Page 1

VRC 4000 Series

RS 2200/3200 Series

Installation Guide

Page 2

1997 SYMBOL TECHNOLOGIES, INC. All rights reserved.

Symbol reserves the right to make changes to any product to

improve relia bi lit y, function, or design.

Symbol does not assume any product liability arising out of, or

in connection with, the application or use of any product, circuit,

or application described herein.

No license is granted, either expressly or by implication,

estoppel, or otherwise under any patent right or patent,

covering or relating to any combinatio n, system, apparatus ,

machine, material, method, or process in which Symbol

products might be used. An implied license only exists for

equipment, circuits, and subsystems contained in Symbol

products.

Symbol and Spectrum24 are registered trademarks of Symbol

Technologies, Inc. Other product names mentioned in this

manual may be trademarks or registered trademarks of their

respective compa nie s and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, N.Y. 11742-1300

http://www.symbol.com

Installation Guide

Page 3

Introduction

Symbol Technologies’ Vehicular Radio Computers (VRC) 4000

series are PC-compatible computers ruggedized to withstand

the physical shock and vibration extremes of harsh industrial

environments. All VRC systems provide a touchscreen, full

VGA display (either electrol uminescent or color LCD), multi ple

network options, and full I/O capability. Each VRC system is

fully PC-compatib le with the MS-DOS Versions 3.3 thr ough 6.22,

Windows 3.1, Windows 95, and Windows NT operating

systems. There are two versions of the VRC: the VRC 4000 and

the VRC 4040. Each of these versions are available with option s

such as additional memory, operating systems, and network

configurations.

VRC 4000

The VRC 4000 is designed for fixed-mount applications. It is

powered by a standard 110 VAC o u tlet via a plug-in pow er

supply. It is hard-wired into the local area network (LAN).

Standard Ethernet or Token Ring hard-wired LAN connections

are supported.

VRC 4040

The VRC 4040 is designed for vehicular-mounted applications

such as those on forklifts, hysters, and motorized pallets. It is

powered from the vehicle’s el ectrical system (battery) through a

choice of two power converters. It uses Symbol’s Spectrum24

2.4 GHz spread-spectrum radio link to communicate with radio

frequency (RF) netw ork access po ints har d-wir ed into t he LAN.

Antenna options include patch and ‘rubber duck’ types.

®

1

Page 4

2

About This Guide

This guide provides basic setu p, inst a llat ion , and mainte na nc e

instructions. Topics discussed include:

• Parts of the VRC 4000

• Setting up the VRC 4000

• Mounting the bracket assemblies

•Mounting the VRC

• Attaching the keyboard assembly

• Providing power to the VRC 4000

• Providing power to the VRC 4040

• Maintaining the VRC 4000.

Installation Guide

Page 5

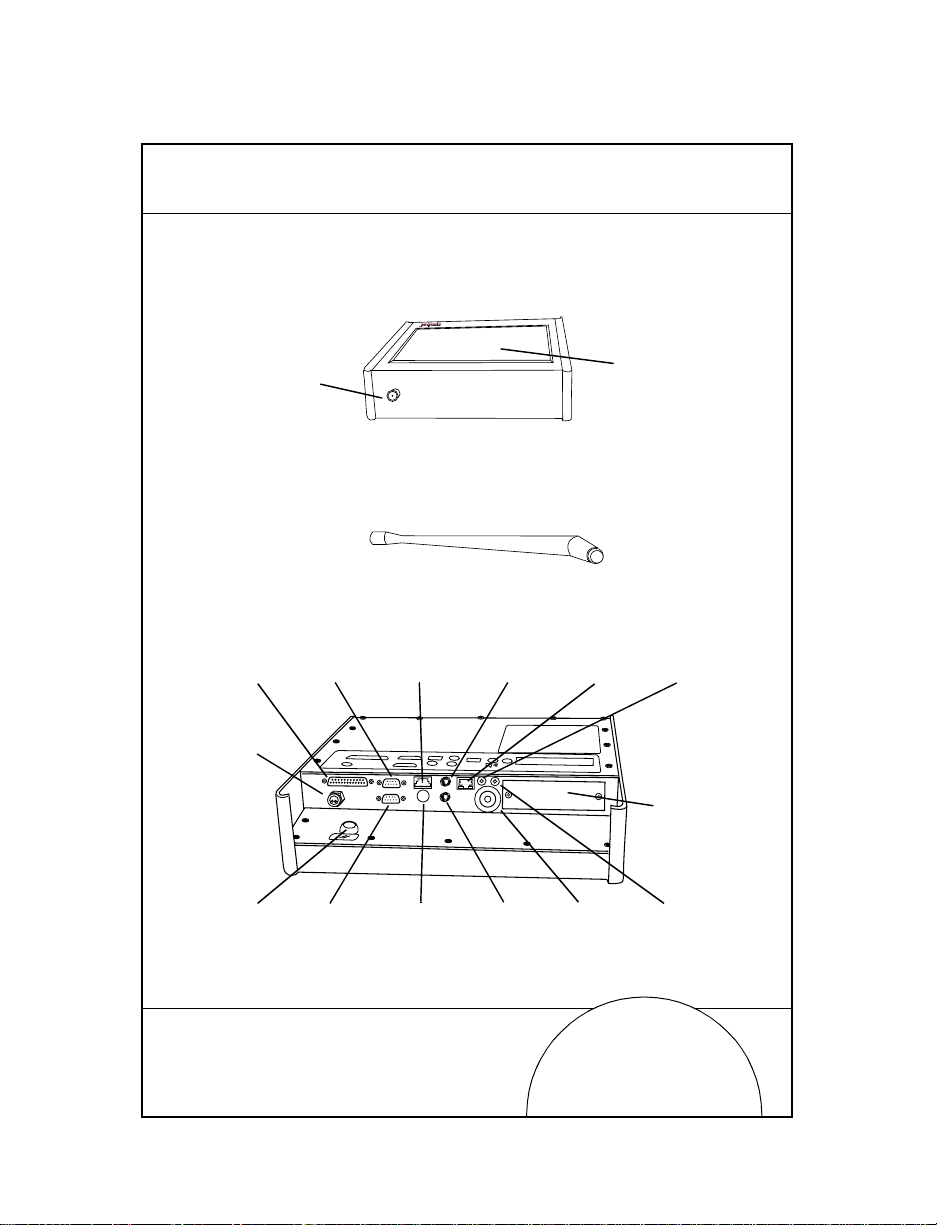

Parts of the VRC

3

LPT1

Parallel

Port

DC

PWR

Port

Reset

Switch

Antenna

Port

Serial Port

COM1

Serial

Port

COM2

Locking

Keyboard

Port

RF

Connection

Antenna

Keyboard

DIN

Connector

Mouse

Connector

Network

Connector

Audio

Indicator

Touchscreen

Speaker

PCMCIA

Card

Slot

Cover

Microphone

Port

Page 6

4

Set-Up

To set up your equipment, first unpack your terminal and

accessories, and ensure that the parts shipped match the parts

ordered. Keep the shipping container and packing material in

case you need to return your computer for repair at a later date.

The VRC is factory-equi pped with a network interfac e and the

appropriate network software for communicating with the

network. The network ports on the VRC use different connectors

for each type of ne twork. For Token Ring connections, a DB9

connector is used. For Ethernet connections, an RJ-45 connector

is used. For wireless network communications, an FCC

mandated, non-stand ard RF antenna connector is prov ided.

Note: The VRC 4040 uses Spectrum24 2.4 GHz spread-

spectrum radio link to communicate with (RF) network access points hard-wir ed into the LAN. These

access points must be set up before the terminal can

communicate with the host. Refer to the Access Point

User Documentation for detailed ins truc tions on se tting up the access points.

Mounting the Bracket Assemblies

The VRC 4000 can be mounted almost anywhere that is

convenient to the operator. The mounting location must be near

a standard 1 10 VAC electrical outlet, and there must be sufficient

space below the unit for cable access to the rear panel, which

faces downward when the unit is wall-mounted. Secure the

mounting bracket to a wall prior to attaching the VRC 4000 to

the bracket.

The VRC 4040 mounts to a forklift or other vehicle with a custom

bracket assembly. Operating power is obtained from a DC

power converter that attaches to the vehicle’s electrical system

Installation Guide

Page 7

via an access cord. Installation of the VRC 4040 requires

mounting the bracket assembly, installing the DC power

converter , and attaching the ac cess cord to the vehicle’s electrical

system.

Caution

For proper operation on electric fork lifts, the VRC must be

isolated from the chassis. Damage to terminal could result.

The three types of mounting bracket assemblies are:

• univers al mounting ass embly

• hyster mounting assembly

• crown mounting assembly.

Crown Mounting Assembly

The crown moun ting assembly has an L-shape d bra cket at the

top that permits mou nt ing of the assembly onto a flat vertical

wall or bracket. To mount the assembly:

5

Mounting Surface or

Bolt

Wall

Mounting Assembly

(without keyboard

assembly)

Nut

Page 8

6

1. Place the mounting assembly up against th e wall or

bracket. Make sure assembly is level.

2. Mark location for mounting holes.

3. Drill mounting holes using 13/32” drill bit.

4. Secure mounting bracket to wall using two bolts (3/8” x 16

x 3/4”) and two nuts.

5. Install VRC using procedure in VRC Mounting on page 8.

Universal Mounting Assembly

The universal mounting assembly has an U-shaped bracket at

the top that permits mounting of the assembly onto a horizontal

bracket. To mount the assembly:

Nut

Mounting

Bracket

U-Shaped

Bracket

Mounting

Assembly

(without

keyboard

assembly)

Bolt

1. Place the U-shaped bracket up against surface to use as a

template for drilling mountin g holes.

2. Mark location for mounting holes.

3. Drill two mounting holes using 13/32” drill bit.

4. Place bolts (3/8” x 20 x 3”) through the slots i n the assembly and through horizontal mounting bracket.

Installation Guide

Page 9

5. Place the U-shaped bracket over bolts and secure the U-

shaped bracket to th e assembly using two nuts.

6. Install VRC using procedures in VRC Mounting on pag e 8.

Hyster Mounting Assembly

The hyster mounting assembly has an L-shaped bracket at the

bottom that permit s mounting the bracket onto a flat vertical

wall or bracket. To mount the assembly:

Bracket

Assembly

(without

keyboard

assembly)

Nut

7

Bolt

Mounting Surface

or Wall

1. Place the assembly up against wall or bracket. Make sure

assembly is level.

2. Mark location for mounting holes.

3. Drill six mounting holes using 9/32” drill bit.

4. Secure assembly to wall or bracket using six bolts (1/4” x

20 x 3/4”) and six nuts.

5. Install VRC using procedures in VRC Mounting on pag e 8.

Page 10

8

VRC Mounting

After the mou nting bra cket is installed, m ount th e VRC on to the

assembly. To mount the VRC:

Bracket

Assembly

VRC

1. Align mounting holes on the sides of the VRC with the

holes on the arms of the mounting assembly.

2. Slide two rubber friction washers bet ween the mounti ng

assembly arms and the VRC. These washers must be

aligned with the mounting holes in the VRC and the

mounting assembly.

3. Insert the tw o knob scr ews thr ough the ho les in the mou nting assembly arms and into the mounting holes on the

VRC.

4. Position VRC at a desired viewing angle and turn knobs

clockwise to tighten.

5. Connect all required cables to the VRC.

Knob

Friction

Washer

Installation Guide

Page 11

Keyboard Assembly

The VRC mounting assembly may be configured with or

without the keyboard assembly. If the keyboard assembly is not

originally configur ed, it can be ad ded to the mounting a ssembly

at a later time. To mount the keyboard assembly onto the

mounting bracket assembly:

Bracket

Assembly

Nut

Keyboard

Assembly

Bolt

9

1. Remove power from the VRC.

2. Disconnect all cables connected to the VRC.

3. Remove two knob screws securing the VRC and rubber

friction washers to the mounting brack et assembly.

4. Align mounting wings of keyboard assembly with mount-

ing wings of mounting bracket.

Page 12

10

5. Insert eight bolts, supplied with the keyboard assembly,

through mounting holes in mounting bracket an d keyboard assembly bracket.

6. Secure bolts using eight nuts.

7. Install VRC using procedures in VRC Mounting on page 8.

8. Connect keyboard cable to connector on rear panel of VRC.

Note: The Symbol-supplied ruggedized keyboard has a

special locking connector which is designed to ensure good cont ac t in the high-vibration veh ic l e

mount application.

9. If a scanner is at tached to the VRC, a spec ial “Y” cable

(P/N STI180-0275) is required to connect the keyboard and

scanner to the keyboard connector on the r ear panel:

a. Connect the keyboard connector to the mating connec-

tor on the special cable.

b. Connect the scanner connector to the mating connector

on the special cable.

c. Connect the special cable to the keyboard connector on

the rear panel of the VRC.

10. Connect all cables removed in step 2.

11. Apply power to the VRC.

Installation Guide

Page 13

Providing Power to the VRC 4000

Power is provided to the VRC 4000 terminal via a locking DCpower adapter, as illustrated below:

All cable connections should be made to the VRC 4000 before

the system is powered up. Since ther e is no ON/OFF sw itch, the

VRC 4000 powers up as soon as the power supply connections

are completed and the power supply is plugged in to the 110

VAC electrical outlet.

Providing Power to the VRC 4040

Power is provided to the VRC 4040 via a DC power converter (12

V or 24-48V) that is connected to the vehicle’s battery. The DC

power converter mounts to a steel surface on the vehicle via

magnetic feet. Locate the converter so as not to interfere with

either moving parts on the vehicle or the operator’s vision. Be

certain that the power cable from the DC power converter can

reach the mating co nnector on the VRC 4 040.

The access cable should be connected to the vehicle’s electrical

system, at the point that provides power at all times and that is

11

Page 14

12

filtered and fu sed. Never c onnect the access cable dir ectly t o the

battery terminals. Possible connection points are at the horn,

lights (feed), or ignition switch (feed).

24-48 V Power Converter

The electrical harness access cable for the 24-48 V Power

converter has two leads at one end which are permanently

wired into the vehicle’s electrical system. The other end of the

cable has a circular 2-pin connector with rubber boot that mates

with a similar connector on the DC power converter’s power

input cable.

Caution

On some older electric fork lifts, it might be necessary to install a 4 amp, 25 mhy f ilter choke (STANCOR p/n C-2686

or equivalent) in series with the positive lead to prevent

motor transients from interfering with the terminal.

The black harness wir e is con nected to a positive voltage source .

The white harness wire is connected to the negative voltage

source. The booted connector end of the cable should be

accessible for conveni ent atta chment to th e DC power conv erter.

Make sure that the DC power converter ON/OFF switch is in

the OFF position. Once the access cable is wir ed to the electr ical

system, mate the connectors on the access cable and the DC

power converter power input cable. All cable connections must

be completed before applying power to the VRC 4040.

12 V Power Converter

The electrical harness access cable fo r t he 12 V pow er conve rter

has three leads at one en d which are perma nently wir ed into the

vehicle’s electrical system. The leads ar e white and black, plus a

third lead that is either shield braid or green. The other end of

the cable has a circular 3-pin connector with rubber boot that

Installation Guide

Page 15

mates with a sim il ar connector on the DC power converter’s

power input cable.

The black harness wire is c onnected to a positive volta ge source.

The white harness wire is connected to a negative voltage

source. The green or braided lead is connected to chassis

ground. The booted connector end of the cable should be

accessible for conveni ent attac hment to th e DC power co nverter.

Make sure the DC power converter ON/OFF switch is in the

OFF position. Once the access cable is wired to the electrical

system, mate the connectors on the access cable and the DC

power converter power input cable. All cable connections must

be completed before applying power to the VRC 4040.

Maintenance

The VRC is designed to operate normally in industrial

environments which may contain high levels of airborne

contaminants inclu ding dirt and s moke. Periodic cle aning of the

VRC is recommended to r emove bu ild-up of for eign sub stances

on the case and touchscreen.

Before cleaning, remove power from the VRC. Wipe

accumulated dirt and dust from the case with a slightly

dampened cloth, paying particular attention t o the ang led edge

of the bezel. Clean the touchscreen with a commercial brand of

computer screen cleaner and a soft, damp cloth or compressed

air.

13

Page 16

14

Regulatory Information

Labeling

Symbol T echnologies, Inc.

Holtsville, NY

(1P) Model:

VRC4040-10C40DUS

Net ID: 00A0F8166421

(S) S/N:

This device complies with Part 15 of the FCC Rules.Operation is subject to the

following two conditions: (1)This device may not cause harmful interference, and

(2)This device must accept any interference received, including interference that

may cause undesired operation. This Class A digital apparatus meets all

requirements of the Canadian Interference-causing Equipment Regulations. CET

appareil Numerique de la classe a respecte toutes les exigences du reglement sur

le materiel brouilleur du Canada.

Y463732

INDUSTRIAL COMPUTER

16WA

LISTED I.T.E. 12 VDC @ 2.5A

3897

Made in USA

Installation Guide

Page 17

Radio Frequency Interference Requirements

This device has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the Federal Communications Commissions

Rules and Regulation. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interfer ence in which case

the user will be required to correct the interference at his own expense.

However, there is no guarantee that interference will not occur in a particular

installation. If the equipment does cause harmful interfer ence to radio or televis ion

reception, which can be determined by turning the e quipment of f and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the e quipment into an outlet on a circuit different from that which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Radio Frequency Interfer ence Requirements

- Canada

This Class A digital apparatus meets the requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe A r espe cte toutes le s exigences du Reglem ent

sur le Materiél Brouilleur du Canada.

15

Page 18

16

CE Marking and European Union Compliance

Products intended for sale within the European Union are marked

with the CE Mark which indicates compliance to applicable

Directives and European Normes (EN), as follows. Amendments to

these Directives or ENs are included:

Applicable Directives

• Electromagnetic Compatibility Directive 89/336/EEC

• Low Voltage Directive 73/23/EEC

Applicable Standards

• EN 55 022 - Limits and Methods of Measurement of Radio Interference

Characteristics of Information technology Equipment

• EN 50 082-1 - Electromagnetic Compatibility - Generic Immunity Standard,

Part 1: Residential, commercial, Light Industry

• IEC 801.2 - Electromagnetic Compatibility for Industrial Process Measurement and Control Equipment Part 2: Electrostatic Discharge Requirements

• IEC 801.3 - Electr omagnetic Compatibility for Industrial Process Measurement and Contr o l Equipment Part 3: Radiat e d Electromagnetic F i eld Requirements

• IEC 801.4 - Electromagnetic Compatibility for Industrial Process Measurement and Control Equipment Part 4: Electrical Fast Transients Requir ements

• EN 60 950 + Amd 1 + Amd 2 - Safety of Information Technology Equipment

Including Elect r ical Business Equipment

• EN 60 825-1 (EN 60 825) - Safety of Devices Containing Lasers

RF Devices

Symbol’s RF products are designed to be compliant w ith the rules and r egulations

in the locations into which they are sold and will be labeled as required. The

majority of Symbol’s RF devices are type approved and do not require the user to

obtain license or authorization before using the equipment. Any changes or

modifications to Symbol Technologies equipment not expressly approved by

Symbol Technologies could void the user’s authority to operate the equipment.

Installation Guide

Page 19

Related Publications

• Spectrum24 Ethernet Access Point User Guide,

p/n 70-12057-XX

• Spectrum24 Ethernet Access Point User Guide Addendum,

p/n 70-12057-XX

• VRC 4000 Product Reference Guide,

p/n 70-19725-XX

Warranty Information

For Warranty & Service Information, Call:

1-800-653-5350

Outside Nort h America, contact your local Symbol

representative

Symbol products are warranted against defects in workmanship and materials for

a period of one year (unless specified otherwise) from the date of shipment,

provided that the product rema ins unmodified and is ope rated under normal and

proper conditions.

This warranty is limited to repair or replacement at Symbol’s option, with

reasonable promptness after being returned to Symbol by a carrier selected and

paid for by the customer. These provisions do not prolong the original warranty

term for any product which has been repaired or replaced by Symbol.

This warranty applies to the original owner and does not extend to any product

which has been subject to misuse, neglect, accidental damage, unauthorized repair

or tampering. Preventive maintenance activities are not covered by warranty.

17

Page 20

This product is covered by one or more of the following U.S. and foreign Patents:

U.S. Patent No. 4,360,798; 4,369,361; 4,387,297; 4,460,120; 4,496,831; 4,593,186;

4,603,262; 4,607,156; 4,652,750; 4,673,805; 4,736,095; 4,758,717; 4,816,660; 4,845,350;

4,896,026; 4,897,532; 4,923,281; 4,933,538; 4,992,717; 5,015,833; 5,017,765; 5,021,641;

5,029,183; 5,047,617; 5,103,461; 5,113,445; 5,130,520; 5,140,144; 5,142,550; 5,149,950;

5,157,687; 5,168,148; 5,168,149; 5,180,904; 5,229,591; 5,230,088; 5,235,167; 5,243,655;

5,247,162; 5,250,791; 5,250,792; 5,262,627; 5,262,628; 5,280,163; 5,280,164; 5,280,498;

5,304,786; 5,304,788; 5,321,246; 5,377,361; 5,367,151; 5,373,148; 5,378,882; 5,396,053;

5,396,055; 5,399,846; 5,408,081; 5,410,139; 5,410,140; 5,412,198; 5,418,812; 5,420,411;

5,436,440; 5,444,231; 5,449,891; 5,449,893; 5,468,949; 5,479,000; 5,479,002; 5,479,441;

5,504,322; 5,528,621; 5,532,469; 5,543,610; 5,545,889; 5,552,592; 5,578,810; 5,589,680;

5,608,202; 5,612,531; 5,619,028; D305,885; D341,584; D344,501; D359,483; D362,453;

D363,700; D363,918; D370,478.

Invention No. 55,358; 62,539; 69,060; 69,187 (Taiwan); No. 1,601,796; 1,907,875;

1,955,269 (Japan).

European Patent 367,299; 414,281; 367,300; 367,298; UK 2,072,832; France 81/03938;

Italy 1,138,713.

Revision A — September 1997

70-32536-01

Loading...

Loading...