Symcom 777-KW/HP, 777-LR-KW/HP, 777-575-KW/HP, 777-HVR-KW/HP, 777-HVR-LR-KW/HP Catalog Page

Page 1

•Digital programmability permits

precise customization.

•Sixteen setpoints can be programmed for

maximum protection.

•Last fault memory provides instant

troubleshooting diagnostics.

•Voltage, current, last 4 faults, kW, hp and

power factor are recordable when using

communications package.

• An RS485 communication port comes

standard for use with computerized

systems using Modbus protocol.

•UL and CSA listed as an overload relay.

2880 North Plaza Drive • Rapid City, SD 57702

(800) 843-8848 • (605) 348-5580 • FAX (605) 348-5685

www.symcominc.com • email:sales@symcominc.com

11/05

Features

Applications

Description

The Model 777-KW/HP can be used on ANY 3-phase motor. It has advantages over current

monitors in low speed motor applications (less than 1800 rpm), lower power applications and in

lightly loaded applications. Some examples include LOW SPEED MIXERS, CAN PUMPS, MAG

DRIVE PUMPS, FRACTIONAL HORSEPOWER PUMPS and MOTORS, SUBMERSIBLE PUMPS AND

COAL BED METHANE WELLS.

The Model 777-KW/HP is a fully-programmable motor and pump protection relay with

power-monitoring capability. Voltage, current and power measurements are displayed on the threedigit display, as well as fault information and setpoints. The display simplifies troubleshooting and

allows the user to easily and precisely configure setpoints. The Model 777-KW/HP has the

following adjustable protection features:

1) Low voltage

2) High voltage

3) Voltage unbalance

4) UL listed/CSA approved overload

5) Trip class (5, 10, 15, 20, 30)

6) Current unbalance

7) Ground fault

8) Low power

9) High power (via network only)

10) Rapid-cycle timer

11) Fault/overload restart delay

12) Underload restart delay

13) Underpower/overpower trip delay

Other user adjustable features include:

1) CT/loop multiplier so overcurrent and power setpoints can be made in actual amps, kW or hp

2) Number of restarts after faults - manual, automatic and semiautomatic options

3) Number of restarts after underload - manual, automatic and semiautomatic options

4) Network address

Adding the optional RS485MS-2W communications module activates the built-in Modbus RTU bus

capabilities. The 777-KW/HP can communicate with the SymCom RM-1000 and RM-2000 remote

display modules, PLCs, RTUs, SCADA systems, PCs and other similar control devices. Real-time

operating parameters can be gathered and setpoints can be viewed or modified via the RS-485 bus

using Modbus RTU protocol.

777-KW/HP

777-LR-KW/HP

777-575-KW/HP

777-HVR-KW/HP

777-HVR-LR-KW/HP

Power Monitor

Motor Protection

Relay

•

Engineered

Protection

• Underload (Low KW or HP)

• High power

• Overload (UL listed)

• Jams

• Undervoltage

• Overvoltage

• Single-phasing

• Unbalance (voltage & current)

• Ground fault (Class II)

• Rapid cycling

• Phase reversal

Additional Features

• Fully programmable

• UL and CSA listed

• CE marked

• Automatic or manual reset

• Tamper guard

• RS-485 communications port

• Surface or DIN rail mountable

• Alphanumeric LED

diagnostic display

• Last fault memory

• Up to 99 individually

programmable addresses

• 5-year warranty

• Made in USA

New Features

• Network programmable

• Ability to clear last fault

• Remote setup,

Diagnostics and control

• Remote data logging

Protects 3-Phase Motors

and Pumps from:

Page 2

2880 North Plaza Drive • Rapid City, SD 57702

(800) 843-8848 • (605) 348-5580 • FAX (605) 348-5685

www.symcominc.com • email:sales@symcominc.com

11/05

Specifications

•

Operating Points

•

Special Options

L1 L2 L3 NO C NC

MODEL 777-KW/HP

OVERLOAD RELAY 20-90A

RESET/

PROGRAM

RD3

#RF

VUB

OC

#RU/ADDR

MULT

RD2 KWS

HV

LKW

RD1

CUB

GF

LV

TC

RUN

DISPLAY / PROGRAM

MODE SELECT

L

3

L

1

L

E

+

O

V

A

V

G

T

L

1

-

L

2

L

2

-

L

3

N

T

C

E

A

A

G

A

V

G

R

R

U

B

C

K

W

SUITABLE 10 KA RMS, 600 VAC MAX

SYMCOM INC. 800-243-8848 RAPID CITY, SD

®

IND. CONT. EQ.

LISTED

784X

LR46510

L1 L2 L3 NO C NC

MODEL 777-KW/HP

OVERLOAD RELAY 20-90A

RESET/

PROGRAM

RD3

#RF

VUB

OC

#RU/ADDR

MULT

RD2 KWS

HV

LKW

RD1

CUB

GF

LV

TC

RUN

DISPLAY / PROGRAM

MODE SELECT

L

3

L

1

L

E

+

O

V

A

V

G

T

L

1

-

L

2

L

2

L

3

N

T

C

E

A

A

G

A

V

G

R

R

U

B

C

K

W

SUITABLE 10 KA RMS, 600 VAC MAX

SYMCOM INC. 800-243-8848 RAPID CITY, SD

®

IND. CONT. EQ.

LISTED

784X

LR46510

SYMCOM RECOMMENDS USING

CTs WITH TERMINALS TO SIMPLIFY

INSTALLATION.

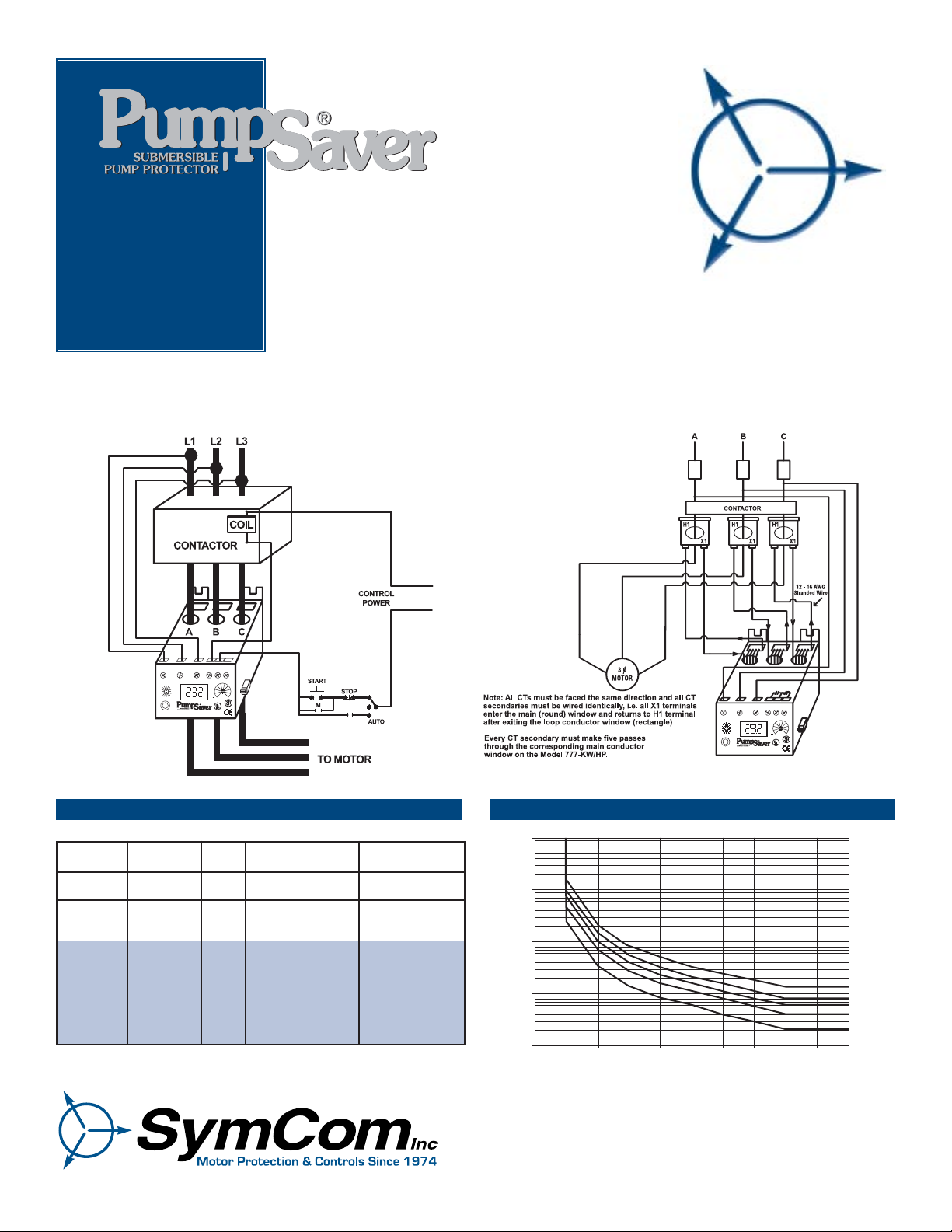

Wiring configuration based on motor amps. Overload T rip Classes

777-KW/HP

External CTs

required. See

wiring diagram

for external CTs

777-LR-KW/HP

Model

1 - 2

2 - 9

Full Load

Amps

# of

Loops

1

0

# of Conductors

through A, B and C

2

1

MULT to Program

(CT Ratio)

2

1

8 - 12

12 - 25

25 - 90

80 - 110

110 - 160

160 - 220

220 - 320

320 - 420

400 - 520

480 - 600

560 - 800

2

1

0

4

4

4

4

4

4

4

4

3

2

1

5

5

5

5

5

5

5

5

3

2

1

100 (100:5)

150 (150:5)

200 (200:5)

300 (300:5)

400 (400:5)

500 (500:5)

600 (600:5)

800 (800:5)

10000

1000

100

10

0 300 400 500

% of OC Setting

Trip Time (Seconds)

600 700 800 900 1000

Class 10

Class 30

Class 20

Class 15

Class 5

200100

1

777-KW/HP

777-LR-KW/HP

777-575-KW/HP

777-HVR-KW/HP

777-HVR-LR-KW/HP

Power Monitor/Motor Protection Relay

TYPICAL WIRING DIAGRAM FOR

MODEL 777-KW/HP (20-90 AMPS)

& 777-LR-KW/HP (2-9 AMPS)

CURRENT TRANSFORMER WIRING DIAGRAM FOR

MODEL 777-KW/HP (80-800 AMPS)

Page 3

2880 North Plaza Drive • Rapid City, SD 57702

(800) 843-8848 • (605) 348-5580 • FAX (605) 348-5685

www.symcominc.com • email:sales@symcominc.com

11/05

3.050"

(77.47)

2.650"

(67.31)

2.280"

(57.91)

3.850"

(

97.79

)

3.600" (91.44)

3.100" (78.74)

0.002" (5.08)

L1 L2 L3 NO C NC

MODEL 777-KW/HP

OVERLOAD RELAY 20-90A

RESET/

PROGRAM

RD3

#RF

VUB

OC

#RU/ADDR

MULT

RD2 KWS

HV

LKW

RD1

CUB

GF

LV

TC

RUN

DISPLAY / PROGRAM

MODE SELECT

L

3

-L

1

L

E

+

O

V

A

V

G

T

L

1

-

L

2

L

2

-

L

3

N

T

C

E

A

A

G

A

V

G

R

R

U

B

C

K

W

SUITABLE 10 KA RMS, 600 VAC MAX

SYMCOM INC. 800-243-8848 RAPID CITY, SD

®

IND. CONT. EQ.

LISTED

784X

LR46510

Dimensions for All 777-KW/HP Units

The Model 777-KW/HP has important advantages over current monitors in

many protection applications.Any motor load that has a small or very non-linear change in current vs. load requires the use of a power monitor for underload, dry-run and dead-head protection.The change in power vs.load is more

linear for most motor loads and is greater in magnitude than the change in current in all motor loads.This is because pow er measurements take into account

both power factor (pf) and current.

Small motors, those under 3 hp and especially fractional horsepower, exhibit

small changes in current vs. load but the change in power is large. When

larger motors are derated, run below their rated horsepower, the change in

current is small vs. load, but again, the change in power is large and linear.

Other typical applications include slower speed mixer or agitator motors up to

50 hp and beyond.These motors and others that run slower than around 3400

rpm usually have small current changes vs. load.

Magdrive and can pumps tend to be small horsepower , positiv e displacementtype pumps. These pumps need the high sensitivity of a power monitor to

protect them from dry-run using the underpower feature and dead-head

conditions using the underpower feature if the motor decouples from the pump

and the overpower feature if the motor does not decouple.

The built-in UL Listed/CSA approved overload, current unbalance, reversephase, single-phase and other protection features are significant benefits ov er

similar products. The Modbus communications capability allows this device to

be directly integrated with the SymCom RM-1000 and RM-2000 remote

displays or other remote monitoring and control equipment.

Specifications

•

Operating Points

•

Special Options

777-KW/HP

777-LR-KW/HP

777-575-KW/HP

777-HVR-KW/HP

777-HVR-LR-KW/HP

Power Monitor/Motor Protection Relay

Advantages:

• Integrated UL Listed/CSA approved

electronic overload relay

• Greater underload sensitivity than

power factor or current monitors

• Built-in undervoltage, overvoltage

and unbalance protection

• Digitally programmable

• Remote programmability

• Digital display

• Optional remote display

• Data logging capabilities

200-480 VAC 3Ø

50/60 HZ

5.050"

(128.27)

4.700"

(119.38)

1.200"

(30.48)

0.650" (16.51)

3.600" (91.44)

3.850"

(

97.79

)

No Load

Power

Current

Full Load No Load Full Load

Power is Linear, equal

sensitivity at both

low and high

loads.

Current is not linear, low

sensitivity for low loads

and high sensitivity

for high loads.

777-KW/HP uses power measurements for sensitive underload protection,

while using current measurements for UL listed overload protection.

Page 4

11/05

Low Setpoint (LV) Nominal Voltage Range High Setpoint (HV)

777-KW/HP

777-LR-KW/HP

777-HVR

777-HVR-LR

777-575

777-575-LR

Nom. Current Range Overcurrent Setpoint (OC) Ground Fault Setpoint (GF)

777, 777-HVR, 777-575

2-25A Looped (20 to 100A)/MULT OFF, (3 to 20A)/MULT

25-90A Direct 20 to 100A OFF, 3-20A

80-800A Ext CTs 80-120% of CT Prim OFF, 10-30% of CT Prim

777-LR, 777-HVR-LR, 777-575-LR

1-2.5A Looped 1-5A 0.15-1A

2-9A Direct 2-10A 0.3-2A

Frequency

Short Circuit

Power Consumption

Output Contact Rating SPDT (Form C)

All 777-XXX-XX KW/HP types except -HVR

777-HVR-KW/HP

777-HVR-LR-KW/HP

Mechanical

Electrical

Voltage

Current

GF Current

Timing

Voltage

Current

UL

CSA

CE

Electrostatic Discharge (ESD)

Radio Frequency Immunity (RFI), Conducted

Radio Frequency Immunity (RFI), Radiated

Fast Transient Burst

IEC 1000-4-5, Level 3, 2kV line-to-line; Level 4, 4kV line-to-ground

ANSI/IEEE C62.41 Surge and Ring Wave Compliance to 6kV line-line

Hi-potential Test Meets UL508 (2 x rated V +1000V for 1 minute)

Vibration IEC 68-2-6, 10-55Hz, 1mm peak-to-peak, 2 hours, 3 axis

Shock IEC 68-2-27, 30g, 3 axis, 11ms duration, half-sine pulse

Dimensions

Terminal Torque

Enclosure Material

Weight

Maximum Conductor Size Through 777-KW/HP

Pollution Degree

Class of Protection

Relative Humidity

PPrrooggrraammmmaa bbll ee OOppee rr aattiinngg PPooiinnttss

LV, HV, OC, GF

UB- Voltage Unbalance Threshold

MULT- # of Loops or CT Ratio (XXX:5)

LP- Low Power Setting

CUB- Current Unbalance Threshold

TC- Overcurrent Trip Class **

RD1- Rapid Cycle Timer

RD3- Restart Delay After Underload (dry-well recovery timer) 2 - 500 Minutes

#RU- Number of Restarts After Underload

ADDR- RS485 Address

#RF-Number of Restarts After All Faults Except Underload***

1 = 0.01 - 0.99 KW 5 = 0.01 - 0.99 HP

2 = 1.00 - 9.95 KW 6 = 1.00 - 9.95 HP

(PWS = LP Range) 3 = 10.0 - 99.5 KW 8 = 10.0 - 99.5 HP

4 = 100 - 650 KW 9 = 100 - 650 HP

380-480 VAC

LV Setting - 528

450-HV Setting

480-600 VAC

LV Setting - 660

Input Voltage Ranges and Low and High Voltage Setpoints

170-HV Setting

200-480 VAC

LV Setting - 528

Low Power (LP) / Power Range Setting (PWS)

EEll ee cc ttrr ii ccaa ll

Safety Marks

Expected Life

Accuracy at 25° C (77° F)

Repeatability

Standards Passed

MMeecchhaannii cc aa ll

Surge

340-HV Setting

EEnnvv ii rr oo nnmmeenn tt aa ll

RRaannggee

See electrical specifications above

2 - 15% or 999%

IP20, NEMA 1

3

Ambient Storage: -40° to 80° C (-40° to 176°F)

Ambient Operating: -20° to 70° C (-4° to 158°F)

RD2- Restart Delay After All Faults Except Underload

(motor cool down timer)

5, J5, 10, J10, 15, J15, 20, J20, 30, J30

0, 2 - 500 Seconds

0, 1, 2, 3, 4, A(Automatic)

A01- A99

0, 1, oc1, 2, oc2, 3, oc3, 4, oc4, A, ocA

10-95%, non-condensing per IEC 68-2-3

1-10 Loops or 100-800 Ratio

See Power Ranges Below or 0=off

2 - 25% or 999%

IEC 1000-4-6, Level 3 10V/m

0.65" with insulation

1.2 lbs.

Polycarbonate

7 in.-lb.

100 kA

10 Watts (max.)

Nominal Motor Full Load Current and Overcurrent Setpoint

50/60 Hz

Pilot duty rating: 480VA @ 240VAC

General purpose: 10A @ 240VAC

Max Voltage: 277VAC

Pilot duty rating: 480VA @ 600VAC

1 x 106 operations

1 x 105 operations at rated load

±1%

±3%(<100 Amps Direct)

±15%

5% ± 1 second

± 0.5% of nominal voltage

± 1% (<100 amps direct)

2 - 500 Minutes

Temperature Range

IEC 1000-4-2, Level 3, 6kV contact, 8kV air

IEC 60947-1, IEC 60947-5-1

LR46510

UL508, UL1053

3.0"H x 5.1 " D x 3.6"W

IEC 1000-4-4, Level 3, 3.5 kV input power

IEC 1000-4-3, Level 3 10V/m

NOTES: SymCom's 777-KW/HP & 777-LRKW/HP can be preprogrammed prior to installation by applying 120 VAC between the L1 and

L2 terminals.

* 575 volt Model (MS 777-575-KW/HP)

** If J prefix is displayed in trip class setting,

jam protection is enabled.

*** If "oc" is disabled in the #RF setting, the

overcurrent will be included as a normal

fault and the relay will automatically restart

after RD2 expires, otherwise, manual reset

is required after an overcurrent fault.

SymCom warrants its microcontroller based

products against defects in material or workmanship

for a period of five (5) years from the date of

manufacture. All other products manufactured by

SymCom shall be warranted against defects in

material and workmanship for a period of two (2)

years from the date of manufacture. For complete

information on warranty, liability, terms returns, and

cancellations, please refer to the SymCom Terms

and Conditions of Sale document.

Specifications

Loading...

Loading...