Sylvania CDVC-800-D Service manual

SERVICE MANUAL

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

Sec. 2: Deck Mechanism Section

I Standard Maintenance

I Alignment for Mechanism

I Disassembly/Assembly of Mechanism

I Alignment Procedures of Mechanism

Sec. 3: Exploded views

and Parts List Section

I Exploded views

I Parts List

I CBA’s

DVD PLAYER &

VIDEO CASSETTE RECORDER

CDVC800D

POWER

OPEN/CLOSE

DVD

DVD

OUTPUT

TIMER REC

VCR

VIDEO

AUDIO

RECVCRDV D

REW

F.FWDSTOP PLAY

L R

CHANNEL

STOP/EJECT

PLAY

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and

described in this service manual are effective methods of performing service

operations. Some of these service special tools should be used when and as

recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk of

personal injury to service personnel. The possibilit y exists that improper service methods may damage the equipment. It also is important to understand

that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Funai could not

possibly know, evaluate and advice the service trade of all conceivable ways

in which service might be done or of the possible hazardous consequences of

each way. Consequently, Funai has not undertaken any such broad evaluation. Accordingly , a servicer who uses a service pr ocedure or tool which is not

recommended by Funai must first use all precautions thoroughly so that neither his safety nor the safe operation of the equipment will be jeop ardized by

the service method selected.

Manufatured under license from Dolby Laboratories. "Dolby" and

the double-D symbol are trademarks of Dolby Laboratories.

MAIN SECTION

DVD PLAYER &

VIDEO CASSETTE RECORDER

CDVC800D

Sec. 1: Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

TABLE OF CONTENTS

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4-1

Preparation for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5-1

Operating Controls and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

FIRMWARE Renewal Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10-1

Schematic Diagrams / CBA’s and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12-1

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13-1

System Control Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14-1

IC Pin Function Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

Lead Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16-1

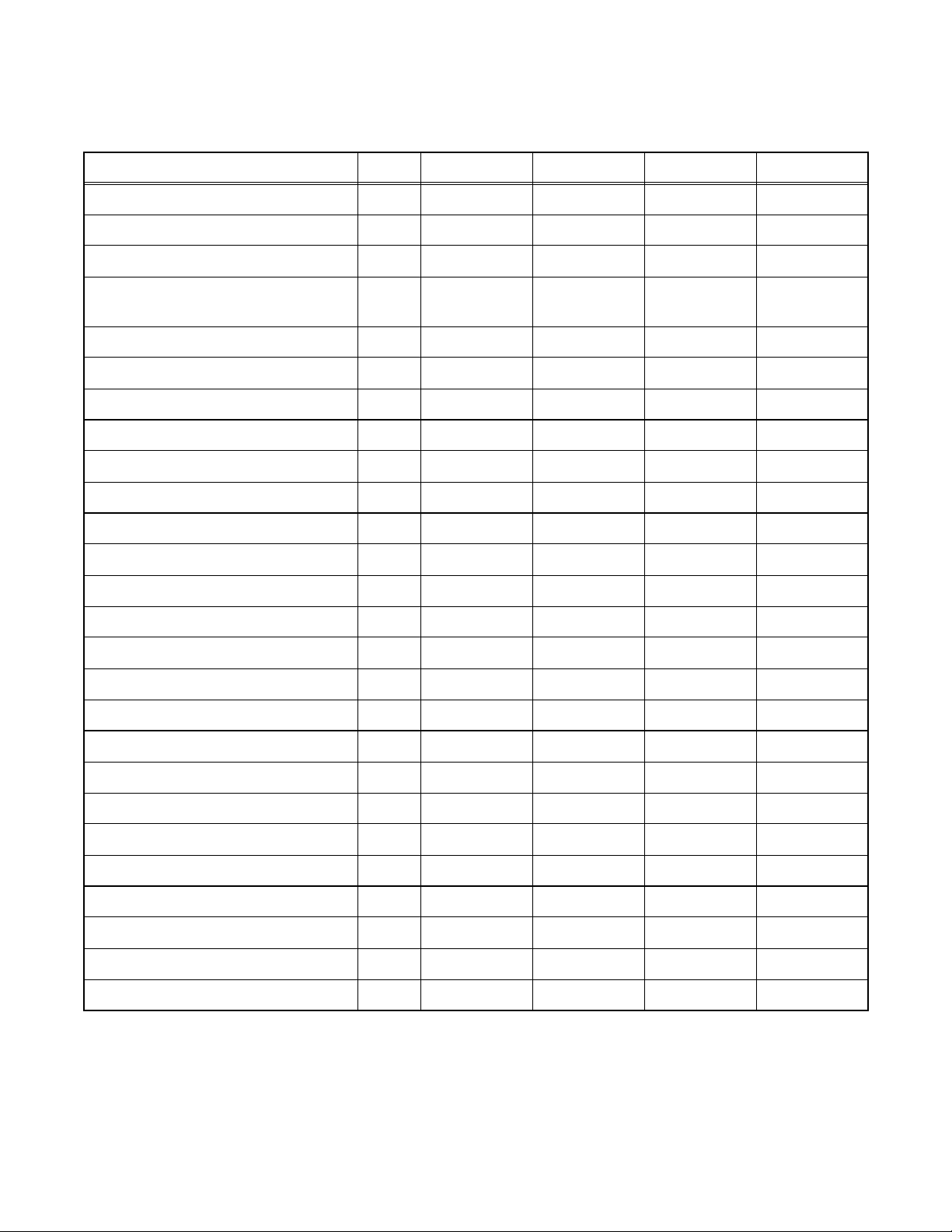

SPECIFICATIONS

< VCR Section >

Description Unit Minimum Nominal Maximum Remark

1. Video

1-1. Video Output (PB) Vp-p 0.8 1.0 1.2 SP Mode

1-2. Video Output (R/P) Vp-p 0.8 1.0 1.2

1-3. Video S/N Y (R/P) dB 40 45

1-4. Video Color S/N AM (R/P) d B 37 41 SP Mode

1-5. Video Color S/N PM (R/P) d B 30 36 SP Mode

1-6. Resolution (PB) Line 230 245 SP Mode

2. Servo

2-1. Jitter Low µsec 0.07 0.12 SP Mode

2-2. Wow & Flutter % 0.3 0.5 SP Mode

3. Normal Audio

3-1. Output (PB) dBV -9 -6 -3 SP Mode

3-2. Output (R/P) dBV -9 -6 -1.5 SP Mode

3-3. S/N (R/P) dB 36 41 SP Mode

3-4. Distortion (R/P) % 1.0 4.0 SP Mode

3-5. Freq. resp (R/P) at 200Hz dB -11 -4 SP Mode

(-20dB ref. 1kHz) at 8kHz dB -14 -4 SP Mode

SP Mode,

W/O Burst

4. Tuner

4-1. Video output Vp-p 0.8 1.0 1.2 E-E Mode

4-2. Video S/N dB 39 42 E-E Mode

4-3. Audio output dB -10 -6 -2 E-E Mode

4-4. Audio S/N dB 40 46 E-E Mode

5. Hi-Fi Audio

5-1. Output dBV -12 -8 -4 SP Mode

5-2. Dynamic Range dB 70 85 SP Mode

5-3. Freq. resp (6dB B.W) Hz 20 ~ 20K SP Mode

Note: Nominal specs represent the design specs. All units should be able to approximate these – some will exceed

and some may drop s lightly below th ese spec s. Limit sp ecs repr esent the a bsolute wo rst conditi on that st ill migh t

be considered acceptable; In no case should a unit fail to meet limit specs.

1-1-1 H9405SP

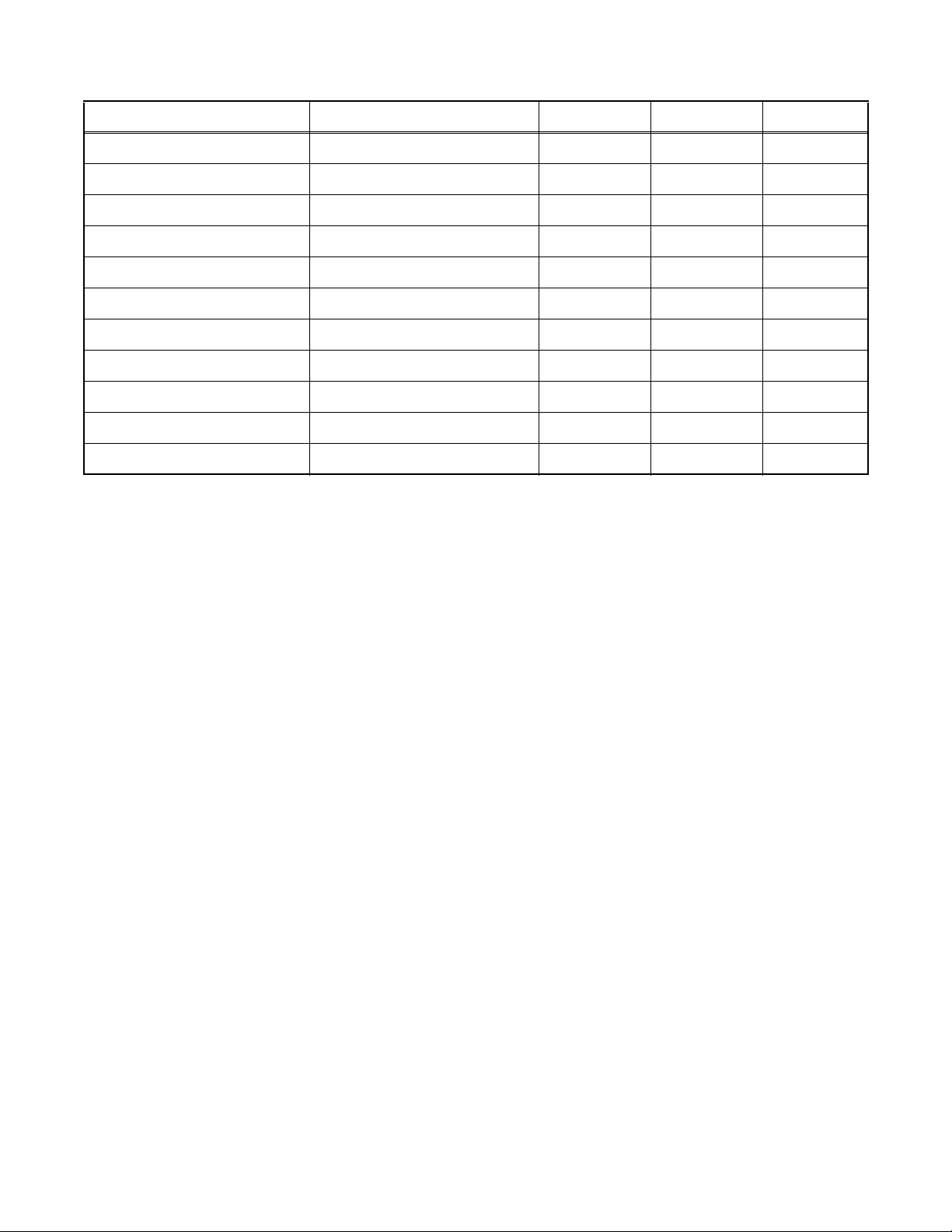

< DVD Section >

ITEM CONDITIONS UNIT NOMINAL LIMIT

1. Video Output 75 ohm load Vpp 1.0 ± 0.1

2. Coaxial Digital Out 75 ohm load mVpp 500 ± 100

3. Audio (PCM)

3-1. Output Level 1kHz 0dB Vrms 2.0

3-2. S/N dB 120

3-3. Freq. Response

DVD fs=48kHz 20~22kHz dB ± 0.5

CD fs=44.1kHz 20~20 kHz dB ± 0.5

3-4. THD+N

DVD 1 kHz 0dB % 0.0025

CD 1 kHz 0dB % 0.003

NOTES:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply : AC120 V 60 Hz

3. Load imp. : 100 K ohm

4. Room ambient : +25

°C

1-1-2 H9405SP

D

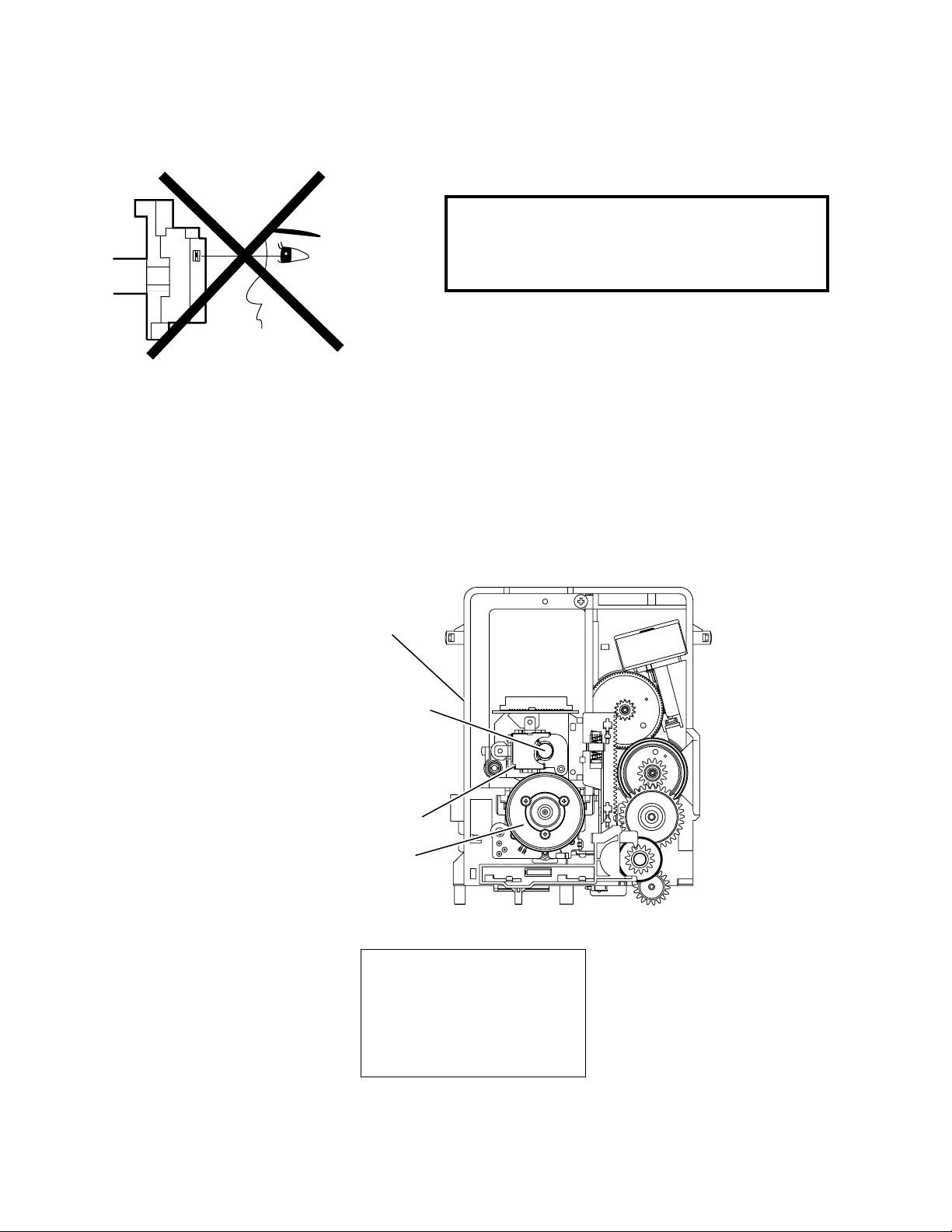

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from the location shown in the figure. W hen checki ng the laser diode , be sure to keep

your eyes at leas t 30cm away f rom the pi ckup lens wh en the diod e is turned on. Do not l ook directl y at the las er

beam.

Caution: Use of controls and a djustments, or doing proce dures other than those s pecified herein, may r esult in

hazardous radiation exposure.

rive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

CAUTION

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

Location: Inside Top of DVD mechanism.

1-2-1 DVD_LASER

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related charac teristics which are often not evident from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special s afe ty c har ac te rist ic s ar e i den tified by a # on schematics and in parts lists. Use of a

substitute replacement that does not have the same

safety characteristics as the recommended replacement part might create shock, fi re, and/or other hazards. The Product’s Safety is under review

continuously and new instructions are issued whenever appropriate. Prior to shipment from the factory,

our products are carefully inspected to confirm with

the recognized prod uct safety and electrical codes of

the countries in whic h th ey are to be sold. However, in

order to maintain such comp lianc e, it is equ ally impor tant to implement the following precautions when a set

is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spur ious rad iation. T hese m ust also be

replaced only with specified re pla ce men ts.

Examples: RF converters, RF c ables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. Observe that the wir es do n ot co ntact h eat pr od uc -

ing parts (heatsinks, oxide metal fil m re sisto rs, fus ible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord h as been repl aced, ch eck that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power tr ansformer uses crimp type connectors

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent

shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector. (Discard it.)

2)Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to th e complete closure of the tool.

L. When connecting or disconnecting the internal

connectors, first, discon nect the AC plug from the

AC outlet.

1-3-1 DVD_SFN1

r

e)

Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deterio ration. Observe that screws , parts,

and wires have been returned to their original positions. Afterwards, do the following tests and confirm

the specified values to verify compliance with safety

standards.

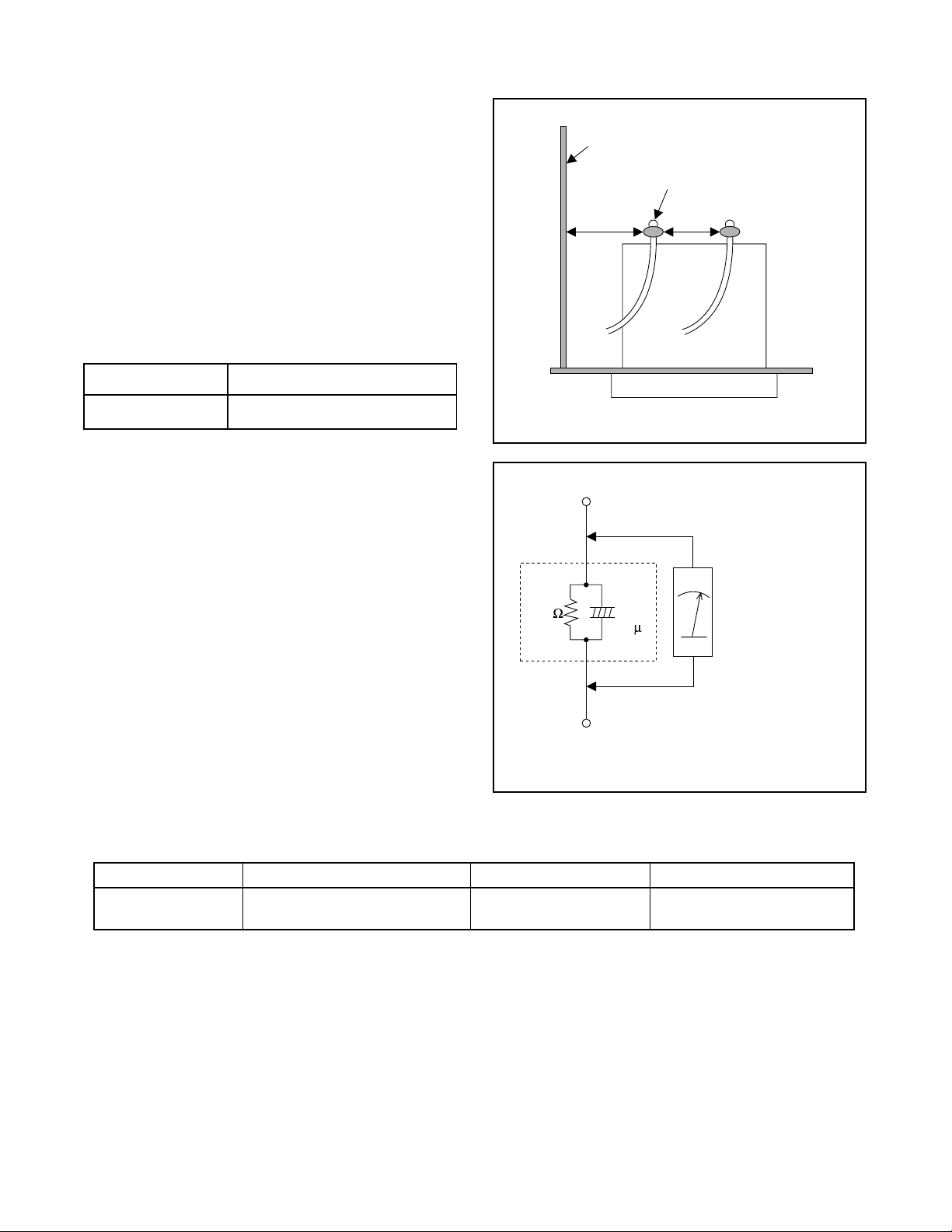

1. Clearance Distance

When replacing primary circuit components, confirm

specified cleara nce distanc e (d) and (d’) between sol dered terminals, and between terminals and surrounding metallic parts. (See Fig. 1)

T able 1: Ratings for selected area

AC Line Voltage Clearance Distance (d) (d’)

Chassis or Secondary Conducto

Primary Circuit Terminals

dd'

120 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure acr oss the ter minals of l oad

Z. See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

≥ 3.2mm (0.126 inches)

0.15µF CAP. & 1.5kΩ RES.

Connected in parallel

Exposed Accessible Part

Z

1.5k

i≤0.5mA Peak Exposed accessible parts

0.15 F

Earth Ground

B

Power Cord Plug Prongs

AC Voltmeter

(High Impedanc

Fig. 1

Fig. 2

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

1-3-2 DVD_SFN1

STANDARD NOTES FOR SERVICING

O

P

P

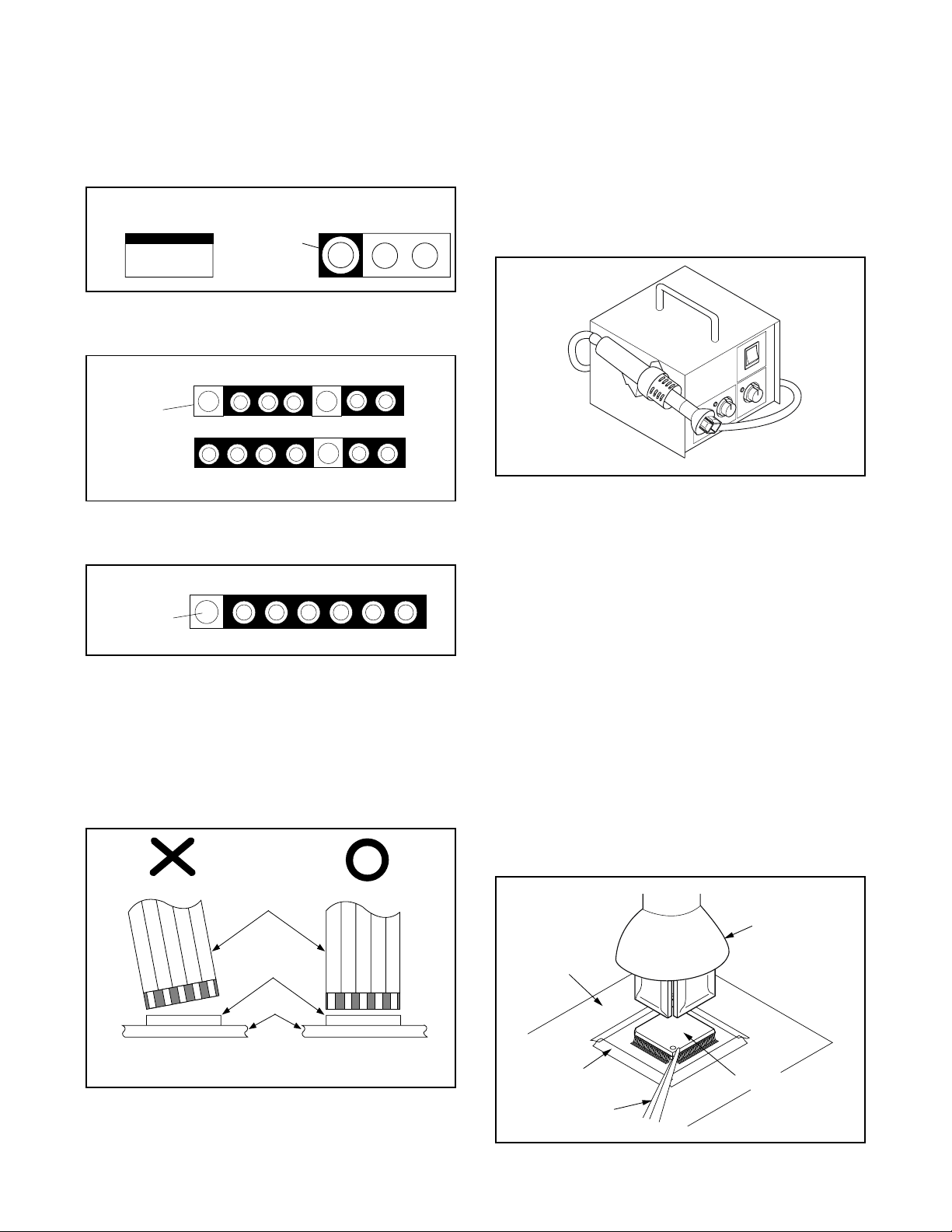

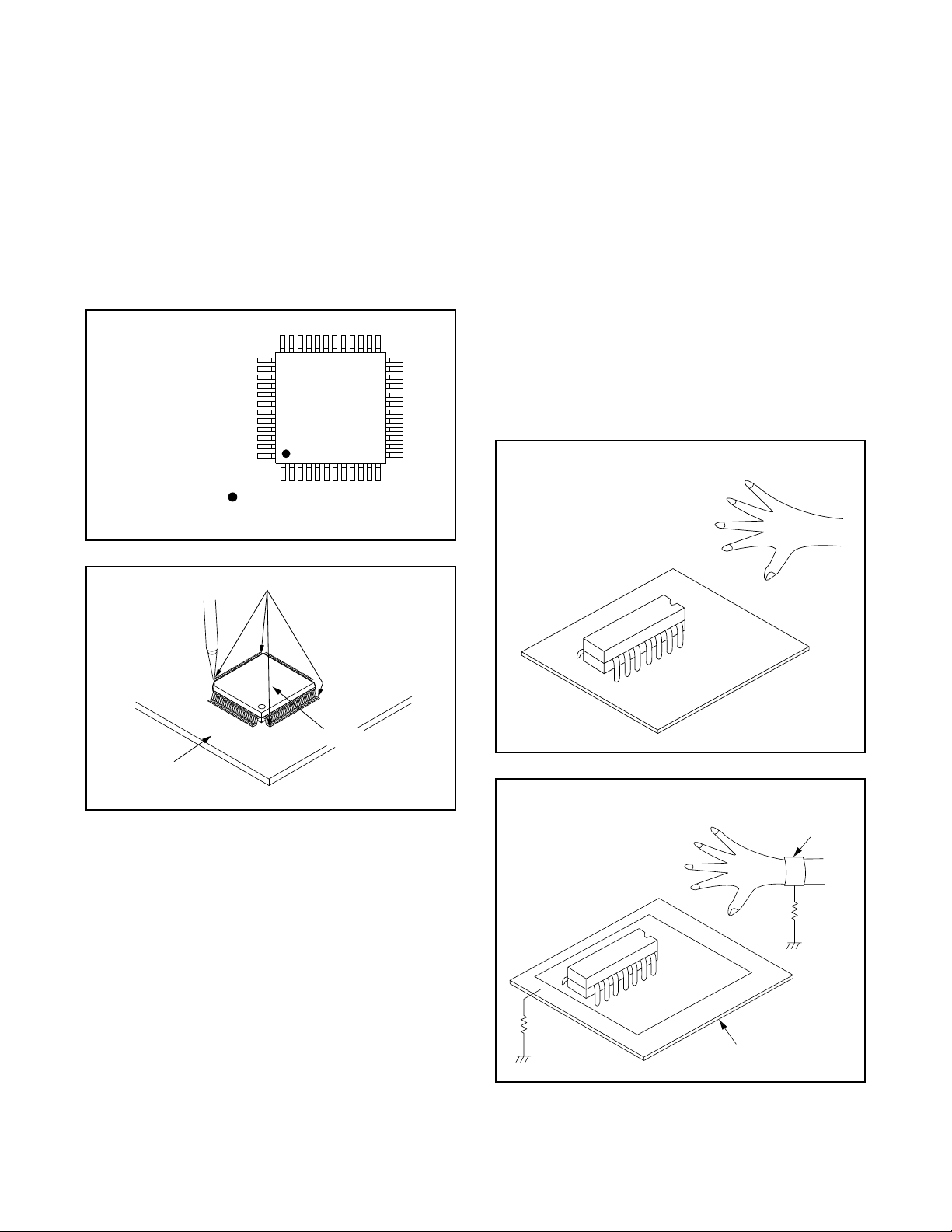

Circuit Board Indications

a. The output pin of the 3 pin Regulator ICs is indi-

cated as shown.

Top View

Input

ut

b. For other ICs, pin 1 and every fifth pin are indicated

as shown.

In

in 1

c. The 1st pin of every male connector is indicated as

shown.

in 1

Bottom View

5

10

How to Remove / Install Flat Pac k-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:.

(1) Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

(2) Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3) Bottom of the flat pack-IC is fixed wit h glue to the

CBA; when removing entire fl at pack-IC, fir st apply

soldering iron to center of the fla t pack-IC and hea t

up. Then remove (glue will be melted). (Fig . S-1-6)

(1) Release the flat pack-IC from the CBA using twe e-

zers. (Fig. S-1-6)

Caution:

Instructions for Connectors

1. When y ou c onn ect o r di scon nec t the FF C ( Flexib le

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

1. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage to

the chip parts may occur. Put maskin g tape a r ound

the flat pack-IC to protect other parts from damage.

(Fig. S-1-2)

2. T h e fla t pack-I C on th e CB A i s a ffixed with g lue , so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

Machine

Flat Pack-IC

Fig. S-1-2

1-4-1 DVD_NOTE

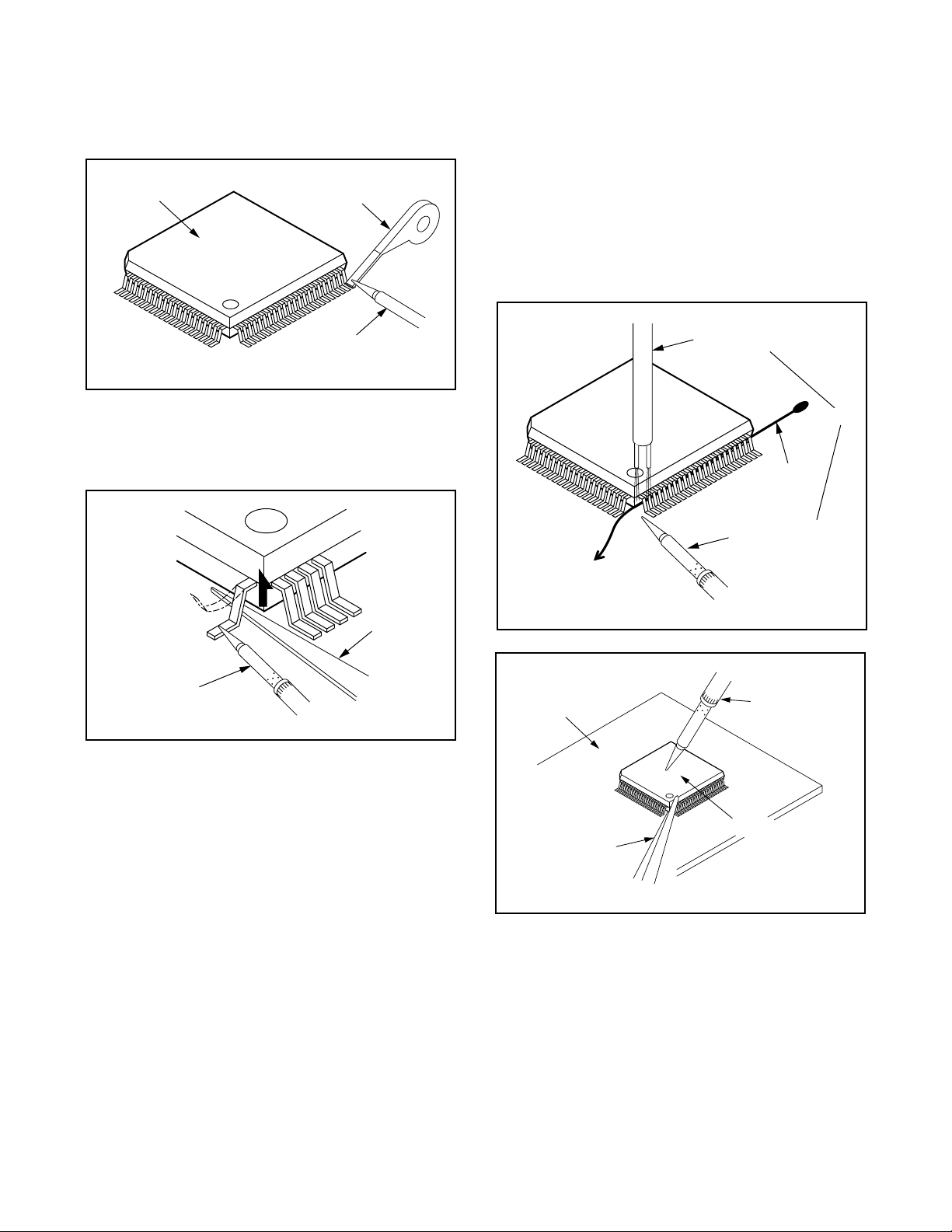

With Soldering Iron:

F

F

S

rp

or

n

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. Wh en you use solder flux

which is applied to all pins of the f lat pack-IC, you

can remove it easily. (Fig. S-1-3)

lat Pack-IC

Desoldering Braid

(4) Bottom of the flat pack-IC is fixed wit h glue to the

CBA; when removing entire fl at pack-IC, fir st apply

soldering iron to center of the fla t pack-IC and hea t

up. Then remove (glue will be melted). (Fig . S-1-6)

(5) Release the flat pack-IC from the CBA using twe e-

zers. (Fig. S-1-6)

Note:

When using a sold ering iron, care must be taken

to ensure that the flat pack-IC is not being hel d by

glue. When the flat pack-IC is removed from the

CBA, handle it ge ntl y bec au se it may be damaged

if force is applied.

Soldering Iron

Hot Air Blower

Fig. S-1-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which sold er will

not adhere (iron wir e). When heati ng the pins, us e

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Iron Wire

Soldering Iron

To Solid

Mounting Point

Fig. S-1-5

Sha

Pin

ine Tip

oldering Iron

Fig. S-1-4

CBA

Fine Tip

Soldering Iro

(3)Bottom of the flat pack-IC is fixed with g lue to the

CBA; when removing enti re flat pack-IC, fi rst apply

soldering iron to c en ter o f th e f lat pack-I C an d h eat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4)Release the flat pack-IC from the CBA usin g twee-

zers. (Fig. S-1-6)

Tweezers

Flat Pack-IC

With Iron Wire:

(1)Using desoldering braid, remove the solder from all

Fig. S-1-6

pins of the flat pack-IC. Wh en you use solder flux

which is applied to all pins of the f lat pack-IC, you

can remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solde r

melts so as to lift the IC leads from the CBA contact

pads as shown in Fig. S-1-5

1-4-2 DVD_NOTE

2. Installation

P

i

d

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replac ement flat pack-IC more

easily.

(2) The “I” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when position ing for installation. Then

presolder the four corners of the flat pack-IC. (S ee

Fig. S-1-8.)

(3)Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

Example :

in 1 of the Flat Pack-IC

s indicated by a " " mark.

Fig. S-1-7

Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a po tential difference ca used by electr ostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a gr oundin g band (1MΩ) that is properly grounded to re move any static electricity th at m ay

be charged on the body.

2. Ground for Workbench

(4) Be sure to place a conductive sheet or copper plate

with proper groundin g (1MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will no t escape through the body grounding band, be careful to avoid contacting semi-conductors with your clothing.

< Incorrect >

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

CBA

< Correct >

Grounding Ban

1MΩ

CBA

1MΩ

Conductive Sheet or

Copper Plate

1-4-3 DVD_NOTE

PREPARATION FOR SERVICING

How to Enter the Service Mode

About Optical Sensors

Caution:

An optical sensor system is used for the Tape Start

and End Sensors on this equipment. Carefully read

and follow the instructions below. Otherwise the unit

may operate erratically.

What to do for preparation

Insert a tape into the D eck Mechanis m Assembly and

press the PLAY button. The tape will be loaded into

the Deck Mechanism Ass embly. Make sure the power

is on, connect TP502 (SENSOR INHIBITION) to GND.

This will stop the functio n of Tape Start Sensor, Tape

End Sensor and Reel Sensors . (If these TPs are connected before plugging in the unit, the function of the

sensors will stay valid.) See Fig. 1.

Q503

Q504

TP502

S-INH

Fig. 1

Note: Because the Tape End Sensors are inactive, do

not run a tape all the way to the start or the end of the

tape to avoid tape damage.

1-5-1 H9400PFS

he

w

ill

ks

.

k

er

re

.

ly

).

rt

y

ch

er

It

h

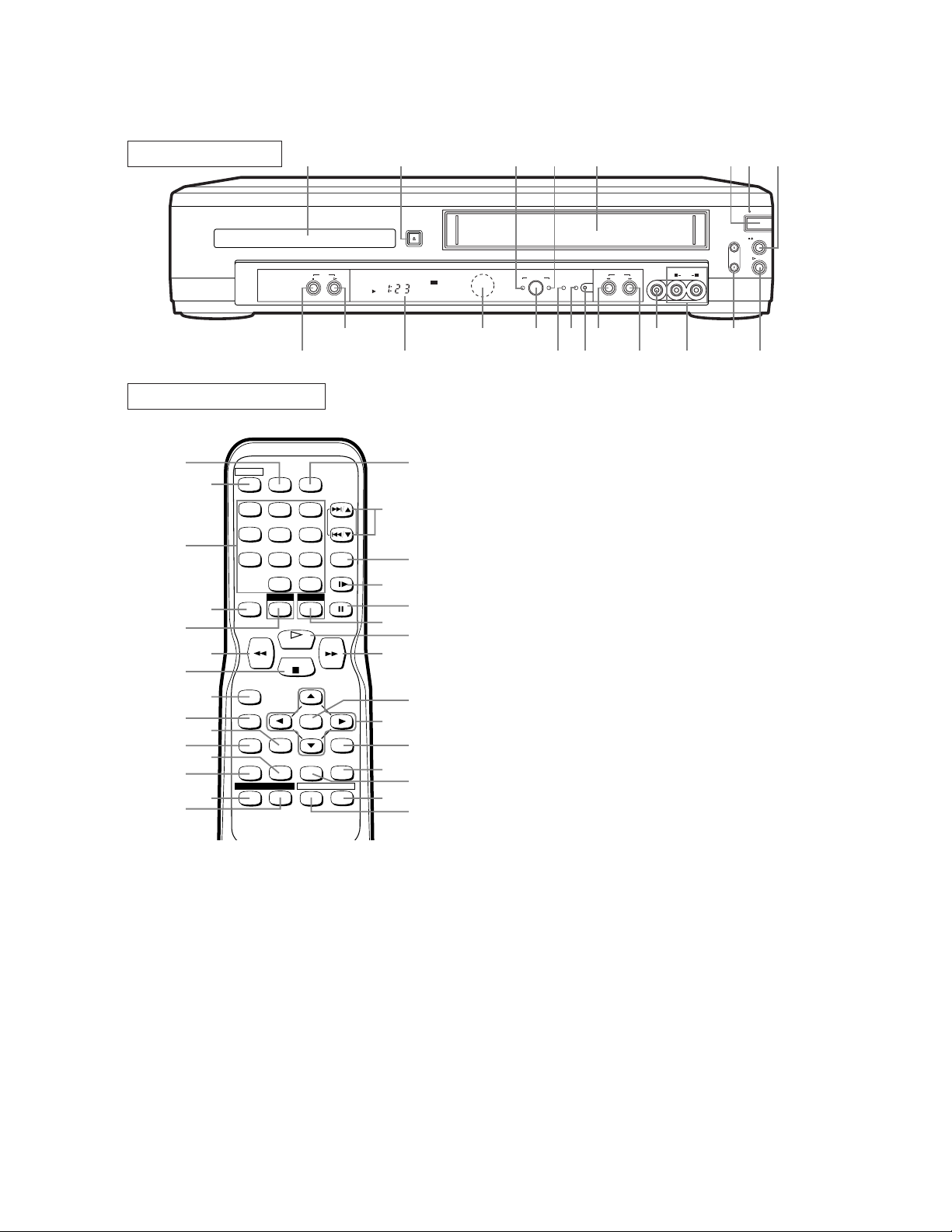

OPERATING CONTROLS AND FUNCTIONS

FRONT PANEL

1

DVD

2 3 4 768

OPEN/CLOSE

21

22

20

REMOTE CONTROL

23

POWER

SPEED AUDIO

24

25

123

456

789

010

DVD VCR

DISPLAY

SKIP/CH.

VCR/TV

SLOW

+

PAUSE

26

27

28

29

31

30

32

RECORD

MENU

SETUP

33

34

35

37

1. Disc loading tray

2. OPEN/CLOSE Button

Press to insert discs into or remove them from the tray.

3. DVD OUTPUT Light (Green)

This light appears when the DVD output mode is selected. You can only watch DVDs when the green DVD

OUTPUT light is on. To make the green DVD OUTPUT light come on, press DVD on the remote control or

OUTPUT on the front panel.

4. VCR OUTPUT Light (Green)

This light appears when the VCR output mode is selected. You can only watch tapes when the green VCR

OUTPUT light is on. To make the green VCR OUTPUT

light come on, VCR on the remote control or OUTPUT

on the front panel.

5. CASSETTE COMPARTMENT

6. POWER Button

Press to turn the power on and off.

SUBTITLE

36

T-S E T

PLAY

STOP

ENTER

SEARCH

ZOOMMODE

MODE

ANGLE REPEAT

RETURNTITLE

CLEAR/

C.RESET

A-B

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

5

POWER

STOP/EJECT

CHANNEL

PLAY

VCR

VIDEO

AUDIO

DVD

19

OUTPUT

RECVCRDV D

TIMER REC

1817161514

REW

F.FWDSTOP PLAY

7. POWER Light

This light appears when the power is on.

8. STOP/EJECT Button (VCR)

EJECT Button

Press to remove the tape from the VCR.

STOP Button

Press to stop the tape motion.

9. PLAY Button(VCR)

Press to begin playback.

10. CHANNEL Buttons

In VCR mode, press to change TV channels on t

VCR; press to adjust the tracking during normal or slo

motion playback; press to remove vertical jitter in a St

picture.

11. AUDIO In Jacks

Connect audio cables coming from the audio out jac

of a camcorder, another VCR, or an audio source here

12. VIDEO In Jack

Connect a video cable coming from the video out jac

of a camcorder, another VCR, or a video source (las

disc player, camcorder, etc.) here.

13. F.FWD Button (VCR)

Press to rapidly advance the tape, or view the pictu

rapidly in forward during playback. (Forward Search)

14. REW Button (VCR)

Press to rewind the tape, or to view the picture rapid

in reverse during the playback mode (Rewind Search

15. REC/OTR Button

Press once to start a recording. Press repeatedly to sta

a One-Touch Recording.

16. REC Light

Lights up during recording.

17. TIMER REC Light

This light appears when the DVD/VCR is in standb

mode for a timer recording or during a One-Tou

Recording. It flashes if T-SET is pressed for a tim

recording, but there is no tape in the DVD/VCR.

flashes when all timer recordings or One-Touc

Recordings are finished.

L R

131211

10

9

1-6-1 H9404IB

1

8. OUTPUT Button

1

2

2

2

2

2

2

2

2

2

2

3

3

e

l

r

e

r

,

c

e

y

t

r

d

o

n

g

o

:

e

Press to select DVD mode or VCR mode.

● You can switch the output mode either by pressing

OUTPUT on the front panel, or by pressing DVD or

VCR on the remote control. However, if you press

OUTPUT on the front panel first, you need to reselect the corresponding mode by pressing D VD or

VCR on the remote control.

9. Remote Sensor Window

0. Display

1. PLAY Button (DVD)

Press to begin playback.

2. STOP Button (DVD)

Stops operation of the disc.

3. SPEED Button

’

Press to select the VCR

4. POWER Button

Press to turn the power on and off.

5. Number Buttons

● DVD mode

Press to select numbered items in a menu.

+10

Use this button to enter number 10 and above.

● VCR mode

Press to select TV channels on the VCR.

To select channels, enter channel numbers as a twodigit number for the quickest results. For example, to

select channel 6, press 0 then 6.

6. DISPLAY Button

● DVD mode

Press to access or remove the display screen during

DVD or Audio CD playback.

● VCR mode

Press to access or remove the VCR

display.

7. DVD Button

Press to select DVD mode for the remote control.

● You can switch the OUTPUT mode either by pressing

OUTPUT on the front panel, or by pressing DVD or

VCR on the remote control. However, if you press

OUTPUT on the front panel first, you need to reselect the corresponding mode by pressing

DVD or VCR on the remote control.

8. h Button

● DVD mode

Press to view the DVD picture in fast reverse motion.

Press PAUSE, then press this button to begin slow

motion playback. Press this button repeatedly to

change the reverse speed of slow motion.

● VCR mode

Press to rewind the tape, or to view the picture rapidly in reverse during the playback mode (Rewind

Search).

9. STOP Button

● DVD mode

Press to stop the disc motion.

● VCR mode

Press to stop the tape motion.

0. RECORD Button

Press once to start a recording.

1. MENU Button

● DVD mode

Press to display the menu of the Disc.

● VCR mode

Press to access the VCR menu.

s recording speed (SP or SLP)

’

s on-screen status

32. TITLE Button

33. SETUP Button

Press to enter DVD player setup mode.

34. ZOOM Button

Enlarges part of a DVD-reproduced image.

35. MODE Button

Activates program playback or random playback mod

when playing CDs or MP3. Sets Black level and virtua

surround.

36. SUBTITLE Button

Press to select the desired subtitle language.

36. T-SET Button

Press to put the VCR into standby mode for a time

recording.

37. ANGLE Button

Press to change the camera angle to see the sequenc

being played back from a different angle.

38. REPEAT Button

Repeats playback of the current disc, title, chapter o

track.

39. A-B REPEAT Button

Repeats playback of a selected section.

40. SEARCH MODE Button

● DVD mode

Press to access or remove the Search display

which allows you to go directly to a specifi

Title/Chapter/Track/Time.

● VCR mode

Press to perform a Time Search or an Index Search.

41. CLEAR/C.RESET Button

● DVD mode

Press to reset the setting.

● VCR mode

Press to reset the counter. Press to exit from th

MENU screen.

42. RETURN Button

● DVD mode

Returns to the previous operation.

43. Arrow Buttons

Use when making settings while watching the displa

on a TV screen.

● VCR mode

p/o Buttons

Press to enter digits when setting program (For exam

ple: setting clock or timer program). Press to selec

the setting modes from the on screen menu.

B Button

When setting program (For example: setting clock o

timer program), press to determine your selection an

proceed to the next step you want to input. Press t

determine the setting modes from the on scree

menu. Press to add or delete channel numbers durin

channel preset.

s Button

Press to cancel a setting of timer program. Press t

correct digits when setting program (For example

setting clock or timer program). Press to add or delet

channel numbers during channel preset.

44. ENTER Button

● DVD mode

Press to accept a setting.

1-6-2 H9404IB

4

5. g Button

4

4

4

SLOW Button

in

k.

to

g

e.

5

5

5

e

to

d

or

R

D

’s

-

ts

re

at

● DVD mode

Press to fast forward the Disc. Press PAUSE, then

press this button to begin slow motion playback.

Press this button repeatedly to change the forward

speed of slow motion.

● VCR mode

Press to rapidly advance the tape, or view the picture

rapidly in forward during playback (Forward Search).

6. PLAY Button

● DVD mode

Press to begin playback.

● VCR mode

Press to begin playback.

7. VCR Button

Press to select VCR mode for the remote control.

● You can switch the OUTPUT mode either by pressing

OUTPUT on the front panel, or by pressing DVD or

VCR on the remote control. However, if you press

OUTPUT on the front panel first, you need to reselect the corresponding mode by pressing DVD or

49.

During tape playback, press to view the video tape

slow motion. Press again to resume normal playbac

This button does not affect DVD playback.

50. VCR/TV Button

Use to select VCR or TV position.

●VCR Position

To view playback, to monitor video recordings or

watch TV using the VCR tuner.

● TV Position

To watch TV or to view one program while recordin

another.

51. SKIP/CH. Buttons

● DVD mode

Press to skip Chapters or Tracks.

● VCR mode

Press to change TV channels on the VCR.

52. AUDIO Button

Press to select a desired audio language or sound mod

VCR on the remote control.

8. PAUSE Button

● DVD mode

Press to pause Disc playback. Press repeatedly to

advance the DVD picture step by step (or one frame

at a time).

● VCR mode

While recording, press to temporarily stop the recording (pause). Press a second time to resume normal

recording. You can not pause a One-Touch

Recording. Or, press during tape playback to freeze

the picture. Press to advance the picture one frame at

a time during still mode.

Notes

To use the remote control to operate the DVD/VC

COMBINATION UNIT and its features, press DV

on the remote control before pressing other DVD

operation buttons. Verify that the green DVD OUT

PUT Light is on.

To use the remote control to operate the VCR and i

features, press VCR on the remote control befo

pressing other VCR’s operation buttons. Verify th

the green VCR OUTPUT Light is on.

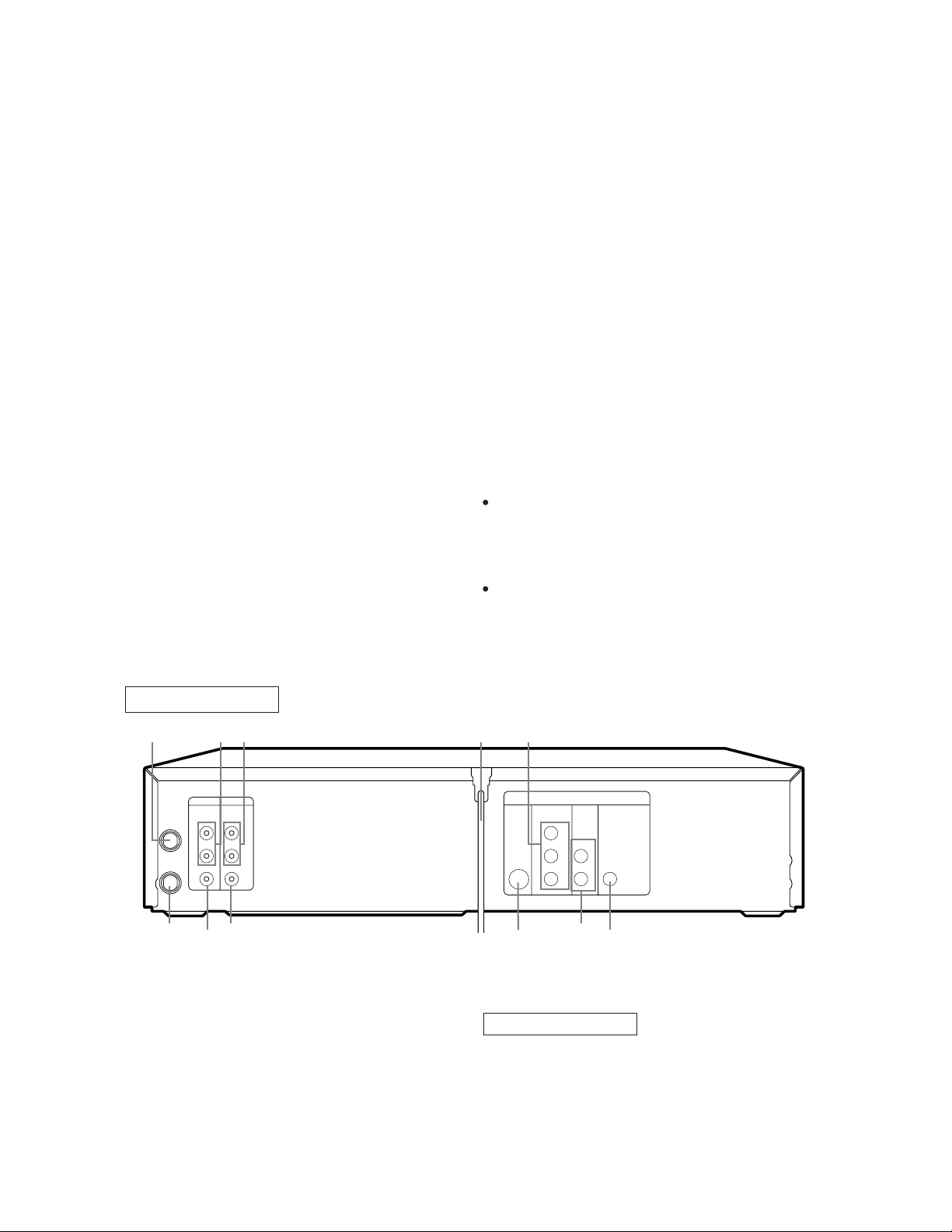

REAR VIEW

5453 55 56 57

DVD/VCR VCR

AUDIO OUT AUDIO IN

ANT-IN

ANT-OUT

63

L

R

VIDEO OUT VIDEO IN

61

62

L

R

3. ANT-IN (Antenna In) Jack

Connect your antenna, Cable Box, or Satellite decoder

box.

4. DVD/VCR AUDIO OUT Jacks

Connect the supplied audio cables here and to the Audio

In jacks of a television or other audio equipment.

5. AUDIO IN Jacks

Connect audio cables coming from the audio out jacks

of a camcorder, another VCR, or an audio source here.

S-VIDEO

OUT

60

56.AC Power Cord

Connect to a standard AC outlet to supply power to th

DVD/VCR COMBINATION UNIT.

DVD Playback only

57. COMPONENT VIDEO OUT Jacks

Connect optional component video cables here and

the component Video In jacks of a television.

58. COAXIAL Jack

Connect an optional coaxial digital audio cable here an

to the Coaxial Digital Audio In jack of a decoder

audio receiver.

COMPONENT

VIDEO OUT

Y

Cb L

Cr R

DVD

AUDIO

OUT

59

DIGITAL

AUDIO OUT

COAXIAL

58

1-6-3 H9404IB

S

w

i

5

9. DVD ANALOG AUDIO OUT Jacks

6

6

o

k

s

y

Connect the supplied audio cables here and to the Audio

In jacks of a television or other audio equipment (DVD

only).

0. S-VIDEO OUT Jack

Connect an optional S-Video cable here and to the SVideo In jack of a television. (DVD only)

1. VIDEO IN Jack

Connect a cable coming from the video out jack of a

camcorder, another VCR, or an audio-visual source

(laser disc player, video disc player, etc.) here.

62. DVD/VCR VIDEO OUT Jack

Connect the yellow video cable (supplied) here and t

the TV’s Video In jack.

63. ANT-OUT (Antenna Out) Jack

Use the supplied RF coaxial cable to connect this jac

to the ANTENNA IN Jack on your TV.

Caution: Do not touch the inner pins of the jack

on the rear panel. Electrostatic discharge ma

cause permanent damage to the player.

Stays on when the

A-B repeat function

is on.

Stays on when the

repeat function is on.

Stays on when

repeat title

function is on.

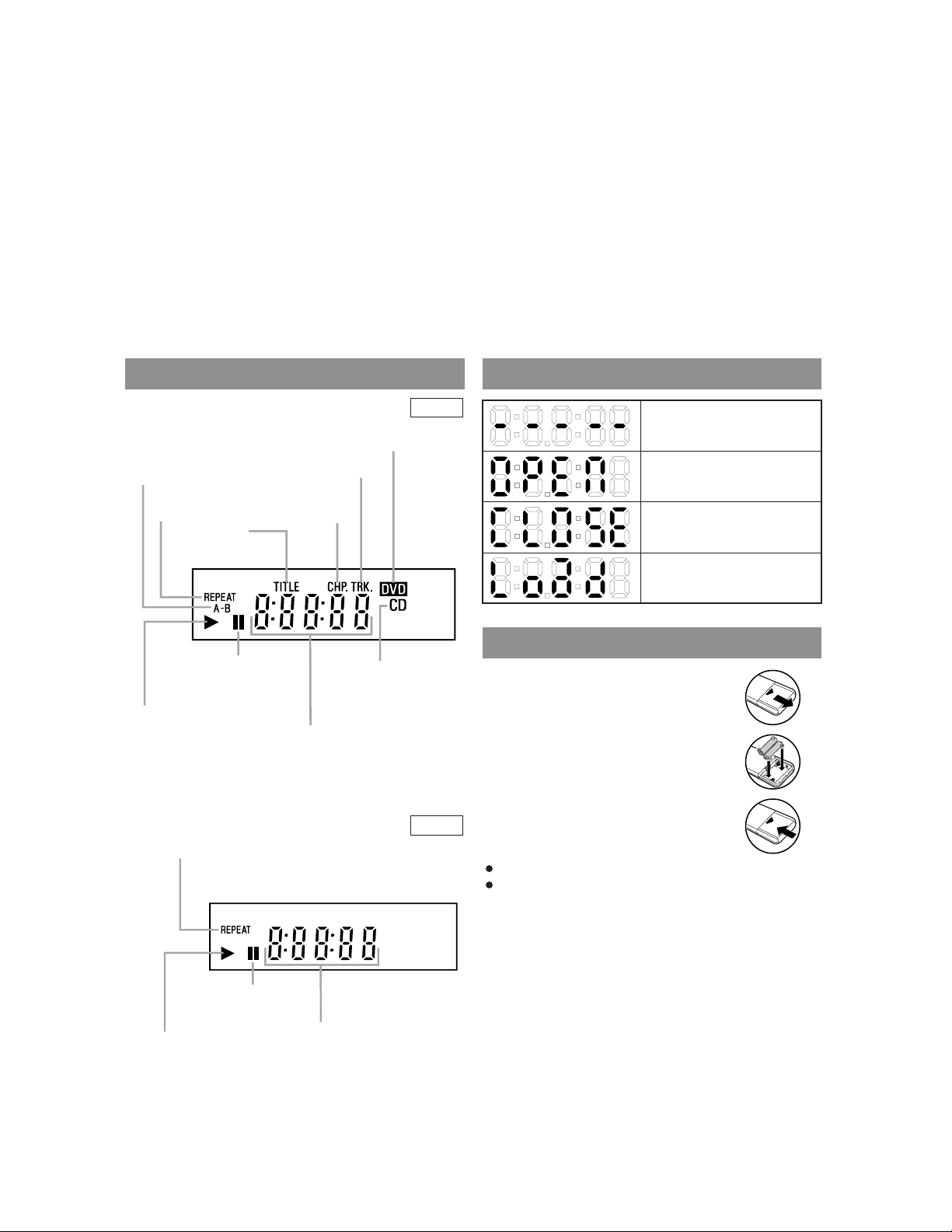

DISPLAY DISPLAYS DURING OPERATION

DVD

Lights up when a DVD

is inserted into the tray.

Stays on when repeat

track function is on.

Stays on when

repeat chapter

function is on.

No disc inserted or playing

DVD menu

Tray open

Tray closed

Loading the Disc

LOADING THE BATTERIES

Lights up when the

inserted disc comes

to a pause.

Stays on when the inserted

disc is being played back.

tays on during playback

hen the repeat function

s on.

Displays how long a current title

or track has been played back. When

a chapter or track has switched, the

number of the a title, chapter or

track is displayed.

Lights up when a

CD is inserted into

the tray.

VCR

1. Open the battery compartment

cover.

2. Insert two AA batteries, with each

one oriented correctly.

3. Close the cover.

Notes

Do not mix alkaline and manganese batteries.

Do not mix old and new batteries.

Lights up when the playback

is in a still or in a slow mode.

Stays on when the inserted

cassette is being played back.

Works as a clock, or a tape counter.

Also displays a channel number,

and remaining time for OTR

1-6-4 H9404IB

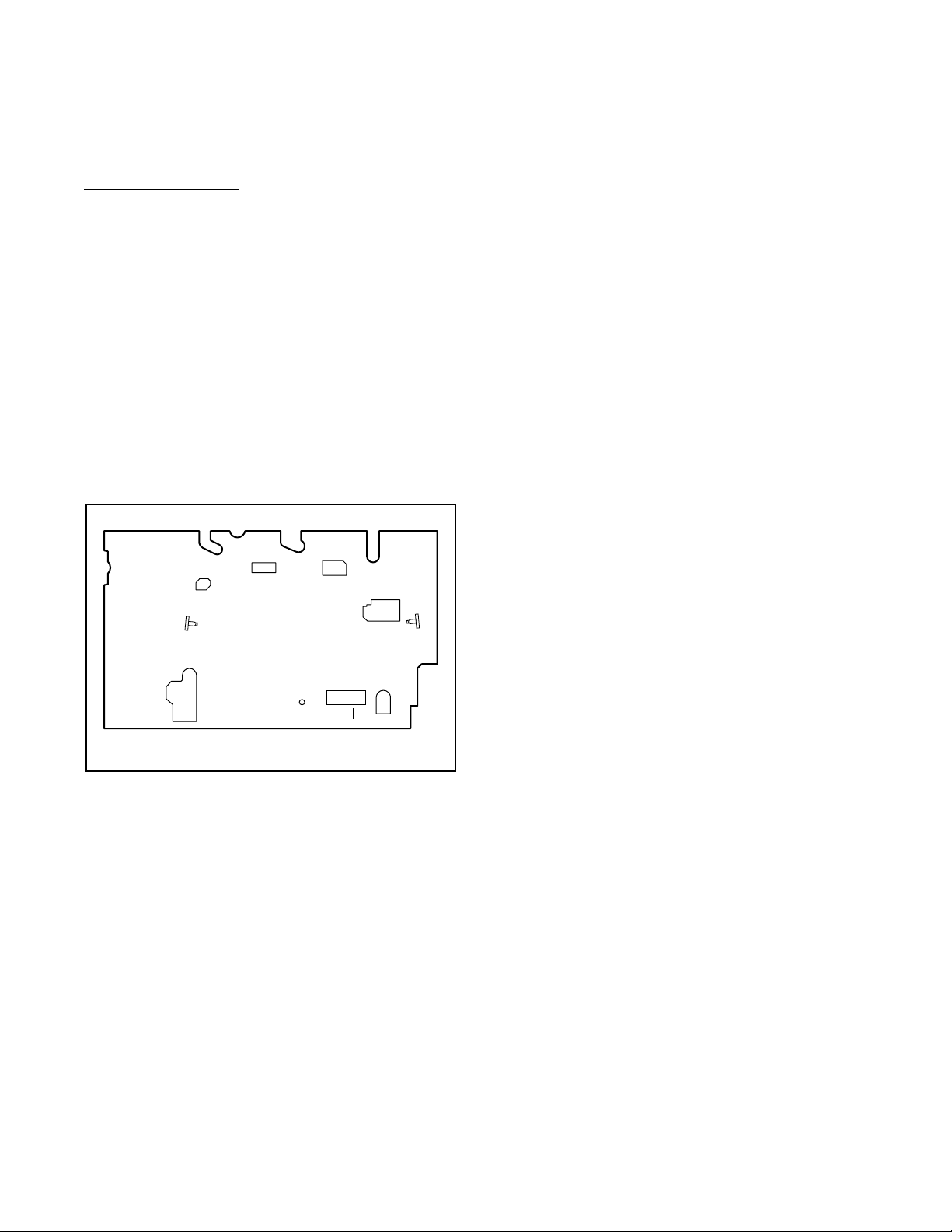

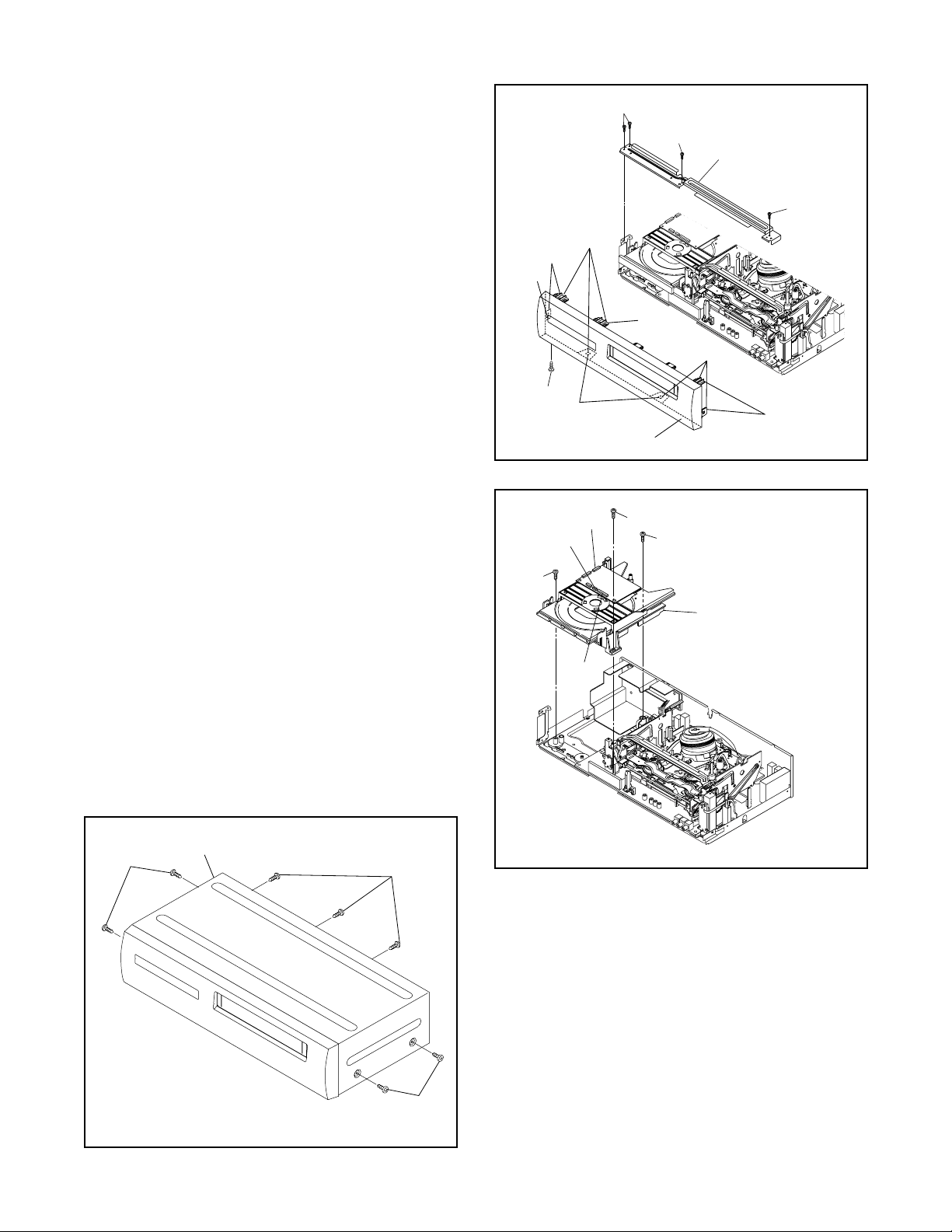

CABINET DISASSEMBLY INSTRUCTIONS

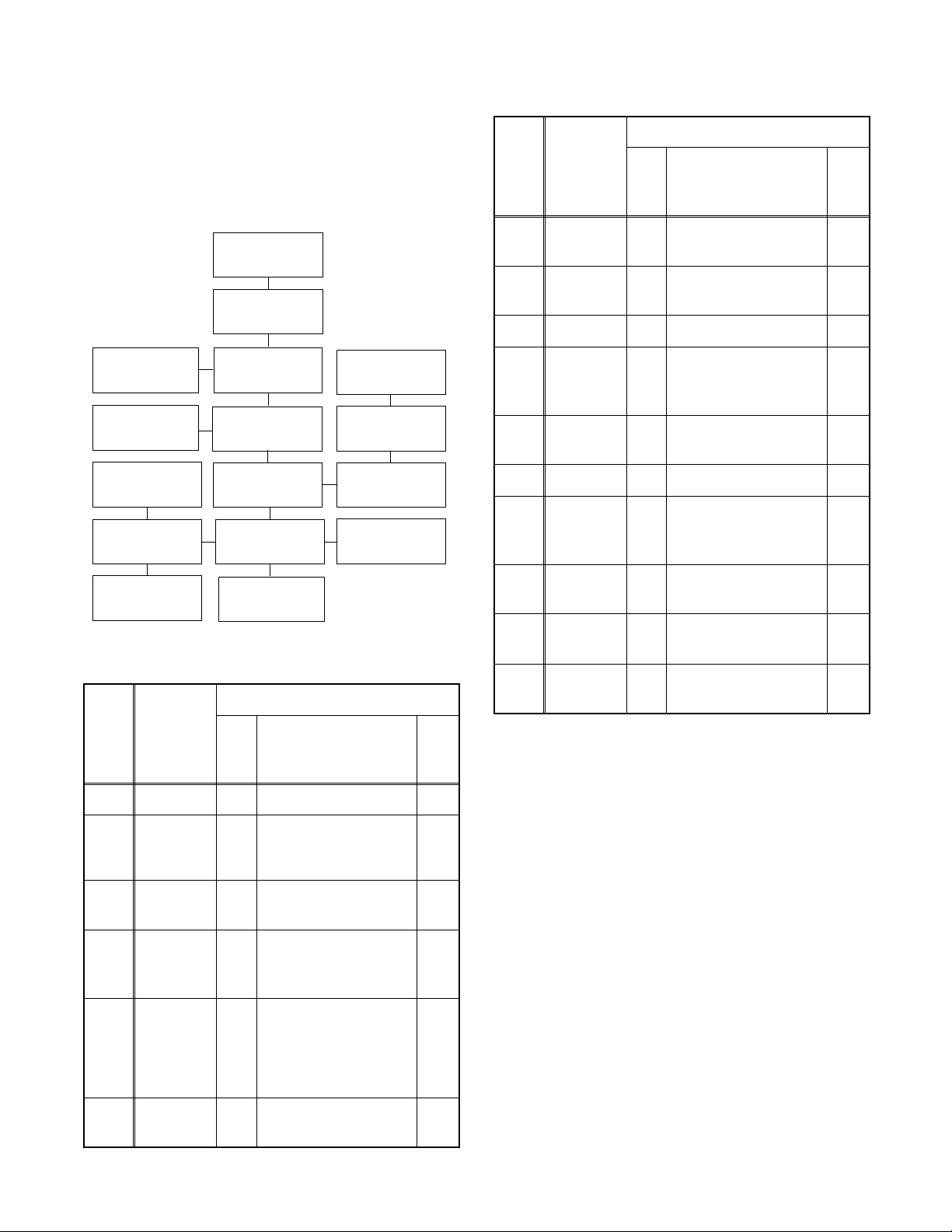

1. Disassembly Flowchart

This flowchart indicates the disassem bly steps to gain

access to item(s) to be se rviced. W hen reass embling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] Top Cover

[2] Front

Assembly

[16] Side

Bracket

[5] DVD Main

CBA Unit

[13] DVD OP/CL

CBA

[12] Main CBA

[3] Top Bracket

[4] DVD Mecha

Assembly

[6] Rear Unit

[10] VCR

Chassis Unit

[9] Rear Panel

[8] PCB Bracket

[7] Power

Supply CBA

[11] Deck

Assembly

REMOVAL

ID/

LOC.

No.

[7]

[8]

[9]

[10]

[11]

[12] Main CBA D8 ---------- -

[13]

PART

Power

Suppy CBA

PCB

Brackt

Rear Panel

VCR

Chassis

Unit

Deck

Assembly

Open/

Close

CBA

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

D6 4(S-8) -

D6 3(S-9) -

D6 ---------- -

D7 5(S-10), 4(S-11) -

D8 Desolder, 2(S-12) 4,5

D8 ---------- -

Note

[14] Function

CBA

[15] Deck

Pedestal

2. Disassembly Method

REMOVAL

ID/

LOC.

No.

[1] Top Cover D1 7(S-1) -

[2]

[3]

[4]

[5]

PART

Front

Assembly

Top

Bracket

DVD

Mecha

Assembly

DVD Main

CBA Unit

REMOVE/*UNHOOK/

Fig.

UNLOCK/RELEASE/

No.

UNPLUG/DESOLDER

D2 (S-3), *7(L-1)

D2 4(S-2) -

3(S-4), *CN401,

D3

*CN601,*CN302

2(S-5), *CN201,

D4

*CN301

Note

1

1-1

1-2

-

2

2-1

2-2

2-3

3

[14]

[15]

[16]

Note:

(1): Identification (location) No. of parts in the figures

(2):Name of the part

(3):Figure Number for reference

(4): Identification of parts to be removed, unhooked,

(5):Refer to “Reference Notes.”

Function

CBA

Deck

Pedestal

Side

Bracket

↓

(1)

unlocked, released, unplugged, unclamped, or

desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

↓

(2)

D8 ---------- -

D9 7(S-13) -

D9 (S-14) -

↓

(3)

↓

(4)

↓

(5)

[6] Rear Unit D5

5(S-6), 3(S-7),

CN1005

-

1-7-1 H9400DC

Reference Notes

(

(

ly

CAUTION 1: Locking Tabs (L-1) are fragile. Be careful

not to break them.

1-1. Remove Screw (S-3).

1-2. Release seven Locking T abs (L-1) (to do this, first

release five Lock ing Tabs (A) at the side and top,

and then release two Locking Tabs (B) at the bottom.)

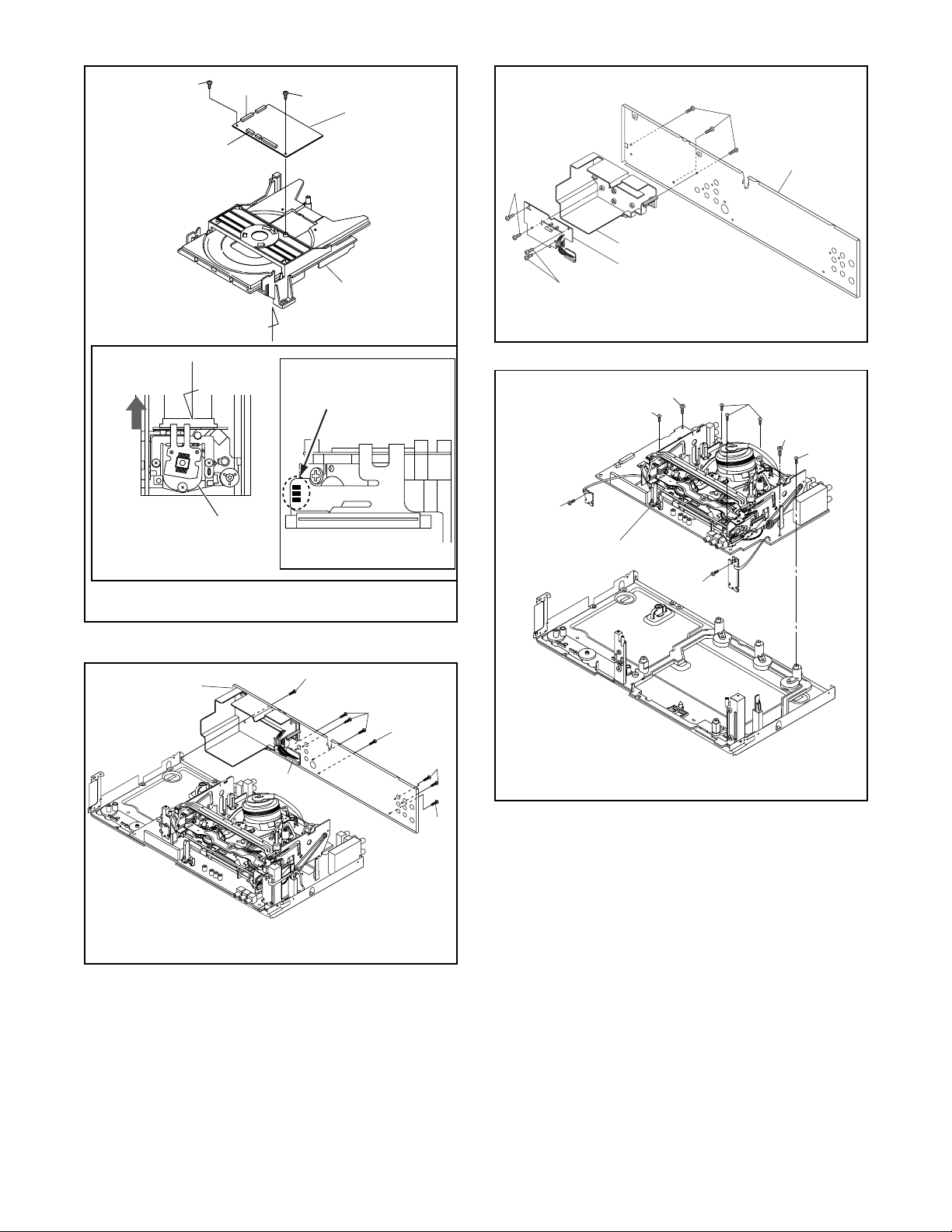

CAUTION 2: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body etc., during

unpacking or repair work.

To avoid damage of pickup follow next procedures.

2-1. Slide the pickup unit as shown in Fig. D4.

2-2. Short the three short lands of FPC cable with sol-

der before removing the FFC cable (CN301) from

it. If you disconn ect the FFC cable (CN3 01), the

laser diode of pickup will be destroyed. (Fig. D4)

2-3. Disconnect Connector (CN201). Remove two

Screws (S-5) and lift the DVD Main CBA Unit.

(Fig. D4)

CAUTION 3: When reassembling, confirm the FFC

cable (CN301) is co nnected c ompletel y. Then remove

the solder from the three short lands of FPC cable.

(Fig. D4)

4. When reassembling, solder wire jumpers as shown

in Fig. D8.

5. Before installing the Deck Assembly, be sure to

place the pin of LD-SW o n Main CBA as shown in

Fig. D8. Then, install the Deck Assembly while

aligning the hole of Cam Gear with the pin of LDSW, the shaft of Cam Gear with the hole of LD -SW

as shown in Fig. D8.

(L-1)

(A)

L-1)

(S-3)

(B)

[2] Front Assembly

CN601

CN302

S-4)

CN401

(S-2)

(S-2)

[3] T op Bracket

(S-2)

(A)

(L-1)

(A)

Fig. D2

(S-4)

(S-4)

[4] DVD Mecha Assemb

[1] T op Cover

(S-1)

(S-1)

(S-1)

Fig. D3

Fig. D1

1-7-2 H9400DC

(S-5)

6)

)

l

(

0)

CN301

CN201

(S-5)

[5] DVD Main

(S-9)

CBA Unit

[9] Rear Pane

(S-8)

[8] PCB Bracket

[7] Power Supply CBA

DVD Mecha

(S-8)

Fig. D6

A

Slide

B

View for A

[6] Rear Unit

Pickup Unit

Short the three short

lands by soldering

View for B

(S-7)

CN1005

(S-6)

Fig. D4

(S-7)

(S-

(S-10)

S-11)

[10] VCR Chassis Unit

(S-11)

(S-11)

(S-10)

(S-11)

(S-1

Fig. D7

(S-7

Fig. D5

1-7-3 H9400DC

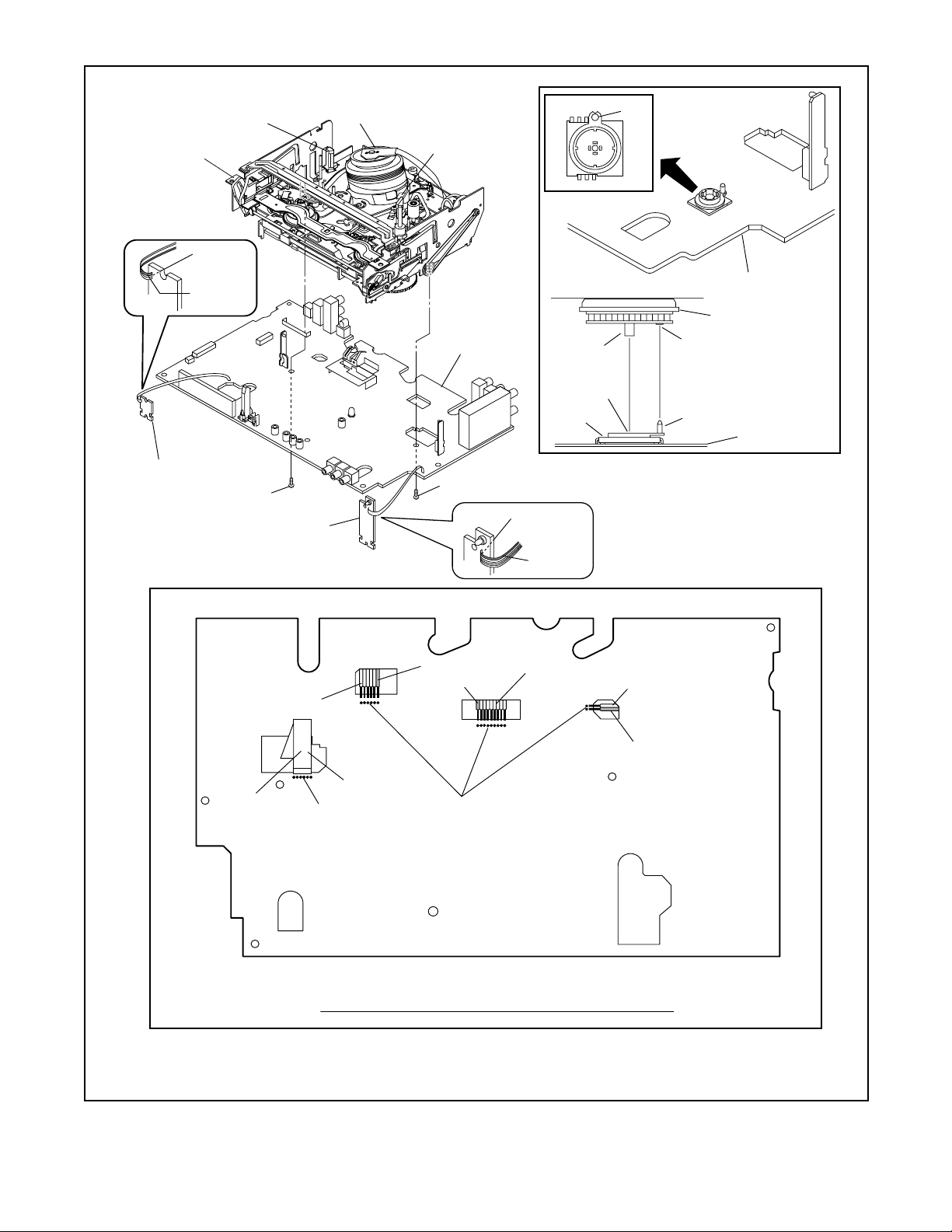

FE Head

[11] Deck

Assembly

Desolder

Lead with

blue stripe

[13] DVD OP/CL CBA

(S-12)

[14] Function CBA

Cylinder Assembly

AC Head

Assembly

[12] Main CBA

(S-12)

Desolder

[11] Deck Assembly

Shaft

Hole

LD-SW

Lead with

blue stripe

Pin

SW507

LD-SW

[12] Main CBA

Cam Gear

Hole

Pin

[12] Main CBA

From

AC Head

Assembly

From

Capstan

Motor

Assembly

From

Cylinder

Assembly

Printing side

Desolder

Lead with

blue stripe

Desolder

BOTT OM VIEW

Lead connections of Deck Assembly and Main CBA

From

FE Head

Lead with

white stripe

Fig. D8

1-7-4 H9400DC

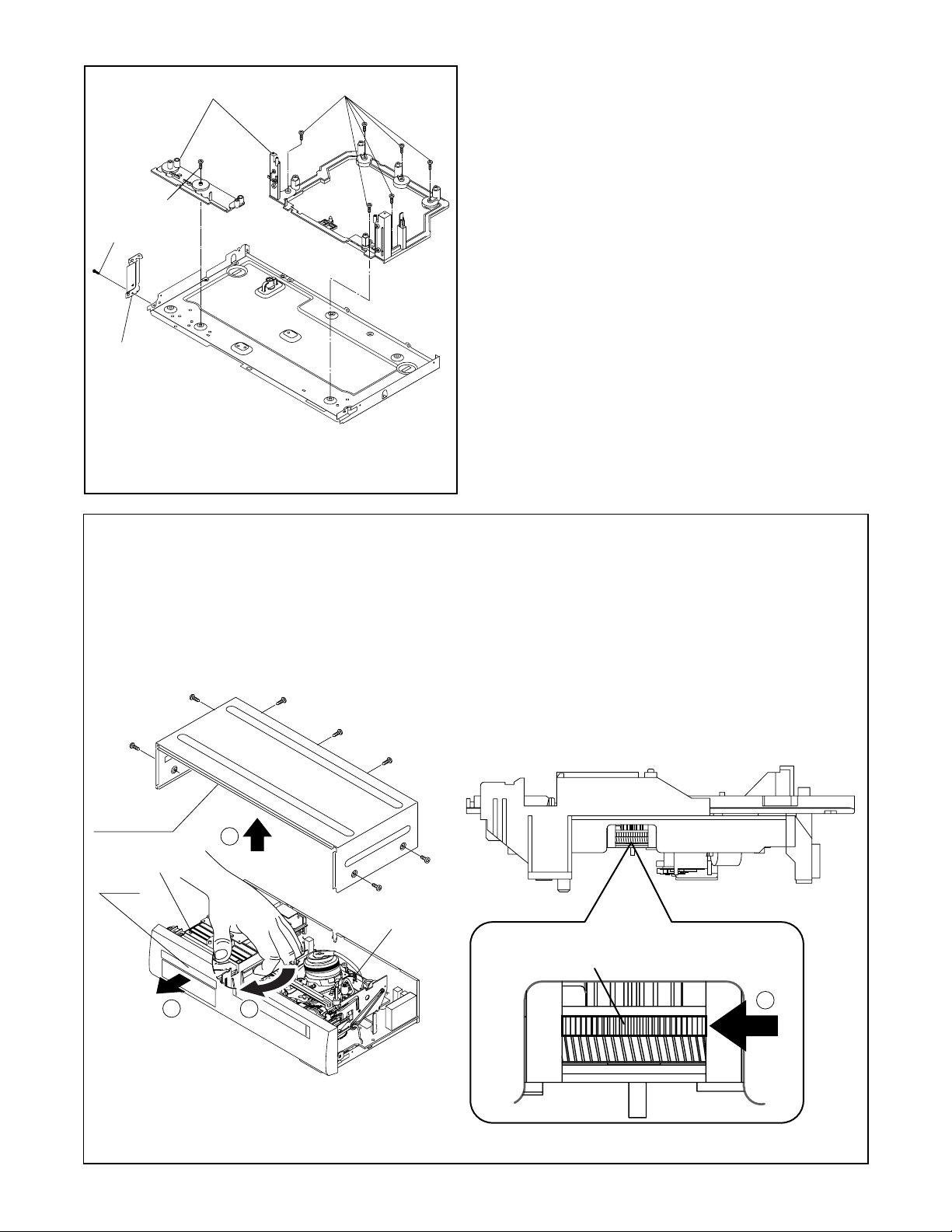

[15] Deck Pedestal

D

(S-13)

(S-14)

[16] Side

Bracket

(S-13)

HOW TO MANUAL EJECT

Fig. D9

1. Remove the Top Case.

2. Rotate this roulette in the direction of the arrow as

shown below.

Top Cover

1

VD Mecha

Tray

Deck Assembly

Rotate this roulette in

3

2

the direction of the arrow

2

1-7-5 H9400DC

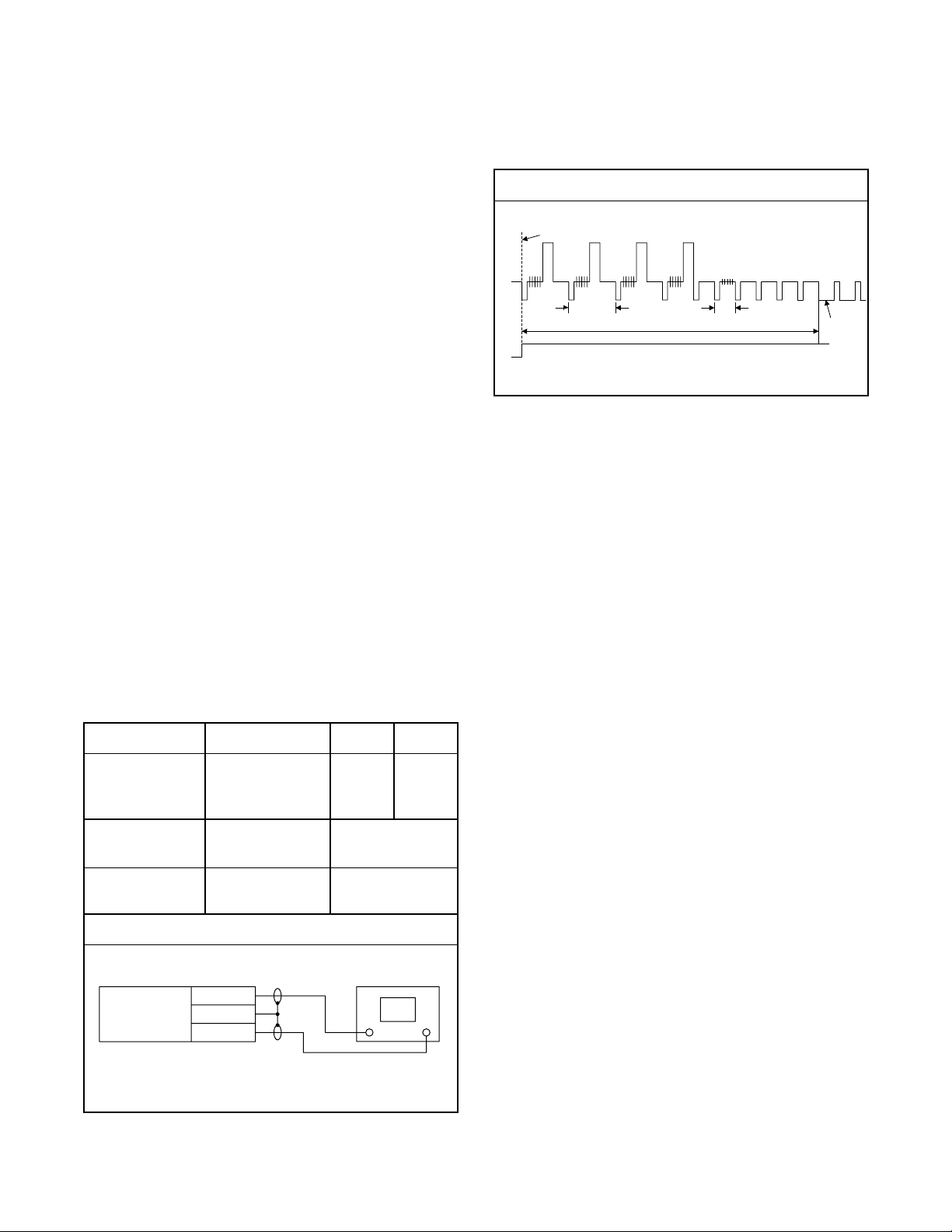

ELECTRICAL ADJUSTMENT INSTRUCTIONS

e

2

)

ync

General Note: "CBA" is an abbreviation for

"Circuit Board Assembly."

NOTE:

1.Electrical adjus tments are required after replacing

circuit components and certain mechanical parts. It

is important to do these adjustments only after all

repairs and replacements have been completed.

Also, do not attem pt thes e adj ustmen ts unles s the

proper equipment is available .

2.To perform these a lignment / confirmation procedures, make sure that the tracki ng co ntrol is set in

the center position: P ress ei ther "CHA NNEL L5 ??" or

"CHANNEL K" b utton o n the front panel first , then

the "PLAY" button on the front panel.

Figure 1

EXT. Syncronize T rigger Point

1

2

1.0H

Switching Pulse

6.5H

0.5H

V-S

Test Equipment Required

1.Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div.,

F-Range: DC~AC-20MHz

2.Alignment Tape (FL8A)

Head Switching Position Adjustment

Purpose:

To determine the Head Switching point during

playback.

Symptom of Mi sadjustm e n t:

May cause Head Switchi ng noise or vertical jitter

in the picture.

Test point Adj.Point Mode Input

TP751(V-OUT)

TP302(RF-SW)

GND

Tape

VR501

(Switching Point)

(MAIN CBA)

Measurement

Equipment

PLAY

(SP)

Spec.

Reference Notes:

Playback the Alignment tape and adjust VR501 so that

the V-sync front edg e of the CH1 video output waveform is at the 6.5H(412.7µs) delaye d p os ition fr om the

rising edge of the CH2 head switching pulse waveform.

-----

FL8A Oscilloscope

Connections of Measurement Equipment

TP751

Main CBA

GND

TP302

6.5H±1H

(412.7µs±60µs)

Oscilloscop

CH1 CH

Trig. (+

1-8-1 H9400EA

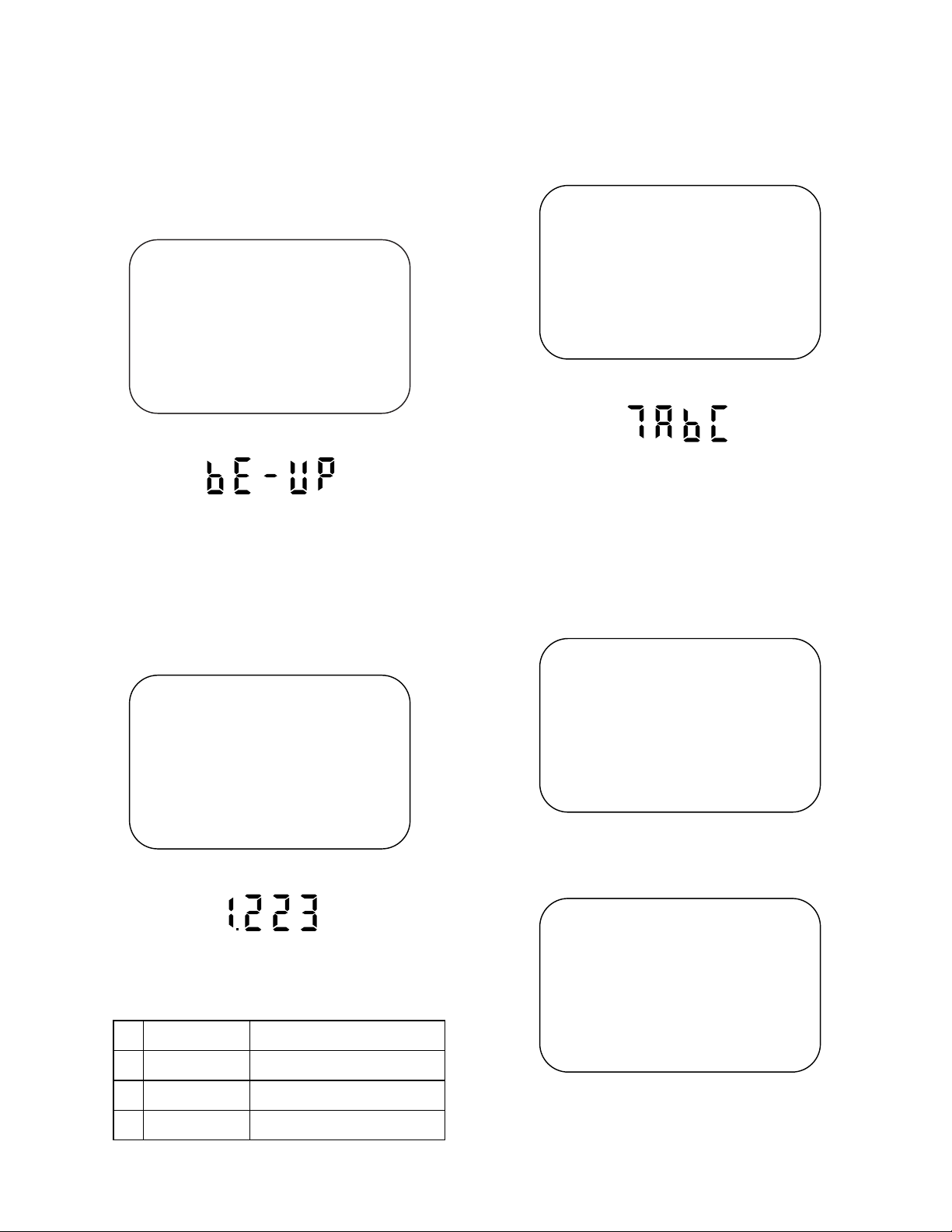

FIRMWARE RENEWAL MODE

F

e

F

e)

F

e)

1. Turn the power on and remove the disc on the tray.

2. To put the DVD player into version up mo de, pr ess

[9], [8], [7], [6], and [SEARCH MODE] buttons on

the remote control un it in that order. The tray wil l

open automatically.

Fig. a appears on the screen and Fig. b appears on

the VFD.

F/W Version Up Mode

Please insert a DISC

for F/W Version Up.

EXIT: POWER

Fig. a Version Up Mode Screen

ig. b VFD in Version Up Mod

The DVD player can also enter the version up

mode with the tray open. In this case, Fig. a wil l be

shown on the screen while the tray is open.

3. Load the disc for version up.

4. The DVD player enters the F/W version u p mode

automatically. Fig. c appears on the screen and

Fig. d appears on the VFD.

F/W Version Up Mode

VERSION : ********

Reading...(*2)

5. A fter progra mming i s finish ed, the tray opens au tomatically. Fig. e appears on the screen and the

checksum in (*3) of Fig. e appears on the VFD.

(Fig. f)

F/W Version Up Mode

VERSION : ********

Completed

SUM : 7abc (*3)

Fig. e Completed Program Mode Screen

ig. f VFD upon Finishing the Programming Mode (Exampl

At this time, no buttons are available.

6. Unplug the AC cord from the AC outlet. Then plug it

again.

7. Turn the power on by pressing the power button

and the tray will close.

8. Press [1], [2], [3], [4], and [DISPLAY] buttons on the

remote control unit in that order.

Fig. g appears on the screen.

model: ****** Ver: **** Region: **

1: VFD TEST

2: TT REPEAT PLAY

3: EEPROM CLEAR

4: MEASUREMENT SERVO

5: DISC READ CHECK

6: MECHA CHECK

7: DISC INFO

8: ERROR RATE

EXIT: POWERRETURN: -----

EXIT: POWER

Fig. c Programming Mode Screen

ig. d VFD in Programming Mode (Exampl

9. Press [3] button on the remote control unit.

Fig. h appears on the screen.

model: ****** Ver: **** Region: **

TEST 3: EEPROM CLEAR

EEPROM CLEAR: OK

Fig. g

The appearance shown in (*2) of Fig. c is

described as follows:

AppearanceNo. State

Reading... Sending files into the memory

1

Erasing... Erasing previous version data

2

Programming...

3 Writing new version data

10.To finish this mode, press [POWER] button.

1-9-1 H9400TEST

Fig. h

EXIT: POWERRETURN: -----

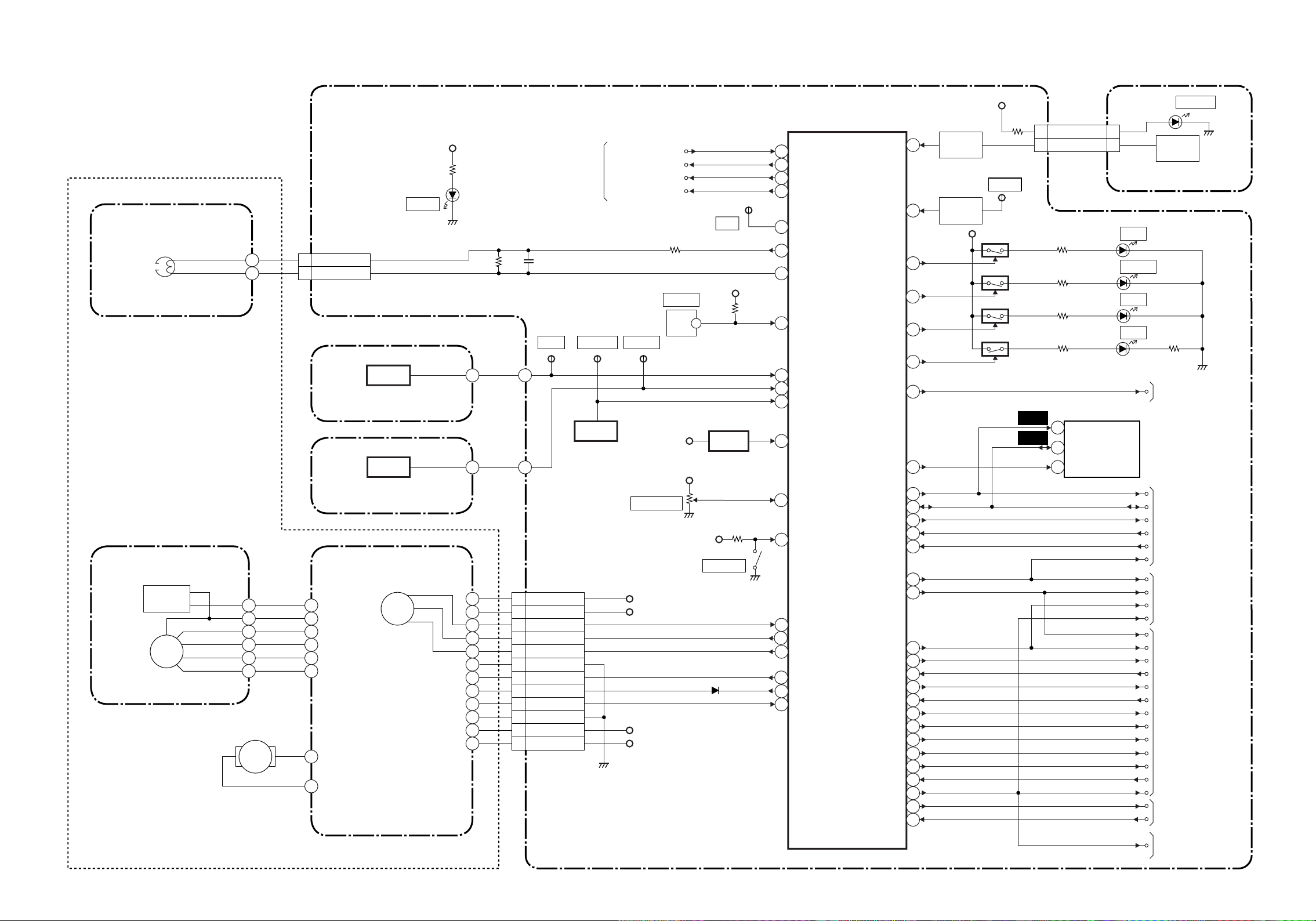

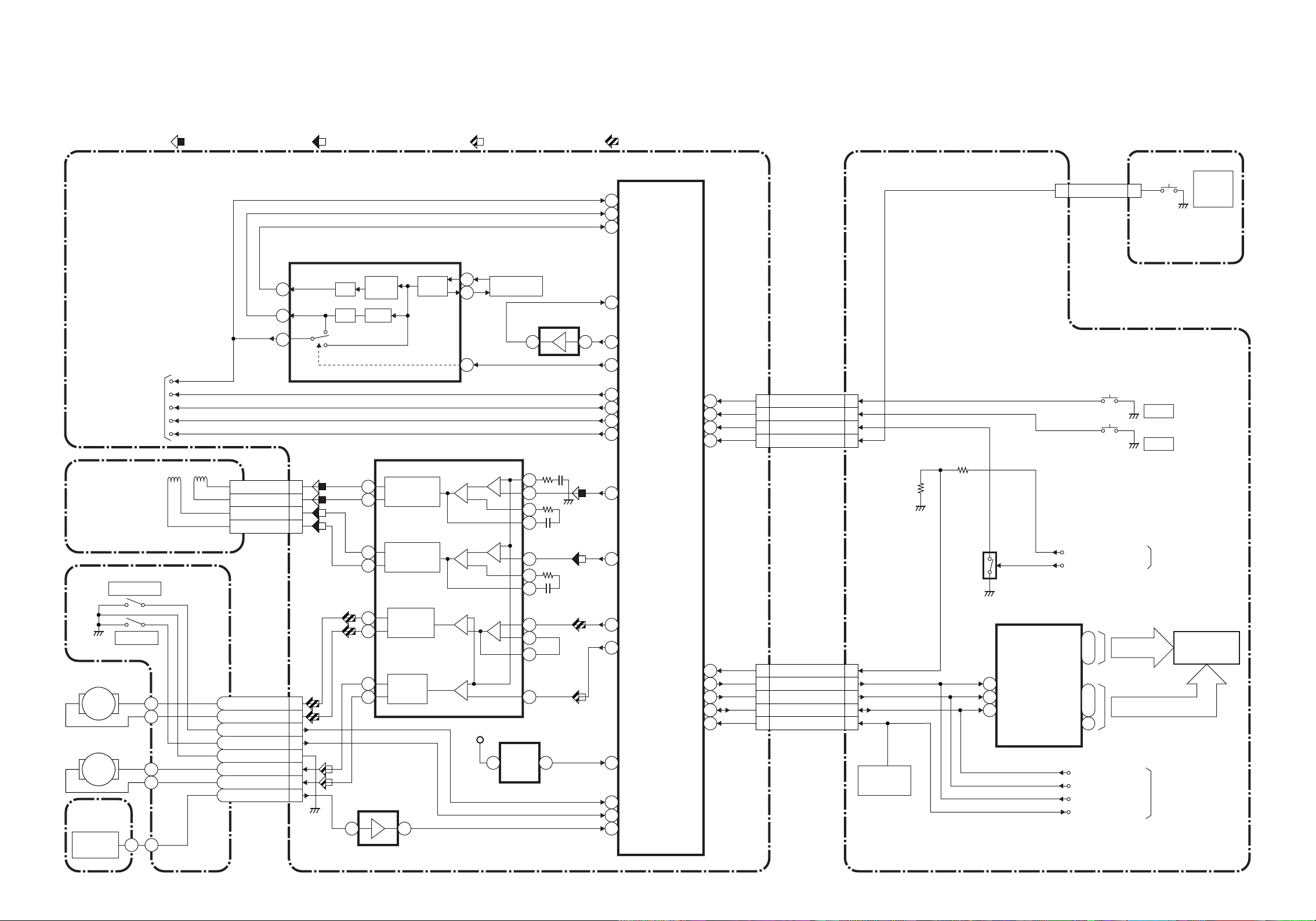

Servo/System Control Block Diagram

(DECK ASSEMBLY)

AC HEAD ASSEMBLY

CN504

CONTROL

HEAD

CL504

5 CTL(+)

6 CTL(-)

MAIN CBA

D555

S-LED

AL+5V

BLOCK DIAGRAMS <VCR SECTION>

IC501

(SERVO/SYSTEM CONTROL)

FROM/TO DVD SYSTEM

CONTROL BLOCK

DIAGRAM

<DVD SECTION>

REMOTE-VIDEO

DISPLAY-CLK

DISPLAY-DATA

DISPLAY-ENA

SW512

LD-SW

TP513

CTL

AL+5V

REMOTE-VIDEO

5

DISPLAY-CLK

6

DISPLAY-DATA

8

DISPLAY-ENA

9

58

CTL

56

CTL(+)

57

CTL(-)

KEY- 1

67

KEY- 2

66

REC-IND

TIMER-IND 75

72

P-ON+9V

KEY

SWITCH

KEY

SWITCH

TP502

S-INH

AL+5V

1 1POWER-LED

2 2KEY-1

Q565

Q563

CL508CL509

FUNCTION CBA

D565

REC

D564 TIMER

D566 VCR

D561

KEY

SWITCH

POWER

CYLINDER ASSEMBLY

PG

SENSOR

DRUM

MOTOR

M

LOADING

MOTOR

M

Q504

ST-S

SENSOR CBA

Q503

END-S

SENSOR CBA

CAPSTAN MOTOR

CAPSTAN

MOTOR

M

TP506

ST-S

CL502

1 AL+12V

2 P-ON+5V

3 C-FG

C-F/R

4

C-CONT

5

GND

6

LM-FWD/REV

7

D-CONT

8

D-PFG

9

GND

10

AL+12V

11

AL+15V

12

TP505

T-REEL

Q506

T-REEL

TP507

END-S

TIMER+5V

VR501

SW-POINT

AL+12V

P-ON+5V

AL+12V

AL+15V

AL+5V

AL+5V

Q501

RESET

SW511

REC SW

LD-SW68

69

ST-S

62

END-S

T-REEL

3

RESET

20

PG-DELAY

65

REC-

2

SAF-SW

49

C-FG

C-F/R

27

C-CONT

28

LM-FWD/REV

21

D-CONT29

D-PFG

47

VCR-IND 70

DVD-IND 71

DVD-POWER

VCR/TV

IIC-BUS SDA

Hi-Fi-H-SW

Hi-Fi/NOR-IN

ST/SAP-IN

A-MUTE-H

D-REC-H

D-PB-L

INSEL/ST-SL

C-SYNC

D-V SYNC

V-ENV

C-ROTA

RF-SW

TRICK-H

H-A-SW

H-A-COMP

OUTPUT-SELECT

P-ON-L

P-DOWN-L

26

77

13IIC-BUS SCL

12

25

59

61

24

23

16

41

19

64

78

18

11

14SP/LP/SLP

79

80

46

22

Q566

Q567

WF12

11

WF13

12

7

OUTPUT-SELECT

OUTPUT-SELECT

1

OUTPUT-SELECT

D567 DVD

DVD POWER

TU701(TUNER UNIT)

CLOCK

DATA

VCR/TV5

IIC-BUS SCL

IIC-BUS SDA

Hi-Fi-H-SW

NORMAL-H

ST/SAP-MODE

A-MUTE-H

A-MUTE-H

D-REC-H

D-PB-L

D-REC-H

D-PB-L

INSEL/ST-SL

C-SYNC

D-V SYNC

V-ENV

C-ROTA

RF-SW

TRICK-H

SP/LP/SLP

H-A-SW

H-A-COMP

P-ON-L

P-DOWN-L

TO DVD SYSTEM

CONTROL BLOCK

DIAGRAM

<DVD SECTION>

FROM/TO

Hi-Fi AUDIO

BLOCK

TO AUDIO

BLOCK

FROM/TO

VIDEO BLOCK

FROM/TO POWER

SUPPLY BLOCK

TO DVD SYSTEM

CONTROL BLOCK

DIAGRAM

1-10-1 1-10-2 H9404BLS

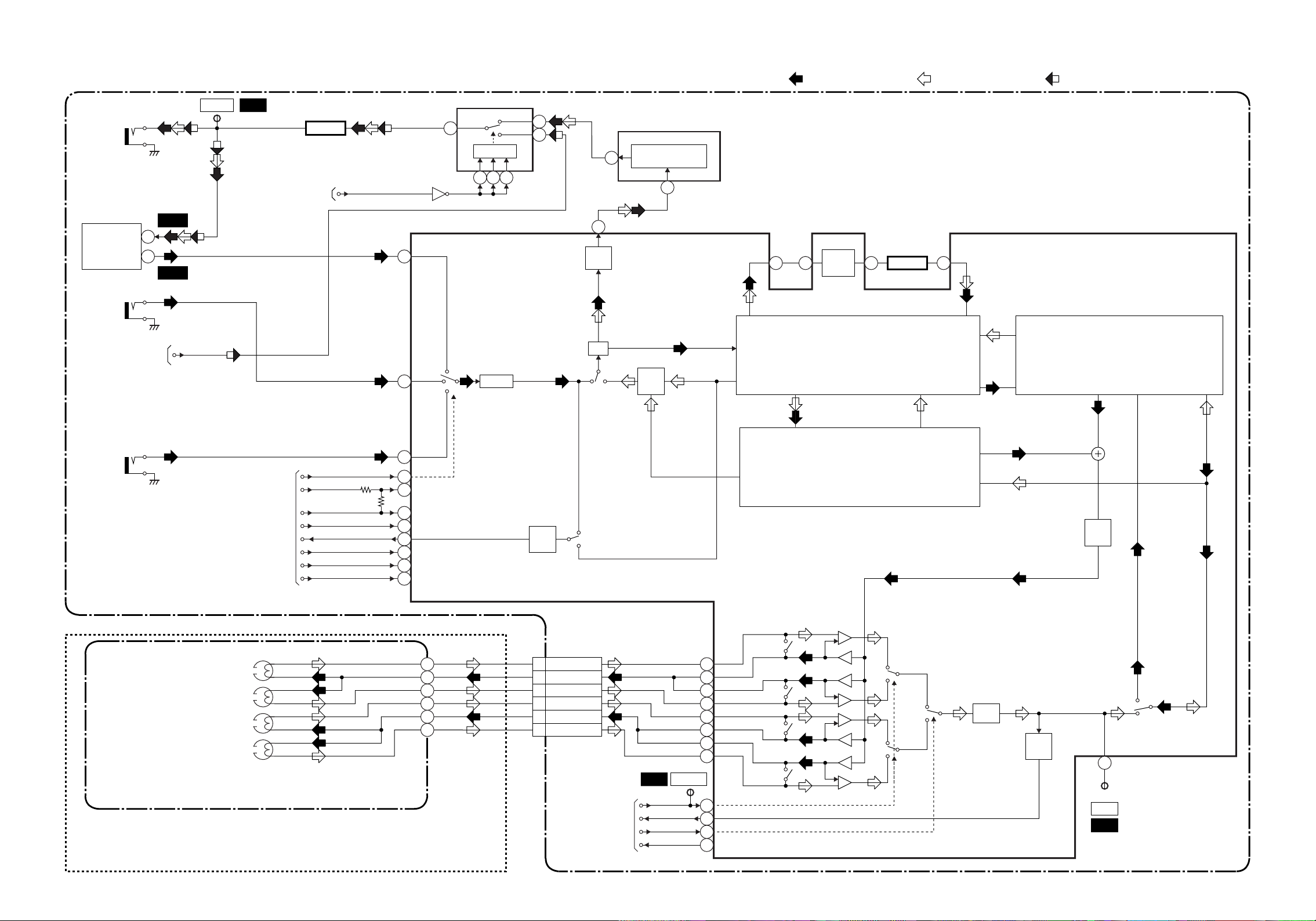

Video Block Diagram

TP751

V-OUT

JK751

V-OUT

TU701

VIDEO IN

VIDEO OUT

JK752

REAR

V-IN

WF11

6

18

WF15

WF1

FROM

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

Q391

BUFFER

OUTPUT SELECT

IC301

42

15

Q760

(Y/C PROCESS)

TUNER

(OUTPUT SELECT)

IC751

SW CTL

9 10 11

VCR

DVD

REC VIDEO SIGNAL PB VIDEO SIGNAL DVD VIDEO SIGNAL MODE: SP/REC

1

IC501

(OSD)

MAIN CBA

2

OSD CHARACTER

38

MIX

40

35

6dB

AMP

45 47 49 44

CCD 1H

DELAY

Q301

BUFFER

FROM DVD

VIDEO/AUDIO

BLOCK DIAGRAM

<DVD SECTION>

JK753

FRONT

V-IN

(DECK ASSEMBLY)

DVD-VIDEO

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

VIDEO (R)-1 HEAD

VIDEO (L)-1 HEAD

VIDEO (L)-2 HEAD

VIDEO (R)-2 HEAD

CYLINDER ASSEMBLY

INSEL/ST-SL

D-PB-L

D-REC-H

TRICK-H

C-SYNC

C-ROTA

D-V SYNC

SP/LP/SLP

REAR

38

FRONT

40

71

16

REC/EE/PB

D-REC-H

11

TRICK

73

34

C-ROTA

14

D-V SYNC

39

SP/LP/SLP

59

V-AGC

SYNC

SEPA

R

P

CL253

V(R)-1

1

V-COM

2

V(L)-1

3

V(L)-2

4

V-COM

5

V(R)-2

6

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

FBC

R P

Y/C

MIX

TP302

RF-SW

WF2

RF-SW

V-ENV

H-A-SW

H-A-COMP

91

90

89

88

85

84

83

82

13

93

15

H-A-COMP

94

DOC YNR Y/C COMB

CHROMINANCE

SIGNAL PROCESS

R

L

L

R

SP

LP/EP

HPF

LUMINANCE

SIGNAL PROCESS

AGC

AMP

R

P

ENV

DET

74

TP301

C-PB

WF3

1-10-3 1-10-4 H9404BLV

Audio Block Diagram

REAR

TU701

SIF

MOD-A

A-OUT (R)

A-OUT (L)

A-OUT (R)

A-OUT (L)

A-IN (R)

A-IN (L)

15

2

JK751

JK756

JK752

WF10

TP753

A-OUT (R)

4

14

TP754

A-OUT (L)

Q760

OUTPUT-SELECT

IC751

(OUTPUT SELECT)

DVD

VCR

DVD

VCR

SW CTL

9 10 11

FROM SERVO/SYSTEM

CONTOL BLOCK

DIAGRAM

12

13

PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC

DVD AUDIO SIGNAL

MAIN CBA

DVD-A(R)

DVD-A(L)

MOD-A

A-IN (L)-F

5

3

IC301

(AUDIO PROCESS) 76

78

80

TUNER

REAR

FRONT

ALC

A-IN (R)-F

A-OUT (R)

A-IN (R)

A-IN (L)

A-OUT (L)

N-A-OUT

N-A-IN

FROM DVD VIDEO/

AUDIO BLOCK

DIAGRAM

<DVD SECTION>

SIF

FROM/TO Hi-Fi AUDIO

BLOCK DIAGRAM

JK754

A-IN (L)-F

FRONT

JK755

A-IN (R)-F

(DECK ASSEMBLY)

AUDIO

HEAD

AUDIO

ERASE

HEAD

FULL

ERASE

HEAD

AC HEAD ASSEMBLY

FE HEAD

CL504

4 A-PB/REC

3 A-COM

1 AE-H

2 AE-H/FE-H

CL501

1 FE-H

2 FE-H-GND

Q422

BIAS

OSC

P-ON+5V

Q423 (PB=ON)

Q425

Q424

(PB=ON)

Q421

SWITCHING

D-REC OFF

P-ON+5V

99

R

4

EQ

AMP

SP/LP-ON

3

AUTO

BIAS

1

2

6

100

7

LINE

AMP

P

REC

AMP

D-REC-H

11 12

MUTE

REC/EE/PB

16

96

98

D-PB-L

A-MUTE-H

D-REC-H

FROM

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

1-10-5 1-10-6 H9404BLA

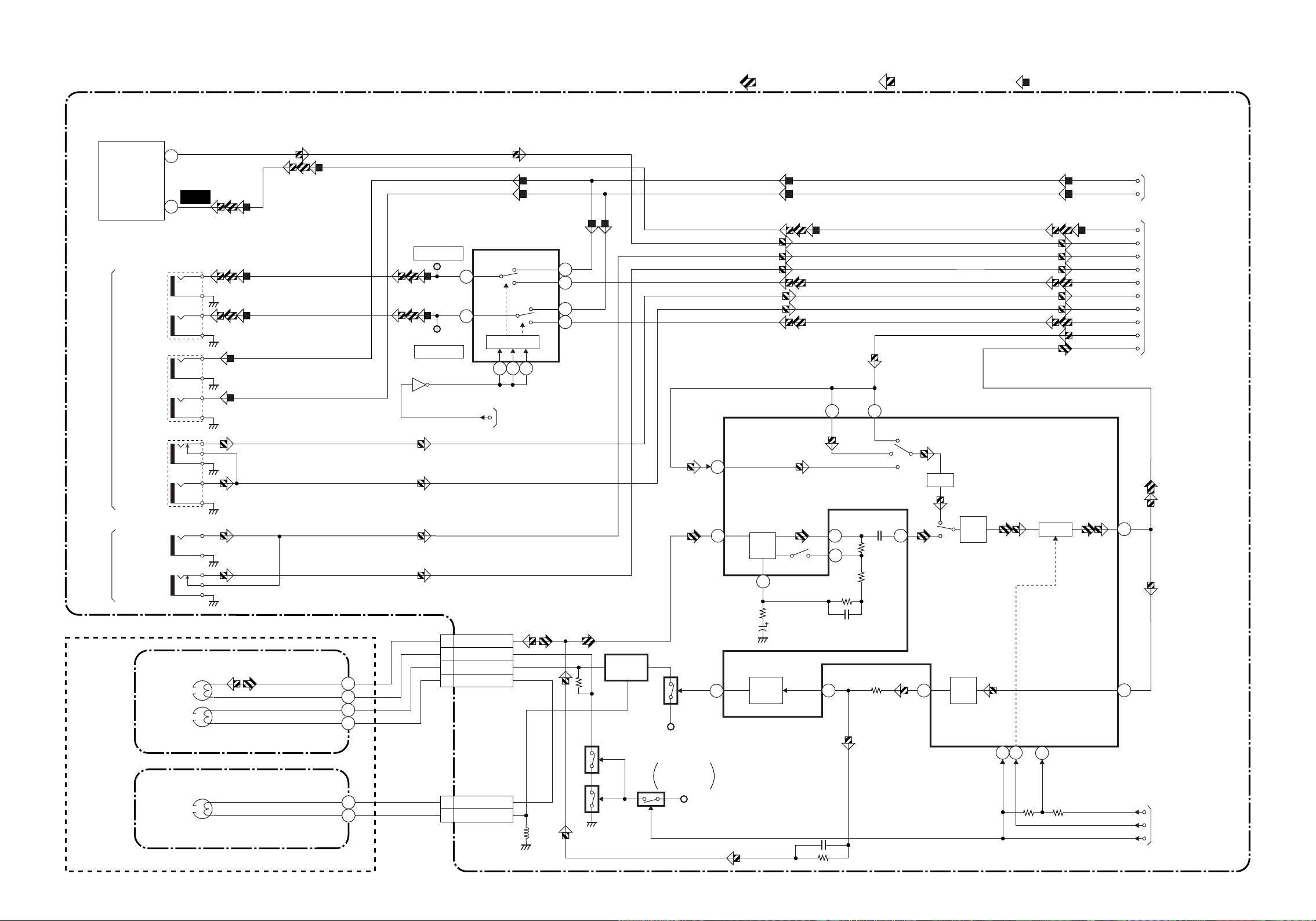

Hi-Fi Audio Block Diagram

SIF

IC451 (MTS/ SAP/ Hi-Fi AUDIO PROCESS/ Hi-Fi HEAD AMP)

57

SAP

DET

SIF

DEMOD

CONT

SAP

FILTER

STEREO

FILTER

PILOT

DET

STEREO

PLL

62 63

SAP

DEMOD

PILOT

CANCEL

MAIN CBA

L-R

DEMOD

ST/SAP

SW

DC

dBX

DEC

MATRIX

REC-AUDIO SIGNALPB-AUDIO SIGNAL Mode : SP/REC

SERIAL

DATA

DECODER

RIPPLE

FILTER

DVD AUDIO SIGNAL

37

38

54

P-ON+9V

IIC-BUS SDA

IIC-BUS SCL

FROM/TO

SERVO/ SYSTEM

CONTROL BLOCK

FROM/TO

AUDIO BLOCK

FROM DVD

AUDIO BLOCK

<DVD SECTION>

A-IN(R)

A-IN(R)-F

N-A-OUT

A-IN(L)

A-IN(L)-F

DVD-A(L)

DVD-A(R)

69

71

12

74

R-CH

PNR

R-CH

INSEL

6

7

9

NOR

SW

L-CH

INSEL

48 47

13 14

P

R

SW

NOISE

LIM DEV

COMP

HOLD

PULSE

NOISE

DET

VCO

LPF

MATRIX

R-CH BPF

OUTPUT

SELECT

COMP

ALC

DO

DET

MUTE

ENV

DET

MODE

OUT

40

23

80

78

77

39

49

26

ST/SAP-MODE

NORMAL-H

4

2

1

N-A-IN

A-OUT (L)

MOD-A

A-OUT (R)

Hi-Fi-H-SW

A-MUTE-H

TO SERVO/SYSTEM

CONTROL BLOCK

FROM/TO

AUDIO BLOCK

FROM

SERVO/SYSTEM

CONTROL BLOCK

CYLINDER

ASSEMBLY

LPF

L-CH BPF

LIM

34 33

R

L

24

27

CL253

Hi-Fi-A(R) 7

Hi-Fi-COM 8

Hi-Fi-A(L) 9

Hi-Fi

AUDIO

(R) HEAD

Hi-Fi

AUDIO

(L) HEAD

L-CH

PNR

LIM DEV

R

SW

P

NOISE

VCO

COMP

H9404BLH1-10-7 1-10-8

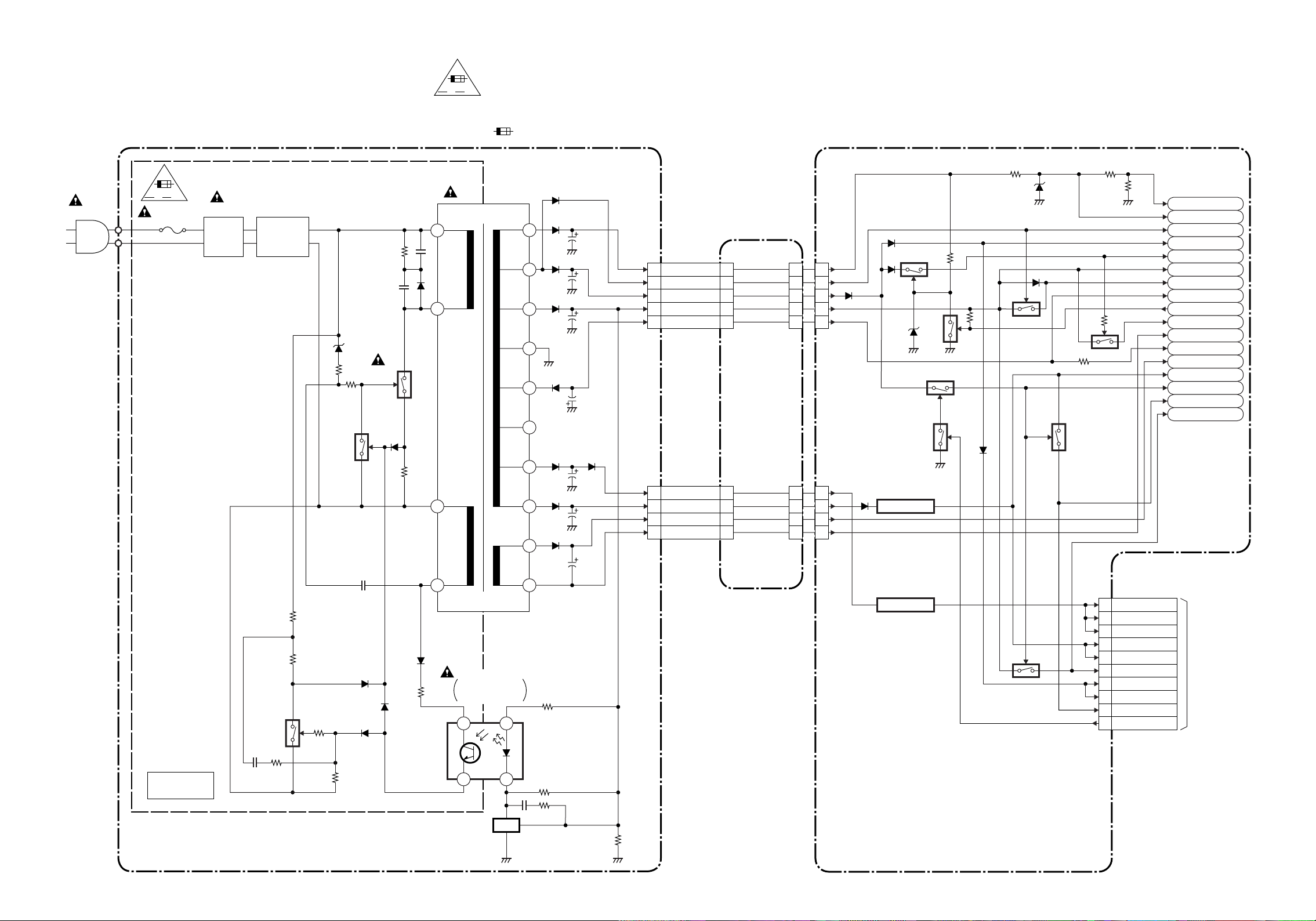

Power Supply Block Diagram

NOTE :

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

HOT CIRCUIT. BE CAREFUL.

F

F

A V

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE.

ATTENTION : POUR UNE PROTECTION CONTINUE LES RISQES

D'INCELE N'UTILISER QUE DES FUSIBLE DE MEMO TYPE.

RISK OF FIRE

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

-REPLACE FUSE AS MARKED.

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F001) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

AC1001

A V

F1001

1A 250V

L1001

LINE

FILTER

D1001 - D1004

BRIDGE

RECTIFIER

Q1008

Q1003

Q1001

T001

2

4

8

7

IC1001

ERROR

VOLTAGE DET

4

AL+15V

AL+33V

20

19

18

17

16

15

14

13

12

CL1002

1 1AL+44V

2 2P-DOWN-L

3 3AL+12V

5 5AL+5V

7 7AL-24V

CL1006 CL1007

1 1AL+2.35V

3 3AL+4V

6 6F1

7 7F2

CL1004 CN1005

CN1003

1

1

2

2

3

3

5

5

7

7

CN1005 CN1003

9

9

11

11

14

14

15

15

Q055

Q1005

IC1004

+3.3V REG.

Q057

Q052

Q056

Q1006

Q1011

P-DOWN-L

AL+12V

P-ON+9V

AL+5V

TIMER+5V

AL-24V

P-ON-L

P-ON+5V

F2

-FL

F1

EV+3.3V

DVD-P-ON+12V

DVD-P-ON+3.3V

DVD-P-ON+5V

JUNCTION

CBA

11

1

IC1002

+1.5V REG.

Q1004

CN1001

1 EV+1.5V

2 EV+1.5V

3 EV+1.5V

4 EV+3.3V

5 EV+3.3V

13 DVD-P-ON+5V

14 EV+9V

15 EV+9V

17 DVD-P-ON+3.3V

19 PWRCON

TO DVD MAIN

CBA UNIT

CN401

HOT

POWER SUPPLY CBA

(SHUNT REGULATOR)

IC1006

23

REG

MAIN CBA

H9404BLP1-10-9 1-10-10

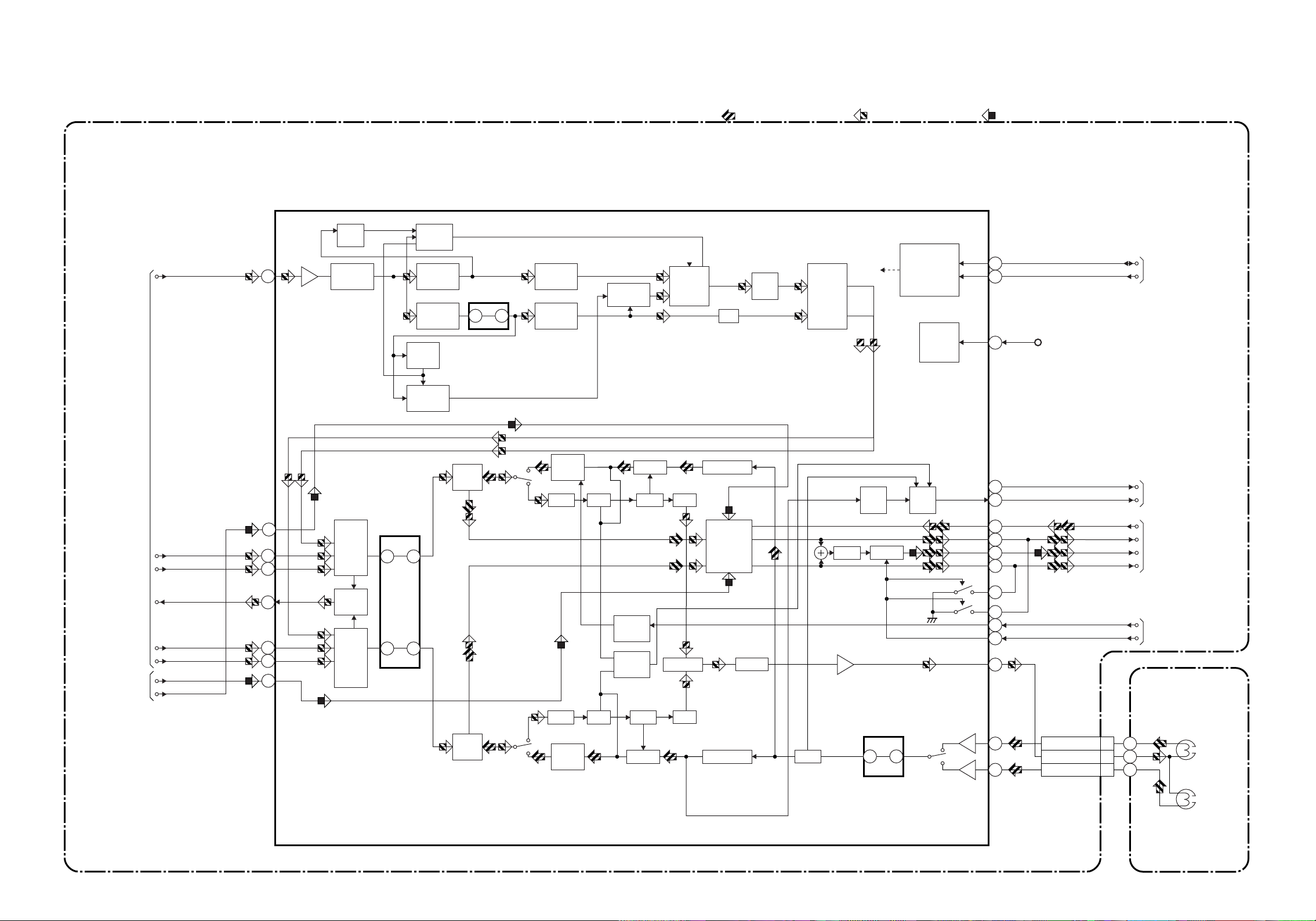

DVD System Control/Servo Block Diagram

BLOCK DIAGRAMS<DVD SECTION>

TO

DVD VIDEO/ AUDIO

BLOCK DIAGRAM

PICK-UP

UNIT

TRAY-OUT

FOCUS SERVO SIGNAL TRACKING SERVO SIGNAL

IC451

(CLOCK GENERATOR)

1/4

1/4

MULTI

PLL

PLL2

IC301

(SERVO DRIVE)

FOCUS

15

ACTUATOR

DRIVE

16

TRACKING

14

ACTUATOR

DRIVE

13

PCM-SCLK

DVD-A-MUTE

ADAC-MD

ADAC-MC

ADAC-ML

FSTS

3

15

10

CN201

FS(+) 18

FS(-) 19

TS(+) 20

TS(-) 17

X'TAL

OSC

SLED SERVO SIGNAL SPINDLE SERVO SIGNAL

IC101

(MICRO CONTROLLER)

EXT CLOCK

172

CLK33M

BE CLOCK

170

X451

7

36.864MHz

OSC

+

14

8

IC202

(OP AMP)

1

27

+

-+

-

-

26

25

24

+

-

1

2

3

3

AD2

146

POFLT

114

1792FSEL

95

DVD-A-MUTE

ADAC-MD

51

50 ADAC-MC

96 ADAC-ML

152

FOCUS DRIVE

TRACKING

150

DRIVE

PLAY

STOP

POWER

OPEN

/CLOSE

48

47

62

94

CN302

SW2001

DVD

OPEN

/CLOSE

OPEN/CLOSE

CL2002CL2003

22

DVD

OPEN/CLOSE CBA

CN2001

PLAY 11

STOP 22

POWER 33

OPEN/CLOSE 44

Q2001

OUTPUT-SELECT

DVD-POWER

SW2003

PLAY

SW2002

STOP

FROM SERVO

/SYSTEM CONTROL

BLOCK DIAGRAM

<VCR SECTION>

SPINDLE

MOTOR

M

SLED

MOTOR

M

FG CBA

FG

SENSOR

TRAY-IN

CN3002 CN301

DRIVE CBA

3SP(+)

4SP(-)

5TRAY-OUT

6TRAY-IN

7GND

8SL(-)

9SL(+)

1FG-IN

1-10-11

SPINDLE

12

MOTOR

DRIVE

11

SLED

17

MOTOR

DRIVE

18

IC202

(OP AMP)

12 14

+

-

+

-

+3.3V

5 4

+

-

IC461

4

5

6

23

RESET

DVD MAIN CBA UNIT

SPDL71

SLD70

OUT-SEL/SKIP-UP

REMOTE-DVD

RESET68

TRAY-OUT

97

TRAY-IN

60

FG-IN

66

FP-STB

FP-DIN 54

FP-CLK

55

59

53

61

CN401

OUT-SEL/SKIP-UP

FP-STB

FP-DIN 1818

FP-CLK

REMOTE-DVD 2222

CN1001

2020

1616

2121

RM2001

REMOTE

SENSOR

1-10-12

IC571

(FRONT PANEL CONTROL)

1G

23

~

7G

17

2

28

STB

DIN

1

CLK

a

~

h

14

i

16

DISPLAY-CLK

DISPLAY-DATA

DISPLAY-ENA

REMOTE-VIDEO

MAIN CBA

FIP502

~

GRID

7

~

SEGMENT

FROM/TO SERVO

/SYSTEM CONTROL

BLOCK DIAGRAM

<VCR SECTION>

FIP

H9404BLSD

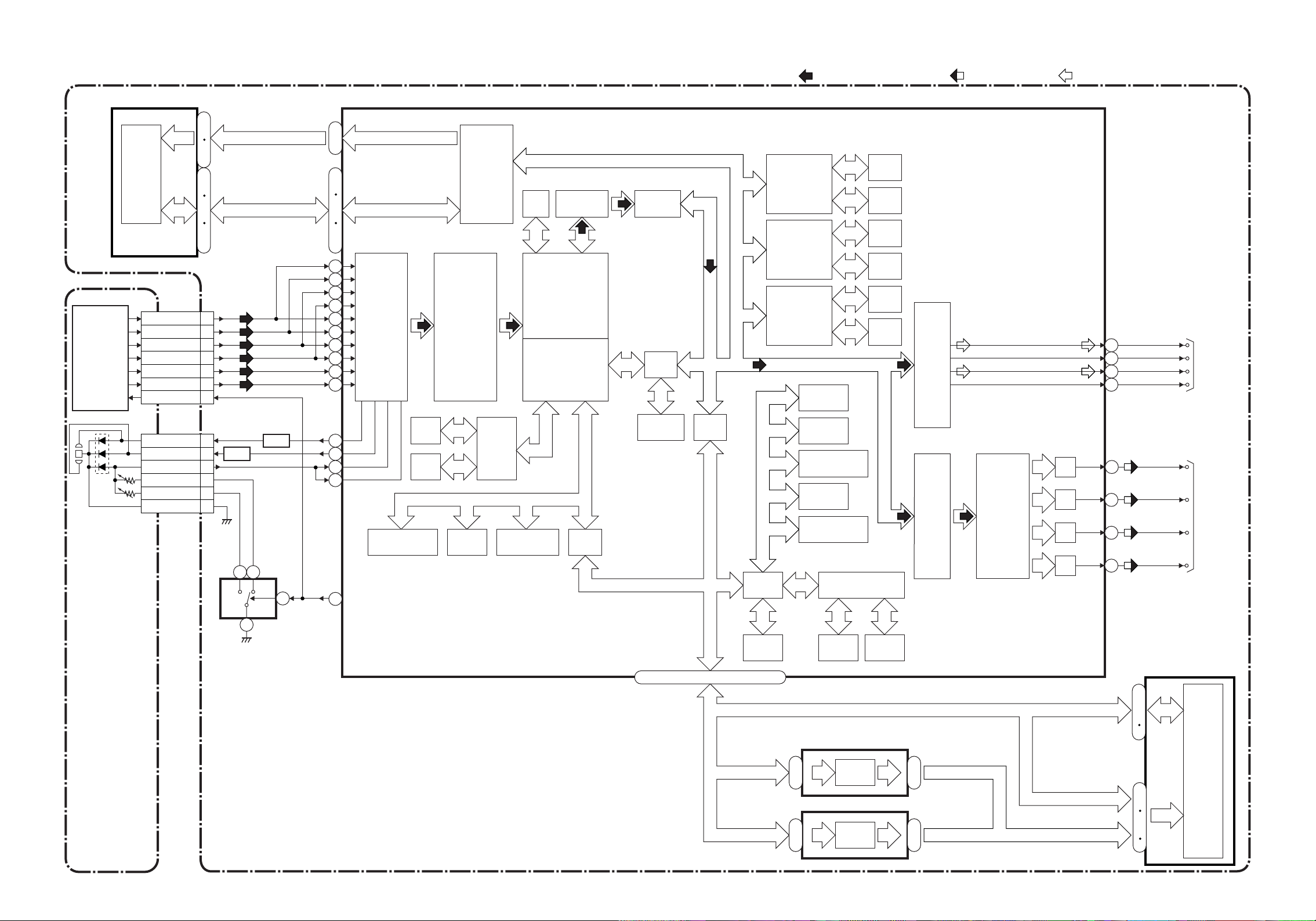

Digital Signal Process Block Diagram

IC102 (SDRAM) IC101 (MICRO CONTROLLER)

24

DETECTOR

SDRAM

27

60

66

2

13

31

56

74

85

C 6

D 7

A 8

B 5

F 10

E 2

CD/DVD 9

~~

~~~

CN201

210

235

2

13

184

205

247

256

124

125

122

123

128

129

126

127

131

130

~

~~~

SDRAM ADDRESS(0-10)SDRAM ADDRESS(0-10)

SDRAM DATA(0-31)SDRAM DATA(0-31)

RF

SIGNAL

PROCESS

CIRCUIT

EXTERNAL

MEMORY

I/F

DVD/CD

FORMATTER

ECC

DECODER

I/F

DMA

BCU

STREAM

I/F

UMAC

DATA(VIDEO/AUDIO) SIGNAL DVD VIDEO SIGNAL

DSP

DECODER

PIXEL

OPERATION

I/O

PROCESSOR

SERIAL

DATA

ROM

INST.

ROM

DATA

ROM

INST.

ROM

DATA

ROM

INST.

ROM

AUDIO

I/F

DATA(AUDIO) SIGNAL

181

175

176

174

SPDIF

PCM-BCK

PCM-DATA0

PCM-LRCLK

TO DVD

VIDEO

/AUDIO

BLOCK

DIAGRAM

PICK UP

UNIT

CD-LD 12

DVD-LD 14

PD-MONI 13

GND(DVD-PD)

GND(CD-PD)

GND(LD)

CN201

15

16

11

Q253,Q254

AMP

AMP

Q251,Q252

1 3

CD DVD

4

6

IC201

(SW)

DVD MAIN CBA UNIT

135

133

132

134

78

INTERRUPT

CONTROLLER

CD/DVD

INST.

ROM

DATA

ROM

TIMER

32BIT

CPU

WATCH DOG

TIMER

CPU

I/F

READ

MEMORY

EXT ADT (0-15), EXT ADR (16-19)

CPU

I/F

BCU

DEBUG

EXT ADT (0-15), EXT ADR (16-19)

EXT ADT (0-7)

EXT ADT (8-15)

GENERAL

I/O

INTERRUPT

CONTROLLER

TIMER

WATCH DOG

TIMER

INST

CACHE

IC105 (LATCH)

2

~

9

IC104 (LATCH)

2

~

9

32BIT CPU

DATA

CACHE

D TYPE

LATCH

D TYPE

LATCH

VIDEO

I/F

12

~

EXT ADR (0-7)

19

12

~

EXT ADR (8-15)

19

NTSC/PAL

ENCODER

D/A

D/A

D/A

D/A

EXT ADT (0-15)

EXT ADR (16-19)

EXT ADR (0-15)

Y

C

Cr

Cb

158

164

161

160

VIDEO-Y

VIDEO-C

VIDEO-Cr

VIDEO-Cb

IC103 (FLASH ROM)

29

~~

36

38

45

FLASH

ROM

1

~

9

16

~

25

48

TO DVD

VIDEO

/AUDIO

BLOCK

DIAGRAM

1-10-13

1-10-14

H9404BLD

Loading...

Loading...