Page 1

DESKTOP BARCODE PRINTER

MJ-2844

User’s Manual

I

Liability Disclaimer

Alacrity barcode technology takes steps to assure that the company’s published

engineering specifications and manuals are correct; however, errors do occur.

Alacrity barcode technology reserves the right to correct any such errors and

disclaims any resulting liability. In no event shall Alacrity barcode technology or

anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any

damages whatsoever (in

clu

ding, without limitation, damages for loss of business

profits, business interruption, loss of business information, or other pecuniary

Product Improvements

Continuous improvement of products is a policy of Alacrity barcode technology All

specifications and signs are subject to change without notice.

loss) arising out of the use of or the results of use of or inability to use such

product, even if Alacrity barcode technology has been advised of the poss

ibility of

such damages.

CAUTION:

Any changes or modifications not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

Page 2

2 3

Table of Contents

Getting Started ..................................................................3

Package Contents ................................................................ 4

Connecting the Power Supply................................................. 5

Getting to Know Your Printer ...........................................6

Parts and Features...................................................................6

Controls and Indicators........................................................... 9

Loading Ribbon and Media ............................................11

Loading Ribbon.................................................................... 11

Loading Media...................................................................... 16

Calibration and Configuration........................................20

Performing Calibration and Configuration ............................ 20

Resetting to Factory Default Settings .................................... 21

Installing the Printer Driver ....................................22

Troubleshooting..............................................................32

LED Di

agnosis ..................................................................... 32

Miscellaneous................................ ....................................... 35

Recovery .............................................................................. 36

Caring for Your Printer....................................................37

Cleaning ............................................................................... 37

Media Sensor ....................................................................37

Thermal Print Head ........................................................... 37

Replacing the Thermal Print Head ..................................... 40

Important notice during TPH replacement ................... 42

Technical Reference ....................................................... 43

Getting Started

Congratulations on choosing the Alacrity

desktop barcode printers.

This manual will help you get to know your new printer.

There are two parts to this manual,

an operation

guide information.

The operatio

n guide

is illustrated to help you quickly become familiar

with the printer.

The related information includes troubleshooting, maintenance

and technical information for your reference.

........

....

....

....

....

Page 3

4

Package Contents

Printer

Power Supply

Power Cord

CD ROM

USB Cable

Media Holder

5

Connecting the Power Supply

Connect the power supply as below.

WARNING! Do not operate the printer and power supply in an

area where they can get wet.

Make sure the power switch is in the "O" position.

1. Insert the barrel connector of the power supply into the power

jack on the back of the printer.

Note the location of the power

jack fo

r different models in the diagrams below.

2. Insert the separate power cord into the power supply.

3. Plug the other end of the cord into an AC electrical outlet.

Note:Pictures for reference only!

Page 4

6

Getting to Know Your Printer

The illustrations that follow describe the printer’s parts, features,

controls, and indicators.

Parts and Features

Top C o ver

P

ower Switch

P

owe

r Indi

cator

Ready Indicator

F

eed Button

7

Media Hanger

Ribbon Pick-up Holder

Release Levers

Page 5

8

Power Switch

Ribbon Supply Holder

Thermal Print head

Platen Roller

9

Controls and Indicators

The printer’s controls and indicators are shown in the diagram

below. The following table explains control and indicator

functions.

Top C o ver

Power Indicator

Ready Indicator

Feed Button

Power Switch

Page 6

10

Control /

Indicator

Function

Power Switch

On: turns on normal operation

Off: turns off power

Note: Turn power off before connecting or

disconnecting cables

Power Indicator

Green light shows the power-on

Light off shows the power-off

Blinking light indicates error has occurred

Ready Indicator

Green shows printer is ready to operate

Blinking light indicates printer is paused or

data transferring

Seagull driver status monitor

Feed Button

Press to advance labels to the first printing

position

Press to take the printer out of "pause"

Press and hold while turning on the power

to print out a configuration profile

11

Loading Ribbon and Media

This section describes how to load ribbon and media in

printer.

Loading Ribbon

Note: This section does not apply to direct thermal printing.

1. Lift the top cover to expose the media compartment.

2. Unlatch the print head module by pushing the two white

release levers on the sides toward the rear.

3. Turn over the print head module to expose the ribbon

supply holder.

Page 7

12

Media Compartment

Rel

ease Lever

Print Head Module

Release Lever

Ribbon Supply Holder

13

4. Unwrap the ribbon roll pack and separate the ribbon roll

and the bare core.

5. Attach the edge of the ribbon on the bare core and wind it

a little bit onto the core.

6. Insert the ribbon roll into the supply holder. (First snap in

the left side and then the right side.)

Ribbon Supply Holder

Ribbon Roll

Bare Core

Page 8

14

7. Turn back the print head module and then insert the bare

core into the pick-up holder. (First snap in the left side, and

then the right side.)

Ribbon Pick-up Holder

Bare Core

15

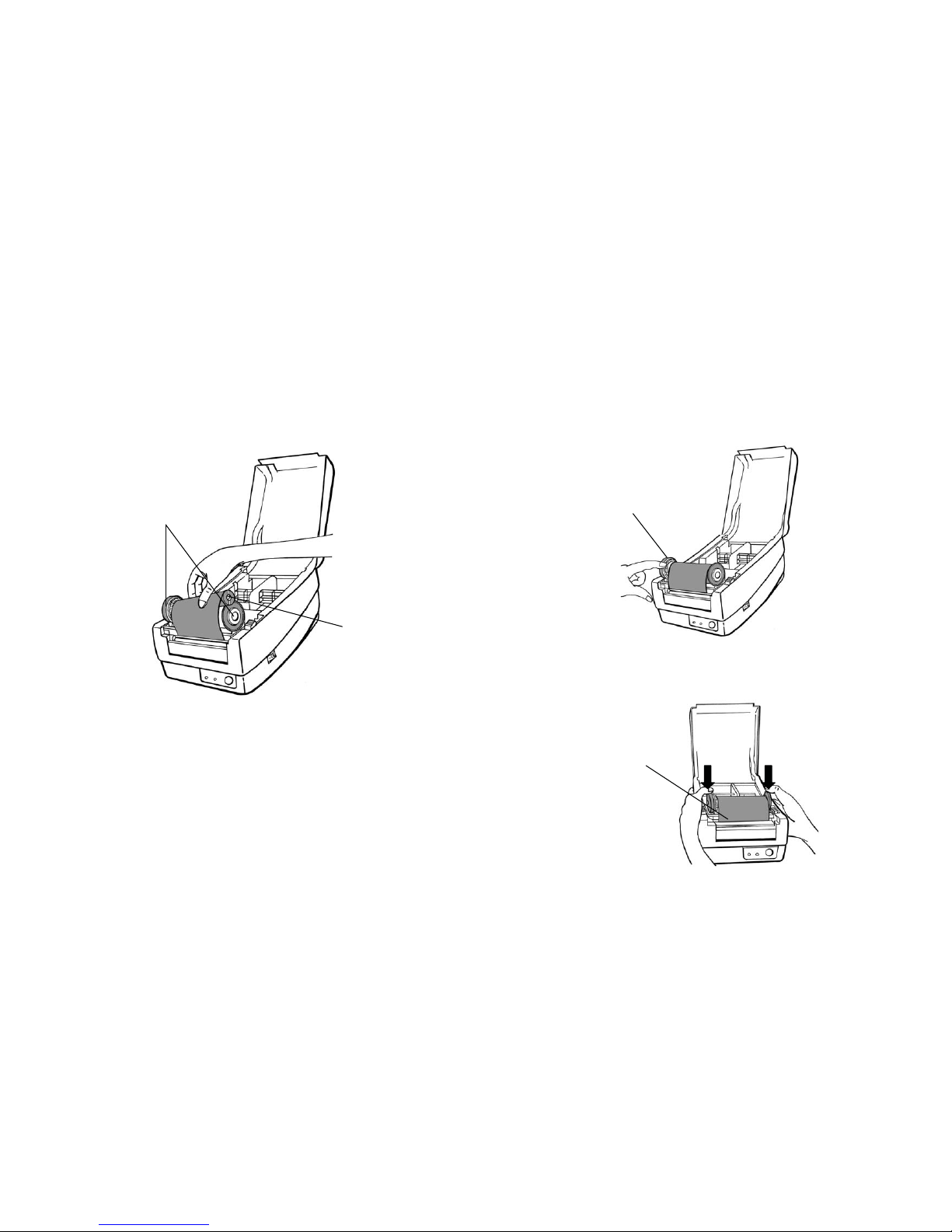

8. Turn the wheel of the print head module to ensure the

ribbon is tightly wound.

9. Press down the print head module firmly until you hear a

snap.

Wheel

Print Head Module

Page 9

16

Loading Media

1. Lift the top cover to expose the media compartment.

17

2. Remove the media hanger.

3. Load the media roll onto the hanger from left to right.

Media Compartment Media Hanger

Media Roll

Media Hanger

Page 10

18

4. Click the media hanger back into the media

compartment.

5. Align the media roll to the left end.

6. Move the shield from right to left until it leans against the

media.

Media Compartment

Shield

Media Roll

19

7. Unlatch the print head module.

8. Hold the print head module upright with one hand to

allow the media to pass under it. Lead the media through

the media guides with the other hand.

9. Lead the media over the platen roller.

Print Head Module

Media Guides

10. Put the print head module down and press down firmly

until you hear a snap.

11. Close the top cover and turn on the printer or press the

"FEED" button if the printer is already on.

Page 11

20

Calibration and Configuration

This section discusses calibration, printing configuration and

resetting the printer to factory defaults.

Performing Calibration and Configuration

1. Turn off the printer power.

2. Press and hold the feed button while turning on the power,

until the printing motor is activated.

3. Calibration is performed while the printer automatically feeds

the label stock for a certain length, the print

ing motor

suspends for one second and then prints out a configuration

profile.

4. The profile includes firmware version, ROM checksum,

RS-232, thermal transfer/direct thermal settings, hardware

configuration, and font types.

5. At PPLB emulation, the printer enters character dump mode.

To exit from dump mode, press the feed button again. (If you

accidentally print the label without exiting from dump mode in

advance, you need to turn o

n the printer or press feed button

again to print normally.)

Important! You must always carry out calibration when

changing media. Failure to do so will result in improper

detection by the label sensor.

Resetting to Factory Default Settings

1. Turn on the printer and wait for 5 or more seconds.

2. Press the "Feed" button for 10 seconds, and the "Ready"

indicator and "Power" indicator will go off in order.

3. When the two indicator

s relight, release the feed button.

4. The printer feeds approximately 3 ~5 blank labels, and

then resets to the factory defaults.

Note: Revise the factory default settings that stored in flash,

even if turn off the power source cannot be eliminated.

21

Page 12

22

3.

23

Select “I accept…”

and click "Next

".

Installing the Printer Driver

1. Turn off the printer. Plug the power cable into the power

socket on the wall, and then connect the other end of the

cable to printer's power socket. Connect the USB cable

to the proper port on the printer and

on your computer.

2. Prepare the documentation and software CD-Rom from

printer package and then install to CD-Rom drive of your

computer.

4. Assign the di

re

ctory to keep driver, (for example:

C:\Seagull)

and click "Next".

Page 13

24 25

5. Click "Finish".

6. Select Install printer drivers and Click "Next"

Page 14

26

27

7. Select model & emulation - the following examples are based

on model OS-214 plus PPLA

A rg ox O S- 21 40 PP LA

Argox OS-2140 PPLA

8. Select the port of the printer and click "Next".

A rg ox O S- 21 40 PP LA

A rgox OS-214 plus PPLA

Page 15

28

29

Argox OS-2140 PPLA

9 . Enter Printer name (i.e. Argox OS-214 plus PPLA) and select

"do not share this printer”, and click "Next".

10. Check all the data on the showing screen, if it is correct, click

"Finish".

Argox OS-214 plus PPLA

Argox OS-214 plus PPLA

USB 001

7.1.9_M-5

Argox OS-214 plus PPLA

Page 16

30

31

11. After the related files have been copied to your system, click

"Finish".

Installing printer ‘Argox OS-214 plus PPLA’…

12. After driver installation is complete, click "Close".

The driver should now be installed.

Installed printer Argox OS-214 plus PPLA

Page 17

32

33

Troubleshooting

Normally, when the printer is in not working properly, the "Power"

LED blinks continuously; while printing and communication

between the host and printer stops.

LED Diagnosis

Power and Ready LEDs blinking continuously indicates printer

errors. To understand the problem, please observe the Power and

Ready LEDs and refer to the following solutions:

LED Indicators: Power and Ready LEDs blink at the same temp

o

Power LED Ready LED

ON ON

OFF OFF

Possible Problems Solutions Remarks

Miss-detect gap

Check the label path

Check the label sensor

If you use a

continuous label roll

and run under

Windows, select

continuous media.

Label stock out Supply the label roll

Label stock not

installed

Install the label roll

Label jam Recover the jam

LED Indicators: Power and Ready LEDs blink alternately

Power LED Ready LED

ON OFF

OFF ON

Possible Problems Solutions Remarks

Ribbon out Supply the ribbon roll

Ribbon jam Recover the jam

Ribbon sensor error Replace ribbon sensor

Not applicable to

direct thermal

type.

LED Indicators: Only the Power LED blinks

Power LED Ready LED

ON ON

OFF ON

Possible Problems Solutions Remarks

Serial IO error Check the baud rate Serial interface only

Memory full Add the extension

RAM(flash memory

card)

Cutter failed, or jam

at cutter

Check the cutter

Recover the jam

Occurs only when

installing or setting the

cutter

Hardware error Call for service

Page 18

34 35

LED Indicators: Only the Ready LED blinks

Power LED Ready LED

ON ON

ON OFF

Possible Problems Solutions Remarks

Print head too hot Printing will stop until the

print head cools to an

acceptable printing

temperature. When it

does, the printer will

automatically resume

operation.

Miscellaneous

If the host shows "Printer Time out"

1. Check if the communication cable (parallel or serial) is

connected securely to your parallel or serial port on the

PC and to the connector on the printer at the other end.

2. Check if the printer power is turned on.

If the data has been sent, but there is no output from the printer.

Check the active printer driver, and see if Seagull driver for your

Windows system a

nd the label printer has been selected.

Vertical streaks in the printout usually indicate a dirty or faulty

print head. (Refer to the following examples.)

Clean the print head. If the problem persists, replace the print

head.

Page 19

36 37

Poor printout quality:

The ribbon may not be qualified.

The media may not be qualified.

Adjust the Darkness (heat temperature).

Slow down the print speed.

Refer to the next chapter and clean the related spare

parts.

Recovery

After correcting problems, simply press the panel button or restart

the printer to continue your print jobs. Make sure the LEDs are not

blinking and remember to resend your files.

Caring for Your Printer

Adhesives and coatings of media can over time transfer onto the

printer components along the media path including the thermal

print head and media sensor. This build-up can accumulate dust

and debris. Failure to clean the print head, media path, and media

sensor could result in inadvertent loss off labels, label jams and

possible damage to the printer.

Note: Turn off the printer before cleaning.

Cleaning

Clea

n the following components of the printer using a cotton bud

dampened with alcohol. Do not soak the cotton bud excessively.

Media Sensor

Debris or dirt on the paper sensor can cause a miss-read or

unstable detection of the label gap. Clean with a cotton bud

dampened with alcohol.

Thermal Print Head

Thermal paper stock and the ribbon release debris on the print

head, which degrades printing quality. Clean the print head with

methanol or isopropy

l alcohol and a cotton bud. Do not touch the

heater element with your fingers. Debris or dirt on the roller should

be cleaned with alcohol.

Page 20

38 39

TPH Cleaning Interval:

It’s strongly recommended to regularly clean print heads at

least when changing every one ribbon roll (in thermal transfer

printing mode), or every one label roll (in direct thermal printing

mode). In addition, if printers are operated under critical

applications and environments, or it’s found print quality is

degraded, please clean print heads more frequently.

TPH Cleaning Material:

Surface of print head’s heating element is very fragile. To

prevent from any possible damage, please use soft cloth or

cotton buds with “Ethanol” or “industry alcohol” to clean print

head surface.

It’s strongly recommended to wear hand gloves during cleaning

progress.

Do not touch print head surface by bare hands or with any hard

equipment. Water or spit should be kept away in case of

corrosion on heating elements.

TPH Cleaning Direction:

When cleaning print head, please always wipe in One-Way

Direction - from Left to Right only, or, from Right to Left only, to

clean “Heating Line” of print head gently without excessive

stress.

Do not wipe back and forth, to avoid dust, dirt, or ribbon residue

on cleaning cotton would be attached onto print head again.

(Please refer to below picture)

Special Caution:

Warranty of print heads will be void if print head serial number

is removed, altered, defected, or made illegible, under every

circumstance.

Page 21

40 41

Replacing the Thermal Print Head

1. Switch off the power and wait for both LEDs to go off.

2. Unlatch the print head module.

3. Remove the ribbon.

4. Push the print head firmly into the casing and shift it to the

left. It will release from the module.

5. Disconnect the print head cable.

6. Disassemble the print head and the mounting bracket by

releasing screws.

7. Replace with a new print head. Reassemble the print head

module in reverse order. Be careful not to touch the print

head elements.

Page 22

42 43

Important notice during TPH replacement

1. Heater line should NOT be touched by bare hands to

prevent any damage caused by ESD or corrosion.

2. Surface of heaters should NOT be hit or scratched by

sharp or hard things to prevent any damage by scratch.

3. Residue or contamination should NOT be removed by a

cutter to prevent any damage by dent or scratch.

4. Connector side should NOT be touched when cleaning

TPH to prevent

delaminated solder between FPC and

wafer. Ink-jet characters could be erased, if cleaning cloth

was touched them on FPC or label.

5. Heater surface should be free from any condensation.

6. TPH should NOT be put heater surface down.

Technical Reference

General Specifications

Specificatio

n

Printing method Direct Transfer/Thermal Transfer

Printing

resolution

203 dpi (8dots/mm)

Printing speed

2~3ips(51~76mm/s)

Printing length

Max 43”(1092mm)

Printing width Max 4.16” (105mm)

Memory

8MB DRAM(6MB user available)

4MB Flash ROM(2MB user available)

CPU type 32 bit RISC microprocessor

Media sensor Reflective x 1

Operation

interface

LED indicator(Power/Ready)x2, Button(Feed)x1

Communication

Interface

USB(2.0)

Centronics Parallel,

Fonts

Internal character sets standard 5 alpha-numeric fonts from

0.049”H ~ 0.23” H (1.25mm ~ 6.0mm)

Internal fonts are expandable up to 24x24 4 direction 0 ~ 270

rotation Soft fonts are downloadable

Page 23

44 45

1D:Code 39, Code 93,Code 128/subset A/B/C, Codabar,

Interleaved 2 of 5, UPC A/E/2/5 add-on, EAN-13/8, UCC/EAN

128, Postnet, Plessey, Interleaved 2 of 5, Interleaved 2 of 5 with

a modulo 10 checksum, Interleaved 2 of 5 with a modulo 10

checksum and shipping bearer bars , Code 128, UCC/EAN

Code 128 Random Weight, HBIC, Telepen , FIM

Barcodes

2D:PDF-417, MaxiCode, Data Matrix (ECC200 only) ,QR

Code, Composite codes

Graphic

PCX, BMP, IMG, HEX ,GDI

Software-Label

editing

Windows Driver (Win 2003/XP/Vista/Windows 7) BarTender ,

Software-Utility Printer Utility, Font Utility

Media Type

Roll-feed, die-cut, continuous, fan-fold, tags, ticket in thermal

paper or plain paper and fabric label

Media

Max Width:4.33”(110mm) Min Width:1”(25.4mm)

Thickness:0.0025”~0.01”(0.0635~0.254mm)

Max roll capacity(OD):4.3”(109mm)

Core size:0.5”(12.7mm) (1”(25.4mm) optional)

Ribbon

Ribbon Width: 1”~4”

Ribbon roll – max OD: 1.45”(37mm)

Ribbon Length: max 92m

Core size – ID: 0.5”(13mm) with notch

Wax, Wax/Resin, Resin (Outside Ribbon)

Dimensions W 182mm x H 161mm x L 280mm

Weight 2.0kgs

Power Source

Universal Switching Power Supply Input: 100V~240V,

1.5A, 50~60Hz, Output: 24VDC, 2.4A

Operation

Environment

Operation Temperature: 40° F~100°F (4°C~ 38°C), 10% ~ 90%

non-condensing,

Storage Temperature: -4°F~122°F (-20°C~50°C)

Loading...

Loading...