Page 1

OPERATING INSTRUCTIONS

2/01/01

SERIES HEATERS

010226, 014372, 014682, 014683, 016501, 016502, 016503, 016504, 017558, 017575

OSRAM

SYLVANIA

Process Heat

⇒ FOR SAFETY AND LONG HEATER LIFE, CAREFULLY READ THIS MANUAL BEFORE USE.

Description

Compact and efficient process air/inert gas heater, capab le of producing exit temper atures up to 1400°F

(760°C). The serpentine coil elem ent is sup ported a long its ent ire leng th by a thre aded ceram ic rod, an d

is protected by a qu artz tube sheath. The Series heater s are avai lable in either open-ended or nozzled

styles. Wattage ranges from 600W to 4000W. If operated correctl y, element life will be greater than

5000 hours.

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

1

Page 2

OPERATING INSTRUCTIONS

2/01/01

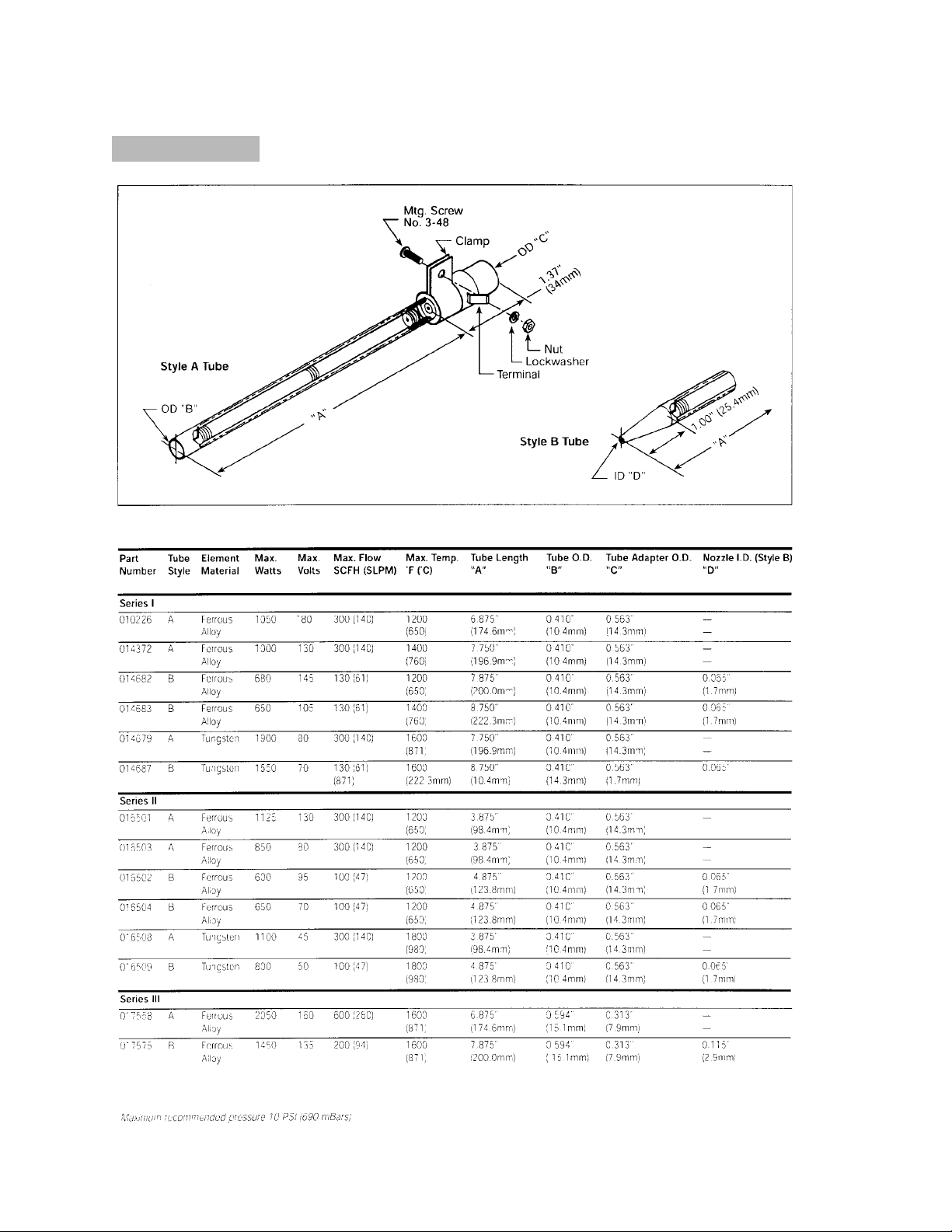

Specifications

OSRAM

SYLVANIA

Process Heat

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

2

Page 3

OPERATING INSTRUCTIONS

2/01/01

OSRAM

SYLVANIA

Process Heat

Safety

SHOCK HAZARD Only qualified individuals should install this heater and related controls. Follow all applicable

!

electrical codes and use proper wiring.

BURN/FIRE/EXPLOSION HAZARD Do not use with or near explosive or reactive gases. Avoid contact with the

!

side, or exposure to the exit-end, during or soon after operation. DO NOT USE NEAR VOLATILE OR

COMBUSTIBLE MATERIALS.

Precautions

!

Use filtered air. Avoid grease, oil, or oil vapors, corrosive or reactive gases that will damage heater.

!

Operate at safe voltages as shown on the PERFORMANCE CURVES. Excess voltage will cause premature

failure.

!

Always have sufficient airflow through the heater before applying power. Otherwise element will overheat very

quickly, and burn out. NOTE: A thermocouple cannot detect temperatures if there is no flow – turn on flow before

applying power, even when a controller with a thermocouple is being used.

!

Use phase angle fired power controllers. On-off controllers may shorten heater life (or burnout element).

!

For closed-loop control, use exposed junction type “K” thermocouple within one inch of the heater exit.

!

For closed-loop control, use a temperature controller with a fast sampling period (500ms) and minimal overshoot.

Installation

" Securely mount the heater.

" Connect the filtered air source to the heater.

" If a thermocouple is used, ensure that it is located within one inch from the heater exit.

Start-up

"

Reference the PERFORMANCE CURVES section for operational parameters before attempting to operate

heater(s).

" Turn on air supply and adjust to desired flow/pressure.

" If using a closed loop system, turn on power to the temperature and power controller, then set the desired

temperature on the temperature controller. If using an open loop system, increase power to the heater through

the power controller until the desired temperature is attained.

Performance Curves

STYLE A (OPEN ENDED) HEATER CURVES:

The attached performance curves show exit air temperatures at different airflows and voltages. Pressure readings

(longer dashed lines) are measured at the inlet to the heater with no entrance or exit restrictions. Solid lines indicate

safe, normal life operating conditions. The shorter dash lines indicate marginal, shorter-life operating conditions

leading to premature burnout. With a known flow (or pressure) at the heater entrance, follow the flow (or pressure)

line across until it meets the desired temperature curve. Drop a line straight down to intersect the x-axis. This point,

along the “Heater volts – true RMS” axis, represents the voltage required to generate the desired exit air temperature

at the chosen flow rate (inlet pressure).

STYLE B (NOZZLED) HEATER CURVES:

With the small nozzle, it is difficult to measure exit end temperature accurately. Therefore, a different set of

performance limits must be used. For these curves, operating with voltages and flows to the left of the curve results

in long heater life. Operating to the right of the curve results in heater burn out.

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

3

Page 4

OPERATING INSTRUCTIONS

2/01/01

OSRAM

SYLVANIA

Process Heat

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

4

Page 5

OPERATING INSTRUCTIONS

2/01/01

OSRAM

SYLVANIA

Process Heat

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

5

Page 6

OPERATING INSTRUCTIONS

2/01/01

OSRAM

SYLVANIA

Process Heat

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

6

Page 7

OPERATING INSTRUCTIONS

2/01/01

OSRAM

SYLVANIA

Process Heat

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

7

Page 8

OPERATING INSTRUCTIONS

2/01/01

OSRAM

SYLVANIA

Process Heat

Warranty

OSRAM SYLVANIA warrants that all products to be delivered hereunder will be free from defects in material and

workmanship at the time of delivery. OSRAM SYLVANIA's obligation under this warranty shall be limited to (at its

option) repairing, replacing, or granting a credit at the prices invoiced at the time of shipment for any of said products.

This warranty shall not apply to any such products which shall have been repaired or altered, except by OSRAM

SYLVANIA, or which shall have been subjected. OSRAM SYLVANIA shall be liable under this warranty only if (A)

OSRAM SYLVANIA receives notice of the alleged defect within sixty (60) days after the date of shipment; (B) the

adjustment procedure hereinafter provided is followed, and (C) such products are, to OSRAM SYLVANIA’s

satisfaction, determined to be defective.

THE WARRANTY SET FORTH IN THE PRECEDING PARAGRAPH IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE OR OF MERCHANTABILITY.

The information contained in this manual is based on data considered to be true and accurate. Reasonable

precautions for accuracy has been taken in the preparation of this manual, however OSRAM SYLVANIA assumes no

responsibility for any omissions or errors, nor assumes any liability for damages that may result from the use of the

product in accordance with the information contained in this manual.

Please direct all warranty/repair requests or inquiries to the place of purchase, and provide the following information,

in writing:

(A) Order number under which products were shipped

(B) Model/Serial Number of product

(C) Reason for rejection

PRODUCTS CAN NOT BE RETURNED TO OSRAM SYLVANIA WITHOUT AUTHORIZATION.

Replacement, repair, or credit for products found to be defective will be made by the place of purchase. All products

found to be not defective will be returned to the Buyer; transportation charges collect or stored at Buyers expense.

131 Portsmouth Ave. Exeter, NH 03833 USA Tel: 800-258-8290 Fax: 603-772-1072

8

Loading...

Loading...