Page 1

1. CONTENTS

1. CONTENTS ........................................................................................................ 1

2. USE GENUINE SPARE PARTS.......................................................................... 3

3. CONTROL LOCATION ....................................................................................... 4

4. SAFE RIDING PRECAUTIONS........................................................................ 14

5. USE OF EACH COMPONENT ........................................................................ 19

Gauges ...................................................................................................................................... 19

Instrument ................................................................................................................................. 20

Function indicator .................................................................................................................... 21

Gearshift indicator .................................................................................................................... 23

Ignition switch ........................................................................................................................... 24

Steering handle lock ................................................................................................................ 25

Use of buttons .......................................................................................................................... 26

Throttle lever ............................................................................................................................. 28

Gearshift lever 1 ....................................................................................................................... 29

Gearshift lever 2 ....................................................................................................................... 30

Seat removal ............................................................................................................................ 31

Fuel tank cap ............................................................................................................................ 32

Brake ......................................................................................................................................... 33

Parking brake ........................................................................................................................... 34

Rear cushion adjustment ........................................................................................................ 35

Accessory socket ..................................................................................................................... 36

6. IMPORTANT POINTS AND CAUTIONS FOR STARTING ENGINE ............... 37

Starting & stopping the engine ............................................................................................... 37

Parking ...................................................................................................................................... 38

1

Page 2

1. CONTENTS

7. INSPECTION AND MAINTENANCE BEFORE RIDING ................................. 39

Brake 1 ...................................................................................................................................... 39

Brake 2 ...................................................................................................................................... 40

Engine oil inspection and change .......................................................................................... 41

Transmission oil inspection and change .............................................................................. 42

Oil filter cleaning ...................................................................................................................... 43

Inspection of fuel level ............................................................................................................ 43

Coolant ...................................................................................................................................... 44

Replenishment of coolant ....................................................................................................... 45

Spark plug replacement & inspection ................................................................................... 48

Battery ....................................................................................................................................... 49

Air cleaner ................................................................................................................................. 51

Fuse ........................................................................................................................................... 52

Tire ............................................................................................................................................. 53

8. TOOL KIT ........................................................................................................ 54

9. PERIODICAL MAINTENANCE SCHEDULE ................................................... 55

10.SPECIFICATION ............................................................................................. 56

11.POSTSCRIPT .................................................................................................. 57

2

Page 3

2. USE GENUINE SPARE PARTS

In order to maintain the ATV best performance, each part’s quality, material, and machined

precision must conform with the design requirements. “SYM Genuine Spare Parts” were

made from the same high quality materials used for the original ATV. No parts would be

sold to the market until they could meet the designed specifications through sophisticated

engineering and stringent quality control. Therefore, it is necessary to purchase “SYM

Genuine Spare Parts” from “SYM Authorized Dealers or Franchised Dealers” when

replacing spare parts. If you buy cheap, or fake substitute parts from the market, no

guarantee can be provided either for the quality or durability. Also, it may result in

unexpected troubles and lower the motorcycle’s performance.

Always use SYM Genuine Spare Parts to keep your ATV pure blood and to ensure its long

service life.

3

Page 4

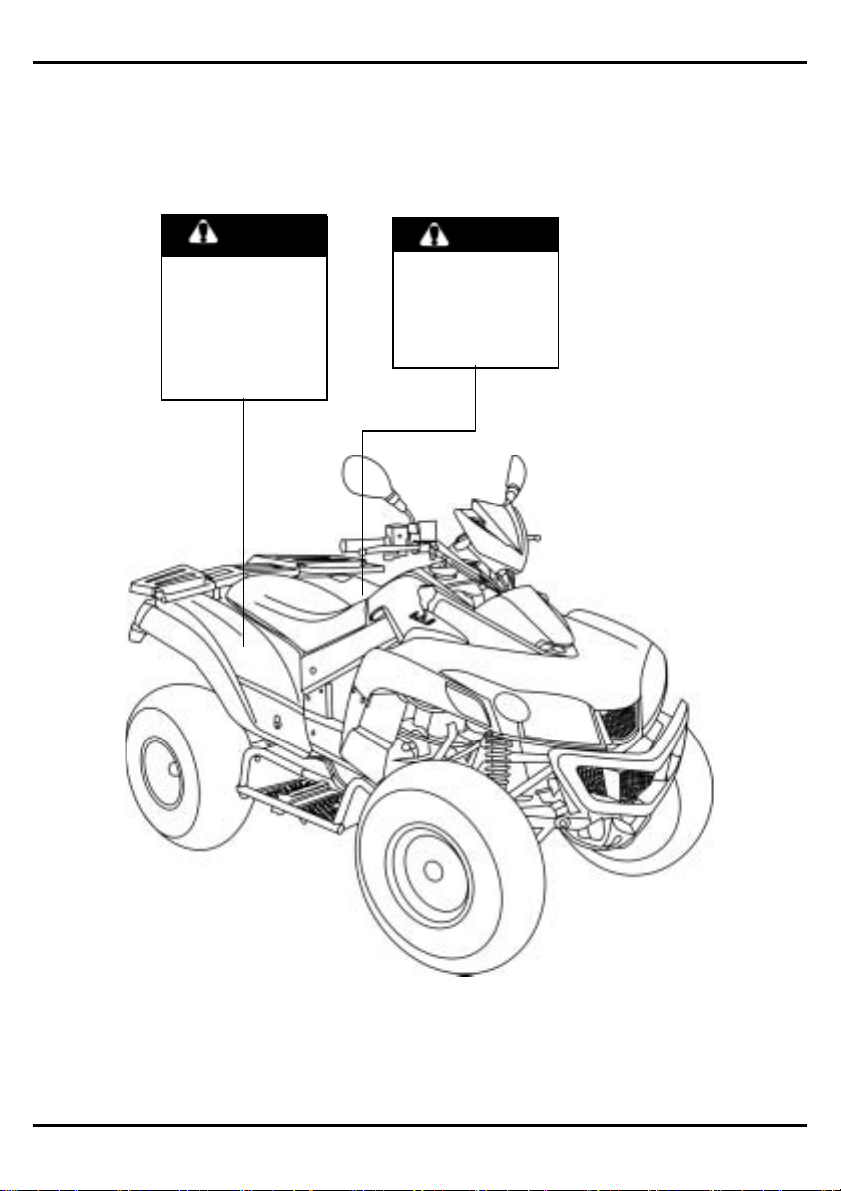

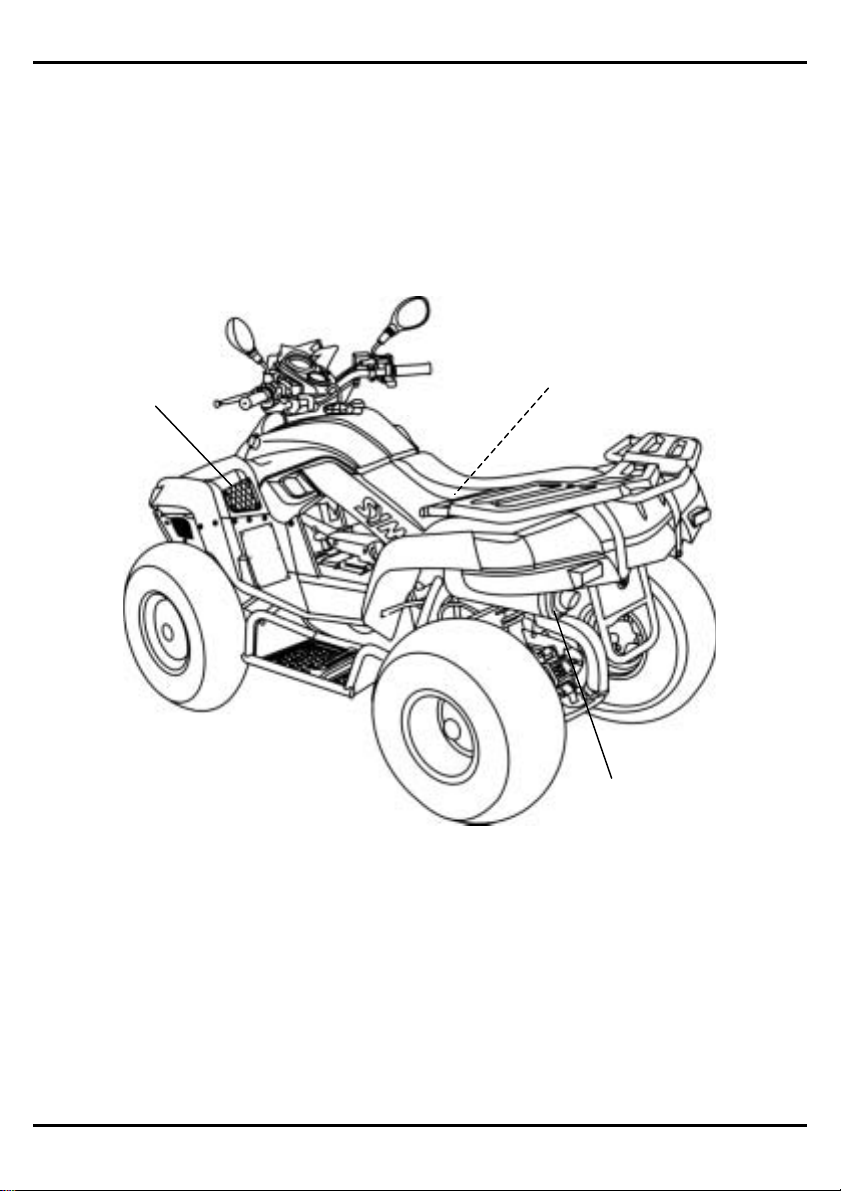

3. CONTROL LOCATION

WARING MARK

WARNING

Improper tire pressure or

Overloading can cause loss of control.

Loss of control can result in

severe injury or death.

COLD TIRE PRESSURE

FRONT :35±1 kpa. 0.35±0.1 kgf/㎠

5±0.2 psi

REAR :35±1 kpa. 0.35±0.1 kgf/㎠

5±0.2 psi

Maximum weight capacity:405 kg

(890 lbs).

WARNING

WARNING

Overloading this ATV or carrying cargo

Improperly can change handling,

stability and braking performance

and can lead to an accident.

Never exceed the maximum rear cargo

Limit(combined weight on the rear rack

And in the storage area) of:30kg(66lbs).

Refer to instructions in the Owner’s

Manual.

4

Page 5

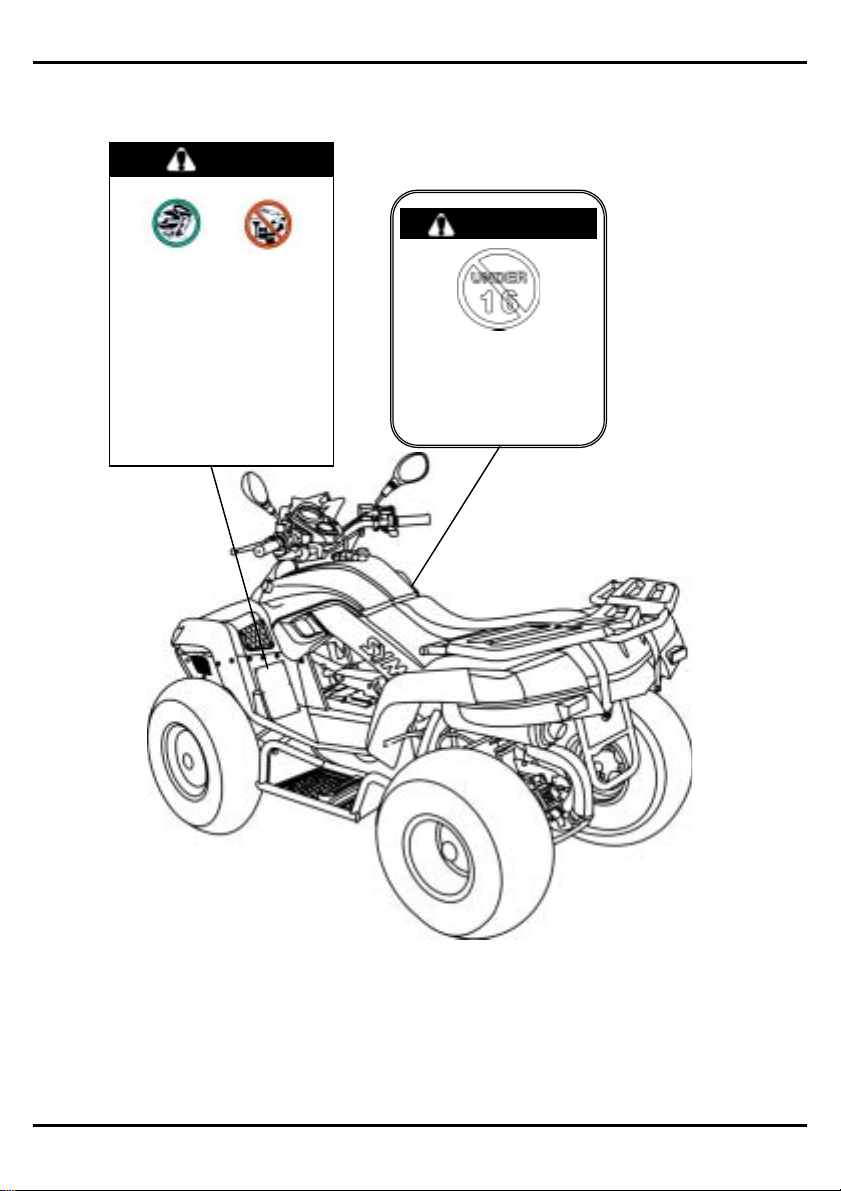

3. CONTROL LOCATION

WARNING

Improper ATV use can result in SEVERE INJURY or DEATH

ALWAYS USE

AN APPROVED

HELMET AND

PROTECTIVE

GEAR

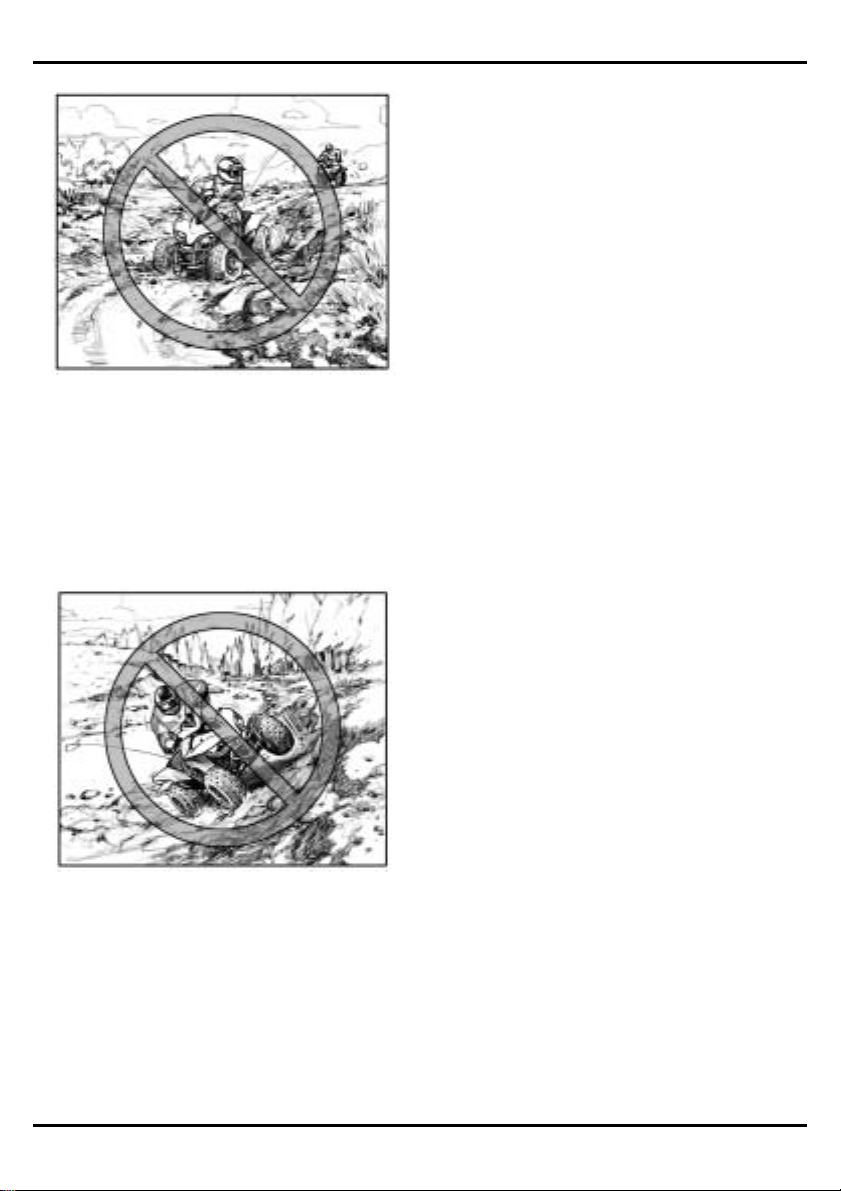

NEVER operate:

y Without proper training or instruction

y At speeds t oo fast for your ski l ls or the conditions

y Do not operat e the vehicl e aft er consuming

DRUGS OR ALCOHOL

ALWAYS:

y Use proper ri di ng tec hniques to avoid vehicle

overturns on hills and rough terrain and in turns

y Avoid paved surfaces-pavement may seriously

affect handling and control

LOCATE AND READ OWNER’S MANUAL.

FOLLOW ALL INSTRUCTIONS AND WARNINGS

NEVER USE

WITH DRUGS

OR ALCOHOL

Operating this ATV if you are under

the age of 16 increases you chance

of severe injury or death.

NEVER

under age16.

WARNING

operate this ATV if you are

5

Page 6

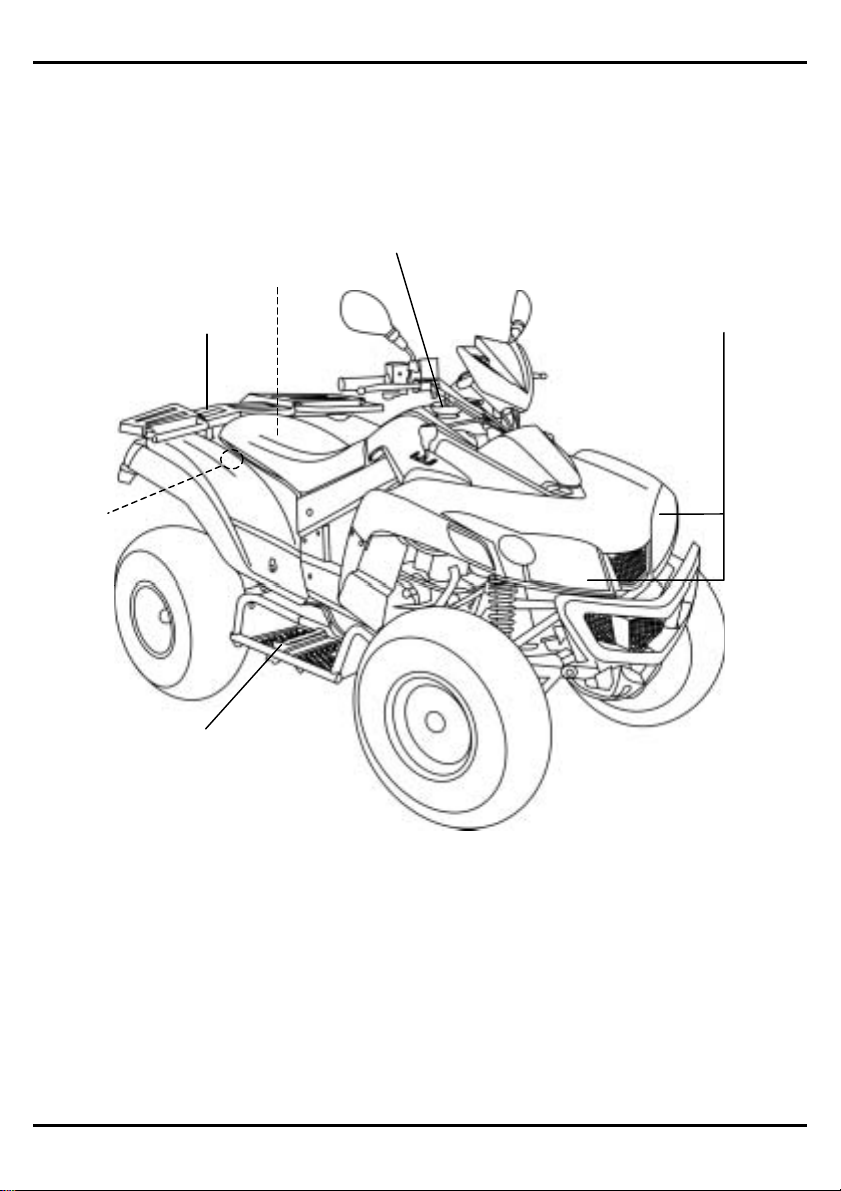

3. CONTROL LOCATION

r

Tool kit compartment

Fuel fill cap

Seat lock leve

Right footpeg

Rear cargo rack

Headlight

6

Page 7

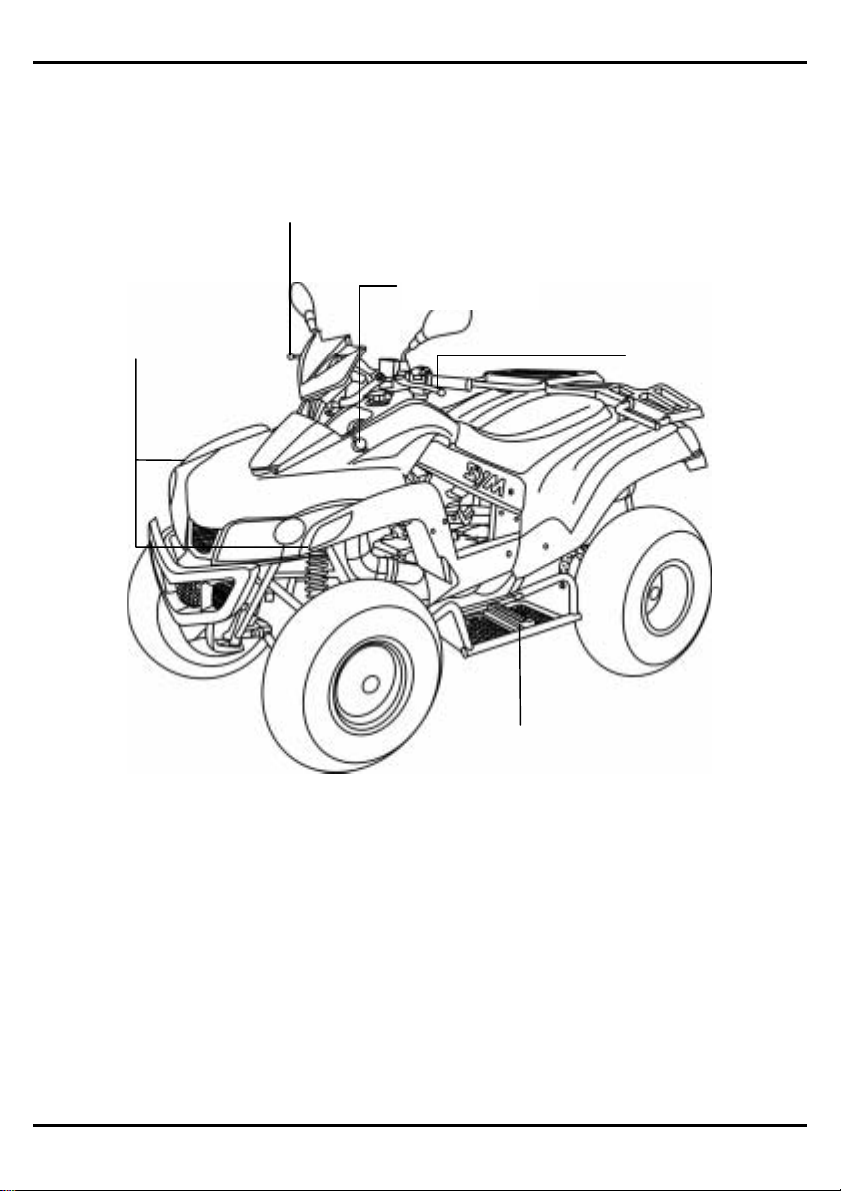

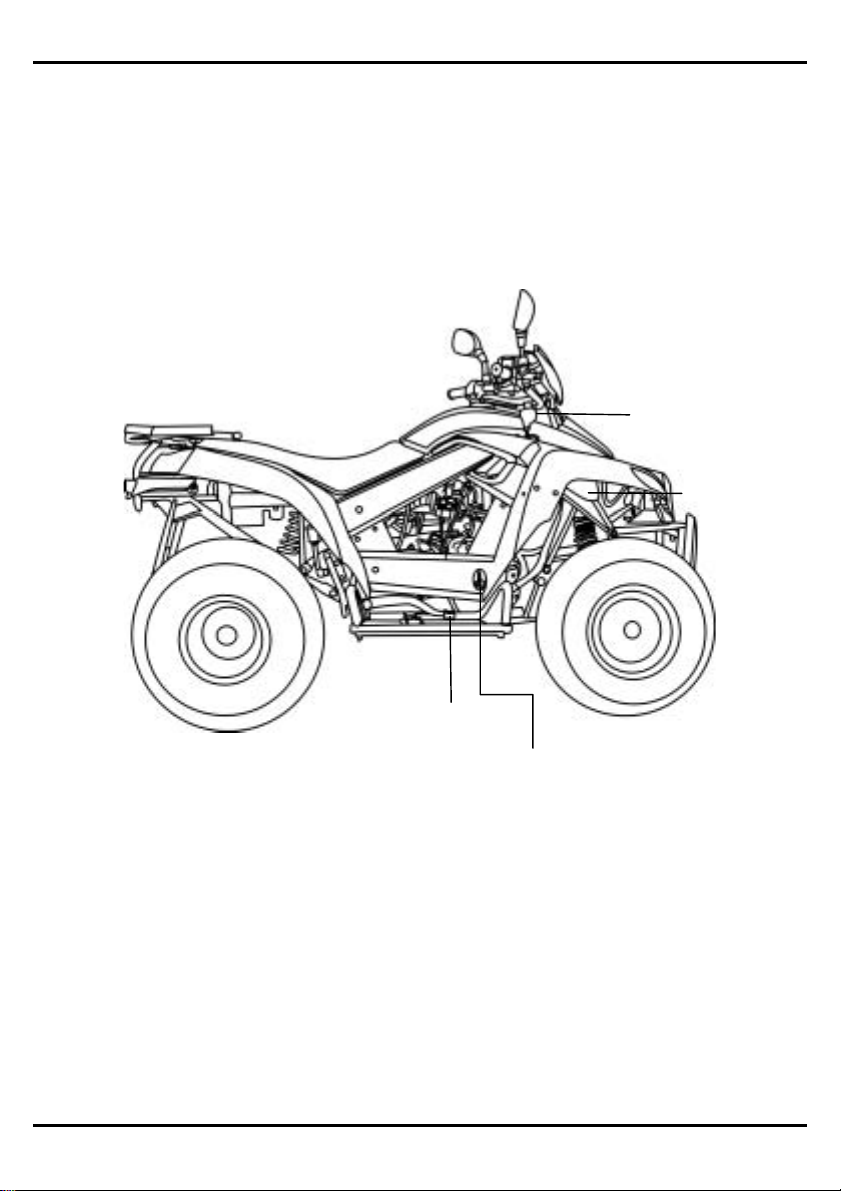

3. CONTROL LOCATION

Front brake lever

Turn signal light

Power supply

Rear brake lever

Left footpeg

7

Page 8

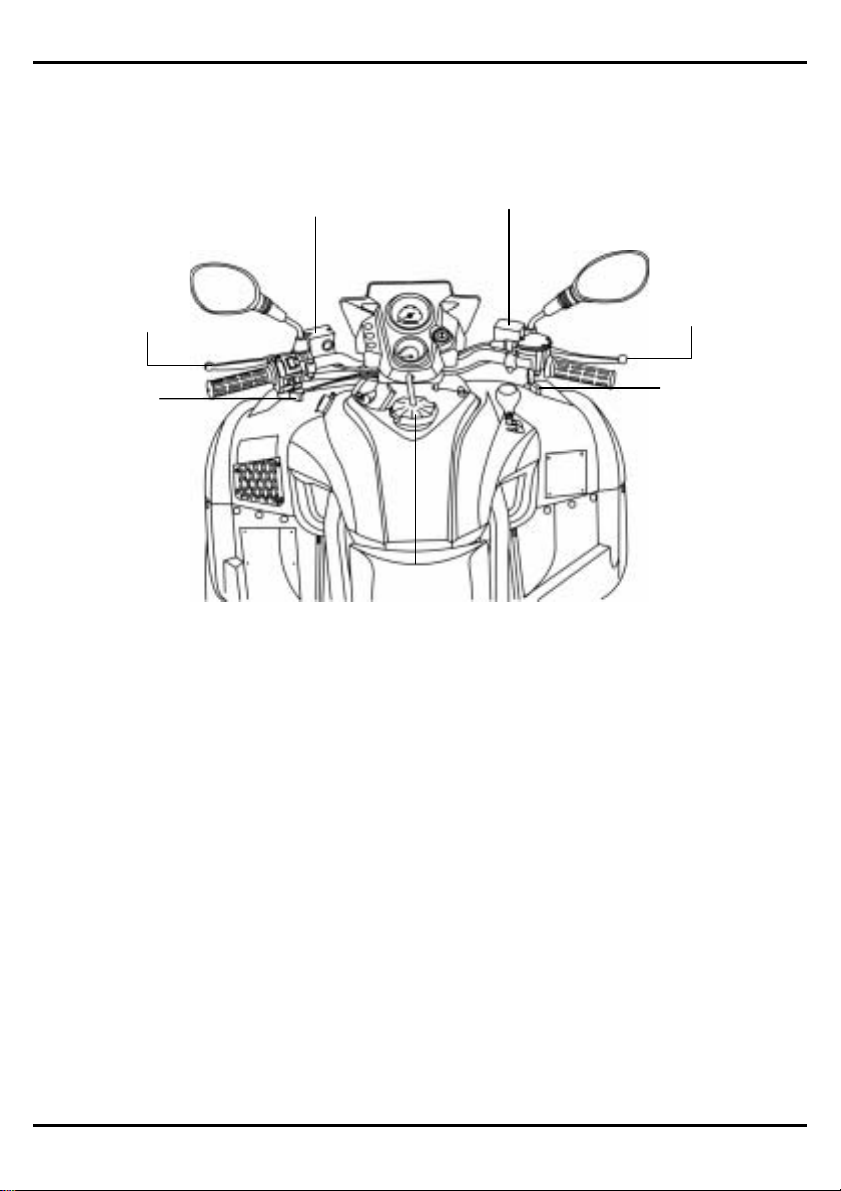

3. CONTROL LOCATION

Setting at basket

Air cleaner

Muffler

8

Page 9

3. CONTROL LOCATION

Gearshift lever

Coolant reserve

tank

Rear brake pedal

Oil filler cap

9

Page 10

3. CONTROL LOCATION

Rear brake fluid lever

Choke Lever

Rear brake fluid reservoir

Front brake fluid reservoir

Front brake fluid lever

Throttle

Fuel fill cap

10

Page 11

3. CONTROL LOCATION

y Operating this ATV if you are under the

age of 16 increases you chance of

severe injury or death.

y Do not operate after consuming alcohol

or drugs.

y Operator’s performance capability is

reduced by the influence of alcohol or

drugs.

11

Page 12

3. CONTROL LOCATION

y Know the terrain where you ride. Ride

cautiously in unfamiliar areas. Stay alert

for holes, rocks, or roots in the terrain,

and other hidden hazards which may

cause the machine to upset.

y Be familiar the terrain where you ride.

You may not have enough time to react

on the unfamiliar terrain such as hidden

rocks, bumps, or holes. Be sure to go

slowly any carefully when operating on

unfamiliar terrain.

12

Page 13

3. CONTROL LOCATION

y If your ATV has stalled or stopped and

you believe you can continue up the hill,

restart carefully to make sure you do not

lift the front wheels which could cause

you to lose control. If you are unable to

continue up the hill, dismount the ATV

on the uphill side. Physically turn the

ATV around and then descend the hill.

y Avoid wheelies and jumping. You may

lose control of the machine or overturn.

13

Page 14

4. SAFE RIDING PRECAUTIONS

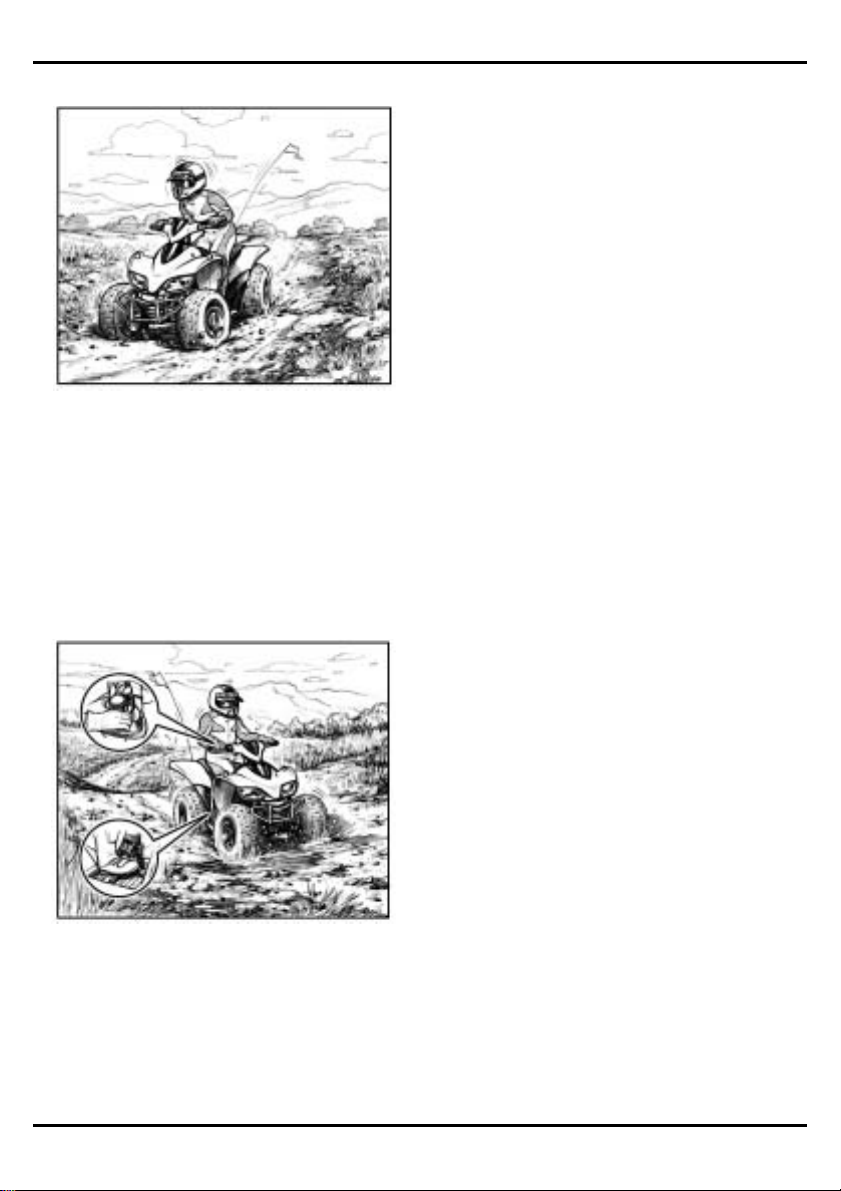

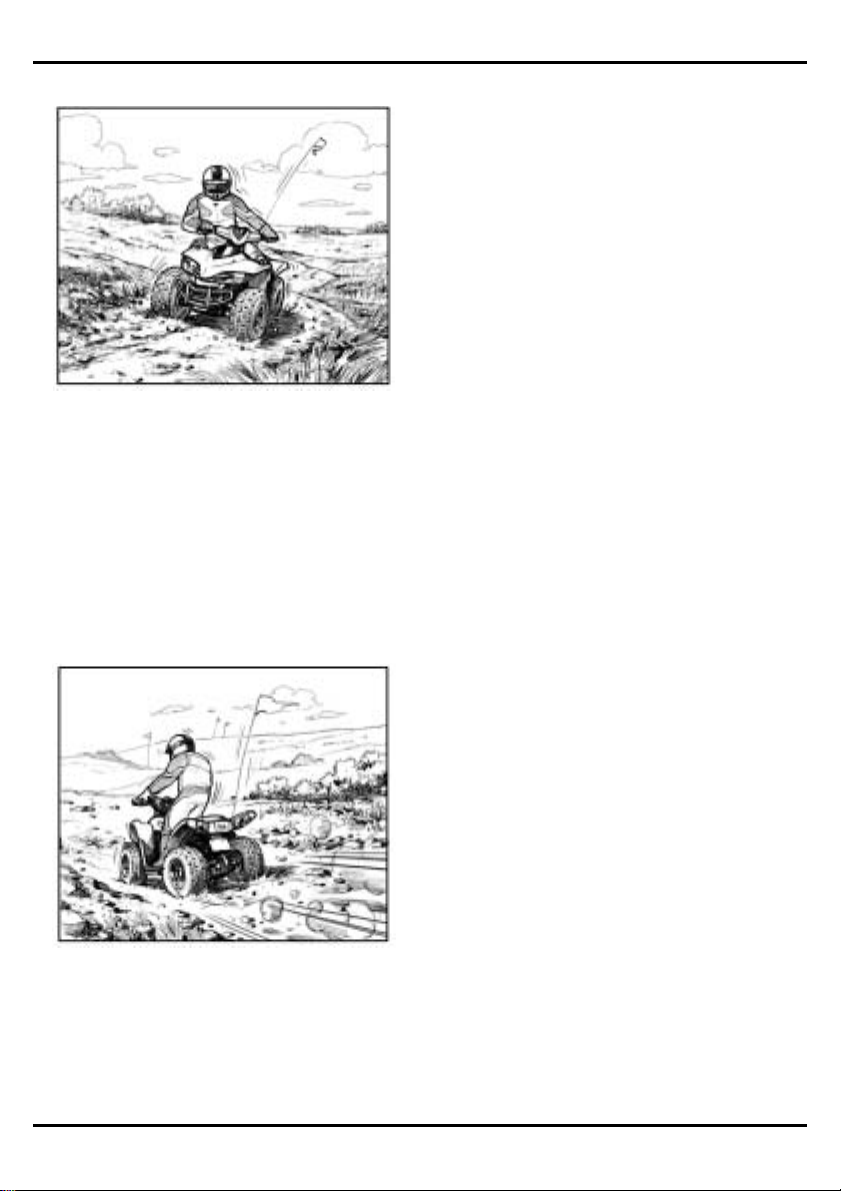

To make a turn on level ground:

y Steer the handleb ar and lean your body

toward the inside of the turn. Leaning

helps balance the vehicle, and it feels

more comfortable. Leaning into a turn is

an important technique to master in

riding an ATV.

y When approaching a curve, slow down

and begin to turn the handlebar. Next,

put your weight on the footboard to the

outside of the turn(opposite the turning

direction) and lean your upper body

forward into the turn. Use the throttle to

maintain an even speed during the turn.

To make a sharp turn at low speed:

y It helps to shift your body slightly

forward on the seat, and lean inside, as

you steer the handlebar. Shifting weight

forward allows the rear wheels to turn

easier, and it also improves front-wheel

steering

.

14

Page 15

4. SAFE RIDING PRECAUTIONS

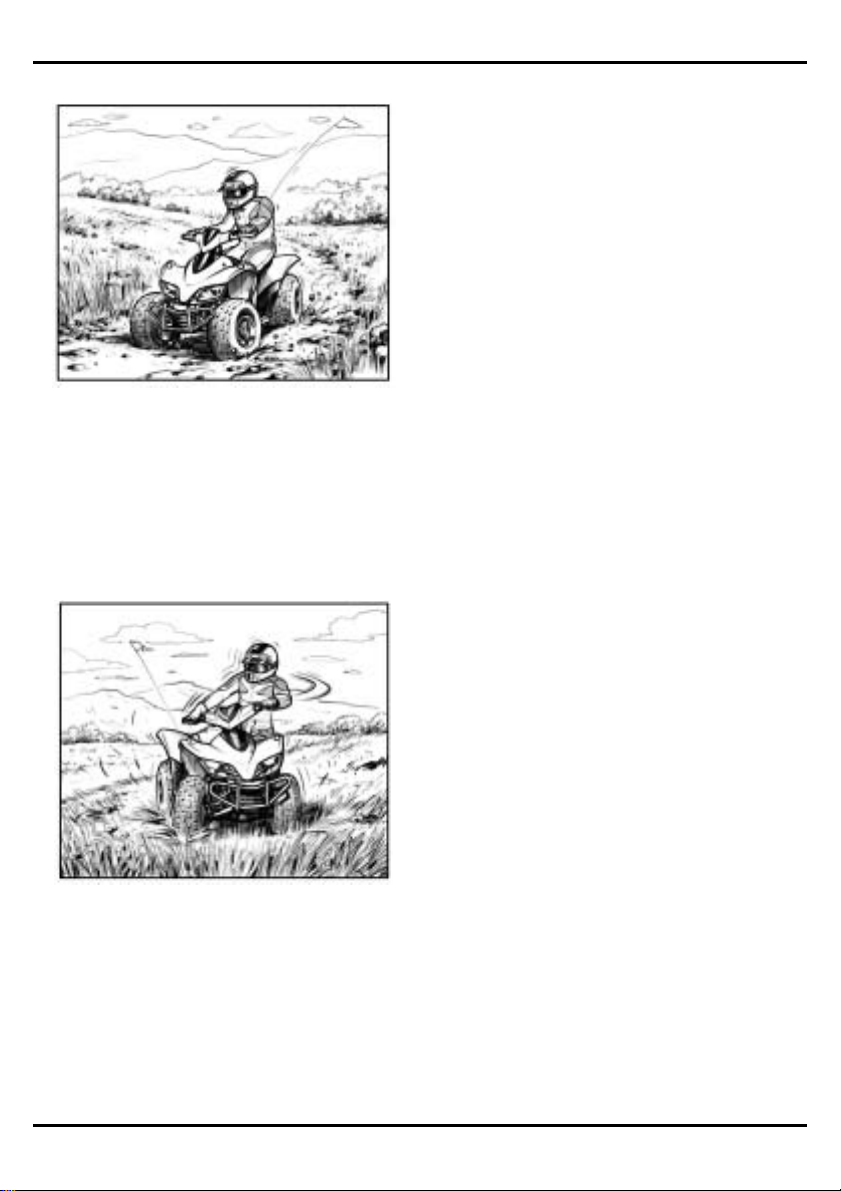

y Travel when easy slippery road surface,

moves the body to front, is helpful to the

vehicles advance.

y Although the from and rear brakes h ave

separate controls, your ATV’s fourwheel drive interconnects all four

wheels. So operating any brake con will

cause braking at both the front and rear

wheels.

y As a general rule, the front braking

system provides about 70 percent of

total stopping power.

y For full braking effectiveness, use both

the pedal and lever simultaneously.

Using braking systems will stop your

ATV faster with greater stability.

y Test your brakes after leaving the water.

Do not continue to ride your ATV without

verifying that you have regained proper

braking ability.

15

Page 16

4. SAFE RIDING PRECAUTIONS

Crossing Hills or Slopes

y To maintain balance and stabilit y when

riding across a slope, you need to shift

weight toward the uphill side of the

vehicle. To do this, move your body off

the center of the seat and lean toward

the uphill side.

y Avoid hills with extremely slippery or

loose surfaces. Shift your weight to the

uphill side of the ATV.

y Avoid crossing hills that are e xcessively

steep, slippery or rough.

Making Turns on Slopes

y Compared to rid ing on level ground, you

may need to shift more weight ant lean

more when making turns on slopes.

y When ATV travel when rugged not good

path, the body slightly stands, is helpful

to the travel when the bodily stability.

y The ATV may slide during riding on

loose or slippery surfaces. To reduce

the tendency for the front wheels to slide

in loose or slippery conditions,

positioning your weight over the front

wheels will help.

y If the rear wheels of ATV start to slide

sideways, steer in the direction of the

slide carefully. Applying the brakes or

accelerating is not recommended until

you have corrected the slide.

16

Page 17

4. SAFE RIDING PRECAUTIONS

y Crossing a sloping surface requires a

properly position on your weight to

maintain proper balance. Be sure that

you have learned the basic riding skills

on flat ground before crossing a sloping

surface. Avoid slopes with slippery

surfaces or rough terrain that may upset

your balance.

y When traveling across a slope, lean

your body in the uphill direction. It may

be necessary to front wheels slightly

uphill. When riding on slopes, do not

make sharp turns.

y If ATV does start to tip over, gradually

steer in the downhill direction if there are

no obstacles. Once recover proper

balance, gradually steer again in the

direction you to go.

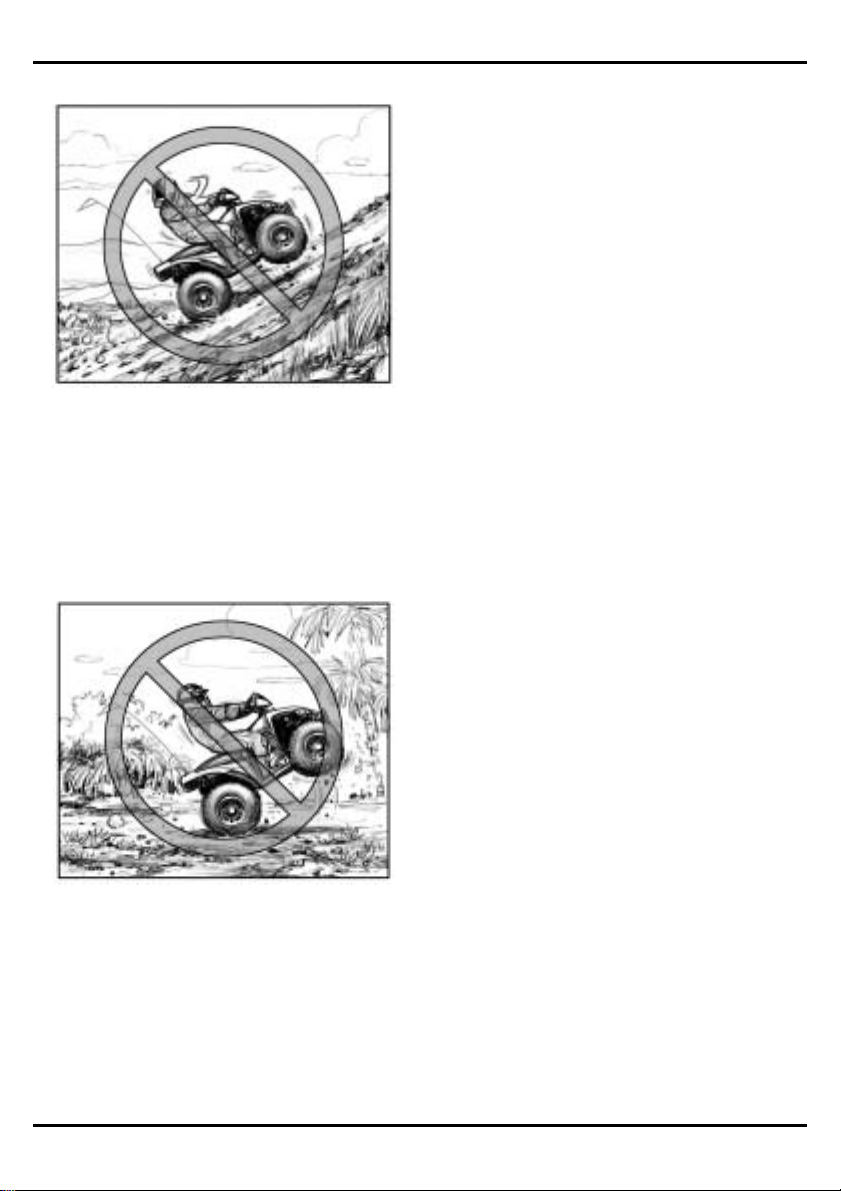

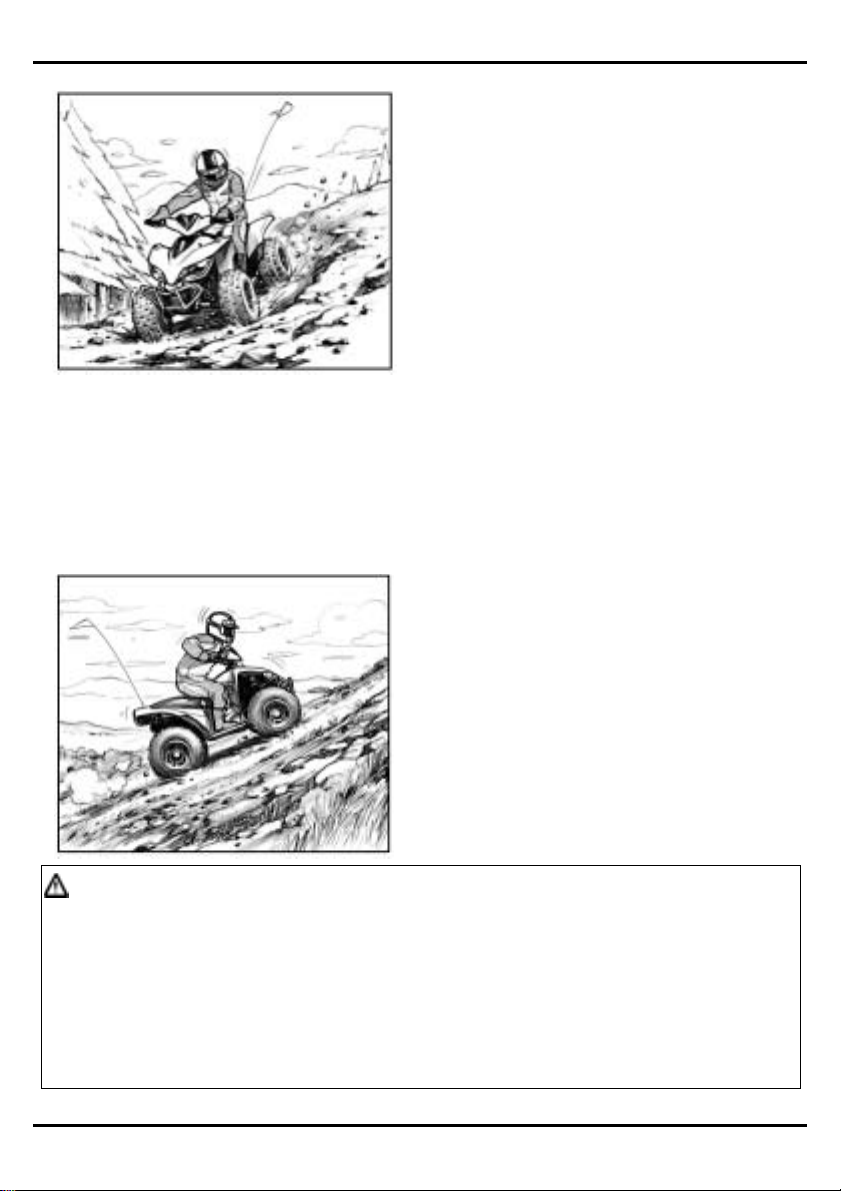

y When climbing hills, you must shift

weight toward the front wheels to help

keep them on the ground. To do this,

shift your body slightly forward on the

seat and lean forward. For greater

weight shift, move your body father

forward and lean forward.

CAUTION:

y Always check the terrain carefully before you startup any hill.

y Never climb hills with excessively slippery or loose surfaces.

y To climb a hill, take a running start in an appropriate gear and speed for the conditions.

Maintain a steady speed as you ascend the hill.

y Never open the throttle suddenly or make sudden gear changes. The ATV could flip

over backward.

y Never go over the top of any hill at high speed. An obstacle, a sharp drop, or another

vehicle or person could be on the other side of the hill.

17

Page 18

4. SAFE RIDING PRECAUTIONS

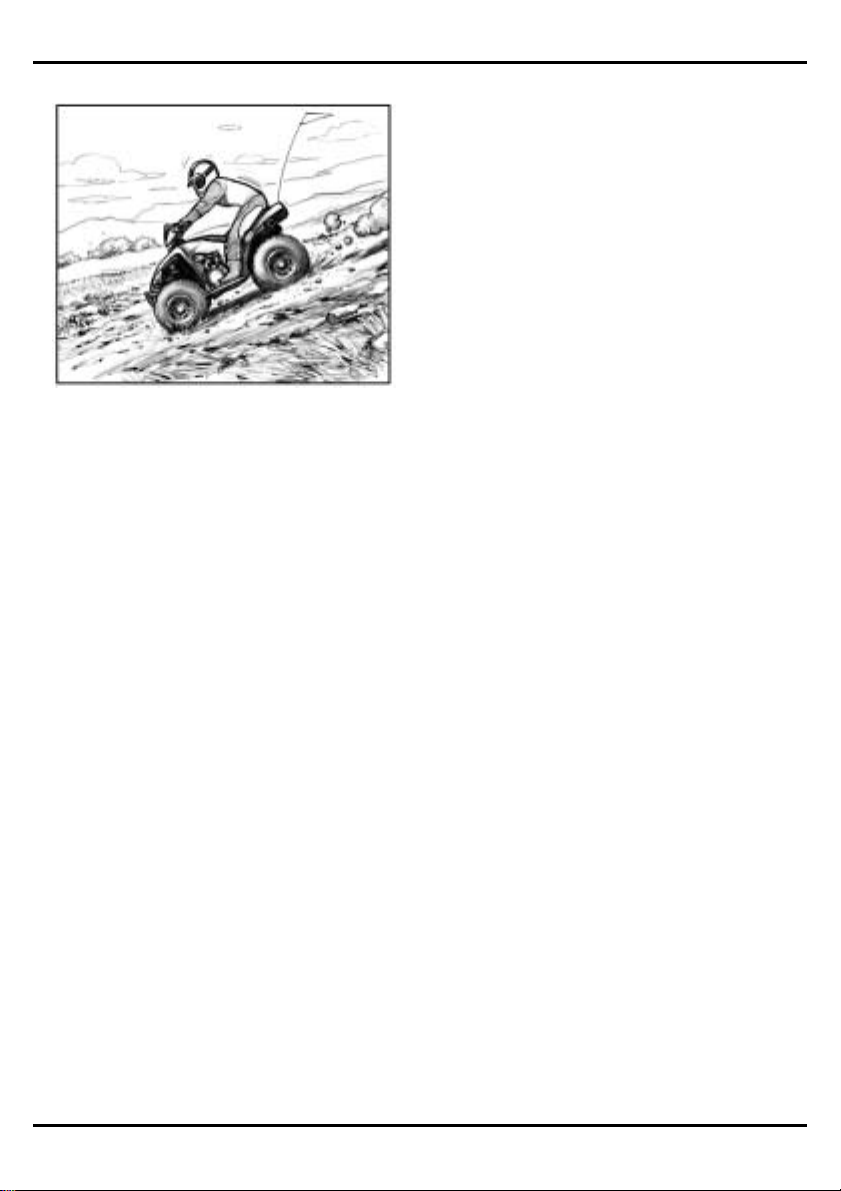

y It’s usually advisable to descend hills

with the ATV pointed straight downhill.

Avoid angles that would cause the

vehicle to lean sharply to one side.

y On downhills, shift your weight back.

y As you approach a downhill, stop and

survey the terrain below. Never ride

past the limit of your visibility. Never go

down a hill at high speed.

y Use mainly the rear brake to control

speed. Avoid using either the front

brake or rear brake hard or abruptly

when riding down hills.

y Remember, braking effectiveness is

reduced on any hill with a loose

surface.

18

Page 19

5. USE OF EACH COMPONENT

Gauges

The following is SYM ATV basic operation. The indicators and displays on your ATV keep

you informed, alert you to possible problems, and make your riding safer and mor e

enjoyable.

⑴

⑶

(1) Instrument:

Speedometer、Odometer

⑷

⑵

(2) Function indicator:

Water temperature indicator、High beam indicator、Turn signal Indicator、Fuel gauge

(3) Gearshift indicator:

Forward indicator、Neutral indicator、Reverse indicator

(4) Ignition switch:

The ignition switch is used for starting and stopping the engine.

19

Page 20

5. USE OF EACH COMPONENT

Instrument

⑴

⑵

(1) Speedometer:

This shows your speed in kilometers per hour (km/h) and in mileage per hour(mph).

(2) Odometer:

This odometer shows the total kilometers this motor has been driven.

20

Page 21

5. USE OF EACH COMPONENT

Function indicator

⑶

⑴⑵

(1) Water temperature indicator:

Lights when coolant temperature is high enough to adversely affect the service life of

the engine.

If the coolant high temperature indicator comes on while you are riding, immediately

bring the vehicle to a stop, turn the engine off and let it cool.

(2) High beam indicator:

This indicator comes on when the high beam headlight switch is turned on.

(3) Turn signal Indicator:

The left or right Indicator will be flashing according to the operated directions of turn

signal light switch when it is turned on.

21

Page 22

5. USE OF EACH COMPONENT

Function indicator

(1)

(1) Fuel gauge:

The pointer in this gauge shows how much fuel remains in the tank.

The pointer stays in “E” position when key switch is turned to “OFF.”

When key switch is turned to “ON”, and the “pointer” also in “E” position (red area).

Refuel immediately.

22

Page 23

5. USE OF EACH COMPONENT

Gearshift indicator

⑴

⑵

⑶

(1) Forward indicator:

Use this position to ride forward.

Use this position for normal riding.

(2) Neutral indicator:

Lights when the transmission is in neutral.

Use neutral when you star the engine, or if it is necessary to stop briefly with the

engine idling.

(3) Reverse indicator:

Lights when the transmission is in reverse.

Use this position to ride reverse.

23

Page 24

5. USE OF EACH COMPONENT

Ignition switch

⑵

⑴

(1) “ ” position:

y Engine can be started in this position.

y Ignition switch key can not be removed.

(2) “OFF” position:

y Engine is shut off and can not be started in this position.

y Ignition switch key can be removed.

24

Page 25

5. USE OF EACH COMPONENT

Steering handle lock

(1)

(1) Steering handle lock

The steering handle lock is located on the steering stem

directly below the steering head.

y Turn the steering handle fully to the left

y Insert the ignition switch key into the lock

y T urn the key clockwise, then the steering handle can be locked.

y Remove the Ignition switch key.

y When unlocking, simply turn the key anti-clockwise.

NOTE:

y For preventing the vehicle to be stolen, lock the handle bar when parked.

y After locked, turn of the handle bar left and right to make sure it.

y When leaving the vehicle, remember to remove the key.

25

Page 26

5. USE OF EACH COMPONENT

Use of buttons

Left handle - switch 1

⑵

(1) Electrical Starter Button

This is a starting motor button (switch) for engine starting.

With the main switch "ON", press this button while holding the front or rear

brake lever will start the engine.

⑴

⑶

(2) High/Low Beam Switch

This is for high beam.

This is for low beam. (Please turn to low beam when riding in city)

When the switch is turned to this position, all lights will go off.

(3) Hazard Switch

The main switch in the〝 ON 〞 position, cuts according to this switch, four

directions lantern festivals dodge extinguish do move, also can simultaneously

dodge on the display board direction indicating lamp extinguishes d oes moves.

If stops the vehicle has when the transportation frequent dangerous position or

the vehicle the breakdown, may use the dangerous police to show the switch.

The cut to this position, on four directions lamps and the display board direction

indicating lamp namely extinguishes.

26

Page 27

5. USE OF EACH COMPONENT

⑵

Use of buttons

Left handle - switch 2

⑴

⑶

(A)

(B)

(1) Turn Signal Light Switch

Right-side turn signal light flashing means you intend to make a right turn.

Left-side turn signal light flashing means you intend to make a left turn.

(2) Horn Switch

Press this button down when ignition switch is in the “ON” position to sound, the horn.

(3) Choke lever

y 〝(A)〞fully OFF ,〝(B)〞fully ON.

y When the engine starts possibly can use reaches this point choke lever.

y If the engine is will be cold, Choke lever transfers completely dials to ON (A) the position.

y In the festival throttle value closed situation, presses the start button.

27

Page 28

5. USE OF EACH COMPONENT

Throttle lever

(A)

⑴

(B)

(1) Throttle lever control

(2) Acceleration :

Pulls the pole with the thumb pressure to be possible to advance engine rpm.

(A) Deceleration :

The release pulls on the pole the pressure, then reduces the engine rpm.

28

Page 29

5. USE OF EACH COMPONENT

Gearshift lev er 1

The gearshift lever has three position: Forward (F)、Neutral (N)、Reverse (R).

Neutral (N)

Use neutral when you start the engine, or if it is necessary to stop briefly with the engine

idling.

Forward (F)

Use this position for normal riding.

Reverse (R)

Use this position to ride in reverse.

If you need to ride in reverse, make sure the area behind you is clear and only operate the

ATV at low speed.

CAUTION:

y Improperly operating reverse could cause you to hit an obstacle or person behind you,

resulting in serious injury.

y Make sure there are no obstacles or people behind you before selecting reverse gear.

When it is safe to proceed, go slowly.

29

Page 30

5. USE OF EACH COMPONENT

Gearshift lev er 2

1.Bring the vehicle to a complete stop, then make sure the transmission is in neutral.

2. Depress and hold down the rear brake level.

3.Be sure there are no obstacles or people in the way.

4.Correctly to catch the rod to disperse into to the R files.

CAUTION:

y If the gearshift lever is moved while the vehicle is moving, the sub transmission may be

damaged.

y If the gearshift lever is moved while the engine revolution is over 3200rpm, the engine will

stop revolving to protect the sub transmission.

y Please always keep the gearshift lever in ‘N’ position when ATV is stop moving.

5.Release the rear brake level.

6.Open the throttle gradually and ride slowly. Do not open the throttle suddenly or make

abrupt turns.

30

Page 31

5. USE OF EACH COMPONENT

Seat removal

(1)

1.Pull the seat lock lever(1) at the Underneath of the seat.

2.The slippery seat back and lifts it.

31

Page 32

5. USE OF EACH COMPONENT

Fuel tank cap

(3)

(2)

(1)

(1) Fuel fill cap

(2) Breather tube

(3) Fuel gauge

FUEL INSPECTION

y Turn main switch key to "ON" position, and check fuel gauge's needle range to make

sure there is enough amount of fuel in the fuel tank.

y This engine is designed for using the unleaded fuel of Octane 90 or above.

y Firmly secure the main stand on the ground, shut off the engine and keep flames away from

the motorcycle when refueling.

y Do not fill above fuel upper limit level when refueling.

y Fuel tank capacity 7.8liters, the red line area oil mass is 2 liters

32

Page 33

5. USE OF EACH COMPONENT

Brake

(1)

(3)

(1) Rear brake lever

The rear brake lever is used to slow or stop your ATV .To operate, pull the lever.

(2) Front brake lever

The front brake lever is used to slow or stop your ATV .To operate, pull the lever.

(3) 4W brake pedal

The rear brake pedal is used to slow or stop your ATV .To operate, depress the pedal.

(2)

y Use front and rear wheel brakes simultaneously when braking.

y Avoid unnecessary sudden braking as this may lead to the wheels locking and the ATV

going out of control.

y Avoid applying the brakes continuously for a long period of time because that may

overheat the brakes and reduce its braking efficiency.

y Slow down and brake early when riding in rainy days on slippery roads. Never apply the

brakes suddenly to prevent the wheels locking and sliding.

33

Page 34

5. USE OF EACH COMPONENT

Parking brake

(A)

(1) Lock lever

(2)

(1)

(2) Front brake lever/parking lever

(A) To lock

y T he lock lever(1)on the front brake lever(2)allows it to be used as a parking brake. To

operate, first squeeze the front brake lever and then lock it with the lock lever.

y Before using parking brake, please make sure your ATV is parking on a flat surface.

34

Page 35

5. USE OF EACH COMPONENT

Rear cushion adjus tment

hard

soft

y The front and rear suspension are both adjustable.

y The rear cushion is 5 stage adjustable type. It's set at 3rd stage when manufactured, and

you can adjust it depending on your need. Turn counterclockwise to harden it, and turn

clockwise to soften it.

y Turn counterclockwise to harden it, and turn clockwise to soften it.

y Mark sure adjust both cus hio n at the same time to be sure the riding stability.

35

Page 36

5. USE OF EACH COMPONENT

Accessory socket

⑶

⑵

⑴

(1) Power supply comp

(2) Accessory socket

(3) Cap

The accessory socket (2) is attached to the left side of the body . You can use the

accessory socket to power a trouble light, spotlight, radio, or cell phone, etc.

CAUTION:

y Do not plug in any head-generating accessory such as an automobile cigarette lighter

because it can damage the socket.

y Do not use the socket in raining day.

y Do not splash water or other liquid on socket when using the socket.

To use accessory socket, turn the ignition switch ON to start the engine. Then turn the

headlights OFF , and open the accessory socket cap(3).

36

Page 37

6. IMPORTANT POINTS AND CAUTIONS FOR STARTING ENGINE

Starting & stopping the engin e

For yours safety, please avoid in the seal area, for example the garage, the start or does

moves the engine. In your ATV waste gas includes the virulent carbon monoxide, can fast

gather in the seal area and can cause the disease or the death.

(1)

(2)

(1) Ignition switch

(2) Neutral indicator

1.Before starting, Select level surface and lock the parking brake .

2.Turn ignition switch key to the “ON” position.

3.The transmission is in NEUTRAL (neutral indicator(2)light on)

4.In the festival throttle value closed situation, presses the start button.

5.Immediately after the engine starts, operate the chock lever to keep fast idle.

6.If idling is unstable, open the throttle slightly.

CAUTION:

y Under a second rolling the electrically operated start button surpasses 5 seconds, then

possibly can cause the starter heat or the damage. Wants in front of the recompression

releases this starter button approximately 10 seconds.

y Before start the engine, be sure that install the battery onto the vehicle. Otherwise the

electrical components. would be damaged.。

y Do not run the engine without the battery fitted on the vehicle.

37

Page 38

6. IMPORTANT POINTS AND CAUTIONS FOR STARTING ENGINE

Parking

y Lock for lever parking area. Make sure the ground surface is firm.

y After bringing your ATV to a stop, hold the brakes while you shift into neutral.

y Set the parking brake.

y Turn the ignition switch OFF.

y If it is necessary to start the engine when your ATV is stopped on a grade in gear, rock

the vehicle back and froth to allow shifting the transmission into neutral.

38

Page 39

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Brake 1

Stops ATV in the level ground, the inspection oil level has in the lower limit?

39

Page 40

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Brake 2

(Replenishment of brake fluid)

1.Loosen the screws and remove the master cylinder cover.

2.Wipe clean foreign materials , dirt around the reservoir, being careful not to let foreign

materials fall into the reservoir.

3.Remove the diaphragm plate and the diaphragm.

4.Add brake fluid to upper level.

5.Install the diaphragm plate and the diaphragm, and install the master cylinder cover. nstall

the diaphragm plate and the diaphragm, and install the master cylinder cover.

6.Please note the diaphragm direction, and do not let foreign materials fall into the reservoir.

And tighten the master cylinder cover securely.

CAUTION:

y To prevent chemical reaction, please do not use brake fluids other than those

recommended.

y Do not fill above the upper limit when adding brake fluid and avoid dropping on

painting or plastic components to prevent damage.

40

Page 41

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Engine oil inspection and change

(1)

Upper limit

Lower limit

(1) Engine oil

INSPECTION

1. Uses main parking places standpoint ATV in the level ground, will remove the oil gauge

later to stop in the engine the 3~5 minute. Wipes the oil mass oil to count with then inserts

it to enter the drive pipe again (Do not rotate it.)

2.Remove the dipstick and check whether oil level is in between the upper and lower marks.

OIL CHANGE:

y Change engine oil after the first 300km or first month, and change the engine oil every

1000km or 3 months thereafter. Clean oil filter after the first 300km or first month, and

clean oil filter every 1,000km or 3 months.

y In order to maintain the engine’s maximum performance, check whether the engine oil

is enough every month. Add oi l to upper limit if the engine oil has been found to be

inadequate.

y Engine Oil : Use API SH, SAE 10w-30 grade or better engine oil. Otherwise, damage

will not be covered by warranty.

41

Page 42

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Transmission oil inspection and chang e

INSPECTION:

y When ATV is stopped in the level ground, stop the engine and wait 3~5 minutes, Wipe

the transmission oil screen and check whether the oil level is above lower limit or not.

OIL REPLACEMENT:

y Stop the engine on a level ground. Remove the infusion bolt and drain bolt, drain out

the oil.

y Install the drain bolt and tighten it. Fill ne w transmission oil (650 c.c.), and install the infusion

bolt and tighten it. (make sure that bolts are tightened and check that there’s no leakage.)

※ Recommend Oil: Genuine SYM HYPOID GEAR OIL (SAE 85W-140).

42

Page 43

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Oil filter cleaning

Open the filter nut assembly of the element, and remove the element. Remove the

foreign materials from the element by using a gasoline or air spraying gun.

WARNING:

y Oil level will not be correct when checking the oil level with the motorcycle parked on an

unleveled ground or immediately after the engine stopped.

y Engine and exhaust pipe are hot right after engine stopped. Pay special attention not to

get burned when checking or replacing engine oil.

Inspection of fuel level

y Uses main parking places standpoint ATV in the level ground,, turn the main switch to

“ON” position, check if the fuel meter needle moves.

y Fuel gauge may be defective or electric circuit disconnected if there is some fuel in the

tank, but the needle does not move. Pleas e ride slowly to an authorized service

station to have your ATV checked.

WARNING:

y Do not check the fuel level or refuel while the engine is running. It is not necessary to start

engine to check the fuel level.

y Make sure fuel cap on tank is closed tightly before riding ATV.

y Do not run engine in an enclosed space. Ensure proper ventilation as exhaust fumes

may be dangerous and over exposure to same may result in illness, injury or death.

y There is a danger of fire and explosion when handling fuel. Never refuel in an enclosed

space.

y Do not over fill the fuel tank.

y Do not spill fuel onto hot engine or related parts.

43

Page 44

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Coolant

(2)

(1)

(1) Main radiator

(2) Reserved tank

Maintaining the coolant will allow the cooling system to work properly and prevent freezing,

overheating, and corrosion.

COOLING SYSTEM INSPECTION

1. Stops ATV in the level place

2. Check reserved tank from viewing window to see if coolant level is between the upper

limit and lower limit mark.

3 Add coolant up to upper mark if coolant is close to the lower mark.

44

Page 45

7. INSPECTION AND MAINTENANCE BEFORE RIDING

(1)

(2)

(3)

(1) Reserved tank

(2) UPPER level mark

(3) LOWER level mark

(Check the cooling system for leakage)

y Check radiator and piping for leakage.

y Check the ground where the vehicle is parked for water dripped from the vehicle.

Replenishment of c oolant

Always keep radiator cap tightly closed.

1.Support vehicle on a level ground.

2.Remove the front cover.

y Open reserved tank cap, refill coolant until reaches the upper limit.

y If coolant level becomes too low and occurs too often, it may indicate there is something

wrong with the coolant system.

y To avoid radiator getting rusty, do not use coolants other than those recommended.

45

Page 46

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Coolant recommended: SYM Bramax radiator agent

Concentration: 50%

Radiator capacity:: Main radiator: 800 c.c.

Reserved tank: 350 c.c.

CAUTION:

y Use soft water when mixing coolant.

y Please pay special attention that using poor quality coolant may shorten the service life

of the radiator.

y Coolant should be changed once a year normally.

CAUTION:

y Please refer to a table showing what percentage of anti-freeze should be used

under different temperatures if the vehicle is to be operated in the low temperature

areas. (below 0℃)

46

Page 47

7. INSPECTION AND MAINTENANCE BEFORE RIDING

A reference table for anti-freeze concentration percentages under different temperatures

1. Radiator anti-freeze specification for this ATV is H68. (SYM Bramax radiator agent)

2. Proper anti-freeze percentages for different frozen temperatures are as follows:

Anti-freeze percentage Frozen temperature Remark

20% -8

30% -15

40% -24

50% -36

3. If the specified anti-freeze is unavailable, use an equivalent with the same high quality.

4. Increase radiator maintenance intervals when the weather is extremely cold.

50% concentration is

used for all ATV before

delivery to ensure the

effectiveness of antifreeze.

CAUTION:

y Removing the radiator cap while the engine is hot can cause the coolant to spray out,

seriously scalding you.

y Always let the engine and radiator cool down before removing the radiator cap.

47

Page 48

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Spark plug replacement & inspection

(1)

(1) Spark plug cap

0.8mm

CHECKING THE SPARK PLUG

y Remove the cap of spark plug cable (remove the spark plug using the spark plug wrench

in the tool kit.

y Check the electrode if it is dirty or fouled by carbon deposits.

y Remove the carbon deposits on the electrode with steel wire, and clean the spark plug

with gasoline, then, wipe dry with a rag.

y Check the electrode, and adjust its gap to 0.8 mm. (Check it with a feeler gauge)

y Hand tight the spark plug as far as it can go and then tighten it another 1/2~3/4 turns with

a wrench.

CAUTION:

y The engine is extremely hot after running. Allow ATV to cool completely before

removing the spark plug to avoid being burned or other possible injury.

※Use only spark plugs suitable for the engine specifications of this motorcycle

recommended by the manufacturer. (Refer to specifications.)

48

Page 49

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Battery

The storage battery is located underneath the seat.

(1)

(2)

(1) Battery

(2) Battery band

1. make sure the ignition switch is OFF.

2. Remove the seat.

3. Release the rings and remove the rubber band.

4. Disconnect the negative (-) terminal lead from the battery first, then disconnect the

positive(+) terminal lead.

5. Remove the battery.

6. Only if you have regularly ride otherwise charges the battery.

7. Store your battery in an easy to obtain location off the floor, in an area protected from

freezing temperature and direct sunlight.

8. Slow charge the battery once every 30 day

.

49

Page 50

7. INSPECTION AND MAINTENANCE BEFORE RIDING

INSTALLATION

1. Install in reverse order of removal.

2. Check all bolts and other fasteners are secure.

Negative

Positive

CAUTION:

y Keep the ATV battery clean. If the battery’s posts are corroded and/or are covered with

white powder clean them with warm water.

y If there is obvious corrosion on the battery terminals, disconnect the battery cables and

remove the corrosion with a steel brush.

y If the battery needs to be replac ed, replace with a same closed-type battery (Maintenance-

Free).

CAUTION:

y This ATV uses a sealed type (Maintenance-Free) battery; never remove the battery caps.

y In order to prevent electrical leakage and self-discharge when the battery sits idle for long

periods of time, remove the battery from ATV and store it in a well-ventilated and dimly

lighted area. Store battery out of reach of children. If the battery is to be kept on the

ATV, disconnect the battery’s negative cable.

y Replace the battery cables after cleaning and apply a thin coat of grease to the battery

terminals when reconnecting the same.

50

Page 51

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Air cleaner

(1)

(1) Retainer clips

《DISASSEMBLE PRCEDURE》

1. Remove mounting screws from air cleaner cover.

2. Remove the air cleaner cover, then remove filter element.

3. Take the element out and clean it. (Refer to maintenance schedule.)

《ASSEMBLE PRCEDURE》

Assemble the air cleaner in reverse order of disassemble. Before put the filter

element in, please add about 10g SAE30 oil on the element to keep the ability of

filtering.

CAUTION:

y Dust deposit is one of the major causes of reducing output horsepower and increasing fuel

consumption.

y Change the air cleaner element more frequently to prolong the engine’s service life if the

ATV is driven on dusty area very often.

y If air cleaner is installed improperly, dust will be absorbed into cylinders, which may cause

a premature wear and reducing output power and engine life.

y Be careful not to soak the air cleaner when washing the ATV. Otherwise, it will cause

engine hard to start.

51

Page 52

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Fuse

Fuse box is on the frame body, remove the seat then you can see the fuse box is on the

frame body right side. Turn off ignition switch, and check fuses if they are intact. Replace

the blown fuse with a new one having the same specified amperage rating (30A or 15A or

10A). Using a fuse which the amperes is larger than specification, a brass or iron wire to

replace a blown fuse is strictly prohibited to avoid damaging the electrical system and the

circuit.

• Remove the seat, and you’ll find the fuse box near light.

• Open the fuse box cover, and pull out the fuse. Check it for damage or broken.

• Fuses must be firmly secured with wire connectors when replacing. Loose connections will

result in overhead and damage.

• Use only parts having the specified specification to replace electrical components such as

light bulbs. Using parts not having the specified specifications for replacement may cause

the fuse to blow and over-discharge the battery.

• Avoid spraying water directly on or around fuse box when washing the ATV.

• Take your ATV to your dealer for an inspection if a fuse is blown by unknown causes.

52

Page 53

7. INSPECTION AND MAINTENANCE BEFORE RIDING

Tire

AIR PRESSURE

The suitable gasification barometric pressure tire provides is holding controls, the tire

mileage and rides while comfortableness and so on an aspect best combination. Generally

speaking, the barometric pressure is insufficient the tire can wear unevenly, regarding holds

controls as well as has many possibly can because the adverse effect which the heat so that

damages. The barometric pressure excessively high tire, can cause you rides while ATV

when to be able to cause the automobile body even more production to beat, and easily

receives the damage and the non-uniform attrition because of the ground interference.

Make sure the valve stem caps are secure. If necessary, install a new cap.

TIRE INSPECTION

• Tires should be checked and inflated with the engine shut off.

• If a tire’s ground contacting curve is abnormal, check it with an air pressure gauge and

inflate it to the specified pressure to meet applicable standard before riding.

• Tires pressure must be checked when the tire is cool.

• Visual check tires for frontal and lateral side walls for crack or damage.

• Visual check tires for any nails or small stones wedged in the tread.

• Check the “tread wear indicator” condition to see if tread groove depth is insufficient.

• A tire with a wear bar showing is worn out and should be replaced immediately.

TIRE REPLACEMENT

Is designed in your ATV tire matches your ATV the

performance, and provides in holds controls, in the ghost

vehicle and the comfortable best combination.

Best each time 4 in turn together replace, however if is

impossible time, you must pair make the replacement,

and the use and the original factory same size and the

pattern tire replaces, the single do not replace a tire.

CAUTION:

y Installs not the suitable tire on ATV, can affect the vehicles to hold controls the nature

and the stability. And possibly can cause the collision, causes personn el's casualties.

y The usual use suggests the use in this vehicle owner handbook the tire size and the

pattern..

The suggestion use on your ATV vehicle tire is:

Front : AT22×7-10 / Rear: AT22×10-9、3.8 ±0.2psi

53

Page 54

8. TOOL KIT

This tool bag is the storage underneath the seat in the storage room storage box.

The tools in the kit are sufficient to perform routine maintenance and simple repairs.

(1)

(1) Tool kit

The tool kit includes the following items:

※Standard / phillips screwdriver

※ 10╳12mm open end wrench

※ 14╳17mm open end wrench

※ spark plug wrench

※ tool bag

54

Page 55

9. PERIODICAL MAINTENANCE SCHEDULE

Maintenance

Item

Check Items

1 Air cleaner element(Remark) IC R

2 Fuel filter IIR

3 Oil filter(Screen) CC

4 Engine oil change R Replacement for every 1,000KM or 1 months

5 Tire, pressure II

6 Battery inspec tion II

7 Brake & free ply check II

8 Steering handle check II

9 Cushion operation check II

10 Every screw tightening check II

11 Gear oil check for leaking II

12 Spark plug check or change IIR

13 Gear oil change R Replacement for every 5,000KM or 5 months

14 Frame lubrication L

15 Exhaust pipe II

16 Ignition timing II

17 Emission check in idling AI

18 Throttle operation II

19 Engine bolt tightening II

20 CVT driving device (belt) IR

21 CVT driving device (roller) C

22 Drive chain I/L I/L C

23 Lights/electrical equipment/multimeters II

24 Fuel lines II

25 Cam chain II

26 Valve clearance IA

27 Lines&connections in cooling system II

28 Coolant reservoir II

29 Coolant II R

kilometer

Maintenance Interval 1 Month 3 Months 6 months 1 Year

300KM

Every

1,000KM

Every

3,000KM

Every

6,000KM

Every

12,000KM

Remarks

☆The above maintenance schedule is established by taking the monthl y 1,000 kilometers

as a reference which ever comes first.

※Have your ATV checked and adjusted periodically by your SYM Authorized Dealer or

Franchised Dealer to maintain the ATV at the optimum condition.

Code:I ~ Inspection, cleaning, and adjustment R ~ Replacement

C ~ Cleaning (replaced if necessary) L ~ Lubrication

Remark: 1.Clean or replace the air cleaner element more often when the ATV is operated on

dusty roads or in the Heavily- polluted environment.

2.Maintenance should be performed more often if the ATV is frequently operated in

high speed and after the ATV has accumulated a higher mileage.

Preventine maintenance

3.

a. Ignition system-Perform maintena nce and check when continuous abnormal

ignition, misfire, after-burn, overheating occur.

b. Carbon deposit removal-Remove carbon deposits in cylinder head, piston

heads, exhaust system when power is obvious lower. Than ever

【Notes in the remarks are used to indicate the applicable models.】

55

Page 56

10. SPECIFICATION

Model

Item Specification

length 1,890 mm

width 1,055 mm

Height 1,115 mm

Wheel base 1,200 mm

Net Weight 223kg

Type 4- stroke 4V electroplated cer amic cylinders engine

Fuel UNLEADED(OCTANE 92 OR HIGHER)

Cooling type Water-cooled

Displacement 249.4

Compression ratio 10.5:1

Max. HP 19.2 ps / 6,500 rpm

Max. torque 2.28 kgf-m / 5,500 rpm

Starting methods Electrical & foot type

Front shock absorber UNIT SWING

Rear shock absorber UNIT SWING

Clutch Centrifugal type

Transmission CVT

Front tire AT 22X7-10

Rear tire AT 22X10-9

Tire pressure Front : AT22×7-10 /Rear: AT22×10-9、3.8 ±0.2psi

Front brake Disc type (Ø 175 mm)

Rear brake Disk type (Ø 220mm)

Front light bulb(high, low) 12V 55W / 55W X 2

Brake light bulb(tail light) 12V 5W/21W X2

License light bulb 12V 5W

Turn signal light bulb 12V 21W×4

Speedometer light bulb 12V 1.7W

Engine oil capacity 1.4L( 1.2L for change)

Transmission oil capacity 750cc( 650cc for change)

Fuel tank capacity 12L

Fuse 30A X 1 15A X 2 10A X 1

Spark plug NGK CR8E

Battery capacity YTX12-BS

Air cleaner sponge wet type

Front light General type

Rear grab frame

UA25A-6

Can not load cargo

56

Page 57

11. POSTSCRIPT

SYMEN 2005/05

57

Loading...

Loading...