Short Instruction For Use EN

HF Inverter e@syDrive® 4638

EN

Distribution:

SycoTec GmbH & Co. KG

Wangener Strasse 78

88299 Leutkirch, Germany

Phone +49 7561 86-0

Fax +49 7561 86-371

info@sycotec.eu

www.sycotec.eu

Manufacturer:

SIEB & MEYER AG

Auf dem Schmaarkamp 21

21339 Lüneburg, Germany

Phone +49 (0)4131 203-0

Fax +49 (0)4131 203-2000

info@sieb-meyer.de

www.sieb-meyer.com

This short instruction for use includes only the essential control functions.

It does not however replace the Sieb & Meyer Hardware Description "Drive System

SD2S" that must be downloaded before commissiong:

- on the SycoTec homepage at the download area under

https://www.sycotec.eu/en/about-sycotec/downloads2/

respectively

- at Sieb & Meyer under

https://www.sieb-meyer.com/file-detail.html?item=421

The safety information have to be observed before commissioning!

EN

Content

1.0 Scope of Supply and Accessories 4

1.1 Scope of Supply 4

1.2 Accessories 4

2.0 Connections 4

3.0 Safety Circuit and Restart Lock 4

4.0 Motor 5

4.1 Motor Temperature Sensor 5

4.2 Assignment of the Parameter Sets 5

4.3 Connection choke 6

5.0 Power Supply 6

6.0 Digital and Analog Inputs / Outputs 6

6.1 Digital inputs 7

6.2 Digital Outputs 7

6.3 Analog Inputs 8

7.0 External Ballast Resistor 8

8.0 Example of remote control element 9

9.0 Connecting to the computer 9

10.0 Activate another parameter set 10

11.0 Load parameter file 10

12.0 Load Project 11

13.0 Status Display and Error Messages 12

Warranty Conditions 13

CE Declaration of Conformity 13

EN

4

1.0 Scope of Supply and Accessories

1.1 Scope of Supply

HF Inverter e@syDrive® 4638 Material no. 2.001.6091

(Drive System SD2S / device variant 0362121EC)

SycoTec – Short Instruction For Use Material no. 2.001.8020

HF Inverter e@syDrive® 4638

1.2 Accessories

Motor choke (220 µH, 12 A

eff

) Material no. 2.002.2384

Ballast resistor (400 W, 10 Ohm) Material no. 2.002.2385

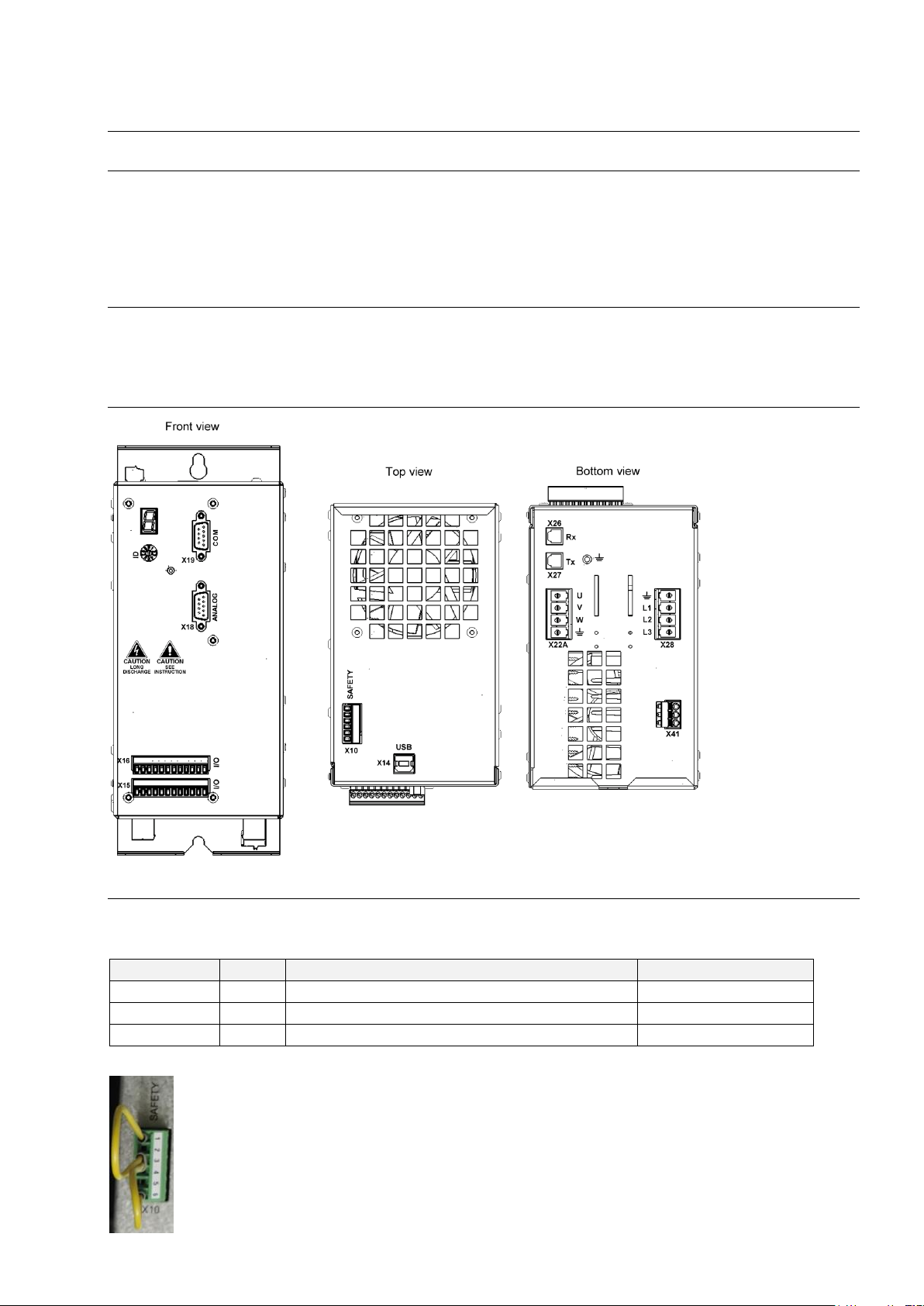

2.0 Connections

3.0 Safety Circuit and Restart Lock

The power supply unit is only activated when SAFEA and SAFEB are connected. If the safety function is not

required, pin1 and pin 3 must be bridged to pin 5.

Name

I/O

Meaning

Pin

SAFEA

I

Enable of safety circuit

X10/1

SAFEB

I

Enable of safety circuit

X10/3

24 V

O

Logic voltage 18 – 28 V

X10/6

The 24V output is not suited to supply external safety circuits.

EN

5

4.0 Motor

Name

I/O

Meaning

Pin

U O Motor phase U

X22A/U

V O Motor phase V

X22A/V

W O Motor phase W

X22A/W

PE Protective conductor

X22A/PE

4.1 Motor Temperature Sensor

Name

I/O

Meaning

Pin

Temp

I

Motor temperature sensor (towards GND)

X16/9

GND

I/O

Ground

X16/11,12

4.2 Assignment of the Parameter Sets

Assignment

Parameter set of motor spindle

Remark

P00

4060 E

P01

4060 ER

P02

4060 ER-S

P03

4060/4061 AC

P04

4060 AC-T

P05

50100 AC-duo

P06

4060/4061 DC-S_SVC

Motor spindle must be operated with an

upstream choke / external inductance of

220 µH

P07

4060/4061 DC-T_SVC

P08

4064 DC SK_SVC

P09

4064 DC HSK_SVC

P10

5045 DC-HV 60.P4_SVC

P15

4060/4061 DC-S_HSPWM

Alternative function types, without choke

P16

4060/4061 DC-T_HSPWM

P17

4064 DC_HSPWM

EN

6

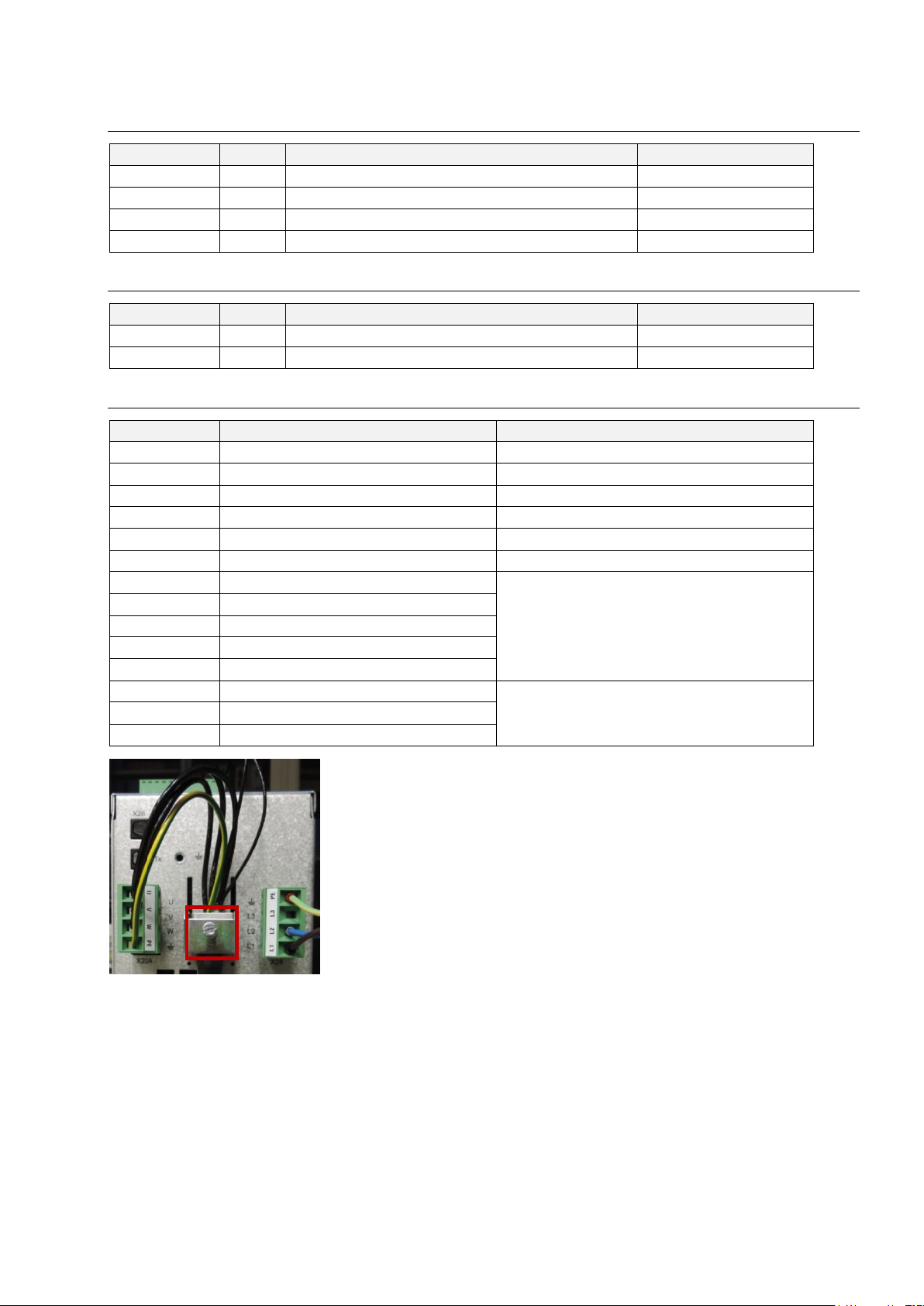

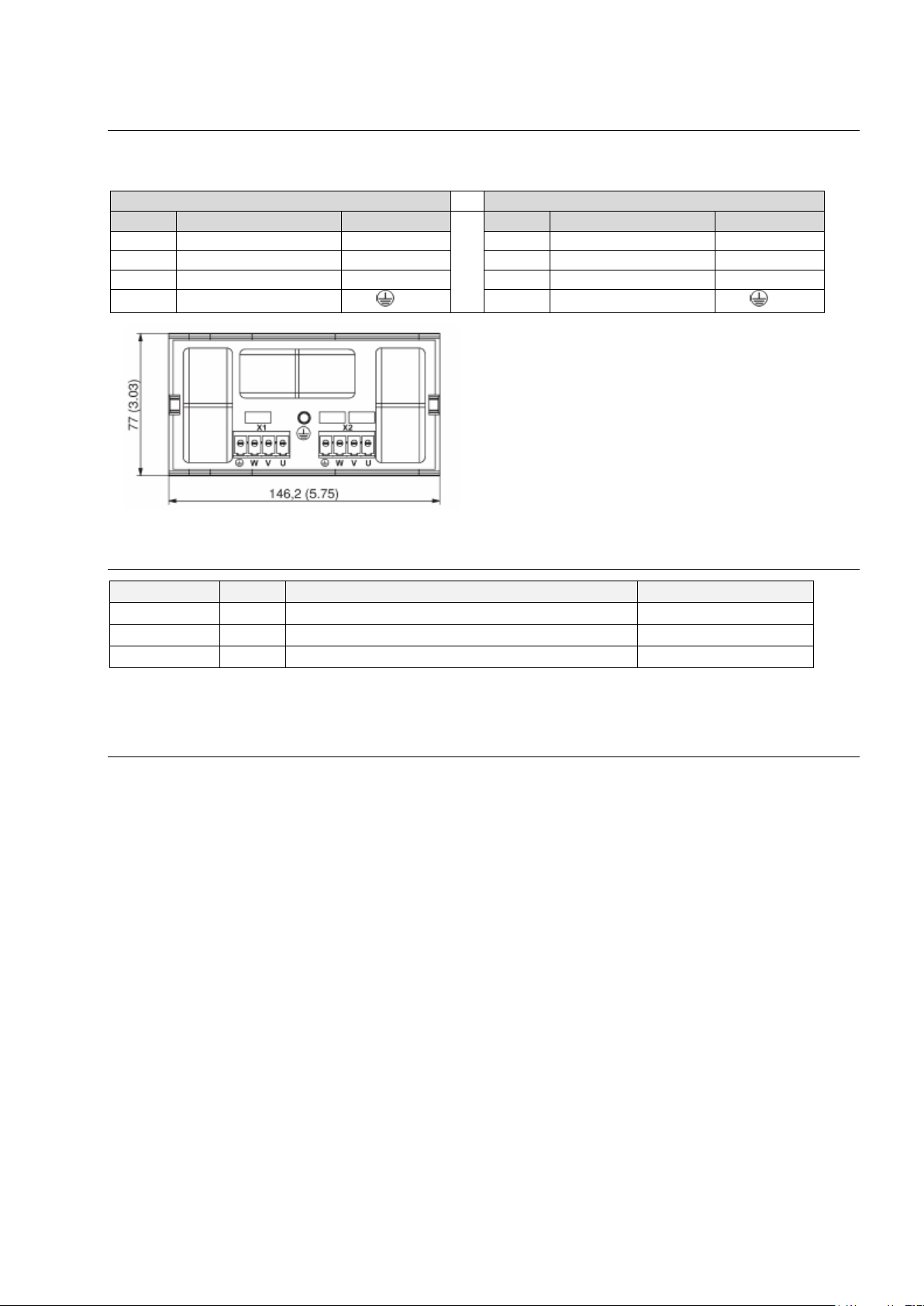

4.3 Connection choke

The connection X22A (Motor) of the frequency inverter is connected to connection X1 (Drive) of the choke.

The motor phases are connected to X2 (Motor) of the choke.

X1 (Drive)

X2 (Motor)

Name

Meaning

Pin (Choke)

Name

Meaning

Pin (Choke)

U

Motor phase U

X1/U

U

Motor phase U

X2/U

V

Motor phase V

X1/V

V

Motor phase V

X2/V

W

Motor phase W

X1/W

W

Motor phase W

X2/W

PE

Protective conductor

X1/

PE

Protective conductor

X2/

5.0 Power Supply

Name

I/O

Meaning

Pin

L1 I Main supply

X28/L1

L2 I Main supply

X28/L2

PE Protective conductor

X28/PE

Voltage range: 150 V AC -10% to 230 V AC +10%

6.0 Digital and Analog Inputs / Outputs

If you want to make use of the digital inputs and outputs, connect pin x15/9 to 24 V.

The functions / assignments of the inputs and outputs can be configured via the "drivemaster2" software.

By default, the following functions / assignments are set.

EN

7

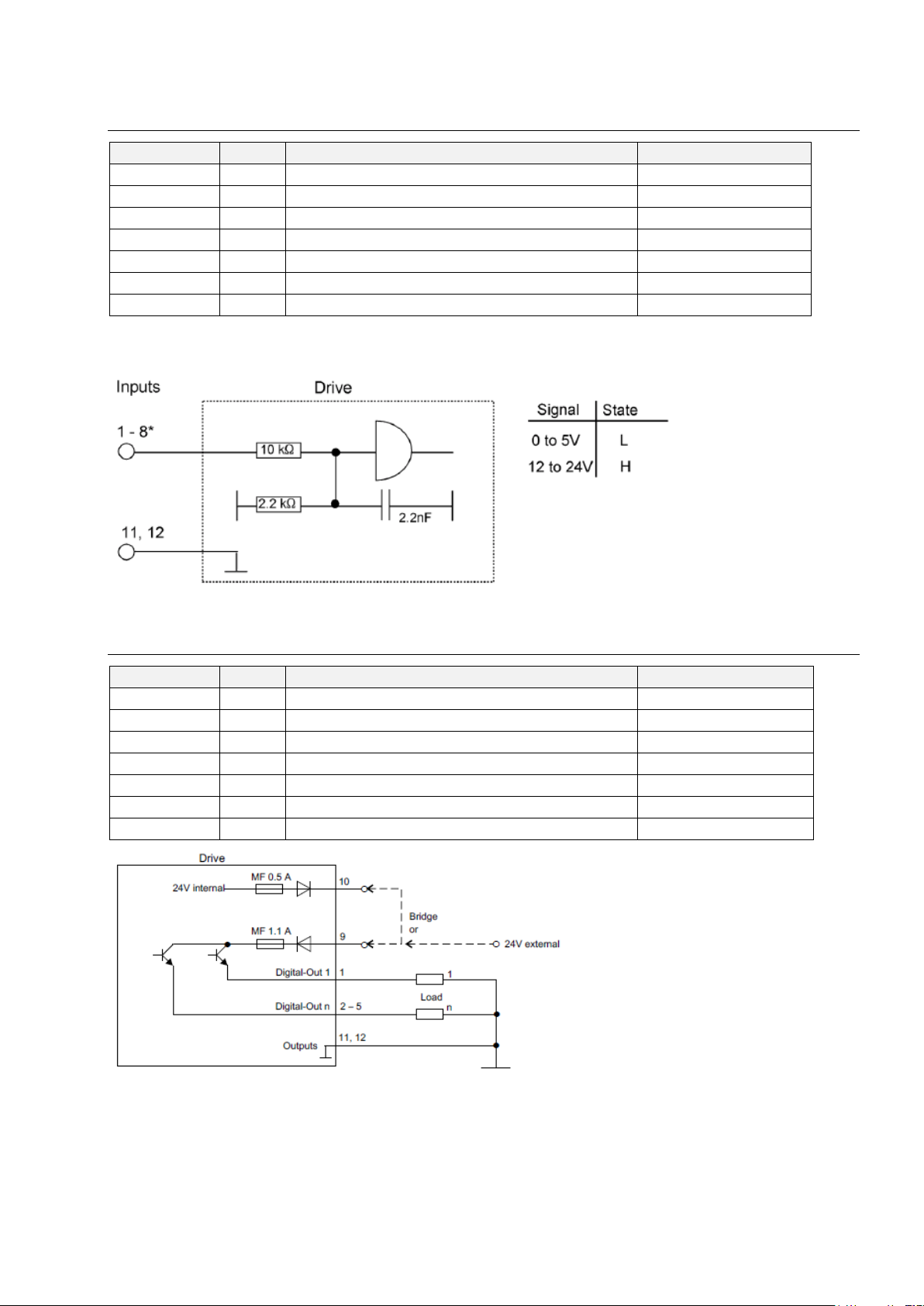

6.1 Digital Inputs

Name

I/O

Function / Assignment

Pin

IN0 I Switch on

X16/1

IN1 I Operation enable

X16/2

IN2 I Error reset

X16/3

IN6 I Speed direction

X16/7

GND

I/O

Ground

X16/11,12

VCC-IO

I

24 V supply for IO

X15/9

VCC-OUT

O

24 V output for IO (max. 0,3 A)

X15/10

IN0 "Switch on" activates the controller, the holding current is applied to the motor spindle.

If the controller is active, the motor spindle can be started with IN1 "Operation enable".

[*] Yet another digital input is located at the connector X15, pin 6.

6.2 Digital Outputs

Name

I/O

Function/Assignment

Pin

OUT0

O

Ready type 1

X15/1

OUT1

O

M02 - Message operation enabled

X15/2

OUT2

O

M12 - Speed zero

X15/3

OUT3

O

M10 - Ref. value reached

X15/4

VCC-IO

I

24 V supply for IO

X15/9

VCC-OUT

O

24 V output for IO (max. 0,3 A)

X15/10

GND

I/O

Ground

X15/11,12

Every output can be loaded with 100 mA.

EN

8

6.3 Analog Inputs

Name

I/O

Function/Assignment

Pin

AIN0+

I

Speed reference value

X18/3

GND

I/O

Ground

X18/4

AIN0-

I

Reference point for AIN0+ (bridge with ground)

X18/7

VCC_10

O

10 V supply voltage

X18/9

Voltage interface with input voltage range: ± 10 V

Can also be connected to potentiometer (500 Ohm – 5 kOhm

7.0 External Ballast Resistor

Name

Function / Assignment

Pin

Rextern

External ballast resistor

X41/1

Rintern

Internal ballast resistor

X41/2

UB+

X41/3

If no external ballast resistor is used, pin 1 and pin 2 of connector X41 must be bridged.

The technical data of the optionally connected external ballast resistor must be entered via the

"drivemaster2" software.

By default no external ballast resistor is set.

EN

9

8.0 Example of remote control element

9.0 Connecting to the computer

➢ Connect the inverter via USB interface to the computer

➢ Plug in the inverter

➢ Start Sieb & Meyer "SD2 Windows software drivemaster2"

https://www.sieb-meyer.com/file-detail.html?item=413

To establish a connection to the device click "Setup connection to the device", adjust "USB" for connection

type and select "Search devices + connect".

EN

10

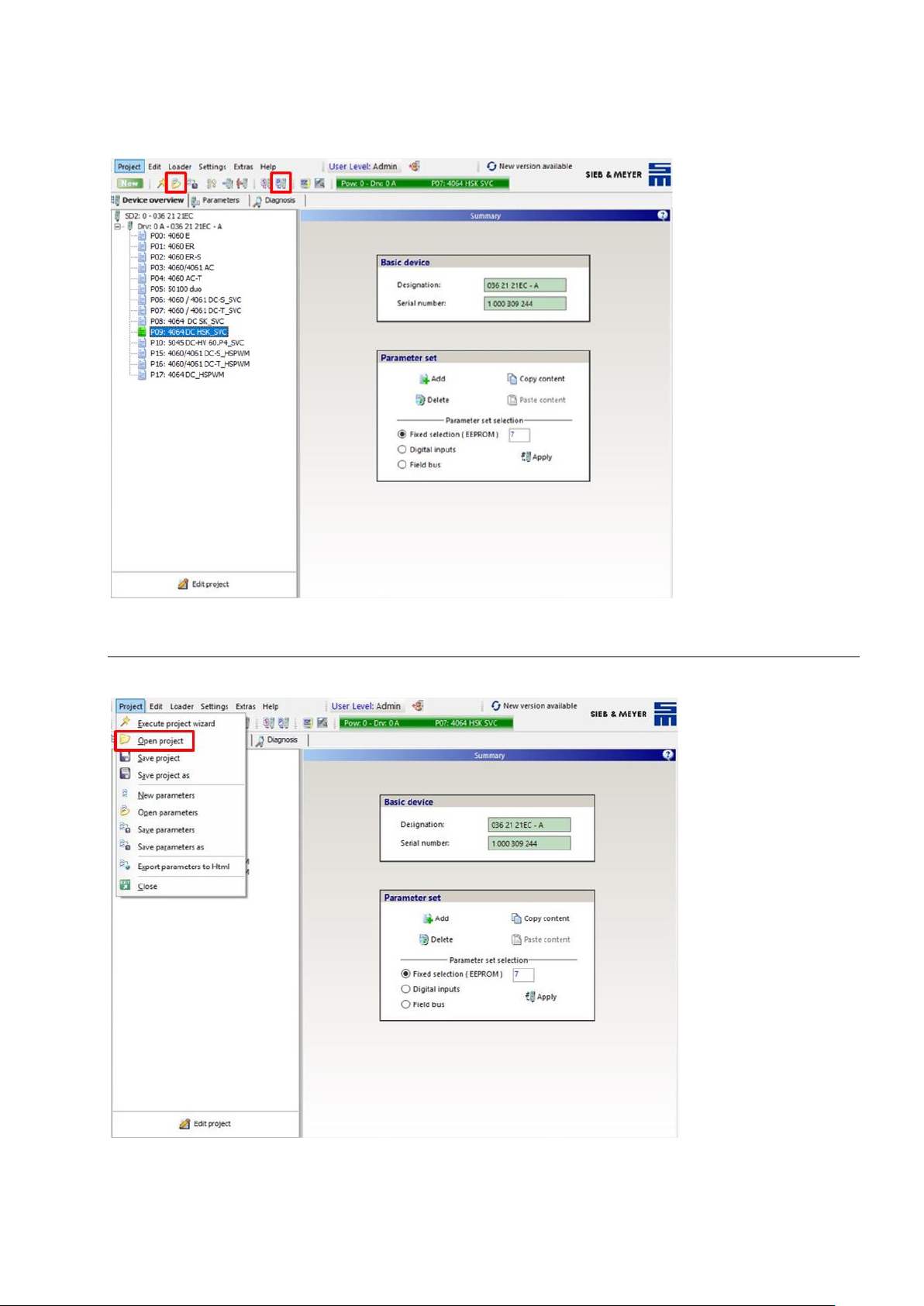

10.0 Activate another parameter set

To activate a different parameter file, enter the number (P00 … Pxx) of the required parameter file and click

"Apply".

11.0 Load parameter file

Before opening the parameter file select the right position (Pxx) or add a new parameter set.

EN

11

To open a parameter file click "Open parameters" on the toolbar and select the required parameter file.

To write the parameter file into the inverter click "Write parameters to drive" on the toolbar.

12.0 Load Project

To open a project select "Project" and then "Open project". Select the required project file and click "Open".

EN

12

To write the project to the inverter select "Loader" in the menu bar and then "Write project to drive".

13.0 Status Display and Error Messages

The 7-segment display shows status and error messages.

All messages end with dot behind the last digit. When the first digit is "E.", there is a permanent error.

Examples:

1.

Startup Message

- Controller is in boot loader mode: Display appears short-time when

the device is booted and when the system software is loaded.

2.

Ready To Switch On

- Controller is switched off

- No error

3.

Controller Active

- Controller is switched on

- No error

4.

Error Message

- Controller is switched off due to error E40

The error is not present anymore

5.

Persistent Error Message

- Controller is switched off due to error E40

- The error is still present

EN

13

Warranty Conditions

Under current SycoTec delivery and payment conditions, SycoTec undertakes warranty for satisfactory

function and freedom from faults in material and manufacture for a period of 12 months from the date of

sale certified by the vendor.

In the event of justifiable complaints, SycoTec shall supply spare parts or carry out repairs free of charge

under warranty. SycoTec accepts no liability for defects and their consequences which have arisen or could

have arisen as a result of natural wear and tear, improper handling, cleaning or maintenance, noncompliance with the maintenance, operating or connecting instructions, corrosion, impurities in the air

supply or chemical or electrical influences which are unusual or not admissible in accordance with

SycoTec's standards. The warranty claims shall become null and void if defects or their consequences can

be attributed to interventions in or modifications to the product. Warranty claims can only be validated if they

are notified immediately in writing to SycoTec.

A copy invoice or delivery note clearly showing the manufacture number shall be attached if products are

returned.

CE Declaration of Conformity

The CE Declaration of conformity may be requested or downloaded from www.sycotec.eu.

2.001.8020 / 201

9-06

(DE = original)

Loading...

Loading...