Page 1

FOREWORD CONTENTS

HOW TO USE THIS MANUAL SERIAL NUMBER

Quad Raider 600

SERVICE MANUAL

Page 2

FOREWORD

Homepage

Contents

This service manual contains the technical data of each component inspection and

repair for the SANYANG QuadRaider 600 ATV. The manual is shown with

illustrations and focused on “Service Procedures”, “Operation Key Points”, and

“Inspection Adjustment”, providing technician with service guidelines.

If the style and construction of the ATV, QuadRaider 600, are different from the

photos, pictures shown in this manual, the actual vehicle shall prevail.

Specifications are subject to change without notice.

Service Department

SANYANG INDUSTRY CO., LTD.

Page 3

Homepage

Contents

HOW TO USE THIS MANUAL

This service manual describes basic information of different system parts and

system inspection & service for SANYANG QuadRaider 600ATV. In addition,

please refer to the manual contents in detailed for the model you serviced in

inspection and adjustment.

The first chapter covers general information and trouble diagnosis.

The second chapter covers service maintenance and special tools information.

The third to the 11th chapters cover engine and driving systems.

The 12th chapter is cooling system.

The 13th to the 16th chapter contain the parts set of assembly frame body.

The 17th chapter is electrical equipment.

The 18th chapter is wiring diagram.

Please see index of content to acquire the special parts and system information

quickly.

There are 4 buttons, “Foreword”, “Contents”, “How to use this manual” and

“Mechanism Illustrations” on the PDF version, and can be access to these items by

clicking on them.

If user wants to look for the content of each chapter, selecting the words of each

chapter on the contents can link to each chapter. There are two buttons,

“Homepage and contents, onto the top line of first page of the each chapter. Thus,

if the user needs to check other chapters, he can click the top buttons to back to

the homepage or contents. The content of each chapter can be selected too.

Therefore, when the user needs to check the content of the chapter, click the

content words of the chapter so that can back to the initial section of the content.

In addition, there is a “To this chapter contents” button on the top of the following

pages; clicking the button can back to the contents of this chapter.

Page 4

CONTENTS

Homepage

Page Content Index

1-1 ~ 1-17

GENERAL INFORMATION

1

2-1 ~ 2-17

MAINTENANCE INFORMATION

2

3-1 ~ 3-8

LUBRICATION SYSTEM

3

4-1 ~ 4-13

FUEL SYSTEM

4

5-1 ~ 5-6

ENGINE REMOVAL

5

6-1 ~ 6-17

CYLINDER HEAD/ VALVE

6

7-1 ~ 7-8

CYLINDER/ PISTON

7

8-1 ~ 8-17

“V” BELT DRIVING SYSTEM

8

9-1 ~ 9-14

TRANSMISSION

9

10-1 ~ 10-16

WHEEL DRIVE SHAFT/ PROPELLER SHAFT

10

11-1 ~ 11-11

A.C. GENERATOR/ STARTING CLUTCH

11

12-1 ~ 12-8

CRANKCASE/ CRANKSHAFT

12

13-1 ~ 13-14

COOLING SYSTEM

13

14-1 ~ 14-8

BODY COVER

14

15-1 ~ 15-12

FRONT BRAKE AND FRONT WHEEL

15

16-1 ~ 16-13

STEERING/ FRONT SUSPENSION

16

17-1 ~ 17-18

REAR BRAKE/ REAR WHEEL/ REAR CUSHION

17

18-1 ~ 18-21

ELECTRICAL SYSTEM

18

19-1 ~ 19-2

ELECTRICAL DIAGRAM

19

Page 5

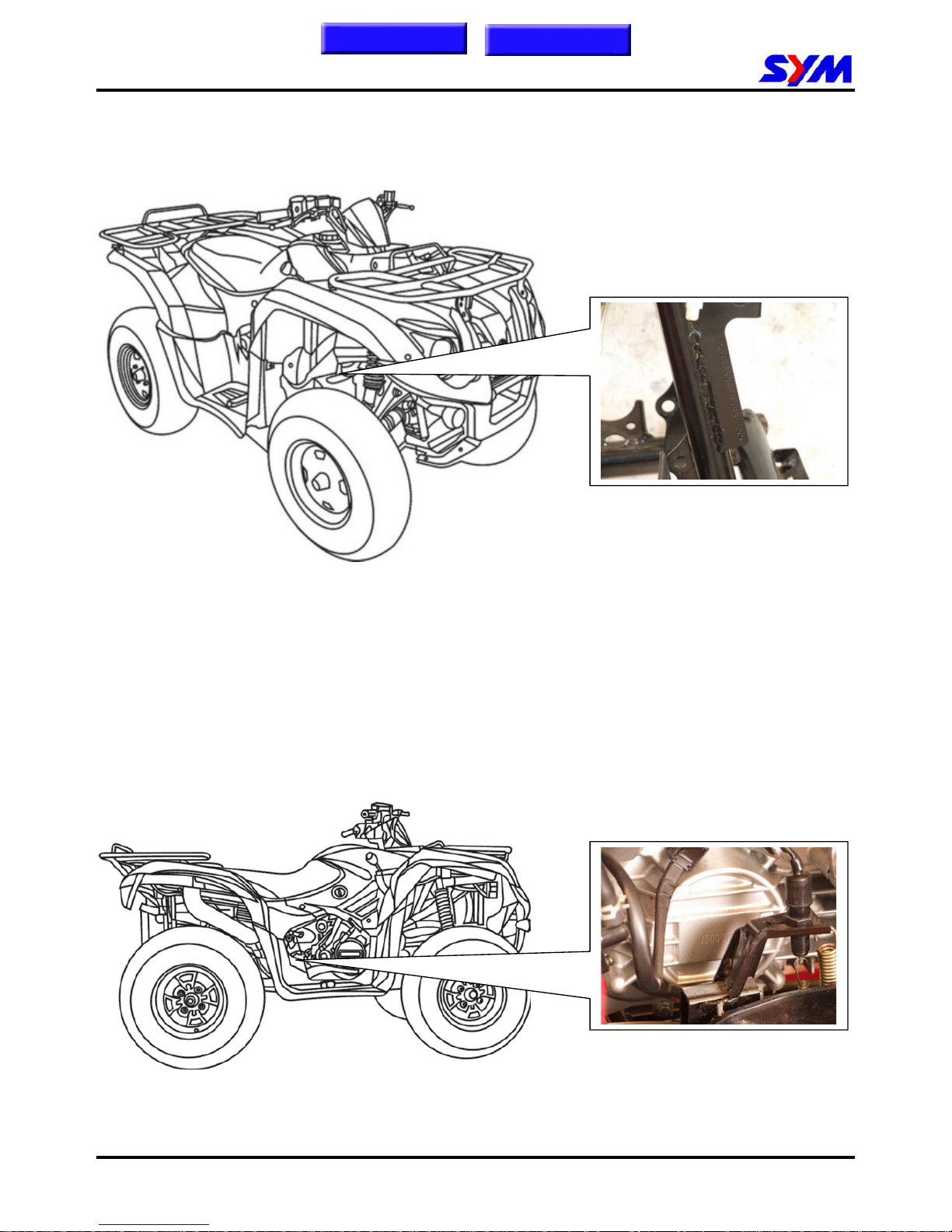

SERIAL NUMBER

Home page

Contents

Frame number

Engine number

Page 6

Homepage

Contents

1. GENERAL INFORMATION

Symbols and Marks............................. 1-1

Torque Values .................................... 1-10

Troubles Diagnosis............................ 1-12

Lubrication Points ............................. 1-17

General Safety ..................................... 1-2

Service Precautions ............................ 1-3

Specifications ...................................... 1-9

Symbols and Marks

Symbols and marks are used in this manual to indicate what and where the special service are needed, in

case supplemental information is procedures needed for these symbols and marks, explanations will be

added to the text instead of using the symbols or marks.

Warning

Means that serious injury or even death may result if procedures are not

followed.

Caution

Means that equipment damages may result if procedures are not followed.

Engine oil

Limits to use SAE 10W-30 API SG class oil. Warranty will not cover the

damage that caused by not apply with the limited engine oil.

(Recommended oil: KING MATE G-3 oil)

Grease King Mate G-3 is recommended.

Gear oil

King Mate gear oil serials are recommended. (Bramax HYPOID GEAR OIL

# 140)

Locking sealant

Apply sealant; medium strength sealant should be used unless otherwise

specified.

Oil seal

Apply with lubricant.。

Renew

Replace with a new part before installation.

Brake fluid

Use recommended brake fluid DOT3 or WELLRUN brake fluid.

Special tools

Special tools

Correct

Meaning correct installation.

Wrong

Meaning wrong installation.

Indication Indication of components.

Directions

Indicates position and operation directions

Components assembly directions each other.

Indicates where the bolt installation direction, --- means that bolt cross

through the component (invisibility).

1

1-1

Page 7

1. GENERAL INFORMATION

To this chapter contents

General Safety

Carbon monoxide

If you must run your engine, ensure the place is

well ventilated. Never run your engine in a closed

area. Run your engine in an open area, if you have

to run your engine in a closed area, be sure to use

an extractor.

Caution

Exhaust contains toxic gas, which may cause one

to lose consciousness and even result in death.

Gasoline

Gasoline is a low ignition point and explosive

material. Work in a well-ventilated place, no flame

or spark should be allowed in the work place or

where gasoline is being stored.

Caution

Gasoline is highly flammable, and may explode

under some conditions, keep it away from

children.

Used engine oil

Caution

Prolonged contact with used engine oil (or

transmission oil) may cause skin cancer although

it might not be verified.

We recommend that you wash your hands with

soap and water right after contacting. Keep the

used oil beyond reach of children.

Hot components

Caution

Components of the engine and exhaust system

can become extremely hot after engine running.

They remain very hot even after the engine has

been stopped for some time. When performing

service work on these parts, wear insulated

gloves and wait until cooling off.

Battery

Caution

• Battery emits explosive gases; flame is strictly

prohibited. Keeps the place well ventilated

when charging the battery.

• Battery contains sulfuric acid (electrolyte)

which can cause serious burns so be careful

do not be spray on your eyes or skin. If you

get battery acid on your skin, flush it off

immediately with water. If you get battery acid

in your eyes, flush it off immediately with

water and then go to hospital to see an

ophthalmologist.

• If you swallow it by mistake, drink a lot of

water or milk, and take some laxative such as

castor oil or vegetable oil and then go to see a

doctor.

• Keep electrolyte beyond reach of children.

Brake shoe

Do not use an air hose or a dry brush to clean

components of the brake system; use a vacuum

cleaner or the equivalent to avoid dust flying.

Caution

Inhaling brake shoe or pad ash may cause

disorders and cancer of the breathing system

Brake fluid

Caution

Spilling brake fluid on painted, plastic, or rubber

parts may cause damage to the parts. Place a

clean towel on the above-mentioned parts for

protection when servicing the brake system.

Keep the brake fluid beyond reach of children.

1-2

Page 8

1. GENERAL INFORMATION

To this chapter contents

Service Precautions

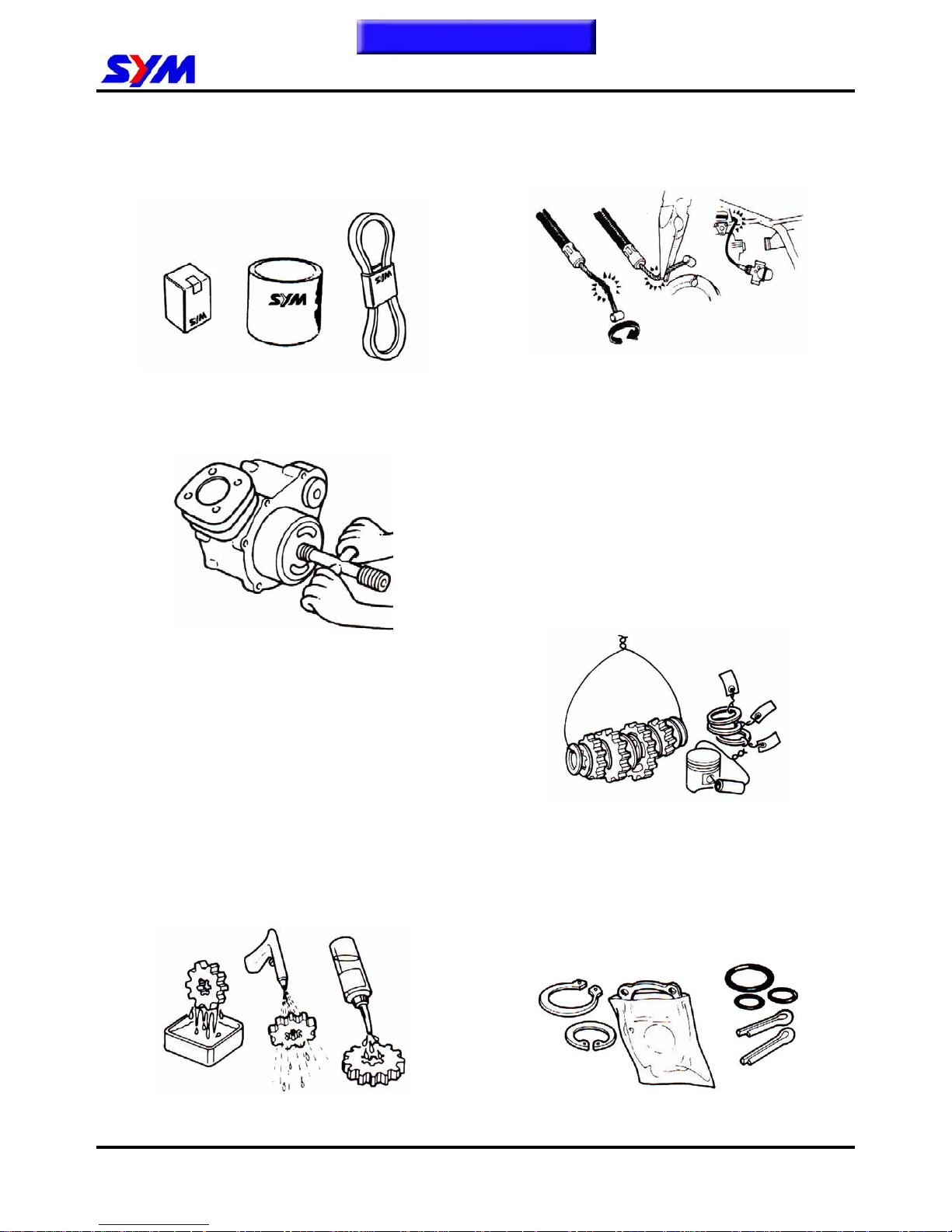

Always use with SANYANG genuine parts and

recommended oils. Using non-designed parts for

SANYANG ATV may damage the ATV.

Special tools are designed for remove and install

of components without damaging the parts being

worked on. Using wrong tools may result in parts

damaged.

When servicing this ATV, use only metric tools.

Metric bolts, nuts, and screws are not

interchangeable with the English system, using

wrong tools and fasteners may damage this

vehicle.

Clean the outside of the parts or the cover before

removing it from the ATV. Otherwise, dirt and

deposit accumulated on the part's surface may

fall into the engine, chassis, or brake system to

cause damage.

Wash and clean parts with high ignition point

solvent, and blow dry with compressed air. Pay

special attention to O-rings or oil seals because

most cleaning agents have an adverse effect on

them.

Never bend or twist a control cable to prevent

unsmooth control and premature worn out.

Rubber parts may become deteriorated when old,

and prone to be damaged by solvent and oil.

Check these parts before installation to make

sure that they are in good condition, replace if

necessary.

When loosening a component, which has

different sized fasteners, operate with a diagonal

pattern and work from inside out. Loosen the

small fasteners first. If the bigger ones are

loosen first, small fasteners may receive too

much stress.

Store complex components such as transmission

parts in the proper assemble order and tie them

together with a wire for ease of installation later.

Note the reassemble position of the important

components before disassembling them to

ensure they will be reassembled in correct

dimensions (depth, distance or position).

Components not to be reused should be

replaced when disassembled including gaskets

metal seal rings, O-rings, oil seals, snap rings,

and split pins.

1-3

Page 9

To this chapter contents

1. GENERAL INFORMATION

1-4

The length of bolts and screws for assemblies,

cover plates or boxes is different from one

another, be sure they are correctly installed. In

case of confusion, Insert the bolt into the hole to

compare its length with other bolts, if its length

out side the hole is the same with other bolts, it is

a correct bolt. Bolts for the same assembly

should have the same length.

Tighten assemblies with different dimension

fasteners as follows: Tighten all the fasteners

with fingers, then tighten the big ones with

special tool first diagonally from inside toward

outside, important components should be

tightened 2 to 3 times with appropriate

increments to avoid warp unless otherwise

indicated. Bolts and fasteners should be kept

clean and dry. Do not apply oil to the threads.

When oil seal is installed, fill the groove with

grease, install the oil seal with the name of the

manufacturer facing outside, and check the shaft

on which the oil seal is to be installed for

smoothness and for burrs that may damage the

oil seal.

Remove residues of the old gasket or sealant

before reinstallation, grind with a grindstone if the

contact surface has any damage.

The ends of rubber hoses (for fuel, vacuum, or

coolant) should be pushed as far as they can go

to their connections so that there is enough room

below the enlarged ends for tightening the

clamps.

Groove

Clamp

Connector

Rubber and plastic boots should be properly

reinstalled to the original correct positions as

designed.

Boots

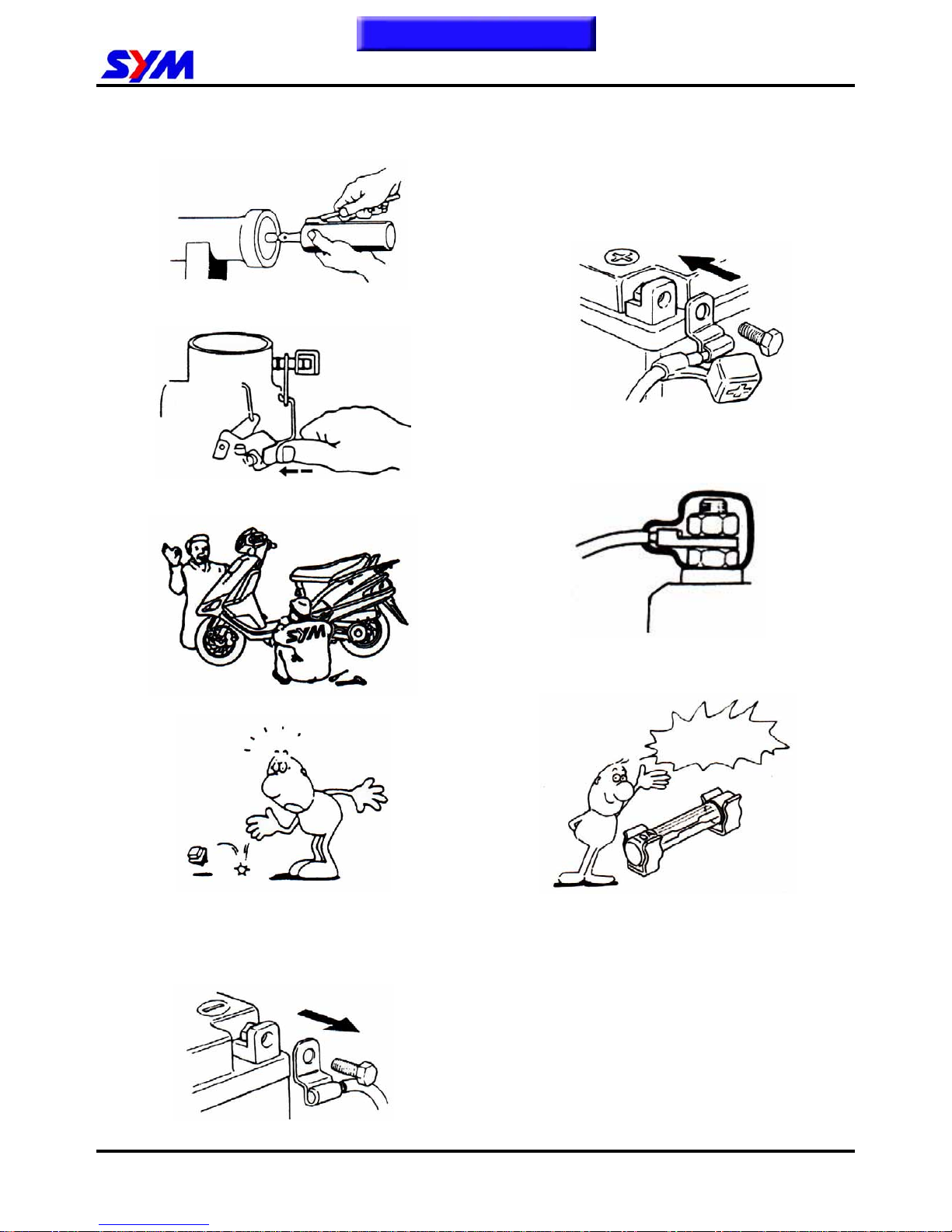

The tool should be pressed against two (inner

and outer) bearing races when removing a ball

bearing. Damage may result if the tool is pressed

against only one race (either inner race or outer

race). In this case, the bearing should be

replaced. To avoid damaging the bearing, use

equal force on both races.

Manufacturer's name

Both of these examples can result in

bearing damage.

Page 10

1. GENERAL INFORMATION

To this chapter contents

Lubricate the rotation face with specified

lubricant on the lubrication points before

assembling.

Check if positions and operation for installed

parts is in correct and properly.

Make sure service safety each other when

conducting by two persons.

Note that do not let parts fall down.

Before battery removal operation, it has to

remove the battery negative (-) cable firstly.

Notre tools like open-end wrench do not contact

with body to prevent from circuit short and create

spark.

After service completed, make sure all

connection points is secured.

Battery positive (+) cable should be connected

firstly.

And the two posts of battery have to be greased

after connected the cables.

Make sure that the battery post caps are located

in properly after the battery posts had been

serviced.

If fuse burned, it has to find out the cause and

solved it. And then replace with specified

capacity fuse.

Capacity

verification

1-5

Page 11

1. GENERAL INFORMATION

To this chapter contents

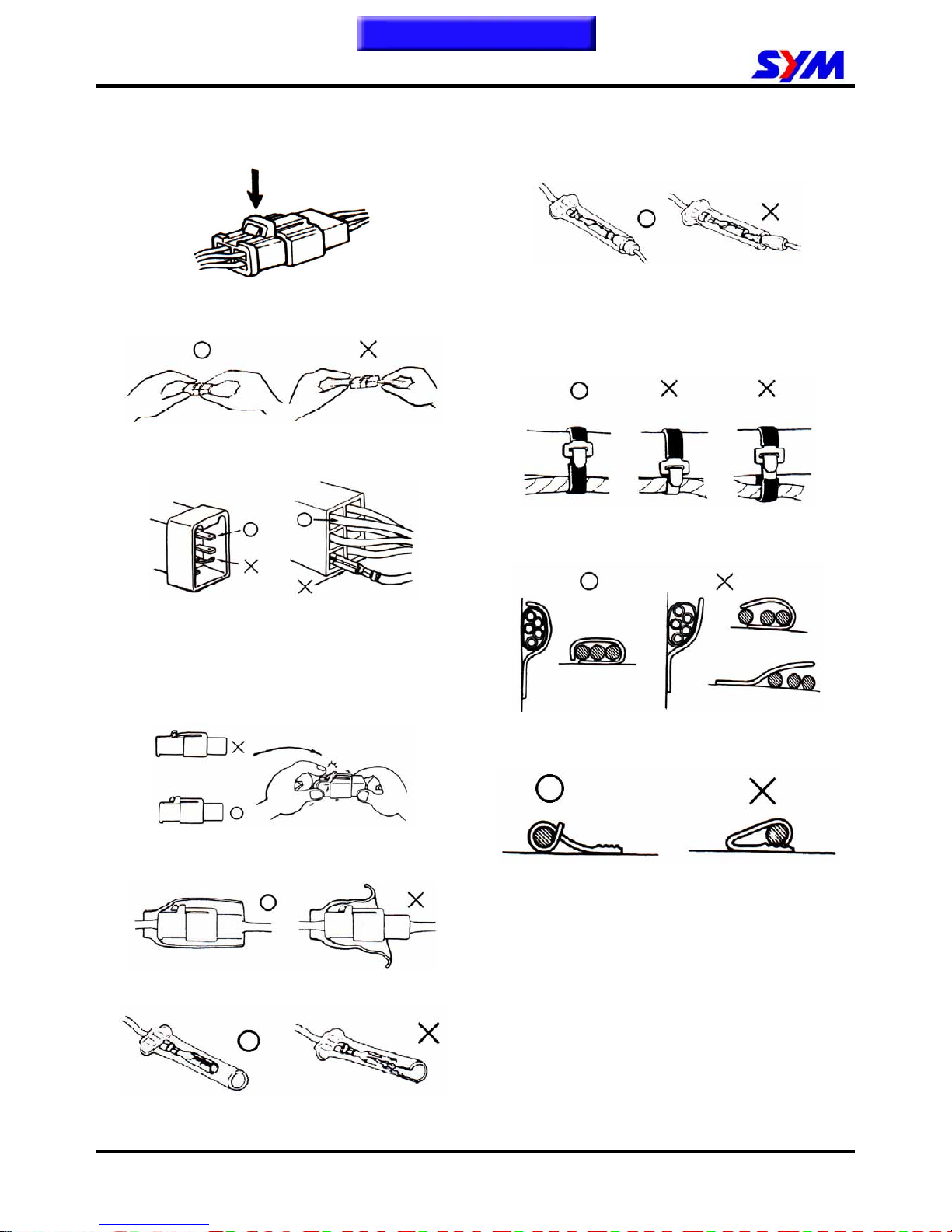

When separating a connector, it locker has to

be unlocked firstly. Then, conduct the service

operation.

Do not pull the wires as removing a connector

or wires. Hold the connector body.

Make sure if the connector pins are bent,

extruded or loosen.

Insert the connector completely.

If there are two lockers on two connector sides,

make sure the lockers are locked in properly.

Check if any wire loose.

Check if the connector is covered by the twin

connector boot completely and secured properly.

Before terminal connection, check if the boot is

crack or the terminal is loose.

Insert the terminal completely.

Check if the boot covers the terminal.

Do not let boot open facing up.

Secure wires and wire harnesses to the frame

with respective wire bands at the designated

locations. Tighten the bands so that only the

insulated surfaces contact the wires or wire

harnesses.

Wire band and wire harness have to be clamped

secured properly.

Do not squeeze wires against the weld or its

clamp.

1-6

Page 12

1. GENERAL INFORMATION

To this chapter contents

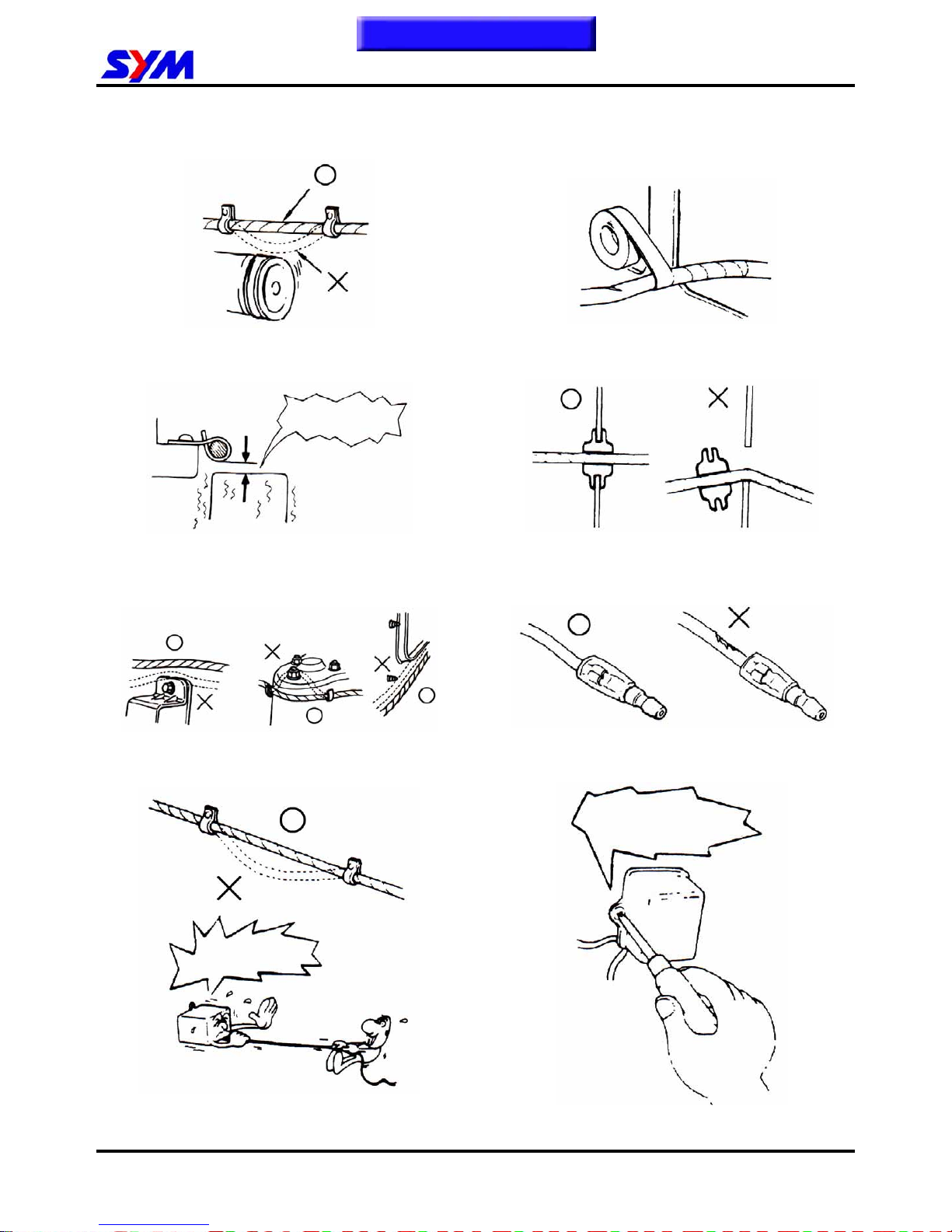

Do not let the wire harness contact with rotating,

moving or vibrating components as routing the

harness.

Keep wire harnesses far away from the hot

parts.

Route wire harnesses to avoid sharp edges or

corners and also avoid the projected ends of

bolts and screws.

Route harnesses so that they neither pull too

tight nor have excessive slack.

Protect wires or wire harnesses with electrical

tape or tube if they contact a sharp edge or

corner. Thoroughly clean the surface where

tape is to be applied.

Secure the rubber boot firmly as applying it on

wire harness.

Never Touch

Never use wires or harnesses which insulation

has been broken. Wrap electrical tape around

the damaged parts or replace them.

Never clamp or squeeze the wire harness as

installing other components.

Never clamp or

squeeze the wire

harness

Never too tight

1-7

Page 13

To this chapter contents

1. GENERAL INFORMATION

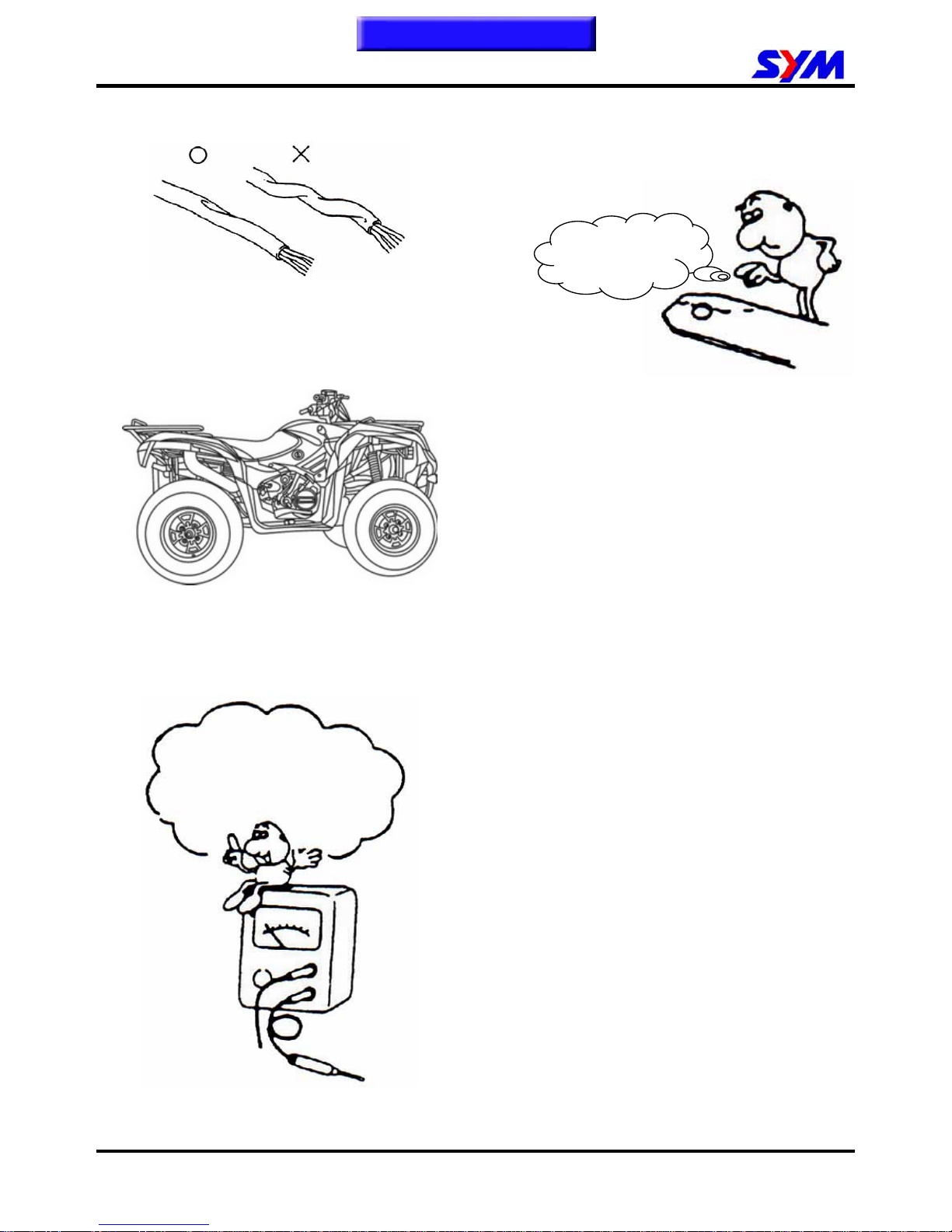

Do not let the wire harness been twisted as

installation.

Wire harnesses routed along the handlebar

should not be pulled too tight or have excessive

slack, be rubbed against or interfere with

adjacent or surrounding parts in all steering

positions.

Before operating a test instrument, operator

should read the operation manual of the

instrument. And then, conduct test in

accordance with the instruction.

With sand paper to clean rust on connector

pins/terminals if found. And then conduct

connection operation later.

Clean rust

Do you know how to set the

instrument to its

measurement position and

the insert locations of its

two probes?

1-8

Page 14

1. GENERAL INFORMATION

To this chapter contents

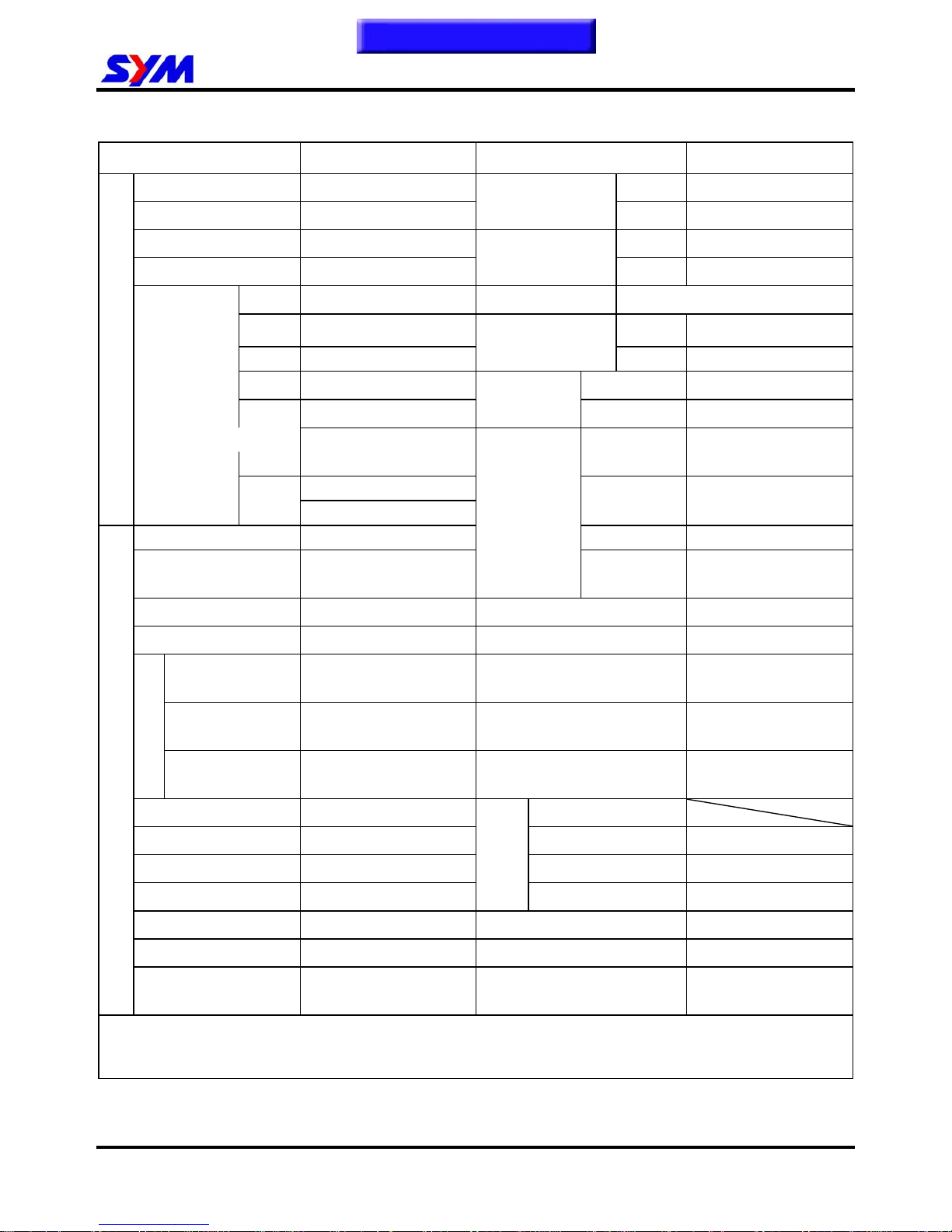

Specifications

MAKER SANYANG MODEL UA60A-6

Overall Length 2110 mm Front Double arm

Overall Width 1150 mm

Suspension

System

Rear Unit Swing

Overall Height 1220 mm Front AT25x8-12 (off road)

Wheel Base 1300 mm

Tire Specifications

Rear AT25x8-12 (off road)

Front 900 mm Rim Aluminum

Dimension

Wheel tread

Rear 895 mm Front Disk (ψ220mm)

Front 180 kg

Brake System

Rear Disk (ψ180mm)

Rear 165 kg Max. Speed Above 80 km/hr

Curb Weight

Total 345 kg

Performance

Climb Ability Below 25°

Passengers/Weight Two /150 kg

Front 215 kg

Primary

Reduction

Belt

Rear 280 kg

Weight

Total Weight

Total 495 kg

Secondary

Reduction

Gear / Sprocket

Type 4-Stroke Engine Clutch Centrifugal, dry type

Installation and

arrangement

Vertical, below center,

incline

Reduction

Transmission

C.V.T., auto speed

change

Fuel Used Above 92 unleaded Speedometer 0 ~ 100 km/hr

Cycle/Cooling 4-stroke/water cooled Horn 93~112 dB/A

Bore Ø92 mm Muffler

Expansion & Pulse

Type

Stroke 85 mm

Exhaust Pipe Position and

Direction

Left side, and

Backward

Cylinder

Number/Arrange

ment

Single Cylinder Lubrication System

Forced circulation &

splashing

Displacement 565cc Solid Particulate

Compression Ratio 10.2 CO Below 7.0 g/ km

Max. HP 20.4ps / 6000rpm HC Below 1.5g/ km

Max. Torque 3.6 Kg m / 2750rpm

Exhaust

Concentration

Nox Below 0.4g/ km

Ignition Full Transistor Ignition E.E.C. ―

Starting System Electrical Starter P.C.V. ―

Engine

Air filtration Sponge

Catalytic reaction control

system

―

1-9

Page 15

1. GENERAL INFORMATION

To this chapter contents

To this chapter contents

Torque Values

The torque values listed in above table are for more important tighten torque values. Please see standard

values for not listed in the table.

Standard Torque Values for Reference

Type Tighten Torque Type Tighten Torque

5 mm bolt、nut

0.45~0.6kgf-m 5 mm screw 0.35~0.5kgf-m

6 mm bolt、nut

0.8~1.2kgf-m

6 mm screw、SH nut

0.7~ 1.1kgf-m

8 mm bolt、nut

1.8~2.5kgf-m

6 mm bolt、nut

1.0 ~1.4kgf-m

10 mm bolt、nut

3.0~4.0kgf-m

8 mm bolt、nut

2.4 ~3.0kgf-m

12 mm bolt、nut

5.0~6.0kgf-m

10 mm bolt、nut

3.5~4.5kgf-m

Engine Torque Values

Item Q’ty Thread Dia. (mm) Torque Value(kgf-m) Remarks

Cylinder stud bolt 4 10 1.0~1.4

Cylinder head nut 4 8 3.6~4.0

Cylinder head right bolt 2 8 2.0~2.4

Cylinder head side cover bolt 2 6 1.0~1.4

Cylinder head cover bolt 4 6 1.0~1.4

Cylinder head stud bolt (inlet pipe) 2 6 1.0~1.4

Cylinder head stud bolt (EX. pipe) 2 8 2.4~3.0

Air inject pipe bolt 4 6 1.0~1.4

Air inject reed valve bolt 2 3 0.07~0.09

Tappet adjustment screw nut 4 5 0.7~1.1 Apply oil to thread

Spark plug 1 10 1.0~1.2

Tensioner lifter bolt 2 6 1.0~1.4

Carburetor insulator bolt 2 6 0.7~1.1

Oil pump screw 2 3 0.1~0.3

Water pump impeller 1 7 1.0~1.4

Engine left cover bolt 9 6 1.1~1.5

Engine oil draining bolt 1 12 3.5~4.5

Engine oil strainer cap 1 30 1.3~1.7

Mission draining bolt 1 8 1.1~1.5

Mission filling bolt 1 12 3.5~4.5

Shift drum fixing bolt 1 14 3.5~4.5

Clutch driving plate nut 1 28 5.0~6.0

Clutch outer nut 1 14 5.0~6.0

Drive face nut 1 14 8.5~10.5

ACG. Flywheel nut 1 14 5.0~6.0

Crankcase bolts 7 6 0.8~1.2

Mission case bolt 7 8 2.6~3.0

1-10

Page 16

1. GENERAL INFORMATION

To this chapter contents

Frame Torque Values

Item Q’ty Thread Dia. (mm) Torque Value(kgf-m) Remarks

Handlebar upper holder bolt

4 6 2.40

Steering shaft nut

1 10 5.00

Steering tie-rod nut

4 10 5.00

Knuckle nut

2 10 5.00

Steering shaft holder bolt

2 8 3.40

Tie rod lock nut

4 10 3.60

Handlebar under holder nut

2 8 4.00

Front wheel nut

8 10 2.40

Front axle castle nut

2 14 5.00

Rear axle castle nut

2 14 5.00

Rear wheel nut

8 10 2.40

Engine hanger nut

4 12 8.50

Rear axle holder bolt

4 12 9.20

Drive gear bolt

2 10 4.6

Driven gear nut

4 10 4.6

Swing arm pivot bolt

1 14 9.20

Front suspension arm nut 4 10 5.00

Front / Rear cushion mounting bolt 6 10 4.60

Brake lever nut

2 6 1.00

Brake hose bolt

13 10 3.50

Brake caliper bolt

6 6 3.25

Brake disk mounting bolt

11 8 4.25

Air-bleed valve

3 5 0.50

Exhaust muffler mounting bolt

2 8 3.00

Exhaust muffler connection nut

2 7 1.20

1-11

Page 17

To this chapter contents

1. GENERAL INFORMATION

Troubles Diagnosis

A. Engine hard to start or can not be started

Check and adjustment Fault condition Probable causes

Cylinder compression

pressure normal

Loosen carburetor drain bolt to

check if there is gasoline inside

the carburetor

Fuel supplied tom

carburetor sufficient

No fuel is supplied to

carburetor

Remove spark plug, install it

into spark plug cap, and perform

a spark test against engine

g

round.

Perform cylinder compression

pressure test.

Check if sparks Weak sparks, no spark at

all

Low compression

pressure or no pressure

Re-start by following the starting

procedures

No ignition

There are some signs of

ignition; nut engine can

Remove the spark plug again

and check it.

Remove carburetor after 30

minutes and connect a hose

onto fuel rich circuit. Then blow

the hose with air

Dry spark plug Wet spark plug

Blowing in normal Blowing clogged

No fuel in fuel tank

Check if the pipes, fuel tank to carburetor

and intake vacuum, are clogged.

Float valve clogged

Lines in fuel tank evaporation system

clogged

Malfunction of fuel pump

Loosen or damaged fuel pump vacuum

hose

Fuel filter clogged

Malfunction of spark plug

Spark plug foul

Malfunction of CDI set

Malfunction of AC generator

Ignition coil is in open or short circuit

Ignition coil leads open or short circuit

Malfunction of main switch

Piston ring seized

Malfunction of cylinder valves

Worn cylinder and piston ring

Cylinder gasket leak

Sand hole in compression parts

Malfunction of throttle valve operation

Air sucked into intake manifold

Incorrect ignition timing

Fuel level in carburetor too high

Malfunction of throttle valve operation

Throttle valve opening too wide

Malfunction of automatic by- starter

1-12

Page 18

To this chapter contents

1. GENERAL INFORMATION

B. Engine run sluggish (Speed does not pick up, lack of power)

Check and adjustment Fault condition Probable causes

Try gradual acceleration and

check engine speed

Engine speed can be

increased.

Engine speed cannot be

increased.

Check ignition timing (Using

ignition lamp)

Check cylinder compression

pressure (using compression

Ignition timing correct Incorrect ignition timing

Compression pressure

correct

No compression pressure

Check if carburetor jet is

clogged

No clogged

Clogged

Remove spark plug

Check if engine over heat

No foul or discoloration

Fouled and discoloration

No knock

Knock

Air cleaner clogged

Poor fuel supply

Lines in fuel tank evaporation system

clogged

Exhaust pipe clogged

Fuel nozzle clogged in carburetor.

Fuel nozzle clogged in carburetor.

Malfunction of CDI

Malfunction of AC alternator

Cylinder & piston ring worn out

Cylinder gasket leaked

Sand hole in compression parts

Valve deterioration

Seized piston ring

Remove foreign

Remove dirt

Incorrect spark plug heat range

Piston and cylinder worn out

Lean mixture

Poor fuel quality

Too much carbon deposited in

combustion chamber

Ignition timing too advanced

Poor circuit on the cooling system

Normal

Engine overheat

Continually drive in acceleration

or high speed

Too much carbon deposited in

combustion chamber

Lean mixture

Poor fuel quality

Ignition timing too advanced

1-13

Page 19

To this chapter contents

1. GENERAL INFORMATION

C. Engine runs sluggish (especially in low speed and idling)

Check and adjustment Fault condition Probable causes

D. Engine runs sluggish (High speed)

Check ignition timing (using

ignition lamp)

Check for fuel supplying system

in automatic fuel cup

Check if carburetor clogged

Incorrect ignition timing (malfunction of

CDI or AC alternator)

Rich mixture (loosen the screw)

Lean mixture (tighten the screw)

Poor heat insulation gasket

Carburetor lock loose

Poor intake gasket

Poor carburetor O-ring

Vacuum hose crack

Spark plug fouled

Malfunction of CDI

Malfunction of AC generator

Malfunction of ignition coil

Open or short circuit in spark plug leads

Malfunction of main switch

Insufficient fuel in fuel tank

Fuel filter clogged

Restricted fuel tank vent

Good

A

bnormal

Good spark Poor

No air sucked

A

ir sucked

Good Poor

Normal

A

bnormal

A

ir sucked through carburetor

gasket

A

djust the airscrew of

carburetor

No clogged Clogged

Cleaning

Remove spark plug, install

spark plug into spark plug cap

and perform spark test against

engine ground

Check and adjustment Fault condition

Probable causes

Check ignition timing

Malfunction of CDI

Malfunction of AC alternator

A

bnormal Normal

1-14

Page 20

To this chapter contents

1. GENERAL INFORMATION

E. Clutch, driving and driving pulley

Clutch weights spring broken

Clutch outer stuck with clutch weights

Connection parts in clutch and shaft worn out or burned

Engine can be started but

motorcycle can not be moved.

FAULT CONDITIONS

PROBABLE CAUSES

Drive belt worn out or deformation

Weight roller worn out

Movable drive face shaft worn out

Driven pulley spring deformation

Driven pulley shaft worn out

Greased in drive belt and driven face.

Poor initial driving (Poor climbing

performance)

Engine running and misfire as

motorcycle initial forward moving or

j

umping suddenly (rear wheel

rotating as engine in running)

Drive belt worn out or deformation

Ramp plate of movable drive face damaged

Driving pulley spring broken

Clutch weights broken

Drive slide-shaft gear groove broken

Transmission gear damaged

F. Poor handling

Steering is heavy

FAULT CONDITIONS

PROBABLE CAUSES

One wheel is wobbling

Vehicle pulls to one side

Bent rim

Improperly installed wheel hub

Excessive wheel bearing play

Bent swing arm

Bent frame

Swing arm pivot bushing excessively

Worn

Bent tie-rod

Incorrect tie-rod adjustment

Rear tie air pressure incorrect

Improper wheel alignment

Bent frame

Damaged steering bearing

Damaged steering shaft bushing

1-15

Page 21

To this chapter contents

1. GENERAL INFORMATION

G. Loss power

Check and adjustment Fault condition Probable causes

Raise wheels off ground and

spin by hand

Brake dragging

Drive chain too tight

Damaged wheel bearing

Wheel bearing needs lubrication

Spin freely

A

bnormal

Punctured tire

Faulty tire valve

Fuel / air mixture ratio too rich or lean

Clogged in air cleaner

Clogged in muffler

Restricted fuel flow

Clogged fuel tank cap breather hole

Faulty pulse generator

Faulty CDI unit

Leaking head gasket

Worn cylinder and piston rings

Clean

Clean the spark plug

Spark plug is incorrect heat range

Excessive carbon deposited in

combustion chamber

Wrong type of fuel

Fuel / air mixture ratio is lean

Use of poor quality fuel

Worn piston and cylinder

Fuel / air mixture ratio is lean

Wrong type of fuel

Ignition timing too advanced

Excessive carbon deposited in

combustion chamber

Check tire pressure

Normal

A

bnormal

A

ccelerate lightly, engine speed

can be increase

Normal

A

bnormal

Check ignition timing

Normal

A

bnormal

Test cylinder compression

Normal

A

bnormal

Check carburetor

Normal Clogged

Check spark plug

Normal Fouled or discolored

Check for engine overheating

Normal Overheating

A

ccelerate or run at high speed

Knocks Normal

1-16

Page 22

1. GENERAL INFORMATION

Lubrication Points

Acceleration cable/ Front & rear brake/ Lever Pivot

To this chapter contents

Wheel bearing

1-17

Page 23

2. MAINTENANCE INFORMATION

2-1

Precautions in Operation ···················· 2-1

Periodical Maintenance Schedule ······ 2-2

Fuel Lines············································· 2-3

Acceleration Operation ······················· 2-3

Air Cleaner············································ 2-3

Spark Plug ············································ 2-4

Valve Clearance ··································· 2-4

Carburetor Idle Speed Adjustment····· 2-5

Ignition System ···································· 2-6

Cylinder Compression Pressure ········ 2-6

Drive Belt·············································· 2-7

Propeller Shaft ····································· 2-7

Front Differential ·································· 2-8

Rear Axle Gearbox······························· 2-8

Brake System ······································· 2-9

Brake Light Switch······························· 2-10

Headlight Beam Distance ···················· 2-11

Clutch Disc Wear ································· 2-11

Cushion················································· 2-11

Steering Handle···································· 2-12

Wheel/Tire············································· 2-12

Nuts, Bolts Tightness ·························· 2-12

Special Tools List ································ 2-13

Precautions in Operation

Specification

Fuel Tank Capacity 12000 c.c.

Capacity 1400 c.c.

Engine Oil

Change 1200 c.c.

Capacity 1300 c.c.

Transmission Gear oil

Change 1200 c.c.

Engine + radiator 850 c.c.

Capacity of coolant

Reservoir upper 420 c.c.

Clearance of throttle valve 1~3 mm

Type NGK CR8E

Spark plug

Gap 0.8 mm

“F” Mark in idling speed BTDC 10º / 1700 rpm

Full timing advanced BTDC 27º / 4000 rpm

Idling speed 1700±100 rpm

Cylinder compression pressure 12.0 ±2 kgf/cm²

Valve clearance IN: 0.10 ± 0.02 mm EX: 0.15 ± 0.02 mm

Front AT22x7-10

Tire dimension

Rear AT22x10-9

Tire pressure (cold) 3.8±2 psi

Battery 12V10Ah (MF battery) type: GTX12-BS

Home page

Contents

2

Page 24

2. MAINTENANCE INFORMATION

2-2

Periodical Maintenance Schedule

Maintenance

Code

Item

Every

300KM

1 Month

Every

3 month

Every

6 month

Every

1 year

Every

15 month

Every

1 Air cleaner

I C R

2 Fuel filter

I I R

3 Oil filter

C C

4 Engine oil change

R Replacement for every 1000 km

5 Tire pressure

I I

6 Battery inspection

I I

7 Brake & free ply check

I I

8 Steering handle check

I I

9 Cushion operation check

I I

10 Every screw tightening check

I I

11 Gear oil check for leaking

I I

12 Spark plug check or change

I I R

13 Gear oil change

R Replacement for every 12000 km

14 Frame lubrication

L

15 Exhaust pipe

I I

16 Ignition timing

I I

17 emission check in Idling

A I

18 Throttle operation

I I

19 Engine bolt tightening

I I

20 CVT driving device(belt)

I R

21 CVT driving device(roller)

C

22 Drive chain

I / L I / L

C

23

Lights/electrical

equipment/multi-meters

I I

24 Fuel lines

I I

25 Cam chain

I I

26 Valve clearance

I A

27

Lines & connections in cooling

I I

28 Coolant reservoir

I I

29 Coolant

I I R

Code: I ~ Inspection, cleaning, and adjustment R ~ Replacement

C ~ Cleaning (replaced if necessary) L ~ Lubrication

Have your ATV checked, adjusted, and recorded maintenance data periodically by your SYM Authorized Dealer to

maintain the ATV at the optimum condition

The above maintenance schedule is established by taking the monthly 1000 kilometers as a reference which ever

comes first.

Remarks: 1. Clean or replace the air cleaner element more often when the ATV is operated on dusty roads or in

the Heavily- polluted environment.

2. Maintenance should be performed more often if the ATV is frequently operated in high speed and

after the ATV has accumulated a higher mileage.

3. Preventive maintenance

a. Ignition system-Perform maintenance and check when continuous abnormal ignition, misfire,

after-burn, overheating occur.

b. Carbon deposit removal-Remove carbon deposits in cylinder head, piston heads, exhaust system

when power is obvious lower.

To this chapter contents

Page 25

2. MAINTENANCE INFORMATION

2-3

Fuel Lines

Remove the seat.

Loosen 2 screws and 2 bolts

Remove the tank cover.

Check all lines, and replace the lines when they

are deteriorated, damaged or leaking.

Warning

Gasoline is a low ignition material so any kind of

fire is strictly prohibited as dealing it.

Acceleration Operation

Have a wide open of throttle valve as handle in

any position and release it to let back original (full

closed) position.

Check handle if its operation is smooth.

Check acceleration cable and replace it if

deteriorated, twisted or damaged.

Lubricate the cable if operation is not smooth.

Measure the throttle lever free play in its flange

part.

Remove rubber boot, loosen fixing nut, and then

adjust it by turning the adjusting screw.

Tighten the fixing nut, and check acceleration

operation condition.

Free play: 1~3 mm.

Air Cleaner

Remove the seat.

Loosen 5 hooks from the air cleaner cover and

then remove the cover.

Loosen the clamp strip and 1 screw of air cleaner

element, and then remove the air cleaner element.

Clean the element with non-flammable or

high-flash point solvent and then squeeze it for

dry.

Caution

Never use gasoline or acid organized solvent to

clean the element.

Soap the element into cleaning engine oil and then

squeeze it out. Install the element onto the

element seat and then install the air cleaner cover.

Fuel tank

Fuel hose

Fuel filter

To this chapter contents

Lock nut

Throttle adjustment screw

Element

Clamp

Fuel valve

Carburetor

Screw

Page 26

2. MAINTENANCE INFORMATION

2-4

Spark Plug

Recommended spark plug: CR8E

Remove the spark plug cap.

Clean the dirt around the spark plug hole.

Remove the spark plug.

Measure the spark plug gap.

Spark plug gap:0.8 mm

Carefully bend ground electrode of the plug to

adjust the gap if necessary.

Hold the spark plug washer and install the spark

plug by screwing it.

Tighten the plug by turning 1/2 turn more with plug

socket after installed.

Tighten torque: 1.0~1.2kgf-m

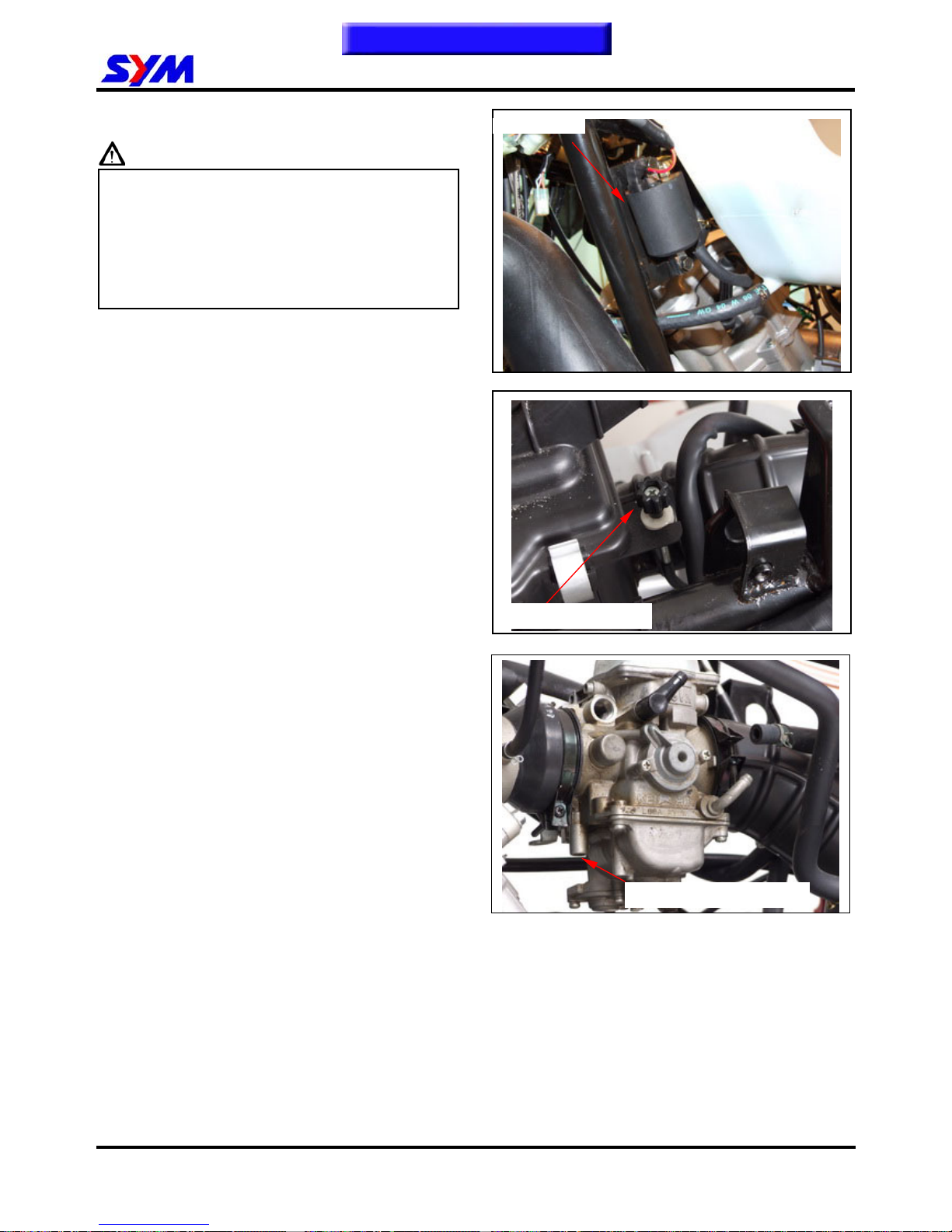

Valve Clearance

Caution

Checks and adjustment must be performed when

the engine temperature is below 35℃.

Remove front fender, fuel tank cover and fuel tank.

Remove cylinder head cover.

Remove cylinder head side cover.

Turn camshaft bolt in C.W. direction and let the “T”

mark on the camshaft sprocket align with cylinder

head mark so that piston is placed at TDC position

in compression stroke.

Caution

Do not turn the bolt in C.C.W. direction to prevent

camshaft bolt looseness.

Valve clearance inspection and adjustment

Check & adjust valve clearance with feeler gauge.

Standard Value: IN 0.10 ± 0.02 mm

EX 0.15 ± 0.02 mm

Loosen fixing nut and turn the adjustment nut for

adjustment.

Caution

Re-check the valve clearance after tightened the

fixing nut.

To this chapter contents

2 bolts

Timing mark

0.8~0.9mm

Ground electrode

Central electrode

Page 27

2. MAINTENANCE INFORMATION

2-5

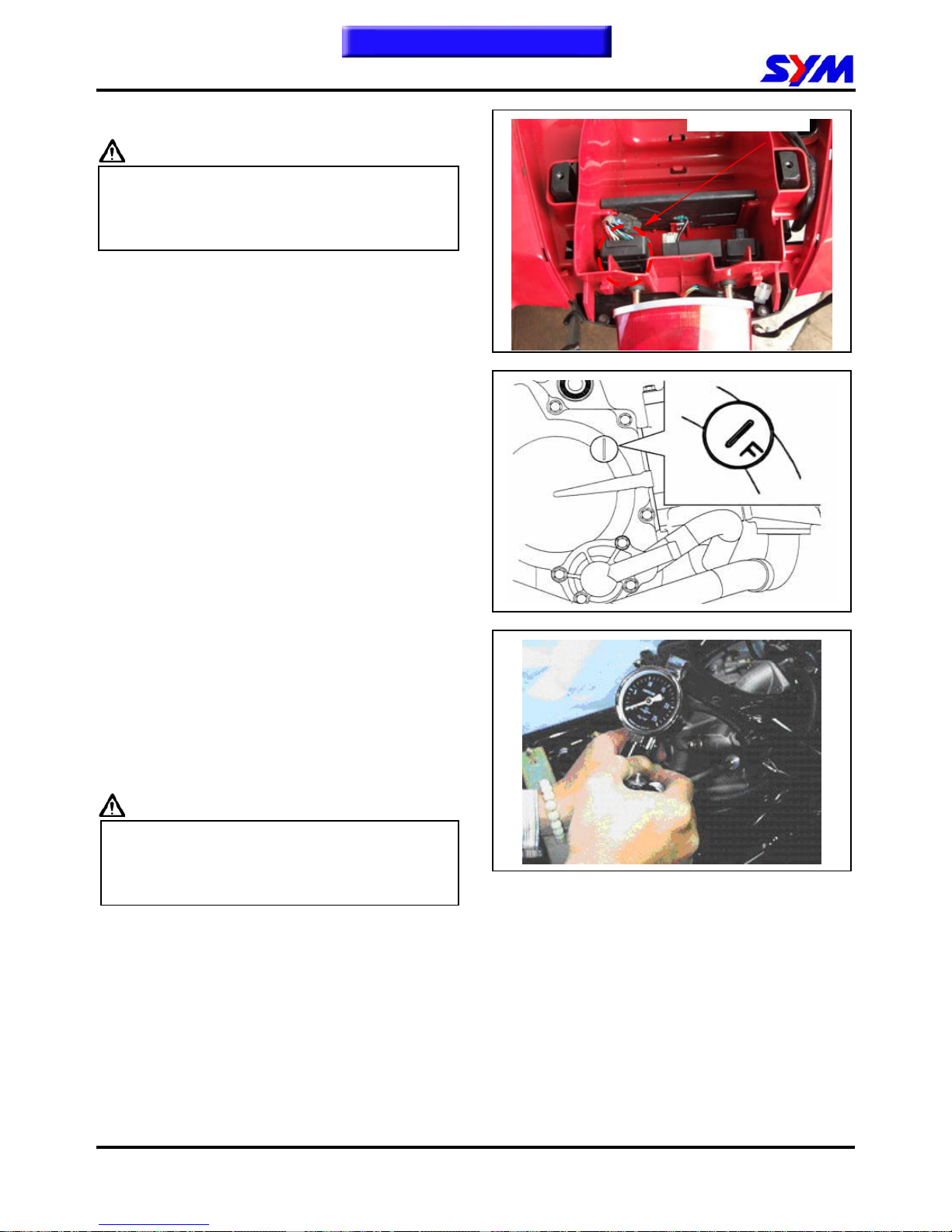

Carburetor Idle Speed Adjustment

Caution

Inspection & adjustment for idle speed have to

be performed after all parts in engine that

needed adjustment have been adjusted.

Idle speed check and adjustment have to be

done after engine being warmed up. (It is

enough that operates engine from stop to

running for 10 minutes.)

Park the ATV warm up engine.

Connect tachometer (the wire clamp of tachometer

is connected to the high tension cable).

Turn the throttle valve stopper screw to specified

idle speed.

Specified idle speed: 1700 ± 100 rpm

Emission adjustment in idle speed

Warm up the engine for around 10 minutes and

then conduct this adjustment.

1. Connect the tachometer onto engine.

2. Adjust the throttle valve stopper screw and let

engine runs in 1600±100 rpm.

3. Insert the exhaust sampling pipe of exhaust

analyzer into the front section of exhaust pipe.

Adjust the air adjustment screw so that

emission value in idle speed is within standard.

4. Slightly accelerate the throttle valve and

release it immediately. Repeat this for 2~3

times.

5. Read engine RPM and value on the exhaust

analyzer. Repeat step 2 to step 4 procedures

until measured value within standard.

Emission standard CO: below 0,8~1.5%

HC: below 900ppm

Ignition coil

Idle speed adjust screw

To this chapter contents

Air/fuel adjusting screw

Page 28

2. MAINTENANCE INFORMATION

2-6

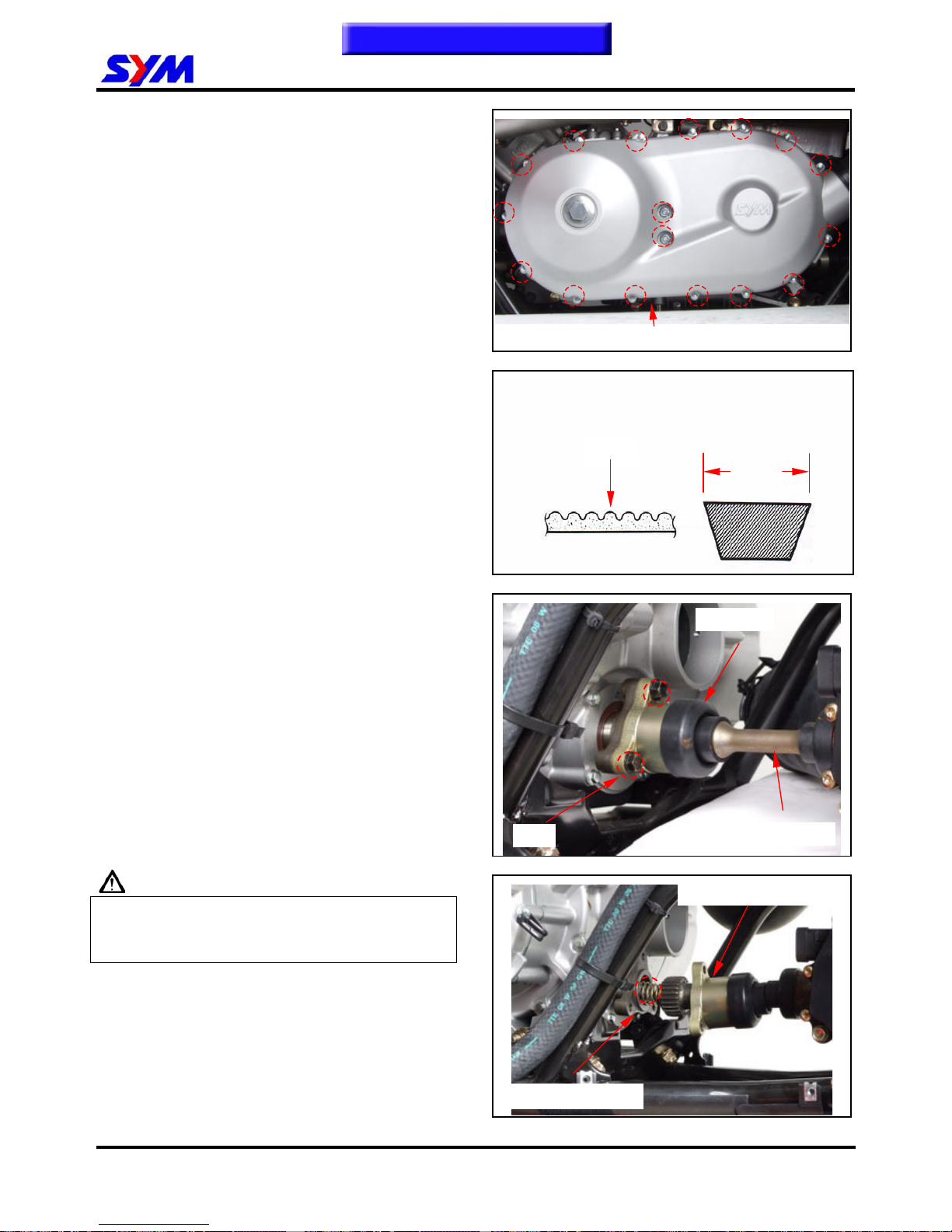

Ignition System

Caution

Full transistor ignition system is setup by the

manufacturer so it cannot be adjusted.

Ignition timing check procedure is for checking

whether ignition function is in normal or not.

Connect tachometer and ignition light.

Start engine.

As engine in idle speed: 1600 rpm, aim at the

mark “F” with the ignition light which means that

ignition timing is correct.

Increase engine speed to 6000 rpm to check

ignition advance degree. If indent is located within

the ignition advance degrees, it means that the

ignition advance degree is normal.

If ignition timing is incorrect, check the full

transistor ignition set, rotor and pulse generator.

Replace it if malfunction of these parts is found.

Cylinder Compression Pressure

Warm up engine.

Turn off the engine.

Remove the trunk.

Remove the central cover.

Remove spark plug cap and spark plug.

Install compression gauge.

Full open the throttle valve, and rotate the engine

by means of starter motor.

Caution

Rotate the engine until the reading in the gauge

no more increasing.

Usually, the highest-pressure reading will be

obtained in 4~7 seconds.

Compression pressure: 12 ± 2 Kg/cm²

Check following items if the pressure is too

low:

Incorrect valve clearance.

Valve leaking.

Cylinder head leaking, piston, piston ring and

cylinder worn out.

If the pressure is too high, it means carbon

deposits in combustion chamber or piston head.

To this chapter contents

Page 29

2. MAINTENANCE INFORMATION

2-7

Drive Belt

Loosen the 2 clamp strips of left crankcase cover,

and then remove the left crankcase cover

ventilation pipe.

Remove 17 bolts.

Remove the left crankcase cover.

Check if the belt is cracked or worn out.

Replace the belt if necessary or in accordance

with the periodical maintenance schedule to

replace it.

Width limit: 32.7 mm or above

Propeller Shaft

Remove 3 bolts from the propeller shaft connector.

Check the propeller shaft for any wear.

Check the rubber boots for any damage.

Caution

Don’t lose the propeller shaft spring.

Coat the propeller shaft gear with grease before

assembling the propeller shaft.

Teeth

Width

To this chapter contents

Propeller shaft spring

9 bolts

Propeller shaft connector

Front propeller shaft

3 bolts

Rubber boot

Page 30

2. MAINTENANCE INFORMATION

2-8

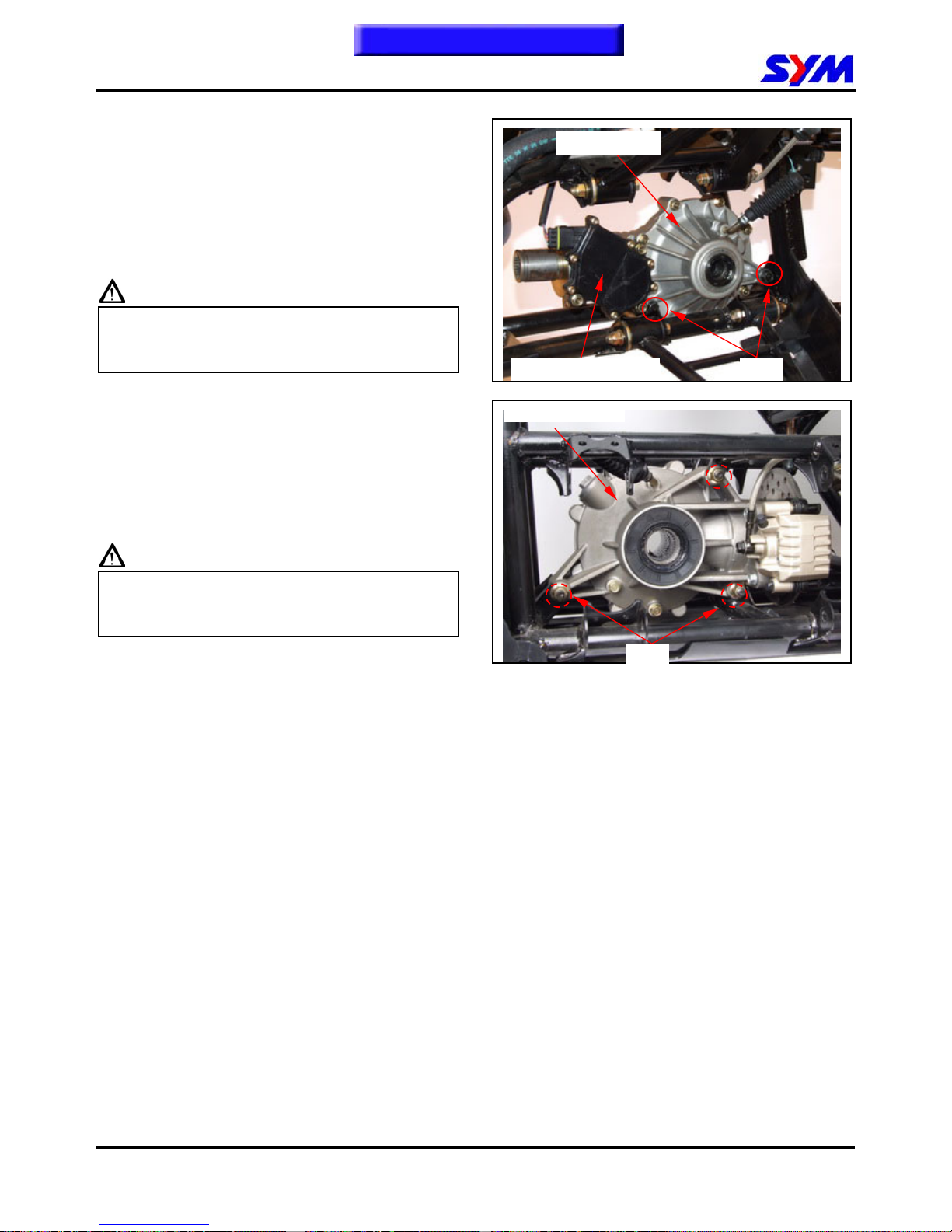

Front Differential

Check the front differential for abnormal noise or

unsmooth rotation.

Caution

Do not attempt to disassemble the Front

Differential. Please exchange the whole

assembly if necessary.

Rear Axle Gearbox

Check the rear axle gearbox for abnormal noise or

unsmooth rotation.

Caution

Do not attempt to disassemble the Rear

Gear Box. Please exchange the whole

assembly if necessary.

2 bolts

Front differential

Differential control unit

3 bolts

Rear axle gearbox

To this chapter contents

Page 31

2. MAINTENANCE INFORMATION

2-9

Brake System

Brake System Hose

Check the brake hoses for corrosion or leaking oil.

Brake Fluid

Check brake fluid level in the brake fluid

reservoir. If the level is lower than the LOWER

limit, add brake fluid to UPPER limit. Also check

brake system for leaking if low brake level found

Caution

In order to maintain brake fluid in the reservoir

in horizontal position, do not remove the cap

until handle stop.

Do not operate the brake lever after the cap

had been removed. Otherwise, the brake fluid

will spread out if operated the lever.

Do not mix non-compatible brake fluid together.

Filling Out Brake Fluid

Tighten the drain valve, and add brake fluid.

Operate the brake lever so that brake fluid

contents inside the brake system hoses.

Air Bleed Operation

Connect a transparent hose to draining valve.

Hold the brake lever and open air bleeding valve.

Perform this operation alternative until there is no

air inside the brake system hoses.

Caution

Before closing the air bleed valve, do not release

the brake lever.

Added Brake Fluid

Add brake fluid to UPPER limit lever.

Recommended brake fluid: DOT3 or DOT4 WELL

RUN brake fluid.

Caution

Never mix or use dirty brake fluid to prevent from

damage brake system or reducing brake

performance.

To this chapter contents

Transparent hose

Air bubble

Drain valve

Screws

Diaphragm plate

Upper

Diaphragm

Master cylinder cap

Page 32

2. MAINTENANCE INFORMATION

2-10

Brake Lining Wear

The indent mark on brake lining is the wear

limitation.

Replace the brake lining if the wear limit mark

closed to the edge of brake disc.

Caution

To check front brake lining must be remove

front wheel first.

It is not necessary to remove brake hose when

replacing the brake lining.

Brake Lining Replacement (refer chapter

14)

Make sure the brake lining condition. Replace

the lining if the brake lining wear limitation groove

close to the brake disc.

Caution

Do not operate the brake lever after the clipper

removed to avoid clipping the brake lining.

In order to maintain brake power balance, the

brake lining must be replaced with one set.

Brake Light Switch

The brake light switch is to light up brake light as

brake applied.

Make sure that electrical starter can be operated

only under brake applying.

Brake lining wear

limitation groove

Rear brake

To this chapter contents

Lining

Brake disk

Brake lining wear

limitation groove

Front brake

Brake switch

Brake switch

Page 33

2. MAINTENANCE INFORMATION

2-11

Headlight Beam Distance

Turn on main switch.

Turn the headlight adjusting screw to adjust

headlight beam height.

Caution

To adjust the headlight beam follows related

regulations.

Improper headlight beam adjustment will

make in coming driver dazzled or insufficient

lighting.

Clutch Weight

Run the ATV and increase throttle valve opening

gradually to check the clutch operation.

If the ATV is in forward moving and shaking, check

clutch disc condition. Replace it

Cushion

Front cushion

Press down the front cushion for several times to

check it operation.

Check if it is damage

Replace relative parts if damage found.

Tighten all nuts and bolts.

Rear Cushion

Press down the rear cushion for several times to

check it operation.

Check if it is damage

Replace relative parts if damage found.

Warning

Do not ride the ATV with poor cushion.

Looseness, wear or damage cushion will make

poor stability and drive-ability.

Adj

ustingscrew

Clutch weight

To this chapter contents

Page 34

2. MAINTENANCE INFORMATION

2-12

Steering Handle

Caution

Check all wires and cables if they are interfered

with the rotation of steering handle bar.

Lift the front wheel off ground.

Turn handle from right to left alternative and check

if turning is smoothly.

If handle turning is uneven and bending, or the

handle can be operated in vertical direction, then

check the handle top bearing.

Wheel/Tire

Caution

Tire pressure check should be done as cold

engine.

Check if tire surface is ticked with nails, stones or

other materials.

Appointed tire pressure

Tire size Front tire Rear tire

Tire pressure as cold

3.8±2

psi

Check if front and rear tires’ pressure is normal.

Measure tire thread depth from tire central surface.

Replace the tire if the depth is not come with

following specification:

Front tire: 1.5 mm

Rear tire: 2.0 mm

Nuts, Bolts Tightness

Perform periodical maintenance in accordance

with the Periodical Maintenance Schedule.

Check if all bolts and nuts on the frame are

tightened securely.

Check all fixing pins, snap rings, hose clamp, and

wire holders for security.

To this chapter contents

Page 35

2. MAINTENANCE INFORMATION

2-13

Special Tools List

NAME

Rocker arm pin puller

NAME

Tappet adjusting wrench

NAME

Tappet adjusting wrench

NO SYM-1445100 NO SYM-9001200 NO SYM-1472100

NAME

Tappet adjuster

NAME

Valve cotter remove &

assembly tool

NAME

AC.G. Flywheel puller

NO SYM-2301000-HMA NO SYM-1471110/20 NO SYM-3110000-HMA

NAME

KNUCKLE BODY BRG.

6006 driver

NAME

Drive shaft puller

NAME

Driveshaft BRG. 6228 driver

NO

SYM-5024000-REA 6006

NO SYM-2341120-REA NO

SYM-2341110-REA 6228

NAME

BEVEL GEAR HOUSHING

BRG 6306 driver

NAME

WHEEL DRIVE SHAFT

BALL SET tool

NAME

Countershaft OIL SEAL

20*40*5

NO SYM-2343700-REA A6306 NO SYM-4423500-REA NO SYM-9121000-REA

To this chapter contents

Page 36

2. MAINTENANCE INFORMATION

2-14

NAME

NEEDLE BRG. 2220C driver

NAME MDF. Fixer NAME Final shaft gear stopper

NO SYM-9100400-REA 2220 NO

SYM-2211000-REA

NO

SYM-2343100-REA

NAME

Driveshaft BRG. 6328 driver

NAME

OUTPUT SHAFT OIL SEAL

42*52*7

NAME

OUTPUT SHAFT OIL SEAL

38*52*7

NO SYM-9100500-REA A6328 NO SYM-9120900-REA NO SYM-9120800-REA

(12*28*7)

(6901)

NAME Water pump oil seal driver NAME

WATER PUMP BRG. 6001

driver

NAME

Water pump mechanical seal

driver

NO SYM-9120200-REA NO SYM-6001300-REA A6001 NO SYM-1721700-H9A

NAME

CLUTCH COVER BRG. 6207

driver

NAME

R COVER OIL SEAL GUIDE

NAME Lock nut driver

NO SYM-9610000- REA A6207 NO SYM-1133000-REA NO SYM-9020100

To this chapter contents

Page 37

2. MAINTENANCE INFORMATION

2-15

NAME Inner bearing puller NAME Inner bearing puller NAME

Outer bearing puller

NO SYM-6204002 NO SYM-6204022 NO SYM-6204001

NAME Universal holder NAME Clutch nut wrench NAME Crankcase tool

NO SYM-2210100 NO SYM-9020200 NO SYM-1120000-ALL

(55mm)

(55mm)

NAME Rear axle nut wrench NAME

Torque wrench

NAME

Rear axle nut torque wrench

NO SYM-HT06007 NO SYM-HT07004-RA1 NO

SYM-4230200

NAME ARM SUSPENSION NAME

WHEEL KNUCKLE BODY

SEAL 40*55*8 driver

NAME

WHEEL KNUCKLE BODY

SEAL 40*50*6.5 driver

NO SYM-2300000 NO SYM-9123200-REA NO SYM-9123000-REA

To this chapter contents

Page 38

2. MAINTENANCE INFORMATION

2-16

NAME

MAIN BRG. UP/LWR

40*44*20 driver

NAME NAME

PULLEY DRIVEN FACE

41*44*4 OIL SEAL GUIDE

NO SYM-9100110-REA NO SYM-9100400 G5A ADA NO SYM-9121100-REA

NAME

ENG L COVER RADIAL BALL

BRG. 6006 driver

NAME

FINAL SHAFT BRG 6307

driver

NAME

PULLEY DRIVEN FACE

expander

NO SYM-9615010-REA 6006 NO SYM-2343110-REA 6307 NO SYM-2321000-REA

NAME

CLUTCH COVER 35*55*8

OIL SEAL

NAME

DRIVEN PULLEY

Disassemble tool

NAME

PULLEY DRIVEN FACE

SEAL COLLER tool

NO SYM-9120300-REA NO SYM-2301000-REA NO SYM-2323700-REA

NAME

R CASE PARK GEAR

CLIP GUIDE & installer

NAME

Driveshaft oil seal driver

NAME

OUTPUT SHAFT BRG

6307 driver

NO SYM-9060200-REA NO SYM-9120600-REA NO SYM-2346000-REA A6307

To this chapter contents

Page 39

2. MAINTENANCE INFORMATION

2-17

NAME

MAIN BRG. UP/LWR

40*44*20 assemble tool

NAME

L COVER FR. BRG. 6302

driver

NAME Drive plate fixer

NO SYM-9100100-REA NO SYM-9615000-REA 6302 NO

SYM-2230000-REA

NAME

NAME

NAME

NO NO NO

NAME NAME NAME

NO NO NO

NAME

NAME

NAME

NO NO NO

To this chapter contents

Page 40

Home page

3. LUBRICATION SYSTEM

Contents

Mechanism Diagram·································3-1

Precautions in Operation ·························3-3

Troubleshooting ·······································3-3

Engine Oil··················································3-4

Engine Oil Strainer Clean·························3-4

Oil Filter Unit ·············································3-5

Oil Pump ····················································3-6

Mechanism Diagram

3

3-1

Page 41

To this chapter contents

3. LUBRICATION SYSTEM

Cam Shaft

Spray Lubrication

Spray Lubrication

Press-In Lubrication

Con-Rod

Oil Route

Valve Rocker Arm

Oil Route

3-2

Page 42

To this chapter contents

3. LUBRICATION SYSTEM

Precautions in Operation

General Information:

This chapter contains maintenance operation

for the engine oil pump and gear oil

replacement.

Specifications

Engine oil capacity Disassembly: 3000 c.c.

Replacement: 2400 c.c.

Replacement with oil filter replaced: 2700 c.c.

Oil viscosity SAE 10W-30 (Recommended

King serial oils)

Rear axle gear oil replacement: 100c.c.

Front differential gear oil replacement: 200c.c.

Gear oil viscosity SAE 80 or 90

(Recommended SYM Hypoid gear oil)

Items Standard (mm) Limit (mm)

Inner rotor clearance 0.15 0.20

Clearance between outer rotor and body 0.15~0.20 0.25

Oil pump

Clearance between rotor side and body 0.04~0.09 0.12

Torque value

Torque value oil strainer cap 1.3~1.7kgf-m

Engine oil drain bolt 3.5~4.5kgf-m

Gear oil drain bolt 1.1~1.5kgf-m

Gear oil join bolt 3.5~4.5kgf-m

Oil pump connection screw 0.1~0.3kgf-m

Troubleshooting

Low engine oil level

Oil leaking

Valve guide or seat worn out

Piston ring worn out

Low oil pressure

Low engine oil level

Clogged in oil strainer, circuits or pipes

Oil pump damage

Dirty oil

No oil change periodically

Cylinder head gasket damage

Piston ring worn out

3-3

Page 43

To this chapter contents

3. LUBRICATION SYSTEM

Engine Oil

Turn off engine, and park the ATV in flat surface.

Check oil level with oil dipstick.

Do not screw the dipstick into engine as

checking.

If oil level is nearly low level, fill out

recommended oil to upper level.

Oil Change

Caution

Drain oil as engine warmed up so that makes

sure oil can be drained smoothly and completely.

Place an oil pan under the ATV, and remove oil

drain bolt.

After drained, make sure washer can be re-used.

Install oil drain bolt.

Torque value:3.5~4.5kgf-m

Engine Oil Strainer Clean

Drain engine oil out.

Remove the oil strainer and spring.

Clean the oil strainer.

Check if the `O-ring can be re-used.

Install oil strainer and spring.

Install oil strainer cap.

Torque value:1.3~1.7kgf-m

Refill oil to crankcase (oil viscosity SAE 10W-30)

Recommended using King serial oil.

Engine oil capacity: 2400c.c. when replacing

Install dipstick, start the engine for running

several minutes.

Turn off engine, and check oil level again.

Check if engine oil leaks.

Drain bolt

Oil strainer cap

Oil strainer

3-4

Page 44

To this chapter contents

3. LUBRICATION SYSTEM

3-5

Oil Filter Unit

Remove the oil filter unit with special tool.

Special Service Tool:

Tool No: SYM-1445100

Install the oil filter unit by hand.

Lock the oil filter unit with special tool.

Special Service Tool:

Tool No: SYM-1445100

Torque value:1.3~1.7kgf-m

Drain bolt

Page 45

To this chapter contents

3. LUBRICATION SYSTEM

3-6

Oil Pump

Oil Pump Removal

Remove the recoil starter and the AC Generator.

(Refer to chapter 10) 。

Remove the cir clip and take out the oil pump

sprocket.

Make sure that pump shaft can be rotated freely.

Remove 3 screws on the oil pump, and then

remove the oil pump.

Oil Pump Disassembly

Remove the screws on oil pump cover and

remove the cover.

Remove the oil pump shaft roller and shaft.

Cir Clip

3 screws

1 screw

Roller Pin

Page 46

3. LUBRICATION SYSTEM

Oil Pump Inspection

Check the clearance between oil pump body and

outer rotor.

Limit: 0.25 mm

Check clearance between inner and outer rotors.

Limit: 0.20 mm

Check clearance between rotor side face and

pump body

Limit: 0.12 mm

Oil Pump Re-assembly

Install the inner and outer rotors into the pump

body.

Align the indent on driving shaft with that of inner

rotor.

Install the oil pump shaft and roller.

Install the oil pump cover and fixing pins properly.

Pins

To this chapter contents

3-7

Page 47

To this chapter contents

3. LUBRICATION SYSTEM

3-8

Tighten the oil pump screw.

Oil Pump Installation

Install the oil pump, and then tighten screws.

Torque value:0.1~0.3kgf-m

Make sure that oil pump shaft can be rotated

freely.

Install the oil pump sprocket, and then install cir

clip onto oil pump shaft.

1 screw

Roller

3 screws

Cir Clip

Page 48

To this chapter contents

3. LUBRICATION SYSTEM

Notes:

3-9

Page 49

Home page

Contents

4. FUEL SYSTEM

`

Vacuum Chamber ............................. 4-6

Float Chamber................................... 4-7

Adjustment of Idle Speed................. 4-9

Fuel Tank........................................... 4-10

Air Cleaner ........................................ 4-11

Mechanism Diagram ......................... 4-1

Precautions in Operation ................. 4-2

Trouble Diagnosis............................. 4-3

Carburetor Removal / Installation.... 4-4

Air Cut-off Valve................................ 4-5

Mechanism Diagram

UA60A-6

Fuel tank

Carburetor

Fuel valve

Fuel Strainer

4

Fuel tank cap

4-1

Page 50

4. FUEL SYSTEM

To this chapter contents

Precautions in Operation

General Information

Warning

Gasoline is a low ignition point and explosive materials, so always work in a well-ventilated place and

strictly prohibit flame when working with gasoline.

Cautions

Do not bend off throttle cable. Damaged throttle cable will make unstable drive-ability.

When disassembling fuel system parts, pay attention to O-ring position, replace with new one as

re-assembly

There is a drain screw in the float chamber for draining residual gasoline.

Do not disassemble air cut valve arbitrarily.

Specification

ITEM UA60A-6

Carburetor diameter 35 mm

I.D. number AG8

Fuel level 17 mm

Main injector #132

Idle injector #92

Idle speed 1700±100 rpm

Throttle handle clearance 1~3

Pilot screw 1 1/2

Tool

Special service tools

Vacuum/air pressure pump

Fuel level gauge

4-2

Page 51

To this chapter contents

4. FUEL SYSTEM

Trouble Diagnosis

Poor engine start

No fuel in fuel tank

Clogged fuel tube

Too much fuel in cylinder

No spark from spark plug(malfunction of ignition

system )

Clogged air cleaner

Malfunction of carburetor chock

Malfunction of throttle operation

Stall after started

Malfunction of carburetor chock

Incorrect ignition timing

Malfunction of carburetor

Dirty engine oil

Air existing in intake system

Incorrect idle speed

Rough idle

Malfunction of ignition system

Incorrect idle speed

Malfunction of carburetor

Dirty fuel

Intermittently misfire as acceleration

Malfunction of ignition system

Late ignition timing

Malfunction of ignition system

Malfunction of carburetor

Power insufficiency and fuel consuming

Fuel system clogged

Malfunction of ignition system

Mixture too lean

Clogged fuel injector

Vacuum piston stick and closed

Malfunction of float valve

Fuel level too low in float chamber

Clogged fuel tank cap vent

Clogged fuel filter

Obstructed fuel pipe

Clogged air vent hose

Air existing in intake system

Mixture too rich

Clogged air injector

Malfunction of float valve

Fuel level too high in float chamber

Malfunction of carburetor chock

Dirty air cleaner

4-3

Page 52

4. FUEL SYSTEM

To this chapter contents

Carburetor Removal / Installation

Removal

Remove the fuel tank.

Turn the fuel valve lever on off.

Remove 1 screw from throttle lever cap them

remove throttle lever cap.

Loosen throttle cable adjustment nut and remove

throttle cable

Remove the sleep adjustment wire.

Disconnect the fuel hose and by-starter and drain

tube

Release 2 clamps strip of air cleaner and inner

pipe.

Remove the carburetor.

Installation

Install in reverse order of removal procedures.

throttle cable

adjustment wire

By-starter

1 screw

Drain tube

Fuel hose

2 clamps

adjustment nut

4-4

Page 53

To this chapter contents

4. FUEL SYSTEM

4-5

Air Cut-Off Valve

Disassembly

Remove 2 screws.

Remove air cut-off valve cover, spring and valve.

Inspection

Check the valve is in normal.

If the valve is in normal, it will restrict air-flow.

If air-flow is no restricting, replace carburetor

assembly.

Check the vacuum pipe o-ring is in normal.

Assembly

Install in reverse order of removal procedures.

2 screws

O-ring

Air cut-off valve

Spring

Cover

Page 54

4. FUEL SYSTEM

To this chapter contents

Vacuum Chamber

Disassembly

Removal

Loosen drain screw, and drain out residual fuel in

float chamber.

Remove screws (4 screws) of vacuum chamber

cover and the cover.

Remove compress spring and vacuum piston.

.

Remove fuel needle seat, spring, and injector

needle.

Check if the vacuum piston for wear out, crack or

other damage.

Check if the diaphragm for damage or crack.

Cautions

vacuum chamber cover

Spring

Do not damage vacuum diaphragm.

needle

seat

needle

Spring

vacuum

piston

4 bolts

4-6

Page 55

To this chapter contents

4. FUEL SYSTEM

4-7

Float Chamber

Disassembly

Remove 4 mounting screws and remove float

chamber cover.

Remove the float pin, float and float valve.

Inspection

Check float valve and valve seat for damage,

blocking.

Check float valve for wearing, and check valve

seat face for wear, dirt.

Caution

In case of worn out or dirt, the float valve and

valve seat will not tightly close causing fuel level

to increase and as a result, fuel flooding. A worn

out or dirty float valve must be replaced with a

new a new one.

Float

PinFloat valve

Check for wear or damage

4 Screws

Pin

Float valve

Float

Page 56

To this chapter contents

4. FUEL SYSTEM

Remove main jet, needle jet holder, needle jet,

slow jet and air adjustment screw.

Caution

Take care not to damage jets and adjust screw.

Before removing adjustment screw, turn it all

the way down and note the number of turns.

Does not turn adjust screw forcefully to avoid

damaging valve seat face.

Clean jets with cleaning fluid. Then use

compressed air to blow the dirt off.

Blow carburetor body passages with compressed

air.

Assembly

Install main jet, needle jet holder, needle jet, slow

jet and air adjustment screw.

Caution

Set the air adjustment screw in according to

number of turns noted before it was removed.

Install the float valve, float, and float pin.

Checking fuel level

Caution

Check again to ensure float valve, float for

proper installation.

To ensure correct measurement, position the

float meter in such a way so that float chamber

face is vertical to the main jet.

Fuel level: 14.8mm

Installation of carburetor

Install carburetor in the reverse order of removal.

Following adjustments must be made after

installation.

˙Throttle cable adjustment.

˙Idle adjustment

Air adjustment screw

Float gauge

Needle jet Needle jet holder

Slow jet

Main jet

Lock nut

Rubbe

Throttle adjustment screw

4-8

Page 57

To this chapter contents

4. FUEL SYSTEM

4-9

Adjustment of Idle Speed

Caution

Air screw was set at factory, so no adjustment is

needed. Note the number of turns it takes to

screw it all the way in for ease of installation.

The parking brake must be used to stop the ATV

to perform the adjustments.

Use a tachometer when adjusting engine RPM.

Screw in air adjustment screw gently, then back up

to standard turns.

Standard turns: 2 turns

Warm up engine; adjust the throttle stopper wire of

throttle valve to standard RPM.

Idle speed rpm: 1700 ± 100 rpm

Connect the hose of exhaust analyzer to exhaust

front end. Press test key on the analyzer.

Adjust the pilot screw and read CO reading on the

analyzer

CO standard value: 0.5~1.0 %

Accelerate in gradual increments; make sure rpm

and CO value are in standard value after engine

running in stable. If rpm and CO value fluctuated,

repeat the procedures described above for

adjusting to standard value.

Air adjustment screw

Parking brake

Throttle valve stopper wire

Page 58

To this chapter contents

4. FUEL SYSTEM

4-10

Fuel Tank

Fuel tank removal

Open the seat.

Remove the front cover and front top center cover.

Remove the side covers and lower side covers.

Remove the front fender.

Remove fuel unit wire from tank.

(Covers remove please

refer chapter 13)

remove 2 fuel tubes from fuel valve.

Remove 4 bolts from tank rear side & front side

and then remove fuel tank.

.

Installation

Install the tank in the reverse order of removal.

Fuel unit

4 bolts

Fuel tube

FRONT REAR

Page 59

To this chapter contents

4. FUEL SYSTEM

4-11

Air Cleaner

Removal

Loosen the clamp strip of air cleaner and

carburetor, and then remove the vapor hose.

Loosen the clamp strip of air cleaner, and then

remove the air cleaner vapor hose.

Remove the air cleaner (4 bolts).

Installation

Install the tank in the reverse order of removal.

Cleaning air cleaner element

Remove the air cleaner cover (5 catch hooks).

Remove element mounting screw.

Loosen the clamp strip of air cleaner element.

Clamp

4 bolts

Clamp

Clamp

5 Catch hooks

Page 60

4. FUEL SYSTEM

To this chapter contents

Remove the air cleaner element.

Clean the element with non-flammable or

high-flash point solvent and then squeeze it for

dry.

Caution

Never use gasoline or acid organized solvent to

clean the element.

Soap the element into cleaning engine oil and then

squeeze it out. Install the element onto the

element seat and then install the air cleaner cover.

Element

4-12

Page 61

To this chapter contents

4. FUEL SYSTEM

4-13

Notes:

Page 62

Contents

Home page

5. ENGINE REMOVAL

Precautions in Operation...................... 5-1

Engine Removal .................................... 5-2

Engine Installation ................................ 5-6

Precautions in Operation

General Information

The engine has to be supported with special service tools that can be lifted or adjustable.

The following parts can be serviced as engine being mounted on frame:

Carburetor

Drive pulley, drive belt, clutch, and movable drive face assembly.

Start motor.

AC. Generator, oil pump and start one-way clutch.

Specification

Item Capacity

Replacement 2400 c.c.

Replacement with oil filter changed 2700 c.c.

Engine oil capacity

Disassembly 3000 c.c.

Rear axle gear oil capacity Replacement 100 c.c.

Front differential gear oil capacity Replacement 200 c.c.

Engine & radiator 1980 c.c.

Reservoir 420 c.c.

Coolant capacity

Total 2400 c.c.

5

Torque Value

Engine hanger bolt 7.5~9.5kgf-m

Exhaust muffler mounting bolt 2.8~3.2kgf-m

Exhaust muffler connection nut 1.0~1.4kgf-m

5-1

Page 63

To this chapter contents

5. ENGINE REMOVAL

Engine Removal

Negative

Remove the seat.

Positive

Remove the battery negative terminal (-).

Remove the battery positive (+) terminal.

Remove front fender and the footrest (refer

chapter 13).

Remove the starter motor wire.

Remove the spark plug cap.

Disconnect A.C. Generator wire couplers.

Spark plug cap

A.C.G wire couplers

Starter motor wire

5-2

Page 64

5. ENGINE REMOVAL

To this chapter contents

Remove the front left and rear left tires.

Remove the idle speed adjustment nut.

Remove 2 bolt on the muffler.

Remove the muffler.

Remove the throttle cable.

Remove 2 nuts and 1 bolt.

Remove the exhaust pipe.

Remove the choke cable and ventilation tube.

Remove 2 nuts, and then remove exhaust pipe.

Idle speed adjustment nut

Throttle cable

Choke cable

Ventilation tube

5-3

Page 65

To this chapter contents

5. ENGINE REMOVAL

5-4

Remove 2 manifold clamps.

Remove the carburetor.

Remove 4 bolts.

Remove the air cleaner.

Remove 2 bolts.

Remove the muffler.

Remove 2 nuts and 1 bolt.

Remove the exhaust pipe.

Manifold clamps

4 bolts

2 bolts

2 nuts

Bolt

Page 66

5. ENGINE REMOVAL

To this chapter contents

Remove the coolant drain bolt and drain out

coolant.

Remove the coolant inlet pipe from the water

pump cover and the outlet pipe from the

thermostat cover.

Remove the PCV pipe.

Remove 2 bolts.

Remove the starter motor.

Remove 3 bolts on the front propeller shaft

connector.

Remove the front propeller shaft.

Remove 3 bolts on the rear propeller shaft

connector.

Remove the rear propeller shaft.

Be careful not to do any damage to the rubber

boot.

PCV pipe

Coolant pipe

Starter motor

Rubber boot

2 bolts

3 bolts

3 bolts

Rubber boot

5-5

Page 67

To this chapter contents

5. ENGINE REMOVAL

5-6

Remove the rear brake pedal.

Remove the coolant reserve tank.

Remove the front and rear side engine hanger

mounting nuts and bolts.

Remove left side engine hanger, and then remove

engine by left side.

Engine Installation

Check the bush of engine hanger parts for any

damage.

Install the engine in the reverse procedures of

removal.

Caution

Be careful when removing and installing the

engine.

Do not bend or twist the wires and tubes.

Cables wires have to be routed in accordance

with normal layout.

Engine hanger Bolt:

Torque value: 7.5~9.5kgf-m

3 bolts

2 bolts

Engine hanger

Page 68

6. CYLINDER HEAD/VALVE

6-1

Mechanism Diagram ··························· 6-1

Precautions in Operation ··················· 6-2

Troubleshooting·································· 6-3

Cylinder Head Removal······················ 6-4

Cylinder Head Inspection··················· 6-7

Valve Stem Replacement··················· 6-10

Valve Seat Inspection and Service ··· 6-11

Cylinder Head Reassembly··············· 6-13

Cylinder Head Installation················· 6-14

Valve Clearance Adjustment············· 6-16

Mechanism Diagram

6

0.7~1.1kgf-m

1.0~1.4kgf-m

1.0~1.4kgf-m

1.0~1.2kgf-m

3.6~4.0kgf-m

Home page

Contents

2.4~3.0kgf-m

1.0~1.4kgf-m

1.0~1.4kgf-m

1.0~1.4kgf-m

1.0~1.2kgf-m

Page 69

6. CYLINDER HEAD/VALVE

6-2

Precautions in Operation

General Information

This chapter is contained maintenance and service for cylinder head, valve, and camshaft as well as

rocker arm.

Cylinder head service can be carried out when engine is in frame.

Specification

Item Standard Limit

Compression pressure 12±2 kg/cm2 ---

Intake 36.478 36.458

Camshaft Height of cam lobe

Exhaust 36.847 36.832

ID of valve rocker arm 13.000~13.018 13.098

Rocker arm

OD of valve rocker arm shaft 12.991~13.009 11.936

Intake 4.975~4.990 4.900

OD of valve stem

Exhaust 4.955~4.970 4.900

ID of valve guide 5.000~5.012 5.030

Intake 0.010~0.037 0.080

Clearance between

valve stem and guide

Exhaust 0.025~0.062 0.100

Inner 33.700 30.100

Free length of valve

spring

outer 38.800 35.200

Valve seat width 1.600 ---

Intake 0.10±0.02mm ---

Valve

Valve clearance

Exhaust 0.15±0.02mm ---

Tilt angle of cylinder head --- 0.050

Torque Value

Cylinder head cover bolt 1.0~1.4kgf-m

Exhaust pipe stud bolt 2.4~3.0kgf-m

Cylinder head bolt 1.0~1.4kgf-m

Cylinder head Nut 3.6~4.0kgf-m

Sealing bolt of cam chain auto-tensioner 0.8~1.2kgf-m

Bolt of cam chain auto-tensioner 1.2~1.6kgf-m

Cylinder side cover bolt 1.0~1.4kgf-m

Cam sprocket bolt 1.0~1.4kgf-m

Tappet adjustment screw nut 0.7~1.1kgf-m

Spark plug 1.0~1.2kgf-m

Tools

Special service tools

Valve reamer: 5.0mm

Valve guide driver: 5.0mm

Valve spring compressor

To this chapter contents

Page 70

6. CYLINDER HEAD/VALVE

6-3

Troubleshooting

Engine performance will be affected by troubles on engine top parts. The trouble usually can be

determined or by performing cylinder compression test and judging the abnormal noise generated.

Low compression pressure

1. Valve

Improper valve adjustment

Burnt or bent valve

Improper valve timing

Valve spring damage

Valve carbon deposit.

2. Cylinder head

Cylinder head gasket leaking or damage

Tilt or crack cylinder

3. Piston

Piston ring worn out.

High compression pressure

Too much carbon deposit on combustion chamber or piston head

Noise

Improper valve clearance adjustment