Page 1

INSTALLATION AND OPERATION INSTRUCTIONS FOR

REVERSE OSMOSIS SYSTEMS

Basic™

Premium™

MetalsMaster™

BioMaster™

Other / Custom

Page 2

Table of Contents

A. Component Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. Component Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

C. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

D. Startup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

E. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

F. Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

G. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

A. Component Placement

A.1 Faucet Placement

Proper faucet placement should ensure a no-splash waterfall pattern into the

sink. The faucet handle should normally be positioned to either the left or the

right of your existing faucet as one faces the sink.

A.2 Pressurized Storage Tank

In a typical installation, the closer to the faucet that the storage tank can be,

the better. If you locate the storage tank under the sink it should be placed so

that it can be easily removed from under the sink. Avoid placing the storage

tank in an out-of-the-way location. There are two reasons for this: First, the

difficulty of installation increases significantly; Second,when the storage tank is

located further away from the faucet, the flow rate decreases.

A.3 RO System Assembly Placement

The reverse osmosis system assembly bracket should be hung on a wall or sink

cabinet side wall with the two screws provided. Be sure to either:

3.1 Leave enough length of both blue and orange tubing so the system

assembly can be lifted off the mounting screws and removed from under

the sink for periodic cartridge replacement , or...

3.2 Leave enough bottom clearance to remove and replace the cartridges

from their respective housings after the housings have been unscrewed for

servicing.

A.4 Pressurized Storage Tank Placement

The storage tank can be placed anywhere within the vicinity of the reverse

osmosis system. It can be placed vertically or horizontally. It is suggested for

proper flow rate not to exceed placement more than 5 feet away from the

reverse osmosis system. If a distance of more than 5 feet from the reverse

osmosis system is required, larger tubing may need to be installed between the

storage tank and the reverse osmosis system.

B. Component Information

B.1 Filter Cartridges

Sediment Cartridges

Sediment cartridges are designed to remove large amounts of suspended

particals from water to help reduce the probability of clogging the reverse

osmosis membr

ane.

2

Page 3

Carbon Cartridges (Basic and Premium Series)

Carbon cartridges remove taste and odor, chlorine, pesticides, and other

contaminants from the water. These are a necessity on chlorinated water as a

pretreatment for systems with thin film membranes (TFM), because the chlorine

will greatly reduce the life of this type of membrane. They also help prevent

fouling on the quartz sleeves in systems with ultraviolet sterilizers.

Special Metals Reduction Cartridge (MetalsMaster and BioMaster Series only)

B.2 Reverse Osmosis Membranes

The reverse osmosis membrane is made from a semi-permeable material. Its

function is to separate water molecules from dissolved impurities in the water.

This is accomplished by the application of pressure greater than the osmotic

pressure in water containing dissolved solids.

There are two main types of reverse osmosis membranes. The first type (used in

Basic Series) is made of cellulose acetate (CA).These have a higher resistance

to chlorine, but should not be used on water supplies that have bacteriological

contamination. The second type (used in Premium, MetalsMaster, and

BioMaster Series) are made of a thin film composite material (TFM).These have

a poor resistance to chlorine, but will not be destroyed by bacteriological

contamination. These usually also have higher flow rates available.

B.3 Ultraviolet Sterilizers

The ultraviolet light used for sterilizing is at a specific wavelength (254 nm) that

destroys or inactivates the DNA of micro-organisms to render them harmless.

Important Safeguards:

• Never look directly at an unshielded UV lamp.

It can cause permanent

eye damage. Always wear protective eye wear such as eye glasses or

safety glasses.

• Great caution should be exercised when handling a lamp to avoid burns.

UV lamps run extremely hot.

• To prevent electrical shock, never immerse or wash the unit in water while

the bulb is inside or when the unit is plugged in.

• ALWAYS DISCONNECT THE UNIT FROM THE ELECTRICAL POWER SOURCE

before replacing the UV bulb or servicing any part of the unit.

• Never operate the unit if it has malfunctioned, has a damaged cord or

plug, or has been dropped or damaged in any manner.

• Use only those attachments recommended by the manufacturer.

• The Polisher Biolyte™ sterilizer should not be used for any purposes other

than its intended function. This unit is designed to treat possible bacteria

contamination at the rated specifications and operating limits listed

below:

Water Pressure . . . . . . . . . . . . . . . . . . . . . . . 100 psi

Capacity @ 10 mic. Clear Water . . . . . . . . 0.7 gpm (3 liters)

Lamp Life. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,000 hours (12 months)

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30,000 microwatt seconds/cm²

WARNING: This filter must be protected from freezing.Failure to do so may result

in cracking of the filter and water leakage. UV is for bacteria and virus control

only

. UV does not kill giardia, cryptosporidium, or other cysts. Make certain that

the installation complies with all state and local laws and regulations.

3

Page 4

C. Installation

C.1 Drilling the Faucet Hole (Only if a sink hole is not already provided):

Once the location of the faucet has been determined, always check below

the point you are about to drill to ensure it is unobstructed where the hole will

exit, and that it isn't over a reinforcing rib.

1.1 Center punch the desired location to provide a starting point for your drill.

1.2 Drill a 1/8” pilot hole.

1.3 Enlarge the pilot hole with a 1/2” drill (or 1¼”high speed steel hole saw for

an air gap faucet).

1.4 Remove all burrs and sharp edges.

1.5 Immediately clean up sink area.

Note: If an enamel or porcelain sink is encountered, it is very important that a

layer of porcelain be removed before following the steps outlined above. This

can be accomplished by gently grinding away, using a hobby grinder and a

silicon carbide wheel, enough area of porcelain down to the metal base to

accommodate the hole size needed. The drill or hole saw must not contact

surrounding porcelain or chipping can occur.

C.2 Standard Faucet Installation

2.1 Slide the faceplate and black rubber gasket on to the faucet stud.

2.2 Place the stud through the hole from the top of the sink or countertop.

Properly position the faucet, handle, and faceplate with gasket.

2.3 From under the counter, slide on the black locating washer, used where a

1/2” hole is available or reverse when mounting on stainless steel or when

using drilled hole.

2.4 Slide on the washer and nut.

2.5 Be sure faucet spout and body are in proper position, and tighten nut,

while holding the faucet in position with a padded crescent wrench. Be

careful not to over tighten.

C.3 Air Gap Faucet Installation (optional on some equipment)

The air gap faucet includes an anti-siphon device as required by regulatory

agencies in some states. The purpose of the air gap is to prevent water in the

drain from backing up into the RO drinking

water system.It is a dry air gap and allows 1”free

fall above the clear line which satisfies all known

agencies.

3.1 Slide the face plate and rubber gasket on

to the stud.

3.2 Place the stud through the drilled hole.

Properly position the faucet, handle, and

face plate with gasket.

3.3 From under the counter, slide on the steel

slotted washer, white plastic spacer (open

end upw

ar

ds),

washer, and nut.

4

1/4” Black Tube

(reject water from

RO system)

3/8” Black Tube

(to drain)

1/4” Blue Tube

(product water

from RO system)

Page 5

Be sure faucet spout and body are in position,and align the slotted washer and

spacer to allow access to hose barbs. Tighten the hex nut while holding the

faucet in position with a padded crescent wrench.Do not over tighten.

C.4 Angle Stop Valve Installation

4.1 Turn off cold water supply.

4.2 Disconnect riser hose from cold water supply valve.

4.3 Ensure that sealing gasket is fully seated into angle stop valve female thread.

Install angle stop valve (female thread side) on cold water supply valve.

4.4 Connect riser hose to angle stop valve on male thread side.

DO

NOT open the angle stop valve or cold water supply valve at this time.

C.5 Drain Saddle Assembly Installation

The RO system comes supplied with a drain saddle and mounting hardware

which fits around a standard 1½” O.D. drain pipe.

5.1 The drain saddle should be installed above the trap, on the vertical or

horizontal tailpiece. It should never be placed close to the outlet of a

garbage disposal.

5.2 Drill a 5/16” hole in the drain pipe in the location where the drain saddle

will be positioned. Support the drain against drilling pressure. Do not drill

through both sides of the drain pipe.If possible, place the hole so the drain

saddle fitting will angle toward the faucet location.

5.3 Position the drain saddle so that the drain fitting is over the hole in the drain

pipe.

5.4 Tighten the drain saddle screws evenly and firmly so a good seal is made.

Avoid over tightening.

Note: Some state or local codes may require that the drain saddle be served

by a trap other than the one serving the garbage disposal. Before making a

connection, please check your code regulations.

C.6 Pressurized Storage Tank Valve Installation

6.1 Remove the protective plastic cap from the 1/4” NPT fitting on the top of

the storage tank.

6.2 Wrap the 1/4” NPT fitting with Teflon tape (plumbers tape).

6.3 Thread the storage tank valve onto the 1/4”NPT fitting.Avoid over tightening.

C.7 Filter Cartridge Installation

7.1 Unscrew the filter housing sumps by hand or with a spanner wrench.

7.2 Rinse out each of the housings and fill about 1/3 full with water. Add about

2 to 3 tablespoons of bleach and scrub thoroughly with a brush or sponge.

Rinse thoroughly.

7.3 Install the cartridge into the sump making sure that it slips down over the

sump standpipe.

7.4 Turn the sump into the cap and hand tighten. Do not over tighten.

5

Page 6

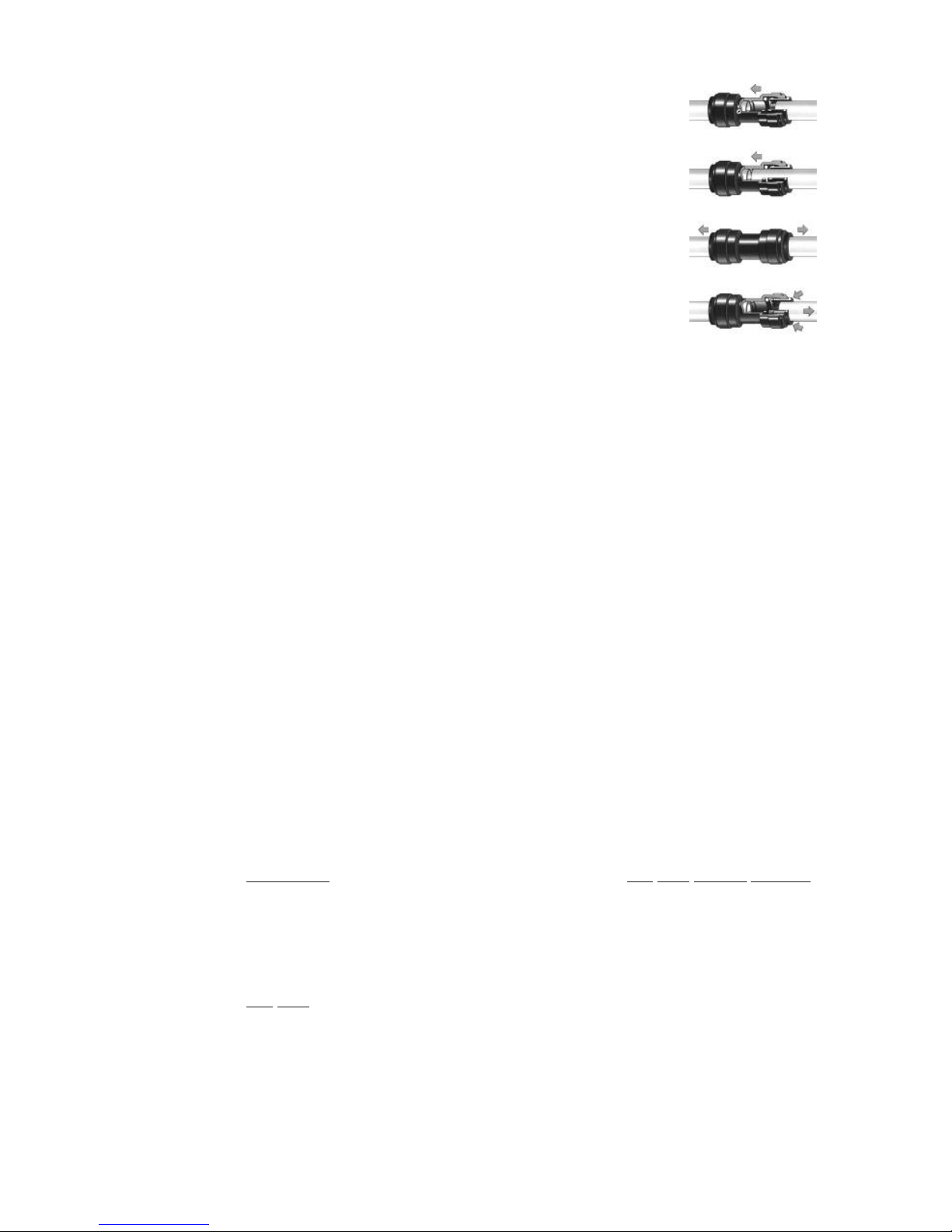

C.8 Using Quick Connect Fittings

8.1 Insert tube through collet of fitting. The fitting will be

gripped before it will seal.

8.2 Push the tube all the way into the fitting to the stop.The

collet has stainless steel teeth which grip the tube while

the o-ring provides a permanent leakproof seal.

8.3 Pull the tube to check that it is secure.It is good practice

to check the system before it is used.

8.4 To disconnect, ensure that the system is depressurized.

Push the collet against the face of the fitting. With the

collet held in this position, pull on the tube to remove it.

C.9 Reverse Osmosis Membrane Installation

9.1 Disconnect the processed water line from the RO housing end cap via the

quick connect fitting.

9.2 Twist off the end cap from the housing.

9.3 Apply a fresh coating of a FDA approved silicone lubricant to the two

o-rings on the end of the membrane.

9.4 Insert the membrane into the housing with the “two o-ring end” first.

9.5 Thread the cap back on and hand tighten firmly.

9.6 Reconnect the processed water line by inserting it into the quick connect

fitting.

C.10 Ultraviolet Lamp Installation

(Systems with the Polisher Biolyte™ Ultraviolet Sanitizer Only)

10.1 Unscrew white cap with silicon plug from stainless steel UV chamber.

10.2 Carefully insert bulb into the quartz sleeve. Be sure the wire is hanging out

of the quartz sleeve.

10.3 Push the stopper (which is attached to the wire) into the quartz sleeve.

10.4 Remove the silicon plug from the white cap.

10.5 Slide the wire through the hole in the cap.

10.6 C

AREFULLY screw the cap onto the UV chamber. DO NOT CROSS THREAD.

There is a glow bottle starter attached to the lamp. This should be left

inside of the cap.

10.7 Replace the silicon plug around the wire into the cap.

10.8 Plug the wire into the power adapter.

10.9 DO

NOT attach the power adapter to a power source at this time.

C.11 Connecting Components

Most connections are with plastic quick connect type fittings (see C.8 above).

The exception is the dr

ain saddle w

hich has a compr

ession type fitting that uses

a nut and a plastic insert. Systems with air gap faucets have two slip-on barbed

tubing connections.

6

Page 7

11.1 Connect the orange tube (feed water) to the angle stop valve on the

cold water supply line.

11.2 Connect the blue tube (product water) from the RO system assembly to

the quick disconnect fitting on the faucet.

11.3 Connect the yellow tube (processed water) to the storage tank valve

fitting.

11.4 Connect the black tube (reject water) to the drain saddle fitting.If you are

using a system with an air gap faucet: connect the 1/4”black tube to the

1/4” barb on the faucet and the 3/8” black tube from the faucet to the

drain saddle fitting. The 3/8” black tube should not have any loops or

should not drop below the drain saddle connection. Shorten the 3/8”

tubing if required.

Note: Make sure there are no kinks in any of the tubing.

D. Startup Procedures

1. Turn on the cold water line valve and check for leaks. Correct any problems if

necessary.

2. Purge the air out of the system by slowly opening the angle stop valve on the

cold water supply line. Be sure the storage tank valve is open.When open, the

valve handle should be parallel with the tubing.

3. Open the faucet.The water should begin to trickle within a few minutes.The RO

system should now be processing water.

4. Close the faucet when water begins to trickle, and DO

NOT open the faucet

again for at least 2 to 3 hours. It will take approximately 2 to 3 hours for the

holding tank to fill.

5. After 2 to 3 hours, open the faucet and completely drain the storage tank.You

should expect air and carbon fines (black powder) from the carbon filter. This is

normal and not hazardous.

6. It is important that the system be flushed at least once. If there is still a slight foul

taste in the water or carbon fines after flushing the system once, repeat steps 4

and 5.

Note: It will not be uncommon to experience air bubbles or effervescence in the

product water. This will disappear after the system is in service for a short period of

time.

WARNING: This reverse osmosis membrane contains a preservative to prevent

microbiological growth and freezing, which, if ingested, may cause irritation of the

gastrointestinal tract, colic, diarrhea, or other similar symptoms. Therefore, 2 to 5

gallons (approximately 1 to 2 full tanks) must be drawn from the faucet to flush out

the preservative before the unit should be considered operational. If there is still a

slight foul taste to the water,run another 2 to 3 gallons of water through the faucet.

7

Page 8

E. Maintenance

E.1 Filter Cartridges

Sediment and carbon filters have different effective lives when used on

different water systems. The amount of use that the cartridge receives also

determines its life. A family of two usually will not use as much filtered water as

a family of six.No amount of water metering or maintenance scheduling will be

an absolute guarantee of performance. Common sense, and the help of your

local water treatment professional is still the best way to maintain a properly

functioning filtration system. New cartridges (and changing cartridges often)

will enhance performance.

A sediment filter’s function is to remove suspended particles from the water,

thus reducing the possibility of clogging the reverse osmosis membrane. The

flow rate will slow down as the cartridge becomes clogged. When the water

flow slows down perceptively, it’s time to change the cartridge. Depending on

your water supply, this could be as soon as 2 months, or as long as 1 year. We

recommend at least an annual change.

Carbon cartridges remove taste and odor, chlorine, pesticides, and other

contaminants from water. Special advanced-style carbon blocks also remove

metals such as lead, iron, and copper. They also prevent iron fouling of the

quartz sleeves in UV equipped systems. The carbon cartridges should be

changed at a minimum every 12 months (or earlier if you notice any change in

the taste or smell of your water). Again, your local water professional will be

familiar with the quality of your water supply and can offer valuable advice

and/or periodic testing, depending on the quality of your feed water.

Replacing Filter Cartridges

1.1 Turn off the feed water supply to the RO system assembly. Open the

RO faucet and let it bleed all the water from the RO holding tank.

1.2 Turn the storage tank valve to the closed position.(90 degree angle to

the water line.)

1.3 Unscrew the filter housing sumps by hand or with a spanner wrench.

1.4 Remove the used cartridge and discard. Rinse out each of the

housings and fill about 1/3 full with water. Add 2 to 3 tablespoons of

bleach and scrub thoroughly with a brush or sponge. Rinse thoroughly.

1.5 Remove the o-ring from the housing and wipe the groove and o-ring

clean. Lubricate the o-ring with a coating of clean petroleum jelly.

Place the o-ring back into the groove. If the o-ring appears damaged

or crimped, it should be replaced immediately.

1.6 Install the new cartridge into the sump making sure that it slips down

over the sump standpipe.

1.7 Turn the sump into the cap and hand tighten. DO

NOT OVER TIGHTEN.

If the membrane needs to be changed, go to

Replacing the RO Membrane

1.8

Slo

wly tur

n on the f

eed (incoming) water supply and allow the housings

to fill with water. Check for any leaks.

1.9

T

ur

n the storage tank valve to the open position (parallel with the

water line).

8

Page 9

E.2 Reverse Osmosis Membrane

RO membranes remove dissolved (not visible) contamination from water (all

the way down to the molecular level). The membrane in your system may last

for several years in the proper application.The most obvious indication that your

membrane needs to be changed is a slow down in the manufacturing of water

(i.e. your storage tank does not refill as quickly with water as it once did). If your

RO system contains a pressure gauge the membrane should be changed

when a 15 psi drop is determined.Your water can also be periodically checked

to determine its TDS level.

Replacing the Reverse Osmosis Membrane

2.1 Turn off the feed waterline. Open the RO faucet and drain the water

from the tank.

2.2 Disconnect the processed water line from the RO housing end cap

via the quick connect fitting.

2.3 Twist off the end cap from the housing. (Reasonable force may have

to be used if the end cap has been on for several years).

2.4 Remove and discard the old membrane.

2.5 Apply a fresh coating of a FDA approved silicone lubricant to the two

o-rings on the end of the membrane.

2.6 Insert the membrane into the housing with the ‘two o-ring end’ first.

2.7 Apply a fresh coating of a FDA approved silicone lubricant to the

o-rings on the membrane housing.

2.8 Thread the cap back on and hand tighten firmly.

2.9 Reconnect the processed water line by inserting it into the quick

connect fitting.

2.10 Slowly turn on the feed water while checking for any leaks.

WARNING: This reverse osmosis membrane contains a preservative solution

to prevent microbiological growth and freezing, which, if ingested, may

cause irritation of the gastrointestinal tract, colic, diarrhea, or other similar

symptoms.Therefore,2 to 5 gallons (approximately 1 to 2 full tanks) must be

drawn from the faucet to flush out the preservative before the unit should

be considered operational.If there is still a slight foul taste to the water, run

another 2 to 3 gallons of water through the faucet.

NOTE: Manufacturer recommends that the flow capillary be changed

every time the membrane is replaced. Disconnect the black reject water

tubing from the RO housing drain port. Remove the flow capillary from the

tubing and replace it with a new one. IMPORTANT: Be sure to match the

size of the new flow capillary to the new membrane.

E.3 Ultraviolet Lamp

(Systems with the Polisher Biolyte™ Ultraviolet Sanitizer Only)

Change the ultraviolet lamp annually. The ultraviolet lamp in your filtration

system emits a very powerful and specific UV wave length for the sterilization of

micr

oor

g

anisms. This wave length is not visible to the naked eye. It is very

important that the lamp be changed once every year even if the lamp is still lit.

Visible light is not an indication of UV output. After one year, a UV lamp

degrades very quickly until it is no longer effective, even if the lamp is still lit.

9

Page 10

Replacing the Ultraviolet Lamp

3.1 Unplug the power adapter from the electrical outlet.

3.2 Unplug the lamp from the power cord.

3.3 Loosen and remove the white silicone plug from the white end cap.

3.4 Unscrew the white end cap with the silicone plug.

3.5 CAUTION: The old lamp could be very hot. Do not handle until lamp

has cooled down sufficiently.

3.6 Slide the old lamp out of the quartz sleeve and discard the lamp and

the silicone plug.

3.7 Carefully insert bulb into the quartz sleeve. Be sure the wire is hanging

out of the quartz sleeve.

3.8 Push in stopper (cap) which is attached to the wire into the quartz

sleeve.

3.9 Remove silicon plug from cap.

3.10 Slide the wire through the hole in the cap.

3.11 Carefully screw the cap onto the UV chamber. DO

NOT CROSS

THREAD. There is a glow bottle starter attached to the lamp. This can

be left inside of the cap.

3.12 Replace the silicon plug around the wire into the cap.

3.13 Plug the wire into the power adapter.

3.14 Plug the adapter into the correct power supply. (The use of a ground

fault protected outlet is recommended).

F. Flow Diagram

10

Pressurized

Storage

Tank

Sediment Prefilter

(Basic,

MetalsMaster,

BioMaster Only)

Carbon Block Prefilter

(Pr

emium, MetalsMaster,

BioMaster Only)

Carbon Bloc

k Postfilter

Polisher™ Ultraviolet Sterilizer

(BioMaster Only)

Reverse Osmosis Membrane

A

uto

Shut-off

V

alve

To Tank

(Yellow)

To Faucet

(Blue)

Feed Water

(Orange)

IN

OUT

To Drain

(Black)

T

ANK

Page 11

G. Troubleshooting

Problem Possible Cause Solution

1. No product water/ a. Feed water supply turned off. a. Turn on feed water supply.

not enough product water. b. Feed water pressure too low. b. Feed water pressure must be at least 35psi.

c. Feed water tubing kinked or plugged. c. Remove blockage or kink in line.

d. Flow/pressure control plugged. d. Flush out flow control; replace if necessary.

e. Product water check valve plugged. e. Clean or replace check valve.

f. Membrane fouled/clogged. f. Replace membrane element.

g. Storage tank is over pressurized. g. Drain tank, and relieve air to 10 psi.

h. System has been used too much. h. Convert system to higher production output.

i. Storage tank valve turned off. i. Open tank valve.

j. Prefilter(s) fouled or clogged. j. Replace prefilter(s).

2. Low flow rate from faucet. a. Low precharge in storage tank. a. Increase air pressure to 7 to 10 psi in tank

with product water drained.

b. Storage tank diaphragm ruptured. b. Replace storage tank.

c. Tank valve partially closed. c. Completely open tank valve.

3. High TDS product water. a. Check-valve failure on flow control. a. Replace check-valve tee.

b. Membrane fouled, hydrolyzed, ruptured b. Replace membrane.

or attacked by bacteria.

c. TDS increased in feedwater. c. Contact dealer for revised product water TDS.

d. Filters weren’t flushed properly. d. Flush system again.

4. Bad tasting or smelling a. Increase in product water TDS. a. See High TDS Product Water above.

product water. b. Post-filter exhausted. b. Replace post-filter.

c. Storage tank and system contaminated. c. Replace sediment and carbon filters. Sanitize

tank and system.

d. Product line and waste line connections d. Check lines and make corrections.

are reversed.

e. Membrane life expired. e. Replace membrane and flush system.

f. UV bulb burned out. f. Replace UV bulb.

5. Cloudy water. a. Dissolved oxygen in feedwater, which a. Usually clears up as condition of feedwater

is concentrated in product water. changes. Letting water stand will allow

dissolved air to dissipate.

(CONTINUED ON NEXT PAGE)

11

Page 12

G. Troubleshooting (Continued)

Problem Possible Cause Solution

6. Cloudy ice cubes. a. TDS increased in product water. a. See High TDS Product Water above.

b. Dissolved oxygen in feedwater, which b. See Cloudy Water above.

is concentrated in product water.

c. Larger (square shaped) ice cubes are c. Change ice cube shape. Let water stand to

usually clearest; small, round ice cubes release dissolved oxygen before freezing.

are usually cloudier.

7. Faucet leaks. a. Leak through spout. Valve tee bar is a. Raise tee bar so there is just a little play in

set too low or valve seat is defective. handle in the off position,or replace valve

assembly.

b. Leak around stem. O-ring seals worn b. Replace valve assembly.

on valve assembly.

8. Overflow at faucet air gap. a. Drain tubing kinked or plugged. a. Straighten and clean/flush drain tubing.

b. Tubing connections are reversed. b. Check tubing connections and correct.

c. Air gap plugged. c. Clean with vinegar and/or soap.

d. Drain tubing not in downward sloped d. Check for low spots and loops.

position.

e. Pipe tap (drain saddle) not aligned e. Realign pipe tap (drain saddle).

properly.

9. No blue glow emitting from a. Lamp burnt out. a. Replace lamp.

UV chamber site ports. b. Power adapter not plugged into wall outlet. b. Plug into wall.

c. Lamp not plugged in properly to PIN c. Check connections and adjust.

connector.

d. Ballast is burnt out. d. Replace ballast.

12

03/11

Loading...

Loading...