Page 1

Overload Relays

The Model 777-P2 Series is a family of fully programmable electronic

overload relays. They are designed to monitor and protect any 3-phase 200480VAC (500-600VAC for 777-575-P2) motor drawing 2-800 full load amps

(external CTs are required above 90 amps). They provide unsurpassed

protection from faulty voltage, underload and overload conditions.

Common applications include conveyor systems, HVAC equipment, saws

and grinders, fan motors and almost any pumping application.

Model 777-P2 Series

Features:

• Protects 3-phase motors from:

• High voltage

• Low voltage

• Voltage unbalance

• Reverse-phase

• Overcurrent

• Undercurrent

• Current unbalance

• Single-phase

• Network programmable

• Programmable with 9-volt battery prior to

installation

• Automatic reset with three separate restart delay

timers, or manual reset

• Tamper guard

• RS-485 communications port (communications

module sold separately)

• 3-digit LED diagnostic display

• Last fault memory

• 5-year warranty

• Made in USA

• UL and ULC listed

• CE compliant

• CSA approved

• Surface or DIN rail mount

The 777-P2 Series units can be used as a stand-alone product or the RS485 communications port can be used to form a network to communicate

with a PC, PLC or SCADA system. The 777-P2 units can be used with

CIO modules produced by SymCom for several types of communication

protocols. Up to 99 model 777-P2 units can be networked together and

monitored and controlled by SymCom’s Solutions software. The units can

also be connected to SymCom’s remote monitors for a simple, cost-effective

way to meet new requirements for arc-ash safety.

The 777-P2 Series units incorporate a 3-digit LED display that is used for

programming, providing real-time operational information, and displaying

diagnostic codes to aid in troubleshooting a fault condition.

The unit’s many features include enhanced trip classes beyond the NEMA

standard trip classes. The settable trip class range is 2-60, with or without

jam protection, and a secondary linear trip delay can be set with a range

of 0-60 seconds. If both trip class and linear trip delay are set, the 777-P2

will follow the faster trip time. Another feature is the automatic dry-well

recovery timer that allows the unit to automatically select a restart delay

based on the last cycle’s run time. This allows the 777-P2 to optimize restart

delay times.

The units can be pre-programmed with a 9-volt battery prior to actual

installation. This can save a lot of time during initial installations and avoid

subsequent service calls when commissioning new projects.

AUXILIARY PRODUCTS:

• Remote Displays (RM-1000/RM-2000)

• Communication Modules

• Remote Manual Reset Kit

• Solutions Software

(605) 348.5580 / (800) 843.8848 / Fax (605) 348.5685

customerservice@symcom.com / technicalsupport@symcom.com

Rev. 0110

Page 2

Specications

Functional Specications

Programmable Operating Points

LV-Low Voltage Threshold

HV-High Voltage Threshold

VUB-Voltage Unbalance Threshold

MULT-# of Conductors or CT Ratio (xxx:5)

OC-Overcurrent Threshold

UC-Undercurrent Threshold

CUB-Current Unbalance Threshold

TC-Overcurrent Trip Class and Linear Overcurrent Trip Delay

RD1-Rapid-cycle Timer

RD2-Restart Delay after all faults except undercurrent (motor

cool-down timer)

RD3-Restart Delay after undercurrent (dry-well recovery timer)

#RU- Number of restarts after all undercurrent faults

ADDR-RS485 Address

#RF-Number of restarts after all faults except undercurrent

UCTD-Undercurrent Trip Delay

GF-Ground Fault Current Threshold

Input Characteristics

Supply Voltage

777-P2

777-575-P2

Frequency

Motor Full Load Amp Range

Output Characteristics

Output Contact Rating - SPDT (Form C)

Pilot Duty

General Purpose

Expected Life

Mechanical

Electrical

General Characteristics

Operating Temperature

Ambient Operating

Ambient Storage

Accuracy at 25o C (77o F)

Voltage

Current

Timing

Ground Fault

Repeatability

Voltage

Current

Maximum Input Power

Pollution Degree

Class of Protection

Relative Humidity

Terminal Torque

Standards Passed

Electrostatic Discharge (ESD)

Radio Frequency Immunity (RFI), Conducted

Radio Frequency Immunity (RFI), Radiated

Fast Transient Burst

Short Circuit

Surge

IEC

ANSI/IEEE

Hi-potential Test

Vibration

Shock

Safety Marks

UL

CE

Max Conductor Size through 777-P2

Dimensions

Weight

Mounting Method

*575V units

170-524V (450-649V*)

172-528V (451-660V*)

2-25% or 999 (disabled)

1-10, 100, 150, 200, 300, 400, 500, 600, 700, 800

(20-100A) ÷ MULT of 80-140% of CT Primary

(0, 10-98A) ÷ MULT or 40-140% of CT Primary

2-50% or 999 (disabled)

02-60, J02-J60; L00-L60 or oFF

0-999 seconds

2-500 minutes

2-500 minutes, A (automatic)

0, 1, 2, 3, 4, A (automatic)

A01-A99

0, 1, oc1, 2, oc2, 3, oc3, 4, oc4, A, ocA (automatic)

2-999 seconds (standard)

(3-20A) ÷ MULT or 12-40% of CT Primary or oFF

200-480VAC

500-600VAC

50/60Hz

2-20A, (looped conductors required); 20-90A (direct); 80-800A (external CTs required)

480VA@240VAC, B300

10A@240VAC

1 x 106 operations

1 x 105 operations at rated load

-20o to 70o C (-4o to 158o F)

-40o to 80o C (-40o to 176o F)

± 1%

± 3% (<100A direct)

± 0.5 second

± 15% (<100A)

± 0.5% of nominal voltage

± 1% (<100A direct)

10 W

3

IP20, NEMA 1

10-95%, non-condensing per IEC 68-2-3

7 in.-lbs.

IEC 61000-4-2, Level 3, 6kV contact, 8kV air

IEC 61000-4-6, Level 3 10V

IEC 61000-4-3, Level 3 10 V/m

IEC 61000-4-4, Level 3, 3.5 kV input power

61000-4-5 Level 3, 2kV line-to-line; Level 4, 4kV line-to-ground

C62.41 Surge and Ring Wave Compliance to a level of 6kV line-to-line

Meets UL508 (2 x rated V + 1000V for 1 minute)

IEC 68-2-6, 10-55Hz, 1mm peak-to-peak, 2 hours, 3 axis

IEC 68-2-27, 30g, 3 axis, 11ms duration, half-sine pulse

UL508, UL1053

IEC 60947-1, IEC 60947-5-1

0.65” with insulation

3.0” H x 3.6” W x 5.1” D

1.2 lbs.

Surface mount (4 - #8 screws) or DIN Rail Mount

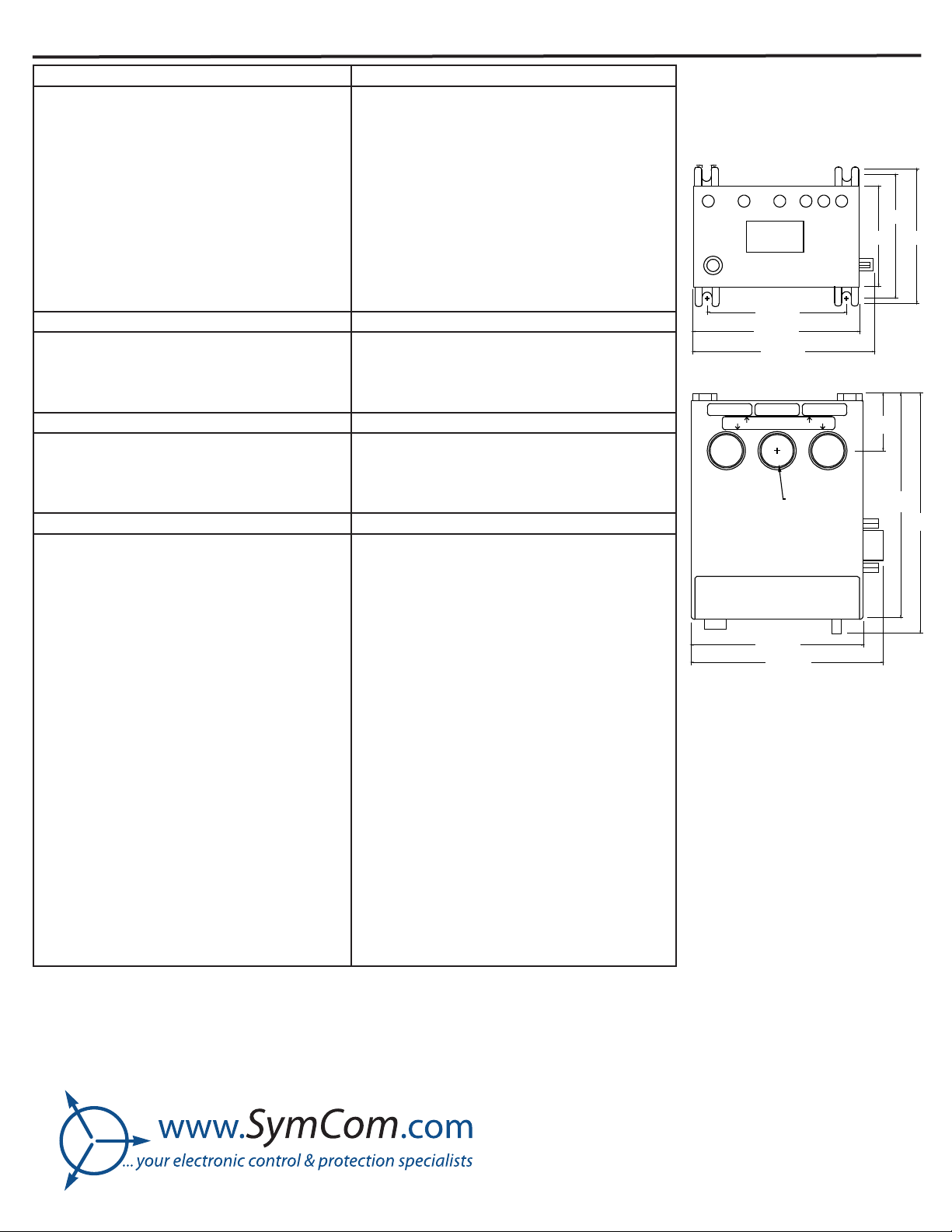

Enclosure Dimensions

0.200" (5.08)

3.100" (78.74)

3.600" (91.44)

3.850" (97.79)

OPTIONAL LOOP HOLES

A B C

MAIN CONDUCTORPASS HOLES

D. 0.650" (16.51)

3.600" (91.44)

3.850" (97.79)

2.280"

(57.91)

(30.48)

1.200"

2.650"

(67.31)

4.700"

(119.38)

3.050"

(77.47)

(128.27)

5.050"

How to order:

Part Number: 777-P2

777-575-P2

(605) 348.5580 / (800) 843.8848 / Fax (605) 348.5685

customerservice@symcom.com / technicalsupport@symcom.com

Rev. 0110

Loading...

Loading...