Sylvania SRDV-495 Service manual

SERVICE MANUAL

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

I Exploded views

I Parts List

Sec. 2: Deck Mechanism Section

I Standard Maintenance

I Alignment for Mechanism

I Disassembly/Assembly of Mechanism

I Alignment Procedures of Mechanism

I Deck Exploded Views

I Deck Parts List

DVD RECORDER &

VIDEO CASSETTE RECORDER

SRDV495

OPEN/CLOSE

PLAYREWPOWER F.FWD STOP/EJECT

VCR

RECORD

CHANNEL

DUBBING

VCR DVD

OUTPUT SELECT

STOP PLAY

DVD

RECORD

S-VIDEO VIDEO L - AUDIO - R

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and

described in this service manual ar e effective methods of perf orming service

operations. Some of these service special tools should be used when and as

recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk of

personal injury to service personnel. The possibility exists that improper service methods may damage the equipment. It also is important to understand

that these CA UTIONS and NO TICES ARE NO T EXHAUSTIVE. Funai could not

possibly kno w , ev aluate and advice the service trade of all conceiv ab le wa ys

in which service might be done or of the possible hazardous consequences of

each way. Consequently, Funai has not undertaken any such broad evaluation. Accordingly , a servicer who uses a service pr ocedure or tool which is not

recommended by Funai must first use all precautions thor oughly so that neither his safety nor the safe operation of the equipment will be jeopar dized by

the service method selected.

Manufactured under license from Dolby Laboratories. "Dolby" and

the double-D symbol are trademarks of Dolby Laboratories.

MAIN SECTION

DVD RECORDER &

VIDEO CASSETTE RECORDER

SRDV495

Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

I Exploded Views

I Parts List

TABLE OF CONTENTS

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2-1

Important Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4-1

Preparation for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

How to Initialize the DVD Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6-7

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7-1

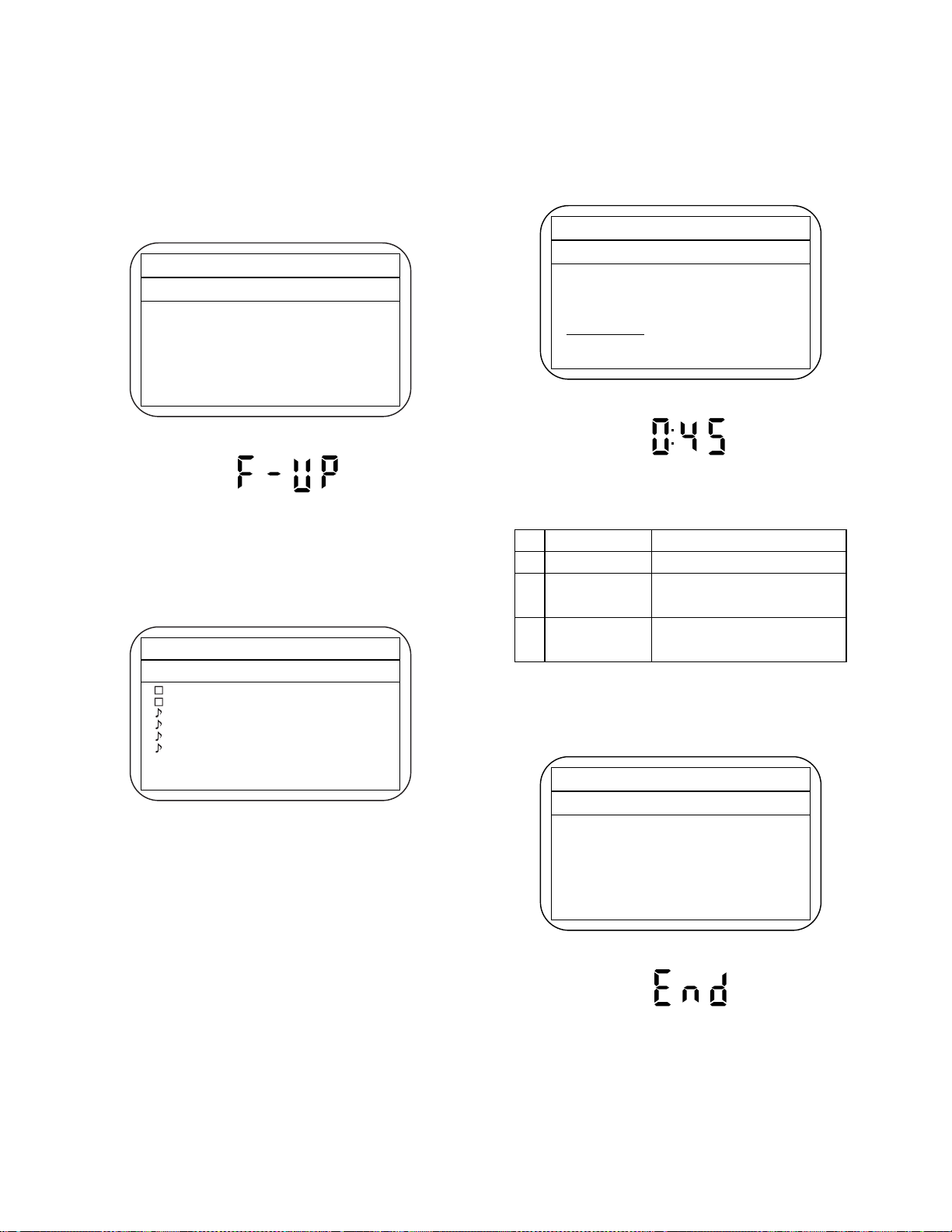

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8-1

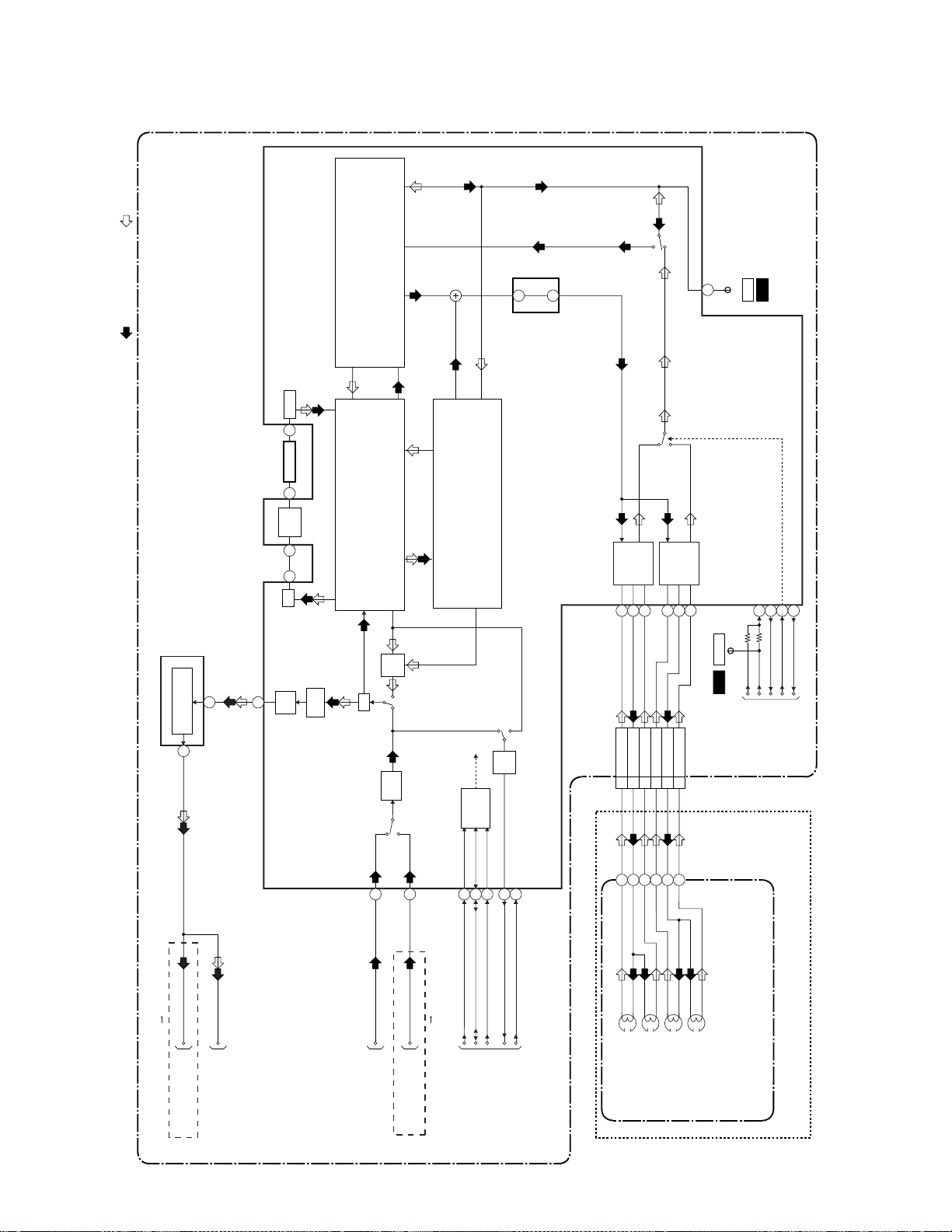

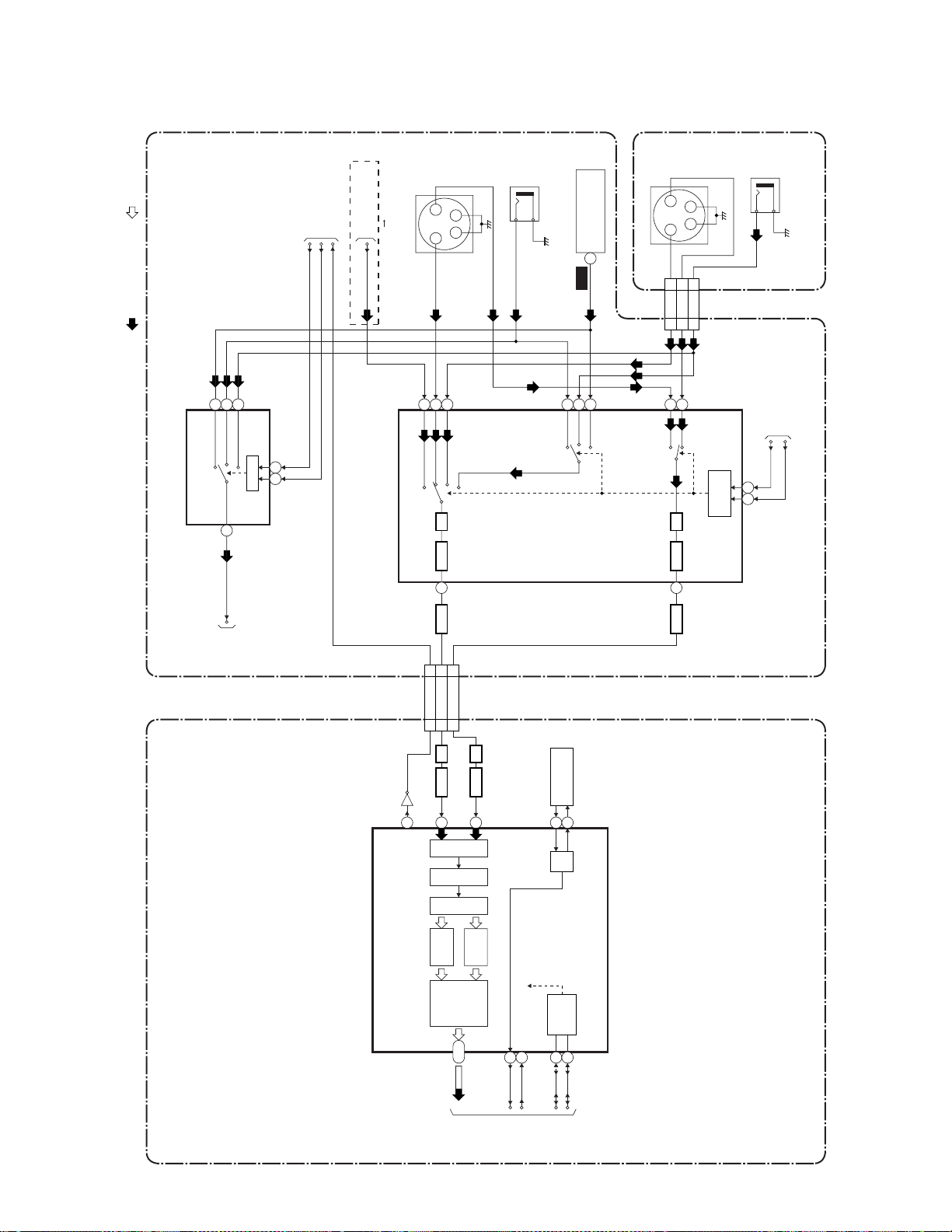

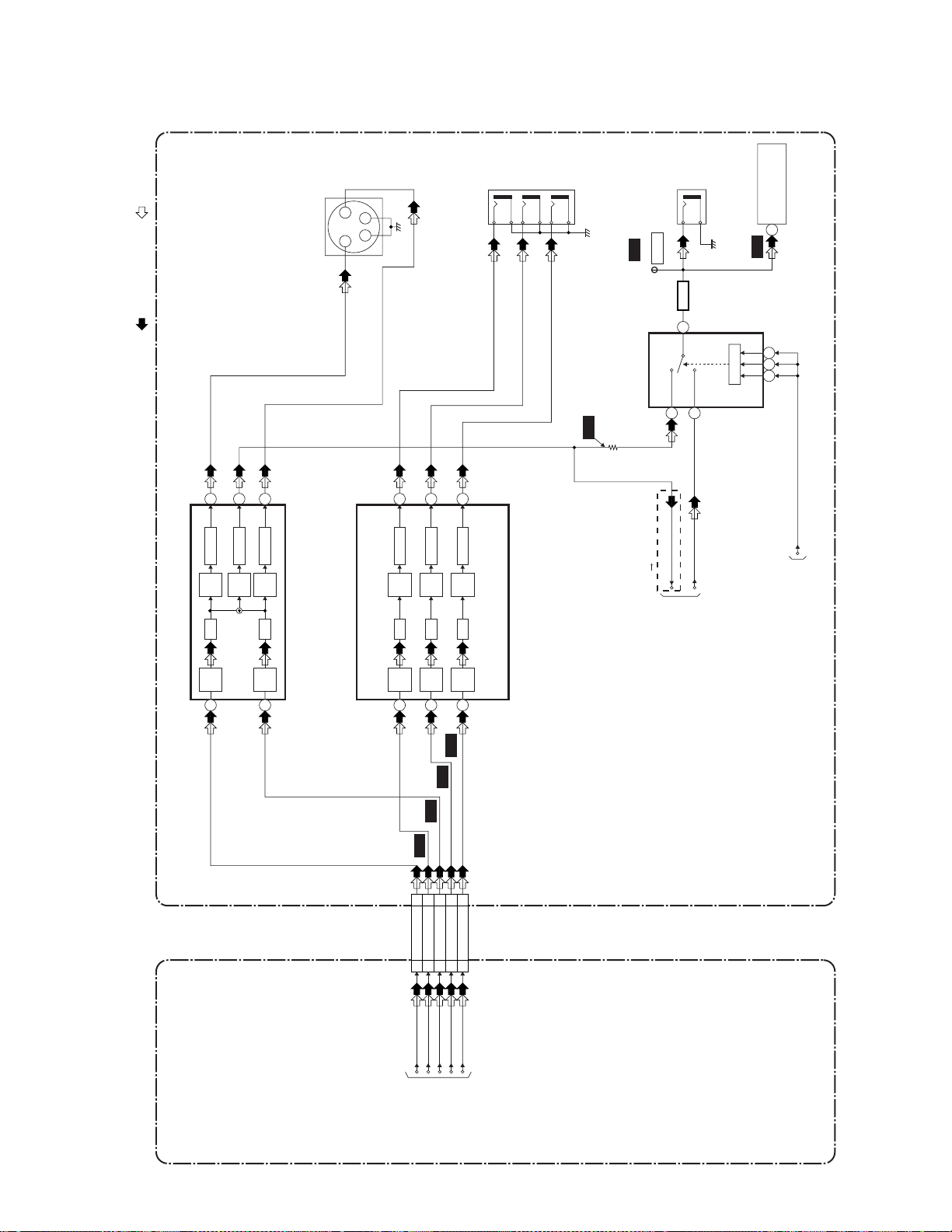

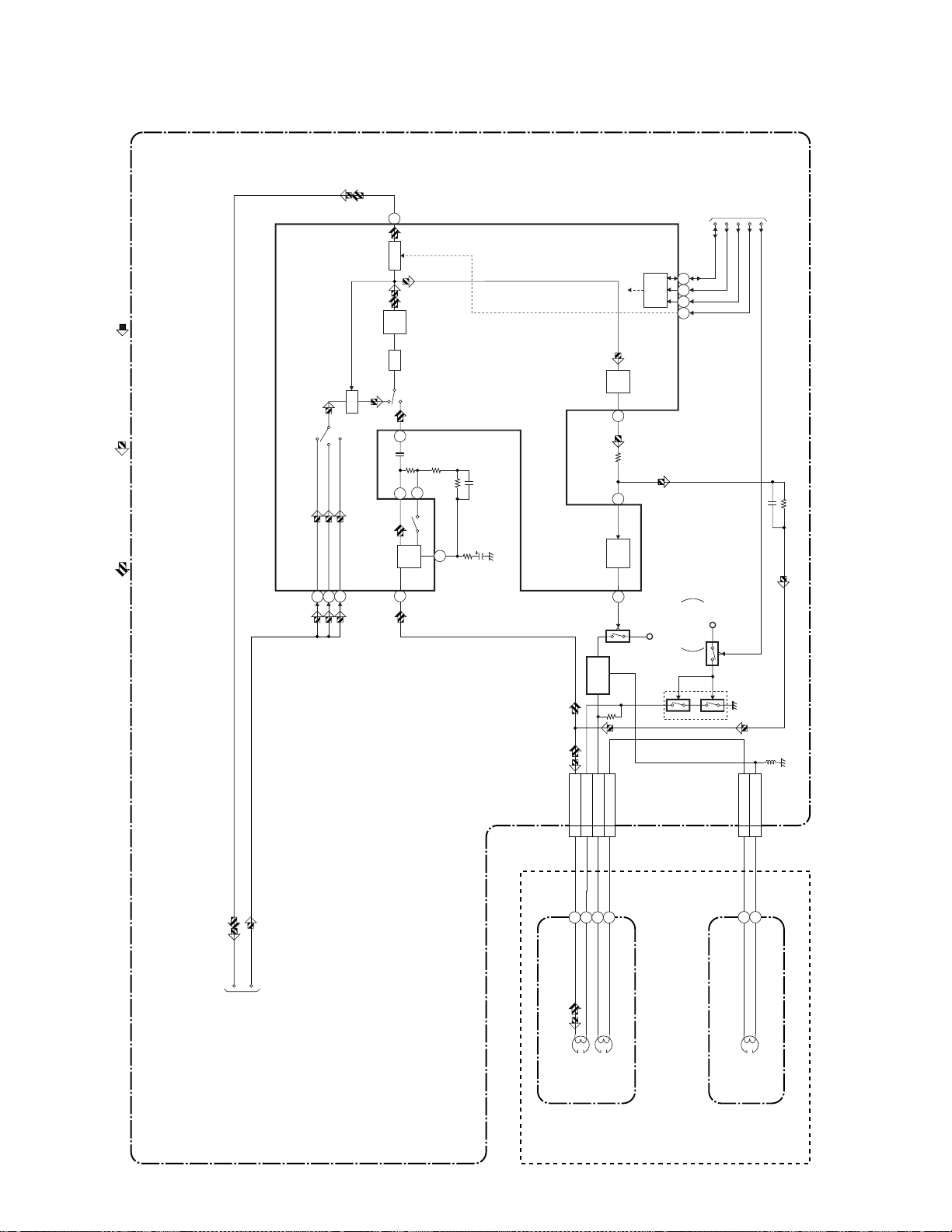

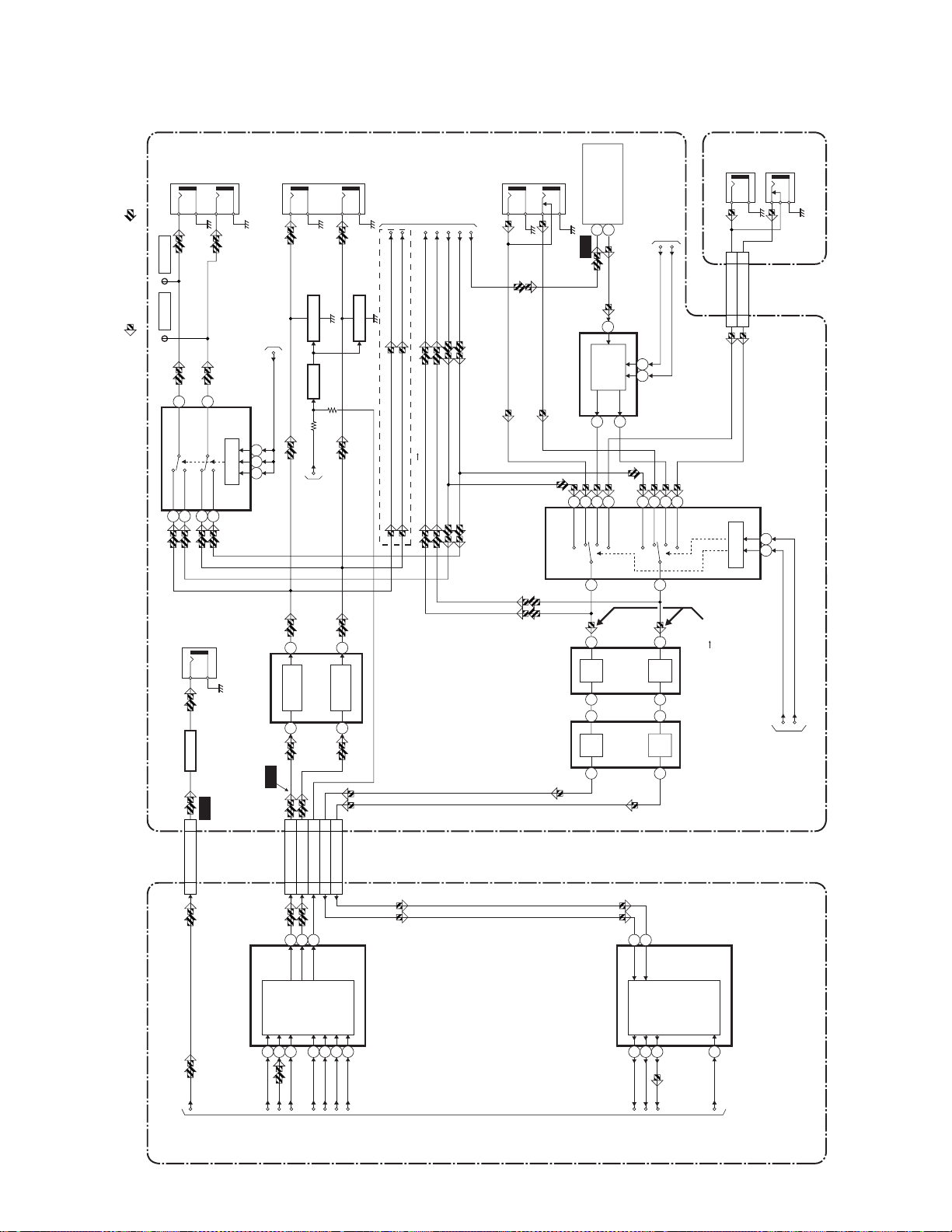

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Function Indicator Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-11

Schematic Diagrams / CBA’s and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11-1

Wiring Diagram < VCR Section > . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Wiring Diagram < DVD Section >. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-2

System Control Timing Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13-1

IC Pin Function Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

Lead Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15-1

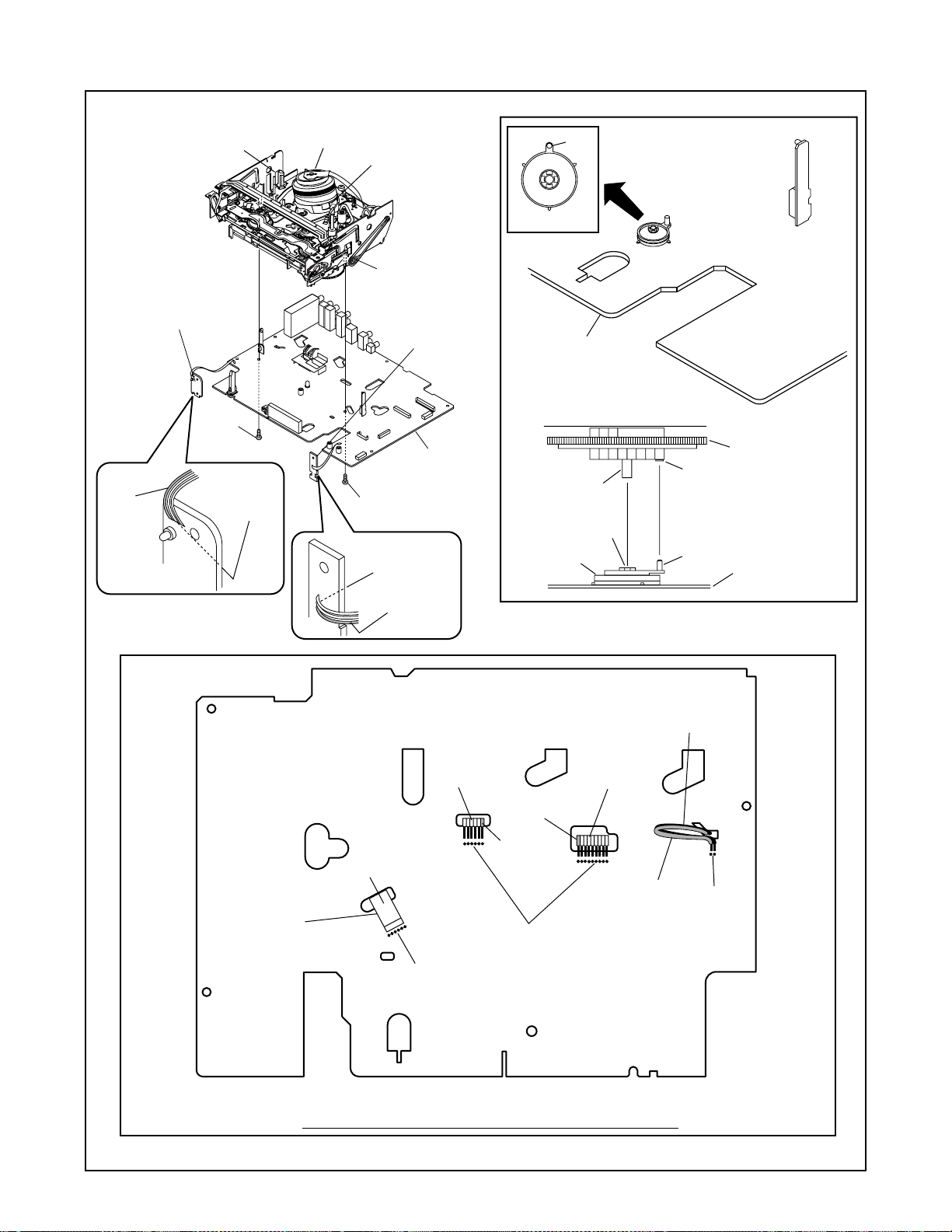

Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16-1

Mechanical Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18-1

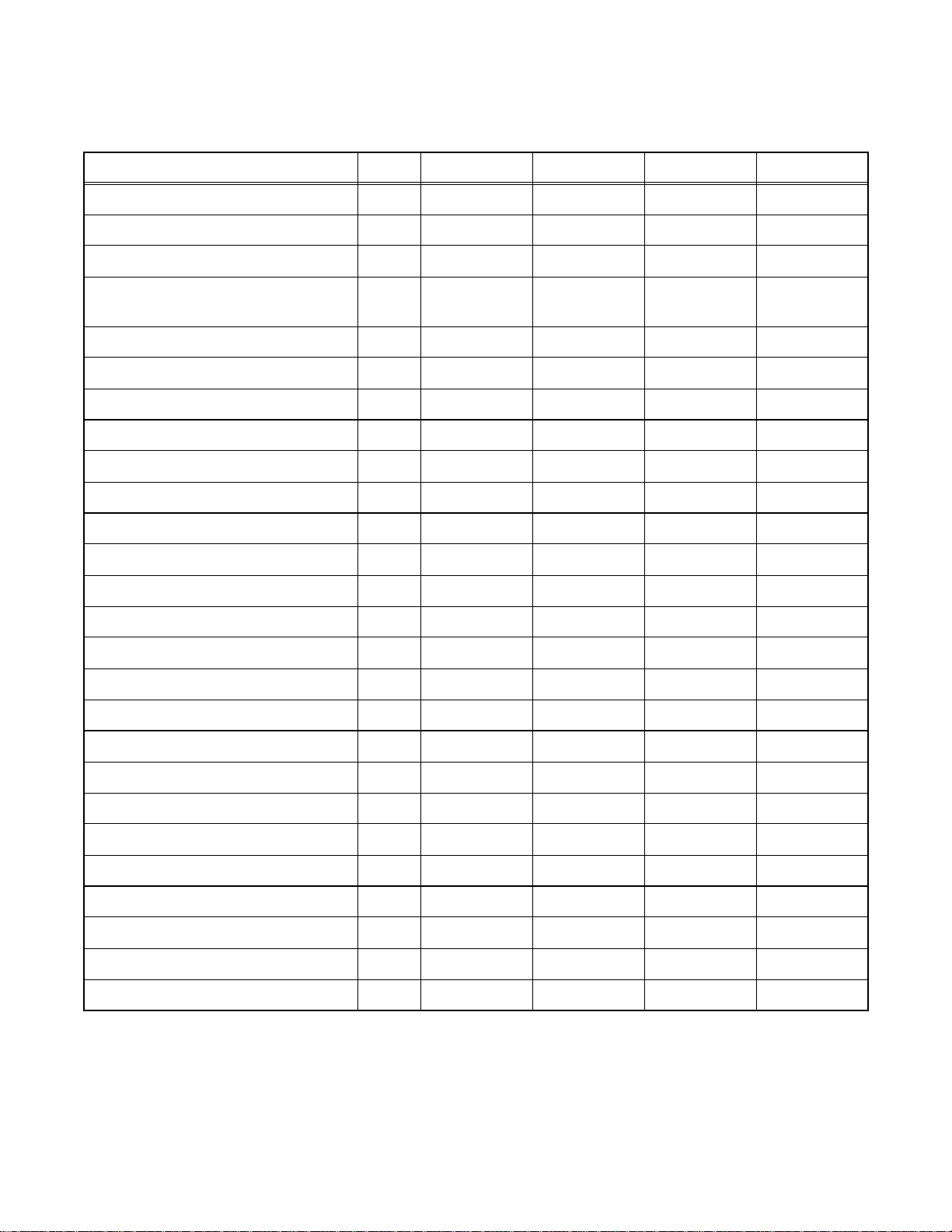

SPECIFICATIONS

< VCR Section >

Description Unit Minimum Nominal Maximum Remark

1. Video

1-1. Video Output (PB) Vp-p 0.8 1.0 1.2 SP Mode

1-2. Video Output (R/P) Vp-p 0.8 1.0 1.2

1-3. Video S/N Y (R/P) dB 40 45

1-4. Video Color S/N AM (R/P) dB 37 41 SP Mode

1-5. Video Color S/N PM (R/P) dB 30 36 SP Mode

1-6. Resolution (PB) Line 230 245 SP Mode

2. Servo

2-1. Jitter Low µsec 0.07 0.12 SP Mode

2-2. Wow & Flutter % 0.3 0.5 SP Mode

3. Normal Audio

3-1. Output (PB) dBV -9 -6 -3 SP Mode

3-2. Output (R/P) dBV -9 -6 -1.5 SP Mode

3-3. S/N (R/P) dB 36 41 SP Mode

3-4. Distortion (R/P) % 1.0 4.0 SP Mode

3-5. Freq. resp (R/P) at 200Hz dB -11 -4 SP Mode

(-20dB ref. 1kHz) at 8kHz dB -14 -4 SP Mode

SP Mode,

W/O Burst

4. Tuner

4-1. Video output Vp-p 0.8 1.0 1.2 E-E Mode

4-2. Video S/N dB 39 42 E-E Mode

4-3. Audio output dB -10 -6 -2 E-E Mode

4-4. Audio S/N dB 40 46 E-E Mode

5. Hi-Fi Audio

5-1. Output dBV -12 - 8 - 4 SP Mode

5-2. Dynamic Range dB 70 85 SP Mode

5-3. Freq. resp (6dB B.W) Hz 20 ~ 20K SP Mode

Note: Nominal specs represent the design specs. All units should be able to approximate these – some will exceed

and some may drop slightly below these specs. Limit s pecs represent the ab solute worst conditi on that still might

be considered acceptable; In no case should a unit fail to meet limit specs.

1-1-1 E9400SP

< DVD Section >

ITEM CONDITIONS UNIT NOMINAL LIMIT

1. VIDEO

1-1. Video Output 75 ohm load Vp-p 1.0

1-2. S-Video Output

Y (Luminance) 75 ohm load Vp-p 1.0

C (Chrominance) 75 ohm load Vp-p 0.286

1-3. Component Output

Y (Luminance) 75 ohm load Vp-p 1.0

Cb (Chrominance) 75 ohm load Vp-p 0.7

Cr (Chrominance) 75 ohm load Vp-p 0.7

2. AUDIO

2-1. Output Level Vrms 2.0

2-2. Frequency Response

DVD-VIDEO LPCM fs = 48kHz 20~22kHz dB ± 0.5

Audio CD fs = 44.1kHz 20~20 kHz dB ± 0.5

2-3. Signal/Noise Ratio

DVD-VIDEO LPCM dB 90

CD dB 90

REC & Playback Input: 2 Vrms, Rec Speed: XP dB 80

2-4. Dynamic Range

DVD-VIDEO LPCM dB 80

CD dB 80

REC & Playback Input: 2 Vrms, Rec Speed: XP dB 80

2-5. THD+N 1 kHz, 0 dB

DVD-VIDEO LPCM % 0.01

CD % 0.01

REC & Playback Input: 2 Vrms, Rec Speed: XP % 0.01

NOTES:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply : AC120 V 60 Hz

3. Load imp. : 100 k ohm

4. Ambient temperature : 5

°C ~ 40 °C

1-1-2 E9400SP

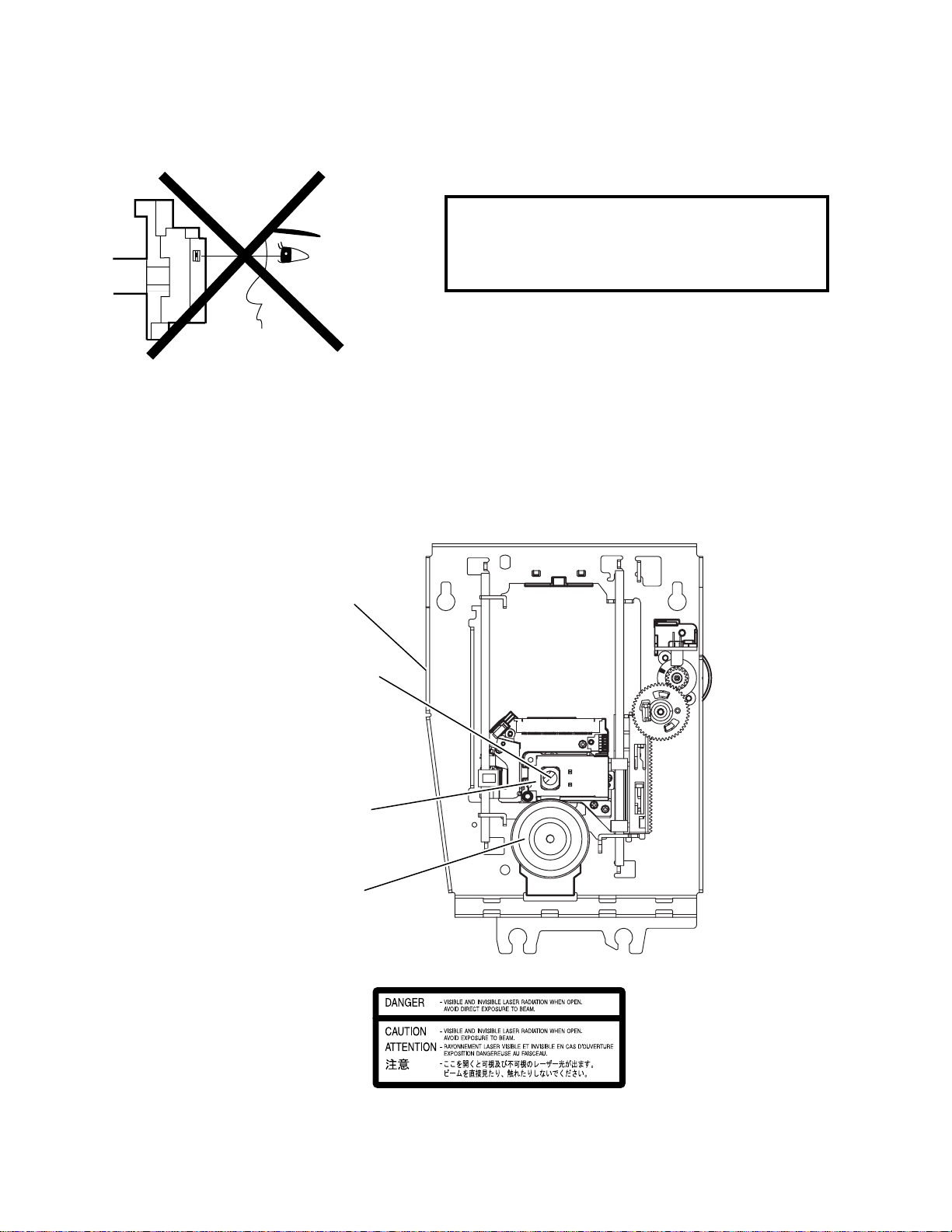

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the l aser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from the locatio n shown in the figure. When ch ecking the laser d iode, be sure to keep

your eyes at least 30cm away from the pickup lens when the diode is tur ned on. Do not loo k directly at the laser

beam.

Caution: Use of controls an d adjustments, or doing pr ocedures other than th ose specified here in, may result in

hazardous radiation exposure.

Drive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of DVD mechanism.

1-2-1 E6_LASER

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety character istics are

identified by a # on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review continuously and new instructions are issued whenever

appropriate. Prior to shipment from the factory, our

products are carefully inspected to confirm with the

recognized product safety and electrical codes of the

countries in which they are to be sold. However, in

order to maintain such compli ance, it is equall y impor tant to implement the following precautions when a set

is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified re pla ce men ts.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wire s

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wires do not co ntact hea t produc-

ing parts (heats inks, oxide metal fil m resis tors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also che ck areas sur round ing repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power transformer uses cri mp type con nector s

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector. (Discard it.)

2)Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to t he complete closure of the tool.

L. When connecting or disconnecting the internal con-

nectors, first, disconn ect the AC plug from the AC

outlet.

1-3-1 DVD_SFN1

Safety Check afte r Servicing

Examine the area surrounding the repaired location for

damage or deteri oration. Observe that screws, par ts,

and wires have been returned to their original positions. Afterwards, do the following tests and confirm

the specified values to verify compliance with safety

standards.

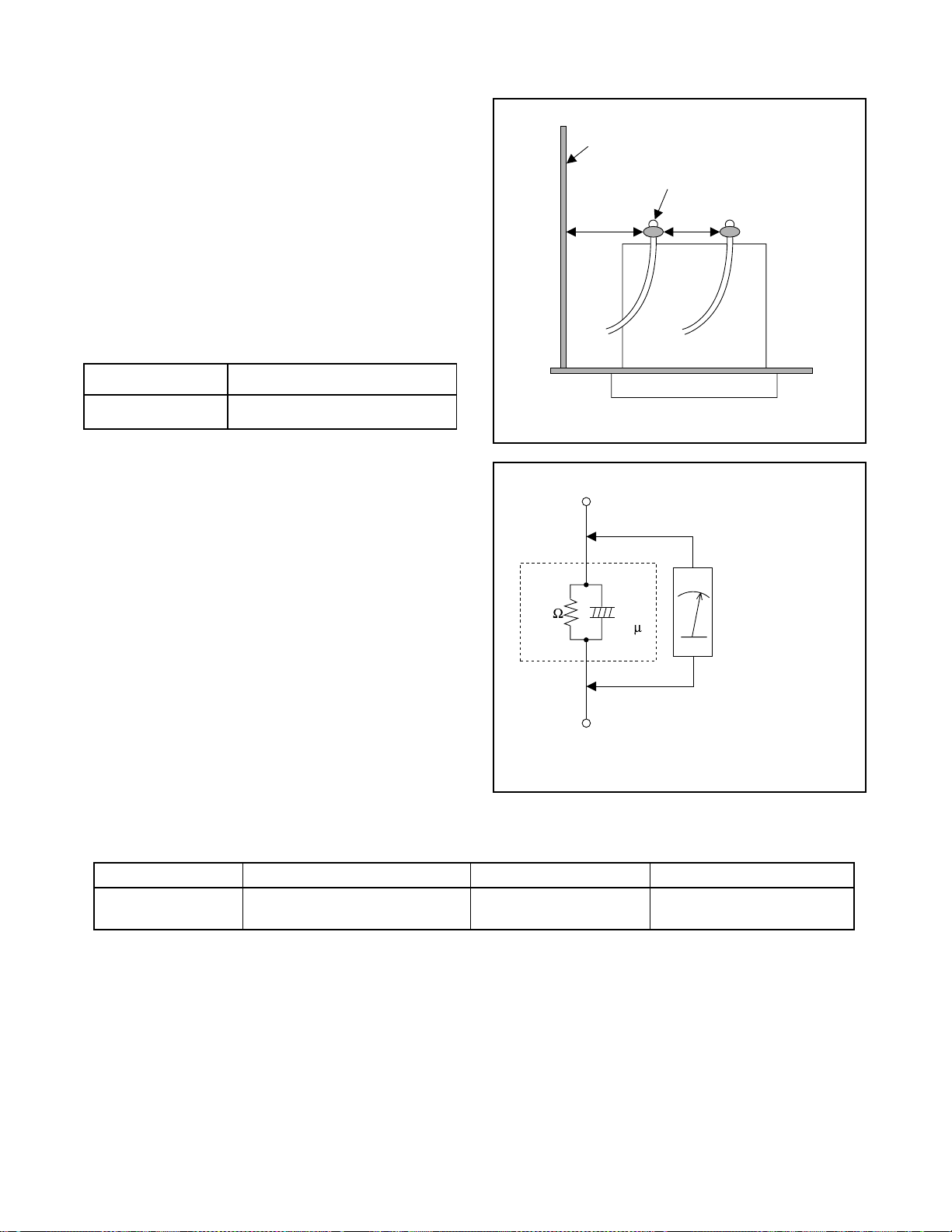

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearanc e distance (d ) and (d’) betwee n soldered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

Chassis or Secondary Conductor

Primary Circuit Terminals

dd'

120 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across the ter minals of load

Z. See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

≥ 3.2mm (0.126 inches)

0.15µF CAP. & 1.5kΩ RES.

Connected in parallel

Exposed Accessible Part

Z

1.5k

i≤0.5mA Peak Exposed accessible parts

0.15 F

Earth Ground

B

Power Cord Plug Prongs

AC Voltmeter

(High Impedance)

Fig. 1

Fig. 2

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

1-3-2 DVD_SFN1

STANDARD NOTES FOR SERVICING

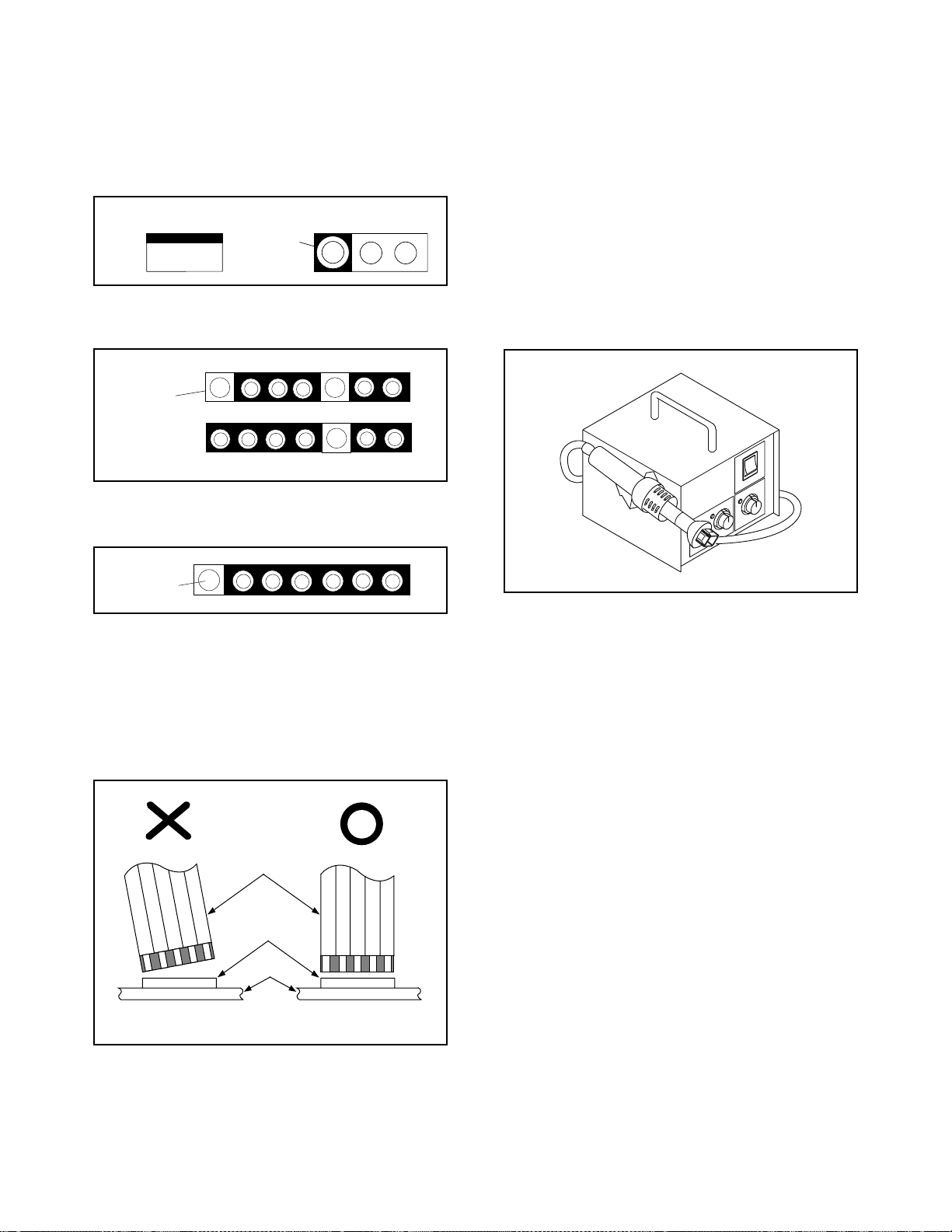

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are indicated

as shown.

Pin 1

3. The 1s t pin of every ma le c on nector i s indi ca ted a s

shown.

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

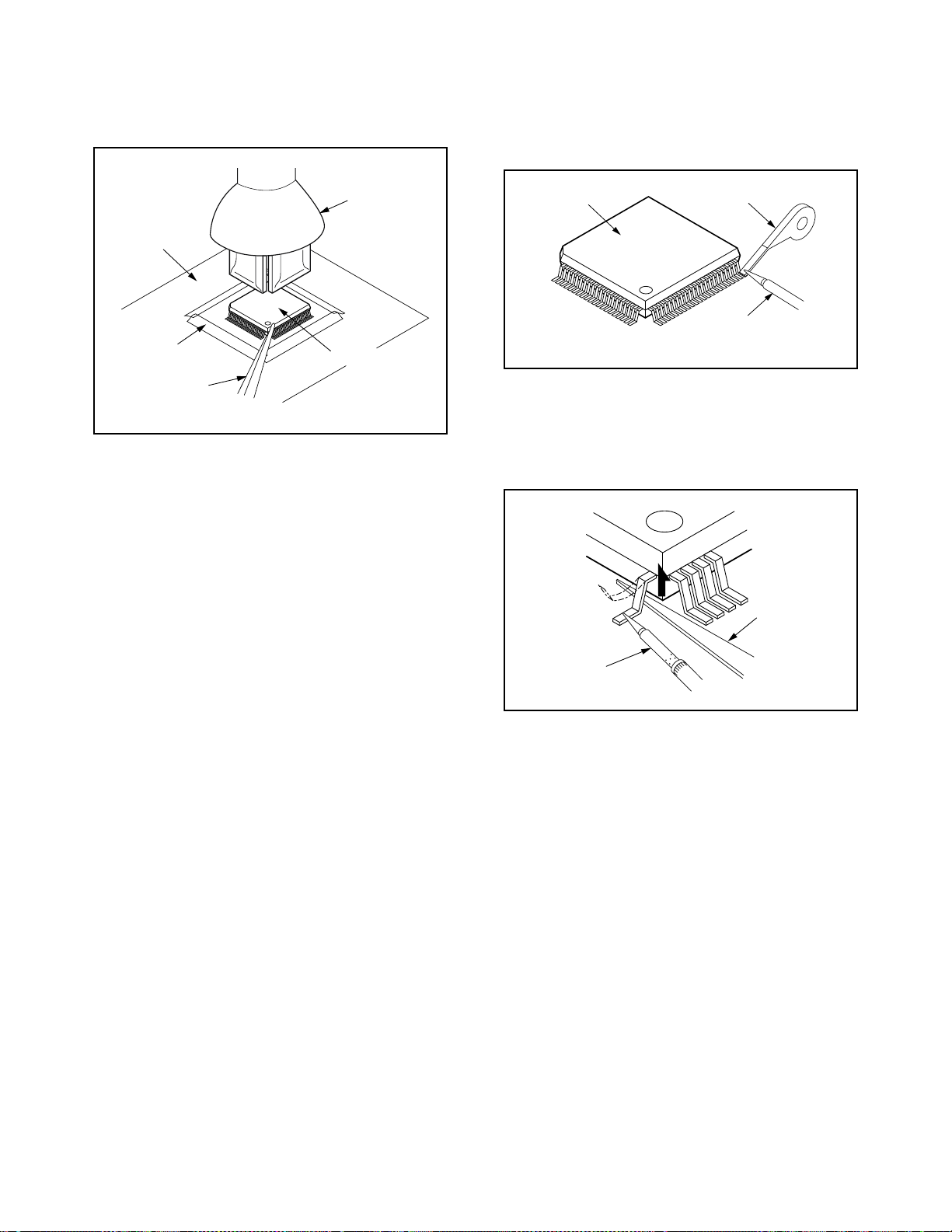

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:.

(1) Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Pin 1

Instructions for Connectors

1. When you conn ect or disconn ect t he FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Fig. S-1-1

(2) Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3) B ottom of the flat pack-IC is fixed with glue to the

CBA; when rem oving enti re flat pa ck-IC, first apply

soldering iron to ce nter of the flat pack-IC and hea t

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) R elease the flat pack-IC from the CB A using twee-

zers. (Fig. S-1-6)

Caution:

1. T he Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. D o not supply hot air to the chip par ts around the

flat pack-IC for over 6 seconds because damage to

the chip parts may occur. Put masking tape around

the flat pack-IC to protect other parts from damage.

(Fig. S-1-2)

1-4-1 E6STA

3. The fla t pa ck-IC on the CBA is a ffi xed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

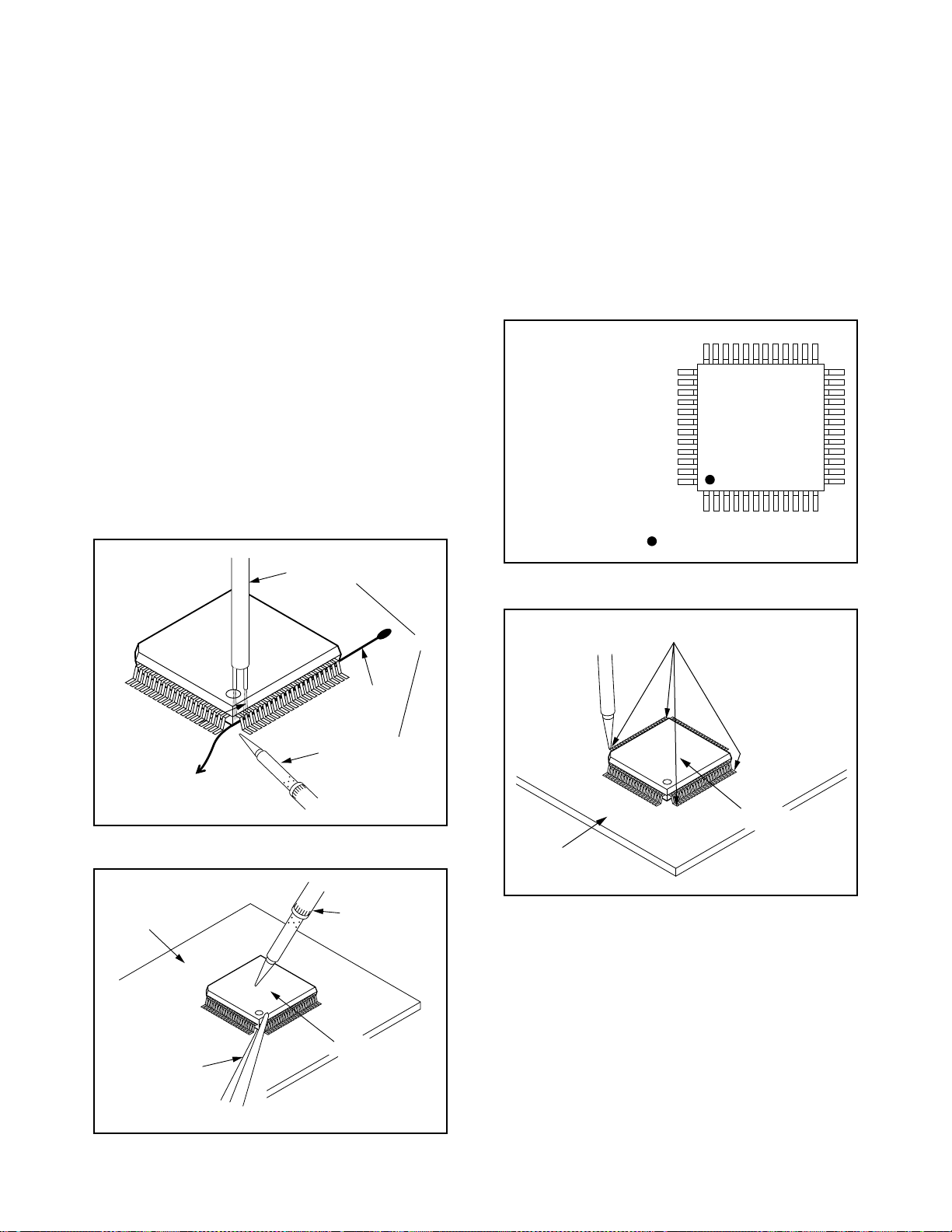

With Soldering Iron:

(1) Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to al l pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a shar p pin or wire to which s older will

not adhere (iron w ire). When h eating the p ins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

(3) B ottom of the flat pack-IC is fixed with glue to the

CBA; when rem oving enti re flat pa ck-IC, first apply

soldering iron to ce nter of the flat pack-IC and hea t

up. Then remove (glue will be melted). (Fig. S-1-6)

(4) R elease the flat pack-IC from the CB A using twee-

zers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 E6STA

With Iron Wire:

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you

can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solde r

melts so as to lift the IC leads from the CBA contact

pads as shown in Fig. S-1-5.

(4)Botto m of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to c en ter of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5)Re lease the flat pa ck-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a solde ring iron, care must be taken

to ensure that the flat pack-IC is not being he ld by

glue. When the flat pack-IC is removed from the

CBA, handle it gently becau se it may be dama ged

if force is applied.

Hot Air Blower

2. Installation

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA so

you can install a replacement flat pack-IC more

easily.

(2)The “I” mark on the f lat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mar k matches the 1

on the PCB when positioning for installation. Then

presolder the four cor ners of the fl at pack-IC. (See

Fig. S-1-8.)

(3) Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-4-3 E6STA

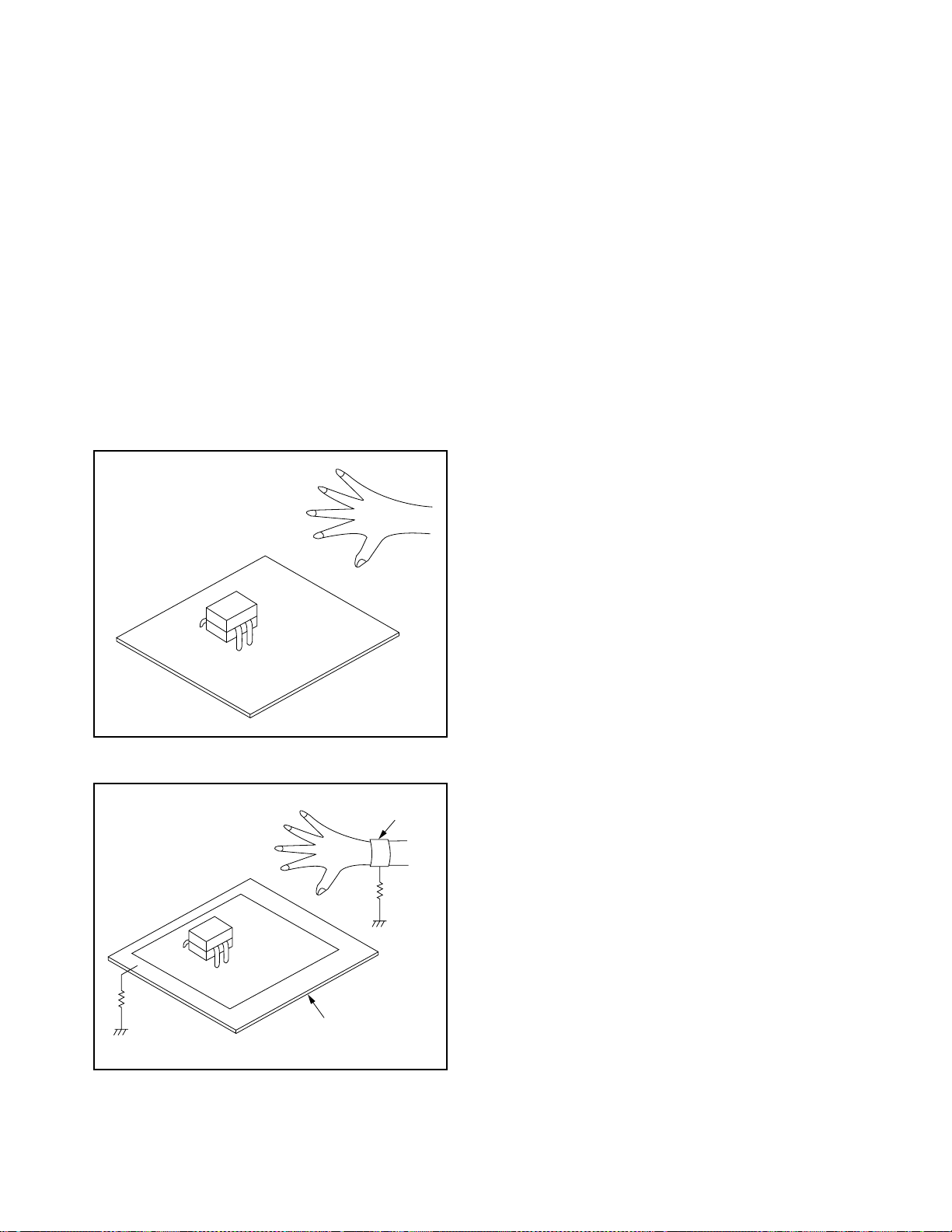

Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential dif ference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding b and (1M Ω) that is prop erly grounded to remove any static ele ctr icity that may

be charged on the body.

2. Ground for Workbench

(1)Be sure to place a conductive sheet or copper plate

with proper grounding (1MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape thr ough the body grounding band, be careful to avoid contacting s emi-conductors with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 E6STA

PREPARATION FOR SERVICING

How to Enter the Service Mode

About Optical Sensors

Caution:

An optical sensor system is used for the Tape Start

and End Sensors on this equipment. Carefully read

and follow the instructions below. Otherwise the unit

may operate erratically.

What to do for preparation

Insert a tap e into the Deck Mechan ism Assembly and

press the PLAY button. The tape will be loaded into

the Deck Mechanism Assembly. Make sure the power

is on, connect TP502 (S-INH) to GND. This will stop

the function of Tape Start Sensor, Tape End Sensor

and Reel Sensors. ( If the se TP s ar e connected before

plugging in the unit, the function of the sensors will

stay valid.) See Fig. 1.

Q503

Q504

TP502

S-INH

Fig. 1

Note: Because the Tape End Sensors are inactive, do

not run a tape all the way to the start or the en d of the

tape to avoid tape damage.

1-5-1 E9400PFS

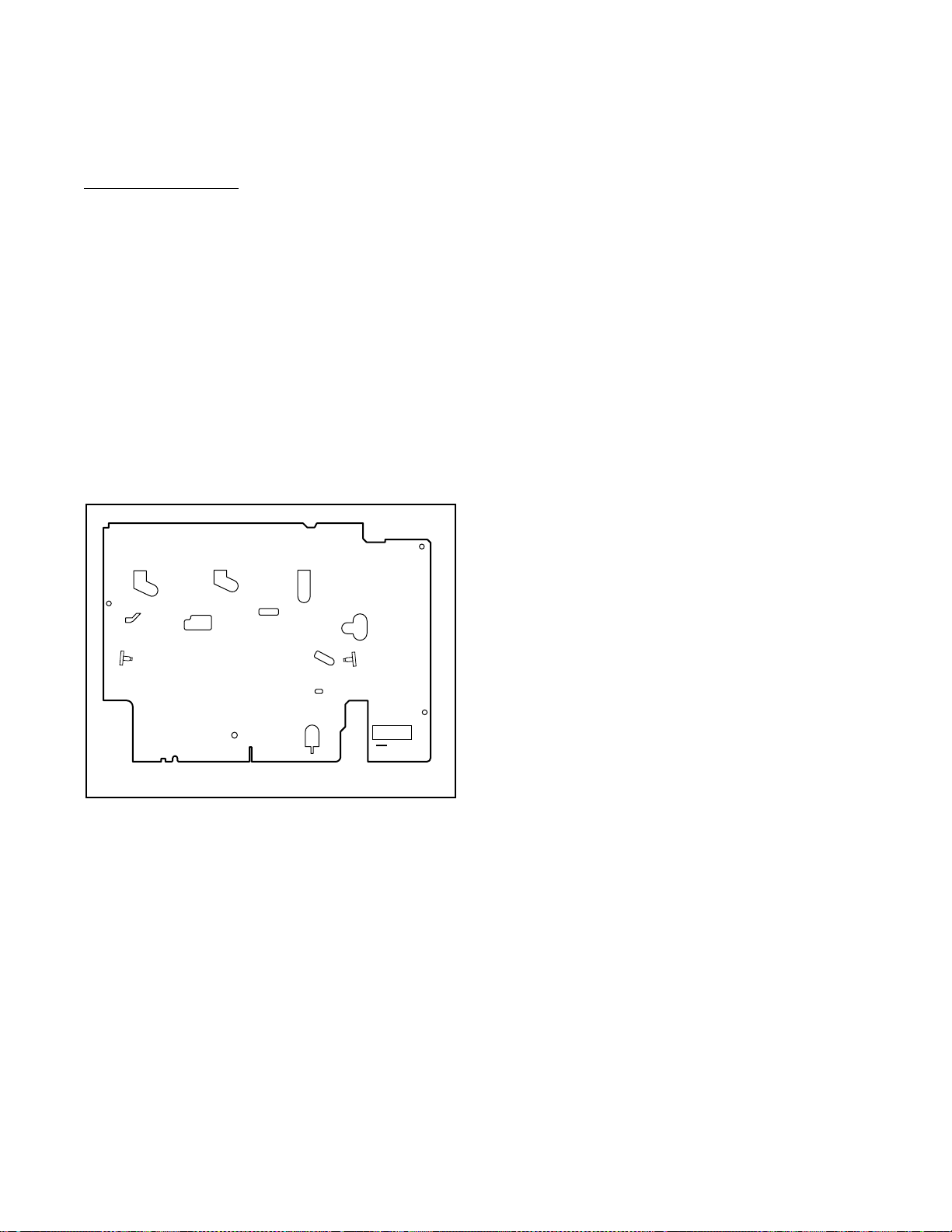

CABINET DISASSEMBLY INSTRUCTIONS

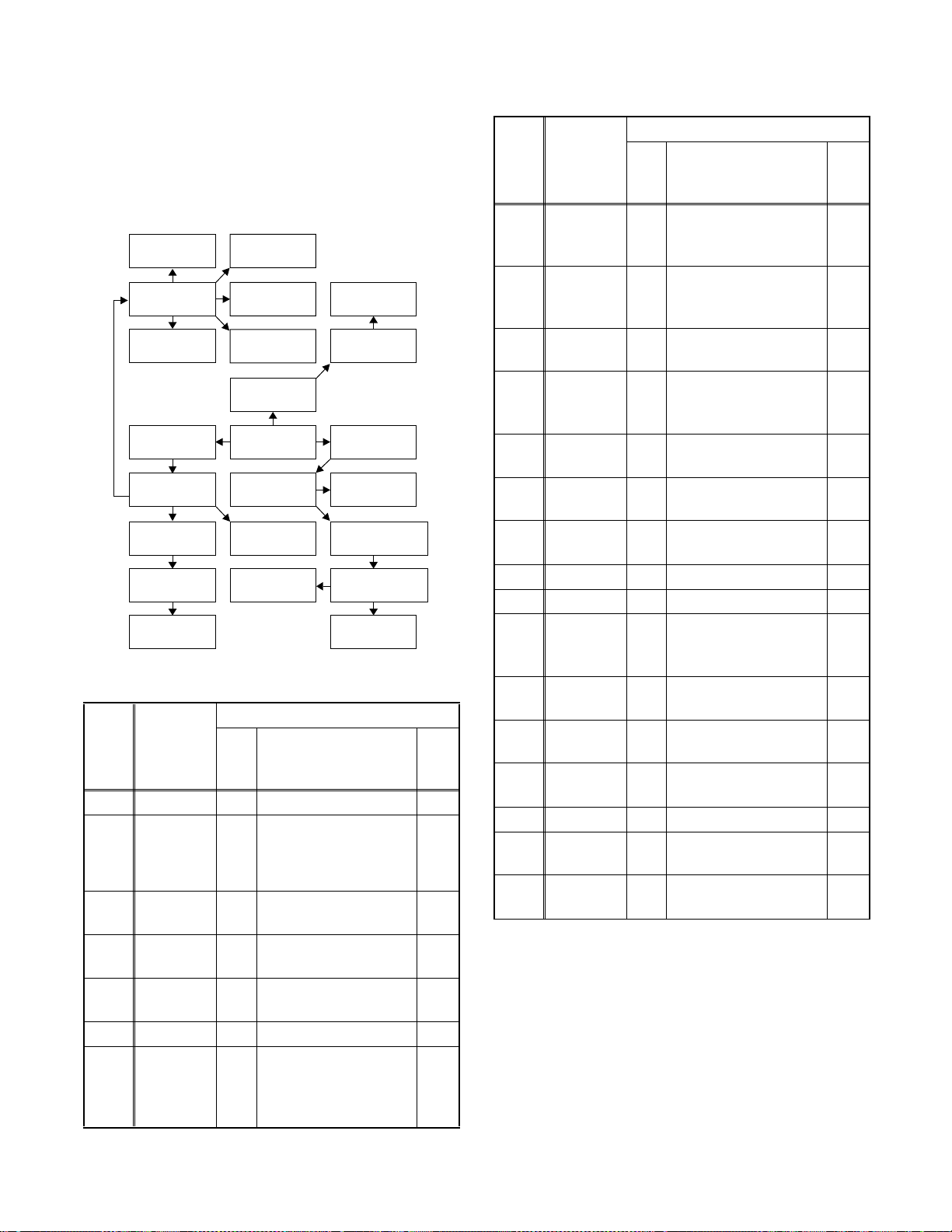

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be ser vic ed. When reasse mbling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[19] Power

SW CBA

[17] VCR

Chassis Unit

[21] Main

CBA

[9] FFC

Friction Plate

[10] Rear

Panel Unit

[11] Power

Supply CBA

[13] PCB

Holder

[14] Rear

Panel

[22] Deck

Pedestal

[18] Deck

Assembly

[20] Function

CBA

[2] Front

Assembly

[1] T op Cover

[4] Radiation

Sheet

[12] DC

Fan Motor

[15] Bracket L

[6] Jack CBA

[5] Jack

Bracket

[3] Front

Bracket

[23] Front

Bracket R

[7] DVD Mecha

& FE Assembly

[8] DVD BE

Main CBA Unit

[16] Bracket R

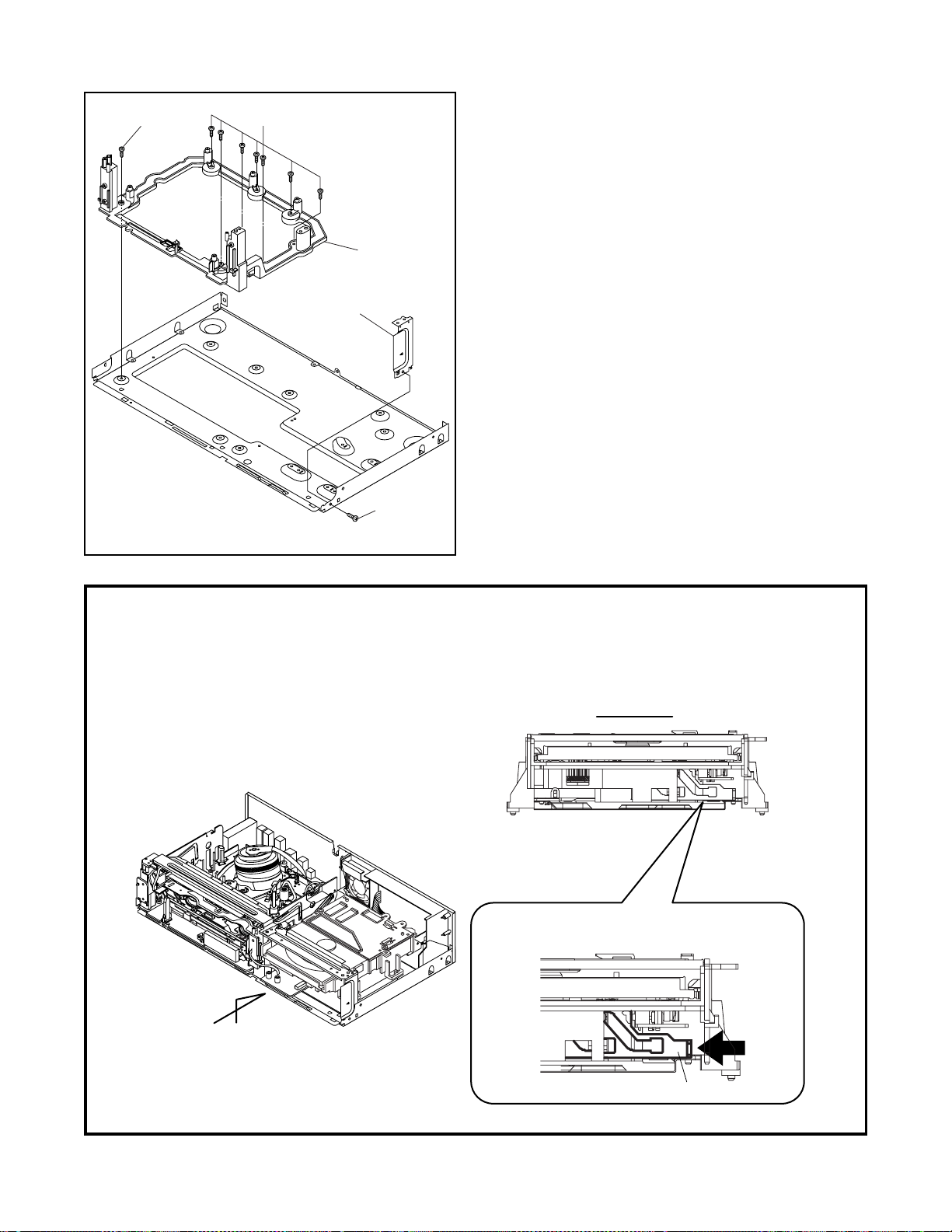

2. Disassembly Method

ID/

LOC.

No.

PART

Fig.

No.

[1] Top Cover D1 6(S-1) ---

Front

[2]

[3]

[4]

[5]

Assembly

Front

Bracket

Radiation

Sheet

Jack

Bracket

D2

D2 2(S-2), 2(S-3) ---

D2 ---------- ---

D3 2(S-4) ---

[6] Jack CBA D3 ---------- ---

DVD

Mecha &

[7]

FE

D4

Assembly

REMOVAL

REMOVE/*UNHOOK/

UNLOCK/RELEASE/

UNPLUG/DESOLDER

*5(L-1), *3(L-2),

*CN1609

2(S-5A), 2( S-5B),

*CN1604, *CN1

Note

1

1-1

1-2

1-3

---

ID/

LOC.

No.

[8]

PART

DVD BE

Main CBA

Unit

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

4(S-6), *CN201,

D4

*CN202

Note

---

FFC

REMOVAL

[9]

Friction

D5 2(S-7) ---

Plate

[10]

[11]

[12]

[13]

[14]

Rear

Panel Unit

Power

Supply

CBA

DC Fan

Motor

PCB

Holder

Rear

Panel

5(S-8), 3(S-9), (S-10),

D5

*CN1606, *CN1608

4(S-11), AC Cord,

D6

Earth Plate

---

---

D6 2(S-12) ---

D6 3(S-13) ---

D6 ---------- ---

[15] Bracket L D7 2(S-14) --[16] Bracket R D7 2(S-15) ---

[17]

[18]

[19]

[20]

VCR

Chassis

Unit

Deck

Assembly

Power

SW CBA

Function

CBA

5(S-16),

D7

5(S-17), (S-17B)

---

(S-18), (S-19)

(S-20), (S-21),

D8

Desolder

D8 Desolder ---

D8 Desolder ---

2

3

[21] Main CBA D8 ---------- ---

Deck

[22]

[23]

↓

(1)

Pedestal

Front

Bracket R

↓

(2)

D9 8(S-22) ---

D9 (S-23) ---

↓

(3)

↓

(4)

↓

(5)

Note:

(1): Identification (location) No. of parts in the figures

(2):Name of the part

(3):Figure Number for reference

(4): Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

1-6-1 E9413DC

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 6(S-1) = six Screws (S-1),

5(L-1) = five Locking Tabs (L-1)

(5):Refer to “Reference Notes.”

Reference Notes

CAUTION 1: Locking Tabs (L-1) and (L -2) are fragile.

Be careful not to break them.

1-1. Release five Locking Tabs (L-1).

1-2. Release three Locking Tabs (L-2)

1-3. Disconnect Connector (CN1609), and remove

the Front Assembly.

2. When re ass em bling, s old er wire j ump er s a s s hown

in Fig. D8.

3. Before installing the Deck Assembly, be sure to

place the pin of LD-SW on M ain CBA as shown in

Fig. D8. Then, install the Deck Assembly while

aligning the hole of Cam Gear with the pin of LDSW, the shaft of Cam Gear with the hole of LD -S W

as shown in Fig. D8.

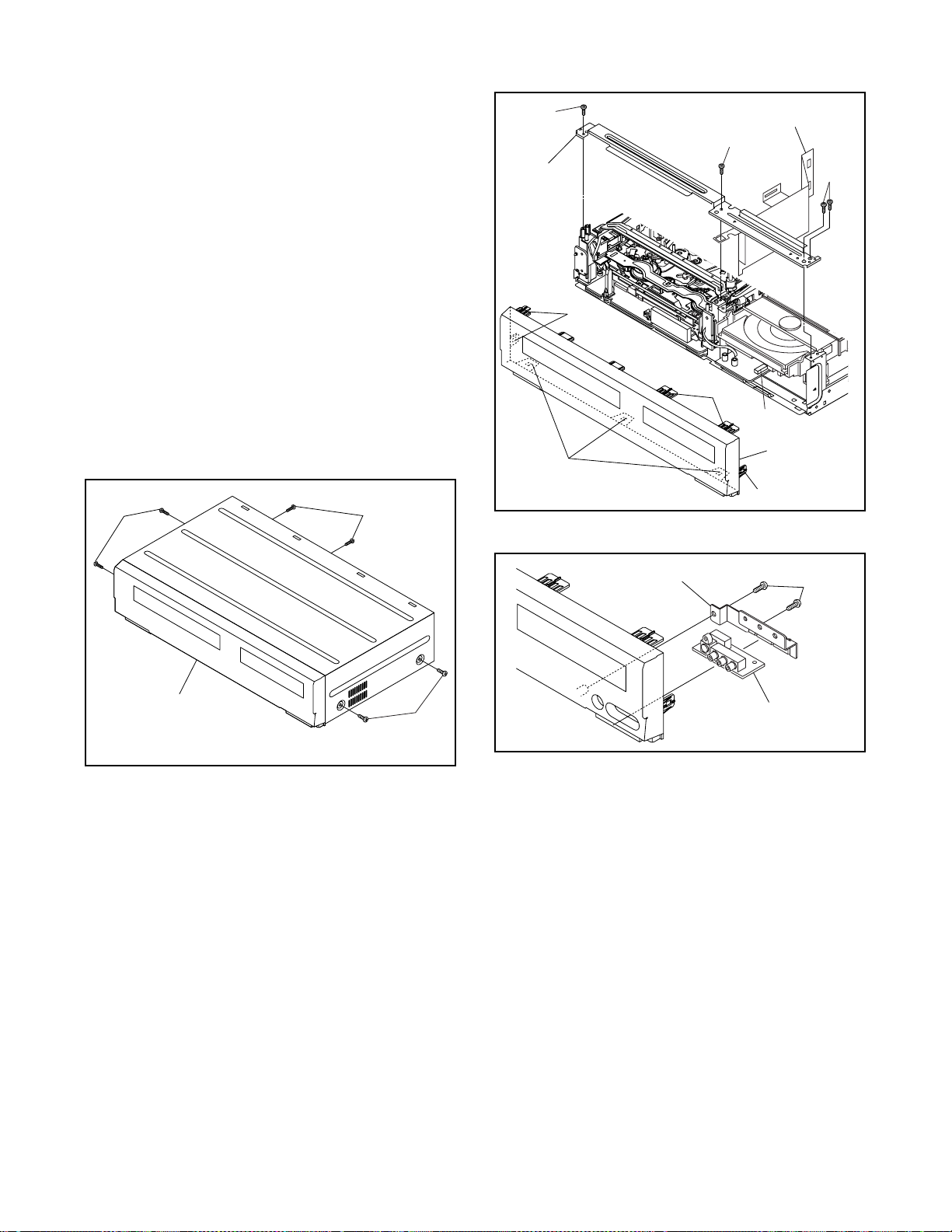

(S-2)

[3] Front

Bracket

(L-2)

[4] Radiation Sheet

(S-2)

(S-3)

(L-1)

(L-1)

CN1609

[2] Front

Assembly

(S-1)

[1] T op Cover

(S-1)

(S-1)

Fig. D1

[5] Jack Bracket

(L-1)

Fig. D2

(S-4)

[6] Jack CBA

Fig. D3

1-6-2 E9413DC

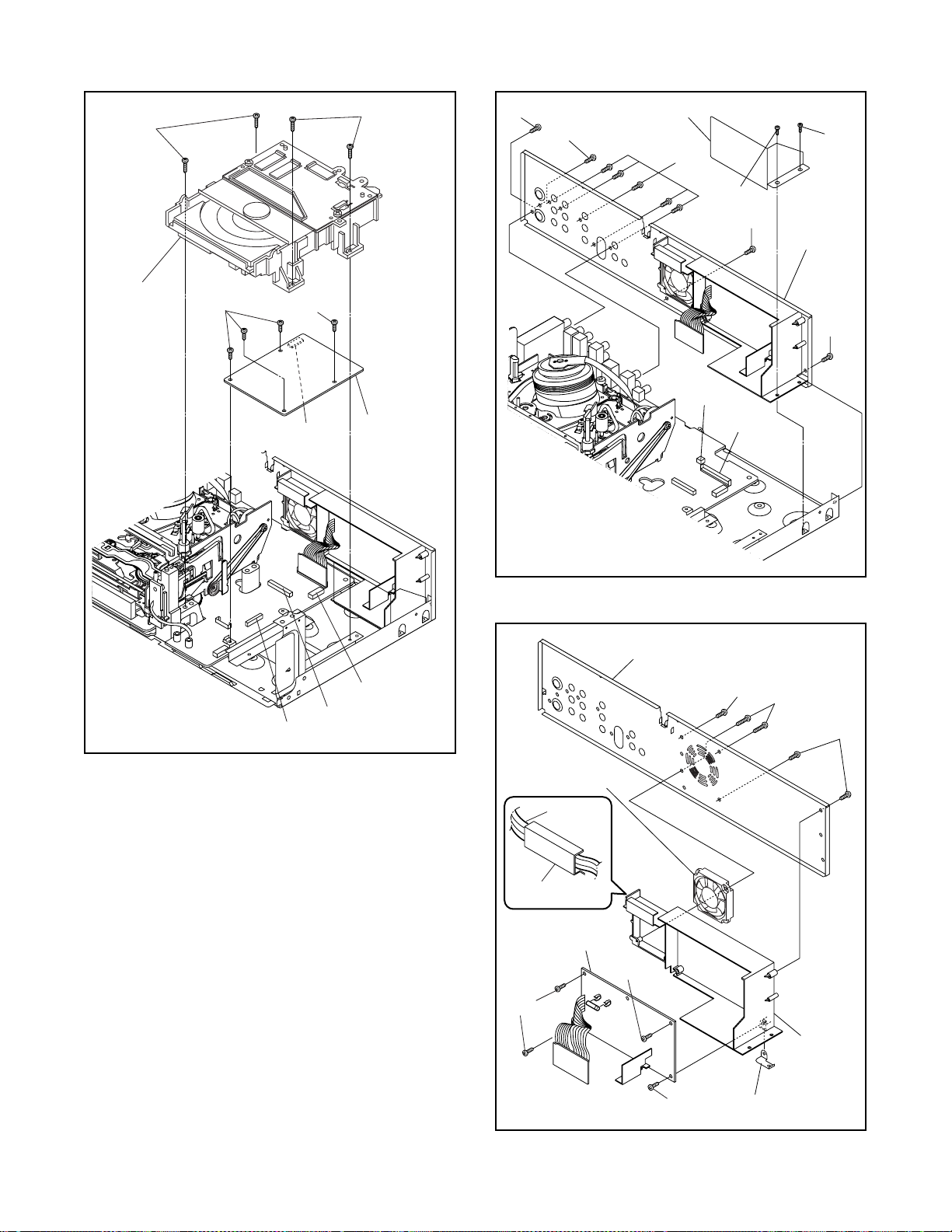

(S-5A)

(S-5B)

(S-9)

[9] FFC Friction Plate

(S-10)

(S-7)

(S-8)

(S-7)

[7] DVD

Mecha

& F/E

Assembly

(S-6)

(S-6)

CN1

[8] DVD BE

Main CBA

Unit

CN1606

CN1608

[14] Rear Panel

(S-9)

[10] Rear

Panel Unit

(S-9)

Fig. D5

CN202

CN201

CN1604

Fig. D4

[12] DC Fan Motor

AC Cord

Hook

[11] Power

Supply CBA

(S-11)

(S-11)

(S-11)

(S-13)

(S-12)

Earth Plate

(S-13)

[13] PCB

Holder

Fig. D6

1-6-3 E9413DC

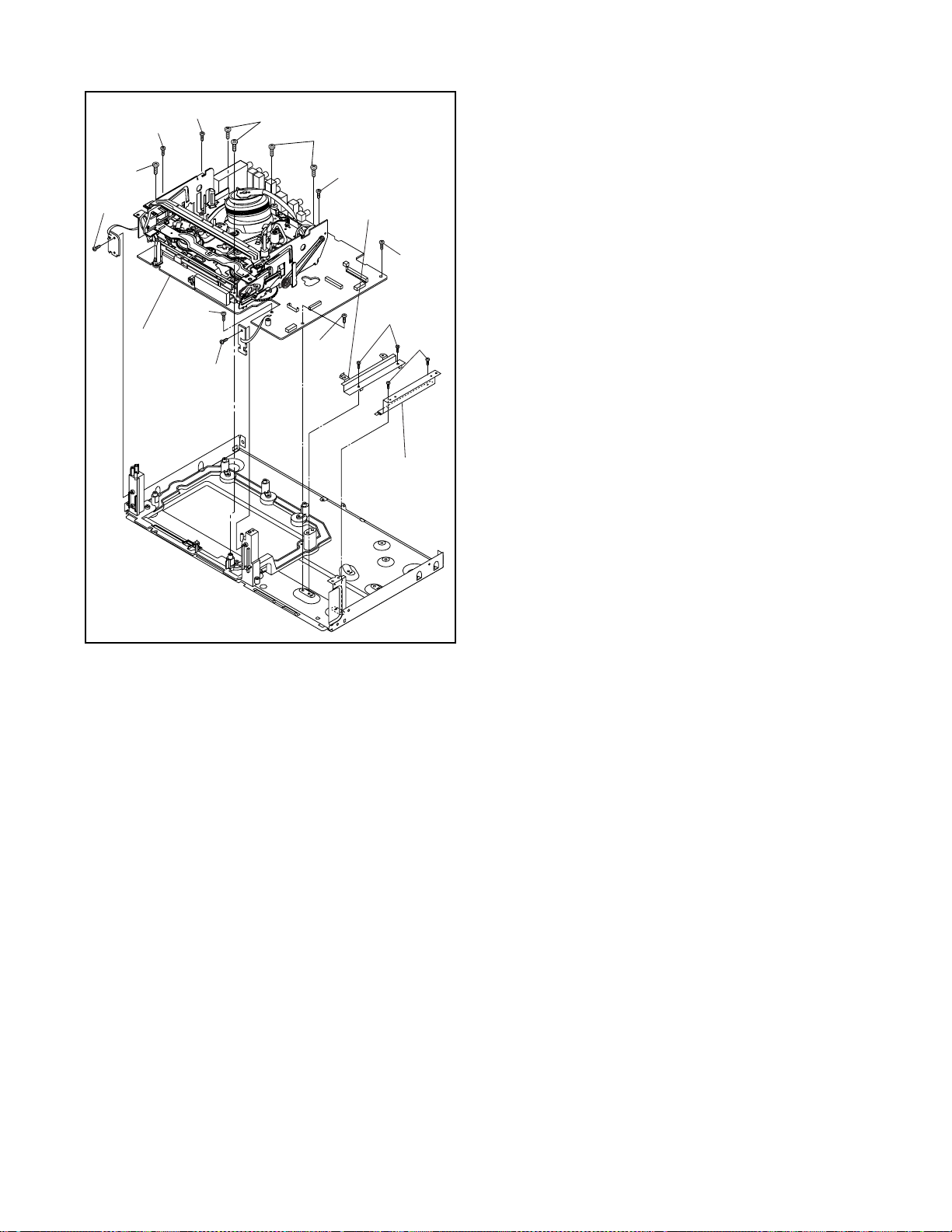

(S-17)

(S-17)

(S-16)

(S-16)

(S-16)

(S-18)

(S-17B)

[17] VCR

Chassis

Unit

(S-19)

(S-17)

[15] Bracket L

(S-17)

[16] Bracket R

(S-17)

(S-14)

(S-15)

Fig. D7

1-6-4 E9413DC

FE Head

[19] Power

SW CBA

Cylinder

Assembly

ACE Head

Assembly

[18] Deck

Assembly

[20] Function

CBA

Pin

SW512

LD-SW

[21] Main CBA

Lead

with

blue

stripe

(S-20)

Desolder

From

Capstan

Motor

Assembly

(S-21)

Desolder

Lead with

blue stripe

Printing side

[21] Main

CBA

From

ACE Head

Assembly

Desolder

LD-SW

Lead with

blue stripe

Lead with

blue stripe

Desolder

[18] Deck Assembly

Shaft

Hole

From

Cylinder

Assembly

Lead with

gray stripe

Hole

Pin

From

FE Head

Cam Gear

[21] Main CBA

Desolder

BOTT OM VIEW

Lead connections of Deck Assembly and Main CBA

1-6-5 E9413DC

Fig. D8

(S-22)

(S-22)

[22] Deck

Pedestal

[23] Front

Bracket R

(S-23)

Fig. D9

HO W TO EJECT MANUALLY

1. Remove the Top Cover.

2. Remove the Front Assembly.

3. Push the lever to the direction of the arrow as shown below.

A

View for A

Push the lever to the

direction of the arrow

Lever

1-6-6 E9413DC

HOW TO INITIALIZE THE DVD RECORDER

To put the program back at the factory-default, initialize

the DVD recorder as the following procedure.

1. Turn the DVD re co rder on.

2. Confir m that no disc is loaded or that the disc tray

is open. To put the DVD recorder into the Version

display mode, press [CM SKIP], [1], [2], and [3] buttons on the remote control in the order.

Fig. A appears on the screen.

Model Name :

Firmware Version

BE : R1F189000E

FE : NRS0051 MST031210

DEFAULT SETTING : ENTER

EXIT : RETURN

*1: "

*2: Firmware Version differ depending on the models,

and indication is one example.

" differ depending on the models.

*******

*******

Fig. A: Version Display Mode Screen

3. Press [ENTER] button, then the DVD recorder

starts initializing. When the initializing is completed,

the DVD recorder exits the Version display mode

and turns off the power automatically.

* To move into the Normal mode from the Version

display mode, press [RETURN] button on the

remote control instead of [ENTER] button.

* When [POWER] button is pressed before [ENTER]

button is pressed, the DVD recorder exits the Version display mode, then the power turns off.

1-6-7 E9413DC

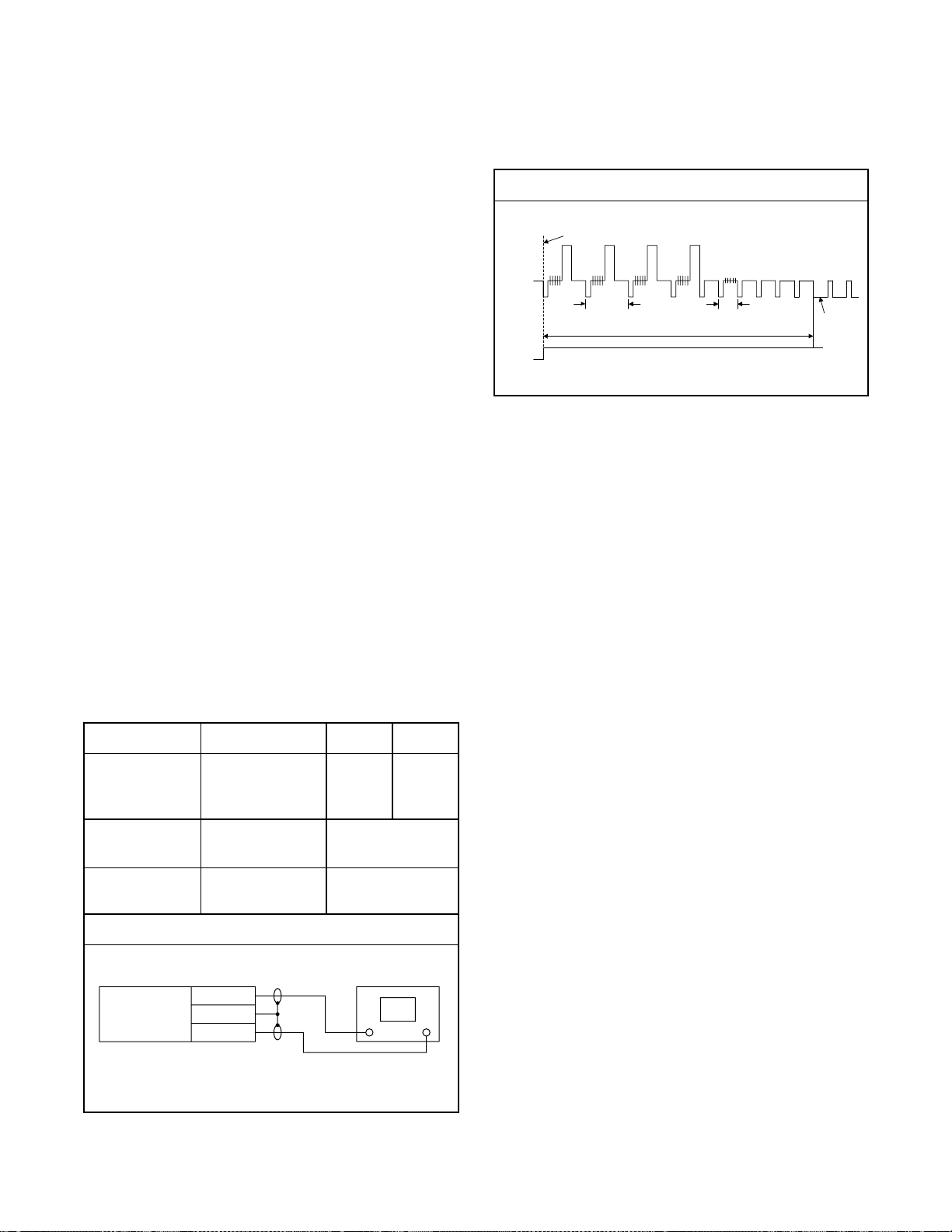

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note: "CBA" is an abbreviation for

"Circuit Board Assembly."

NOTE:

1.Electric al adjust ments are required a fter repla cing

circuit components and ce rtain mechanical par ts.

It is impor tant to do these adjustments only afte r

all repairs and replacements have been completed. Also, do not attempt these adjustments

unless the proper equipment is available.

2.To perform these alignment / co nfirmation procedures, make sure that the tracking control is set in

the center position: P ress ei ther "CHA NNEL L5??" or

"CHANNEL K" button on th e front panel first , then

the "PLAY" button on the front panel.

CH1

CH2

Figure 1

EXT. Syncronize Trigger Point

1.0H

6.5H±1H (412.7µs±63.5µs)

Switching Pulse

0.5H

V-Sync

Test Equipment Required

1.Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div.,

F-Range: DC~AC-20MHz

2.Alignment Tape (FL8A)

Head Switching Po sition Adjustment

Purpose:

To deter mine the Head Switching pos ition during

playback.

Symptom of Mi sadjustm e n t:

May cause Head Switching noise or ver tical jitter

in the picture.

Test point Adj.Point Mode Input

TP751(V-OUT)

TP302(RF-SW)

GND

Tape

VR501

(Switching Point)

(MAIN CBA)

Measurement

Equipment

PLAY

(SP)

Spec.

Reference Notes:

Playback the Alignment tape and adjust VR501 so that

the V-sync front edge of the CH1 video output waveform is at the 6.5H±1H (412.7µs±63.5µs) delayed

position from the risi ng edge of the CH2 head switching pulse waveform.

-----

FL8A Oscilloscope

Connections of Measurement Equipment

TP751

Main CBA

GND

TP302

6.5H±1H

(412.7µs±63.5µs)

Oscilloscope

CH1 CH2

Trig. (+)

1-7-1 E9400EA

FIRMWARE RENEWAL MODE

1. Turn the power on and remove the disc on the tray.

2. To put the DVD recorder into version up mode,

press [CM SKIP], [6], [5], and [4] buttons on the

remote control uni t in the order. The tray will open

automatically.

Fig. a appears on the screen and Fig. b appears on

the VFD.

Firm Update Mode

Please insert a Disc.

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

ver. R1F0467S1E

3. Load the disc for version up.

Fig. c appears on the scr een. The file on the top is

highlighted as the default.

When there is only one file to exist, Step 4 will start

automatically.

Firm Update Mode

UPDATE DISC

JPN

TEST

RIF0025S1E

RIF0035S1E

RIF0056S1E

RIF0078S1E

ver. R1F0467S1E

4. Select the firmware version using arrow buttons,

then press [ENTER] button on the remote control

unit.

Fig. d appears on the screen and Fig. e appears on

the VFD. The DVD recorder starts updating.

Firm Update Mode

R1F0525S1E

File Loading...

*1

Fig. d Programming Mode Screen

Fig. e VFD in Programming Mode (Example)

ver. R1F0467S1E

The appearance shown in *1 of Fig. d is descr ibed

as follows.

AppearanceNo. State

1

File Loading... Sending files into the memory.

Firmware

2

Updating...

Firm Update

-

Failure

Writing new version data.

Failed in updating.

5. A fter updatin g is finished, th e tray opens automatically.

Fig. f appears on the s c reen and Fig. g appears on

the VFD.

Fig. c Update Disc Screen

Firm Update Mode

R1F0525S1E

B/E Firmware

Update End

ver. R1F0467S1E

Fig. f Completed Program Mode Screen

Fig. g VFD in Completed Program Mode

6. P ress [POWER] button to turn t he power off. Then

press it again.

1-8-1 E9400TEST

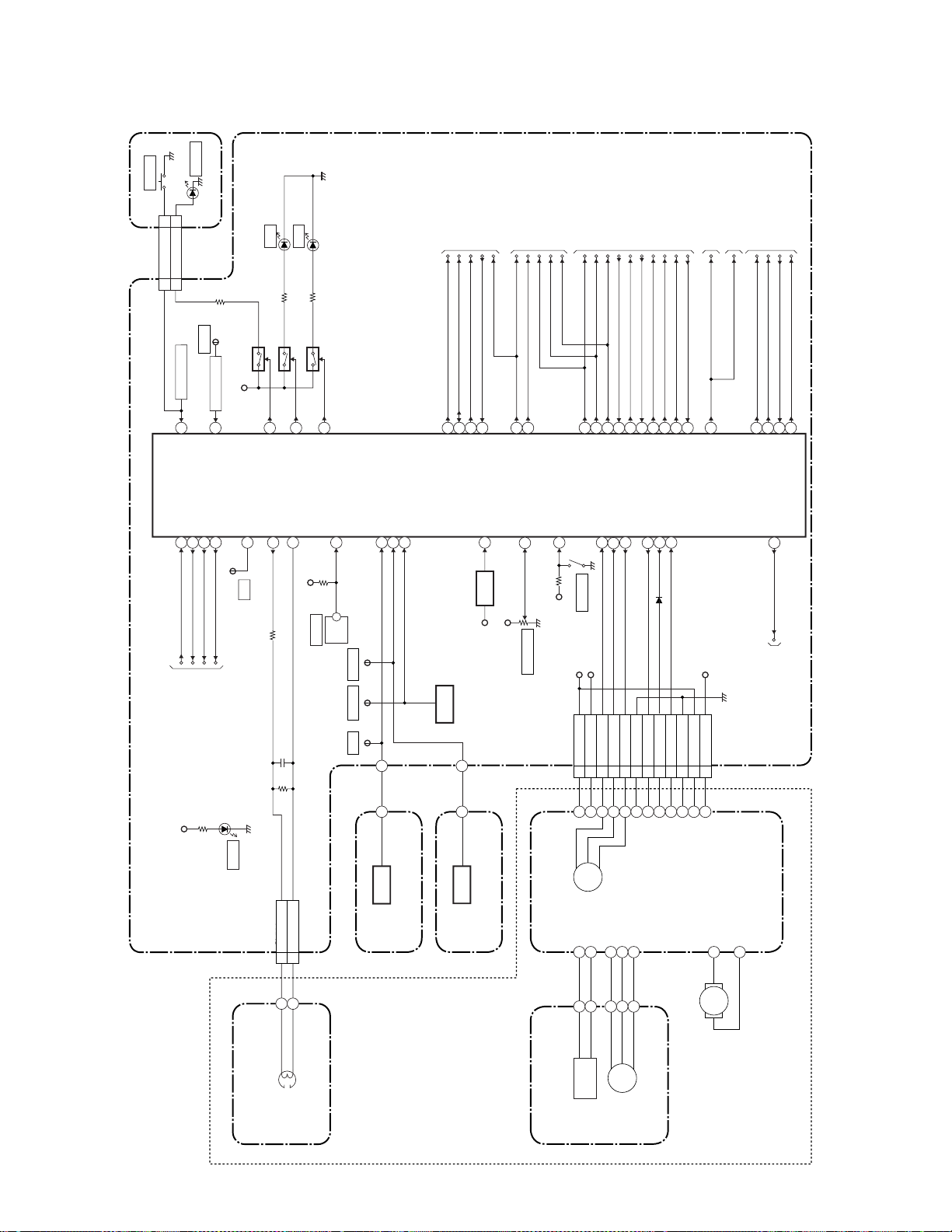

BLOCK DIAGRAMS

Servo / System Control Block Diagram

POWER

D567

POWER

SW501

CN1614

POWER-KEY

33

CN1613

POWER SW CBA

POWER-LED

11

S-INH

TP502

D564 VCR

Q564

Q561

TO Hi-Fi AUDIO

BLOCK

DIAGRAM

D565 DVD

Hi-Fi-H-SW

NORMAL-L

IIC-BUS SCL

IIC-BUS SDA

Q562

A-MUTE-H

A-MUTE-H

TO AUDIO

BLOCK DIAGRAM

YCA-CS

D-REC-H

YCA-SCL

YCA-SDA

YCA-SCL

YCA-SDA

YCA-CS

C-SYNC

D-V SYNC

TO VIDEO

BLOCK DIAGRAM

V-ENV

RF-SW

H-A-SW

C-ROTA

H-A-COMP

TO VIDEO OUTPUT SELECT

BLOCK DIAGRAM

TO AUDIO INPUT/OUTPUT

SELECT BLOCK DIAGRAM

TO SUB SYSTEM CONTROL

BLOCK DIAGRAM

S-CS

S-CLK

S-DATA-IN

S-DATA-OUT

OUTPUT-SELECT

OUTPUT-SELECT

KEY SWITCH

KEY SWITCH

66

67

KEY- 1

KEY- 2

DISPLAY-DATA

DISPLAY-CLK

REMOTE-VIDEO

IC501

(SERVO/SYSTEM CONTROL)

DISPLAY-ENA

5

9

10

11

DISPLAY-ENA

DISPLAY-DATA

DISPLAY-CLK

REMOTE-VIDEO

TO SUB SYSTEM

CONTROL BLOCK

DIAGRAM

AL+5V

D555

MAIN CBA

AL+5V

73

POWER-IND

CTL(+)

CTL58CTL(-)

56

CTL

TP513

S-LED

CN504

CL504

5 CTL(+)

70

VCR-IND

57

AL+5V

SW512

6 CTL(-)

71

DVD-IND

LD-SW

LD-SW

68

TP507

TP506 TP505

END-S

T-REEL

ST-S

Q504

ST-S

69

ST-S

END-S

62

T-REEL

3

T-REEL

Q506

SENSOR CBA

12

13

59

25

Hi-Fi-H-SW

IIC-BUS SCL

Hi-Fi/NOR-IN

IIC-BUS SDA

Q501,Q502

END-S

Q503

26

A-MUTE-H

RESET

PG-DELAY

20

65

RESET

AL+5V

AL+5V

VR501

SENSOR CBA

24

D-REC-H

REC-

SAF-SW

2

REC SW

SW511

AL+5V

SW-POINT

AL+12V(1)

CN502

AL+12V(1)2P-ON+5V3C-FG4C-F/R5C-CONT6GND7LM-FWD/REV

1

CAPSTAN MOTOR

14

15

16

YCA-SCL

YCA-SDA

C-FG

49

P-ON+5V

M

CAPSTAN

MOTOR

41

YCA-CS

C-SYNC

C-CONT

C-F/R

28

27

78

64

19

V-ENV

C-ROTA

D-V SYNC

LM-FWD/REV

D-CONT

29

21

D-CONT9D-PFG10GND11AL+12V(1)

8

79

18

RF-SW

H-A-SW

D-PFG

47

80

46

H-A-COMP

OUTPUT-SELECT

AL+18V

AL+18V

12

7

6

8

1

S-CS

S-CLK

S-DATA-IN

S-DATA-OUT

P-ON-L

22

P-ON-L

TO POWER SUPPLY

BLOCK DIAGRAM

AC HEAD ASSEMBLY

CONTROL

(DECK ASSEMBLY)

HEAD

1-9-1

M

PG

SENSOR

CYLINDER ASSEMBLY

DRUM

MOTOR

M

LOADING

MOTOR

E9413BLS

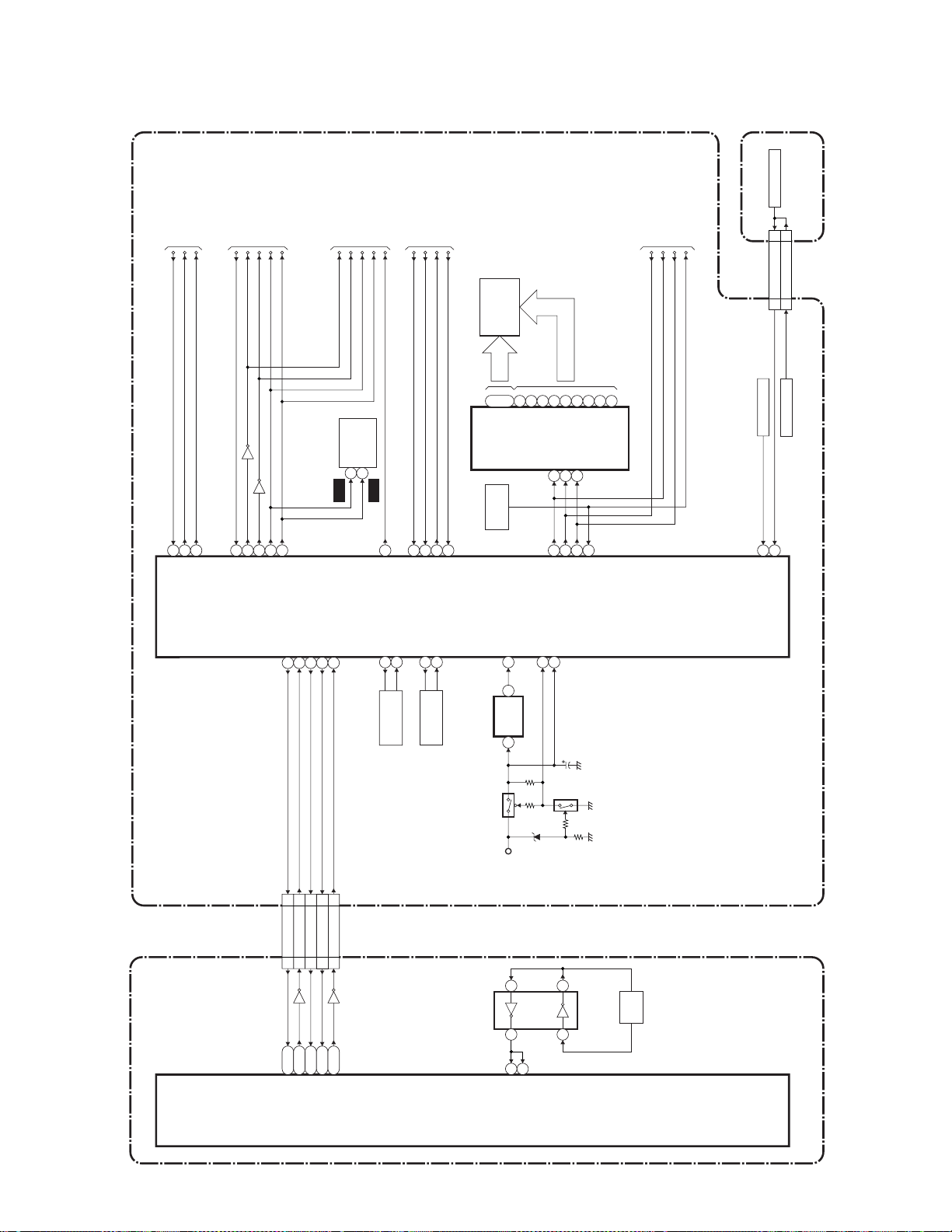

Sub System Control Block Diagram

TO POWER SUPPLY

BLOCK DIAGRAM

TO VIDEO INPUT SELECT

BLOCK DIAGRAM

TO AUDIO INPUT/OUTPUT

SELECT

BLOCK DIAGRAM

TO SERVO/SYSTEM

CONTROL

BLOCK DIAGRAM

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

KEY SWITCH

FUNCTIN CBA

IC200

(SUB MICRO CONTROLLER)

POW-SW

REG-CONT

646125

POW-SW

REG-COUT

PWSW

PWSW

FID

INSEL-0

Q800

FID

INSEL-1

SUB-SCL

SUB-SDA

Q801

454654

53

INSEL-0

INSEL-1

SUB-SCL

SUB-SDA

SUB-RXD

SUB-TXD

SYS-RESET

4052515041

INSEL-0

INSEL-1

SCL

TU900

(TUNER UNIT)

11

WF13

SUB-SCLK

RDY

SUB-SCL

SUB-SDA

SDA

12

WF14

A-MUTE

47

A-MUTE

X IN

X OUT

23

224221

S-CS

S-DATA-OUT

293031

S-CS

S-CLK

S-DATA-IN

S-DATA-IN

S-DATA-OUT

XC OUT

XC IN

20

IC571

(FIP DRIVER)

32S-CLK

FIP502

RM2001

GRID FIP

~

23

~

1G

REMOTE

789

17

a

7G

SENSOR

RESET

19

45

bcd

P-DOWN

16

SEGMENT

10

11

e

DIN

CLK

9

10

FL-CLK

FL-SDA

VCC

57

12

131416

f

g

STB

2281

8

4

FL-STB

REMOTE

DVD-KEY-2 11DVD-KEY-2 2

DISPLAY-CLK

DISPLAY-ENA

DISPLAY-DATA

REMOTE-VIDEO

i

h

2

CN1615 CN1616

KEY SWITCH

KEY SWITCH

MAIN CBADVD BE MAIN CBA UNIT

1

2

DVD-KEY-1

DVD-KEY-2

IC3

(MAIN MICRO CONTROLLER)

CN201

8

CN7

Q16

D22

SYS-RESET

F24

H22

G22

SUB-TXD

SUB-RXD

SUB-SCLK

Q17

RDY 66SUB-SCLK 33SUB-TXD 55SUB-RXD 77SYS-RESET 8

F25

RDY

X200

8MHz

RESETEV+5V

IC7

IC201

(INVERTER)

Q202

16

N23

27MHz CLK

R23

27MHz CLK

C205

Q203

4

3

(BACKUP CAPACITOR)

27MHz

X'TAL

X3

RESONATOR

32.768KHz

X'TAL

X201

1-9-2

E9413BLSUB

Digital Signal Process Block Diagram

TO VIDEO

INPUT SELECT

AD22,AF24

AC21,AB18,

BLOCK DIAGRAM

S-CLK

IC9-RESET

AD21

S-CLK

SCL

SDA

Y4

E25

SCL

IC9-RESET

SPDIF

AD2

SDA

VIDEO-Y(I)

VIDEO-Y(I/P)

AC12

Y

Y(I)

D/A

TO VIDEO

OUTPUT SELECT

BLOCK DIAGRAM

VIDEO-C

AE12

AC13

C

D/A

D/A

VIDEO

ENCODER

VIDEO-Cr

VIDEO-Cb

AD12

Cr

Cb

D/A

AE13

D/A

VID(0-7)

AC19,AE22,

AE23,AC20,

AB23

BCK

AD25

AUDIO

DATA

I/F

AC25

LRCK

AB22

MD

H24

MD

MC

J22

MC

ML

J23

ML

TO AUDIO

INPUT/OUTPUT

SELECT

BLOCK DIAGRAM

SCK

AB19

AC23

SCK

SYSCLK

LRCK

AB20

BCK

AB21

AUDIO

DATA

SYSCLK

DVD BE MAIN CBA UNITDVD FE MAIN CBA UNIT

AD24

I/F

FLASH MEMORY

DDR SDRAM

REC VIDEO SIGNAL PB VIDEO SIGNAL REC AUDIO SIGNAL PB AUDIO SIGNAL

IC3 (MAIN MICRO CONTRLLER)IC5301

VIDEO

I/F

CN1CN5301

BACK-END

DIGITAL

SIGNAL

FRONT-END

PROCESS

DIGITAL

SIGNAL

PROCESS

IC6 (FLASH MEMORY)

IC5401

IC1,IC2 (DDR SDRAM)

SDRAM

DVD MECHA

DVD MECHA & FE ASSEMBLY

IC5202

RF/

ERROR AMP

CN5101

TILT

PICK

IC5501

TRACKING

-UP

FOCUS

MOTOR

DRIVER

CN5603B

SLED

MOTOR

M

CN5502B

LOADING

MOTOR

FLASH

MEMORY

FRONT-END

MICRO

CN5602B

TRAY

CLOSE

TRAY

OPEN

CONTROLLER

LOADER CBA

IC5704

IC5503

MOTOR

CN5501

SPINDLE

MOTOR

DRIVER

M

E9413BLD

IC5703

CN5603

M

FE

ENCODER

ENCODER CBA

1-9-3

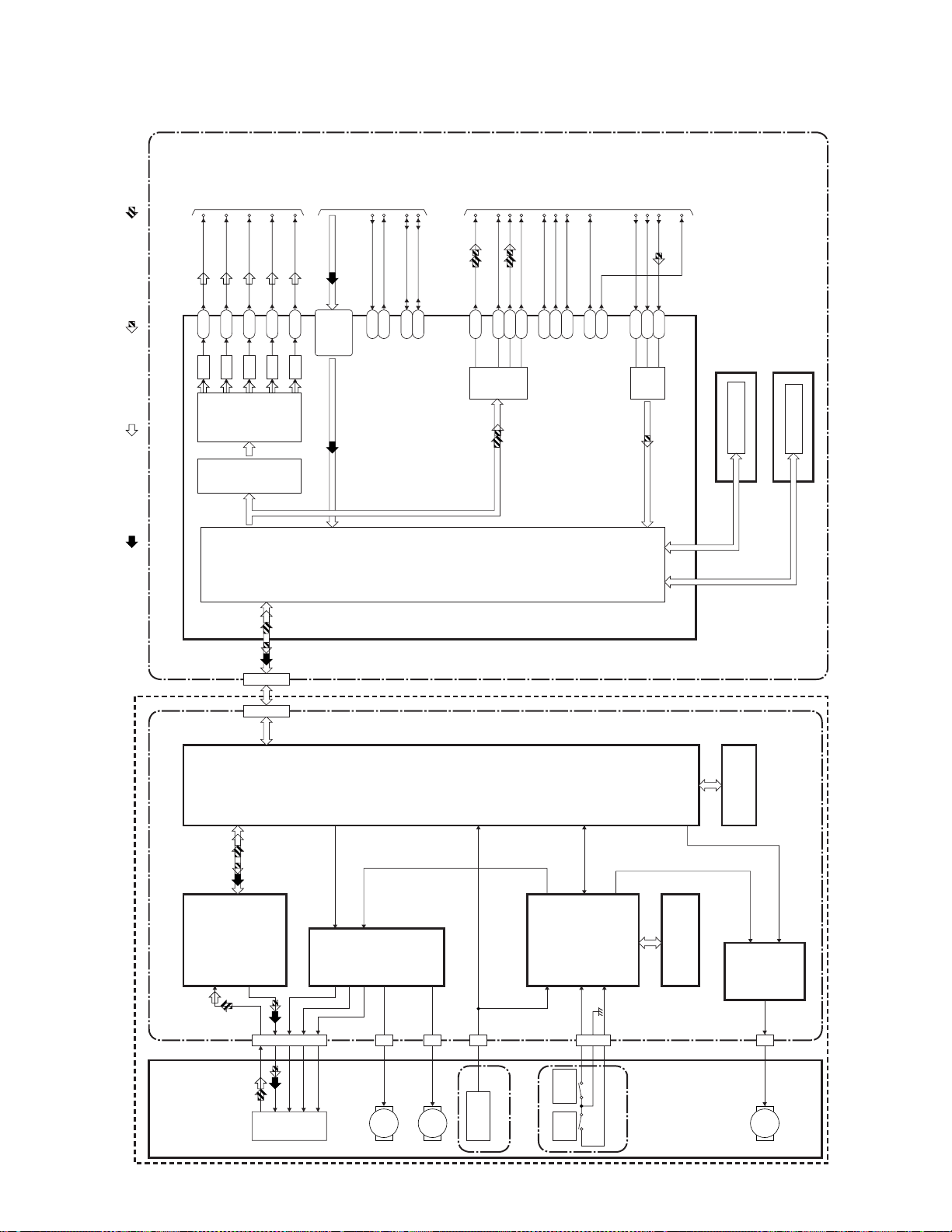

Video Block Diagram

P

R

REC VIDEO SIGNAL PB VIDEO SIGNAL

MAIN CBA

(OSD)

OSD CHARACTER

MIX

IC501

38

LUMINANCE

SIGNAL PROCESS

CLAMP

Q301

BUFFER

DELAY

CCD 1H

36 37 39 34

VCA

40

26

6dB

AMP

QV/QH

YNR/COMB FILTER

Y/C

MIX

FBC

RP

AGC

VIDEO

CHROMINANCE

SERIAL

69

SIGNAL PROCESS

P

R

SEPA

SYNC

I/F

70

SP

SP

HEAD

AMP

727374

V-COM

V(R)-1

V(L)-1

V(L)-2

CN253

123

456

EP

EP

HEAD

66

67

V-COM

V(R)-2

AMP

65

14

TP302

RF-SW

WF2

C-PB

TP301

C-ROTA/RF-SW

57

C-ROTA

RF-SW

TO

WF3

H-A-COMP

ENV-DET

59

58

60

V-ENV

H-A-SW

H-A-COMP

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

PB/EE-VIDEO

VCR-VIDEO(DUB)

(VCR DVD DUBBING)

TO VIDEO INPUT

SELECT BLOCK

DIAGRAM

TO VIDEO OUTPUT

SELECT BLOCK

DIAGRAM

IC301

(VIDEO SIGNAL PROCESS/ HEAD AMP)

30

VCR-VIDEO

TO VIDEO INPUT

SELECT BLOCK

VCR

DVD

28

DVD-VIDEO(DUB)

DIAGRAM

TO VIDEO OUTPUT

SELECT BLOCK

DIAGRAM

255324

54

C-SYNC

YCA-SCL

YCA-SDA55YCA-CS

(DVD VCR DUBBING)

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

1-9-4

D-V-SYNC

D-V-SYNC

VIDEO (L)-1 HEAD

VIDEO (R)-1 HEAD

(DECK ASSEMBLY)

VIDEO (L)-2 HEAD

VIDEO (R)-2 HEAD

CYLINDER ASSEMBLY

E9413BLV

Video Input Select Block Diagram

TO SUB SYSTEM

CONTROL BLOCK

DIAGRAM

TO VIDEO

BLOCK DIAGRAM

(VCR DVD DUBBING)

FID

INSEL-0

INSEL-1

REC VIDEO SIGNAL PB VIDEO SIGNAL

(VIDEO INPUT SELECT)

IC805

245

TU-VIDEO

VIDEO1

VIDEO2

3

SW CTL

10

9

VCR-VIDEO(DUB)

171915

PB/EE

(VIDEO INPUT SELECT)

IC800

JK1401

C

3 4

Y

13

Y1

S-VIDEO

IN1

2

1

COMPOSITE

Y2

BUFFER LPF

JK804

VIDEO IN1

VIDEO OUT

TU900 (TUNER UNIT)

18

WF15

7

9

11

VIDEO1

VIDEO2

TU-VIDEO

JK806

C

3 4

Y

22Y-IN2

CN1609 CN1605

1203

C1

C2

BUFFER LPF

S-VIDEO

IN2

2

1

11C-IN2

44V-IN2

SERIAL

I/F

JK803

22 23

VIDEO IN2

TO SUB SYSTEM CONTROL

BLOCK DIAGRAM

SUB-SCL

SUB-SDA

JACK CBA

MAIN CBA

VCR-VIDEO

TO VIDEO

BLOCK

DIAGRAM

CN201

CN7

Q18

24

V-SYNC

(VIDEO DECODER)

IC9

Q200

44FID

Q19

Y D ATA

BUFFER

18 18VIDEO-Y

20 20VIDEO-C

BUFFER LPF

1

MUX

AGCA/D

PROCESS

FORMATTER

11-18

Q20

BUFFER LPF

2

C D ATA

PROCESS

9

RESET

8

X1

14.31818MHz

X'TAL

5

PLL

SERIAL

21

BUFFER

Q201

6

DVD BE MAIN CBA UNIT

I/F

22

VID(0-7)

1-9-5

S-CLK

TO DIGITAL

SIGNAL

IC9-RESET

PROCESS

BLOCK

DIAGRAM

SCL

SDA

E9413BLVIS

Video Output Select Block Diagram

JK1401

S-VIDEO

OUT

VIDEO-Y

OUT

VIDEO-Cb

OUT

VIDEO-Cr

OUT

COMPOSITE

VIDEO OUT

REC VIDEO SIGNAL PB VIDEO SIGNAL

IC1404 (VIDEO DRIVER)

5

2dB

AMP

LPF DRIVER

4dB

AMP

3

6

DRIVER

8dB

AMP

-6dB

7

2dB

AMP

LPF DRIVER

4dB

AMP

1

2

1

3 4

YC

11

2dB

AMP

LPF DRIVER

4dB

AMP

6

10

2dB

AMP

LPF DRIVER

4dB

AMP

8

13

2dB

LPF DRIVER

4dB

IC1405 (VIDEO DRIVER)

3

AMP

AMP

JK1403

WF6

WF1

IC1406

R1402

(OUTPUT SELECT)

JK751

TP751

V-OUT

BUFFER

Q391

2151

DVD-VIDEO(DUB)

PB/EE-VIDEO

(DVD VCR DUBBING)

TO VIDEO

BLOCK DIAGRAM

VIDEO-IN

TU900 (TUNER UNIT)

6

WF12

109 11

SW CTL

OUTPUT-SELECT

TO SERVO/SYSTEM CONTROL

BLOCK DIAGRAM

WF4

CN201

11VIDEO-Y(I)

CN7

VIDEO-Y(I/P)

VIDEO-Y(I)

WF8

WF7

WF5

14

VIDEO-Y(I/P)

14

16 16VIDEO-C

12 12VIDEO-Cb

10 10VIDEO-Cr

VIDEO-C

VIDEO-Cb

VIDEO-Cr

TO DIGITAL SIGNAL

PROCESS BLOCK

DIAGRAM

1-9-6

DVD BE MAIN CBA UNIT MAIN CBA

E9413BLVOS

Audio Block Diagram

Mode : SP/REC

DVD AUDIO SIGNAL

PB-AUDIO SIGNAL REC-AUDIO SIGNAL

MAIN CBA

(AUDIO PROCESS)

IC301

TUNER

LINE 1

76

LINE 2

80

TO

SERVO/SYSTEM

CONTROL BLOCK

YCA-SCL

YCA-SDA

P-ON+5V

DIAGRAM

YCA-CS

A-MUTE-H

D-REC-H

10

MUTE

SERIAL

I/F

P-ON+5V

Q426

(PB=ON)

58 55 53 54

SWITCHING

D-REC OFF

Q425

LINE

AMP

LPF

REC

AMP

ALC

78

P

R

4

3 2

SP/LP-ON

5

EQ

AMP

6

Q422

BIAS

OSC

9

8

AUTO

BIAS

11

Q421

N-A-IN

TO Hi-Fi AUDIO

N-A-OUT

BLOCK DIAGRAM

1-9-7

AC HEAD ASSEMBLY

(DECK ASSEMBLY)

CN504

4 A-PB/REC

AUDIO

3 A-COM

HEAD

1 AE-H

2 AE-H/FE-H

AUDIO

ERASE

HEAD

CN501

1 FE-H

FE HEAD

FULL

ERASE

2 FE-H-GND

HEAD

E9413BLA

Audio Input/Output Select Block Diagram

AUDIO-L

OUT2

JK751

A-OUT-L

TP754

REC AUDIO SIGNAL PB AUDIO SIGNAL

A-OUT-R

TP753

AUDIO-R

OUT2

AUDIO-L

OUT1

JK805

TO SERVO/SYSTEM

CONTROL BLOCK DIAGRAM

MUTE-ONDRIVE

AUDIO-R

OUT1

Q805

MUTE-ON

DVD-AUDIO(L)

DVD-AUDIO(R)

TO Hi-Fi AUDIO

BLOCK DIAGRAM

VCR-AUDIO(L)

VCR-AUDIO(R)

PB/EE-AUDIO(L)

PB/EE-AUDIO(R)

AUDIO-L

JK804

MOD-A

IN1

AUDIO-R

IN1

TU900 (TUNER UNIT)

)

WF11

AUDIO-IN2

SIF OUT

15

21

TO SUB SYSTEM

CONTROL

BLOCK DIAGRAM

SUB-SCL

SUB-SDA

AUDIO-L

JK801

66A(L)-IN2

CN1609 CN1605

IN2

JK800

88A(R)-IN2

AUDIO-R

IN2

4

14

(OUTPUT SELECT)

IC1406

5

3

12

13

DIGITAL

AUDIO OUT

JK1202

Q1351

BUFFER

WF10

SW CTL

11

9 10

(OP AMP)IC804

OUTPUT-SELECT

WF9

Q804 Q806

A-MUTE

TO SUB SYSTEM

CONTROL

1

OP AMP

2

BLOCK DIAGRAM

7

OP AMP

6

(DVD VCR DUBBING)

L-CH

MTS/SAP AUDIO

(

SIGNAL PROCESS

IC900

425

IN1TUIN2

IN1

(L-CH)

(AUDIO INPUT SELECT)

IC801

)

OP AMP

(

IC802

)

OP AMP

(

IC803

3

2

OP

1

2

OP

1

MTS/SAP

AUDIO

SIGNAL

PROCESS

R-CH

30

29

AMP

AMP

24 27

IN1

IN1TUIN2

(R-CH)

111121514

13

6

OP

AMP

7

6

OP

AMP

7

SW CTL

VCR PB

(VCR DVD DUBBING)

9 10

INSEL-1

INSEL-0

TO SUB SYSTEM

CONTROL

MAIN CBA JACK CBA

BLOCK DIAGRAM

18 18SPDIF

CN6 CN202

SPDIF

IC13

(AUDIO D/A CONVERTER)

123

BCK

27 27A-OUT(L)

CN7 CN201

7

L-CH

DATA

LRCKMDMC

29 29A-OUT(R)

8

R-CH

MUTE

AUDIO D/A

DVD-A-MUTE

21 21

25 25AUDIO(L)

23 23AUDIO(R)

11

CONVERTER

131416

SCK15ML

TO DIGITAL

SIGNAL

PROCESS

BLOCK

1-9-8

DIAGRAM

IC12

(AUDIO A/D CONVERTER)

1

R-CH

L-CH

131415

BCK

LRCK

5

AUDIO A/D

CONVERTER

16

DVD BE MAIN CBA UNIT

DATA

SYSCLK

E9413BLAS

Loading...

Loading...