SYCLOPE electronic HYDRO’Com Series, HYDRO’Com HYD 7000, HYDRO’Com HYD 7020, HYDRO’Com HYD 7010 Installation And Commissioning Instructions

Installation and commissioning instructions

References : HYDCOM, HYD7000, HYD7010 and HYD7020 Rev : 1.2

HYDRO’Com® Communication gateway for private swimming pools

General informations Page 2/36

Installation and commissioning instructions manual

General informations :

SYCLOPE Electronique 2016® Manual of February 7th, 2018 Rev:1.2

Installation and commissioning instructions manual

(Ref : DOC0257)

Editor :

SYCLOPE Electronique S.A.S.

Z.I. Aéropole pyrénées

Rue du Bruscos

64 230 SAUVAGNON - France –

Tel : +33 559 337 036

Fax : +33 559 337 037

Email : syclope@syclope.fr

Internet : http://www.syclope.fr

© 2016-2018 by SYCLOPE Electronique S.A.S.

Subject to modifications

Summary Page 3/36

Installation and commissioning instructions manual

Summary

I. General informations ......................................................................................................... 4

1) Applicability ...................................................................................................................... 4

2) Use of the document ......................................................................................................... 5

3) Symbols and signs ............................................................................................................. 5

4) Stockage et transport ........................................................................................................ 6

5) Packaging ......................................................................................................................... 6

6) Warranty .......................................................................................................................... 6

II. Environment and safety procedures .................................................................................... 7

1) Use of the devices ............................................................................................................. 7

2) User obligations ................................................................................................................ 7

3) Risks prevention ................................................................................................................ 7

4) Identification and localization of the identification plate ....................................................... 8

5) Waste disposal and compliance .......................................................................................... 9

III. Technical features and functions .......................................................................................10

1) Technical features ............................................................................................................10

2) Temperature sensor ranges ..............................................................................................10

IV. Installation and wirings .....................................................................................................11

1) Installation conditions .......................................................................................................11

2) Installation of the communication gateway on wall-mounted ..............................................11

3) Branchements électriques .................................................................................................12

4) Localisations of the components and general connections ...................................................12

5) Connection of the primary power supply ............................................................................14

6) Connections of the “free of potential” power relays ............................................................14

7) Connection of the analog 4…20mA entry ...........................................................................14

8) Connection of the “free of potential” entries .......................................................................15

9) Connection of the RS323C ports used to link the HYDRO controllers ....................................15

10) Connection of the RS485 communication bus .....................................................................15

11) Connection of the GSM, Wifi and Ethernet socket MODEM for internet access ......................16

12) References of the HYDRO’Com® communication gateway with included modem ...................17

V. Presentation of myHYDRO interface ...................................................................................18

1) Login ...............................................................................................................................18

2) Main page ........................................................................................................................18

3) Graphic page ...................................................................................................................21

4) Alarm page ......................................................................................................................22

5) Email page .......................................................................................................................22

6) Programming page ...........................................................................................................23

7) Programming control inputs ..............................................................................................24

8) Programming analogue input ............................................................................................25

9) Programming of the time schedule ....................................................................................25

10) Programming the slaves ...................................................................................................26

11) Programming the modem .................................................................................................27

VI. Using the USB stick...........................................................................................................29

1) Configuring the device ......................................................................................................29

2) Updating the internal embedded software ..........................................................................29

3) Blinking of the USB LED ....................................................................................................29

VII. Maintenance.....................................................................................................................30

General informations Page 4/36

Installation and commissioning instructions manual

I. General informations

1) Applicability

The HYDRO’Com® communication gateway you have just purchased is an electronic device

allowing connections to Internet for the various SYCLOPE apparatuses used for the water

management of private swimming pools. It has been carefully developed and manufactured to

ensure your greatest pleasure and peace of mind.

The internal MODEM allows connection to Internet. The HYDRO’Com® communication gateway is

then connected to the web site “myHydro.com” by internet in real-time according its internal

programmed configuration.

Two RS232 ports and one RS485 port allow to establish a local communication with the different

SYCLOPE devices in order to make the data acquisitions and to ensure the programming of the

parameters. The HYDRO’Com® communication gateway can manage up to 5 slaves on the RS485

bus. Slaves connected to the HYDRO’Com® communication gateway by their RS485 ports and the

RS485 link are also connected to the website http://hydro.mysyclope.com/, thus ensuring a total

management and the monitoring of all parameters.

The HYDRO’Com® communication gateways are equipped with four programmable entries free of

potential used to manage specific actuators in swimming pool water’s treatments through four

power relays with free of potential contacts. Four programmable real-time timers are also available

and one 4…20mA entry for temperature measurement.

The simplicity of operation of the HYDRO’Com® communication gateway, the user friendliness

and the remarkable technical aspects of these devices, will ensure you benefit from their many

options, guaranteeing you full control and supervision of the quality of the water in your swimming

pool.

The following instructions contain all the information required for the installation, the use and the

maintenance of your new HYDRO’Com® communication gateway.

➢ Installation

➢ Technical specifications

➢ Commissioning instructions

➢ Safety tips

If you would like to receive further information or if you encounter any difficulties not described in

this manual, please contact your usual retailer or else directly contact the sales department of

SYCLOPE Electronique S.A.S., either at the agency or at the office of your region, or the

technical/quality departments of our establishments. We will do everything in our power to help

you and ensure you benefit from our advice and know-how in the field of measurement and

treatment of swimming-pool water.

Contact : service-technique@syclope.fr

General informations Page 5/36

Installation and commissioning instructions manual

2) Use of the document

Please read this entire document before starting to install, adjust or commission your controller

device, in order to ensure the safety of swimmers, users and equipment.

The information provided in this document must be strictly observed. SYCLOPE Electronique S.A.S.

declines all responsibility in cases where failure to comply with the instructions of this documents is

observed.

The following symbols and pictograms will be used to facilitate reading and understanding of these

instructions.

● Information

► Action to be taken

➢ Item of a list or catalogue

3) Symbols and signs

Identification of a continue voltage or current

Identification of an alternative voltage or current

Protective ground

Functional ground

Risk of injury or accident. Identify a warning concerning a potentially dangerous risk.

Documentation must be consulted by the user with each time the symbol is notified. If the

instructions are not respected, that presents a risk of death, physical injuries or property

damages.

Electric hazard. Identify a warning statement relative to a mortal electric danger. If the

instructions are not strictly respected, that implies an inevitable risk of physical injuries or

death.

Risk of incorrect operation or damage for the device.

Comment or particular information.

Recyclable element.

General informations Page 6/36

Installation and commissioning instructions manual

4) Stockage et transport

It is important to store and transport your HYDRO’Com® communication gateway in its

original packaging in order to minimize risk of damage.

Furthermore, the package must be stored in an environment that is protected against

humidity and exposure to chemical products.

Environmental conditions for transport and storage:

Temperature: -10 °C to 60 °C

Air humidity: Maximum of 90% with no condensation

5) Packaging

The apparatus is delivered without any cable other than that of primary power supply.

The communication gateway is already equipped with mounted cable glands. Additional

cables used must be adapted to the latter to comply with the degree of protection IP65. A

mounting kit is also provided.

Is included in the packaging:

✓ HYDRO’Com

®

communication gateway device,

✓ A complete fixing kit,

✓ The commissioning instruction.

6) Warranty

The warranty is provided according to the terms of our general conditions of sale and delivery as long

as the following conditions are met:

➢ Use of the equipment according to the instructions of this notice

➢ No modifications of the equipment which may modify its behavior and no incorrect

manipulation

➢ Respect for the electrical safety conditions

Consumable material is no longer covered by the warranty when in use

Environment and safety procedures Page 7/36

Installation and commissioning instructions manual

II. Environment and safety procedures

Please:

➢ Read this manual carefully before unpacking, installing or commissioning this equipment

➢ Take into account all the hazards and recommended precautionary measures

Failure to respect these procedures can result in serious injury to users or damage the device.

1) Use of the devices

HYDRO’Com® communication devices have been designed to serve as a gateway to different

SYCLOPE Electronique products or other devices compatible in the context of the possibilities of

use described in this manual.

Any different use is considered improper and must be banned. SYCLOPE Electronique

S.A.S. will not assume any liability and the damages resulting therefrom.

Any use of sensors or non-compliant interfaces to the specifications defined in the operating

instructions must also be banned.

2) User obligations

The user undertakes not to allow its employees to work with the HYDRO’Com® communication device

described in this manual unless they:

➢ Are aware of the fundamental instructions relating to work safety and prevention of accidents

➢ Are trained in the use of the device and its environment

➢ Have read and understood these instructions, warnings and manipulation rules

3) Risks prevention

The installation and connection of the HYDRO’Com® communication gateway should only

be performed by personnel specialized and qualified for this task.

The installation must comply with current safety standards and instructions!

Before turning the device on or manipulating the relay outputs, please, always disconnect

the primary power supply!

Never open the appliance when powered on!

Maintenance operations and repairs must be performed by specialized and authorised

personnel!

Take care when choosing the location for installing the HYDRO’Com® communication

gateway according to the environment!

The HYDRO’Com® communication gateway should not be installed in a hazardous

environment and should be protected against splashing with water or chemical products. It

should be installed in a dry, well-ventilated location, isolated from corrosive vapors.

With the exception of the relay outputs, all connections inputs and outputs must be

connected to very low safety voltages. These tensions are generally provided by the device

and does not exceed 24VDC.

Environment and safety procedures Page 8/36

Installation and commissioning instructions manual

Make sure that the chemical sensors used with this device correspond well to the chemicals

used. Refer to the individual technical note of each sensor. Chemistry of water is very

complex, in case of doubt, contact immediately our engineering service or your approved

installer/reseller.

Chemical sensors are sensitive elements using consumable parts. They must be supervised,

maintained and calibrated regularly using specific calibrator systems not-provided with this

equipment. In the event of defect, a surplus possible hazard of chemical injections can be

noted. In the doubt, a service contract must be taken near your reseller/installer or failing

this near our engineering services. Contact your approved installer/reseller or our business

service for more information.

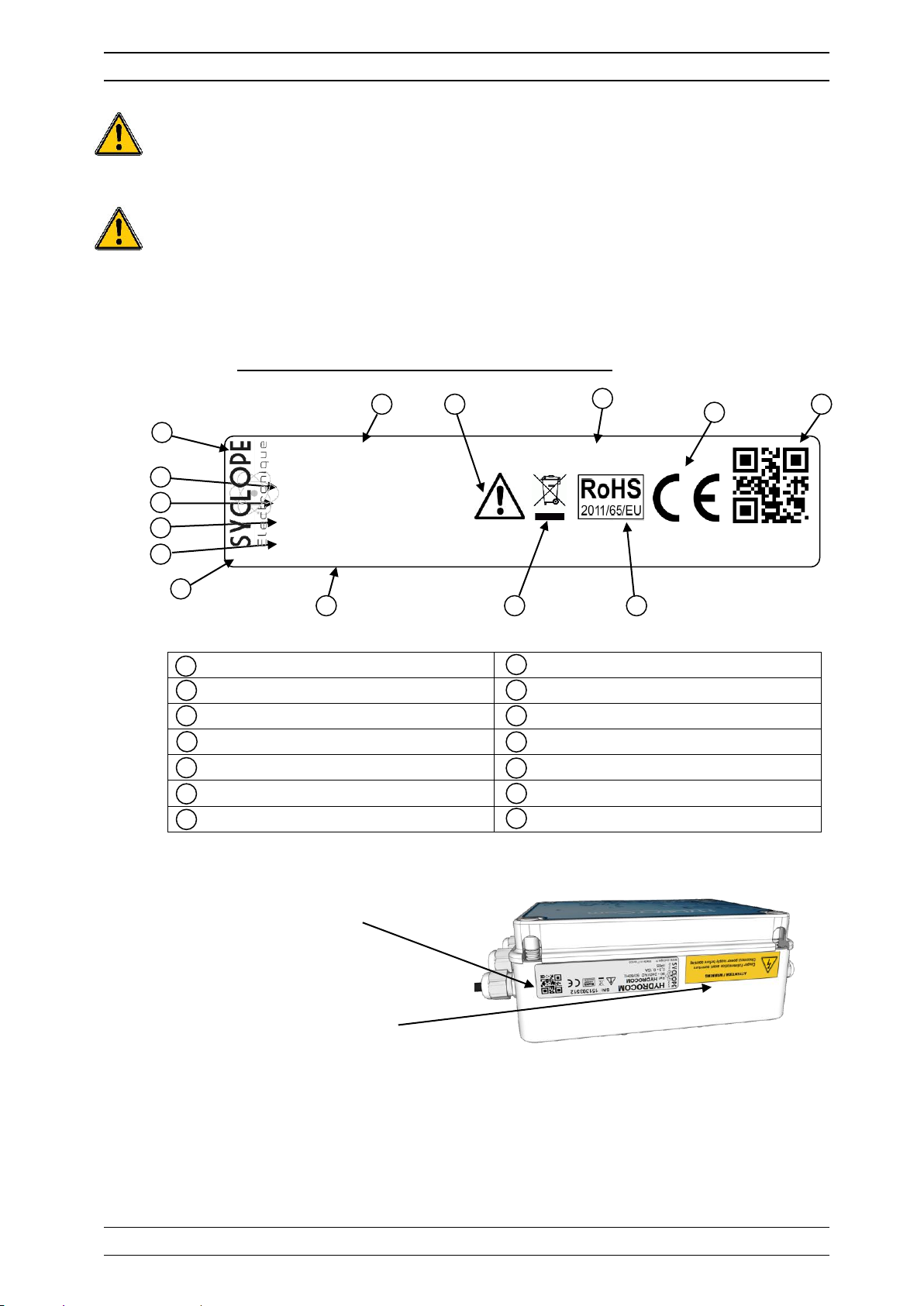

4) Identification and localization of the identification plate

Label of the manufacturer

Serial number

Model of the product

Product which can be recycled

Reference of the product

Limitation of dangerous substances

Power supply range

CE compliance

Maximum current input

Country of the manufacturer

Protection class

Manufacturer square code

Manufacturer identification

Particular risks. Read the manual

Identification plate

Safety instruction sticker

8

9

10

11

12

13

14

1 2 3 4 5

6

7

1

2 3 4 5 6

8

10

11

7

13

14

9

12

HYDRO’Com

Ref: HYD 70x0

90 - 240VAC 50/60Hz

www.syclope.fr Made in France

0,25 - 0,1A

IP65

S/N: 13044217

Environment and safety procedures Page 9/36

Installation and commissioning instructions manual

5) Waste disposal and compliance

The recyclable packaging of the HYDRO’Com® devices must be disposed of according to current

regulations.

Elements such as paper, cardboard, plastic or any other recyclable elements must be taken

to a suitable sorting center.

WEEE : According to European directive 2002/96/EC, this symbol means that as of 12

August 2005 electrical appliances cannot be thrown out together with household or industrial

waste. According to current regulations, consumers within the European Union are required,

as of this date, to return their used devices to the manufacturer, who will take care of

disposing them at no extra expense.

RoHs2 : According to the European directive 2011/65/CE, this symbol means that the

HYDRO’Com® communication gateway is manufactured in compliance with the restriction

of hazardous substances.

CE : According to low-voltage directive (2014/35/UE) and the electromagnetic compatibility

directive (2014/30/UE), this symbol means that the HYDRO’Com® communication gateway

has been manufactured in compliance with the previously cited directives.

Technical features and functions Page 10/36

Installation and commissioning instructions manual

III. Technical features and functions

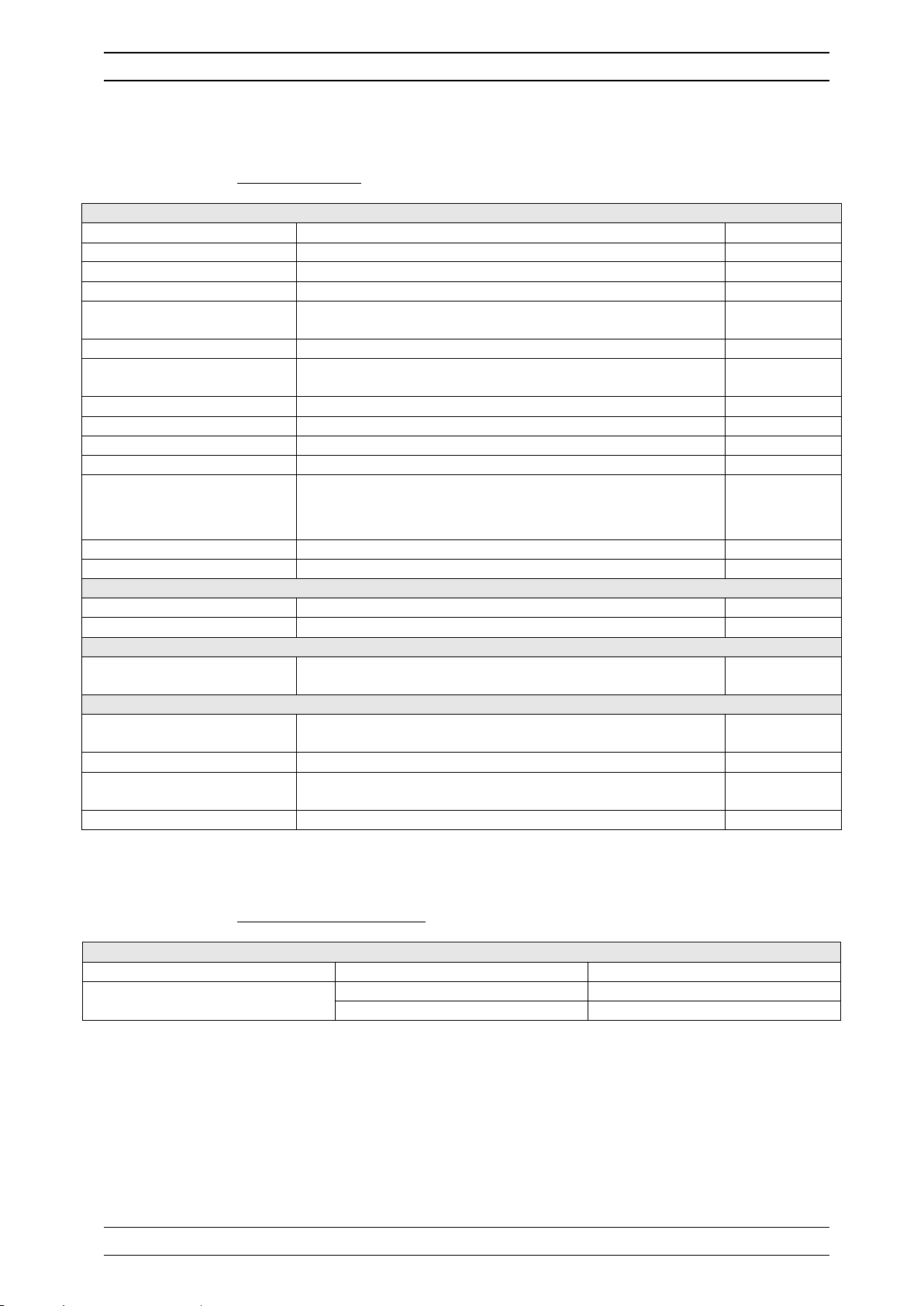

1) Technical features

General characteristics

Type

Specification(s)

Mark(s)

Consumption

0,25A Maxi. (90VAC) to 0,1A Maxi. (240VAC)

-

Power supply requirements

Between 90 to 240VAC +/-10%

-

Voltage category

Class II

Temporary overvoltage

Accept temporary overvoltage from the power supply

system. Electric protection

Fuse 315 mA Time-lag 5x20 Miniature type TR5

F1

Maximum temperatures of

operation

-5 °C to 45°C

-

Storage temperature

-10 °C to 60°C

-

Humidity

Max. 90% without condensation

-

Altitude

Use lower than 2000m

-

Material

ABS

-

Dimensions

Length : 190 mm (7.5 inches)

Width : 140 mm (5.5 inches)

Height : 70 mm (2.75 inches)

-

Weight

0,5 kg - Protection rating

IP 65

-

Entries

Measurement input

1x 4…20 mA current input generating 24VDC

T°C

Control imputs

4x Isolated control input free of potential

E1 to E4

Outputs

Relay outputs

4x Relays free of potential

Max. 2A/250VAC

S1 to S4

Communications

BRS485 Bus

1x Communication port RS485 type for compatible software

protocol type “MODBUS RTU” or “MODBUS ASCII”.

RS485

Modem (Option)

1x Slot for GSM or WiFi or Ethernet socket MODEM

-

RS232 Ports

2x Communication port RS232C for connecting SYCLOPE

HYDRO® controllers.

RS232-1

RS232-2

USB

1x USB port for memory stick

USB

2) Temperature sensor ranges

Measurement and control

Parameter

Range(s)

Accuracy

T°C

-5 to 45°C

± 0,5 %

0 to 100°C

± 0,5 %

Installation and wirings Page 11/36

Installation and commissioning instructions manual

IV. Installation and wirings

1) Installation conditions

To guarantee the users safety and to ensure correct operation of the HYDRO’Com®

communication gateway, please observe strictly the following instructions:

➢ Install the controller in a dry location.

➢ The communication gateway must be protected against rain, frost and direct sunlight.

➢ The room temperature must range between -5°C and 45°C, with no condensation.

➢ Choose an installation location free of vibration, on a suitable support and with no

deformation.

➢

If these instructions are not observed:

➢ The communication gateway is at risk of being damaged

➢ The measurements and communications can be disrupted

➢ The warranty is not applicable!

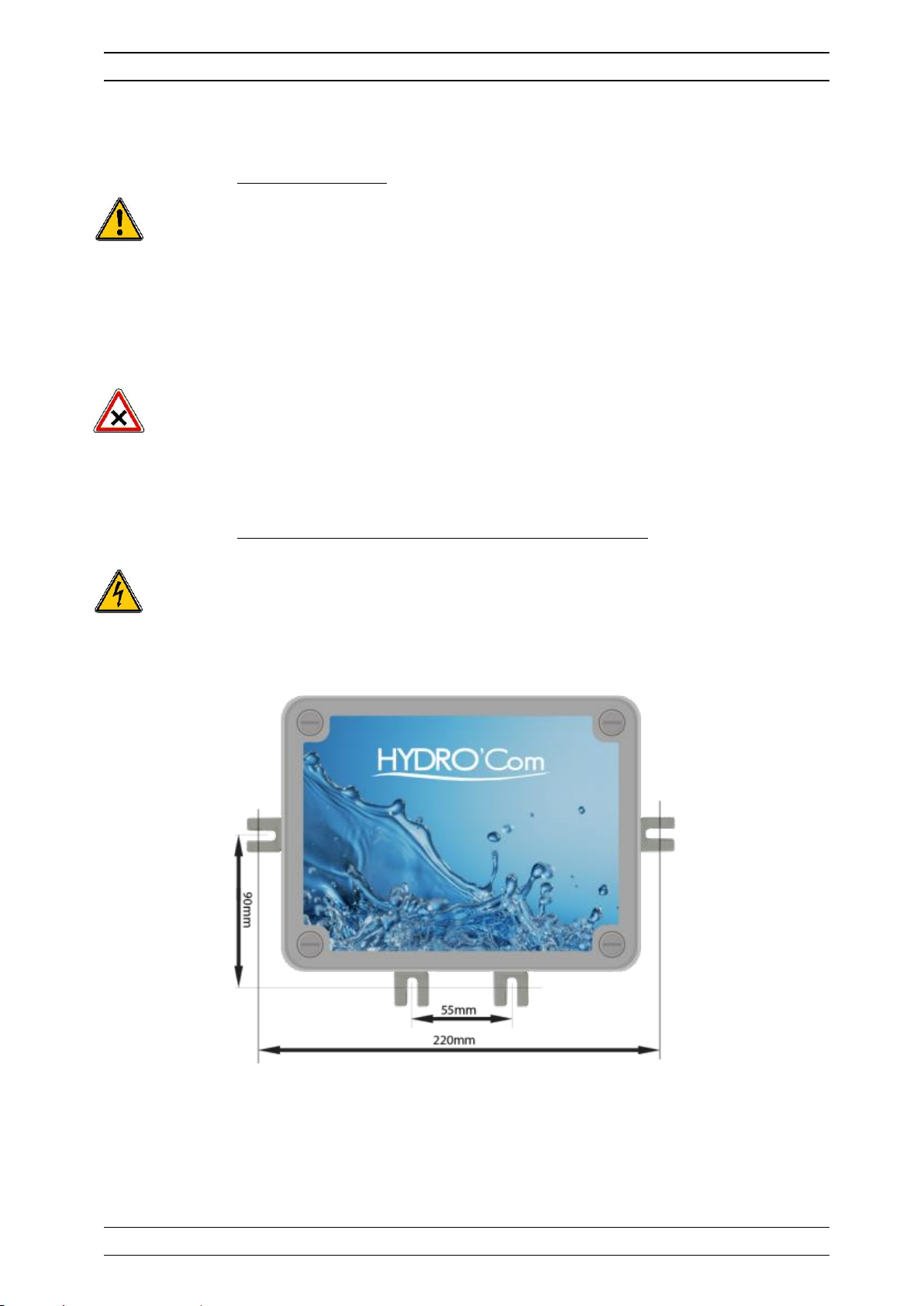

2) Installation of the communication gateway on wall-mounted

Before performing the installation and electrical connections, remember to turn off the

primary power supply!

The IP65 protection’s indice is only guaranteed when the closing cover is closed and when

the cable glands match to the diameters of the cables and are correctly sealed.

► Drilling four holes ( 5-mm) according to the following drilling-plan,

► Insert the 5-mm plugs using a hammer,

► Insert the upper screws (top screw) first without completely tightening it,

► Insert the lower screws and tighten them,

► Tighten the upper screw,

► Use a spirit level to check for correct and accurate fixing to the wall.

Loading...

Loading...