Page 1

BA_DF_0003_E_07_04

Page 2

1 SYSTEM OVERVIEW 3

2 FUNCTION 3

3 SAFETY 4

3.1 Regular Use 4

3.2 Identification of Dangers 4

3.3 Operational Safety 4

3.4 Technical Progress 4

4 MOUNTING AND INSTALLATION 5

4.1 Delivery Range 5

4.2 Auxiliary 5

4.3 Mounting of the Measuri ng Pipe 5

4.4 Overview of the Connection of the Senor Pipe and E val uation Unit 7

5 COMMISSIONING 9

6 MENU STRUCTURE OF DENSFLOW 11

7 MENU PARAMETERS OF THE SYSTEM IN DETAIL 12

8 MAINTENANCE 16

9 WARRANTY 16

10 TROUBLE SHOOTING 16

11 TECHNICAL DATA 17

2

Page 3

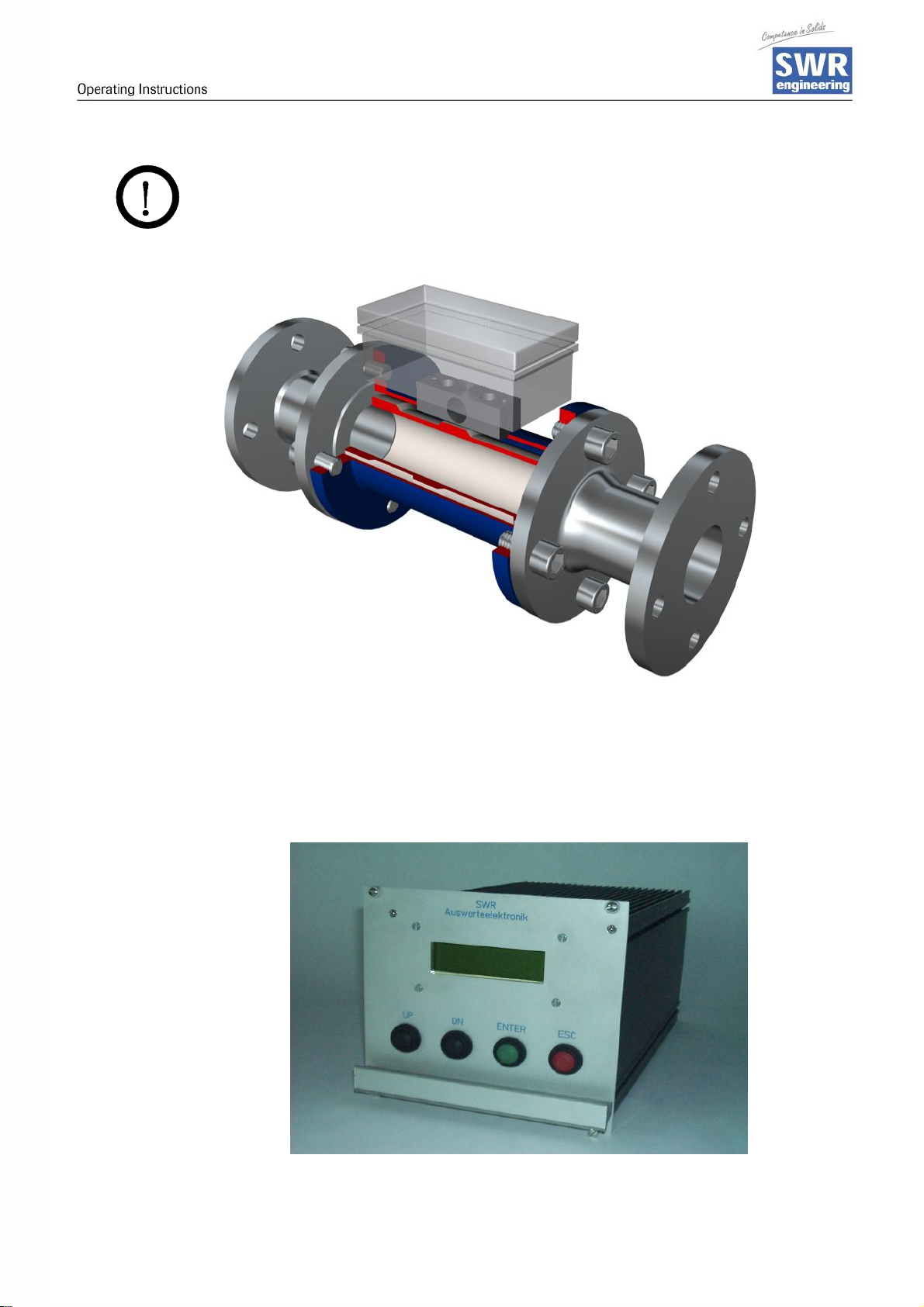

1 System Overview

Overview of the measuring system

Sensor (Measuring Pipe) Evaluation Unit

2 Function

• DensFlow is a measuri ng system especially developed for measuri ng the flow rate of

conveyed solids in densephase.

• DensFlow is working according to the latest micr oprocessor technology. By special

capacitive linking of an electromagnetic wave a homogeneous measuring field is

produced in the pipe.

• The electromagnetic wave brought into the pipe is reciprocall y acting with the solid

particles. These signals are evaluated in frequency and amplitude.

• The measurement of the solid speed is done by means of correlation. Two capacitive

sensors are used for the production of the correlation signals.

• A complete measuring unit consists of the sensor (measuring pipe) and the

evaluation unit.

Fig. 2: Coupling of the microwaves

3

Page 4

3 Safety

• The measuring system DensFlow was designed, built and tested to be safe and was

shipped in safe condition. Nevertheless persons or objects may be endangered by

components of the system if these are operated in an inexpert m anner. Therefore the

operational instruc tions must be read compl etely and the safety notes m ust be

followed.

In case of inexpert or irregular use, the manufacturer will refuse any liability or

guarantee.

3.1 Regular Use

• The measuri ng system must be instal led for measuring the flow rate onl y. Other usage and

modifications of the measuring system are not permitted.

• Only original spare part s and accessories of SWR engineering must be used.

• In order to prevent defects on the electronics, caused by e.g. electrostatic surge, the

flow velocity has to be below 50 m/s (e.g. free-blowing backwards).

3.2 Identification of Dangers

• Possible dangers when using the measuring system are marked by the foll owing

symbols i n the operating instructions:

Warning!

• This symbol in the operating instructions marks act ions, which may represent a

danger for life and limb of persons when carried out in an inexpert manner.

Attention!

• All actions which may endanger objects are marked with this sym bol in the operating

instructions.

3.3 Operational Safety

• The m easuring system must be install ed by trained and authori sed personnel only.

• Switch off the supply voltage for all maintenance, cleaning or inspection works on the

tubes or on components of the DensFlow. Follow the notes of the chapter

maintenance.

• The components and electrical connections m ust be checked for damages regularly.

If a damage is found, it is to be repaired before further operation of the instruments.

3.4 Technical Progress

• The m anufacturer reserves the right to adapt technical data to the technical progress

without parti cular advance notice. If you have any questions, SWR engineering will be

pleased to inform you on possible changes and extensions of the operating

instructions.

4

Page 5

4 Mounting and Installation

4.1 Delivery Range

• Measuring instrument in a 19"-rack system.

• Sensor for installation into the pipe.

• Seal-ring for adjustment to the pipe.

• Operating instructions.

4.2 Auxiliary

• Appropriate wrench or ring wrench for screwing.

• Tools for adjusting the wiring.

4.3 Mounting of the Measuring Pipe

• The sensor is to be mounted as follows:

• Determine the place of mounting on the pipe. On horizontal or incli ned pi pes the

sensor should be mounted from top.

• Follow the necessary distances of valves, bows, fans or cellular wheel sluices etc.

and also other measurement devices like temperature and pressure etc. to the sensor

(see fig. 3).

The mounting has to be in a vertical position.

Fig. 3: Minimal distances of the sensor to pipe bends and baffles.

5

Page 6

WARNING !

Before t he installat ion you hav e t o check, if there is a burr, a disalignm ent or a

seal in the i ntersection of the pipe and measuring sensor. If so, these

resistances in the pi pe must be removed.

Fig. 4: Installation of the sensor accommodation.

• The electronic equipment should be installed at a maxim um distance of 300 m from

the sensor. The housing is prepared for the 19"-rack system.

6

Page 7

4.4 Overview of the Connection of the Senor Pipe and Evaluation

Unit

Fig. 5: Wiring of the Sensor Pipe and Meas uring Instrument

A max imum length of 300 m of the sensor cabl e shoul d not be exceeded.

A 5-wired cable is needed between sensor and evaluati on unit.

7

Page 8

Electrical Connection

• Fig. 6: Electrical Connection

Evaluation Unit

Terminal No. Connection

Connection of the Supply Voltage

2a/c + 4a/c Input Supply Voltage +24 V DC

6a/c + 8a/c Input Supply Voltage GND

Connections

RS485

Throughput

Density

Velocity

Sensor

10a RS 485 Data A

12a RS 485 Data B

16c Output 4..20mA +

16a Output 4..20mA – (GND)

18c Output 4..20mA +

18a Output 4..20mA – (GND)

20c Output 4..20mA +

20a Output 4..20mA – (GND)

12c

22c Velocity A 0..20mA

24c Velocity B 0..20mA

28a/c Output Supply Volt age +24V +24V DC

32a/c Output Supply Volt age 0V GND

Density 0..20mA

8

Page 9

5 Commissioning

• For start-up the measurement system it is necessary to adj ust the sensor.

After swit ching on the power supply there is at least a warm-up time of 5

minut es required before any adjustment starts. Please check again :

• The correct cabl ing between sensor and the ev aluation unit.

• The correct adjustment of the sensor pipe.

Commissioning DensFlow

For start-up t he sensor has to be cal ibrated and param eterized to each

Basic Function At least a two-point-calibration (normally min and max)

product, which will be measured. It is necessary to assign

the mass flow to the display and i nitial value. The menu

functions are mostly sel f-explaining. Following a short

introduct ion to the overview:

By leaving the menu level and conf irmi ng the memory

function all values changed are transferred.

are suff icient for measuri ng the density f unction. Enter

the data in menu 3.5 and 3.6.

The v elocity measurement is firmly defined as an

absolute measurement by the distance of the sensor

plates and does not have to be cali brated.

Min-Poi nt Set point 1 to 0, when the mass flow is shut down and the

measuring pi pe is empty, calibrate this point now.

Max-Point Set point 2 to known maxi mum flow rate with normal

conveying and cali brate as well. Thi s value can be

adjusted later on when weighi ng by adjustment of

correcti on factor 2. 6.

Thus the basic f unction of t he measuring system is given

and it is now ready for operation

Adjustment See menu 2, point 1 to 6 f or the adjustment s to the

individual local condi tions regarding m aterial, measuring

units, etc.

Analog Output 1 is fi rmly configured for the m easuring of the throughput.

The measuring range is adjusted in menu point 2.2.

0 = 4 mA

Max =20 mA

Analog Output 2 is fi rmly configured for the m easuring of the vel ocity.

The measuring range is adjusted in menu point 2.1.

0 = 4mA

Max = 20mA

Analog Output 3 is fi rmly configured for the m easuring of the vel ocity.

The measuring range is fix adjusted to

0 m/s = 4 mA

10m/s = 20 mA

9

Page 10

Average The measuring range filter is used for the adjustment to

slower working devices or for a continuous output of the

analog output.

Menu point 2.3 for velocity and

Menu point 2.4 for density.

Storage Adjusted values are conf irmed by pressing t he ENTER-

button. Leaving the menu level by pressing the ES Cbutton. All changes are autom aticall y stored and the new

values are set as standard.

Suggestion for the Calibration Procedure:

Step 1 Input of the requested throughput value of the final value of the measuring range

in menu point 2.2

e.g.: 20mA = 20000 Kg/h

Step 2 Input of the requested density value of the fi nal value of the measuring range in

menu point 2.1

e.g.: 20mA = 800 Kg/m³

Step 3 Alignment of the mini mum densit y val ue with empty pipe.

min = 0 kg/m³ i n menu point 3. 5

Step 4 Alignment of the maximum densi ty value by complete fi lled pipe (e.g. 800 kg/m ³)

in menu point 3.6

Step 5 Input the di ameter of the pipe in menu point 2.5

Step 6 Conveying of the product on maximum throughput rate over a constant time

interval (e. g. 10 min. ). During this time period the throughput must not change.

Step 7 Measurement of the throughput quantity by weighi ng.

Step 8 Calculat ion of the correction factor by diff erentiati on

Value measured

Correction factor = -------------------------

Value weighted

Step 9 Correction of the m easured value by entering the correction f actor in m enu

point 2.6

10

Page 11

6 Menu Structure of DensFlow

1.1 Display

Density

1.2 Display

Throughput

1.3 Display

Velocity

2. Options

1.4 Display

Totalisator

2.1 – Density measuring range

2.2 – Throughput measuring

range

2.3 – Average velocity

2.4 – Average density

2.5 – Pipe diameter

2.6 – Correction factor

2.7 - Send parameters

2.8 - Language

11

3. Service menu

3.1 - ADC-1 (Density)

3.2 - ADC-2 (Velocity)

3.3 - DAC-Simulation

3.3.1 - DAC1 (preset 4,8,12,16,20mA)

3.3.2 - DAC2 (preset 4,8,12,16,20mA)

3.4 - Density min-value

3.5 - Density max-value

3.6 - Velocity Range

3.7 - DAC-Calibration

3.7.1 - Ofs DAC1

3.7.2 - Ofs DAC2

3.7.3 - v DAC1

3.7.4 - v DAC2

3.8 - Slave Adress

Page 12

7 Menu Parameters of the System in Detail

1. Display of the Measured

Values

1.1 - Density 2.1 - Density measuring range

1.2 - Throughput 2.2 - Throughput measuring range

1.3 - Velocity 2.3 - Average v elocity 3.3 - Current output

1.4 - Totalisator 2.4 - Average density 3.4 - Density min value

2. Options 3. Diagnosis

3.1 - A/D-1 (Density)

[kg/m³]

3.2 - A/D-2 (Velocity)

[kg/h]

(mA – preset)

2.5 - Pipe diameter [mm] 3.5 - Density max

value

2.6 - Correction fact or 3.6 - V elocity measur ing range [m/s]

2.7 - Send param eters 3.7 - DAC-Calibration

2.8 - Language 3.8 - Slave Adress

Use of the Evaluation Unit by:

ENTER-button à Selection and Confirming

UP- / DN-button à Changing

ESC-button à Backwards

1.0 Display:

1.1 Displ ay of t he measured density i n kg/m ³

1.2 Display of t he cal cul ated throughput from

density and velocity [kg/h]

1.3 Displ ay of t he measured veloci ty i n m/ s

DENSITY

0.0 Kg/m3

THROUGHPUT

0.0 Kg/h

VELOCITY

0.00 m/s

12

1.4 Displ ay of t he tot al flowrate since last reset

TOTALISATOR

0.00 Kg

Page 13

2. Options:

Press ENTER Button

OPTIONS

2.1 Entry of the density measuring range in

50 kg/m³ - steps.

2.2 Ent ry of the throughput range in 100 kg/m³ - steps.

Final value of measuri ng range [kg/h] = 20mA

2.3 Entry of the average time for the

velocity (0..120s)

à Damping of the signal

2.4 Entry of the average time for the

density (0.. .120s)

à Damping of the signal

2.5 Entry of the pipe diameter in mm.

Necessary for the cor rect calculation

of the quant ity.

2.6 Entry of the correction factor for the

throughput (0.1...10)

Here the value received can be corr ected

lateron by changing the preset value to 1.

Density Range

= 800 [Kg/m³]

Throughput Range

= 20000 Kg/h

Average V

= 10s [ 25 ]

Average D

= 10s [ 25 ]

Pipe Diameter

= 32.0 mm

Correction Factor

= 1.0

2.7 Send parameter

By pressing YES the parameters factor correction,

throughput range, densi ty measuring range will be

send via RS485 interface to all connected instrum ents

2.8 Select Language

between German and English

Parameter send

= No / Yes

Language

English

13

Page 14

3. Service menu:

To get int o the diagnostic mode press

ESC and ENTER button at the same time

Service menu

3.1 Display current val ue A/D-c onverter 1 (Density)

3.2 Display Vol t age level A/D-c onverter 2 (Veloci t y)

3.3 Select i on Current value f or test purposes.

Here a constant current ( 4, 8, 12, 20m A)

can be presetted on output 1 for testing purposes.

Here a constant current ( 4, 8, 12, 20m A)

can be presetted on output 2 for testing purposes.

ADC 1 (Density)

I=0.0mA [ 0h]

ADC 2 (Velocity)

I=0.0mA [ 0h]

DAC Simulation

DAC 1 [ENTER]

I = 04mA

DAC 2 [ENTER]

I = 04mA

3.4 Entry of the mi ni m um value f or the densit y range.

usually 0-value (Measuring pipe empt y).

The dim ensi onless value must be changed

so far, until 0% are indicated.

3.5 Entry of the max i mum v al ue for the density range.

Here you can enter the value, which can

maximally be expected or a second measuring

point. T he dimensionless value must be changed

so far, until the requested percentage is indicated.

3.6 I nput of the v eloci t y

Standard = 10m/s ex works presetted.

3.7 DAC- Cal ibrat ion f or current outputs

press ENTER to select subm enu

Offset Calibration

for 4 mA output 1 (throughput)

Density Min

= 0072 [ 0.0%]

Density Max

= 2568 [ 100%]

Velocity range

= 10.0 m/s

DAC-Calibration

DAC-Calibration

Of's DAC1 +0

14

Page 15

Offset Calibration

for 4 mA output 2 (densit y)

DAC-Calibration

Of's DAC2 +0

Span Calibration

for 20 mA output 1 (throughput)

Span Calibration

for 20 mA output 2 (densit y)

3.8 Slav e Adress

select slave adress for ModBus - comunication

Totalisator

with the totalisator function it is possible to m onitor

entire flow rate since the last reset of the Totalisator

A RESET of the counts can be accomplished over

pressing the ENTER and selection of YES or NO

with UP / DOWN button.

DAC-Calibration

V DAC1 +1

DAC-Calibration

V DAC2 +1

Slave Adress

001

TOTALISATOR

1,0 Kg

TOTALISATOR

Reset: 'NO'

Stop Totalisator

press ESC

TOTALISATOR

H: 1,0 Kg

15

Page 16

8 Maintenance

• Warning!

Danger of shock with opened housing!

• Switch off the suppl y voltage for all maintenance or repair works on the measuring

system. The pipe must not be in operati on during a sensor exchange.

• Repair and mai ntenance work must be carri ed out by trained or expert personnel only.

9 Warranty

Warr anty is granted for two years starting from deli very date under the conditi on t hat

the operational instructions have been followed, no interventions on the appliances

have been m ade and the components of the system show no mechanical damage or

wear resist ance.

In case of a defect during the warranty period, defective components are repaired or

are replaced free of charge. Replaced parts turn into the property of SWR. If desired

by the customer that the part s should be repaired or replaced in its factory, then the

customer has to take over the costs for the SWR-service staff.

SWR is not responsible for damage, which did not develop at the delivery arti cle;

especially SWR is not responsible for escaped profit or other financial dam ages of

the customer.

10 Trouble shooting

• Warni ng!

The electrical installation must only be checked by expert personnel.

Problem Cause Measure

Measuring system

does not work.

Measuring system

outputs wrong values

Relay flickering Hysteresis too small.

Power supply interrupted.

Break of a cable.

Fus e defective.

Device defect ive.

Calibration not correct.

Calibration shifted by

abrasion on front end of

sensor.

Check the power supply.

Check the connecting cables for a possible

break of a cable.

Exchange the fuse in the field housing .

Delete input signal correction, new calibration

according to section 6.

Delete input signal correction, new calibration

according to section 6.

Increase hysteresis, check effects caused by

exter nal devi ces.

Do not open, as otherwise the warranty claim expires!

16

Page 17

11 Techni cal Data

Sensor Pipe

Housing: Steel St52, powder-coated

(stainless steel 1.4541) option

NW 10.. ..250, Flange DIN 2576

Inner pipe: Ceramics, POM, PTFE

Protection category: IP65

Operating temperature: Sensor pipe: -20....+ 120 °C

Option: -20....+ 220 °C

Sensor electronic: 0....+ 60 °C

Max. working pressure: 10 bar, option20 bar

Max. accept. flow velocity 50 m/s

Working frequency: 100kHz

Transmitting power: max. 2 mW

Weight: Depending on nominal size

Dimension: Ø NW + 90mm , L 500mm

Accuracy: +/- 2...5% i n calibrated range

Evaluation Unit

Supply voltage: 24V DC

Power consumption: 12 W

Operating temperature: –10...+45 °C

Dimension: 19"-rack system, 3HE, 28TE, L=227mm

Weight: approx. 0.7 kg

Additional Data:

Input: 2 x Velocity 0..20mA or 0..10V

1 x Density 0..20mA

1 x PFM-Input 14V, Imax 35mA, 30..3kHz

Connections: Connector (DIN 41612)

Type B, 32-pol., connector

Current output: Throughput: : 4...20mA

Density : 4...20mA

Velocity : 4...20mA

Load < 500 Ω

Serial output: RS232 / 485, MOD-Bus-Prot ocol

Sub-D 9-pol., connector

Control unit: LCD-Display, li ghted, 16 x 2 digi ts

4 x push buttons

Data storage: EEPROM

17

EN 070507

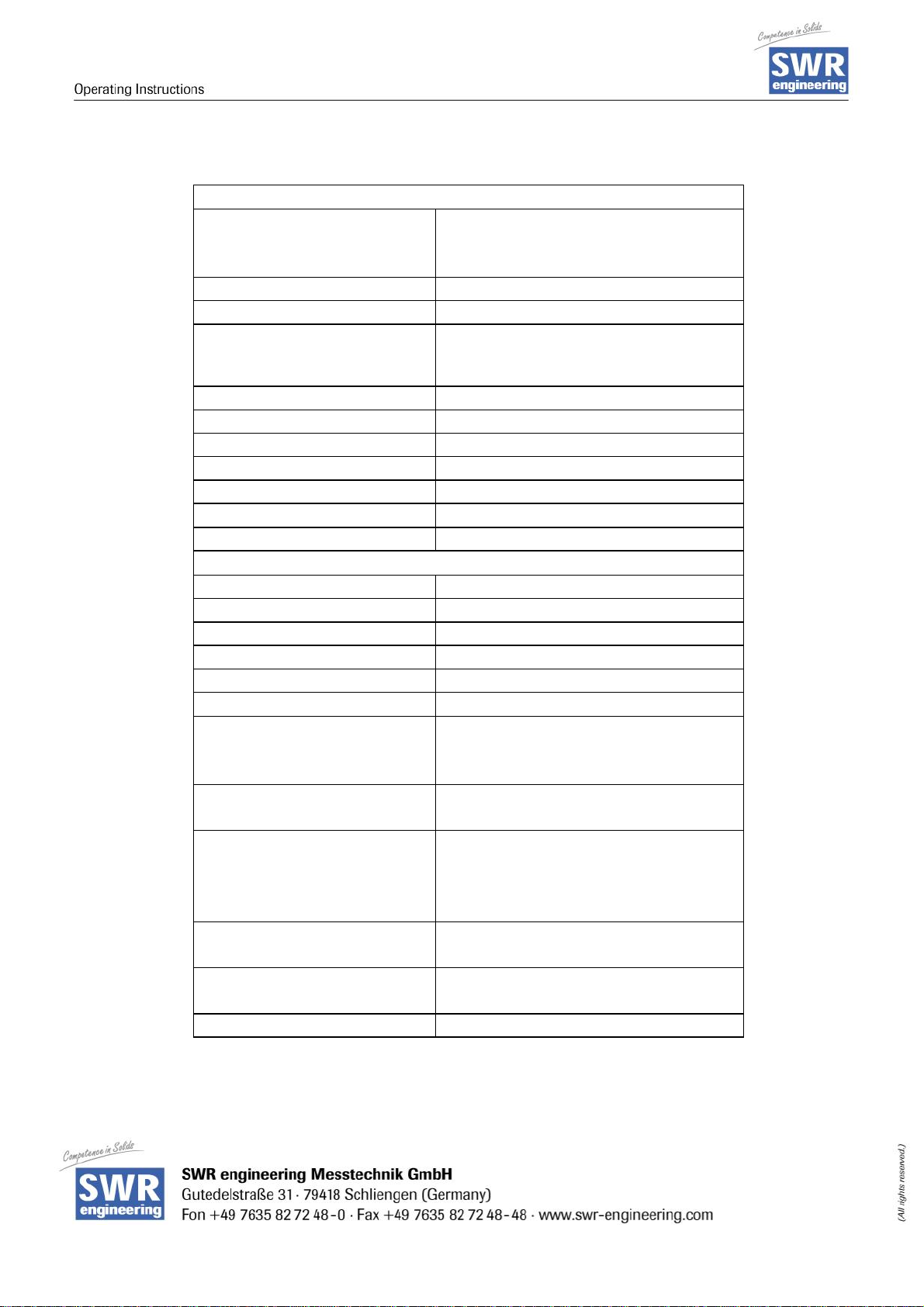

Loading...

Loading...