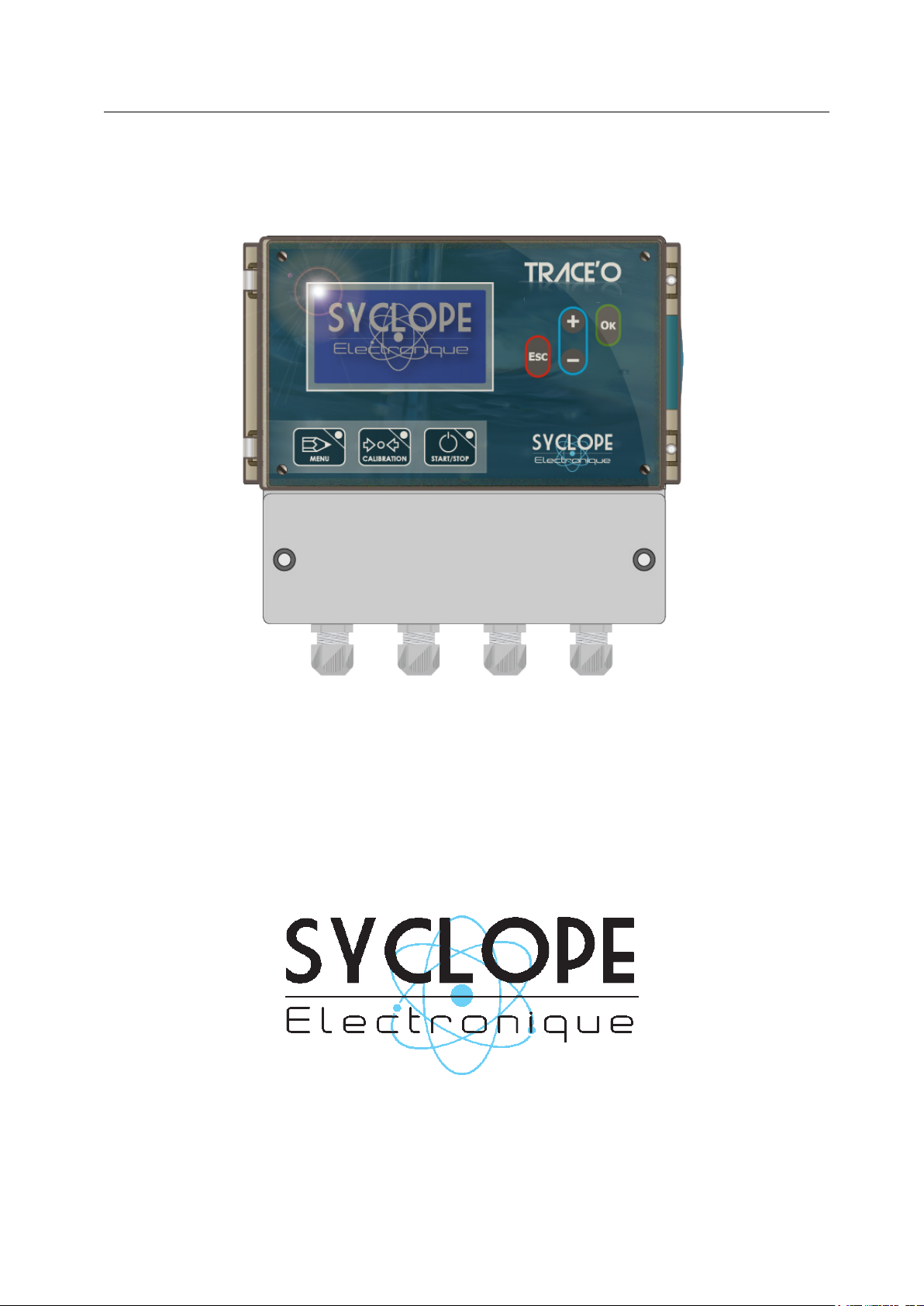

SYCLOPE TRACE’O® : Universal controller for trace detection (Part 1)

Installation and starting instructions

Reference : CTR 0001 Rev : 2

General information Page 2/40

►

Parts of the general documentation

1 : Installation and starting instructions

Part

2 : Programming instructions

Part

3 : Communications instructions

Part

General information :

®

SYCLOPE Electronique 2016

Manual of 2016, February 18th Rev 2

Universal controller for standard and trace measurement.

Product line TRACE’O

®

Part 1 : Installation and starting instructions (Ref. DOC0321)

Editor :

SYCLOPE Electronique S.A.S.

Z.I. Aéropole pyrénées

Rue du Bruscos

64 230 SAUVAGNON - France

Tel : (33) 05 59 33 70 36

Fax : (33) 05 59 33 70 37

Email : syclope@syclope.fr

Internet : http://www.syclope.fr

© 2015 - 2016 by SYCLOPE Electronique S.A.S.

Subject to modifications

Installation and starting instruction manual SYCLOPE TRACE’O

®

Summary Page 3/40

Summary

General informations ......................................................................................................... 4

I.

1) Applicability ...................................................................................................................... 4

2) Use of the document ......................................................................................................... 5

3) Symbols and signs ............................................................................................................. 5

4) Storage and transport ........................................................................................................ 6

5) Packaging ......................................................................................................................... 6

6) Warranty .......................................................................................................................... 6

II. environment and safety procedures .................................................................................... 7

1) Use of the equipment ........................................................................................................ 7

2) User obligations ................................................................................................................ 7

3) Risk prevention ................................................................................................................. 7

4) Identification and localization of the identification plate ....................................................... 8

5) Disposal and conformity ..................................................................................................... 9

III. Technical specifications and functions ................................................................................10

1) Features ..........................................................................................................................10

2) Main functions ..................................................................................................................11

3) Measurement parameters, scales and control ranges ..........................................................12

a) Basic versions : Direct entries (2x 4…20mA) or isolated entries (2x 4…20mA) ......................12

b) Version with 1 isolated potentiometric entry and 1 isolated 4-20mA entry ............................13

c) Version with 2 potentiometric entries .................................................................................14

IV. Installation and wiring ......................................................................................................15

1) Installation conditions .......................................................................................................15

2) Installation of the wall-mounted controllers........................................................................15

3) Electrical connections .......................................................................................................15

4) Connection of the primary power supply ............................................................................16

5) Connexion of the free of potential relays (KA, KB, KC et KD) ...............................................17

6) Connection of the measurement inputs ..............................................................................17

7) Connections of the analogue outputs (IA1 and IA2 .............................................................20

8) Connection of the remote control input (CAD) ....................................................................20

9) Connection of the flow control entry sensor (Flsw) or low level detection tank .....................21

10) Connection of the counter entry (Flow) or low level detection tank ......................................22

11) Connection of the RS232C printer output ...........................................................................22

12) Branchements du bus de communication RS485 .................................................................22

13) Connections of the MODEM port for communications ..........................................................23

14) Connection of GMS, Wifi and Ethernet modems for internet access .....................................24

15) Connection of the internal socket modem ..........................................................................24

V. Expendable external connection box ..................................................................................25

VI. General uses ....................................................................................................................26

1) Using « standard » mode ..................................................................................................26

2) Using « trace » mode .......................................................................................................27

VII. Introduction to the human-machine interface (HMI) ...........................................................28

1) Display and control keypad ...............................................................................................28

2) Internal connections .........................................................................................................29

3) Terminal block connections ...............................................................................................29

VIII. Commissioning .................................................................................................................30

1) Choosing the language .....................................................................................................30

2) Setting real-time clock ......................................................................................................31

3) Contrast adjust (Only when « Stopped ») ..........................................................................31

4) Setting display screens .....................................................................................................31

5) Programming setpoints .....................................................................................................33

6) Programming technical alarms ..........................................................................................34

7) Calibration of measurement probes ...................................................................................34

8) Start processes and dosages .............................................................................................35

IX. Guide and maintenance. ...................................................................................................37

Installation and starting instruction manual SYCLOPE TRACE’O

®

General informations Page 4/40

I. General informations

1) Applicability

SYCLOPE TRACE’O® controller range you have just purchased is an electronic special equipment for

measuring standard chemistry in trace range. It has been carefully developed and manufactured to

ensure your greatest pleasure and peace of action.

Its remarkable capacity of adaptation to the different situations means it can be installed in the most

difficult environments where processes and measurements of water are decisive.

®

Designed according to the needs of the customer, the SYCLOPE TRACE’O

controller is equipped with

four analog inputs for specific sensors for treating water and also include alarm functions and

regulations with cyclic commands transmitted by means of 4 configurable relays to control pH chemistry

levels of the water.

®

When using chlorine or ozone measurement, SYCLOPE TRACE’O

controller is able to measure

automatically some traces of chemistry with a special processing for guarantying the good working of

the respective sensors.

Two ports, RS232 and RS485, for a printer and/or a computer link, allows communication by direct link

or modem to a desktop computer (PC) for filing and graphic processing of the acquisition data.

®

The SYSCOM

software application has been developed to perform these functions.

®

TRACOM

software also developed by SYCLOPE Electronique S.A.S. makes it possible to ensure the

maintenance and the programming of the basic functions as well as the functions necessary to the

communications with the Internet.

®

With an adequate interface carrying out internet connectivity, SYCLOPE TRACE’O

will be connected

in real-time to Internet site “mysyclope.com” thus ensuring a management and a total follow-up of

all the parameters as well as a management of alarms by email or SMS in all circumstances. (Yearly

subscription of access to be envisaged)

®

The simplicity of operation of the SYCLOPE TRACE’O

, the user friendliness and the remarkable

technical aspects of these controllers, will ensure you benefit from their many options, guaranteeing

you full control and supervision of the quality of the water.

The following instructions contain all the information required for the installation, use and maintenance

of your new equipment.

Installation

Technical specifications

Commissioning instructions

Safety tips

If you would like to receive further information or if you encounter any difficulties not described in this

manual, please contact your usual retailer or else directly contact the sales department of SYCLOPE

Electronique S.A.S., either at the agency or at the office for your region, or the technical/quality

departments of our establishments. We will do everything in our power to help you and ensure you

benefit from our advice and know-how in the field of measurement and treatment of swimming-pool

water.

Contact : service-technique@syclope.fr

Installation and starting instruction manual SYCLOPE TRACE’O

®

General informations Page 5/40

2) Use of the document

Please read this entire document before starting to install, adjust or commission your controller device,

in order to ensure the safety of swimmers, users and equipment.

The information provided in this document must be strictly observed. SYCLOPE Electronique S.A.S.

declines all responsibility in cases where failure to comply with the instructions of this documents is

observed.

The following symbols and pictograms will be used to facilitate reading and understanding of these

instructions.

● Information

► Action to be taken

Item of a list or catalogue

3) Symbols and signs

Identification of a continue voltage or current

Identification of an alternative voltage or current

Protective ground

Functional ground

Risk of injury or accident. Identify a warning concerning a potentially dangerous risk.

Documentation must be consulted by the user with each time the symbol is notified. If the

instructions are not respected, that presents a risk of death, physical injuries or property

damages.

Electric hazard. Identify a warning statement relative to a mortal electric danger. If the

instructions are not strictly respected, that implies an inevitable risk of physical injuries or

death.

Risk of incorrect operation or damage for the device.

Comment or particular information.

Recyclable element

Installation and starting instruction manual SYCLOPE TRACE’O

®

General informations Page 6/40

4) Storage and transport

It is important to store and transport your SYCLOPE TRACE’O® in its original packaging in

order to minimize risk of damage.

Furthermore, the package must be stored in an environment that is protected against

humidity and exposure to chemical products.

Environmental conditions for transport and storage:

Temperature: -10 °C to 70 °C

Air humidity: Maximum of 90% with no condensation

5) Packaging

The controller is delivered without electrical power cable.

The pre-holes of the box are drilled and equipped with according electrical glands in

compliance with IP65 level protection. Cables must be adapted to the electrical glands to

respect the level of protection.

Grounded cables for connecting pH and ORP (Redox) sensors are not provided.

Content of the packaging :

®

One analyzer/controller SYCLOPE TRACE’O

Installation and starting instruction notice

Programming notice

Communication notice (Option)

6) Warranty

The warranty is provided according to the terms of our general conditions of sale and delivery as long

as the following conditions are met:

Use of the equipment according to the instructions of this notice

No modifications of the equipment which may modify its behavior and no incorrect

manipulation

Respect for the electrical safety conditions

Consumable material is no longer covered by the warranty when in use.

Installation and starting instruction manual SYCLOPE TRACE’O

®

Environment and safety procedures Page 7/40

II. environment and safety procedures

Please:

Read this manual carefully before unpacking, installing or commissioning this equipment

Take into account all the hazards and recommended precautionary measures

Failure to respect these procedures can result in serious injury to users or damage the device.

1) Use of the equipment

The SYCLOPE TRACE’O® system has been designed to measure and control physico-chemical

parameters by means of sensors and controls of suitable actuators in the context of the possible uses

described in this manual.

All other uses are considered to be non-conforming and must therefore be forbidden.

SYCLOPE Electronique S.A.S. will not be responsible in any case for any damages that result

from such uses.

Any use of sensors or interfaces not-in conformity to the features defined in this handbook

must also be proscribed.

2) User obligations

The user undertakes not to allow its employees to work with the SYCLOPE TRACE’O® equipment

described in this manual unless they:

Are aware of the fundamental instructions relating to work safety and prevention of accidents

Are trained in the use of the device and its environment

Have read and understood these instructions, warnings and manipulation rules

3) Risk prevention

The installation and connection of the SYCLOPE TRACE’O® equipment should only be

performed by personnel specialized and qualified for this task.

The installation must comply with current safety standards and instructions!

Before switching the controller on or manipulating the relay outputs, remember always to

cut off the primary power supply!

Never open the controller when it is powered on!

Maintenance operations and repairs should only be performed by trained, specialized

personnel!

Take care when choosing the location for installing the equipment according to the

environment!

®

The SYCLOPE TRACE’O

electronic box should not be installed in a hazardous

environment and should be protected against splashing with water or chemical products. It

should be installed in a dry, well-ventilated location, isolated from corrosive vapours.

Installation and starting instruction manual SYCLOPE TRACE’O

®

Environment and safety procedures Page 8/40

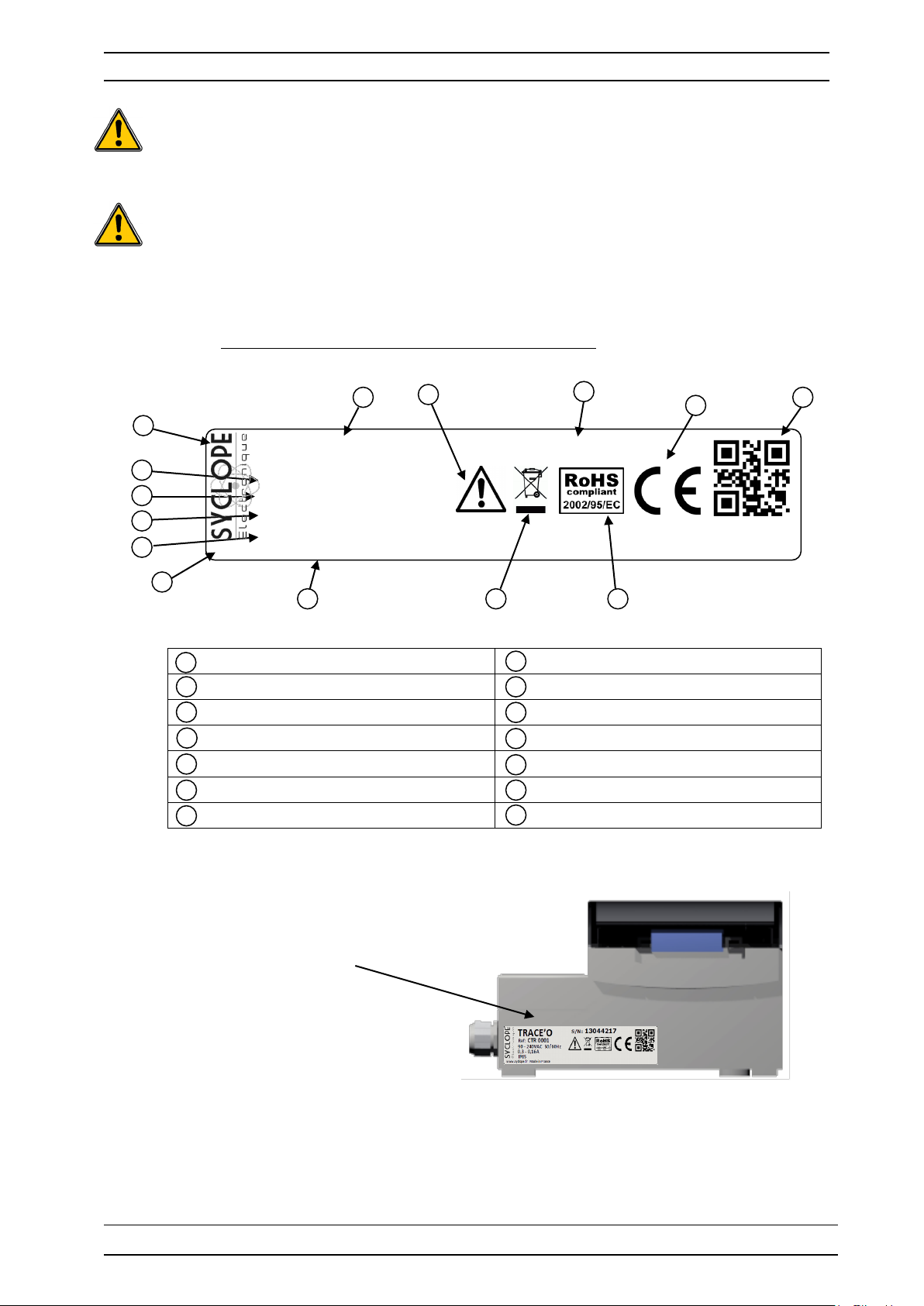

8

9

11

12

13

14

15

1

2

3 4 5

6 7 1

2 3 4 5 6

8

11

12

7

14

13

10

15

TRACE’O

Ref: CTR 0001

90 - 240VAC 50/60Hz

www.syclope.fr Made in France

0,3 - 0,16A

IP65

S/N: 13044217

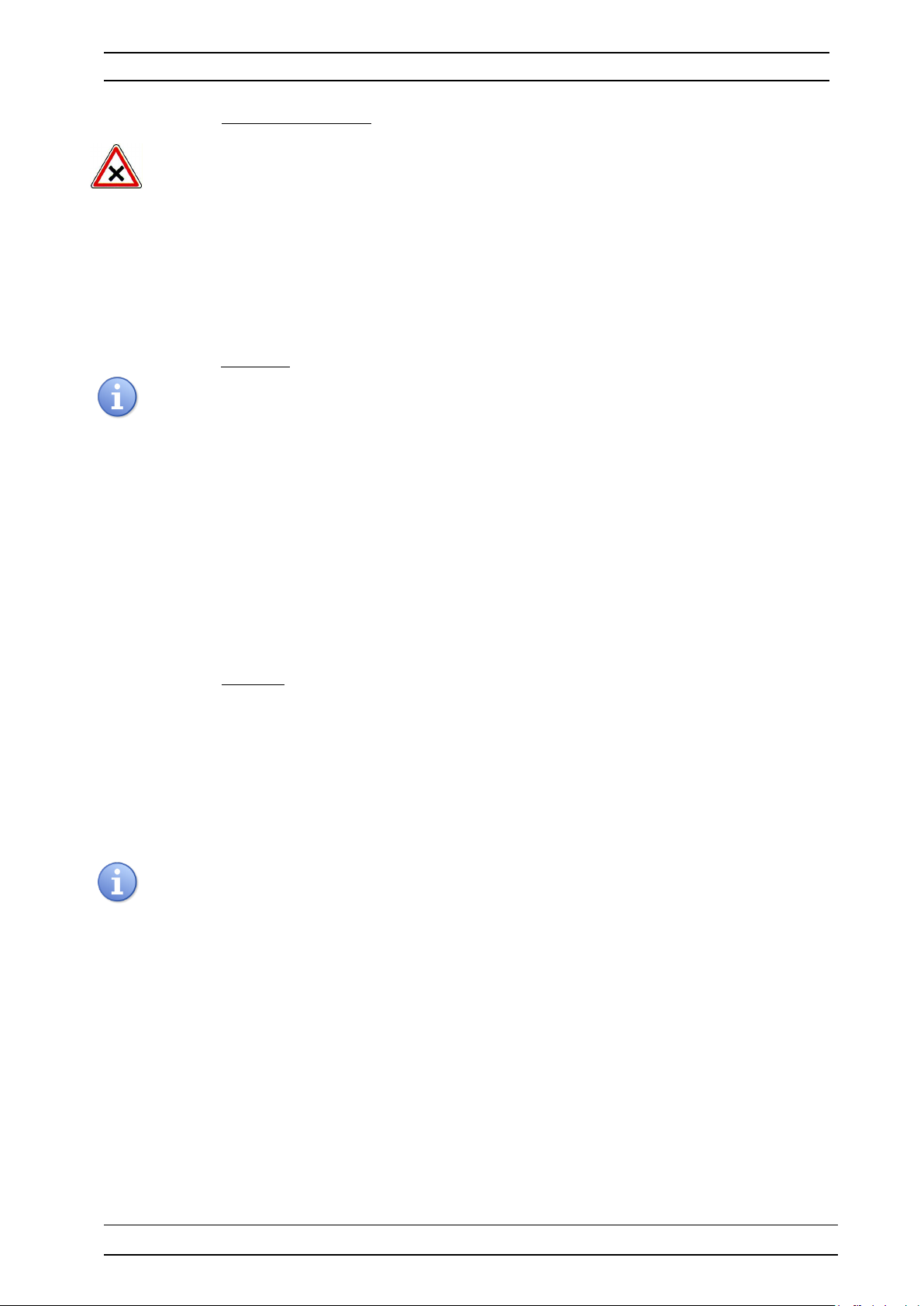

Make sure that the chemical sensors used with this device correspond well to the chemicals

used. Refer to the individual technical note of each sensor. Chemistry of water is very

complex, in case of doubt, contact immediately our engineering service or your approved

installer/reseller.

Chemical sensors are sensitive elements using consumable parts. They must be supervised,

maintained and calibrated regularly using specific calibrator systems not-provided with this

equipment. In the event of defect, a surplus possible hazard of chemical injections can be

noted. In the doubt, a service contract must be taken near your reseller/installer or failing

this near our engineering services.

Contact your approved installer/reseller or our business

service for more information.

4) Identification and localization of the identification plate

Label of the manufacturer Serial number

Model of the product Particular risks Read de manual

Reference of the product Product which can be recycled

Range of the power supply Limitation of dangerous substances

Values of the maimum current EC compliance

Class of the protection Country of the manufacturer

Identification of the manufacturer Manufacturer Square code

Identification plate

Installation and starting instruction manual SYCLOPE TRACE’O

®

Environment and safety procedures Page 9/40

5) Disposal and conformity

The recyclable packaging of the SYCLOPE TRACE’O® equipment must be disposed of according to

current regulations.

Elements such as paper, cardboard, plastic or any other recyclable elements must be taken

to a suitable sorting center.

According to European directive 2012/19/UE, this symbol means that as of 2012, July 4

th

electrical appliances cannot be thrown out together with household or industrial waste.

According to current regulations, consumers within the European Union are required, as of

this date, to return their used devices to the manufacturer, who will take care of disposing

them at no extra expense.

According to European directive 2011/65/UE, this symbol means that the SYCLOPE

®

TRACE’O

controller is designed in compliance with the restrictions on hazardous

substances

According to low-voltage directive (2014/35/UE), the electromagnetic compatibility directive

(2014/30/UE) and the RoHs2 directive (2011/65/UE) this symbol means that the device has

been designed in compliance with the previously cited directives

,

Installation and starting instruction manual SYCLOPE TRACE’O

®

Technical characteristics Page 10/40

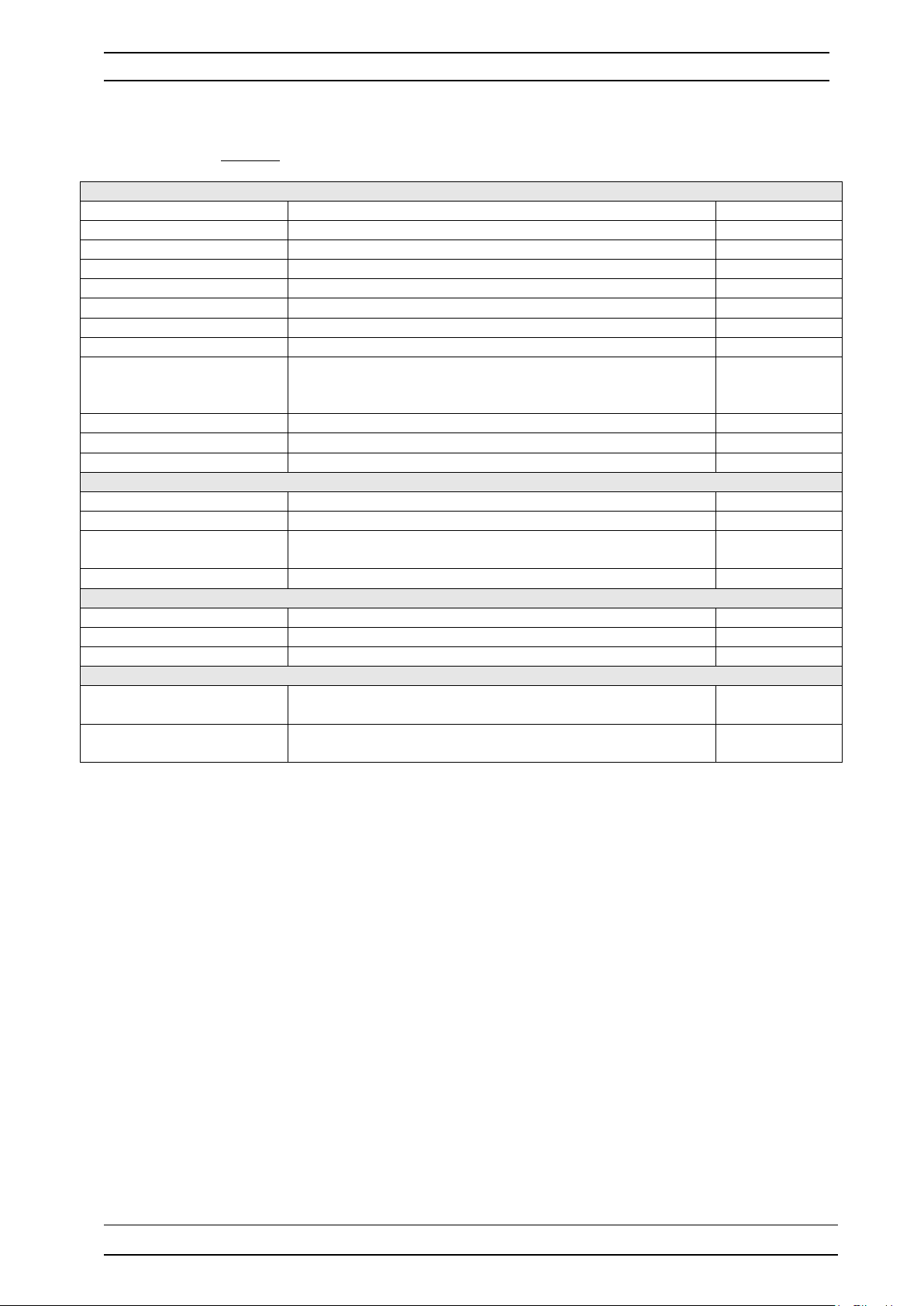

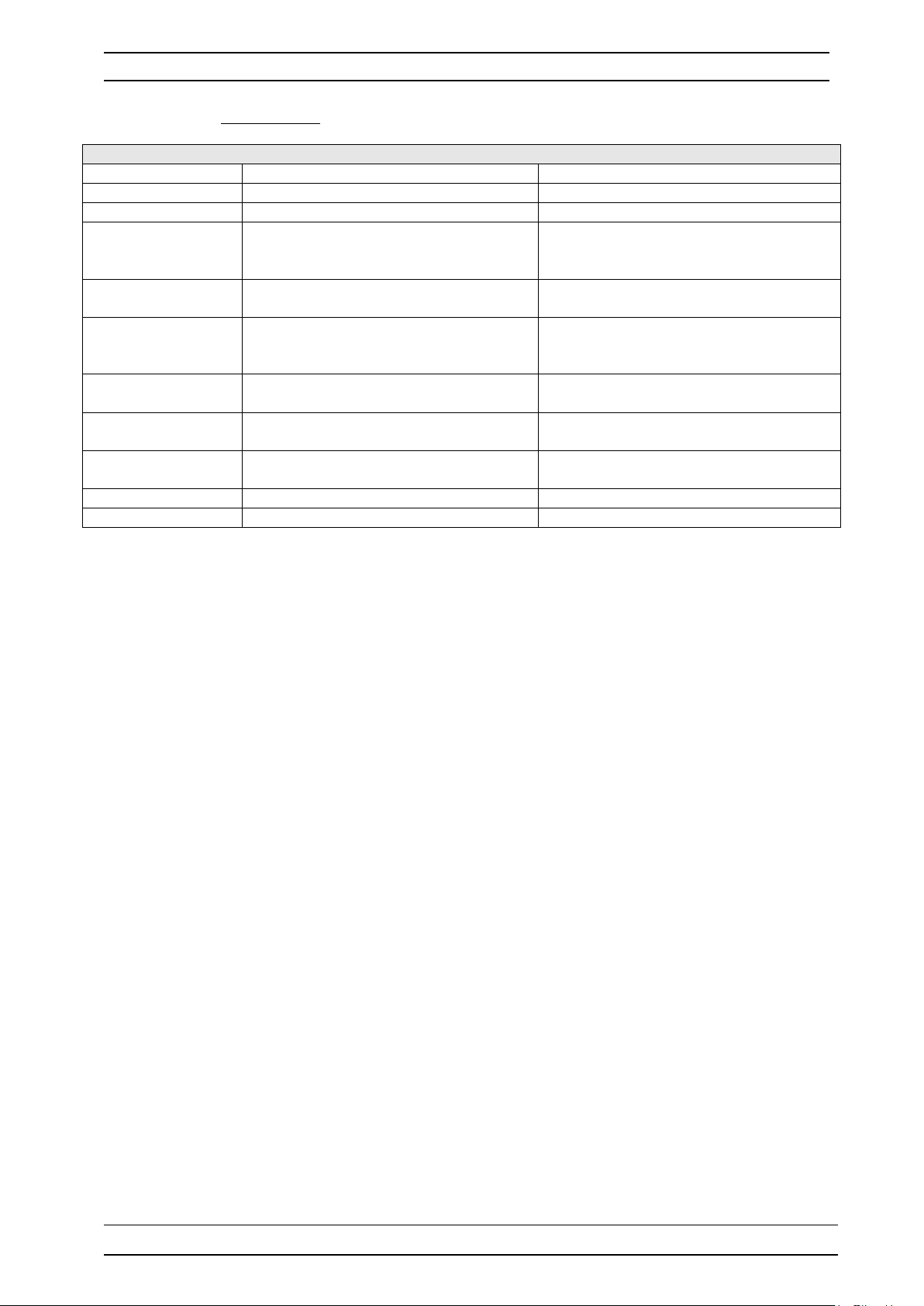

General characteristics

Type

Specification (s)

Marker(s)

Consumption

0,3 to 0,15A Maxi. (Without external load)

-

Power supply required

Between 90VAC and 240VAC +/-10%

-

Electric protection

Fuse 315 mA Time-lag 5x20 glass

F1

Operating Temp. (°C)

-5 °C to 45 °C

-

Storage temperature (°C)

-10 °C to 70 °C

-

Humidity

Max. 90% without condensation

-

Case material

ABS or Polycarbonate (US et Canada)

-

Length : 185 mm (7,3 inches)

Height : 119 mm (4,7 inches)

-

Weight of the case

1,2 kg

-

Protection rating

IP 65 - Display

Blue back-light 128x64 LCD screen

-

Inputs

Measurement inputs

2x 4…20mA inputs on special configuration modules

Auxiliary input

1x 4…20mA auxiliary input for additional function (Option)

1x control input for external Start/Stop

1x control input for level tank or flow-level input

CAD

Flsw

Metering input

1x flow meter pulse input or chemical product level tank

Flow

Outputs

Relay outputs

4x Free of potential relays Max. 5A 250VAC

KA;KB;KC;KD

Analog outputs

2x Analog outputs 0/4…20 mA Max 500 Ω

IA ; IB

Printer output

1x RS232 for serial printer

SV3

Communications

1x Communication port RS485 type for compatible software

protocol type “MODBUS RTU”

RS485

1x RJ-45 connector for phone line socket modem or GSM,

WIFI or Ethernet internal modem.

Modem line

III. Technical specifications and functions

1) Features

Case dimensions

Control inputs

RS485 Bus

Modem (Optional)

Width : 185 mm (7,3 inches)

Installation and starting instruction manual SYCLOPE TRACE’O

®

Technical characteristics Page 11/40

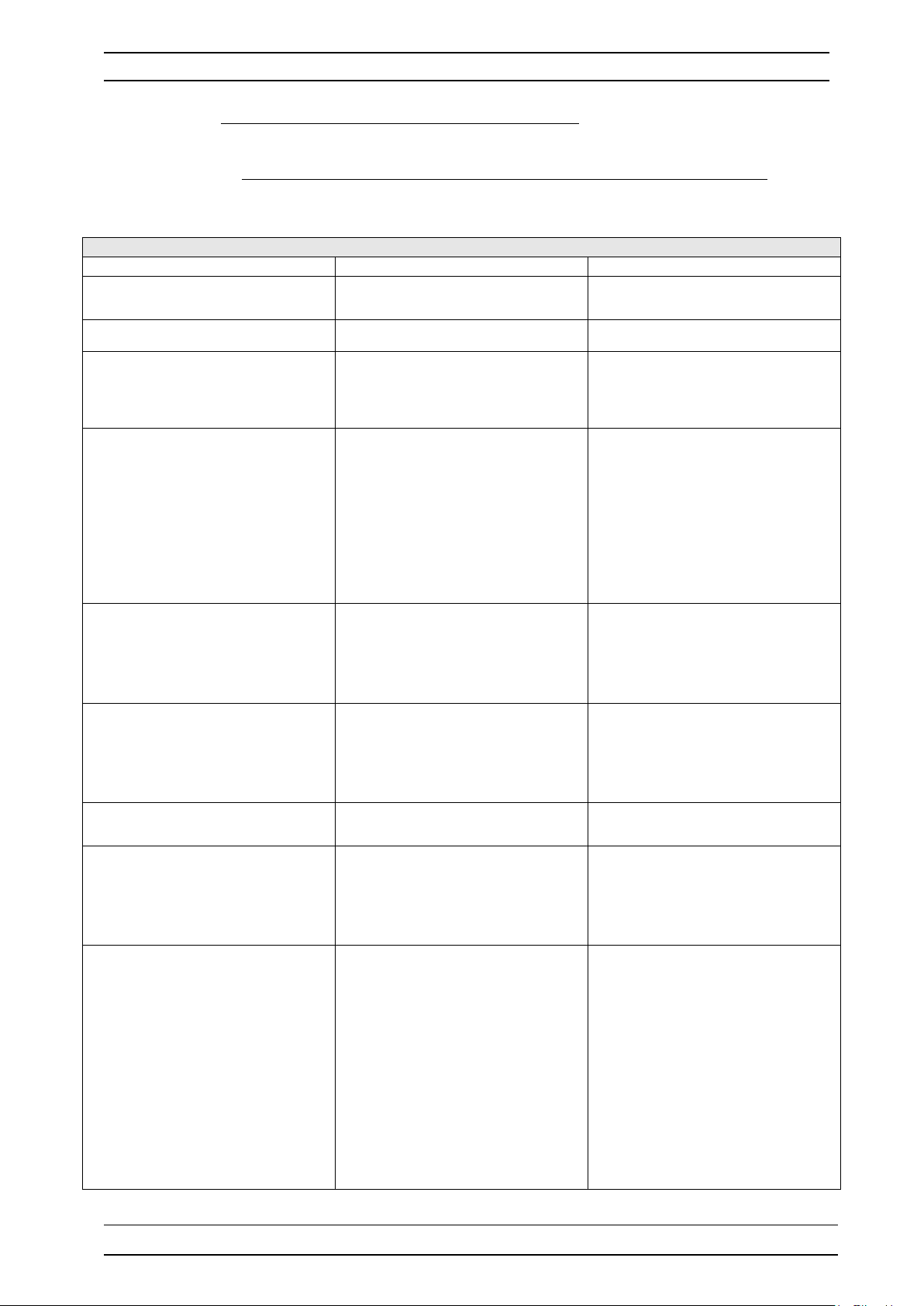

Main functions

Function

Specification (s)

Comment(s)

Controls

Controls of the 2 selected parameters

According the version

Trace detection

Total chlorine / Ozone

Specific processes

PWM command

On/Off command with hysteresis

Expressed in real measurement values

Control of top and bottom thresholds

Closed-loop control of injections with an

or with flow-switch control from cell.

Control of each injection channel to one

or two external contact(s). (Flow et Flsw)

Programming of polarisation

depolarisation controls timers

According to the type of measurement

entries.

External communication port with

“MODBUS RTU” supported.

Maintenance

Assistance to maintenance

Checking of general good working

Supervision

Remote supervision via modem

Event tracking

2) Main functions

Actuator type

4x Free of potential relays outputs

0/4…20 mA outputs

Alarms Low, high and technical alarms

Closed-loop control

Remote control

Flow rate control

Level tanks Low level detection for chemical tanks

Timers

Communication RS485 local port half-duplex

Impulse command

external contact (filtering, for example)

Installation and starting instruction manual SYCLOPE TRACE’O

®

Technical characteristics Page 12/40

Measurements and controls

Parameter

Range of measurement

Accuracy

0 to 1mg/l

0 to 0,5mg/l

0 to 5000mg/l

3) Measurement parameters, scales and control ranges

a) Basic versions : Direct entries (2x 4…20mA) or isolated entries (2x 4…20mA)

The main and auxiliary entries are programmable as bellow:

T°C /°K / °F

pH 2 to 11 pH ± 0,5 %

Free chlorine

Active chlorine

Total chlorine (Trace function)

Chlorine dioxide

Chlorites

Bromine

-5 to 45°C

0 to 100°C

0 to 2mg/l

0 to 5mg/l

0 to 10mg/l

0 to 1mg/l

0 to 2mg/l

0 to 5mg/l

0 to 10mg/l

0 to 20mg/l

0 to 50mg/l

0 to 100mg/l

0 to 200mg/l

0 to 250mg/l

0 to 1mg/l

0 to 2mg/l

0 to 5mg/l

0 to 10mg/l

0 to 20mg/l

0 to 0,5mg/l

0 to 1mg/l

0 to 2mg/l

0 to 5mg/l

0 to 10mg/l

0 to 1mg/l

0 to 2mg/l

0 to 1mg/l

0 to 2mg/l

0 to 5mg/l

0 to 10mg/l

0 to 20mg/l

± 0,5 %

± 0,5 %

± 0,5 %

± 0,5 %

± 0,5 %

± 0,5 %

± 0,5 %

Oxygen

0 to 1mg/l

0 to 2mg/l

0 to 5mg/l

0 to 10mg/l

0 to 50mg/l

0 to 100mg/l

0 to 200mg/l

0 to 250mg/l

0 to 500mg/l

0 to 1000mg/l

0 to 2000mg/l

Installation and starting instruction manual SYCLOPE TRACE’O

± 0,5 %

®

Loading...

Loading...