Swiss Fluid SSV-B Series Product Manual

PRODUCT MANUAL PM

SSV-B: Product Info

82 Inline Sampling Ball Valves

PM 82 M.00 e

January 2007

Swissfluid AG, Industriestrasse 40, CH-5600 Lenzburg/Switzerland

info@swissfluid.ch

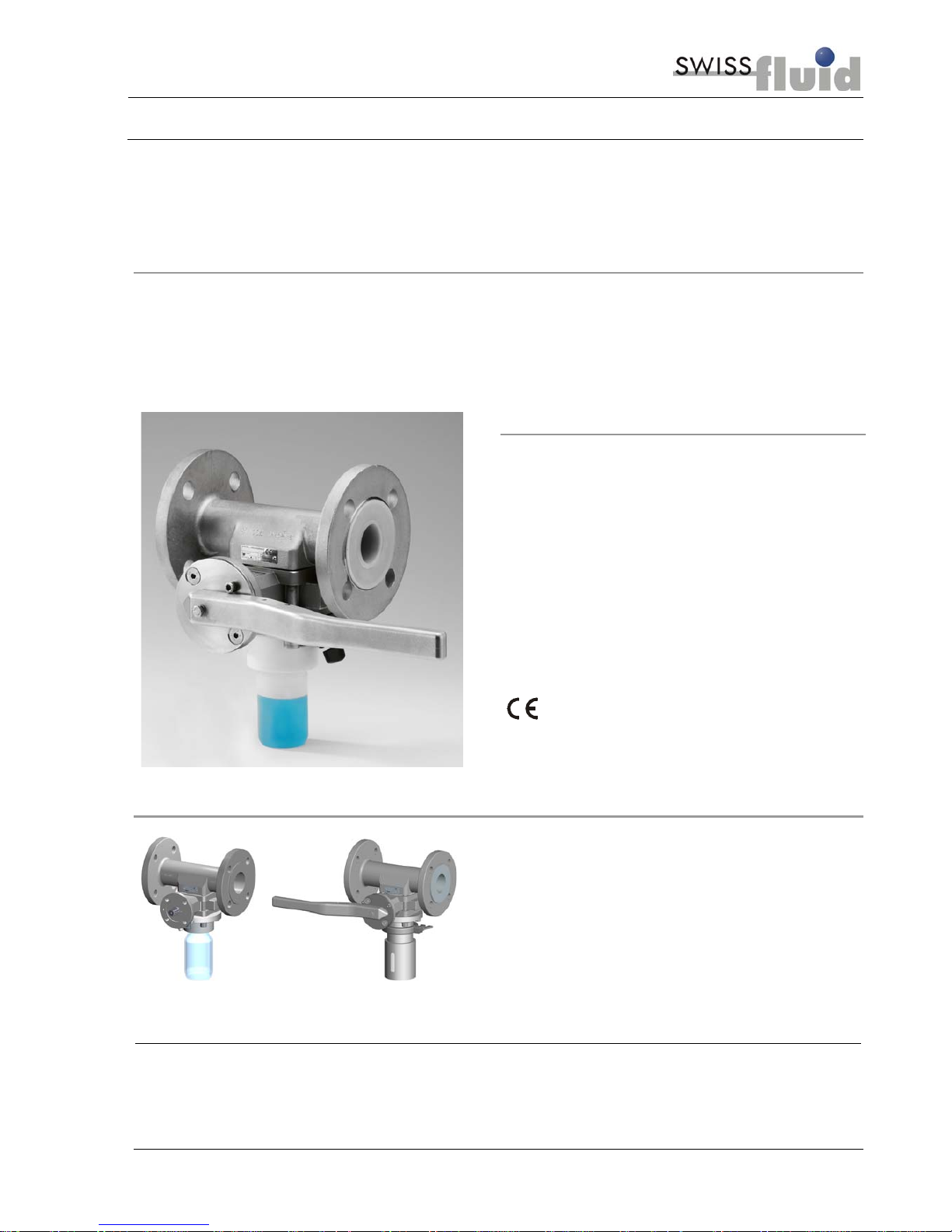

Inline Sampling Ball Valves SSV-B Series

for safe and representative sampling of aggressive or even toxic liquids from pressurized pipelines or vessels,

without any process interruptions.

Modular Design

Inline Sampling Ball Valves SSV-B Series are available as DIN- or ANSI-valves, with standard handlever for

90° operation. The valves are distinguished by its dead-space-free design as well as the extremely short

outlet way for the representative sample.

The sturdy bodies are made of stainless steel casting 1.4408 (CF-8M) or optional with resistant linings such

as PFA or PFA-AS (anti-static).

Hauptmerkmale

• Full-port design, no pressure drop

• Only one opening to the atmosphere

• Easy and safe operation handlever, optionally

with pneum. quarter turn actuator

• One-piece ball/shaft, PFA-encapsulated,

for defined sampling volume of approx. 45 ml

• All-purpose valve unit – installation on large size

pipelines, vessels etc.

• Sizes DN15 - 80 PN16, ½" - 3"-150lbs

• Face to face acc. to EN 558-1, range 1

Conformity acc. to European

Pressure Equipment Directive 97/23/EC (PED)

Standard Options / Accessories

Valve with bare shaft with handlever 180°and

spring-loaded protection tube

• Bodies with heating jacket

• Bottle support, adjustable

• Flange plate for 180° operation

• Safety cabinet with inspection windows

• Flanges with groove, PN40, ANSI 300lbs etc.

• Safety padlock

• Activated carbon filter

• Vertical adapter

• Metal safety basket

PRODUCT MANUAL PM

SSV-B: Technical Data, Construction

82 Inline Sampling Ball Valves

PM 82 M.01 e

January 2007

Swissfluid AG, Industriestrasse 40, CH-5600 Lenzburg/Switzerland

info@swissfluid.ch

Operating Conditions

• Temperature range from –40°C up to +200°C (depending on selected materials)

• Line pressure max. 16 bar

Testing / Marking

• Pressure- and tightness testing acc. to EN 12266-1, leakage rate A, and spark testing at 35 kV

to assure lining integrity. Marking of valves on body and name plate acc. to EN 19.

• Material- resp. test certificate acc. to EN 10204-3.1

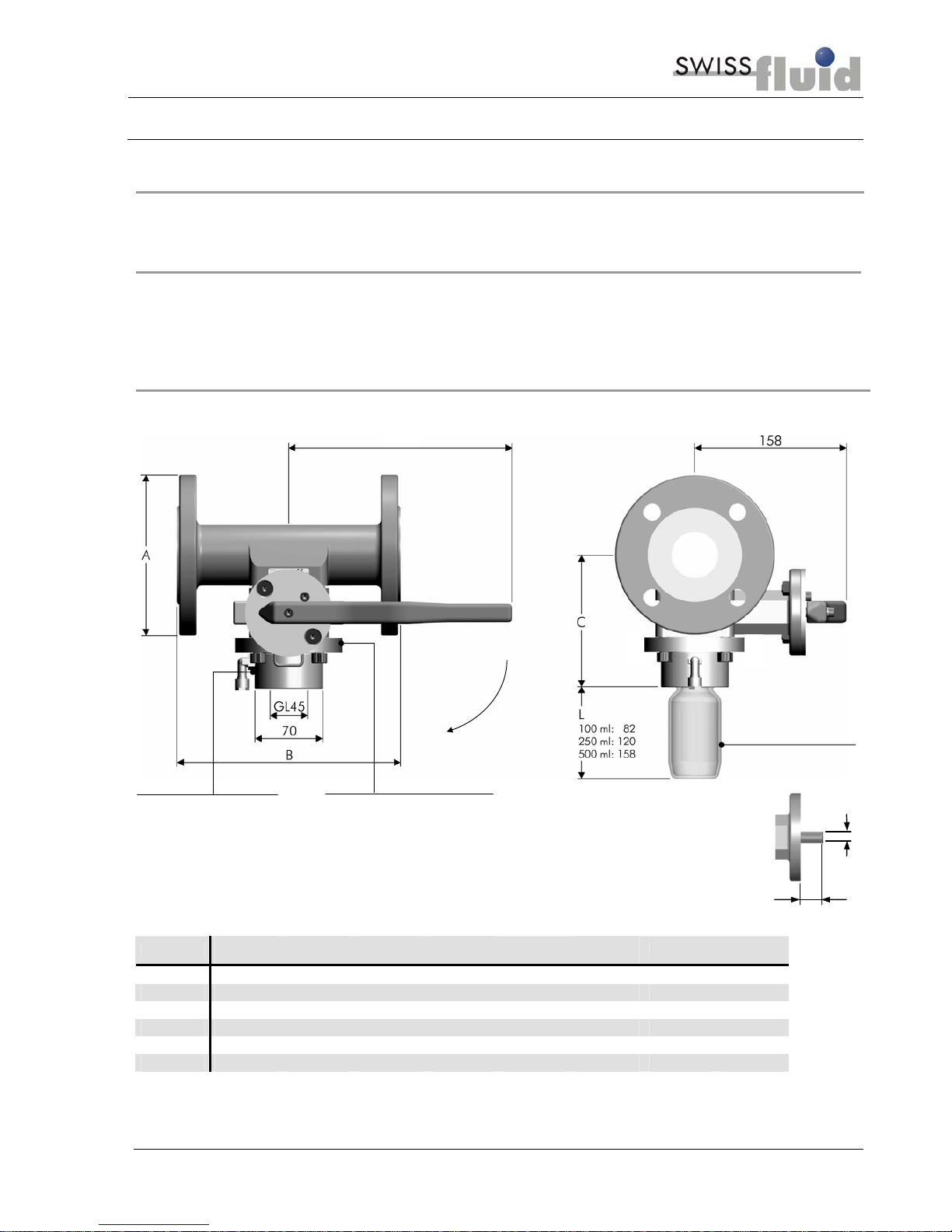

Construction of Valve

Technical Data Dimensions in mm (Kv = Cv / 1.16)

DN

A

DIN

A

ANSI

B

DIN

B

ANSI

C

Cv

m3/h

Nm** Kg*

15/½"

95 95 160 160 119 14 35 5.3

20/¾"

98 98 160 160 125 25 35 6.3

25/1"

115 108 160 165 125 58 35 6.8

40/1½"

150 127 200 165 132 145 35 8.9

50/2"

165 152 230 178 137 230 35 10.6

80/3"

200 190 310 203 151 620 35 16.0

F/F acc. to DIN EN 558-1 range 1 resp. range 3 and ASME B16.10

* Weights (estim. values, without bottle) ** Break-away torque without safety factor for pneum. quarter turn actuators

Bottle adapter made of

PTFE glassfibre-reinforced,

with PVDF vent connection

Sampling bottle

acc. to DIN 168-1

Valve block made of ss casting

1.4408 (CF-8M), valve seat of

PTFE and PFA-encapsul. ball

(core made of Duplex 1.4462)

270

Handle position 1:

taking sample from

process system

Volume/operation

approx. 45 ml

Position 2:

sampling into bottle

23

Bare Shaft

ISO flange F07

Ø14/

DD11

V

ent

Loading...

Loading...