Jam) (51)

• Ground Fault—Zero-Sequence (50Ns)

• Manual Motor Reset input

• Phase Time-Overcurrent (51)

• Phase Reversal (47), voltage based

• Voltage Unbalance (47)

• Motor Starting/Running

• Start Motor Run-Timer

• Thermal Capacity Utilization (TCU)

• Contactor Failure Protection

• Positive Temperature Coefficient (PTC) OverTemperature Switching Thermistor (49)

• Undervoltage (27)

• Overvoltage (59)

• Power Elements (32)

2.2.2 Monitoring Features

• Event Summaries that contain relay ID, date and

time, trip cause, and current/voltage magnitudes

• Sequential Multiple Events Recorder (SER)

• Power Factor

• Running times

• Number of starts

• A complete suite of accurate metering functions

• Thermal Capacity Used

2.2.3 Communications and Control

• Ethernet Modbus TCP, Ethernet FTP, Ethernet/IP

• Bluetooth 4.0 (Bluetooth Low Energy - BLE)

2.2.4 Connectivity

• Voltage: direct connection (as high as 690 VAC,

line-to-line); three-wire delta, open-delta or singlephase connected Potential Transformers

• Current: Built-in pass-through current transformers

for 0.5-100A phase current measurements

• External current transformer inputs for >100A

phase current measurements

• Zero-Sequence Ground Fault CT input

• Positive Temperature Coefficient Input (PTC)

• Digital Outputs: one Form-A output contacts, one

Form-C output contact

• Digital Inputs: Externally wetted to 110/240 VAC

2.2.5 Security

• Pairing and Setpoint change pass codes on side

labels, unique to each MP8000

2.2.6 Power Supply

• Wide input range 85-264VAC

2.3 Models, Options, and Accessories

2.3.1 Models

Complete ordering information is not provided in this

instruction manual. See the latest MP8000 Model

Option Table at www.littelfuse.com.

2.3.2 Accessories

Contact your Technical Service Center or the Littelfuse

factory for additional detail and ordering information

for the following accessories/options:

• Zero-Sequence CTs

Page 8

MP8000 Motor Protection Relay

Page 6

REV. 0-A-030818

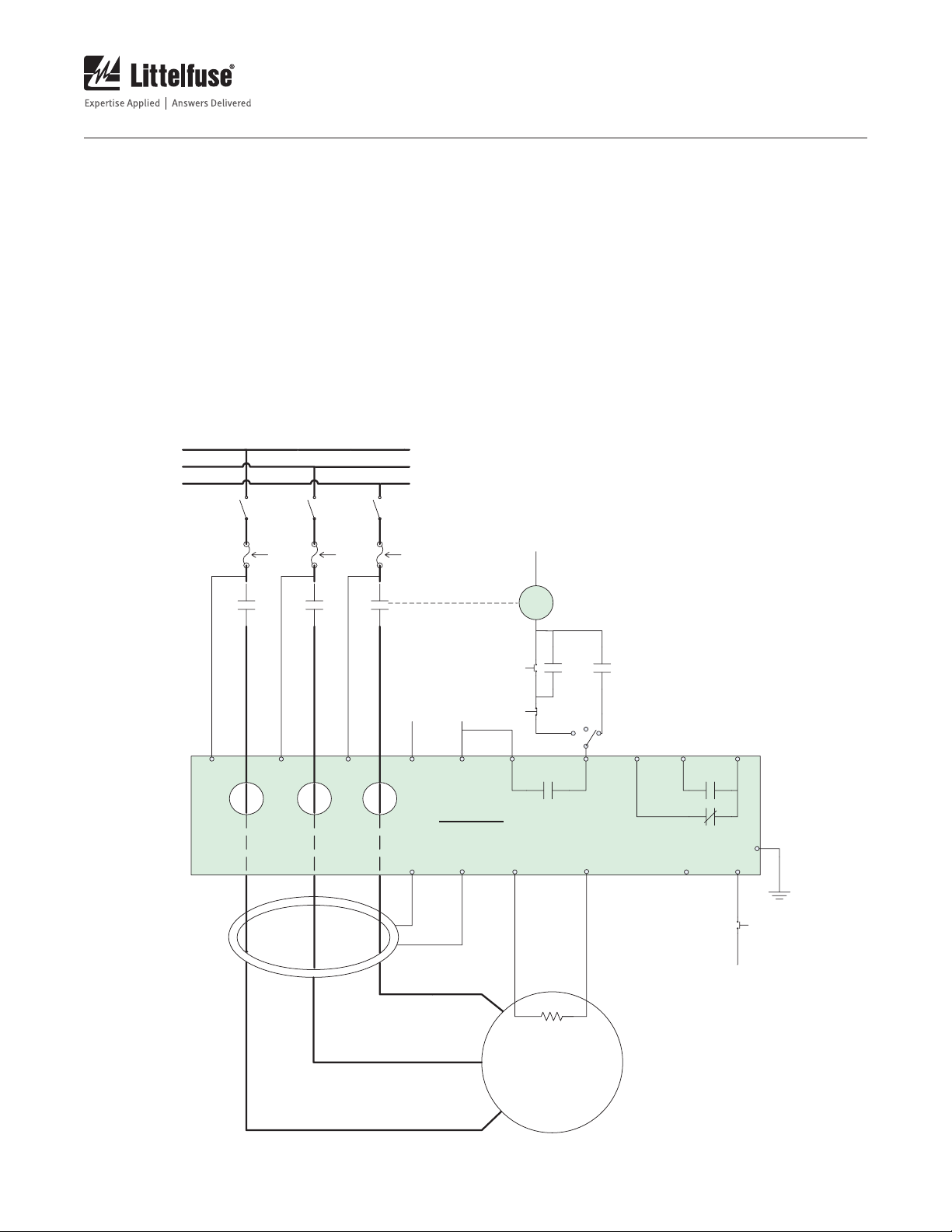

2.4 Applications

Section 3: Installation includes connection diagrams

for various applications. The following is a list of

possible application scenarios:

• With or without external current and/or

voltage transformer

• Full voltage non-reversing (FVNR) starter

(across the line)

• Forward/reverse starter – Accomplished by

placing the MP8000 “above” the forward and

reverse contactors.

PHASE A

PHASE B

PHASE C

90 - 690 VAC

0.5 - 100A (100A+ using external CTs)

Figure 2.1 shows across-the-line starting AC

connections with optional ZSCT and PTC. Refer to

Section 3: Installation for additional applications and

the related connection diagrams.

FROM A1

C

AUX VOLTAGE

SUPPLY

85 – 264 VAC

L1 L3L2 A2/L

A

B

ZERO-SEQUENCE

CURRENT

TRANSFORMER

(OPTIONAL)

A1/N

C

MP8000

Z1

START

STOP

C

(95)

Z2 T1

C

HAND

NO

(96)

PTC

(OPTIONAL)

M

OFF

PILOT

AUTO

NO

NC

(15)

(14)

T2

C

(13)

I.2 I.1

.

FROM A2

PE

RESET

Figure 2.1 AC Connections - Across-the-Line Starting

Page 9

MP8000 Motor Protection Relay

Page 7

REV. 0-A-030818

2.5 Getting Started

Understanding basic relay operation principles and

methods will help you use the MP8000 effectively.

This section presents the fundamental knowledge

you need to operate the MP8000, organized by task.

These tasks help you become familiar with the relay

and include the following:

• Powering the relay

• Establishing communication

• Inputting configuration settings

• Checking relay status

Perform these tasks to gain a fundamental understanding

of relay operation.

2.5.1 Powering the Relay

Power the MP8000 with 85-264 VAC.

• Connect the earth ground lead; see figure 2.1 for

Power Supply Connections.

• Once connected to power, the relay does an

internal self-check , flashing all LEDs. After the

self-check, either the green STATUS LED, or the

red ERROR LED will be illuminated. If the green

STATUS LED is on, the relay status is “ok”, and

the control relay will be closed. If any condition

is present that will not allow the control relay to

close, or the relay is tripped (and/or restarting), the

red ERROR LED will be illuminated and the green

STATUS LED will be off.

2.5.2 Establishing Communication

The standard MP8000 has a Bluetooth Low Energy

(BLE) interface via Littelfuse MP8000 app and an

Ethernet port via Littelfuse MP8000 Software. When

the MP8000 has successfully connected to a Bluetooth

Low Energy enabled device running the MP8000 app,

the blue LED is illuminated.

See Section 4: Littelfuse MP8000 Smartphone and

Tablet App for more information on app installation and

operation.

See Section 5: PC Interface for more information on

MP8000 Software installation and operation.

2.6 Specifications

NOTE: Motors/loads with FLA > 100 amps must use external CTs. You

must use CTs that have a rated secondary current of 5 amps (examples

50:5, 100:5, 200:5, etc.).

2.6.1 Compliance

CE Mark: EMC Directive Low-Voltage

Directive

IEC: IEC 60947-1 Edition 5.2 (UL 60947),

IEC 60947-8-1, EC 60947-4-1

UL, cUL: UL-1053, C.22.2 No. 14

RCM: AS/NZS 4417.1

AS/NZS 4417.2

2.6.2 General

AC Current Inputs—Phase

Full Load Amperage (FLA): 0.5–100.0 A

(> 100 A with external CTs)

Rated Frequency: 50/60 Hz

Burden (Per Phase): 0.0025 VA @ 30 A

Zero-Sequence CT Current (IN)

Zero-Sequence CT Ratio: 100:1

Input Rated Current Range: 0.010–50.0 mA

Input Rated Continuous

Thermal Current: 150 mA

One Second Thermal

Current: 1.5 A

Saturation Current: 5-50 mA

Burden: 0.09 VA at 50 mA

AC Voltage Inputs (Line-to-Line)

Rated Operating

Voltage (Ue): 90–690 VAC

Rated Continuous Voltage: 800 VAC

Rated Frequency: 45/65 Hz

Burden: < 0.72 VA @ 690 VAC

Power Supply

Rated Supply Voltage: 85-264 VAC

Power Consumption: < 5 W

Interruptions: 20 ms minimum

Output Contacts

General

Mechanical Durability: 100,000 no load operations

Pickup/Dropout Time: < 10 ms

(coil energization to contact closure)

AC Output Ratings for relays;

CONTROL (Form A),

ALARM (Form C)

Contact Rating

Designation: B300

(B = 5 A, 300 = rated insulation voltage)

Maximum Operational

Voltage: 250 VAC

Maximum Operational

Current: 5 A

Rated Frequency: 50/60 ±5 Hz

Electrical Durability Make

VA Rating: 3600 VA

Electrical Durability Break

VA Rating: 360 VA

Page 10

MP8000 Motor Protection Relay

Page 8

REV. 0-A-030818

Optoisolated Control Inputs

(Externally Wetted to 110/240 VAC)

Maximum Current Draw: 5 mA @ 110 VAC, 10 mA @ 240 VAC

Rated Impulse Withstand

Voltage (Uimp): 4000 V

Pickup Time: < 200 ms

Dropout Time: > 1000 ms

Frequency and Phase Rotation

System Frequency: 50, 60 Hz

Phase Rotation: ABC, ACB

Frequency Tracking: 45–65 Hz

Time-Code

Format: Unix Time (UTC)

Accuracy (Clock Drift): 10 minutes per year, typically

Communications Ports

Ethernet Port: Single, 10/100BASE-T copper

(RJ45 connector)

Communications Protocols

Modbus TCP, FTP, Ethernet/IP

Operating Temperature

Rated Operating Range: -40° to +70°C (-40° to +158°F)

Rated Storage Range: -40° to +85°C (-40° to +185°F)

Operating Environment

Pollution Degree: 3

Overvoltage Category: III (up to 300 VAC to earth)

II (up to 600 VAC to earth)

Atmospheric Pressure: 80–110 kPa

Relative Humidity: 5–95%, non-condensing

Maximum Altitude

Without Derating: 3000 m

(Consult Factory for Higher Altitude Derating)

Dimensions

Height: 74.4 mm (2.9 in.)

Width: 103.6 mm (4.1 in.)

Depth: 121.7 mm (4.8 in.)

Weight 0.4 kg (0.9 lbs)

Terminal Connections

Compression Plug

(Black, 5.08mm spacing)

Tightening Torque

Maximum: 0.62 Nm (5.5 in-lb)

Earth Ground Lug Tightening

Torque Maximum: 0.89 Nm (7.9 in-lb)

2.6.3 Type Tests

Dielectric Strength and Impulse Tests

Dielectric (HiPot): (See Table 2.1)

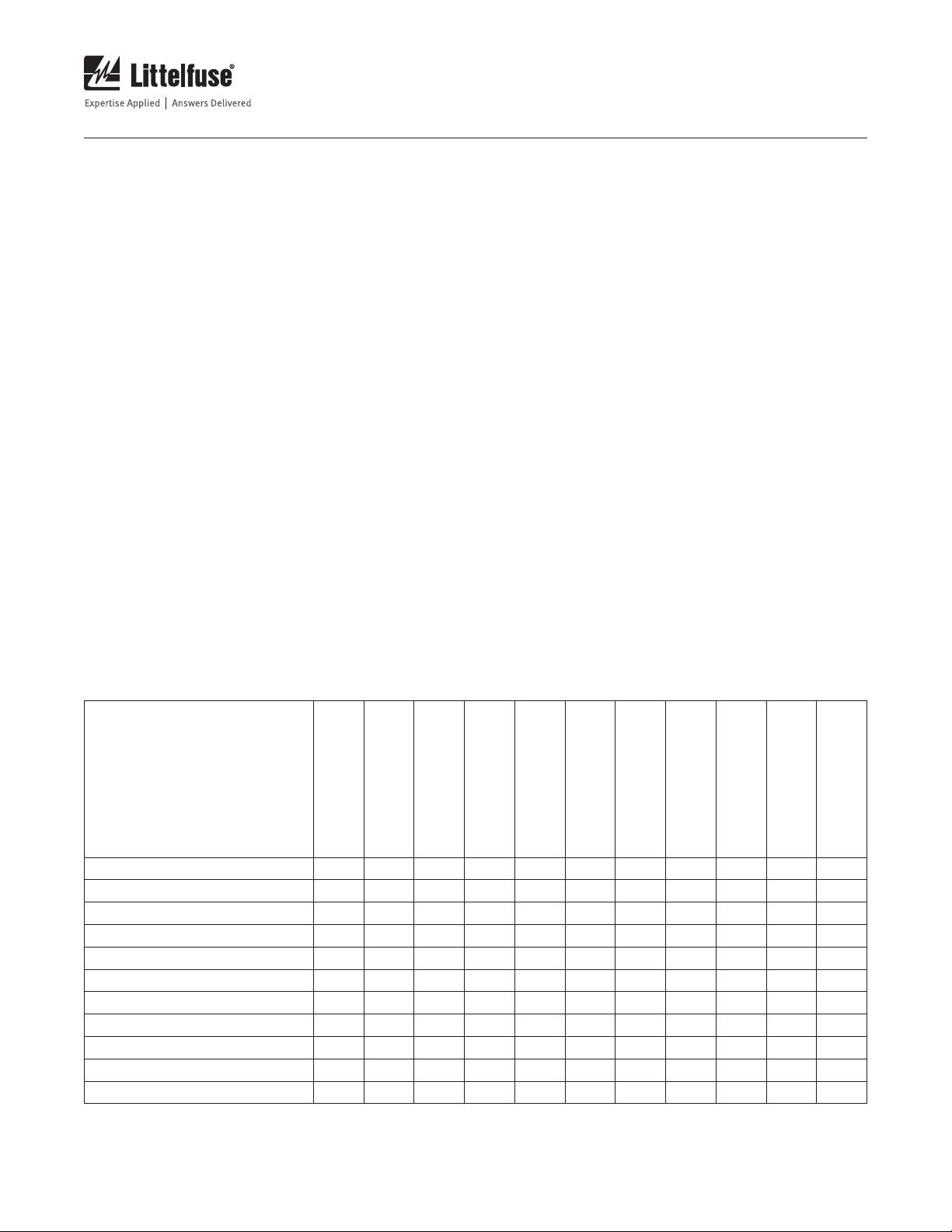

Table 2.1 MP8000 Insulation Between Inputs And Outputs

Dielectric Strength (Volts)

Measuring Input (L1, L2, L3)

Measuring Input (L1, L2, L3) X 2380 2380 2380 2380 2380 2380 2380 2380 2380 2380

Power Supply (A1, A2) 2380 X 1528 1528 1528 1528 X 1528 1528 1528 1528

Relay-Alarm (C (13), NO (15), NC (14)) 2380 1528 X 1528 1528 1528 1528 1528 1528 1528 1528

Relay-Control (C (95), NO (96)) 2380 1528 1528 X 1528 1528 1528 1528 1528 1528 1528

ZSCT (Z1, Z2) 2380 1528 1528 1528 X 1528 1528 X 1528 1528 1528

PTC (T1, T2) 2380 1528 1528 1528 1528 X 1528 1528 1528 1528 1528

Digital In (I.1) 2380 X 1528 1528 1528 1528 X 1528 1528 1528 1528

Ground Terminal 2380 1528 1528 1528 X 1528 1528 X 1528 1528 1528

RS485 2380 1528 1528 1528 1528 1528 1528 1528 X 1528 1528

CAN Bus 2380 1528 1528 1528 1528 1528 1528 1528 1528 X 1528

Ethernet 2380 1528 1528 1528 1528 1528 1528 1528 1528 1528 X

Power Supply (A1,A2)

Relay-Alarm

(C (13), NO (15), NC (14))

Relay-Control

(C (95), NO (96))

ZSCT (Z1, Z2)

PTC (T1, T2)

Digital In (I.1)

Ground Terminal

RS485

CAN Bus

Ethernet

Page 11

MP8000 Motor Protection Relay

Page 9

REV. 0-A-030818

RFI and Interference Tests

Electrostatic Discharge (ESD): IEC 61000-4-2, Level 3, 6kV contact,

8kV air

Radio Frequency Immunity

(RFI), Conducted : IEC 61000-4-6, Level 3 10V/m

Radio Frequency Immunity

(RFI), Radiated: IEC 61000-4-3, Level 3 10V/m

Fast Transient Burst: IEC 61000-4-4, Level 3,

3.5kV input power

Surge: IEC 61000-4-5, Level 3, 2kV line-to-

line; Level 4, 4kV line-to-ground

FCC Rating: Part 15.107 for emissions, Part

15.247 for intentional radiators

Fault Events Recorder

Number of faults stored: 1,000 (most recent faults)

Time-Stamp Resolution: 1 second

Time-Stamp Accuracy

(With Respect to

Time Source): ±1 second

2.6.4 Internal Current Transformers (CTs)

Our Full-Load Current

(FLA) Limits: 0.5–100.0 A

NOTE: Motors/loads with FLA > 100 amps must use external CTs. You

must use CTs that have a rated secondary current of 5 amps (examples

50:5, 100:5, 200:5, etc.).

2.6.5

Relay Elements

See section Littelfuse MP8000 Smartphone and Tablet App >

Configuration Page for details on programming relay behavior.

The numbers in parenthesis in the following specifications are

ANSI device numbers.

Phase-to-Phase Under Voltage (27)

NOTE: Motors/loads operating at voltages higher than 690 VRMS must

use external PTs.

Parameter Name: Low Voltage (LV)

Enable/Disable: No disable available

Setting Range: 90 V

minimum

RMS

Accuracy: ±1% of setting ±2 VRMS

High Power (49)

Parameter Name: High Kilo-Watt (HKW)

Enable/Disable: Default is disabled

Setting Range: Not limited

Accuracy: ±5% of setting ±5 Watts

Under Power (37P)

Parameter Name: Low Kilo-Watts (LKW)

Enable/Disable: Default is disabled

Setting Range: Not limited

Accuracy: ±5% of setting ±5 Watts

Undercurrent (Load Loss) (37)

Parameter Name: Under Current (UC)

Enable/Disable: Default is enabled

Setting Range: Not limited; Suggest 0.75–0.95 • FLA

Accuracy: ±2% of setting ±0.01 ARMS

Pickup/Dropout Time: 1 second + programmable delays

Current Unbalance and Phase Loss (46)

Parameter Name: Current Unbalance (CUB)

Enable/Disable: Default is enabled

Setting Range: Not limited; Default 5; Suggest

5–45%

Accuracy: ±5% of setting

Maximum Pickup/

Dropout Time: See Table 2.2. Additional delays for

motor startup may apply

Table 2.2 CUB Trip Time, CUTD=30

MEASURED VALUE OF CURRENT UNBALANCE TRIP TIME

CUB setting

CUB setting + 1% 15 seconds

CUB setting + 2% 10 seconds

CUB setting + 3% 8 seconds

CUB setting + 4% 6 seconds

CUB setting + 5% 5 seconds

CUB setting + 6% 4 seconds

CUB setting + 10% 3 seconds

CUB setting + 15% or more

30 seconds

2 seconds

Example:

CUB setting = 5% If measured value of current

unbalance is 6% the MP8000 will

trip in 15 seconds

Voltage Unbalance (47)

Parameter Name: Voltage Unbalance (VUB)

Enable/Disable: Default is enabled

Setting Range: Not limited; Default 5%;

Suggest 2%-25%

Accuracy: ±1% of setting ±2 VRMS

Phase Reversal (47)

NOTE: This condition is detected prior to motor startup. After startup this

condition is not monitored.

Rotation Direction: Programmable; Default ABC

Page 12

MP8000 Motor Protection Relay

Page 10

REV. 0-A-030818

Incomplete Sequence (Load Jam/Stall) (48)

Parameter Name: Stall Percentage Current (STLP)

Enable/Disable: Default is disabled

Setting Range: Not limited; Suggest is 400% of OC

Accuracy: ±2% of setting

Maximum Pickup/

Dropout Time: Programmable

(Stall Time Delay seconds)

PTC Over-Temperature (49)

Type of Control Unit: IEC 60947-8, mark A

Max. Number

of Thermistors: Must adhere to the limits below

Over Temp Trip Resistance: ≥ 1650 ± 80 ohms

Reset Range: ≥ 25 ohms and ≤ 1500 ohms

Short circuit Detection

Resistance: ≤ 20 ± 5 ohms

Maximum Cold Resistance: 1500 ohms

Ground Fault - Residual Method (Zero-Sequence)(50N)

Best protection is with a resistively grounded system

Parameter Name: Ground Fault Trip Current (GFTC)

Ground Fault Trip Delay (GFTD)

GFTC Setting Range: GFTC = 0 is OFF (disabled);

Default is disabled.

Suggested Range is 0.20–4.5 A

Accuracy: ±2% of setting ±0.01 A

RMS

Time Delay: Class I operation 0.5 – 1.0 seconds

Class II operation 1.1 – 5.0 seconds

Values above 5 seconds are

non-standard

Timing Accuracy: ±250 ms

Overcurrent (51)

Parameter Name: Linear Overcurrent Trip Delay

(LINTD)

Enable/Disable: Default is disabled

Setting Range: Not limited; Default is 5 Seconds; 1

second minimum

Accuracy: ±2% of setting ±0.1 second

Figure 2.2 Overcurrent Trip Curves

Page 13

MP8000 Motor Protection Relay

Page 11

REV. 0-A-030818

Inverse-Time Overcurrent (51)

Parameter Name: Trip Class (TC)

Enable/Disable: Default is enabled

Setting Range: Not limited; common values 5, 10,

15, 20, 30

Accuracy: See Figure 2.2; ±2% of setting

±0.1 second

Phase-to-Phase Overvoltage (59)

NOTE: Motors/loads operating at voltages higher than 690 VRMS must

use external PTs.

Parameter Name: High Voltage (HV)

Enable/Disable: No Disable available

Setting Range: Not limited

Accuracy: ±1% of setting ±2 V

Timers (See section 4.7 for details on RD0-RD3)

Setting Range: Various

Accuracy: ±0.5% of setting ±1 second

2.6.6 Metering

Accuracies are specified at 20°C, 50 or 60 Hz nominal frequency,

AC currents within 0.5 – 100 ARMS, and ac voltages within

90–690 VRMS unless otherwise noted.

Line-to-Line Voltages: ±1% of reading ±0.5 VRMS

Voltage Unbalance (%): ±1% of reading

Phase Currents: ±2% of reading ±0.05 ARMS

Current Unbalance (%): ±2% of reading

Real Power (kW): ±5% of reading for 0.10 < pf < 1.00

Power Factor: ±3% of reading

Thermal Capacity Used: ±5% of reading

THE FOLLOWING ITEMS ARE ONLY AVAILABLE

THROUGH NETWORK ACCESS OF THE MEMORY MAP:

System Frequency: ±0.1 Hz of reading for frequencies

within 45–65 Hz (V1 > 90 V)

IG (Ground Current): ±2% of reading ±0.001 ARMS

Page 14

MP8000 Motor Protection Relay

3. INSTALLATION

Page 12

REV. 0-A-030818

3.1 Overview

The first steps in applying the MP8000 Motor

Protection Relay are installing and connecting the

relay. This section describes common installation

features and requirements. To install and connect the

relay safely and effectively, you must be familiar with

relay configuration features and options. You should

carefully plan relay placement, cable connections, and

relay communication.

This section contains drawings of typical AC and DC

connections to the MP8000. Use these drawings

as a starting point for planning your particular relay

application.

3.2 Smartphone/Tablet Application

The installation details for the Littelfuse MP8000 app

are presented in Section 4. There are two options:

• Android (supports versions 4.3 and higher)

• iOS (supports versions 9.0 and higher)

Universal Control Power

85 – 264 VAC

Relay Output

Control/Alarms

3.3 Relay Placement

Proper placement of the MP8000 helps to ensure

years of trouble-free motor management. Use the

following guidelines for proper physical installation of

the MP8000.

3.3.1 Physical Location

Mount the MP8000 in a sheltered indoor environment

(a motor control center drawer or bucket, a building,

or an enclosed cabinet) that does not exceed the

temperature, humidity, and IP ratings for the relay.

See environmental specifications in section 2.6.

3.4 Relay Features and Connections

Figure 3.1 shows the relay features and connections

to cover all the ordering options. The wiring terminal

blocks are labeled as shown on the relay.

Built-In Current Transformers (CTs)

0.5A – 100A Direct

>100A with External CTs

Voltage Inputs

90 – 690 VAC (50/60 Hz)

1-phase or 3-phase

Zero-Sequence

CT Input for Direct or

Resistive Grounded

Power Systems

PTC (Optional)

Figure 3.1 Relay Features and Connections

Ethernet Port

Earth Ground

Connection Lug

External Reset Button Input

Page 15

MP8000 Motor Protection Relay

2.93 (74.42)

2.50 (63.50)

4.08 (103.63)

2.50 (63.50)

4.08 (103.63)

Figure 3.2 shows the relay drawings with dimensions

to cover all the ordering options. The wiring terminal

blocks are labeled on the relay.

Page 13

REV. 0-A-030818

3.10 (78.74)

4.79 (121.67)

Figure 3.2 Relay Panel-Mount Dimensions

3.4.1 Relay Mounted on DIN Rail

The MP8000 can be mounted on a 35 mm (1.38 in)

DIN rail. Install the relay on the DIN rail as shown in

Figure 3.3 and push the relay towards the rail until the

bottom clip latches and the relay clicks into place.

To remove the relay, use a small flat-bladed screw

driver or other similar tool. Insert the tool into the

latching clip and pry it towards the relay. The clip slides

away from the DIN rail, releasing it.

Figure 3.3 Relay Mounting on DIN Rail

Page 16

MP8000 Motor Protection Relay

3.4.2 Relay Mounted on Solid Surface or Panel

The drawing in Figure 3.4 shows how the relay is

mounted on a panel or a flat surface. The screws are

#8 or 4 mm and the tightening torque specification is

9.0 in-lbs (1.0 Nm). Use the panel drilling template for

the location of the screw holes.

Page 14

REV. 0-A-030818

Figure 3.4

Relay Mounting on Solid Surface or Panel

3.5 Relay Connections

This section will provide a guide to complete

connections to the relay for various functions.

3.5.1 Terminal Block Connections

The connection terminal blocks are labeled on the

relay as shown in Figure 3.5

Figure 3.5 Relay Terminal Block connections labeling

The terminal blocks are depluggable and can be

removed by gently prying them with a small, flat

screwdriver. The torque requirements for the terminal

blocks are:

• Compression Plug (Black, 5.08mm spacing)

Tightening Torque

• Maximum: 0.62 Nm (5.5 in-lb)

• Earth Ground Lug Tightening Torque

• Maximum: 0.89 Nm (7.9 in-lb)

3.5.2 Wire Sizes

Acceptable wire sizes for earth grounding and terminal

blocks are shown in Table 3.1. Conductors used for

carrying the motor load should be determined by NEC

code. Strip the wire insulation for terminal blocks to 8

mm (0.31 in) before installation.

Table 3.1 Wire Connection Selection Guide

CONNECTION TYPE MIN. WIRE SIZE MAX. WIRE SIZE

Earth Grounding

Connection

Terminal Blocks 18 AWG (0.8 mm2) 12 AWG (3.3 mm2)

18 AWG (0.8 mm2) 14 AWG (2.1 mm2)

3.5.3 Voltage Connections (L1, L2, L3)

Terminals L1, L2, and L3 are used to measure the

input voltages and detect phase sequence/rotation.

The acceptable phase rotation is programmable. See

Section 4.8, Phase ACB Rotation.

Table 3.2 AC Voltage Inputs

(as High as 690 VAC Line-to-Line)

TERMINAL LABEL DESCRIPTION

L1 Line 1 (Phase A) voltage input

L2 Line 2 (Phase B) voltage input

L3 Line 3 (Phase C) voltage input

Page 17

MP8000 Motor Protection Relay

Page 15

REV. 0-A-030818

3.5.4 Power Supply Connections (A1, A2)

The POWER terminals on the relay A1 and A2 must

connect to 85-264 VAC power source (see Power

Supply in section 2.6.2 for complete power input

specifications). The POWER terminals are isolated

from chassis ground.

3.5.5 Relay Contacts (1 Form C and 1 Form A)

Connections

The MP8000 comes with one Form C (AUXILIARY)

and one Form A (CONTROL) relay contacts. They are

rated for continuous carry current of 5A at 70 degrees

C. See Table 3.3 below.

• The Motor Contactor relay coil is energized if all

conditions for safe motor operation are met.

• When the MP8000 generates a trip signal, the

relay coil is de-energized.

• The relay coil is also de-energized if the MP8000 power

supply voltage is removed or if the MP8000 fails.

The MP8000 Auxiliary relay may be energized for

alarms or other control.

Table 3.3 Two (2) Relay Contact Connections

TERMINAL LABEL DESCRIPTION

C (13)

NO (15)

NC (14)

C (95)

NO (96)

Auxiliary relay (Form C) May be energized for

alarms or other control functions.

Motor Contactor Control (Form A) If no trip or

hold-off condition is present these contacts

will close.

3.5.6 Current Connections

IMPORTANT, THE WIRING REQUIREMENTS LISTED

BELOW ARE REQUIRED FOR ACCURATE POWER

FACTOR AND POWER MONITORING:

1. The current carrying conductor connected to the

L1 voltage must pass through the Phase A hole.

2. The current carrying conductor connected to the

L2 voltage must pass through the Phase B hole.

3. The current carrying conductor connected to the

L3 voltage must pass through the Phase C hole.

The MP8000 has markings on the top to indicate the

direction of the current flow. The SOURCE side (A,B,

C) is the side from which the current from the power

system flows through the relay.

The MP8000 directly supports currents up to FullLoad Amps (FLA) of 100 A. Refer to Figure 2.1 for an

application example. The CT ratio setting is set equal to

1 for the direct current inputs. For higher FLA currents,

the relay supports external CT connections. Figure 3.6

shows an application example with external CTs. This

application requires a CT ratio equal to or greater than

10, and a CT setting equal to the primary of the CT.

For the additional information, please see Section 4.8.

All external CTs require the secondary to be 5 Amps

(150:5, 400:5, etc.).

LOW CURRENT APPLICATIONS

If improved accuracy of the current readings is desired

for applications where the FLA is less than 2 amps

the current wires may be passed through each phase

current ‘window’ multiple times (up to 10 times max).

In this configuration the CT number reflects the

number of passes through the window the wires have

been ‘looped’. Example: 5 passes of each conductor

through each CT window will require a CT ratio setting

of 5. See Table 4.3 for examples.

3.5.7 Ground Terminal Connection

Connect the ground terminal of the relay to the chassis

or cabinet ground. See Figure 2.1. Ground connection

is required to meet all EMC requirements.

3.5.8 Inputs, PTC, ZSCT Connections (optional)

Table 3.4 Input, PTC Input, ZSCT input

TERMINAL LABEL DESCRIPTION

I.1 (Reset)

T2 (PTC)

T1 (PTC)

Z2 (ZSCT)

Z1 (ZSCT)

Normally Open Reset Button Input

(relay reset button - momentary)

PTC Thermistor input terminals

Zero-Sequence Ground Fault Current

Transformer input terminals

3.5.9 Input Connections (I.1) (optional)

Connect Terminal I.1 as a Reset (relay reset) input.

When the Normally Open Reset button is pressed,

A2 terminal voltage should be applied to I.1 (Reset)

input. Figure 2.1 shows the connection diagram for an

MP8000 Reset (relay reset) button.

Page 18

MP8000 Motor Protection Relay

Page 16

REV. 0-A-030818

3.5.10 PTC Connections (T1, T2) (optional)

Connect the positive temperature coefficient (PTC)

thermistor to Terminals T2 (PTC) and T1 (PTC). Table

3.6 shows the maximum cable lengths for the

PTC connections.

Table 3.5 PTC Cable Requirements

WIRE SIZE, TWISTED

PAIR AWG NO.

20 200 100

18 300 100

17 400 100

16 600 100

14 1000 100

MAXIMUM LENGTH (METERS)

SHIELDED CABLE UNSHIELDED CABLE

3.5.11 Zero-Sequence Current Transformer

(ZSCT) (Z1, Z2)

(for Ground Fault detection) (optional)

The ZSCT input terminals Z1, Z2 allow you to connect

a zero-sequence current transformer for measuring

the ground fault current directly from the three-phase

motor conductors passing through it. This method

is best suited for use on high-impedance grounded

power systems. It is also preferred when a sensitive

measurement is required. The maximum length of the

twisted pair of wires from the ZSCT to the MP8000

relay terminals Z1, Z2 should be limited to 5 feet or

less and currently limited to 100A zero-sequence CTs.

Refer to Figure 2.1 for an example of ZSCT application

connections. Refer to Basic Settings in Section 4:

Littelfuse MP8000 Smartphone and Tablet

Section 4.8.5 for details on ZSCT application and

settings considerations.

3.5.12 Connecting to a PC (optional)

The PC Ethernet port is connected to the MP8000

Ethernet port using a Standard Ethernet (RJ-45) cable.

See Section 5: PC Interface for more information on

MP8000 Software installation and operation.

3.5.13 Connecting to the Littelfuse MP8000 App

Connection to the Littelfuse MP8000 App is performed

over a Bluetooth Low Energy (BLE) wireless interface.

The Littelfuse MP8000 App is available for iPhone,

iPad, and Android smartphones and tablets.

See Section 4: Littelfuse MP8000 Smartphone and

Tablet App for more information on app installation

and operation.

3.6 Motor Configuration Connection

Diagrams

The following section describes various types of

applications for the MP8000 and provides the

connection for each one. If the 3-phase voltage inputs

are not connected properly, the MP8000 will not allow

motor operation. The voltage inputs must be aligned

with the current inputs (pass through window/hole).

L1 input must connect to Line 1 (Phase A) and the

Phase A motor power wire must pass through the

Phase A "window" (hole). It must pass through the

window with the power source (side with the letter

"A") and load (motor) being on the correct side of

the MP8000.

3.6.1 Three-Phase Motor under 100 FLA with

optional ZSCT and PTC connected

See Figure 2.1. Refer to Sections 4.7 and 4.8 for

appropriate settings.

Page 19

MP8000 Motor Protection Relay

PHASE A

Page 17

REV. 0-A-030818

3.6.2 Three-Phase Motor over 100 FLA

Refer to Figure 2.1 for all voltage and control wiring.

Refer to Figure 3.6 for external current transformer

wiring. Refer to Sections 4.7 and 4.8 for all settings.

PHASE B

PHASE C

HI

X1

HI

X1

HI

External CT’s

X1

NOTE: CT ratio must be changed to accommodate the

CT ratio used. Example: a CT ratio of 200:5, program

200 for CT.

NOTE: For accurate power measurements, the CT

must be wired as shown in Figure 3.6 for both direction

and polarity.

A

B

M

Figure 3.6 Power wiring for three-phase motors greater than 100 FLA

MP8000

See Figure 2.10 for

additional control

C

wiring

Page 20

MP8000 Motor Protection Relay

PHASE A

3.6.3 Single-Phase Applications

Refer to Figure 3.7 for single-phase motor applications.

Refer to Sections 4.7 and 4.8 for all settings.

Page 18

REV. 0-A-030818

PHASE B

L1 L3L2 A2

A

B

C

90 - 690 VAC

0.5 - 100A

AUX VOLTAGE

SUPPLY

85 – 264 VAC

A1

Z1

(95)

MP8000

Z2 T1

FROM A1

START

STOP

C

C

C

HAND

NO

(96)

OFF

T2

PILOT

AUTO

NC

(14)

NO

(15)

I.2 I.1

.

C

(13)

PE

Figure 3.7 Typical Single-Phase Motor

RESET

PTC

(OPTIONAL)

FROM A2

M

Page 21

MP8000 Motor Protection Relay

4. LITTELFUSE MP8000 SMARTPHONE AND TABLET APP

Page 19

REV. 0-A-030818

4.1 Overview

The MP8000 has an iPhone/iPad and Android

application. We will refer to app screens or displays as

pages. All pages are scrollable.

4.2 Installing the Android App

The Android app can be obtained at the Google Play

Store. Using the stores search tool type “littelfuse”

(notice unique spelling of littel). You will see an app for

the MP8000 listed.

4.3 Installing the iPhone/iPad App

The iPhone/iPad app can be obtained at the Apple App

Store. Using the stores search tool type “littelfuse”

(notice unique spelling of littel). You will see an app for

the MP8000 listed.

You can watch the progress of the install by finding

a red icon on one of your app pages that shows the

status of the install. See Figure 4.1.

4.4 Running the Littelfuse MP8000 App

After you have installed the Littelfuse MP8000 App,

a Littelfuse icon should be visible on one of your app

pages. See Figure 4.2. Touching the icon starts the app.

Figure 4.2 Littelfuse MP8000 App icon

Figure 4.1 App installing

4.5 Advertising Page

The advertising page displays a list of all energized

MP8000’s that are within range of the smartphone or

tablet. This is usually up to 30 feet depending upon

the smartphone/tablet used, enclosure type or the

environment. MP8000’s that have not been configured

will be identified with a NOT CONFIGURED message

with a red background as seen in Figure 4.5. MP8000’s

that have been configured will be identified with a

CONFIGURED message with a green background

as seen in Figure 4.3. The number displayed to right

of the MP8000’s name is a relative signal strength

number. The app's version number is displayed in the

lower right of the Advertising page, see Figure 4.3.

The MP8000 can be pre-programmed prior to

installation by applying 115 or 230 VAC control power

to A1/A2 terminals.

Page 22

MP8000 Motor Protection Relay

Page 20

REV. 0-A-030818

Figure 4.3 Advertising page

Select the MP8000 you would like to view. If it is the

first time that this smartphone or tablet has accessed

this MP8000 a pairing request will be presented. The

pairing code for the MP8000 is located on the side

adhesive label and on additional labels provided in the

package. The pairing code is unique to each MP8000

and should be kept in a secure location. Pairing is only

required one time per smartphone/tablet per MP8000.

See Figure 4.4.

Figure 4.5 Automated Configuration request

If cancel is chosen you will return to the Advertising

page. If No is chosen you will be taken to the RealTime page, however you will not have access to the

Fault page for this MP8000 until it is configured. If

Configure is chosen you will be taken to the Basic

Configuration page. See Figure 4.6. You may choose

to configure/re-configure the MP8000 at any time in

the future as well.

4.6 Configuration Pages

There are two Configuration pages, Basic and

Advanced Settings. See Figure 4.6

Figure 4.4 Pairing request

If this MP8000 has never been configured you will be

asked if you want to configure the device. See Figure 4.5.

Figure 4.6 Configuration – Basic and Advanced Settings

Page 23

MP8000 Motor Protection Relay

Page 21

REV. 0-A-030818

The first time you attempt to modify a parameter your

authorization credentials will be requested. The factory

default password is unique to each MP8000 and is

located on the side adhesive label and on additional

labels provided in the package. See Figure 4.7.

Figure 4.7 Authentication request

The Littelfuse MP8000 app ensures that the value

you provided was successfully programmed into

the MP8000 and renders a message affirming the

modification. See Figure 4.9

Figure 4.9 Success message

for parameter modification

Once you have successfully provided your authorization

credentials you can modify all Basic and Advanced

parameters to match your systems requirements.

These credentials will allow modification as long as

this session of the app remains the active app. See

Figure 4.8

4.7 Configuration Basic Page

(Protective Features)

The following Basic Settings MUST be programmed

by the user in order to provide proper protection

for the application. Settings vary by situation and

application and should be selected and tested for each

unique installation. All parameters are actual values.

See Programming Examples for recommended setup

instructions. Consult the motor manufacturer for

appropriate settings. Failure to program all setpoints

could result in nuisance tripping or prevent the device

from protecting the motor.

4.7.1 Low Voltage (LV)

The low voltage setting is the minimum voltage

required for the motor to start. The recommended

setting according to the NEMA MG1 standard is -10%

of the motor’s nameplate voltage. The LV setting uses

the average voltage measured.

Example: Nameplate voltage = 230 V

LV = 90% x 230=207 V

Figure 4.8 Numeric parameter

modification

Page 24

MP8000 Motor Protection Relay

Page 22

REV. 0-A-030818

4.7.2 High Voltage (HV)

The high voltage setting is the maximum voltage

allowed for the motor to start. The recommended

setting according to the NEMA MG1 standard is +10%

of the motor’s nameplate voltage. The HV setting uses

the average voltage measured.

Example: Nameplate voltage = 230 V

HV = 110% x 230 = 253 V

4.7.3 Voltage Unbalance (VUB)

Voltage unbalance is the maximum voltage unbalance

allowed for the motor to start. The NEMA MG1

standard says a motor should not be operated above

a 1% voltage unbalance without derating the motor.

Most utility supplied power sources have a difficult

time sustaining a 1% VUB. Voltage unbalance is

calculated as follows:

%Voltage Unbalance = [(Maximum deviation from the

average)/Average] x 100%

Example: Measured line-to-line voltages = 203, 210,

and 212. The average = (203 + 210 + 212) /

3 = 208.3. The maximum deviation from the

average is the greatest difference between

the average voltage (208.3) and any one

voltage reading: 212 - 208.3 = 3.7, 210 - 208.3

= 1.7 and 208.3 - 203 = 5.3. The maximum

deviation from the average is 5.3, thus voltage

unbalance = 5.3 / 208.3 x 100 = 2.5%.

4.7.4 Overcurrent (OC)

The overcurrent setting is the maximum allowable

current that allows continuous operation without

tripping the relay. This is typically set to the

service factor amperage (SFA) of the motor or

100-135% of motor full-load amps (FLA). If any phase

exceeds the OC setting, the MP8000 will trip according

to the Trip Class (TC) settings.

4.7.5 Undercurrent (UC)

The undercurrent setting is the minimum allowable

current that allows continuous operation without

tripping the relay. Undercurrent is typically set

between 60-80% of the motor's operating current.

This setting is usually adequate to detect the loss of

load from pumps, broken belts, couplings, etc. The

MP8000 examines average current to determine if an

undercurrent trip condition exists.

NOTE: a normal motor shutdown will not cause an

undercurrent trip.

4.7.6 Current Unbalance (CUB)

Current unbalance is the maximum current unbalance

allowable for continuous operation without tripping

the relay. The same formula for calculating voltage

unbalance in section 4.7.3 can be used by replacing

voltage with current.

4.7.7 Trip Class (TC)

Determines how quickly the MP8000 will trip when an

overcurrent (overload) condition is detected.

The standard trip classes are 5, 10, 15, 20, and 30.

TC can be set from 2–60, allowing the unit to follow a

trip curve in-between the “standard” trip class curves

shown in Figure 2.2.

The motor manufacturer should be contacted for an

exact TC setting. Table 4.1 describes the trip classes,

and Figure 2.2 shows the trip class curves.

Table 4.1 Trip Class Descriptions

TRIP CLASS APPLICATION DESCRIPTION

Small fractional horsepower motors where

5

10

15 Specialized applications

20

30

Non-Standard

Trip Classes

acceleration times are almost instantaneous or

where extremely quick trip times are required

(Fast Trip) Hermetic refrigerant motors, compressors,

submersible pumps and general-purpose motors that

reach rated speed in less than 4 seconds

(Standard Trip) Most NEMA-rated general-purpose

motors will be protected by this setting

(Slow Trip) Motors with long acceleration times

(>10 seconds) or high inertia loads

Trip time in seconds when any phase current is 600%

of OC. Time is approximately 90% of the TC setting

4.7.8 Restart Delay Zero (RD0)

RD0 is referred to as the power-up timer, in seconds.

The purpose of this timer is to provide protection

against power system fluctuations. The purpose of

this timer is to delay the start of a motor for a period of

time after good power returns. Each motor in a multimotor environment should have this set to different

values to allow each motor to start at different times

after power returns to normal to avoid overloading the

power system. This ensures that no two motors will be

drawing startup current levels at the same time. This

timer is initiated when acceptable power is applied to

the L1, L2, L3 terminals, and will also be reloaded if

the incoming power does not meet the LV, HV, or VUB

settings when the motor is not running. When power

returns to within these settings, the RD0 timer will

count down and close the relay. If RD0 timer is set to

0, this timer will be disabled.

Page 25

MP8000 Motor Protection Relay

Page 23

REV. 0-A-030818

4.7.9 Restart Delay One (RD1)

RD1 is referred to as the rapid-cycle timer, in seconds.

The purpose of this timer is to provide protection

against short cycling of the controls between motor

starts. This timer is initiated after the motor has been

stopped by breaking the control power. At this time

the control relay is opened and the output relay will

energize (the NO will close) as soon as RD1 timer

expires. If RD1 is set to zero this delay will be disabled.

4.7.10 Restart Delay Two (RD2)

RD2 is referred to as the motor cool-down timer, in

seconds. RD2 is used to restart the motor after an

operating motor trips due to OC, CUB, or HKW.

4.7.11 Restart Delay Three (RD3)

RD3 is referred to as the underload restart timer, in

seconds. RD3 is used to restart the motor after an

operating motor trips due to UC or LKW. An example

of the use of this timer is to set it to the period of time

required for a well to recover. This setting varies widely

by application and there is no typical setting.

4.7.12 Undercurrent Restart Attempts (RU)

RU is the number of restarts the MP8000 will attempt

after an underload fault before the unit locks out and

requires a manual reset. This counter is cleared one

minute after restarting if the MP8000 does not trip

again on underload during that period. If RU is set to

“0”, the MP8000 will require manual resetting after all

underload faults.

4.7.13 Other Faults Restart Attempts (RF)

RF is the number of restarts the MP8000 will attempt

after tripping on OC, CUB, or HKW before the unit

locks out and requires a manual reset. This counter

will be cleared one minute after restart if the unit does

not trip again for the same fault condition during that

period. If RF is set to “0”, the MP8000 will require

manual reset after tripping on OC, CUB, or HKW.

4.7.14 Basic Settings Default Values

Table 4.2 Default values for basic settings

ACRONYM DEFAULT UNITS

LV 600 VAC (RMS)

HV 0 VAC (RMS)

VUB 5.0 Percent Voltage unbalance

OC 10.0 Amps (RMS)

UC 5.0 Amps (RMS)

CUB 7.0 Percent Current unbalance

TC 5 Trip Class

RD0 0 Seconds

RD1 0 Seconds

RD2 300 Seconds

RD3 300 Seconds

RU 1 Underload restart count

RF 1 CUB/OC

4.8 Configuration Advanced Page

(Protective Features)

The following settings are optional depending upon

your application. Settings vary by situation and

application and should be selected and tested for

each unique installation. See Programming Examples

for sample setup instructions. Failure to program all

setpoints could result in nuisance tripping or prevent

the device from protecting the motor.

4.8.1 Current Transformer Ratio (CT)

The default value of 1 implies that the current inputs are

directly from the motor with only one pass (no loops)

through each window. This parameter should only be

changed if you are using external CTs or if you want

improved current measurement accuracy with motors

having an FLA that is less than 2 amps. See Table 4.3

for examples of recommended configurations.

Table 4.3 Common CT Ratios and CT Setting

FULL LOAD AMPS

CURRENT RANGE (AMPS)

MIN MAX

0.5 2 5 5 N/A

2.0 100 1 1 N/A

101 200 1* 200 200:5

201 400 1* 400 400:5

401 800 1* 800 800:5

# OF PASSES

THROUGH

EACH WINDOW

CT

SETTING

EXTERNAL

CT PRI:SEC

* External CT Secondary

NOTE: Other CT XXX:5 Ratios can be programmed. Consult

manufacturer for appropriate applications. Additional CT

primaries can be used and should be sized so that the FLA

of the motor is between 60-90% of the CT primary.

Page 26

MP8000 Motor Protection Relay

L1

L3

L2

MP8000

A B C

(b) Open Delta voltage Connections

L1

L3

L2

MP8000

A B C

L1

L3

L2

MP8000

A B C

(a) Single PT Voltage Connections

(b) Open Delta voltage Connections

Page 24

REV. 0-A-030818

4.8.2 Potential Transformer Ratio (PT) for

Medium-Voltage Applications Greater

Than 690 VAC

Refer to Figure 2.1 for control wiring. Refer to Figure

4.10 for potential transformer wiring options. Refer to

Sections 4.7 and 4.8 for all settings.

This parameter should only be changed if you are

using external PTs. The default value of 1 implies that

the voltage inputs are a direct connection. Common

ratios can be seen in Table 4.4.

NOTE: a PT ratio must be changed to accommodate

the PT ratio used. Example: a PT ratio of 4160:120,

program 35 for PT.

Table 4.4 Common PT Ratios and PT Setting

PT PRIMARY

VOLTAGE

2400 120 2400:120 = 20

4200 120 4200:120 = 35

4800 120 4800:120 = 40

7200 120 7200:120 = 60

8400 120 8400:120 = 70

(a) Single PT Voltage Connections

A B C

PT SECONDARY

VOLTAGE

L1

MP8000

L2

PRI:SEC =

PT RATIO

4.8.3 Underload Trip Delay (ULTD)

The length of time, in seconds, the unit will allow

the motor to run in an underload situation before

de-energizing its relay.

4.8.4 Linear OC Trip Delay (LINTD)

The length of time, in seconds, the unit will allow the

motor to run if one current exceeds the OC value. This

process runs in parallel with the TC process.

NOTE: LINTD is defaulted 0=off. Changing the setting

to a non-0 number enables linear overcurrent trip delay.

4.8.5 Ground Fault Trip Current (GFTC)

The maximum allowable current that can flow to

ground before the MP8000 trips or alarms. See GFMT

Section 4.8.14 for configuration of trip or alarms. This is

a Class 1A/1B ground fault, not intended for personnel

safety. The GFTC is defaulted 0=off. Setting a non-0

number enables ground fault and requires an external

zero-sequence CT. A typical setting for GFTC is 1-4

amps of ground current. The GF test procedure in this

installation instruction manual must be conducted

before the device is brought online. See Section 7.

4.8.6 Ground Fault Trip Delay (GFTD)

The delay time in seconds from detection of the

ground fault current exceeding the GFTC value before

the relay trips and/or the auxiliary relay is activated.

This setting determines at which ground fault class the

relay will operate.

L3

(b) Open Delta voltage Connections

A B C

L1

MP8000

L2

(c) Delta-Delta Voltage Connections

A B C

L3

L1

MP8000

L2

L3

To L1

Figure 4.10 External PT Voltage Connections

(for voltages greater than 690 VAC)

60947 Class 1A, GEFD no inhibit current level (trip

at all current levels), trip delays less than 1s

60947 Class 1B, GEFD no inhibit current level (trip

at all current levels), trip delays greater than 1s and

less than 5s

non-60947 GEFD beyond 5 seconds may be

applicable to resistively grounded systems

4.8.7 Low Power Trip Limit (LKW)

The threshold for low power trip condition. If the load

drops below this kW setpoint, the relay will trip after

the ULTD delay expires. LKW is defaulted 0=off. A

non-0 setting will enable this feature.

4.8.8 High Power Trip Limit (HKW)

The threshold for high power trip condition. If the load

exceeds this kW setpoint, the relay will trip after the

HPTD delay expires. HKW is defaulted 0=off. A non-0

setting will enable this feature.

Page 27

MP8000 Motor Protection Relay

Page 25

REV. 0-A-030818

4.8.9 High Power Trip Delay (HPTD)

The delay, in seconds, before a trip condition occurs

once the HKW threshold has been exceeded.

4.8.10 Stall Percentage (STLP)

This parameter sets the current threshold for the

jam/stall condition. A jam/stall condition exists if any

phase current is greater than or equal to the Jam/Stall

percentage of the OC setting. Example: STLP=400%,

OC=50A. Stall trip point=4*50=200A.

4.8.11 Stall Trip Delay (STTD)

This parameter is the time that the jam/stall condition

must be present before the MP8000 trips on overcurrent.

4.8.12 Stall Inhibit Delay (STID)

This parameter is the amount of time that the Jam/

Stall feature is inhibited after each motor start.

4.8.13 Advanced Settings Default Values

Table 4.5 Default values for advanced settings

ACRONYM DEFAULT UNITS

CT 1 (no CTs) CT Primary:5

PT 1 (no PTs) Turns Ratio

UCTD 5 Seconds

LINTD 0=Off Seconds

GFTC 0=Off Amps (RMS)

GFTD 5 Seconds

LKW 0=Off KW

HKW 0=Off KW

HPTD 60 Seconds

STLP 0=Off Percentage

STTD 5 Seconds

STID 0 Seconds

4.8.14 Hardware Configuration Fields

Single-Phase Motor (SPM)

Enabling this feature allows single-phase motors to be

monitored. The following changes in settings are made

by enabling this setting:

1. Voltage unbalance and voltage single-phase

protection is disabled

2. Phase sequence protection is disabled

3. Contact failure trip disabled

4. Only voltage across L1 and L2 is monitored. HV

and LV settings are still active.

5. Only conductors in A and B are measured.

Measured current average calculated as (A+B)/2.

6. Current unbalance and current single-phase

trip disabled

7. Reference Figure 3.7 for appropriate wiring

Single-Phase PT Enable (SPT)

Enabling this feature allows a single potential

transformer to be used on a 3-phase motor. Enabling

single-phase PT disables the following functions:

phase rotation protection, voltage unbalance/singlephase, and contactor failure. See Figure 4.10, the (a)

drawing for the PT connections.

PTC Enable (PTC)

Enabling this feature implies the following:

1. An external PTC is properly connected to the

MP8000-T1/T2 terminals. PTC will trip according

to the specifications. See Figure 2.1

2. The MP8000 will trip if the PTC registers

overheating conditions.

ACB phase rotation (ACB)

Enabling this feature changes the expected wiring

sequence connected to L1, L2, L3 from the default of

ABC to ACB.

Ground Fault Motor Trip (GFMT)

Ground fault detection is enabled in GFTC. The GFMT

setting will decide if the motor is tripped from the

ground fault, or if the auxiliary relay is energized as

an alarm. Enabling GFMT will trip the control relay on

ground fault, and disabling GFMT will energize the

auxiliary relay on ground fault.

Table 4.6 Hardware Configuration fields

NAME ACRONYM DESCRIPTION DEFAULT

SinglePhase

Motor

SinglePhase PTSPT

PTC

Enable

ACB

phase

rotation

Ground

Fault

Motor

Trip

SPM

PTC

ACB

GFMT

Enable if this is a single-phase

motor. See Figure 3.7 for

special wiring considerations.

Enables a single PT to be used

on a 3-phase motor.

An external PTC is properly

connected to the MP8000.

ACB phase rotation is expected

if enabled

Ground fault detection is

enabled in GFTC. GFMT will

trip the motor control relay if

enabled or the auxiliary relay

alarm if disabled.

disabled

disabled

disabled

disabled

enabled

Page 28

MP8000 Motor Protection Relay

Page 26

REV. 0-A-030818

4.8.15 Communication Settings

Not used.

4.8.16 RTD Module

Not used.

4.8.17 Change Device Name

Touching this button enables the user to change the

name displayed for this MP8000. The name can be

seen at the top of the screen and on the advertising

page for each unit.

4.8.18 Change Password

Momentarily touching the Change Password button

on the MP8000 app will allow an authorized user to

change the password from the default or previously

changed password. The user will need to enter the

new password twice to verify it was properly entered.

The new password will take effect the next time any

user connects to this MP8000.

4.8.19 Reset Password

To reset the MP8000 back to its original default

password, follow the steps below:

1. Locate the authorization key, which is shipped

with the product (the Reset Password sticker that

should be kept in a secure location).

2. If a normally-open manual reset button has been

installed between A2 and I.1 as shown in Figure

2.1, proceed to step 4.

3. If a normally-open manual reset button as shown

in Figure 2.1 is not installed, the user will need

to be ready to momentarily jumper between the

A2 and I.1 terminals at the appropriate time during

this process.

4. Ensure that the LEDs on the front of the MP8000

are visible.

5. Press and hold for a second, the Change Password

button on the MP8000 app to cause the Reset

Password authorization window to open.

sure you have the correct authorization key and

repeat the above steps.

8. During the 10 second countdown period, press the

normally-open manual reset button (if installed)

or momentarily jumper between the A2 and I.1

terminals.

9. Once successfully completed, the blue Bluetooth

LED will stop blinking, and the MP8000 app will

return to the “advertising page”.

10. Reconnect to the MP8000 using the Littelfuse

MP8000 app.

11. The default password may now be used for

changing configuration settings.

4.9 Real-Time Page

(Measurements & Monitoring)

The Real-Time page provides updates every second for

all the motor's vital measurements. See Figure. 4.11.

If something other than a Status of OK is displayed

on the app's Real-Time page, see the troubleshooting

section for more information.

4.9.1 Device ID

The name of the MP8000 you are connected to is

displayed here.

4.9.2 Reset Relay

This button requires the user to enter the correct

setpoint password. It resets the relay from a manual

reset, or will bypass all active timers, allowing it to

energize and supply power to the motor.

4.9.3 System Status

This field displays the status of the relay. Hold-off and

trip conditions are displayed here.

4.9.4 Active Timer

If any delay timer is active, the remaining time is

displayed here. Also the identity of which delay timer

is active (RD0, RD1, RD2, or RD3).

6. Enter the authorization key on the MP8000 app to

reset the password.

7. If the authorization key is entered correctly, the

blue Bluetooth LED on the MP8000 will begin to

blink and a popup showing a 10 second countdown

timer will appear on the MP8000 app. If the blue

Bluetooth LED does not blink and the 10 second

countdown timer does not appear, check to make

Page 29

MP8000 Motor Protection Relay

Figure 4.11 Real-Time Page

4.9.5 Line-to-Line Voltage

The input voltages, L1, L2, and L3, are measured and

displayed as line-to-line RMS AC voltages.

4.9.6 Voltage Unbalance

Voltage unbalance (VUB) is the NEMA voltage

unbalance percentage

Page 27

REV. 0-A-030818

4.9.14 Fault Page

The main Fault page is scrollable and lists up to 1,000

faults with the most recent faults first. See Figure 4.12.

4.9.7 Line Current

Current, A, B, and C are measured and displayed as

RMS AC line current.

4.9.8 Current Unbalance

Current unbalance (CUB) is the NEMA current

unbalance percentage.

4.9.9 Power

Power is displayed in Kilowatts.

4.9.10 Power Factor

The Power Factor (PF) is displayed in decimal form.

The Power Factor (PF) is obtained by taking the cosine

of the angular difference between the voltage and

current measurements.

4.9.11 Motor Run-Time

Run-Time is the amount of time the motor has run

since the timer was cleared (hours:minutes:seconds).

4.9.12 Start Count

Start Count is the number of motor starts that

have occurred.

4.9.13 Thermal Capacity

The displayed value is Thermal Capacity Used (TCU). It

is a percentage. If the TCU is at 100% the motor has

used all of its thermal capacity and will be shut down

as an overcurrent fault, to allow the motor to cool off.

Figure 4.12

Main Fault Page

NOTE: fault screens are not accessible prior to

configuration of the MP8000.

The faults can be scrolled or a date can be entered if

you want to jump to that date. Just touch the date bar

and a calendar is displayed. See Figure 4.13.

Figure 4.13

Fault Calendar

Page 30

MP8000 Motor Protection Relay

Page 28

REV. 0-A-030818

All vital measurements for each fault can be viewed by