Page 1

REPAIR MANUAL

ZT2560

Swisher Mower Co

Warrensburg, MO

Page 2

TABLE OF CONTENTS

1. If engine won’t crank

2. If engine won’t crank – continued

3. If engine cranks but won’t start

If engine stalls when PTO is engaged

4. If PTO clutch will not engage

Hour meter not operating

5. Wire identification at switches

6. Wire identification at switches – continued

7. Drive control adjustment

8. Drive control adjustment – continued

Drive control overview

9. Electrical components

10. Parking brake and neutral switch operation

11. Deck lifting system

12. Deck belt replacement

13. Repairing or replacing blade driver

14. Replacement Parts – Quick reference

Page 3

IF ENGINE WON’T CRANK

ALWAYS CHECK FUSE FIRST

TEST #1

Using a remote starter switch or suitable device, make a

connection between the large terminals on the solenoid.

If engine does not crank!!!

•Battery may be weak or dead

•Starter may be bad

•Battery cables may have bad connections

•Do not go to Test #2 until this test gives results

TEST #2

If engine did crank in test #1, disconnect green wire at

spade connector and apply positive voltage from the

battery to the primary wire on the solenoid. Make sure

the one with the eyelet is grounded. If engine doesn’t

crank now, replace the solenoid. Remember, all other

tests are useless unless these two tests make the

engine turn over.

TEST #3

If engine did crank in the first part of test #2, reconnect

green wire to solenoid. Make sure the drive controls are

out in neutral position. Using a jumper wire attached to

the positive terminal of the battery, apply 12 volts to

the red wire on terminal B of the ignition switch. Try to

crank, using the ignition switch. If engine cranks, the

fuse or the fuse holder, or related wiring is defective

somewhere back to the solenoid.

TEST #4

If engine did not crank in test #3, make sure the drive

controls are in neutral position. This time move the

jumper wire attached to the positive terminal of the

battery, to the green wire on S

switch. If all components in the circuit are working, the

engine should crank. If it doesn’t, move on to next test.

terminal of the ignition

1

Page 4

A neutral switch is located on the lower end of both

drive control handles and is activated when the handles

are outward in the neutral position. Check that the

plunger buttons on both switches are depressed at least

3/8”. Meter should go to zero when checking continuity

across switch terminals with plungers depressed.

If any of the switches in this circuit tested bad, install a new

one and perform Test #4 again. If all switches are good, a

connecting wire must be at fault. Don’t move past Test #4

until it assures a good circuit. When you do get good results,

hook all wires back to original position and try the ignition

switch again. If no results, you will need to replace the

ignition switch.

With PTO switch in

the off position, meter

should go to zero

when checking

continuity across these

two terminals.

2

Page 5

ENGINE CRANKS BUT WON’T START

Checks for electrical problems

•While turning ignition switch to its first position, listen for the fuel solenoid on the

carburetor to click. It must click to supply fuel to the carburetor.

•Try a new spark plug.

•Check for spark at plug when it is removed and the threaded end is grounded.

•Unplug the six-position socket that connects engine wiring to mower wiring harness.

Engine will still crank. If plug doesn’t have a spark now, ignition module is probably

defective.

Checks for mechanical problems

•Make sure the tank gas valve is turned on.

•Remove air filter element to check for signs of gas in the throat of the carburetor.

•If no gas, check to see if choke is working properly.

•If all above checks show positive, carburetor must have an internal problem. Remove and

clean the carburetor.

ENGINE STALLS WHEN PTO IS ENGAGED

The seat safety switch plug not being properly inserted, or a

defective plug can cause this problem. If the plug is not

inserted or is defective, the spark plug is grounded out when

the PTO is engage.

To check, remove plug from the PTO switch. Using an

ohmmeter, place one probe on the terminal connected to the

black wire going to the seat safety switch plug. Place the

other probe on a good chassis ground. The meter should be

on zero with no weight on the seat. Pulling the seat down

should open the circuit.

3

Page 6

IF PTO CLUTCH WILL NOT ENGAGE

Apply a negative ground to this terminal

Apply 12 volts to this terminal. Clutch should activate,

if it doesn’t, clutch is defective.

If clutch checks OK, use a voltmeter to measure if

there is 12 volts at the brown wire’s terminal. First

turn ignition switch to the ON position but don’t start

the engine. Now engage the PTO switch. For the first

test put the negative probe on a good ground, not on

the white wire’s terminal in the plug. If no voltage is

measured, move on to next test.

With the PTO switch ON there should be continuity

between these two connectors, if not, replace switch. If

switch tested good, check wires and connectors back

to ignition switch and back to clutch plug.

If all checked good in the two previous tests, the

problem may now be a poor ground on the white wire

in the clutch plug. Check by testing for continuity to

ground or check for voltage between the two terminals

HOUR METER NOT OPERATING

Hour meter has a positive and a

negative post. Gray wire should go on

the positive. Power is supplied from the

ignition switch.

Green wire from hour meter is

grounded by the oil pressure switch,

therefore only has a ground when the

engine is running.

4

Page 7

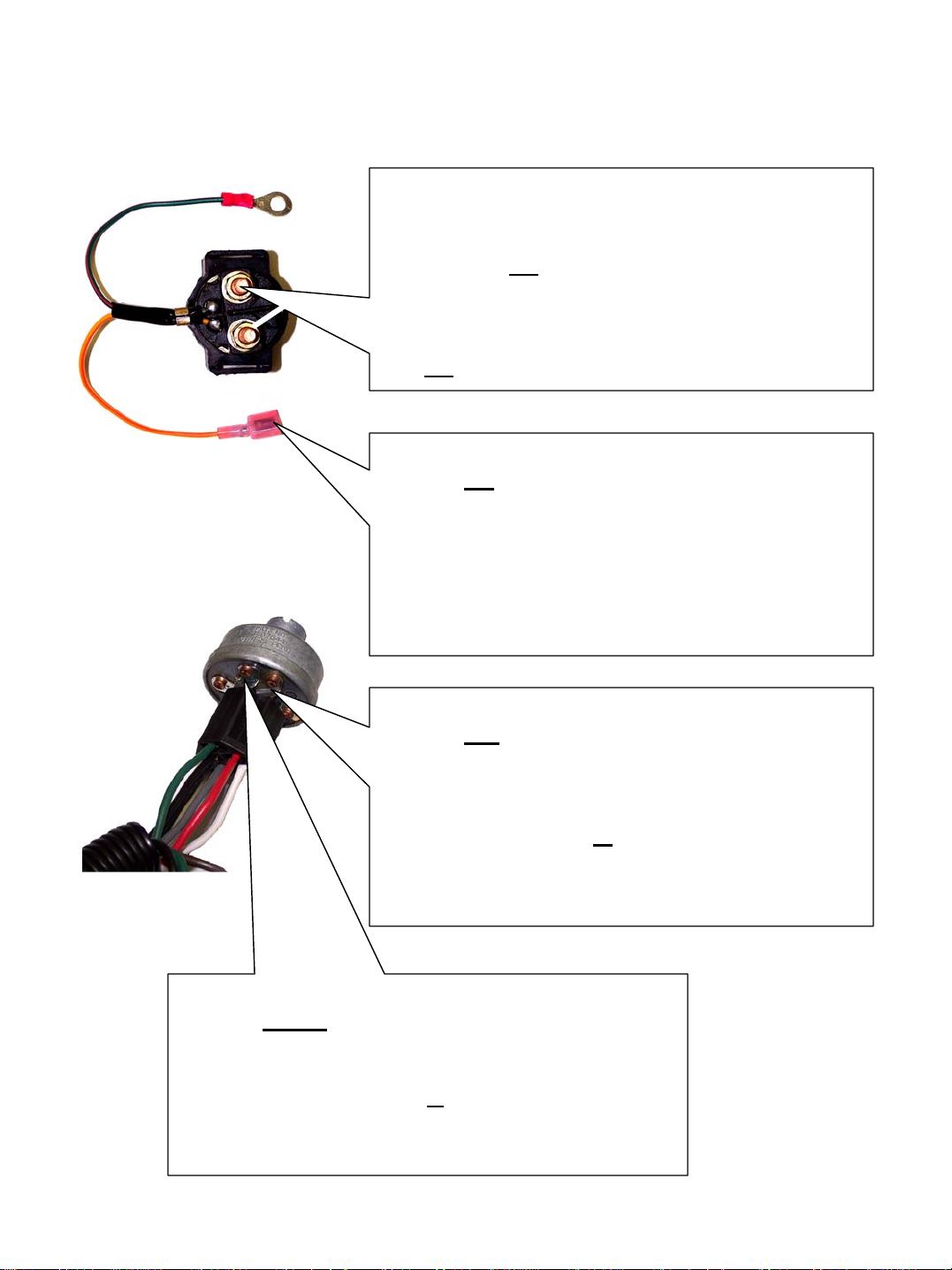

WIRE IDENTIFICATION AT SWITCHES

PTO switch and the other

goes to the hour meter

One black wire goes

to PTO switch and

the other goes to the

engine plug

3623 IGNITION SWITCH

Green wire goes to PTO switchOne gray wire goes to the

Red wire goes to fuse and

on to battery positive at

the solenoid terminal.

One white wire goes to clutch

and other one goes to ground.

STARTER SOLENOID

Green wire goes to

neutral switches

and on to the

ignition switch.

Green wire with

orange stripe goes

to the ground.

Red wire goes to

ignition switch.

Black wire goes to the

ignition switch.

Green wire goes to the

ignition switch.

Heavy red cable

goes to the starter.

Red wire goes

to engine plug.

Heavy red cable

goes to the

positive post of the

battery.

PTO SWITCH PLUG

Black wire goes to the seat

switch.

Green wire goes to the

neutral switches.

Gray wire goes to the

ignition switch.

Brown wire goes to the

clutch.

5

Page 8

WIRING HARNESS TO ENGINE PLUG CONNECTION

Gray wire goes to carburetor fuel solenoid

Green wire goes to oil pressure switch

Black wire goes to engine ignition module

Red wire goes to engine charging system

Green wire goes to hour meter

Red wire goes to terminal on solenoid

with the positive battery cable.

WIRING HARNESS PLUG TO ENGINE

Gray wire goes to hour meter

Green wire goes to hour meter

Black wire goes to the ignition switch.

Gray wire goes to hour meter

Red wire goes to

terminal on solenoid

with the positive

battery cable.

Black wire goes to the

ignition switch.

6

Page 9

Voltage

Regulator

BATTERY CHARGING SYSTEM

Red wire goes to the engine plug and

then on to the positive terminal of the

solenoid to keep the battery charged.

Easiest way to check if the charging is

taking place is to measure the DC

voltage of the battery before you start the

engine. Then start the engine. Measure

the voltage at the battery with the engine

running. The voltage should be at least

one volt higher right after the engine is

started. This voltage will drop a little as

the battery gets recharged.

To test alternator before it goes to the

regulator, unplug the yellow connector

and measure the AC voltage across the

the two gray wires inside this

connector.There should be at least 20

volts AC.

CARBURETOR FUEL SOLENOID

Black wire goes to engine ground.

Gray wire goes to the engine plug,

then on to the ignition switch where it

receives power to activate the fuel shut

off valve.

Fuel shut off solenoid is a Briggs part

and is available through them only.

7

Page 10

DRIVE CONTROL ADJUSTMENTS

LEFT SIDE SHOWN

Control plate shown

in neutral position

Hydro linkage

Start your adjustments by putting the

drive control arms in the neutral position.

Remove the linkage from the control

plate at the Eaton hydro by removing the

cotter pin and washer on the under side.

By moving the control plate forward and

backwards by hand you can easily find

the neutral position on the hydro.

With the drive control handles in the

neutral position, this linkage pivot should

be close to straight up and down.

With control plate on hydro still in the

neutral position, try to put hydro linkage

back into the hole on the plate. If it won’t

go in without forcing one way or the

other, adjust threads here to make an

easy hookup.

With the control linkage once again

removed, move the control plate forward

as far as it will go.

Move the control handle forward until

this linkage contacts the adjusting bolt in

front of it.Again try to put the control

linkage in to the control plate. Do not

adjust the control linkage to make this

happen, adjust the bolt in front instead.

This adjusting bolt will now be used to

set both drive wheels to pull equally.

With the control handles fully forward,

observe which side is turning the fastest.

Extend the bolt rear ward to slow the

travel of that side until they are pulling

the same on both sides.

8

Page 11

DRIVE CONTROL ADJUSTMENTS (CONTINUED)

LEFT SIDE SHOWN

Once both hydro units are pulling

equally, make your final control handle

adjustment with this ball linkage.

Whichever handle is going the farther

forward, lengthen the linkage on that

side until the handles are straight across

when mower is traveling in a straight

line. If a lot of adjustment is needed,

shorten the linkage on the opposite side

for half of the adjusting.

OVERVIEW OF DRIVE CONTROL LINKAGE

RIGHT SIDE SHOWN

Right side control handle

Pivot point for control handle movement

Adjustment threads on control rod

Pivot point

Forward and reverse control on hydrostat

9

Page 12

PARKING BRAKE AND NEUTRAL SWITCH OPERATION

Right side drive control handle.

Parking brake cable attaches here. Right

side is shown. Control panel has been

removed for better view.

Parking brake is activated by this bolt as

the drive control handle is swung

outward in the neutral position. Tension

on brake cable can be adjusted by raising

or lowering this bolt, but the main

adjustment is performed on the other end

of the cable down by the rear wheels.

Safety switch rocker arm

pivots on a bolt at this point.

This is the neutral safety switch that

prevents the engine from cranking unless

the drive controls are both swung

outward in neutral position. The switch

has a slotted mount bracket so the travel

of the push button can be adjusted to

depress about 3/8” to activate. Further

information about checking this switch is

found in the electrical diagnosing section

The parking brake can be adjusted by

moving the nuts on this cable. A nut is

located on each side of this frame. As the

outer cable moves forward, the brake

will become tighter.

10

Page 13

DECK LIFTING SYSTEM

Three rocker arms are activated by the

deck lift handle. This is the right side

control. Note the routing of the cable. It

drops straight below to the deck.

This center rocker arm lifts the front

center of the deck. It also drops through

the lower frame but is directed by two

pulleys under the mower frame to the

front of the deck.

The deck lift system has two springs to

assist in raising the deck. The ease of

lifting the deck can be adjusted by

tightening this nut equally on each

spring.

The guide pulley for the front center

deck lift cable.

Front guide pulley for the center lift cable.

To level the deck, start by lowering the

deck lift handle to its lowest position. If

the deck is not setting on the ground,

turn the nuts under these three brackets

until it does. The left and right cables in

the rear should then be tightened until

the back end of the deck is level across

and rides about 1\4 inch higher than the

front end.

11

Page 14

DECK BELT REPLACEMENT

ENGINE TO DECK BELT

•Lower the deck to lowest setting

•Loosen tension on tension idler

•Remove worn or damaged belt

•Using part# 10263 belt, route it around

the engine pulley as shown in the diagram.

•Retighten the tension idler and check the

operation

Belt coming from the electric clutch

will be routed around this idler pulley

on the outside.

Tension on belt can be

adjusted by tightening or

loosening this nut.

As belt leaves the previous idler pulley

it will be routed around this flat idler

pulley to the inside and then forward

to the deck.

DECK CROSS BELT

•Remove the belt covers

•Remove the engine to deck belt from

deck pulley

•Loosen the tension to the tension idler

•Remove the worn or damaged belt and

replace with part# 5058 belt

•Reinstall the engine to deck belt and

retighten both tension idlers

12

Page 15

REPAIRING OR REPLACING BLADE DRIVER

Torque top nut to 90 ft/lbs

Replacing this nut each

time is recommended.

Machine washers are used

to keep the pulley from

contacting the outer race

of the bearing. When

applying torque to the top

nut the pressure is to the

inner race only and onto

the shank on the inner

shaft.

Bottom end of the shaft

has the same ¾ in. SAE

threads as the top end.

This washer is wide

enough to to cover the full

bottom of the housing and

is used as a protector for

the seal in the bearing.

Machine washer used

as a spacer just like

those on top of the

upper bearing.

Since there are no hubs on

our pulleys, this Belleville

washer is important to apply

friction to the pulley to turn

the shaft. Make sure the

outer lip is down to best

contact the pulley.

Pulley does not have a hub.

When removing, just lift it

off like a washer, no puller is

needed.

Bearings are sealed. They

can be driven out and new

ones pressed in for repairing

the spindle assembly. It can

also be purchased as a unit

for easier repair.

This adaptor block is right

hand threaded onto the ¾ in.

shaft. Torque this block to

90 ft/lbs just like the nut at

the top of the shaft.

Install the blade adaptor block to the bottom of the shaft. Before applying torque, install the

blade to the block using only the outer two bolts. Leave the center bolt out for now. Block

the blade to outer deck edge by using a 4x4 or similar stop. Using a torque wrench on the

top nut above the pulley, apply 90 ft/lbs. The top nut and the adaptor block will equally

receive the tightening. Now put the washer on the center bolt and install into the shaft.

Torque the three bolts to 35 ft/lbs. The center bolt will lock the block so it won’t come off.

13

Page 16

For additional assistance on service

Contact Swisher Mower Co., Inc.

Phone 1-800-222-8183

Fax 1-660-747-3160

E-mail cust.serv@swisherinc.com

14

Loading...

Loading...