Page 1

INSTALLATION

INSTRUCTIONS

Rapid City, SD, USA, 02/2010

MODELS 201A-AU

201-575-AU

Revision B1

II_201A-AU_B1

2880 North Plaza Drive, Rapid City, South Dakota 57702

(800) 843-8848 · (605) 348-5580 · fax (605) 348-5685

Page 2

BE SURE POWER IS DISCONNECTED PRIOR TO INSTALLATION!

FOLLOW NATIONAL, STATE AND LOCAL CODES.

SymCom’s MotorSaver

designed to protect 3-phase motors regardless of size. It is used on 190-480VAC (475-600 for

Model 201-575-AU), 50/60 Hz motors to prevent damage caused by single-phasing, low voltage,

high voltage, phase reversal, or voltage unbalance conditions.

CONNECTIONS

READ THESE INSTRUCTIONS ENTIRELY BEFORE INSTALLATION.

®

Model 201A-AU is an auto ranging plug-in voltage / phase monitor

1. Locate a convenient location in or near the motor control panel. If the location is wet or

dusty, the MotorSaver

2. Mount an 8-pin socket to the motor control back panel (SymCom P/N OT08-PC, sold

separately, is required for UL rating).

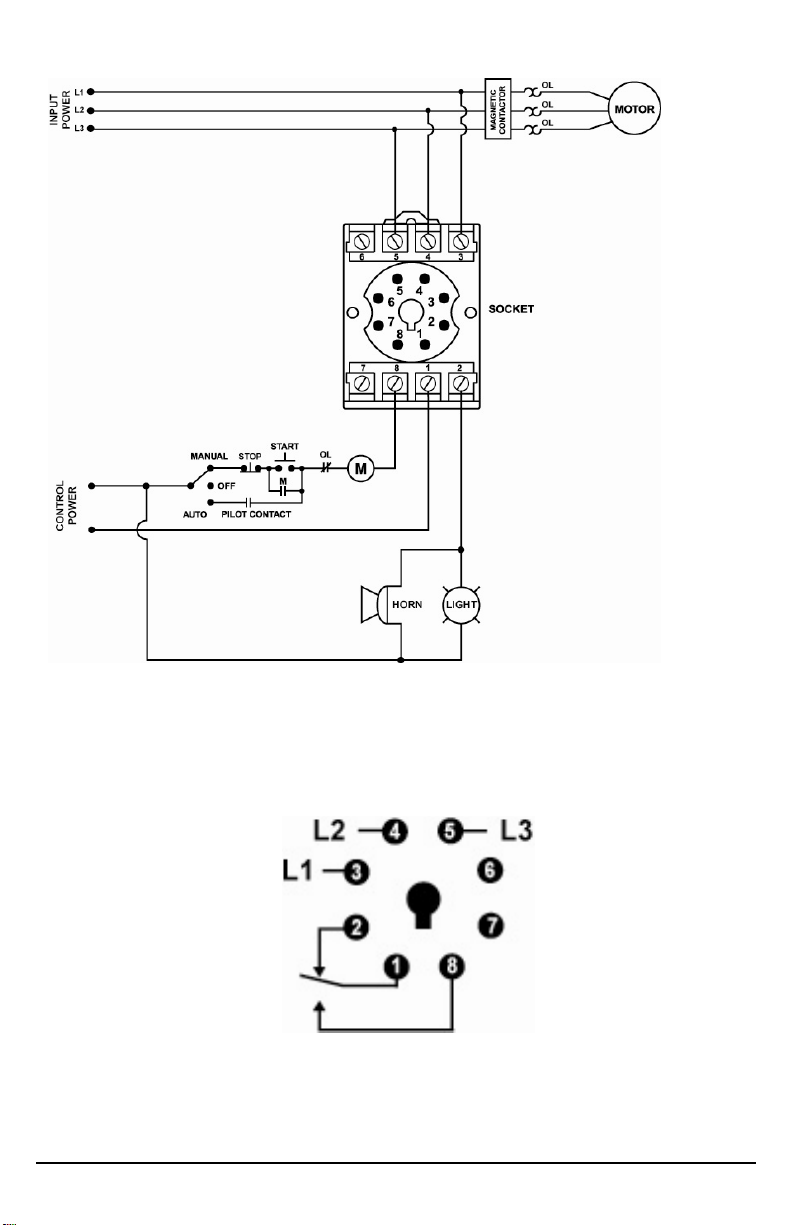

3. Connect L1, L2 and L3 (terminals 3, 4 & 5 on the relay socket) to the LINE SIDE of the

motor starter as shown in Figure 1.

4. Connect the output relay to the circuitry to be controlled. For motor control, connect the

normally open contact in series with the magnetic coil of the motor starter, and for alarm

operation, connect the normally closed contact in series with the control circuit. See Figure

1 for details.

5. Plug the MotorSaver

®

should be mounted in a NEMA 4 or 12 enclosure.

®

into the socket.

© 2010 SymCom, Inc. All Rights Reserved 2

Page 3

Figure 1: Typical Wiring Diagram for Control and Alarm

Figure 2: Pin-Out Diagram

© 2010 SymCom, Inc. All Rights Reserved 3

Page 4

SETTINGS

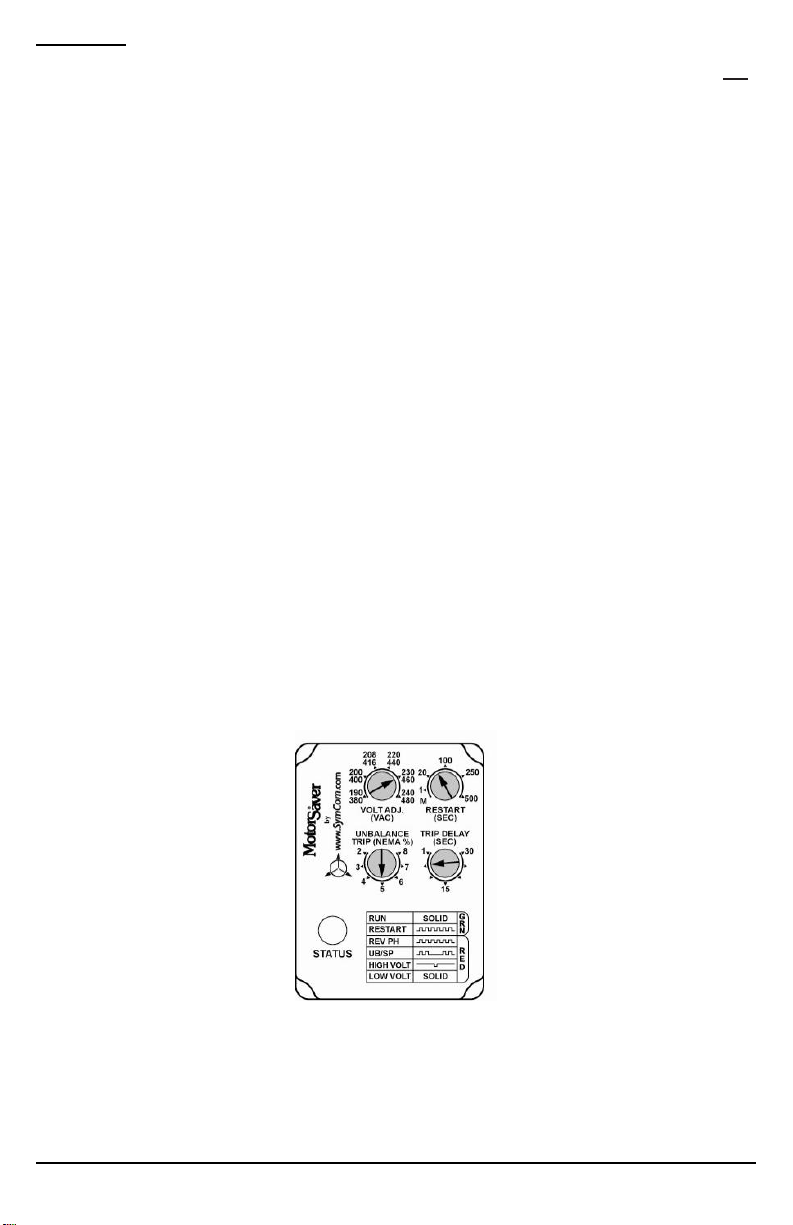

Rotate the knobs to the appropriate setting for the application following the guidelines below. Do not

apply excessive force when adjusting settings.

L ine Voltage

Rotate the VOLT ADJ. (VAC) knob to the nominal 3-phase line voltage feeding the motor to be

protected.

R estart Delay

Rotate the RESTART (SEC) knob to the desired position. The restart delay is the time between the

MotorSaver® measuring acceptable voltage and closing its output contacts. For compressor

applications, the restart delay should be set for the approximate time it takes for the head pressure to

bleed off of the compressor. For other applications, the restart delay is typically set between 10 and

20 seconds.

T rip Delay

Rotate the TRIP DELAY (SEC) knob to the desired setting. This setting does not affect the trip delay

on single-phasing faults (See SPECIFICATIONS Table). Typically, the trip delay is set between 1 and

5 seconds. In areas where voltage fluctuations are frequent, the trip delay may be set greater than 10

seconds.

V oltage Unbalance

Rotate the UNBALANCE TRIP (NEMA%) knob to the desired unbalance trip level. The NEMA MG1

standard does not recommend operating a motor above 1% voltage unbalance without derating the

motor. The NEMA MG1 standard also recommends against operating a motor above a 5% voltage

unbalance under any circumstances. SymCom recommends consulting the motor manufacturer for

specific tolerances.

Figure 3: Adjustment Knobs

© 2010 SymCom, Inc. All Rights Reserved 4

Page 5

Calculating Voltage Unbalance

NEMA MG1 Unbalance Formula

% Voltage Unbalance = Maximum Deviation from the Average

Average

Example: The measured line-to-line voltages are 203, 210, and 212.

Average = 203 + 210 + 212

3

The maximum deviation from the average is the largest difference between the average voltage

(208.3) and any one voltage reading.

The maximum deviation from the average is 5.3.

208.3

x 100%

= 208.3

208.3 - 203 = 5.3 210 - 208.3 = 1.7 212 - 208.3 = 3.7

% voltage unbalance = 5.3

x 100 = 2.5% unbalance

© 2010 SymCom, Inc. All Rights Reserved 5

Page 6

OPERATION

After applying power to the MotorSaver®, the green RUN light will blink during the restart delay. After

the restart delay time has expired, the MotorSaver

normally closed and close the normally open contacts) and the RUN light will turn solid green.

®

will energize its output contacts (open the

Automatic Reset Mode

Set the RESTART (SEC) knob to the desired restart delay time. Apply 3-phase power to the motor.

The MotorSaver’s green RUN light will blink during the restart delay. Once the restart delay time has

expired, the MotorSaver® will energize its output contacts and the green RUN light will illuminate.

Manual Reset Mode

Once power has been applied to the MotorSaver®, set the RESTART (SEC) knob to M to operate in

manual reset mode. When the MotorSaver

®

trips on a fault, the red STATUS light will display the fault

code until the condition clears and the unit is reset by turning the RESTART (SEC) knob away from

the M position until the STATUS light turns green. The RESTART (SEC) knob can then be turned

back to the M position, requiring a manual reset after the next fault occurs. If power is lost before the

MotorSaver® is reset, the fault code will again be displayed once power is reapplied. This allows for

identification of the last fault even after power conditions have returned to normal.

If the contacts do not energize and the RUN light does not turn solid green, see the

TROUBLESHOOTING section.

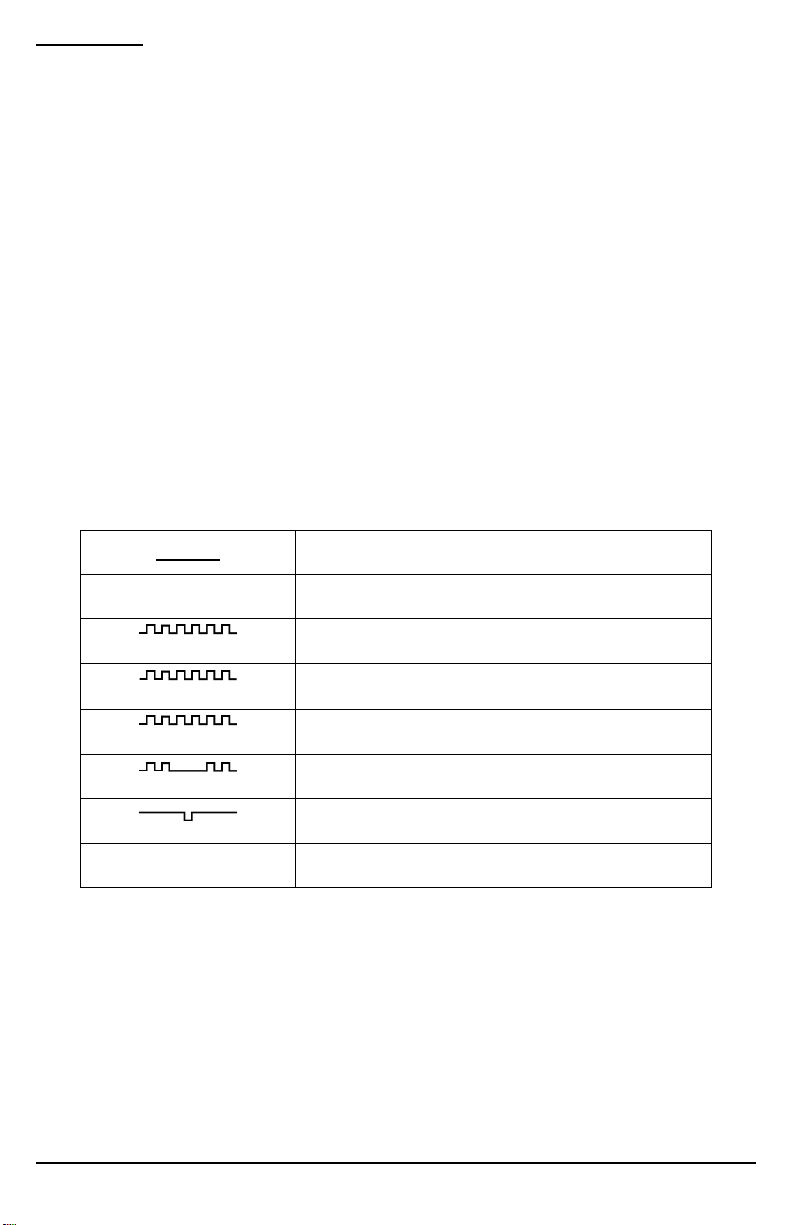

STATUS

INDICATOR LIGHT

GREEN RUN

GREEN

GREEN

RED

RED

RED

RESTART DELAY (Automatic Reset Mode)

MANUAL RESET REQUIRED (Manual Reset Mode)

REVERSE PHASE

UNBALANCE / SINGLE PHASE

HIGH VOLTAGE

RED LOW VOLTAGE

Table 1: Diagnostic Indicator Lights

© 2010 SymCom, Inc. All Rights Reserved 6

Page 7

TROUBLESHOOTING

SYMPTOM

No lights are on -

the unit seems

completely dead

Red light is blinking

(on initial power-up)

Red light is blinking

(after the motor has

been running)

Red light is blinking

in this pattern

Red light is blinking

in this pattern

Red light is on

steady

Green light blinks

and motor is not

running

Green light is on

steady, but motor

does not start

LIGHT

PATTERN

GREEN

GREEN

N/A

RED

RED

RED

RED

RED

SOLUTION

Verify L1, L2 & L3 are connected to terminals 3, 4 & 5.

Measure the three line-to-line voltages. If any of the

voltages are below the specified operating voltage, the

MotorSaver

®

does not have enough power to operate

its internal electronics. If the voltages are correct, call

SymCom at (800) 843-8848 or (605) 348-5580.

Turn off the 3-phase power. Swap any two leads

powering the MotorSaver

50-50 chance of connecting L1, L2 and L3 correctly the

®

(L1, L2, or L3). There is a

first time. Reapply 3-phase power.

The incoming lines have been reverse-phased. The

MotorSaver

backwards. Correct the phase sequence.

®

is preventing the motor from running

The voltage is unbalanced or single-phased. Measure

the incoming line voltages and calculate the %

unbalance according to the procedure outlined earlier

in this document. If the voltage unbalance does not

exceed the % unbalance reset value, call SymCom at

(800) 843-8848 or (605) 348-5580.

The voltage is high. Measure the three line-to-line

voltages. Calculate the average according to the NEMA

unbalance formula. If the average voltage is 7% above

the nominal voltage as selected by the LINE VOLTAGE

ADJUST setting, the MotorSaver

®

is functioning

properly. If the voltage is within 7%, call SymCom at

(800) 843-8848 or (605) 348-5580.

The voltage is low. Measure the three line-to-line

voltages. Calculate the average according to the

NEMA unbalance formula. If the average voltage is 7%

below the nominal voltage as selected by the LINE

VOLTAGE ADJUST setting, the MotorSaver

®

is

functioning properly. If the voltage is within 7%, call

SymCom at (800) 843-8848 or (605) 348-5580.

The MotorSaver

and will energize its contacts when finished, or the

MotorSaver

®

is timing through the restart delay

®

is in manual reset mode and requires a

manual reset to energize its contacts.

The MotorSaver® is in run mode. Ensure other control

devices are allowing the motor to start. Check control

circuit for loose wires or malfunctioning switches.

© 2010 SymCom, Inc. All Rights Reserved 7

Page 8

DIMENSIONS

S

NOTE: Use of the OT08-PC or RB08-PC octal socket, manufactured by Custom Connector Corp., is

required for the MotorSaver to qualify as a UL Listed device. The OT08-PC is 35mm DIN rail

compatible.

2.375

(60.331)

BOTTOM

IDE

.5

(12.7)

1.75

(44.55)

3.15

(80.01)

© 2010 SymCom, Inc. All Rights Reserved 8

Page 9

MOTORSAVER® 201A-AU SPECIFICATIONS

Functional Characteristics

Low Voltage Trip 90% of setting Reset 93% of setting High Voltage Trip 110% of setting Reset 107% of setting Voltage Unbalance Trip 2-8% Reset Trip setting - 1% (5-8%)

Trip Delay High/Low Voltage and Unbalance 1-30 seconds, adjustable Single-Phasing 1 second, fixed Restart Delay 1-500 seconds, adjustable; Manual

Input Characteristics

Line Supply Voltage 201A-AU 190-480VAC 201-575-AU 475-600VAC Frequency 50/60Hz

Output Characteristics

Output Contact Rating Pilot Duty 480VA @ 240VAC General Purpose 10A @ 240VAC

General Characteristics

Environmental Ambient Operating Temperature Relative Humidity 10-95%, non-condensing per IEC 68-2-3 Maximum Input Power 5 W Standards Passed Electrostatic Discharge (ESD) IEC 61000-4-2, Level 3, 6kV contact, 8kV air Radio Frequency Immunity, Radiated 150 MHz, 10V/m Fast Transient Burst IEC 61000-4-4, Level 4, 4kV input power and controls Surge Immunity IEC IEC 61000-4-5, Level 4, 4kV line-to-line; Level 4, 4kV

ANSI/IEEE C62.41 Surge and Ring Wave Compliance to a level of

Hi-Potential Test Meets UL508 Safety Marks

UL listed (OT08 octal socket required) UL508 (File #E68520) CE IEC 60947-6-2 Dimensions 1.750” H x 2.375” W x 4.125” D (with socket) Weight 9 oz. Enclosure Polycarbonate Mounting Method Plugs into OT08 Socket Wire Gauge 12-22 AWG Solid or Stranded Terminal Torque for P/N OT08 Socket 12 in. - lb

1

Trip setting - 0.5% (2-4%)

-40° to 70°C (-40° to 158°F)

line-to-ground

6kV line-to-line

(2 x rated V +1000 V for 1 minute)

1

The ambient air temperature is the air temperature directly surrounding the product.

© 2010 SymCom, Inc. All Rights Reserved 9

Page 10

NOTES

© 2010 SymCom, Inc. All Rights Reserved 10

Page 11

NOTES

© 2010 SymCom, Inc. All Rights Reserved 11

Page 12

For warranty information, please see Terms and Conditions at

www.symcom.com

Visit us at www.symcom.com to see

our complete product listing!

Need something special?

Contact SymCom today

for your custom solution!

800-843-8848

© 2010 SymCom, Inc. All Rights Reserved 12

Loading...

Loading...