SwissQprint Nyala Operating Manual

Operating manual

Nyala

High-End UV Inkjet System

Translation of the original (German) operating manual

date 08-2014

author swissQprint AG

version 020

3

Content

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.

2 Summary of the documentation . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Installation preparation . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Volume 1 - Operating manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.3 Volume 2 - Software operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.4 Volume 3 - Service handbook * . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Structure of this operating manual. . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4

Points to note when reading this operating manual .

. . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Where to keep the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.6 Current status of documentation . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7 Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.8

Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 P

roduct description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Directional information. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.

1 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.

3 Technical information. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3.3 Print specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9

2.3.

4 Electrical connection, power consumption. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.5 Print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 S

afety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

3.1.

2 Latest technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2

Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3

Examples of improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 Hazards, important instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.1 Explanation of the hazard label. . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 Areas of responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.1 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

3.5.

2 The owner or person authorised by him . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5.3 Operating personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6 Personnel requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.7 Rules and occupational health and safety. . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . 28

3.8 Procedure in case of malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4

3.9 Danger areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.9.1 Printing, material supply, adjustment work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.9.2 Definition of the danger areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.10 Safety and monitoring devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.10.1 Emergency stop switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1

0.2 Control switch at purge tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.10.3 Print head carriage protection switch . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . 34

3.10.4 Control switch at vacuum slide cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.10.5 X-Bumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

3.1

0.6 Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3

.10.7 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.1

0.8 Safety shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.1

1 Safety equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.12

Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.12.1 Meaning of the safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.12.2 Mandatory sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

3.1

2.3 Warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3

.13 Electrical hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.14 Mechanical hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.14.1 Getting caught, being pulled in. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.14.2 Catching or impacting foreign objects . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . 40

3.15 Burns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.

16 Chemical burns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.

17 Risk of fire and explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.17.1 In the event of a fire: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

3

.18 Risk of poisoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.19 Handling and storage of chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.19.1 Handling chemicals safely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3.20 Environmental protection measures . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . 46

3.21 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.

22 Measures against UV radiation and ozone. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . 47

3.23 Safety instructions for operators . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.24 Safety precautions for service personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4 Controls and operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.1 Safety at work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.2

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.

2.1 Emergency stop switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.2.2 Membrane keyboard with LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.3 Daily commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.3.1 Daily checks prior to start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4 Switching on the printing system. . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . 55

4.5 Maintenance of print heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.5.1 Checking the print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5

4.5.2 Cleaning print heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.5.3 Cleaning instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5.4 Notes on avoiding stray light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.6 Positioning print material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.6.1 Changing the rotation direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.6.2 (De)activating the automatic tensioning device. . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.6.3 Supporting short material rolls . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.7 Roll printing with reinforced roll option . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.7.1 Preparing the roll holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.7.2 Fitting the roll holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.

7.3

Preparatory tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.7.4 Feeding through the roll material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.7.5 Changing the rotation direction . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.7.6 (De)activating the automatic tensioning device. . . .

. . . . . . . . . . . . . . . . . . . . . . . . 77

4.8 Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.8.

1 Operation using the membrane keyboard . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 78

4.8.2 Setting the position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.8.3 Sett

ing the position with 220 mm UV lamps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.8.4 Setting the vacuum intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.9 Breaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.10 After work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

83

5 M

aintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.1 General notes on maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.2 Safe maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.3 Operating resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.3.1 Handling operating materials . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.3.2 Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 87

5.3.3 Cleaning fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.3.

4 Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.4

Maintenance list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.4.

1 Labelling and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.4.2 Maintenance list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

90

5.5

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.5.1 Checking for dirt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

92

5.5.

2 Cleaning the vacuum plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.5.3

Waxing the vacuum plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.5.4 Cleaning the UV lamp air filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.5.5 Replacing the UV lamp air filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.5.6 Replacing UV lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.5.7 Emptying/cleaning the purge tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6

7

Introduction

© swissQprint AG, 2014

1 Introduction

1.1 Foreword

To the customer

By deciding to purchase our product, you are participating in the success of swissQprint printing

systems.

The modular design of our system guarantees you:

• A system solution that meets your individual requirements in terms of speed and quality.

• The availability of the most up-to-date technology thanks to constant developments.

Contact

swissQprint AG

Schützenwiese 8

CH-9451 Kriessern

T +41 71 7

27 05 60

F +41 71 727 05 06

service@swissqprint.com

www.swissqprint.com

Our approach

Constant and intensive cooperation with successful users is a prerequisite for innovative and practical solutions. We are therefore grateful for any comments or suggestions on how we can improve.

1.2 Summary of the documentation

The documentation supplied is intended to help you to:

• operate the machine safely

• perform routine maintenance

• make optimum use of the machine in all permitted areas

To do this, you need to be able to find what you want within the documentation.

1.2.1 Installation preparation

This manual contains information:

• on the requirements for the place of installation

•on transport

•on unloading

• on preparing for installation

8

Introduction

© swissQprint AG, 2014

1.2.2 Volume 1 - Operating manual

This volume contains information about the technology, installation, operation and maintenance

of the machine.

1.2.3 Volume 2 - Software operating manual

This volume contains information about Amber.

1.2.4 Volume 3 - Service handbook *

This volume contains information on servicing the machine by authorised service personnel.

* optional

9

Introduction

© swissQprint AG, 2014

1.3 Structure of this operating manual

The operating manual consists of separate chapters, which are consecutively numbered.

The table of contents provides information on the layout of the individual chapters.

1.3.1 Optional accessories

There are a number of optional extras available for the machine. Descriptions relating to these optional extras are identified in the operating manual by the * symbol.

You can find the optional accessories for your machine in the sales documents.

10

Introduction

© swissQprint AG, 2014

1.4 Points to note when reading this operating manual

Text references

Chapter headings are numbered consecutively, with the first figure corresponding to the chapter

number. Where reference is made to sections outside the current chapter, note the first figure and

turn to the corresponding chapter, which contains the cited section.

Sketches and schematic representations

These are provided for general information and do not necessarily correspond to the latest version of the machine.

Dimensional information

This is given in the ISO system of measurements.

1.5 Where to keep the manual

Keep Volume 1 "Operating manual" and Volume 2 "Software operating manual" close at hand in

the vicinity of the workstation.

Volume 3 "Service handbook" must be available to maintenance and service personnel if required.

11

Introduction

© swissQprint AG, 2014

1.6 Current status of documentation

In order to make sure that the documentation is complete and up-to-date at all times:

• Do not remove individual documents.

• Request missing or illegible pages from the manufacturer.

• Immediately file new documents delivered with conversion work.

• If the documentation has been amended, file the new versions and destroy the old copies.

If the documentation exists in more than one language, ensure that all languages are kept up to

date.

1.7 Execution

This operating manual makes reference to the following standards:

• EN 82079-1

• EN 62023

• EN ISO 12100:2011

Note!

Other EU standards used are listed in the Declaration of Conformity.

In the interests of our customers, we reserve the right to make changes as a result of technical improvements. This document therefore corresponds to the technical status of the product supplied

and not the manufacturer's current state of development.

12

Introduction

© swissQprint AG, 2014

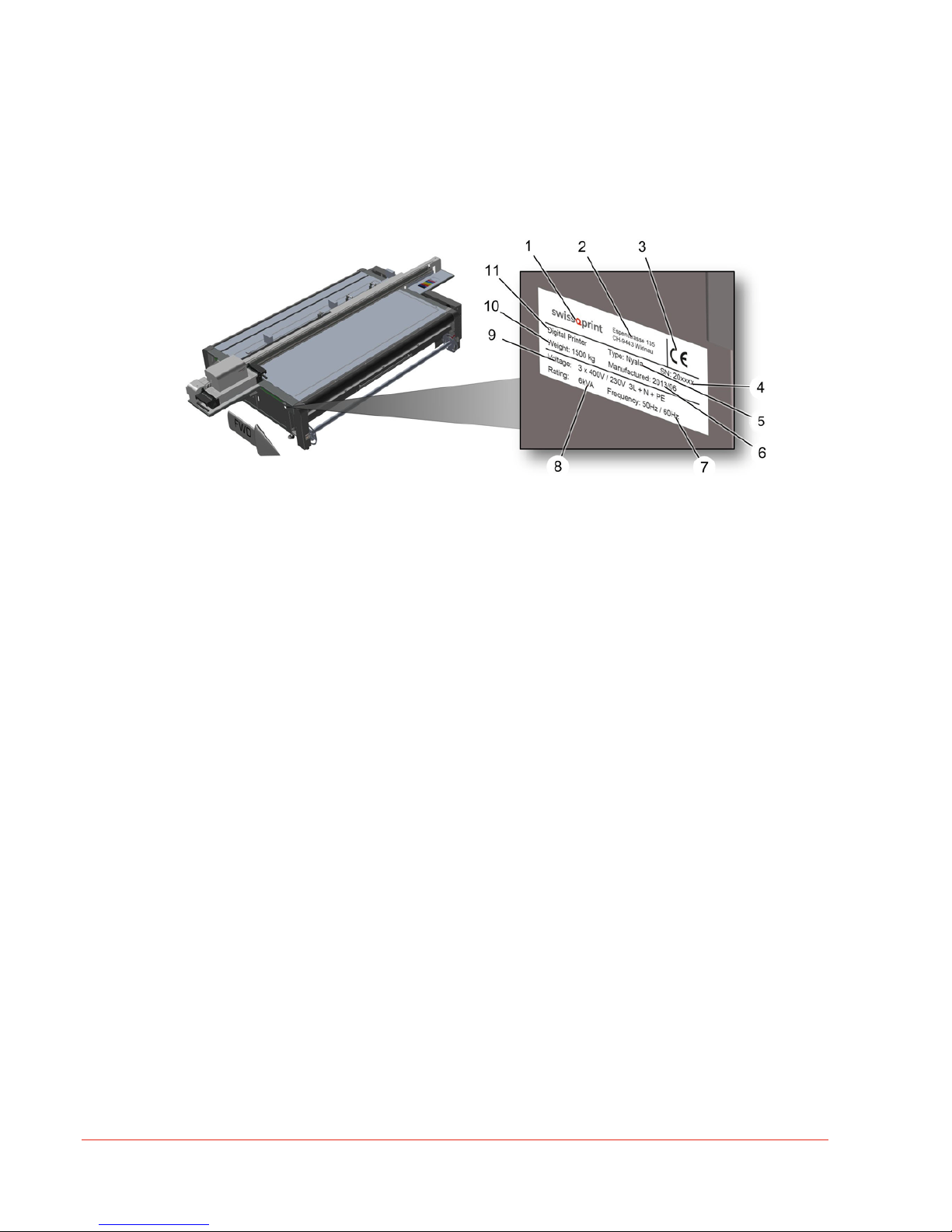

1.8 Rating plate

Note!

The rating plate is used to uniquely identify your machine.

1 Manufacturer 7 Frequency

2 Manufacturer's address 8 Power supply

3CE symbol 9Mains voltage connection

4 Serial number 10 Total weight

5 Machine type 11 Machine name

6 Date of manufacture (YYYY/MM)

13

Product description

© swissQprint AG, 2014

2 Product description

Contents of this chapter

• Information on directional information in the operating manual

• Information on ways of using the machine

• Description of the structure of the main components

• List of important technical data

• General technical description of the machine

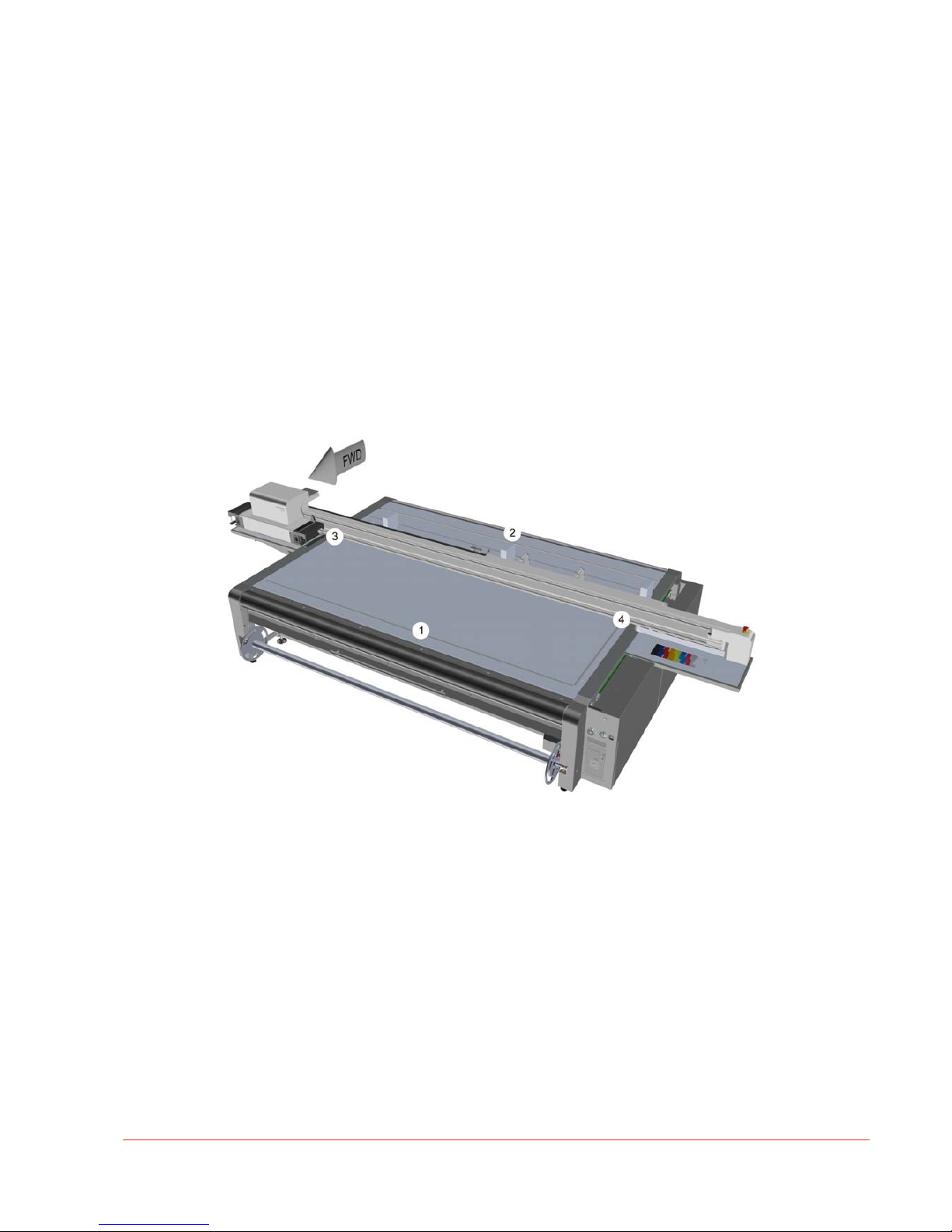

2.1 Directional information

Directional information such as "right, left" or "forwards, backwards" relate to the view of the operator towards the machine during the step described.

1Front

2Rear

3Left

4Right

14

Product description

© swissQprint AG, 2014

2.2 Intended use

The machine may be used for the purposes described in this operating manual only:

• Output station for print data

• Printing on heat-resistant boards or flexible materials

2.2.1 Components

1 Cleaning station 7 Adjusting wheel for vacuum*

2 Emergency stop switches 8 PC main switch

3Drizzle station 9Beam

4 Switch for vacuum 10 Vacuum plate

5 Main switch 11 Print head carriage

6 Pressure gauge for vacuum 12 Roll printing device*

15

Product description

© swissQprint AG, 2014

2.3 Technical information

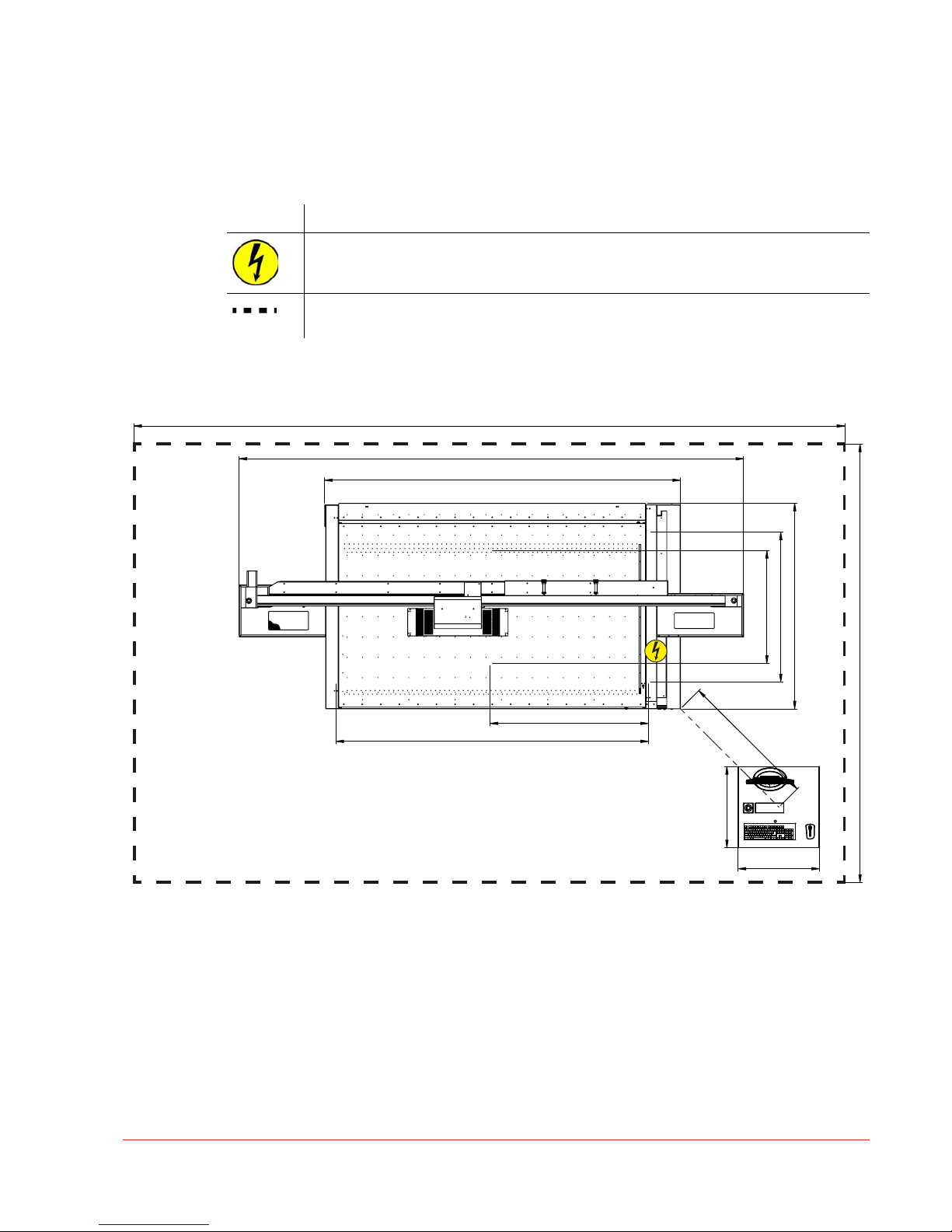

2.3.1 Dimensions and weight

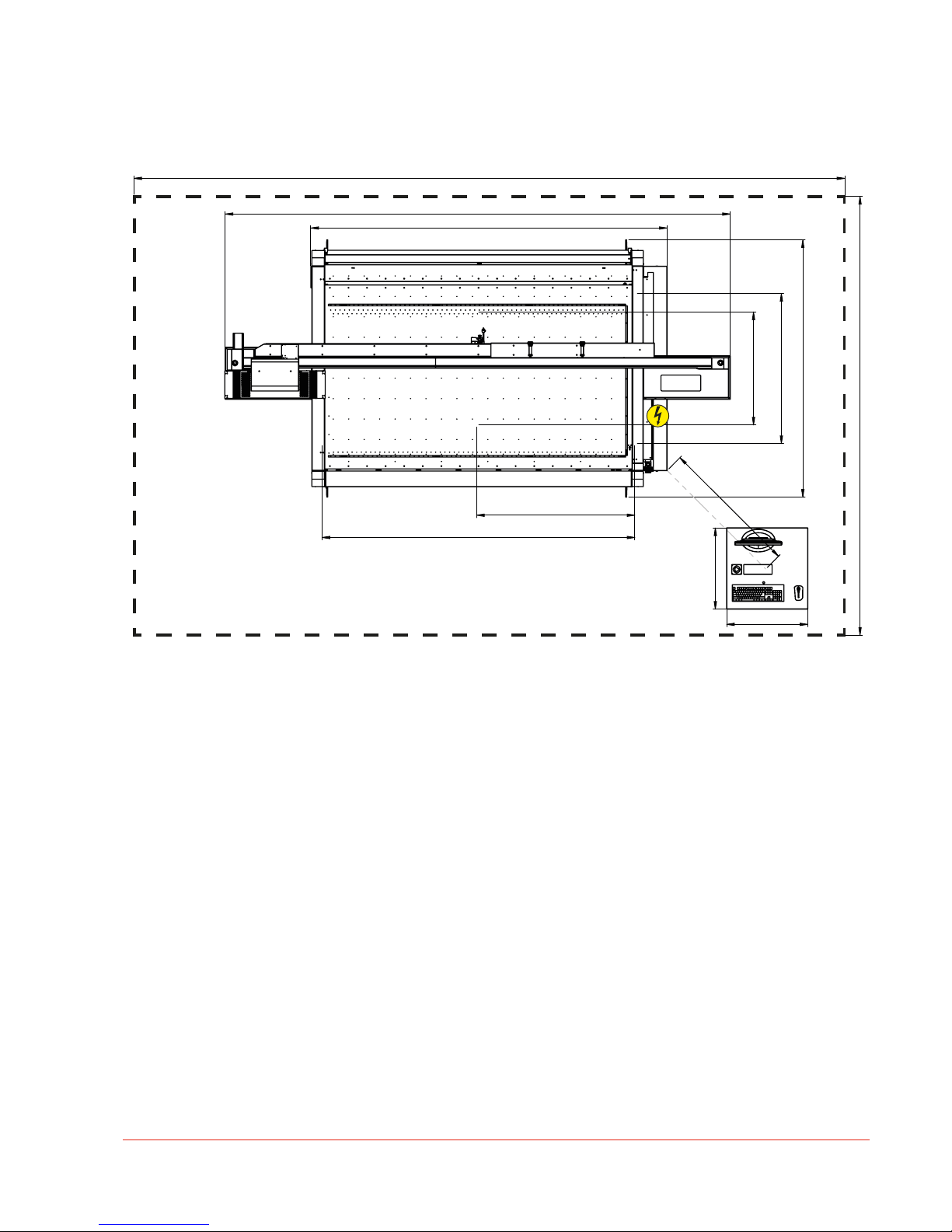

Flatbed

Weight: 1200 - 1700 kg

Symbol Description

Connection point for electricity, network and air

Exhaust outlet for vacuum pump(s)

• Recommended location size

• Barrier marking

a

a

16

Product description

© swissQprint AG, 2014

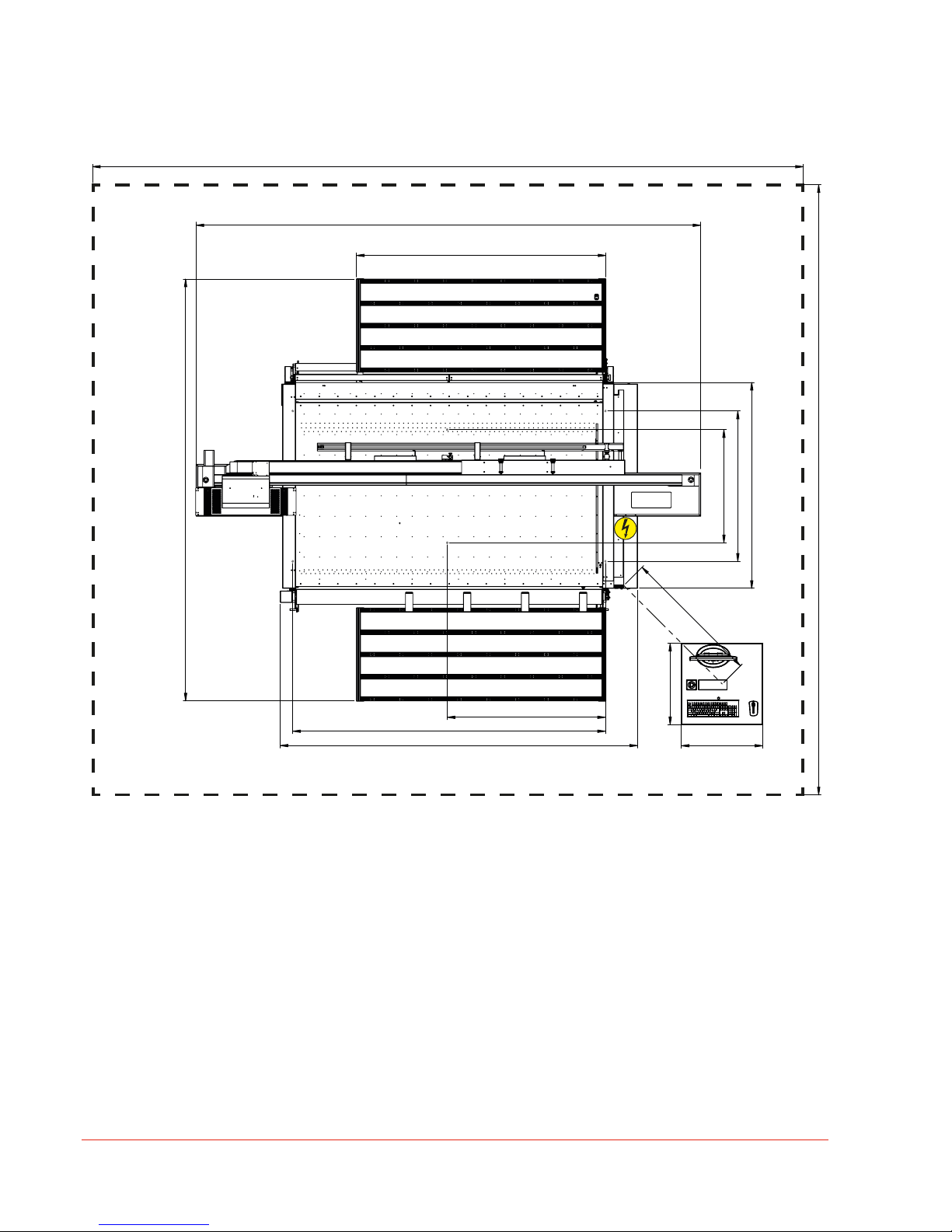

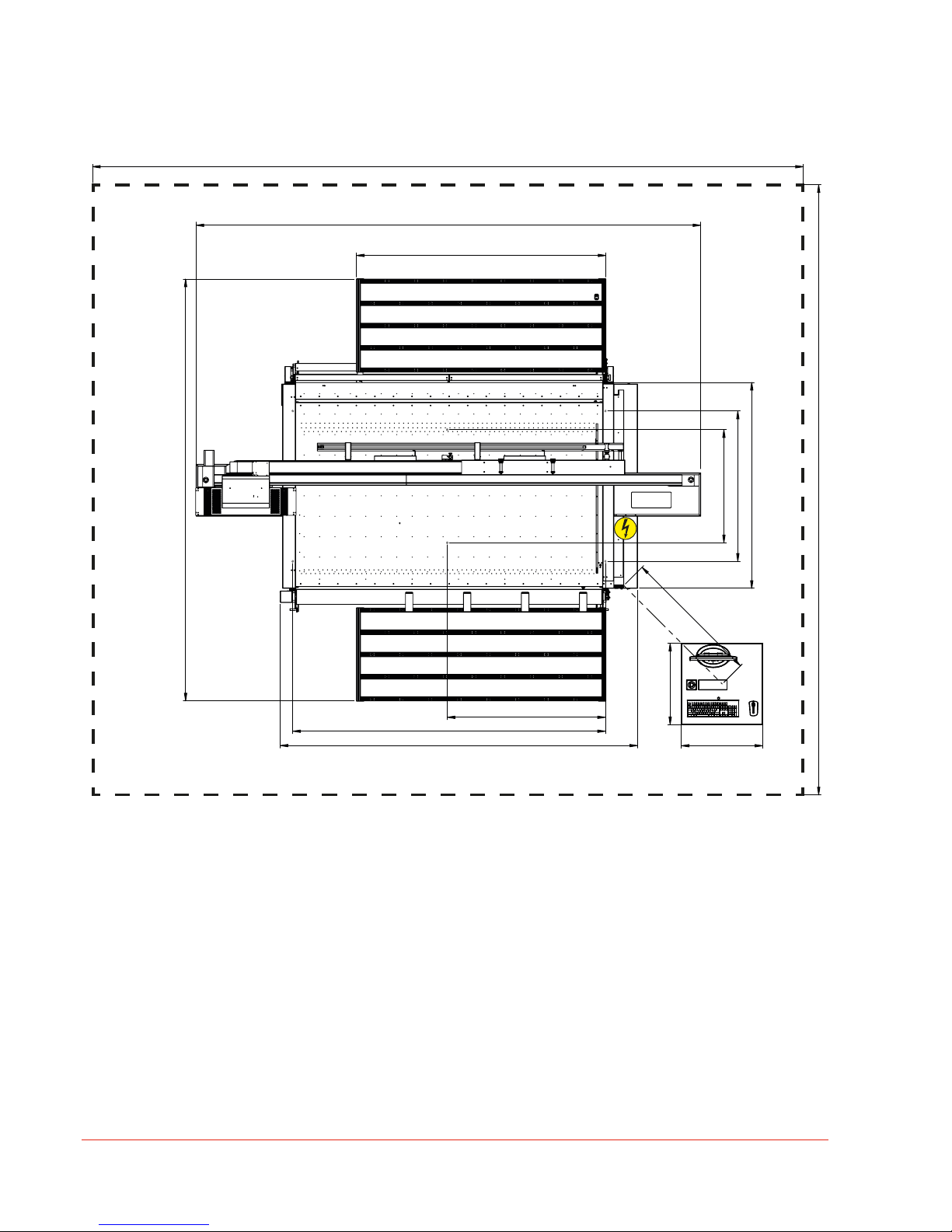

Roll option

Weight: 1200 - 1700 kg

a

a

17

Product description

© swissQprint AG, 2014

Reinforced roll to roll option

Weight: 1200 - 1700 kg

a

a

18

Product description

© swissQprint AG, 2014

Board option

Weight: 1350 - 1850 kg

a

a

19

Product description

© swissQprint AG, 2014

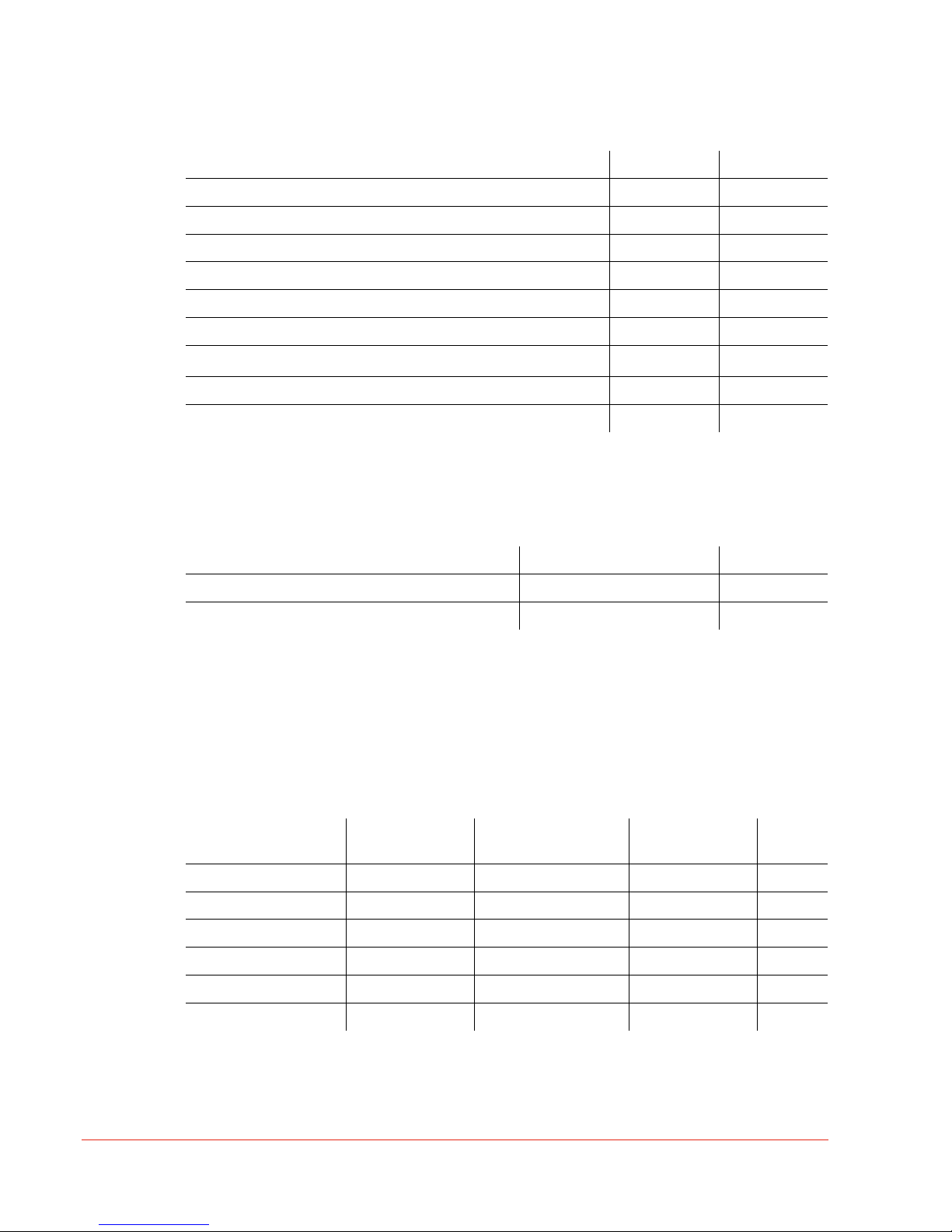

Height

Weight of operating unit: approx. 40 kg

2.3.2 Environmental conditions

2.3.3 Print specifications

Print output with full printing width – flatbed

Print output with full printing width – roll to roll

With "roll to roll", productivity is reduced by approx. 10%

s

s

s

Value Unit

Operating temperature +18 to +30 °C

Storage temperature 0 to +30 °C

Relative humidity 35 - 80%, non-condensing

Ozone charge The measured ozone level is below the prescribed threshold. No

protective measures against excessive exposure to ozone are

therefore required. You should nevertheless provide adequate

ventilation, including at floor level.

2 x CMYK Quality/application

140 m

2

/h

Draft mode

88 m

2

/h

Speed mode

46 m

2

/h

Production mode

36 m

2

/h

Quality mode

20 m

2

/h

Fine art mode

20

Product description

© swissQprint AG, 2014

Print material dimensions

2.3.4 Electrical connection, power consumption

Mains connection

Power consumption

Note!

Due to the unsymmetrical loading of the phases, a CEE32 connection is required for the most

powerful configuration.

The figures are reference values and vary depending on frequency and voltage fluctuations.

* True power approx. 70% of the apparent power

** UV system dependent on selected drying mode

Designation Value Unit

Max. width of material 3200 mm

Max. printing width 3200 mm

Max. length of material 1600 mm

Oversize with roll or panel option 4000 mm

Max. outlet 50 mm

Max. substrate weight 400 kg

Max. surface pressure 100 kg/m

2

Max. roll weight 80 kg

Max. roll weight with increased roll option 180 kg

Designation Value Unit

Operating voltage 3 x 400/230 3L + N + PE V

Mains frequency 50/60 Hz

Machine Pump option*

UV System**

+ PC***

Maximum power Plug

Nyala 1.1 kW 2.6 kW 5.7 kW CEE16

Nyala 1.3 kW 4.6 kW 5.9 kW CEE16

Nyala 2.2 kW 4.6 kW 6.8 kW CEE16

Nyala Tandem 2 x 1.1 kW 4.6 kW 6.8 kW CEE16

Nyala Tandem 2 x 1.3 kW 4.6 kW 7.2 kW CEE16

Nyala Tandem 2 x 2.2 kW 4.6 kW 9.0 kW CEE32

21

Product description

© swissQprint AG, 2014

*** Assumption of 200 W including movement system

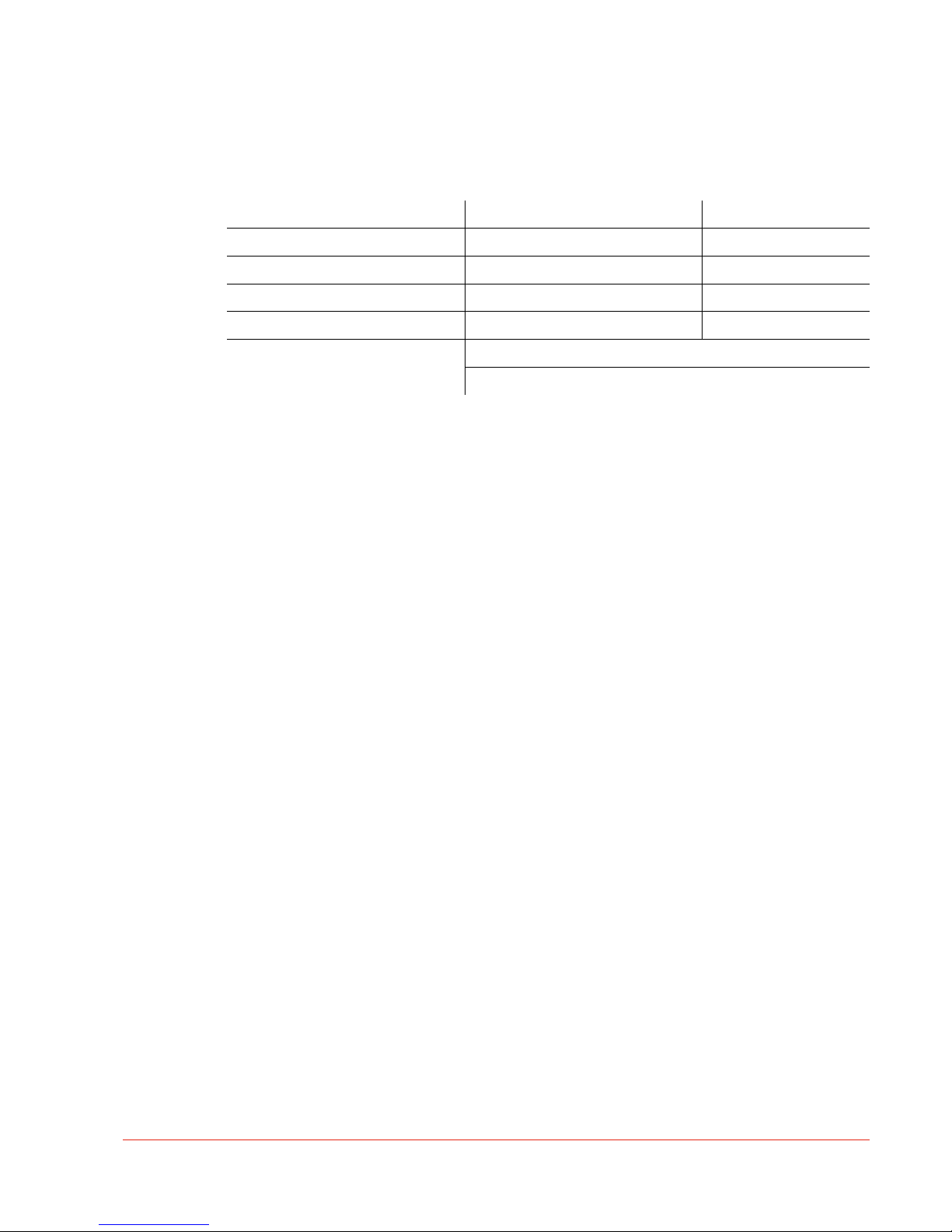

2.3.5 Print head

Designation Value Unit

Variable drop size 9 - 42 Picolitre

Colour channels 9 pcs

Addressable resolution 360 - 1080 DPI

Visual resolution 2160 DPI

Colour configuration

K, C, M, Y, Lc*, Lm*, white*

Spot colours/other*

22

Product description

© swissQprint AG, 2014

23

Safety

© swissQprint AG, 2014

3 Safety

3.1 General information

Your safety – as the operator, service engineer or otherwise – is the primary concern. Certain situations, problems or faults that may occur on the equipment could put your safety at risk if you are

not aware of the steps you should take to avoid the resulting dangers.

3.1.1 Contents

• Stipulation of the correct use of the machine

• Generally applicable safety instructions and safety regulations to be observed

• Explanation of the meaning of symbols and pictograms which are used in this manual and in

signs on the machine

• Location of safety and monitoring devices on the machine

• Information on protective equipment required and of requirements for operators and maintenance personnel

Specific activity-related and situation-related safety instructions are given in the corresponding

procedures in the following chapters of this manual and in other parts of the documentation.

3.1.2 Latest technology

The supplied machine meets the standards of the latest technology at the time of delivery.

However, the equipment may pose dangers unless the safety instructions in this guide are observed and implemented.

24

Safety

© swissQprint AG, 2014

3.2 Proper use

The proper use of the machine is essential for its safe operation.

The equipment supplied

• is listed and labelled;

• determines the possible uses of the machine.

The printing system is essentially designed as an output station for print data and therefore for

printing materials in roll and panel formats up to a thickness of 50 mm.

Its proper use is therefore restricted to the printing of flexible and rigid, non-combustible materials.

Any other use or any use going beyond this scope constitutes improper use. The user bears sole

liability for any damage arising as a consequence.

Proper use of the machine also requires:

• compliance with applicable national safety regulations;

• observation of the safety instructions in this operating manual;

• compliance with the conditions of use and use of the specified operating materials.

25

Safety

© swissQprint AG, 2014

3.3 Examples of improper use

Improper use of the machine can:

•cause injury

• result in serious damage to the machine

• lead to loss of warranty

Improper use of the machine includes, among other things:

• Any structural modification to the machine without written agreement from the manufacturer

• Servicing work performed by untrained or unauthorised personnel

• Installation of spare parts and use of resources not approved by the manufacturer

• Deliberate or careless interference with the machine during operation

• Use of chemicals (ink, cleaning agents) without adequate personal protective equipment

• Commissioning of the machine

– by persons not authorised by the owner

– by untrained personnel

– without the designated protective and safety measures

– if the operating manual is incomplete

• Use of ink and other chemicals not approved by swissQprint

• Non-adherence to maintenance requirements

• failure to react to signs of wear and damage

26

Safety

© swissQprint AG, 2014

3.4 Hazards, important instructions

3.4.1 Explanation of the hazard label

In both the operating manual and on the machine, dangers, important instructions and user tips

are marked by special symbols and signal words as follows.

Note!

• refers to a dangerous situation,

• refers to operational and service risks;

• Warns of serious damage to the equipment or other material damage or consequential

damage.

Tip!

Tip! Is used to designate user tips and useful information which enhance the usability and prolong

the service life of the machine and make the work significantly easier.

Danger!

The Danger safety advice

• refers to an immediate threat

• refers to operational and service risks

• warns of serious effects on health and safety, including life-threatening injuries

Warning!

• refers to a dangerous situation,

• refers to operational and service risks;

• warns of serious effects on health and safety, including life-threatening injuries.

Caution!

The Caution safety advice

• refers to a dangerous situation

• refers to operational and service risks

• warns against injuries that can be treated easily or serious property damage or

consequential damage.

27

Safety

© swissQprint AG, 2014

3.5 Areas of responsibility

3.5.1 Manufacturer

The manufacturer is responsible for delivering the machine in a condition which meets all safety

regulations. The operating manual and the accessories must be included in the delivery as per the

sales documents.

3.5.2 The owner or person authorised by him

The owner or person authorised by him is responsible for the following:

• Ensures that only adequately trained personnel, who have been properly instructed and have

read and understood the content of the safety instructions in this chapter, will operate and

maintain this machine

• Clearly determines the responsibility of the operators and service personnel as required in the

instruction handbook

• Checks the personal protective equipment of operators and service personnel

• Is responsible for the safe condition of the machine

• Ensures that servicing and maintenance is carried out according to the maintenance list

• Notifies the manufacturer of any accident involving the machine that results in serious injury or

substantial material damage

• Takes the machine out of service immediately if defects arise that are detrimental to its operational safety

3.5.3 Operating personnel

The operating personnel is responsible for the following:

• Wear the necessary personal protective gear

• Halt operation immediately in the event of faults

• Report any changes which are detrimental to operational safety

• Keep the equipment clean

• Check if the emergency stop switch works before starting work

3.6 Personnel requirements

The operating personnel must:

• be physically and mentally fit,

• be qualified to use the machine through thorough training,

• have read and understood the operating manual,

• be over the age of 16,

• be familiar with first aid techniques and the use of fire extinguishers.

28

Safety

© swissQprint AG, 2014

3.7 Rules and occupational health and safety

• Operation of the machine is always subject to the on-site safety and accident prevention regulations.

• Before the machine is put into operation: Always check the safety equipment and protective

covers.

• Unauthorised modifications and alterations to the machine are not allowed.

• External devices may be installed with the express written permission of the manufacturer

only.

• Assembly, installation, maintenance and repair of the machine may only be carried out by

service personnel who are authorised by the manufacturer.

• Before maintenance, repair and alteration work:

– Switch off the machine using the on/off switch.

– Safeguard against unauthorised persons turning the machine on by disconnecting the

switch box cables from the power supply.

3.8 Procedure in case of malfunctions

Any troubleshooting work or inspection on the machine may only be carried out when it is

switched off.

Safety devices must never be bypassed or rendered ineffective.

If malfunctions cannot be remedied by the operators using simple measures, then the responsible

service station must be informed.

29

Safety

© swissQprint AG, 2014

3.9 Danger areas

Operation is divided into the following work phases:

•Printing

• Adjustment work

•Material supply

Only one person is allowed to operate the machine during all operating stages.

Other requirements for a safe workplace:

• Keep your workplace clean.

• Do not place folders or similar objects on the operating desk or on the machine.

• Do not store any tools inside or on top of the machine.

• Personal property and items of clothing or protective equipment that have been removed

must not interfere with the operation of the machine.

30

Safety

© swissQprint AG, 2014

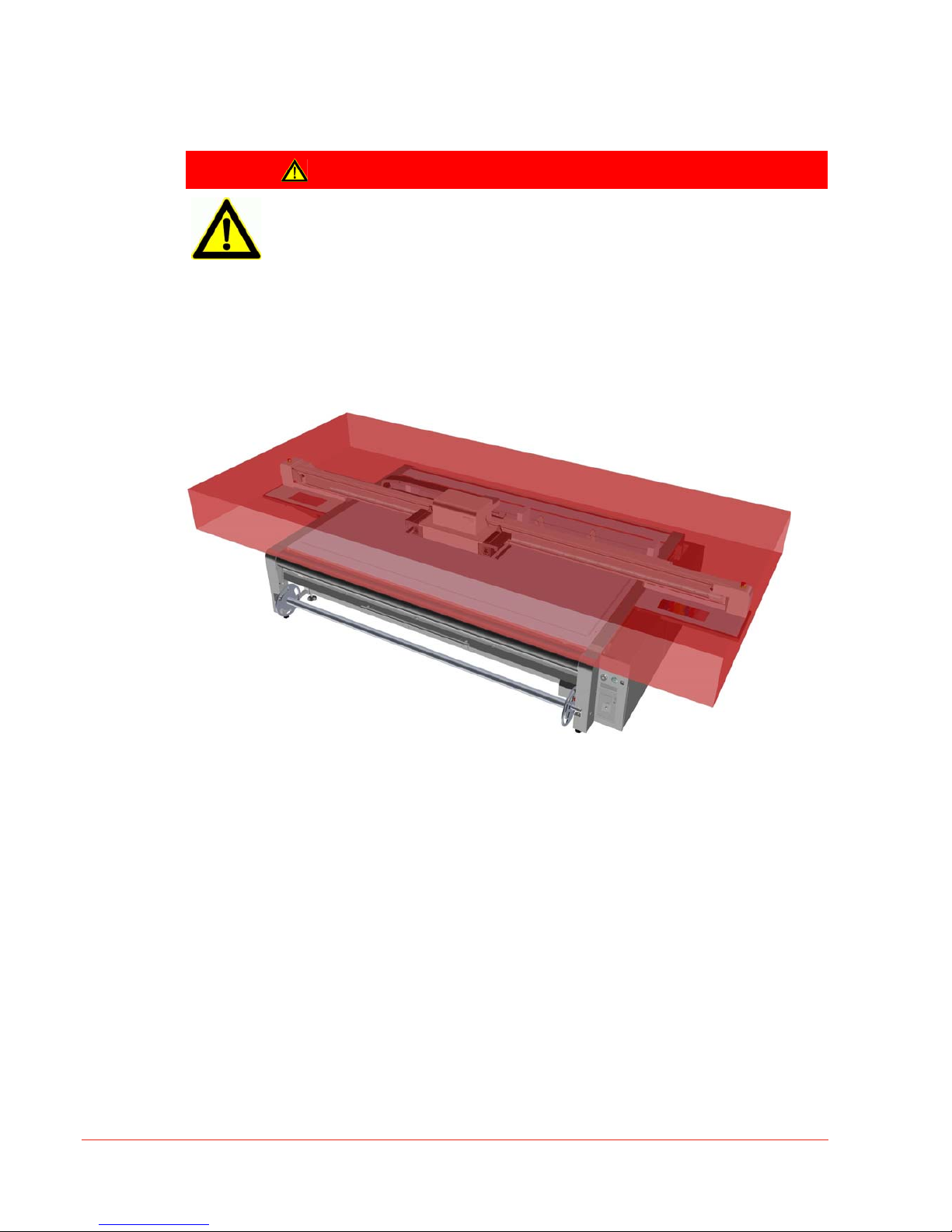

3.9.1 Printing, material supply, adjustment work

The working area of the operating personnel during the actual printing process is defined as follows:

Only one person allowed to operate the machine at the operating unit, to load material and to carry out settings work.

Danger!

Danger due to improper use.

The print head moves at very high speed and can cause very serious injury if the

machine is used incorrectly.

Never reach into the active area of the machine during printing or when the

machine is running.

Loading...

Loading...