Page 1

PumpSaver® ISS-105

IS Super Cell

Installation Guide

Visit our website at www.symcom.com for our

complete catalog and new product listings!

2880 North Plaza Drive, Rapid City, South Dakota 57702

(800) 843-8848 · (605) 348-5580· fax (605) 348-5685

www.symcom.com

Page 2

Introduction .................................................................................... .. 3

warranted aga

two (2) years from the date of manufacture. For complete information on

warranty, liability, terms, returns, and cancellations, please refer to the

Quick Start.....................................................................................4

Model Description..........................................................................5

Time Delay....................................................................................5

Mode Selector ...............................................................................5

Option Selector..............................................................................6

1. Pumping Modes............................................................................ 6

Duplex...........................................................................................6

Triplex: High/Low Alarm.................................................................6

Quadplex.......................................................................................6

Separate Pump Stop (SPS)............................................................7

2. IS Supe r Cel l Funct ions...............................................................7

High Alarm.....................................................................................7

Low Alarm.....................................................................................7

Out-of-Sequence Alarm..................................................................7

Audible Alarm................................................................................8

Audible Alarm Logic/Fail-Safe.........................................................8

Clearing Alarms.............................................................................8

Alternation.....................................................................................8

Alternation On................................................................................9

Alternation On, Non-Alternating Pump Enabled............................... 9

Alternation Off................................................................................9

Disabling Pumps............................................................................9

External Inputs............................................................................. 10

· External Silence / Alarm Rese t...............................................10

· Externa l Power Rese t ............................................................ 10

· Ex terna l Alternation Conf igura tion.......................................... 10

3. Wiring Diagrams........................................................................10

4. 5-Channe l Relay Mode............................................................... 21

Positive/Negative Logic................................................................21

Latched Output............................................................................ 21

Time Delay Output.......................................................................22

· Delay-On-Make.....................................................................22

· Delay-On-Break..................................................................... 22

Model ISS-105 Specifications.........................................................23

SymCom warrants its microcontroller-based products against defects in

material or workmanship for a period of five (5) years from the date of

manufacture. All other products manufactured by SymCom shall be

inst defects in material and workmanship for a period of

SymCom Terms and Conditions of Sale document.

2

12/04

Page 3

Introduction

The PumpSaver® ISS-105 IS Super Cell is a smart, fivechannel, intrinsicall y safe relay and pump controller. It has a

long list of features that are needed for multiple pump

applications. The IS Super Cell can indicate low, high and outof-sequence alarms. It can do alternating pump control, nonalternating pump control, or alternating control with one nonalternating pump. The non-alternating pump can be used as

either a jockey or emergency pump and can optionally start the

non-alternati ng pump after every 50 cycles of the lead pump, to

keep it working freely. Using the built-in DIP switches, individual

pumps can be disabled when taken out of service for repair or

maintenance.

The IS Super Cell has the following features and capabilities:

4High, Low and Out-Of-Sequence Alarms

4Variable Time Delay/Lag Pump Delay

4Separate Pump Stop

4Pump Alternation w/ or w/o Non-Alternating Pump

4Jockey or Emergency Pump

4Duplex, Triplex or Quadplex Pump Modes

4Pump Up or Pump Down Functions

4External Silence, Reset and Alternation Configuration

4Five-Channel Relay

3

12/04

Page 4

Quick Start

The IS Super Cell can operate as an intrinsically safe pump control for

eight different pumping configurations. Duplex, Triplex, Quadplex and

Duplex SPS (Separate Pump Stop) pumping modes are possible for

either Pump Up or Pump Down applications. Refer to page 21 for the

full description of five-channel relay operation.

Read 1. Pumping Modes, page 6, for details of the features and mode

descriptions of the unit.

1. If the desired pump configuration is known, follow Table 1 to the

page showing the typical wi ring diagram and setup for each

mode.

2. If further description is needed in choosing which mode to use, see

Table 2 and Table 3 to view the capabilities of each pumpin g mode

and look at the typical wi ring diagrams of the eight different

pumping modes starting on page 11.

3. Once the desired configuration is determined, punch out and

slide the correct card i nto the slot on the front of the IS Super Cell

to display the input and output connections.

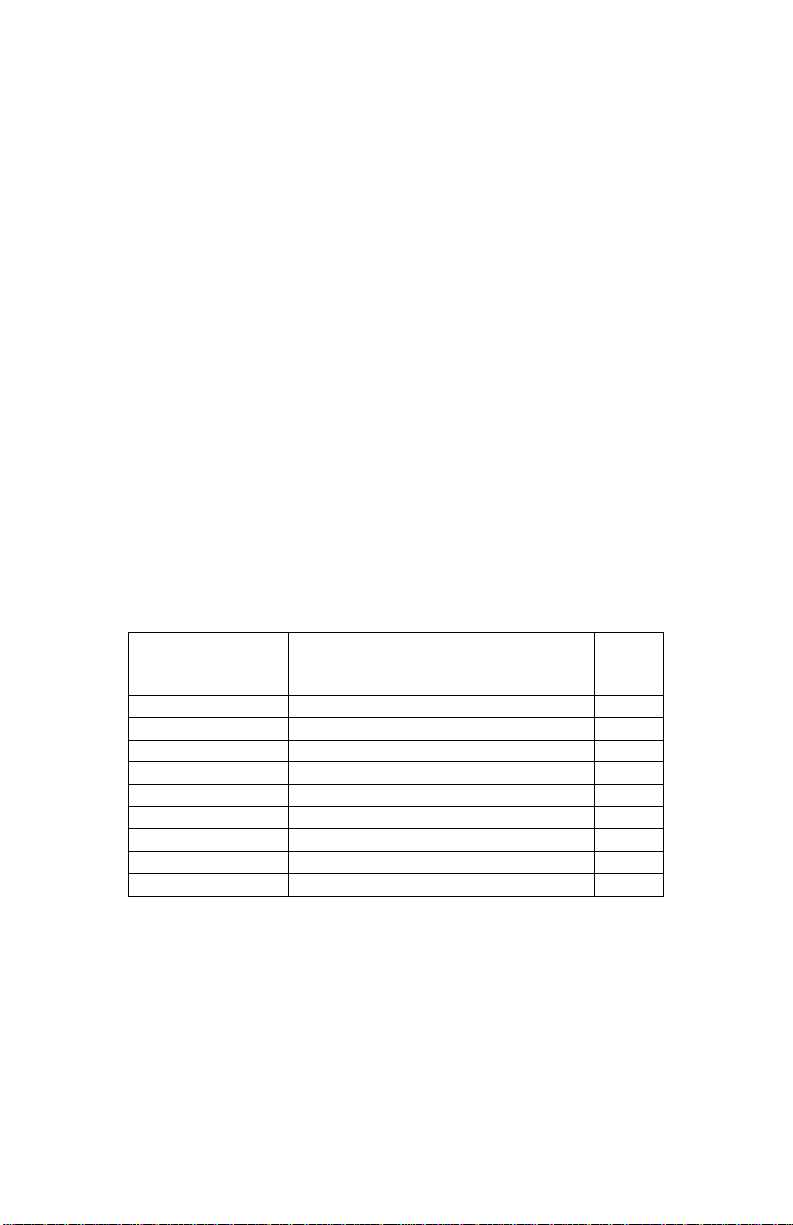

Mode Selector

Switch

Position

0 5-Channel Relay – Mode 0 22

1 Duplex Pump Down – Mode 1 11

2 Triplex Pump Down – Mode 2 12

3 Quadplex Pump Down – Mode 3 13

4 Duplex SPS Pump Down – Mode 4 14

5 Duplex Pump Up – Mode 5 15

6 Triplex Pump Up – Mode 6 16

7 Quadplex Pump Up – Mode 7 17

8 Duplex SPS Pump Up – Mode 8 18

Table 1. Mode Selector

Mode Description Page

4

12/04

Page 5

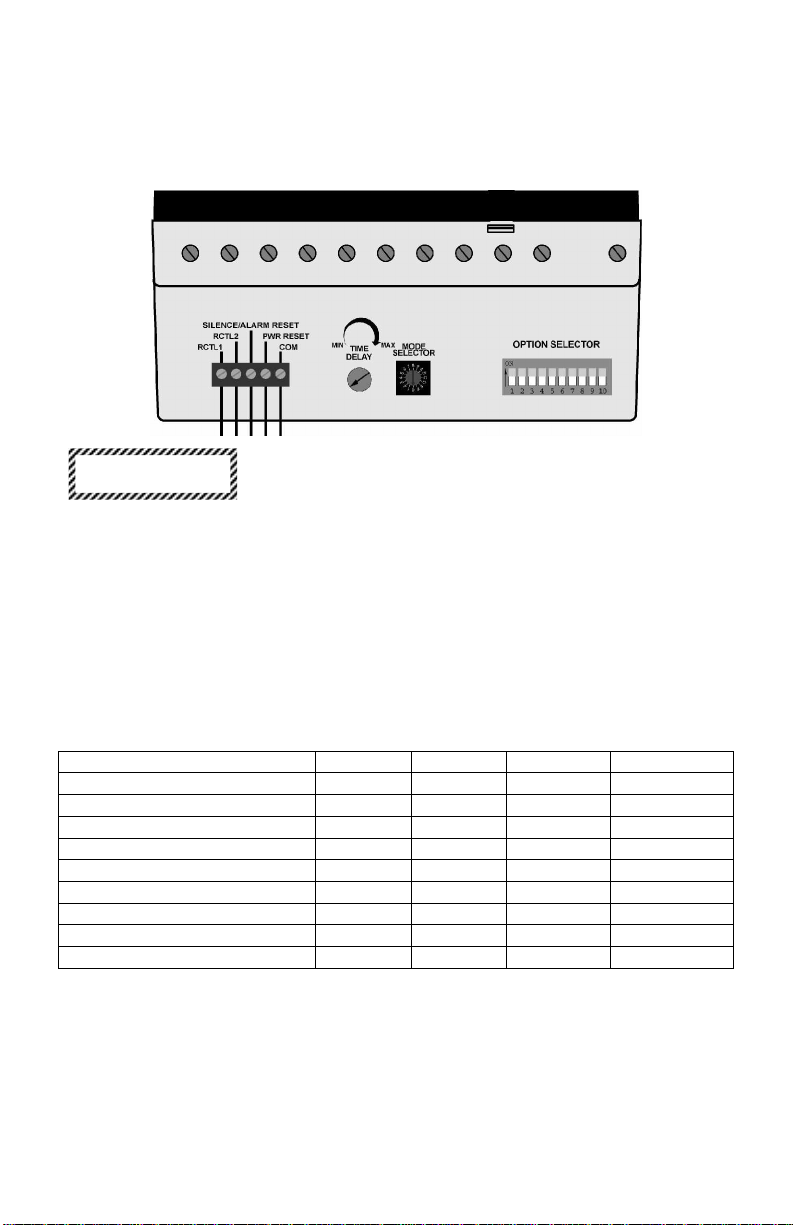

Model Description

WARNING!

The ISS-105 has three adjustable controls to set the mod e of operation:

1. Mode Selector

2. Option Selector

3. Time Delay

To ensure proper initialization and operation,

set the m ode and option selectors before applying

power to the unit.

Time Delay

The Time Delay can be set from 2–255 seconds and is the Lag Pump

delay in each of th e pumping modes. When the Lead Float

opens/closes, the Time Delay starts and once i t expires, the Lag Pump

is ready to turn on. After the Lag Pump turns on, any necessary pumps

will turn on suc cessively after a two-second time delay each.

Mode Selector

This dial is used to select the operation mode. A description of each

mode is shown i n Table 1. The capabilities of each pumping mode and

the Non-Alternating Pump designations are shown in Table 2 below.

Duplex Triplex Quadplex Duplex SPS

# Pumps 2 3 4 2

High Alarm Yes *Yes No **Yes

Low Alarm Yes *Yes No **Yes

Out-of-Sequence Alarm Yes Yes Yes Yes

# Stop Floats 1 1 1 2

Pump Di rection Up/Down Up/Down Up/Down Up/Down

Non-Alternating Start Float Lag 1 Lag 2 Lag 3 N/A

Non-Alternation Pump Pump 2 Pump 3 Pump 4 N/A

Alternator Yes Yes Yes Yes

Table 2. Mode Capabilities

* On a Triplex pump system, either a High or Low Alarm is available, but not both.

See Triplex Mode descriptio n for more details.

** On a Duplex SPS system, a High Alarm is typical on a Pump Down application

and a Low Alarm is typical on a Pump Up.

5

12/04

Page 6

Option Selector

Table 2 describes th e Option Selector for all pumping modes.

(· Indicates the function is available for the pum p mode)

Option

Selector

Position

1 High Alarm

2 Low Alarm

3 Pump 1

4 Pump 2

5 Pump 3

6 Pump 4

7

8

9

10

Function Description Duplex Triplex Quadplex

Audible Alarm Relay

State/Fail Safe

Alternator Select 0,

(ALS-0, see Tabl e 4)

Alternator Select 1,

(ALS-1, see Tabl e 4)

Alternator Select 2,

(ALS-2, see Tabl e 4)

* On a Triplex pump system, either a High or Low Alarm is available, but not both.

See Triplex Mode descriptio n for more details.

1. Pumping Modes

Duplex

In a Duplex mode, two pumps are used with one Stop Float and High

and Low Alarms.

Triplex: High/Low Alarm

In a Triplex mode, three pumps are used with one Stop Float.

In a Triplex Pump Down mode, a High Alarm is the typical

configuration with the Option Selector switches 1=ON (High Alarm) and

2=OFF (Low Alarm).

If a Low Alarm is desired, the al arm float must be moved to the position

in the tank below the Stop Float and Option Selector switches must be

1=OFF and 2=ON.

In a Triplex Pump Up mode, a Low Al arm is the ty pical configuration

with the Option Sel ector switches 1=OFF (Hi gh Alarm) and 2=ON (Low

Alarm).

If a High Al arm is desired, the alarm float must be m oved to the position

in the tank above the Stop Float and Option Selector switches must be

1=ON and 2=OFF

Quadplex

In a Quadplex m ode, four pumps are used with one Stop Float and no

alarms floats.

Duplex SPS

(Separate

Pump Stop)

· *· ·

· *· ·

· · · ·

· · · ·

· ·

·

· · · ·

· · · ·

· · · ·

· · · ·

Table 3. Opti on Selector

6

12/04

Page 7

Separate Pump Stop (SPS)

In the Duplex SPS mode, both the Lead and Lag pumps have their own

stop floats.

In an SPS Pump Down mode, a High Al arm is th e typical configuration with

Option Selector switches 1=ON (High Alarm) and 2=OFF (Low Alarm).

If a Low Alarm is desired, the alarm float must be moved to the positi on

in the tank below the Lead Stop Float, and Option Selector switches

must be 1=OFF, and 2=ON.

In an SPS Pump Up mode, a Low Alarm is the typical configuration with

Option Selector switc hes 1=OFF (High Alarm) and 2=ON (Low Alarm).

If a High Alarm is desired, the alarm float must be moved to the

position in the ta nk above the Lead Stop Float, and Option Sel ector

switches must be 1=ON and 2=OFF.

2. IS Super Cell Functions

High Alarm

The High Alarm is activated when the High Alarm Float closes,

indicating the pumps are unable to keep the water level down on a

Pump Down applic ation. If the High Al arm Float closes at any time, all

pumps will turn on, bypassing th e 10-second out-of-sequence trip delay,

and the adjus table Time Delay.

If a High Alarm is used on a Pump Up application, the alarm will be

activated when the High Alarm Float cl oses indicating the water level

has been pumped too high, possibly due to a defective Stop Float, and

will turn off all pumps.

During a High or Low Alarm, the Alarm LED and Audible Alarm LED will

be on. If the High or Low Alarm condition ends, the Audible Alarm will

turn off and the Alarm LED will flas h indicating the alarm had occu rred,

but is not present now. If the High or Low Alarm occurs again, the

Audible Alarm LED will turn on again, but t he Alarm LED will rem ain

flashing.

The unit must be silenced or reset to clear the flashing al arm LEDs.

Low Alarm

The Low Alarm is activated when the Low Alarm Float opens indicating

the pumps are unable to keep the water level up on a Pump Up

application. If the Pump Up Low Alarm Float opens at any time, except

if a High Al arm is activated, all pumps will turn on.

If a Low A larm is used on a Pump Down application, the alarm will be

activated when the Low Alarm Float opens indicati ng the water level has

been pumped too low. This may be a result of a defective stop float.

The Low Alarm will not turn off the pumps though, but will activate the

low alarm relay; another form of pump-dry protection such as the

SymCom Model 777 may be required.

Out-of-Sequence Alarm

When a float i n the series does not open or close in sequence, the

Audible Alarm will be activated and input LED(s) will flash until t he unit

7

12/04

Page 8

is reset or power is cycled. An out-of- sequence condition has to exist for

10 seconds before th e ISS-105 will alarm. W hen the stop float fai l s open

in pump down mo de or closed in pump up mode, an Out-of- Sequence

Alarm will NOT occur and pumps will not turn on with floats. In this case,

all pumps will turn on when the High/Low Alarm is activated. Thus, in

Quadplex mode, pumps will never turn on if th e Stop Float ma lfuncti ons.

Audible Alarm

The Audible Alarm is activated when a High, Low or Out-of Sequence

Alarm occurs. The Audible Al arm will turn off when there is no longer

high or low alarms or if the unit is silenced.

Audible Alarm Logic/Fail-Safe

The Audible Alarm rela y can be configured to operate in either a FailSafe mode (p osition 7=ON), or a Non Fail-Saf e mode (position 7=OFF).

In Fail-Safe mode, the NC (Normally Closed) contacts will beopen

during normal operation and closed during an alarm. In Non Fail-Safe

mode, the NC contacts will be cl osed during normal operation and open

during an alarm.

Clearing Alarms

The external Silence / Alarm Reset button will clear t he Audible Alarm.

The Reset button or cycling power will clear Out-of-Sequence Alarms.

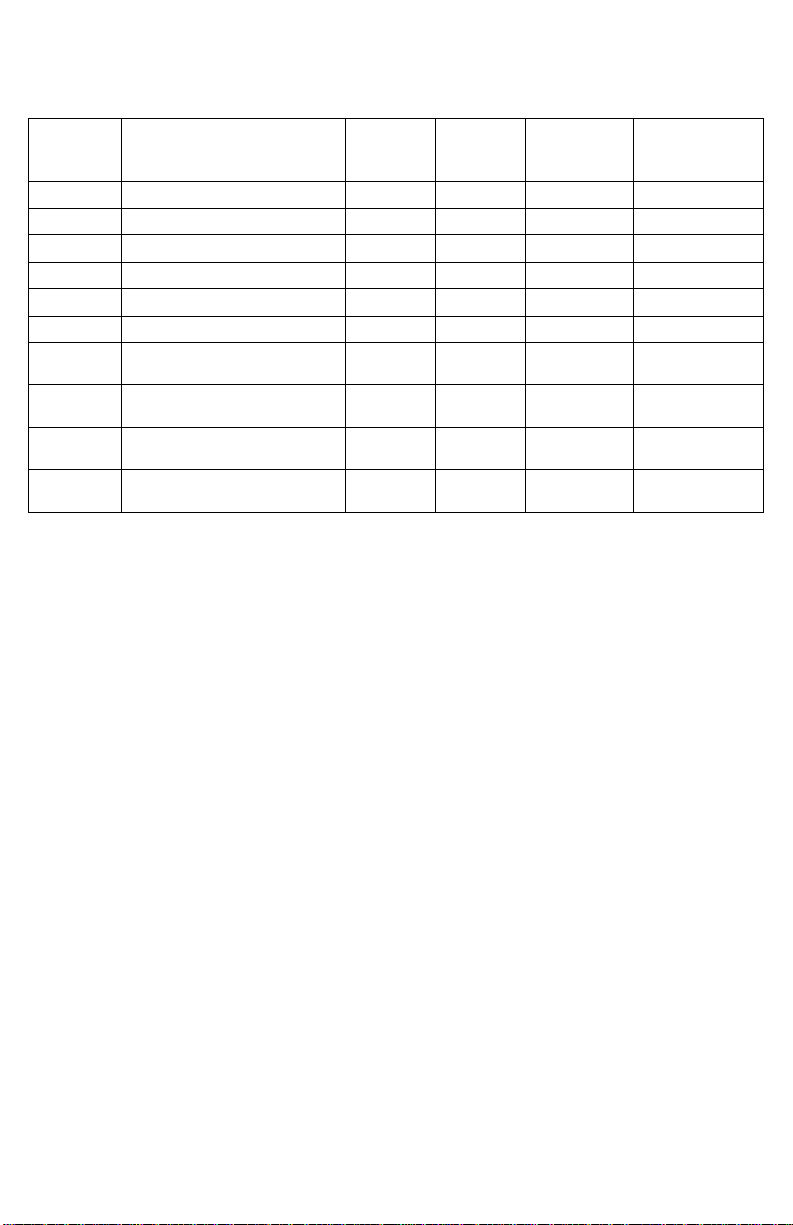

Alternation

The ISS-105 i s equipped with a built-in alternator that determines which

pump will st art each pum ping cycle. This alt ernator is configured using

switches ALS-0, ALS-1 and ALS-2 of the Option Selector.

Function

ALS-0

Position 8

Alternation On ON ON ON

Alternation On OFF ON ON

Alternation On, Non-

Alternating Pump Enabled (1)

Alternation On, Non-

Alternating Pump Enabled (1)

Alternation Off, Force Pum p 1

as Lead

Alternation Off, Force Pum p 2

as Lead

Alternation Off, Force Pum p 3

as Lead (2)

Alternation Off, Force Pum p 4

as Lead (3)

*ON OFF OFF

**OFF OFF OFF

OFF ON OFF

OFF OFF ON

ON ON OFF

ON OFF ON

Table 4. Alternator Options

Note (1) In Duplex Mode, this setting is the same as Alternation On.

Note (2) In Duplex Mode, this will force Pump 1 as lead and will cycl e Pump 2 every 50

Note (3) In Duplex Mode, this will force Pump 2 as lead and will cycle Pump 1 ever y 50

cycles of the lead pump

cycles of the lead pump

* If ALS-0 is ON in this mode, the Non-Alternating Pump will cycle when the NonAlternating Float changes state, or after 50 cycles of the Lead Float.

** If ALS-0 is OFF the Non-Alternating Pump will cycle only when the Non-Alternating

Float changes state.

8

ALS-1

Position 9

ALS-2

Position 10

12/04

Page 9

Alternation On

When the alternator is on, each pump will be alternated as the

Lead Pump (see Table 5).

Cycle 1 Cycle 2 Cycle 3 Cycle 4 Cycle 5

Pump 1 Lead Lag 3 Lag 2 Lag 1 Lead

Pump 2 Lag 1 Lead Lag 3 Lag 2 Lag 1

Pump 3 Lag 2 Lag 1 Lead Lag 3 Lag 2

Pump 4 Lag 3 Lag 2 Lag 1 Lead Lag 3

Table 5. Pump Sequence

Alternation On, Non-Alternating Pump Enabled

The Triplex and Quadplex pump modes are equipped with an

optional Non-Alternating Pump. This pump will not be included in

the normal pump alternation sequence when ALS-1 and ALS-2

(positions 9 and 10) are both OFF. If ALS-0 (position 8) is ON, th e

Non-Alternating Pump will cycle when the Non-Alternati ng Float

changes state or after every 50 cycles of th e Lead Float. If ALS-0

is OFF, the Non-Alternating Pump will only cycle if the NonAlternating Float chang es state.

The last pump i n the float sequence (highest #) is the NonAlternating Pump and can be used as either a jockey or emergency

pump. (See Tabl e 2, page 5 for Non-Alternating Pump and Float

details for each pumpi ng mode.)

A Jockey Pump is typically a smaller pump that will always be

used first in the pump sequence. In order to implement a

jockey pump; the Non-Alt ernating Pump Float must be moved

in the tank to just above the Stop Float in a Pump Down

system, and to just below the Stop Float in a Pump Up system.

See Figure 9 (page 19), an exam ple wiring diagram using a

Jockey Pump in a Duplex Pump Down system.

An Emer gency Pump is usually a larger pump that is always

used last. In order to implement an emergency pump; the

Non-Alternating Pump is already the last pump in the

sequence so there i s no need to mo ve the float. See Figur e 10

(page 20), an example wiring diagram using an Emergency

Pump in a Duplex Pump Down system.

Alternation Off

When the alternator is off, a Lead Pump can be forced by setting ALS-0,

1 & 2 (s ee Table 4). The remaining pumps will start in a sequential

order as each float opens/closes.

Disabling Pumps

Using the built-in DIP switc hes, individual pumps can be disabled, when

taken out of service for repair or maintenance.

9

12/04

Page 10

External Inputs

A five-pin connector is provided for optional external inputs.

· External Silence / Alarm Reset

This input allows for an external NO (Normally Open) pushbutton

that will silence audib le alarms and clear flashing alarm lights.

· External Power Reset

This input allows for an external NO pushbutton to reset the IS

Super Cell, causing th e same effect as a power cycle.

· External Alternation Configuration

For Duplex Mode, a SPDT (Single Pole Double Throw) switch can

be connected to close RTCL1 or RTCL2 (remote controls) to force

Pump 1 or 2 as the Lead Pump. Opti on Selector Positions 8, 9 &

10 must be OFF. If th e switch is i n the middle position, pumps will

be in alternation mode.

For Triplex and Q uadplex Modes t wo SPST (Single Pole Single

Throw) switches can be connected to force Pump 1,2,3 or 4 to be

the Lead Pump. Option Selector Positions 9 & 10 must be OFF.

To force Pump 1 or 2 as Lead, Positi on 8 must be OFF.

To force Pump 3 or 4 as Lead, Positi on 8 must be ON.

For alternation mode, close bot h RTCL1 and RTCL2.

3. Wiring Diagrams

The following Figures 1-10, show ty pical wiring diagrams for all pumping

modes available for th e IS Super Cell.

10

12/04

Page 11

Figure 1. Typical Wiring for Duplex Pump Down - Mode 1

Switch State

Mode Selector Switch 1

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm ON

2 Low Alarm ON

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 NA

6 Pump 4 NA

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 6. Typical Duplex Pump Down Setup

11

12/04

Page 12

Figure 2. Typical Wiring for Triplex Pump Down - Mode 2

Switch State

Mode Selector Switch 2

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm ON

2 Low Alarm OFF

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 ON

6 Pump 4 NA

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 7. Typical Triplex Pump Down Setup

12

12/04

Page 13

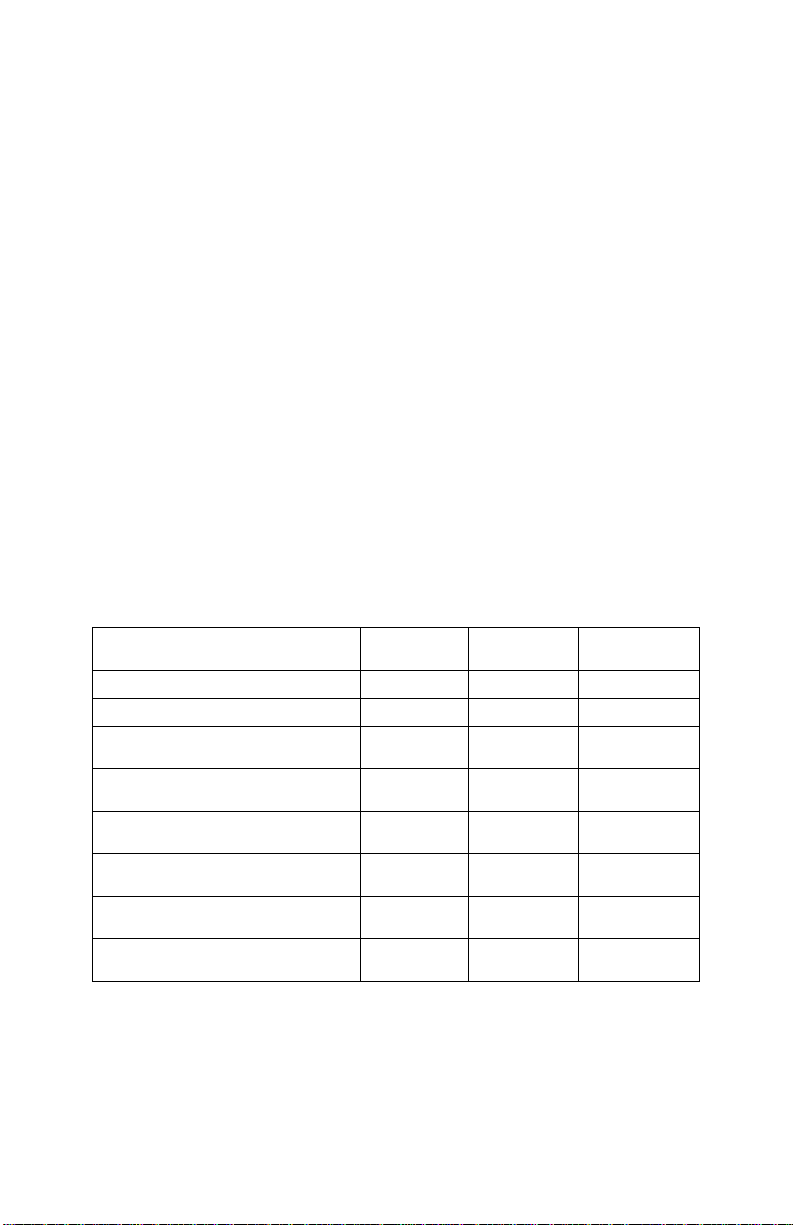

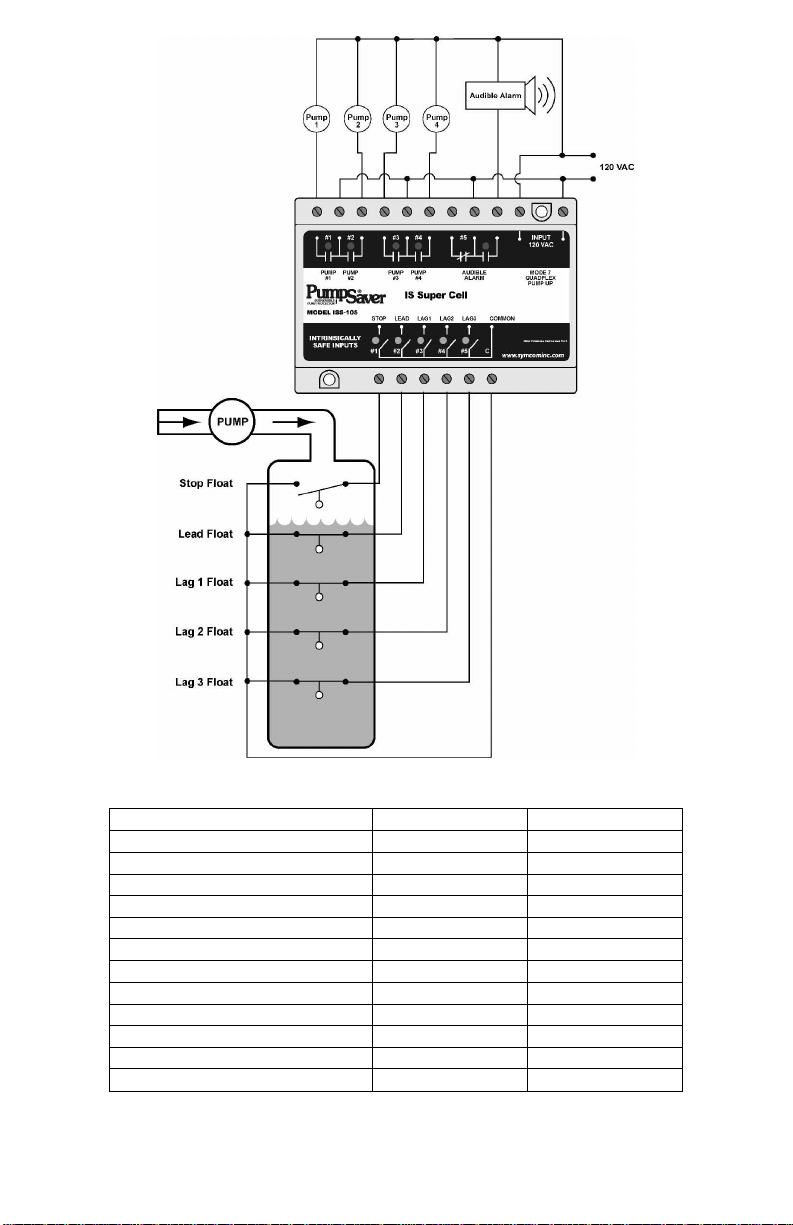

Figure 3. Typical Wiring for Quadplex Pump Down - Mode 3

Switch State

Mode Selector Switch 3

Time Delay Adjustment MIN

Option Selector Switch

1 Hi gh Alarm NA

2 Low Alarm NA

3 Pum p 1 ON

4 Pum p 2 ON

5 Pum p 3 ON

6 Pum p 4 ON

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 8. Typic al Quadplex Pump Down Setup

13

12/04

Page 14

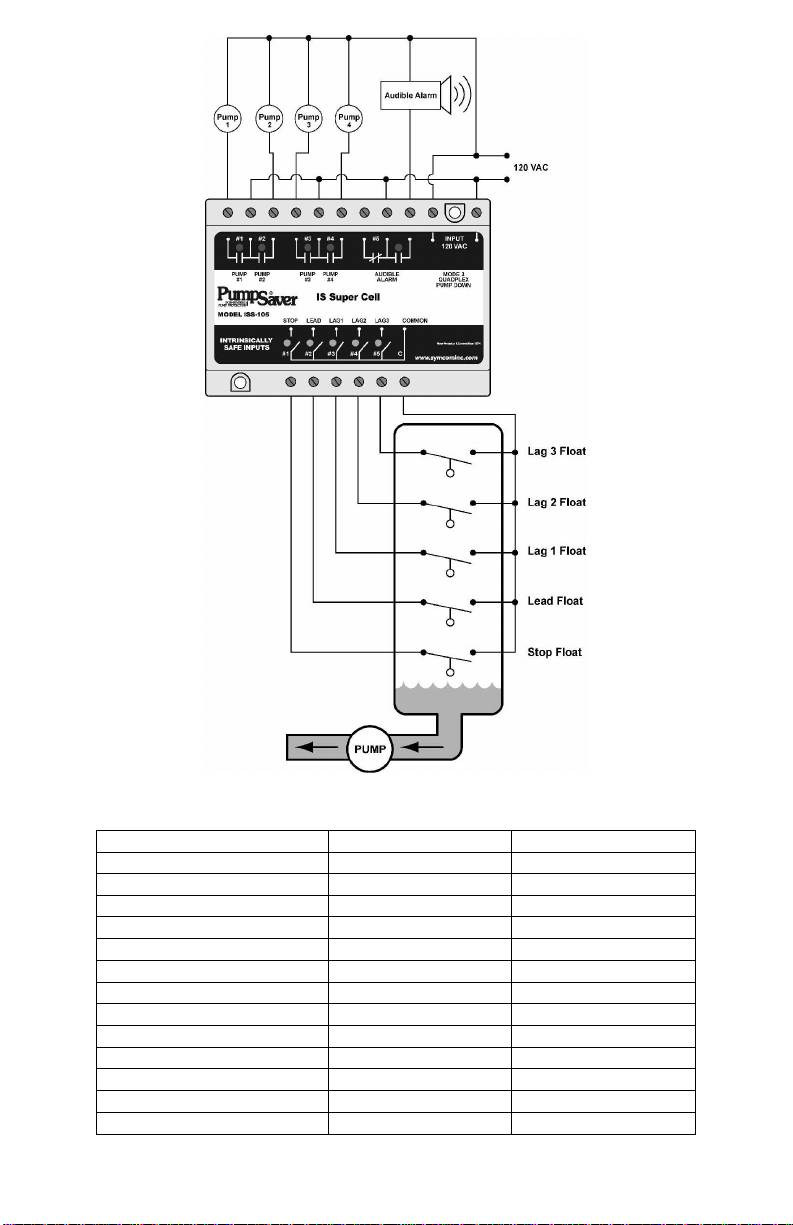

Figure 4. Typical Wiring for Duplex SPS Pum p Down - Mode 4

Switch State

Mode Selector Switch 4

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm ON

2 Low Alarm OFF

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 NA

6 Pump 4 NA

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 9. Typi cal Duplex SPS Pump Down Setup

14

12/04

Page 15

Figure 5. Typical Wiring for Duplex Pump Up - Mode 5

Switch State

Mode Selector Switch 5

Time Delay Adjustment MIN

Option Selector Switch

1 Hi gh Alarm ON

2 Low Alarm ON

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 NA

6 Pump 4 NA

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 10. Typic al Duplex Pump Up Setup

15

12/04

Page 16

Figure 6. Typical Wiring for Triplex Pump Up - Mode 6

Switch State

Mode Selector Switch 6

Time Delay Adjustment MIN

Option Selector Switch

1 Hi gh Alarm OFF

2 Low Alarm ON

3 Pum p 1 ON

4 Pum p 2 ON

5 Pum p 3 ON

6 Pum p 4 NA

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 11. Typic al Triplex Pump Up Setup

16

12/04

Page 17

Figure 7. Typical Wiring for Qua dplex Pump Up - Mode 7

Mode Selector Switch 7

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm NA

2 Low Alarm NA

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 ON

6 Pump 4 ON

7 Fail-Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 12. Typic al Quadplex Pump Up Setup

17

12/04

Page 18

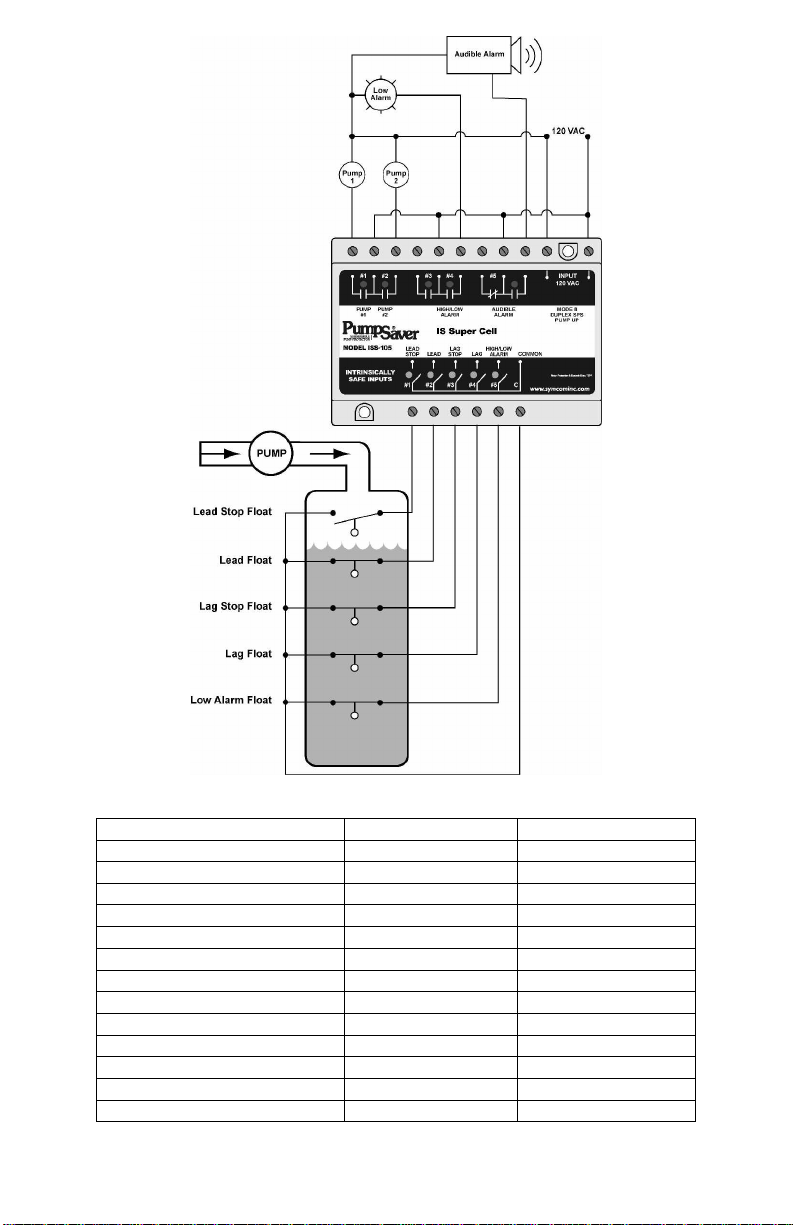

Figure 8. Typical Wiring for Duplex SPS Pum p Up - Mode 8

Switch State

Mode Selector Switch 8

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm OFF

2 Low Alarm ON

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 NA

6 Pump 4 NA

7 Fail- Safe OFF

8 ALS-0 ON

9 ALS-1 ON

10 ALS-2 ON

Table 13. Typical Duplex SPS Pum p Up Setup

18

12/04

Page 19

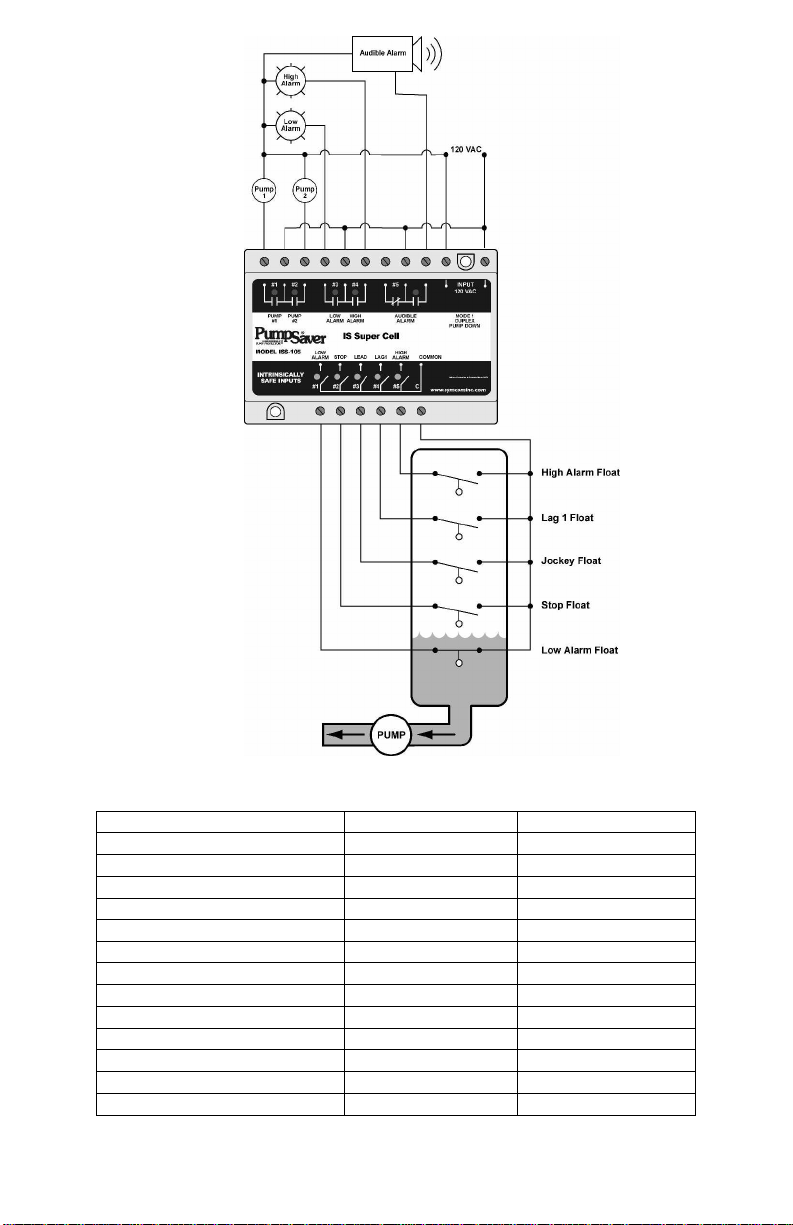

Figure 9. Typical Wiring for Duplex Pump Down with a Jockey

Pump - Mode 1

Switch State

Mode Selector Switch 1

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm ON

2 Low Alarm ON

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 NA

6 Pump 4 NA

7 Fail- Safe OFF

8 ALS-0 OFF

9 ALS-1 ON

10 ALS-2 OFF

Table 14. Typic al Duplex Pump Down w/ Jockey Setup

19

12/04

Page 20

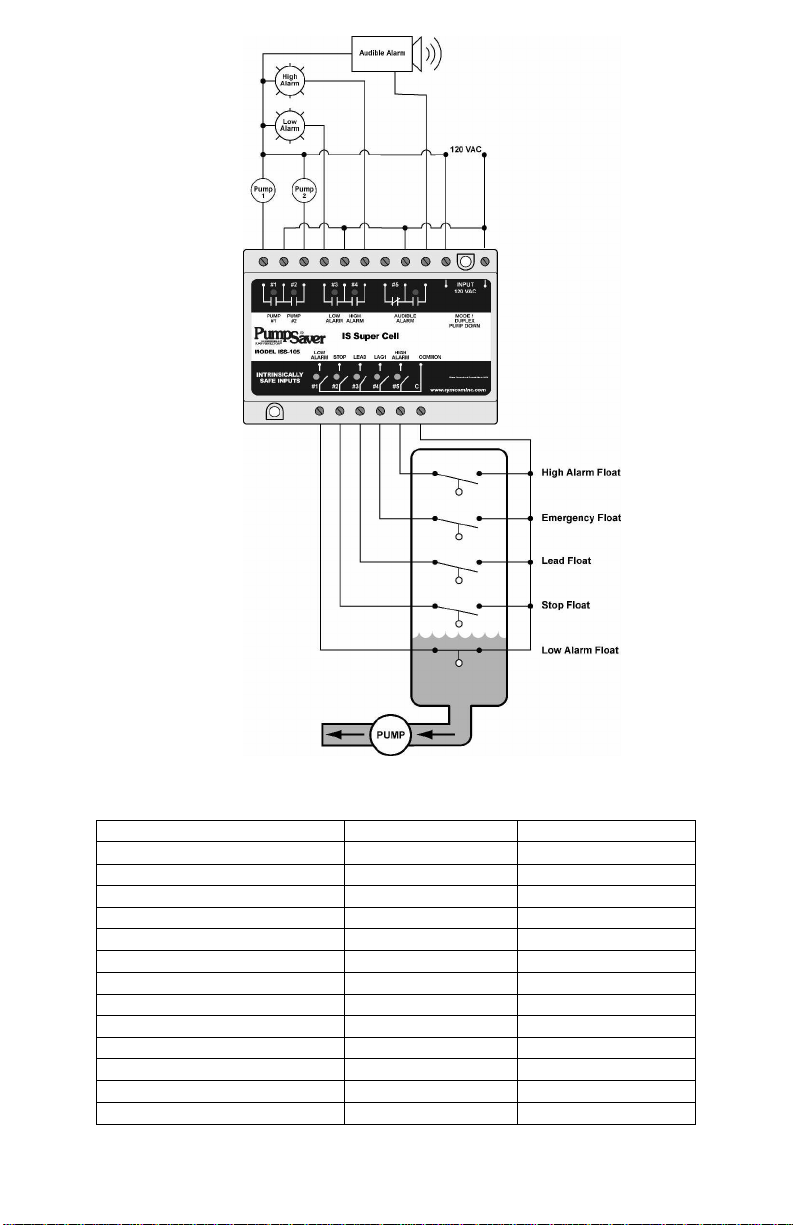

Figure 10. Typical Wiring for Duplex Pump Down with an

Emergency Pump - Mode 1

Switch State

Mode Selector Switch 1

Time Delay Adjustment MIN

Option Selector Switch

1 High Alarm ON

2 Low Alarm ON

3 Pump 1 ON

4 Pump 2 ON

5 Pump 3 NA

6 Pump 4 NA

7 Fail- Safe OFF

8 ALS-0 OFF

9 ALS-1 OFF

10 ALS-2 ON

Table 15. Typic al Duplex Pump Down Setup

20

12/04

Page 21

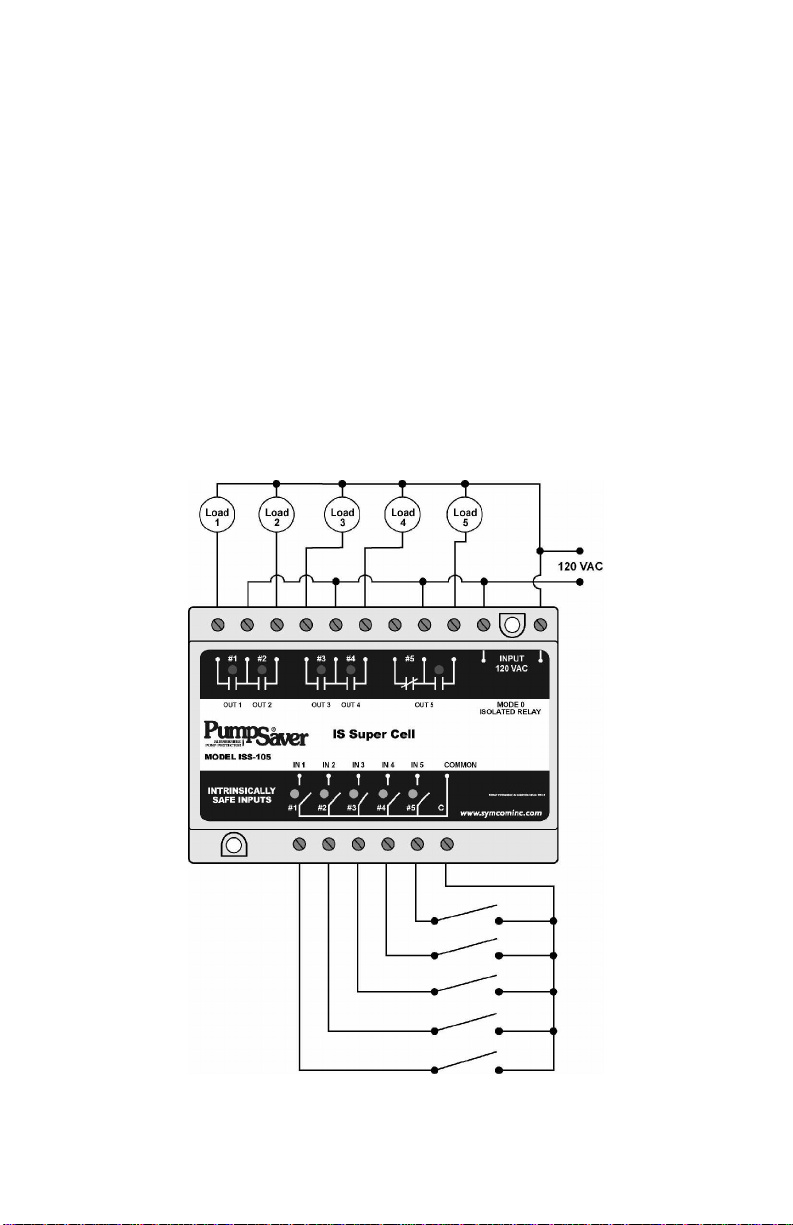

4. Five-Channel Relay Mode

Some unique features of th e Five-Channel Relay mode are descr i bed

below. To use the IS Super Cell in this mode, the Mode Selector

dial must be set to position 0.

Option

Selector

Position

1

2

3 Relay 1 Logic Positive Negative

4 Relay 2 Logic Positive Negative

5 Relay 3 Logic Positive Negative

6 Relay 4 Logic Positive Negative

7 Relay 5 Logic Positive Negative

8

9

10 Not Used ----- -----

Function

Description

Enables Channel 2

Latch

Enables Channel 4

Latch

Selects

Make/Break

Enables Delay-On-

Make/Break Timer

Table 16. Five-Channel Relay Options

ON Function OFF Function

Channel 1 and 2

function normally

Channel 3 and 4

function normally

Delay-On-Break Delay-On-Make

Make/Break Timer

Disabled

Channel 1

Latches Channel 2

Channel 3

Latches Channel 4

Make/Break Timer

Enabled

Positive/Negative Logic

Using positive logic will give the same output as input – if the input is

closed, the corresponding output relay will al so be closed.

If using negative logic, the out put will be the opposite of the input – if

the input is closed, the output relay will be open.

Latched Output

Relays 2 and 4 can be configured as latched relays. Input 2 will cause

relay 2 to close, but this relay will not open until input 1 opens. Relay 4

will close when i nput 4 closes, but will not open until input 3 opens.

21

12/04

Page 22

Time Delay Output

Relay 5 can be confi gured as a Delay-On-Make or a Delay-On-Break

time delay output. All timing starts when the input switch opens or

closes. The time base for this output is adjustable using th e Time Delay

knob and ranges fr om 2-255 seconds.

· Delay-On-Make

If Input 5 closes, the Time Delay will start and LED 5 will flash.

Once the Time Delay has expired, Output Relay 5 will close and the

LED will be on. If Input 5 opens at any point during the timing

cycle, the Time Delay stops and Output Relay 5 remains open.

· Delay-On-Break

If Input 5 opens, the Tim e Delay will start and LED 5 will flash.

Once the Time Delay has expired, Output Relay 5 will open and the

LED will be off. If Input 5 closes at any point during the timing

cycle, the Time Delay stops and Output Relay 5 remains closed.

Figure 11. Typical Wiring for 5-c hannel Relay - M ode 0

22

12/04

Page 23

Model ISS-105 Specifications

Control Voltage 108–132VAC

Frequency 50/60 Hz

Power 4 Watts (max.)

Adjustments

Time Delay/Lag Pump Delay 2–255 sec.

Mode Selector 0–8 (9–F: force mode 0)

Opt ion Selector 1–10, ON/OFF

Silence Button dry input only / non IS

Reset Button dry input only / non IS

External Alternation Configuration ALS-1

External Alternation Configuration ALS-2

Pumping Modes A vailable

Duplex Pump Down 2 pumps w/ high and low alarm s

Triplex Pump Down 3 pumps w/ high alar m (typical)

Quadplex Pump Down 4 pumps

Duplex Pump Down SPS

(Sepa rate Pump Stop)

Duplex Pump Up 2 pumps w/ high and low alarms

Triplex Pump Up 3 pump s w/ low alarm (typical)

Quadplex Pump Up 4 pumps

Duplex Pump Up SPS

(Sepa rate Pump Stop)

5-Channel Relay Mode

5-Channel 1 relay latched / time delay output

Operating Temperature -20 to 55°C

Terminals

Wire AWG 12–20 AWG

Torque 6 in.-lbs.

Relay Contacts

Pump Inrush Delay 2 sec.

Entity Parameters

Provides Intrinsically Safe Circuits in

the Following Locations:

Standards Passed

2 pumps w/ high alar m (typical)

2 stop floats

2 pumps w/ low alar m (typical)

2 stop floats

B 300 or 480VA @ 240VAC, Pilot Duty

240 VAC, 7A (max.), General Purpose

Voc=16.8 V

Isc=1.2 mA

La=100mH

Ca=0.39µF

Po = Voc * Isc

4

Class I, Divisions I & II, Groups A, B, C & D;

Class II, Divisions I & II, Groups E, F & G;

and Class III lo cations

Electrostatic Discharge (ESD) IEC 61000-4-2, Level 3, 6 kv contact, 8 kv air

Radio Frequency Immunity (RFI) IEC 61000-4-2, Level 3, 10V/m

Fast Transients

IEC 61000-4-4, Level 3, 4 kv input power

2 kV inputs/outputs

23

12/04

Page 24

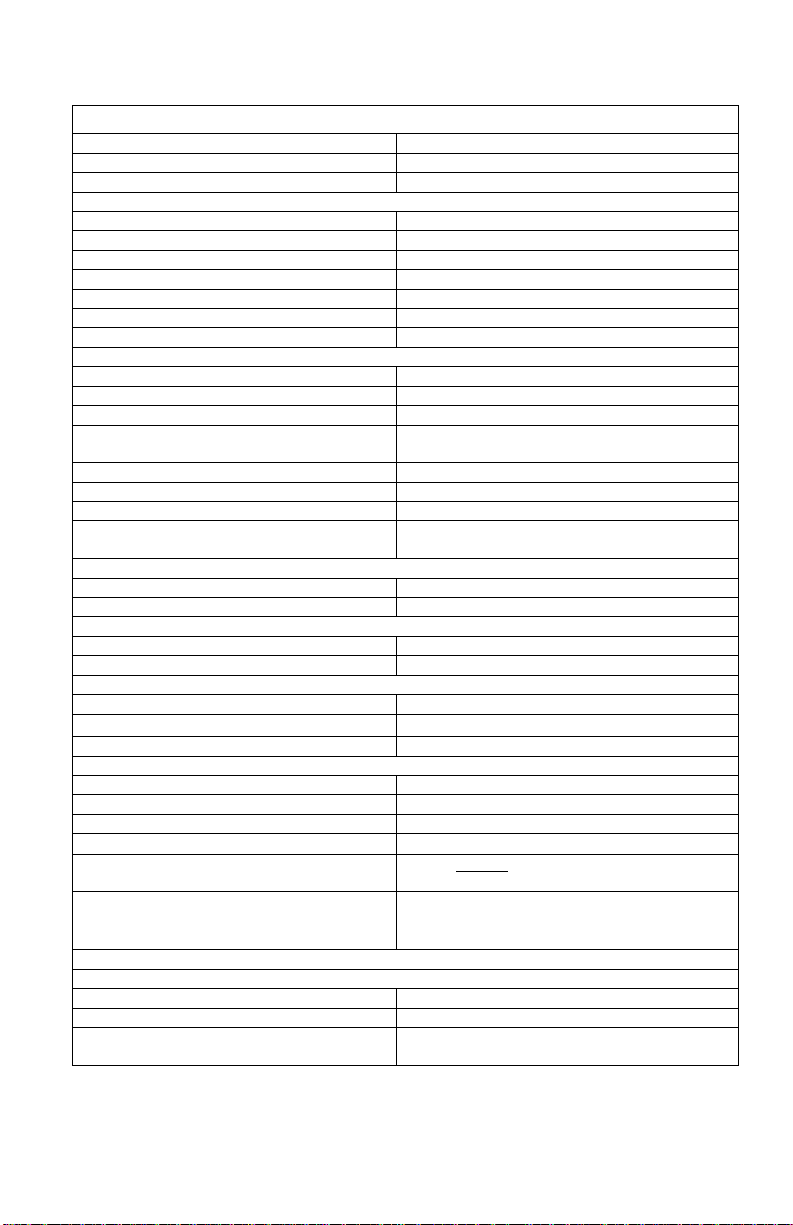

ASSOCIATED APPARATUS / APPAREILLAGE CONNEXE

NITION OF FLAMMABLE OR COMBUST ABLE

ATMOSPHERES, DISCONNECT POWER BEFORE SERVICING.

COMPROMETTRE LA SÉCURITÉ INTRINSÈQUE.

See Note 3

pparatus

shall be calculated and must be included in the system calculations as shown in the table above. Cable

capacitance, Ccable, plus intrinsically safe equipment capacitance, Ci, must be less than the marked capacitance,

iated apparatus used. T he same applies for inductance (Lcable, Li a nd La or Lo,

respectively). Where the cable capacitance and inductance per foot are not known, the foll owing values shall be

Load

Load

1

2

RELAY#1RELAY#2REL AY#3RELAY#4RELAY

MODEL ISS-105

I1I2I3I4I5IC

CONTROL DRAWING ISS-105

Non-Hazardous Location

Supply Voltage

120VAC

Load

3

ISSuperCell

Load4Load

#5

5

INPUT

120 VAC

Relay Output Rating

7 Amps @ 240VAC General Purpose

Pilot Duty 480VA @ 2 40VAC, B300

11 5 VAC

Maximum Ambient Temperature Rating

55°C

DEVICE MUST BE INSTALLED IN A SUITABLE ENCLOSURE

WARNING!

TO PREVENT IG

DEVICE MAY ONLY BE REPAIRED BY THE MANUFACTURER

WARNING!

SUBSTITUTION OF COMPONENTS MAY IMPA IR INTRINSIC

SAFETY.

AVERTISSEMENT!

LA SUBSTITUTION DE COMPOSANTS PEUT

See Notes 1 & 2

Capacitance and inductance of the field wiring from the intrinsically safe equipment to the associated a

Ca (or Co), shown on any ass oc

used: Ccable = 60pF/ft., Lcable = 0.2µH/ft.

(800) 843-8848 · (605) 348-5580 · fax (605) 348-5685

www.symcom.com

Class I, Divisions I & II, Groups A, B, C & D;

Class II, Divisions I & II, Groups E, F & G; and

Class III locations

NOTES:

1. Maximum distance between unit and switch contact is

10,000 feet.

2. All non-intrinsically safe wiring shall be separated from

intrinsically safe wiring. Description of special wiring

methods can be found in the National Electrical Code

ANSI/NFPA 70, Article 504 I ntrinsically Safe Systems.

Check your state and local codes for additional

requirements.

3. All switch contacts shall be non-energy storing,

containing no inductance or capacitance.

4. Entity Parameters:

Voc = 16.8V Ca = 0.39µF

Isc = 1.2mA Po = Voc * Isc

La = 100mH 4

5. Entity Parameter Relationships:

IS Equipment

Associated Apparatus

Vmax (or Ui) ≥ Voc or Vt (or Uo)

Imax (or Ii) ≥ Isc or It (or Io)

Pmax, Pi ≥ Po

Ci + Ccable ≤ Ca (or Co)

Li + Lcable ≤ La (or Lo)

2880 North Plaza Drive, Rapid City, South Dakota 57702

Hazardous Location

Loading...

Loading...