Page 1

ZTR2760BS, ZTR2760BS-CA, ZTR2460BS, ZTR2460BS-CA,

ZTR2460KA, ZTR2460KA-CA

27 or 24 HP (Briggs & Stratton), 24 HP (Kawasaki) – 60” Wide Cut

h

t

i

w

1602 CORPORATE DRIVE; WARRENSBURG, MISSOURI 64093

PHONE: 660-747-8183 FAX: 660-747-8650

TOLL FREE: 1-800-222-8183

Manufacturing quality lawn care equipment since 1945,

Celebrating over 65 years of innovation

18870 REV 12-302

OWNER’S MANUAL

STARTING SERIAL # L112-302001

Page 2

LIMITED WARRANTY

The manufacturer’s warranty to the original consumer purchaser is:

This product is free from defects in materials and workmanship for a period of two (2) years

from the date of purchase by the original consumer purchaser.

As required by CFR § 1060.120, the fuel system related components, which have been

certified to this equipment by SAI are to be free of defects in material and workmanship for a

period of two (2) years from the date of purchase by the original consumer purchaser.

We will repair or replace, at our discretion, parts found to be defective due to materials or

workmanship. This warranty is subject to the following limitations and exclusions:

1) Engine Warranty All engines utilized on our products have a separate warranty

extended to them by the individual engine manufacturer. Any

engine service difficulty is the responsibility of the engine

manufacturer and in no way is Swisher or its agents responsible for

the engine warranty. The Briggs & Stratton Engine Service Hotline is

1-800-233-3723. The Kawasaki Engine Service Hotline is

1-877-364-6404 or email kawpower-website@kmc-usa.com

.

2) Commercial Use This product is not intended for commercial use and

carries no commercial warranty.

3) Limitations This warranty applies only to products which have been

properly assembled, adjusted, and operated in accordance

with the instructions contained within this manual. This

warranty does not apply to any product of Swisher that has

been subject to alteration, misuse, abuse, improper assembly

or installation, shipping damage, or to normal wear of the product.

4) Exclusions Excluded from this warranty are normal wear, normal adjustments, normal

maintenance, and battery*(see battery section).

In the event you have a claim under this warranty, you must return the product to an authorized service

dealer. All transportation charges, damage or loss incurred during transportation of parts submitted for

replacement or repair under this warranty shall be borne by the purchaser. Should you have any

questions concerning this warranty, please contact us toll-free at 1-800-222-8183. The model number,

serial number, date of purchase and the name of the authorized Swisher dealer from whom you

purchased the mower will be needed before any warranty claim can be processed.

THIS WARRANTY DOES NOT APPLY TO ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES AND

ANY IMPLIED WARRANTIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR

ALL EXPRESSED WARRANTIES. Some states do not allow the limitation of consequential damages or

limitations on how long an implied warranty may last, so the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights and you may have other rights, which vary from

state-to-state. This is a limited warranty as defined by the Magnuson-Moss Act of 1975.

2

2

Page 3

LIMITED WARRANTY……..……

OPERATION & FEATURES…....

TABLE OF CONTENTS………..

Features…………………………………………

INTRODUCTION……………...…

Starting……………………………………………

General…………………………………………..

Grass Height of Cut…………………….

Before Operating…………………………..

Deck Level…………………………………….

Uncrating & Assembly…………………

Brake & Bypass………………..

SYMBOLS & DECALS………….

Controls………...……..………………………

SAFETY INSTRUCTIONS……….

Fuel Shut-Off Vavles…………….

General use & Safety Rules……….

SERVICE & ADJUSTMENTS..

Children Safety……………………………...

Adjusting Deck Height…………………

Slope Operation…………………………..

Parking Brakes…………………………….

ROPS & Seat Belt Use……….

Deck Belt Replacement…………….

General use & Safety Rules………..

Belt Replacement……………………….

Seat Adjustment…………………………….

RESPONSIBILITY……………….

PTO Clutch Adjustment………

Operator Presence……………………..

Tires……………………………………………….

WIRING SCHEMATIC…………..

Blade Maintenance………………………

PARTS BREAKDOWN…………..

Battery / Charging Tips….…………….

TROUBLESHOOTING……………

V-belts……………………………………………

MOWER IDENTIFICATION……..

Engine……………………………………………..

REPLACEMENT PARTS………..

Overall Unit Care………….……………….

NOTES…………………………..

Transporting Safety……………………..

SWISHER HISTORY……………..

SPECIFICATIONS……………..

Maintenance……….………………..………..

TABLE OF CONTENTS

2

3

4

4

4

5

6

7

7

8

14

14 -1 5

15

16

16

16

17

17

18

18

CUSTOMER

8

8

9

10

10

10

10

10 - 11

12

12

12

12

13

18

19

20

21

21

Hydro Expansion Tanks…….. 21

22-24

25-34

35-36

37

38

39

40

13

3

3

Page 4

INTRODUCTION

Congratulations!

Thank you for purchasing a Swisher Zero Turn mower. This machine is built for the greatest

efficiency and rapid mowing of large areas. Innovative handle control design and dual

commercial grade hydrostatic transmissions regulated by steering levers contribute to the

machine’s performance.

This manual is a valuable document. Following the instructions for use, service,

maintenance, etc. can greatly increase the lifespan of your machine .

NOTE:

If you have never used a Zero Turn mower before, refer to the Operation Controls section

of this manual before attempting to operate one for the first time.

General:

In this operator’s manual, left and right, backward and forward are used in relation to the normal

operator’s position.

Read Before Operating:

This machine is constructed only for mowing grass on lawns and other free and even ground without

obstacles. This machine is not intended for commercial use. The manufacturer’s directions concerning

operation, maintenance and repairs must be carefully followed.

This machine must only be operated, maintained and repaired by persons that are familiar with the

machine’s special characteristics and who are well versed in safety instructions.

Accident prevention regulations, other general safety regulations, occupational safety rules and traffic

regulations must be followed without fail.

Unauthorized modifications to the design of the machine may absolve the manufacturer from liability for

any resulting personal injury or property damage.

Read engine manufacturer’s operating and maintenance instructions.

Read and observe all safety instructions on your mower and in the manual.

Check engine oil.

Check fuel caps to sure that they are in place.

Know how to set the parking brake.

Be sure mower blades are turned off – PTO switch pushed down.

Know how to stop the engine – Turn key to off.

Know how to stop the unit – Return control handles to neutral.

4

4

Page 5

INTRODUCTION

Uncrating & Assembly:

Tools Required:

• Tire pressure gauge

• Nail bar or claw hammer

• Wire snips

To remove the mower from the crate:

Dispose of top and side panels of the crate.

Remove loose parts and packing material.

Cut any banding or strapping that may be holding the mower to the crate.

Disconnect the spark plug wire and place where it cannot make a connection.

Raise the mower deck to its highest position.

Disengage the parking brake by releasing the lock plates and lowering both handles down to

the “Disengaged” position. SEE INSTRUCTION DECAL ON FLOOR PAN OR GO TO

PAGE 16.

Open the transmission bypasses by pulling up on only the inside handle located below the

right side of the seat. SEE INSTRUCTION DECAL ON FLOOR PAN OR GO TO PAGE 16.

Carefully push the mower off the crate to a safe and level area.

Check engine oil. All engines are filled with oil and tested at the factory. Verify oil level

and add if necessary before starting engine. SEE ENGINE OWNER’S MANUAL.

Check the battery. If the battery is put into service after the “month & year” of the date

on the battery, then it may need to be charged with a 12 volt charger for a minimum of

one hour, but no more than 2 hours at a rate of 6 to 10 amps.

Close the transmission valves by releasing the lock plate and lowering the handle down to the

“Disengaged” position. SEE INSTRUCTION DECAL ON FLOOR PAN OR GO TO PAGE 16.

Reconnect spark plug wire.

Check tire pressure on all four wheels. REFER TO UNIT SPECIFICATIONS TABLE ON PAGE

12.

Read all operating instructions, safety instructions, and customer responsibilities

before operating this machinery.

5

5

Page 6

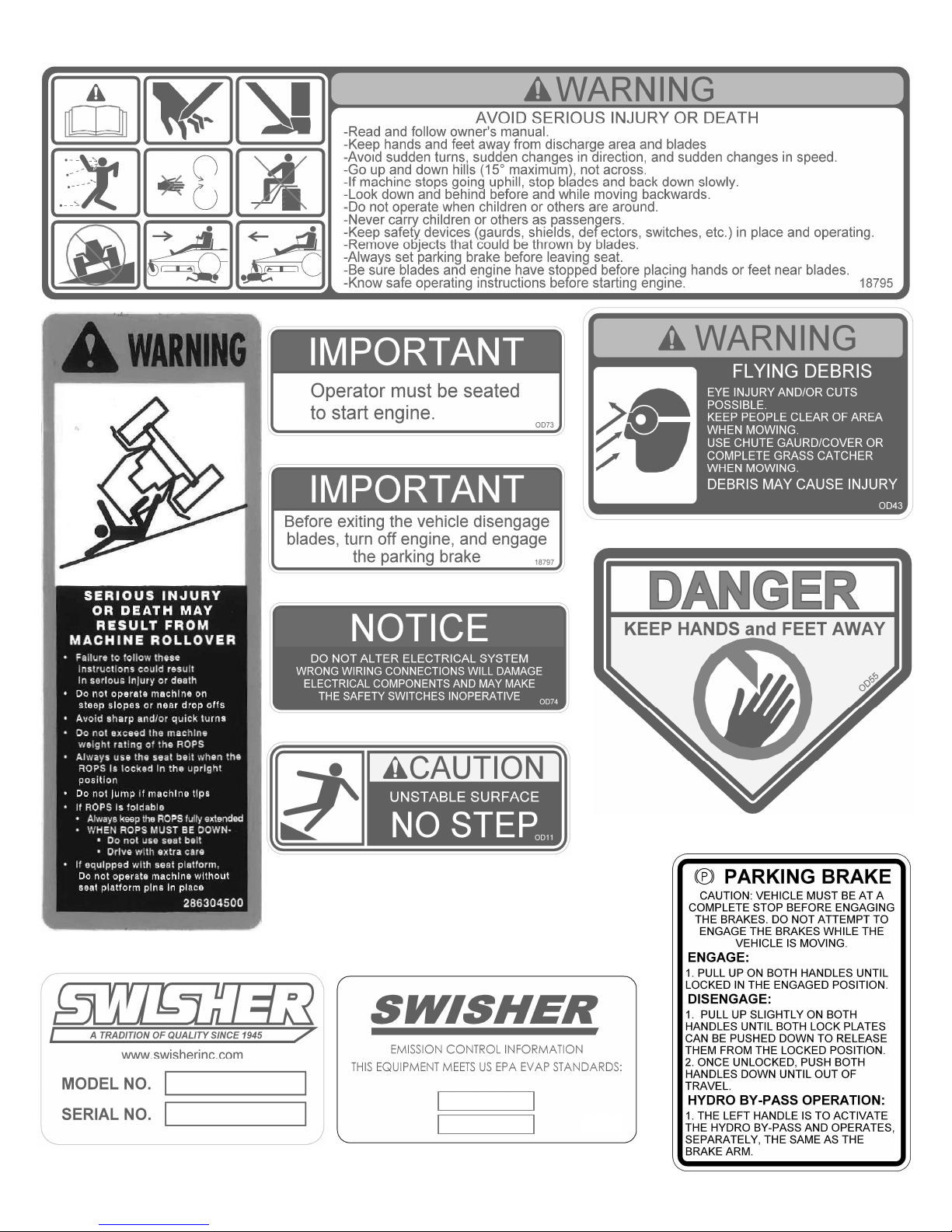

SYMBOLS & DECALS

18795 - Warning Decal

Operator must be Seated Decal - OD73

ROPS Warning Decal

Flying Debris Decal - OD43

Before Exiting Decal - 18797

Notice Do Not Alter Wiring Decal - OD74

Triangle Danger Decal - OD55

No Step Decal - OD11

Serial # ID Tag

EPA / CARB Certification Decal – 18904 / 18967

6

6

Brake / Bypass Decal - 18944

Page 7

These instructions are for your safety. Read them carefully.

General Use:

SAFETY INSTRUCTIONS

This Safety Alert Symbol indicates important messages in this manual. When

you see this symbol, carefully read the message that follows and be alert to the

possibility of personal injury.

Read all instructions in this operator’s manual and on the machine

before starting it. Ensure that you understand them and then abide

by them.

Learn how to use the machine and its controls safely and learn how

to stop quickly. Also learn to recognize the safety decals.

Only allow the machine to be used by adults who are familiar with its

use.

Make sure nobody else is in the area of the machine when you start the engine, engage the drive, or run the

machine.

Stop the machine if someone enters the work area.

Clear the area of objects such as stones, toys, steel wire, etc. that may become caught in the blades or thrown.

DO NOT use this machine without the Discharge Chute in place.

Stop the engine and disconnect the spark plug before cleaning the discharge deck.

Never take passengers. The machine is only intended for use by one person.

Always look around before and during reversing maneuvers.

Slow down before turning.

Disengage the blades when not mowing.

NOTE:

If you have never used a Zero Turn

mower before, refer to the Operation

Controls section of this manual

before attempting to operate one for

the first time.

Be careful when rounding fixed objects, so that the blades do not hit them.

Only operate the machine in daylight or other well-lit conditions.

Keep the machine a safe distance from holes or other irregularities in the ground.

Never use the machine if you are tired, if you have consumed alcohol or if you are taking other drugs or

medications that can affect your vision, judgment or coordination.

Beware of traffic when working near or crossing a road.

Never leave the machine unsupervised with the engine running.

Always shut down the blades, engage the parking brake, stop the engine and remove the ignition key before

leaving the machine.

Never allow children or other persons not trained in the use of the machine to use or service it. Local laws may

regulate the age of the user.

Make sure that you have first aid equipment close at hand when using the machine.

Never use the machine when barefoot. Always wear protective shoes or boots.

Always wear approved protective glasses or a full visor when assembling or driving.

Always wear approved protective ear protection.

Never wear loose clothing that can get caught in moving parts.

7

7

Page 8

SAFETY INSTRUCTIONS

Children:

Serious accidents may occur if you fail to be on guard for

children in the area of the machine. Children are often attracted

to the machine and mowing work.

Never assume that children will stay put where you last saw

them.

Keep children away from the mowing area and under close

supervision by another adult.

Shut off the machine if children enter the work area.

Remember:

The operator is responsible for

avoiding dangers or accidents.

WARNING

Never allow a child to ride with you.

Never allow children to operate the machine.

Be extra cautious near corners, bushes, trees or other objects

that block your view.

Slope Operation:

Remove obstacles such as stones, tree branches, etc.

Mow up and down, not side to side. Never drive the mower on

terrain that slopes more than 15 degrees.

Avoid starting or stopping on a slope. If the tires begin to slip,

shut down the blades and drive slowly down the slope.

Always drive evenly and slowly on slopes.

Make no sudden changes in speed or direction.

Avoid unnecessary turns on slopes, and if it proves necessary,

turn slowly and gradually downward, if possible.

Watch for holes, ruts or bumps. On uneven terrain, the machine

can tip more easily. Long grass can hide obstacles.

When using the machine,

approved personal

protective equipment shall

be used. Personal

protective equipment

cannot eliminate the risk of

injury, but it will reduce the

degree of injury if an

accident does occur. Ask

your retailer for help in

choosing the right

equipment.

Remember:

Drive slowly and use small movements of the steering controls.

Do not mow wet grass. It is slippery, and the tires can lose

their grip, allowing the machine slides.

Do not try to stabilize the machine by putting a foot on the

ground.

The operator is responsible for

avoiding dangers or accidents.

Roll Over Protective Structure (ROPS) & Seat Belt Use:

ALWAYS use the seat belt when the ROPS is in the upright and locked position.

Do not jump if machine tips.

If ROPS is foldable:

• Always keep the ROPS fully extended.

• WHEN ROPS MUST BE DOWN:

- Do not use seat belt.

- Drive with extra care.

If equipped with foldable seat platform, Do not operate machine without seat platform bolts in place.

8

8

Page 9

SAFETY INSTRUCTIONS

General Use Continued…

Mowing Safety:

WARNING – Gasoline is highly flammable.

• Store fuel in containers specifically designed for this purpose.

• Refuel outdoors only and do not smoke while refueling.

• Add fuel before starting the engine. Never remove the cap of the fuel tank or add gasoline while the engine is

running or when the engine is hot.

• If gasoline is spilled, do not attempt to start the engine but move the machine away from the area of spillage

and avoid creating any source of ignition until gasoline vapors have dissipated.

• Replace all fuel tanks and container caps securely.

Replace faulty or damaged muffler.

Before using, always visually inspect to see that the blades, blade bolts and cutter assembly are not worn or

damaged. Replace worn or damaged blades and bolts in sets to preserve balance.

On multi-bladed machines, take care as rotating one blade can cause other blades to rotate.

Maintenance & Storage:

Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

Never store equipment with gasoline in the tank inside a building(s) where fumes can reach an open flame or spark.

Allow the engine to cool before storing in any enclosure.

To reduce the fire hazard, keep the engine, muffler, battery compartment and gasoline in storage area free of grass,

leaves or excessive grease.

Check the grass chute frequently for wear or deterioration.

Replace worn or damaged parts for safety.

If the fuel tank has to be drained, this should be done outdoors in an approved gasoline container and/or properly

disposed of.

When machine is to be parked, stored or left unattended, lower the deck unless a positive mechanical lock is used.

Training:

All drivers should seek and obtain professional and practical instruction. Such instruction should emphasize:

The need for care and concentration when working with ride-on machines.

Control of a ride-on machine sliding on a slope will not be regained by the application of the brake. The main

reasons for loss of control are:

• Insufficient wheel grip.

• Being driven too fast.

• Inadequate braking.

• The type of machine is unsuitable for its task.

• Lack of awareness of the effect of ground conditions, especially slopes.

• Incorrect hitching and load distribution.

Operation:

Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect.

When using any attachments, never direct discharge of material toward bystanders nor allow anyone near the

machine while in operation.

Never operate the machine with defective guards or without safety protective devices in place.

Do not change the engine governor settings or over-speed the engine. Operating the engine at excessive speed can

increase the hazard of personal injury.

Disengage drive to attachments, stop the engine and disconnect the spark plug wire(s) or remove the ignition key:

• Before clearing blockages or unclogging chute.

• Before checking, clearing or working on the machine.

• After striking a foreign object, inspect the machine for damage and make repairs before restarting and

operating the equipment.

• If the machine starts to vibrate abnormally (check immediately), stop the engine and disengage drive to

attachment.

• Before refueling.

• Before removing the grass chute.

• Before making height adjustment unless adjustment can be made from the operator’s position.

9

9

Page 10

CUSTOMER RESPONSIBILITIES

Operator Presence System:

Be sure check that the operator presence and interlock systems are working properly before every use. If your

mower does not function as described, repair the problem immediately.

The engine should not start unless the parking brake is engaged and the PTO (Blade Engagement Switch)

is disengaged (pressed down).

– See OPERATION FEATURES section of this manual

When the engine is running and the brake is disengaged, the operator should never leave the seat without first

setting the parking brake and shutting off the engine. If the operator attempts to leave the seat without first setting

the brake, the engine should shut off.

When the engine is running and the PTO switch is engaged, any attempt by the operator to leave the seat without

first disengaging the PTO switch, should shut off the engine.

The PTO switch should never engage without the operator on the seat.

Tires:

Maintain proper air pressure in all tires (SEE SPECIFICATIONS section)

Keep tires free of gasoline, oil or insect control chemicals which can harm rubber.

Avoid stumps, stones, deep ruts, sharp objects and other hazards that may cause tire damage.

Blade Maintenance:

For best results, mower blades must be kept sharp.

Replace bent or damage blades.

Engage brakes & safely raise front of mower (SEE WARNING).

Hold or block blade from turning.

Loosen blade nut and remove blade.

Replace blade (SEE SPECIFICATIONS).

Battery:

To clean battery and terminals

Remove the BLACK terminal gaurd.

Disconnect the BLACK battery cable and locate it where it

cannot come into contact with the battery.

Remove the RED terminal guard.

Disconnect the RED battery cable and locate it where it

cannot come into contact with the battery.

Remove the battery.

Rinse the battery with plain water and dry.

Clean terminals and battery cable ends with wire brush

until shiny.

Coat terminals with Dielectric Grease or Petroleum Jelly.

(This helps seal and prevent corrosion.)

Reinstall battery.

Reconnect the battery cables. Attach the RED cable first

then the BLACK cable.

CAUTION

Stop engine, apply brakes, and remove

ignition key for safety. Disconnect spark

plug wire. Wear heavy, thick gloves

when holding onto blade. Avoid the sharp

edge of the blade.

WARNING

When it is necessary to raise the mower

for any repair or service, use jackstands

to provide adequate support. DO NOT

rely on hydraulic or mechanical jacks.

WARNING

The battery contains sulfuric acid and

electrolytes which are poisonous and

corrosive.

10

10

Page 11

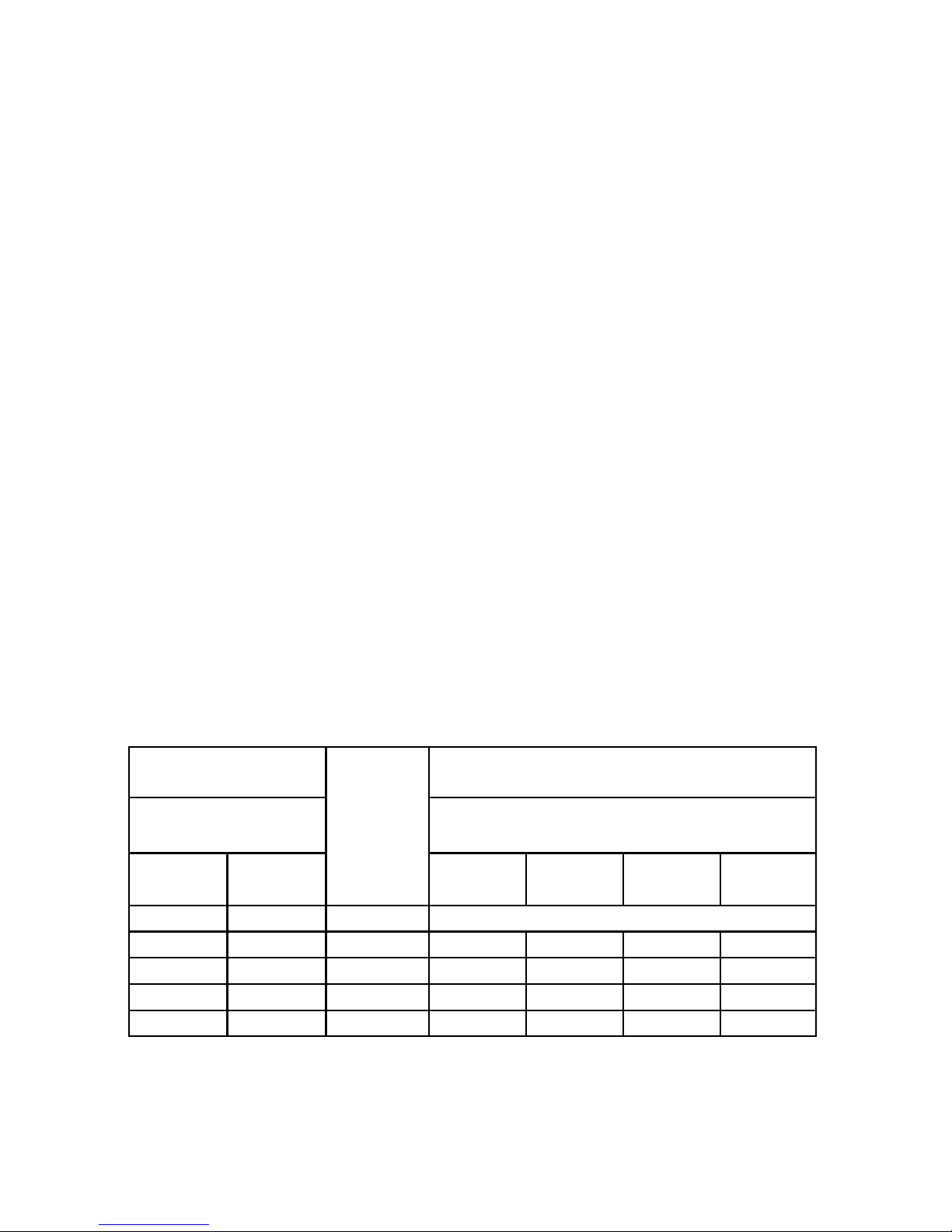

CHARGING TIPS

APPROX. BATTERY CHARGING TIME *

To avoid a battery explosion, never attempt to charge a frozen battery.

Warning: Gel and AGM (Absorbed Glass Mat) batteries require a voltage-limited

charger. Charging a Gel or AGM battery on a typical shop charger, even one time, may

greatly shorten its life.

Important: Never overcharge batteries. Excessive charging will shorten battery life.

Prior to charging, read the manufacturer’s instructions for proper charger hook-up and

use.

Turn off charger prior to hookup to avoid dangerous sparks. PROTECT YOUR EYES!

Warning: If the electrolyte is accessible, verify that plates are covered before beginning

to charge. At the end of charge, add distilled water as needed to bring levels to the

proper height. If water is added, charge for an additional 30 minutes to mix. If electrolyte

levels are low but battery is not accessible, remove battery from service.

The maximum charge rate in amperes should be no more than 1/3 of the battery’s

reserve capacity minute rating. If the terminal voltage exceeds 16.0 volts while charging,

reduce the charge rate.

Continue charging and reduce the rate as needed until a 2 hour period results in no

increase in voltage or decrease in current.

If violent gassing or spewing of electrolyte occurs or the battery case feels hot to the

touch, temporarily reduce or halt charging.

VOLTAGE

STANDARD

BATTERY

6 V 12 V 50 AMPS 30 AMPS 20 AMPS 10 AMPS

6.3 12.6 100%

6.2 12.4 75% 20 MIN. 35 MIN. 48 MIN. 90 MIN.

6.1 12.2 50% 45 MIN. 75 MIN. 95 MIN. 180 MIN.

6 12 25% 65 MIN. 115 MIN. 145 MIN. 280 MIN.

5.9 11.8 0% 85 MIN. 150 MIN. 195 MIN. 370 MIN.

STATE

OF

CHARGE

TO FULL CHARGE AT 80oF/27oC

MAXIMUM RATE AT

FULL CHARGE

* Test wet batteries every 4-6 months and recharge if necessary.

Always test and charge if necessary before installation.

11

11

Page 12

CUSTOMER RESPONSIBILITIES

V-Belts:

Check V-belts for deterioration and wear before each use and replace if necessary. Replace belts if they begin to

slip from wear. SEE SPECIFICATION for belt part numbers and SERVICE section of this manual for instructions

on how to replace the belt.

Engine:

REFER TO YOUR ENGINE OWNERS MANUAL.

Overall Unit Care:

Reduce the risk of fire by removing grass, leaves and other debris that may have accumulated on the

machine.

Allow the machine time to cool before cleaning or putting it in storage.

Wash mower periodically. Clean above and below deck.

Keep all electrical connections clean and tight.

Driving & Transport on Public Roads:

Check applicable road traffic regulations before driving and transporting on public roads.

If the machine is transported, you should always use approved fastening equipment and ensure that the

machine is well anchored to the towing vehicle.

The cutting deck should also be lowered to the lowest position and the parking brake engaged during transport.

Specifications

DUAL 4.0 GAL TANKS; UNLEADED REGULARGASOLINE CAPACITY AND TYPE

SEE ENGINE MANUALOIL TYPE (SPI-SF-SJ):

SEE ENGINE MANUALSPARK PLUG

0 – 8 mphGROUND SPEED

FRONT: 12 X 6 X 6 w/ 5/8 Bearing / REAR: 20 X 10 X 10TIRE SIZE

FRONT: 40 psi Max / REAR: 22 psi MaxTIRE PRESSURE

12V / Heavy Duty 275 CCA / Type U1LBATTERY

27 ±3 ft. lbsHYDRO BOLT TORQUE

35 ft. lbsBLADE BOLT TORQUE

1.5” – 6”CUTTING HEIGHT

60” – Three 20 ½” Gator™ Mulching Blade SystemCUTTING WIDTH

UNIT MEASUREMENTS

Manual LeverPARKING BRAKE

Welded / 1 x 2 x 3/16” Wall Steel Tubing FRONT AXLE

18” Back w/ Arm Rest / 4” Adjustable Slide / Seat BeltSEAT

Commercial Grade Hydro-Gear ZT-2800TRANSMISSION

Foot Operated, Spring AssistedDECK LIFT

LENGTH: 81”

WIDTH: 68” (Including Grass Chute)

HEIGHT: 66 ½” / 46” (w/ ROPS folded down)

WEIGHT: 816 lbs

12

12

Page 13

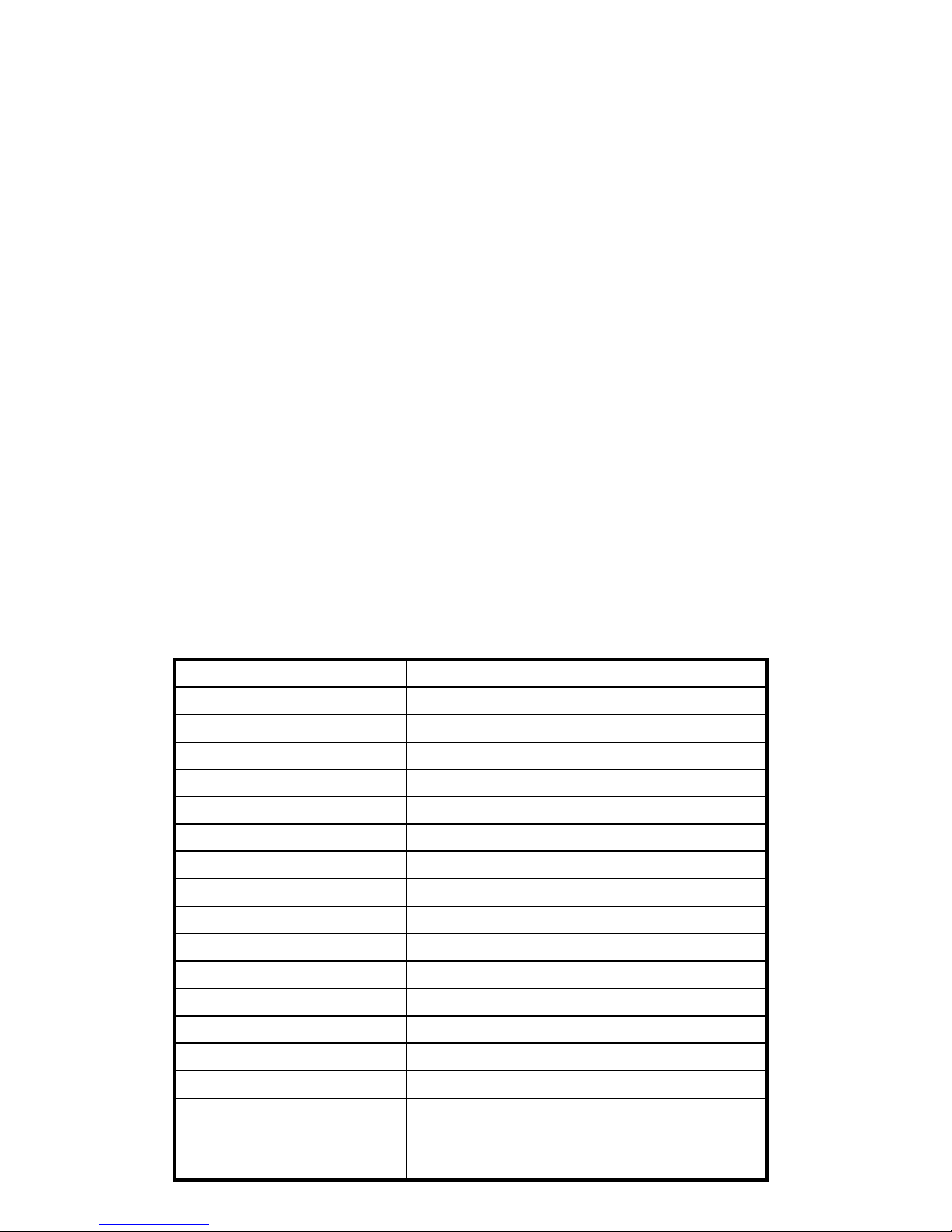

CUSTOMER RESPONSIBILITIES

Maintenance Schedule

Check Brake

Operation

Check Tire

Pressure

Check Operator

Presence

Parking Brake

Check for Loose

Fasteners

Sharpen/Replace

Mower Blades

Check Battery

Clean Battery &

Terminals

Before

Each

Use

X

X

8 Hours 25 Hours 50 Hours 100 Hours Season

XX

XX

X3

Before

Storage

XXX

XX

XX

Check Belts

Check Engine Oil

Change Engine Oil

w/ filter

Change Engine Oil

w/o filter

Replace Oil Filter

Clean Air Filter

Inspect Muffler

Clean Engine

Cooling Fins

Replace Spark Plug

Replace Fuel Filter

X

XX

X1,2

X1,2

X1,2

X2

X

X2

XX

X

1 – Change more often when operating under a heavy load or in high ambient temperatures.

2 – Service more often when operating in dirty or dusty conditions.

3 – Replace blades more often when mowing in sandy soil.

13

13

Page 14

OPERATION & FEATURES

1

7

5

11

14

6

8

4

15

13

10

8

3

2

9

12

1. Throttle Control – Used to control Engine

Speed.

2. Hour Meter – Indicates hours of operation.

3. PTO Switch – Used to engage or disengage

the deck blades.

4. Ignition Switch – Used to start or stop the

engine.

5. Deck Lift Pedal – Used to raise and lower

the cutting deck.

6. Control Lever – Sets the speed of the

mower in both the forward and reverse

directions and also turns the mower.

7. Hydro Bypass – Engages transmissions for

normal operation and disengages

transmissions for pushing or pulling the unit.

8. Fuel Tanks – Dual 4.0 gal.

9. Seat Slide

10. Battery

11. Discharge Chute

12. Front Receiver Hitch

13. Rear Receiver Hitch (Not Shown)

14. Brake Lever

15. Toolbox / Storage compartment

14

14

Page 15

OPERATION & FEATURES

Left Control Panel Right Control Panel

1 3 2 9 4 8 6 5 7

1. PTO / Blade Engagement Switch

2. Hour Meter – Indicates hours of operation

3. Safety Starting Interlock Switch

4. Key Switch

5. Choke Cable (Only on 24HP Kawasaki

Engines & 24HP Briggs & Stratton Engines)

NOTE:

If you have never used a Zero Turn mower before, refer to the Operation Controls section of this

manual before attempting to operate one for the first time.

6. Throttle Control Cable

7. 12V Accessory Outlet Plug

8. Starting Instructions Decal

9. Accessory hole for On/Off Toggle Switch

(P/N 18782)

Starting:

Starting Instructions are also included on the right side control panel decal.

Before starting the vehicle, be sure all people are clear of the area.

Operator must be sitting in the seat. Control handles must be in the neutral (vertical) position.

PTO must be in the disengage position (pushed down). Brake must be engaged.

Depress interlock button on left control panel and turn ignition key simultaneously until engine runs.

Once started, set engine RPM to maximum (Fast) and then engage the blades.

15

15

Page 16

OPERATION

Grass Height & Cutting Suggestions:

Do not attempt to cut wet grass.

The average lawn should be cut to 2 ½” during the cool season and to over 3” during the hot

months. For healthier and better looking lawns, mow often and after moderate growth.

As a rule, never cut more than 1/3 of the total grass blade length. Correct mowing height can

reduce weeds and lawn disease.

For best performance, grass over 6 inches in height should be mowed twice. The first cut

should be set relatively high and the second set to the desired height.

For best looking results and a healthier lawn, mow in different directions each time you mow.

• Example: If you mow going north and south, the next time you should mow going east

and west.

Deck Leveling

Deck leveling is not required as the deck is set level from the factory.

• The only instance where the deck would not be level is if a component(s) is damaged or

broken, which in this instance would need to be replaced.

Brake / Transmission Bypass Operation

Brake:

Be sure the vehicle is not moving before engaging the brake. Only engage the brake on level ground.

DO NOT engage the brake on an inclined surface.

To engage, pull up on the brake handle (outside lever) until the locking plate is seated in the locked

position. Note both handles will come up as they are linked together for the brake application.

To disengage, push down on both lock plates until they are released from the locked position.

Once unlocked, push both arms down until they are out of travel.

Bypass:

Engaging the Transmission bypass will cause the rear wheels to turn freely. Only engage the bypass

on level ground. DO NOT engage the bypass on an inclined surface.

To engage the Transmission bypass, pull up on the by-pass handle (inside lever) only. Note only this

handle should come up.

To disengage, push down on the lock plate until it is released from the locked position. Once unlocked,

push the arm down until it is out of travel.

16

16

Page 17

OPERATION

Controls

Be familiar with all controls, their functions and how to operate them before starting the

machine.

Motion control levers on each side of the console control the direction of movement.

SEE FIGURE BELOW

Control Handles

Neutral Position Slow Forward

Fast Forward

90° Right Turn 90° Left Turn Slow Reverse

NOTE:

If you have never used a

Zero Turn mower before,

refer to the Operation

Controls section of this

360° Right Turn

360° Left Turn

manual before attempting to

operate one for the first time.

Note: The pressure required to operate the mower is very slight.

Fuel Shut-Off Valves

The Swisher ZTR2760BS, ZTR2460BS & ZTR2460KA are equipped with two shut-off valves, one for

each tank. These are located behind the seat and in front of the engine.

Only one tank should be used while operating the machine. When that tank runs empty or is close to

running empty, turn off that fuel shut-off valve and turn on the opposite shut-off valve. Operating the

machine with both valves open could cause the system to pull air from an empty tank.

“ON” Position

(Parallel with fuel line)

17

17

(Perpendicular with fuel line)

“OFF” Position

Page 18

manual parking brake linked

SERVICE & ADJUSTMENTS

Adjusting The Cutting Height

Push forward on the Deck Lift Pedal to raise the deck and place the locator pin in one the of the eight

hole positions to set the desired cutting height. Once the desired height is selected, slowly release the

pedal until the locator pin is engage by the deck lift.

Position 1 is the highest setting and Position 8 is the lowest position.

The cutting range is from approximately 2” to approximately 6”

Parking Brakes / Transmission Bypass Adjustments

The Swisher ZTR2460BS, ZTR2760BS & ZTR2460KA are equipped with a

with transmission bypasses. This system must be engaged by the operator before starting the vehicle

and also before exiting the vehicle.

Only when the control handles are in the neutral position and the machine is not moving should the

brakes be engaged. DO NOT attempt to engage the brake while the vehicle is moving or on an inclined

surface.

Adjustments for the system are located on the right side between the fuel tank and the seat.

Checking if adjustments are needed:

•Raise wheels off the ground and place jack

stands underneath the vehicle.

•Engage the brakes. To see if the brakes are fully

engaged, spin the rear wheel by hand.

•If the rear wheels spin more than 10° while the

brake is set to engaged then adjustments are

needed.

Making Adjustments:

•Disengage the brake before performing

adjustments.

•Start by loosening the front adjustment nut.

•Tighten the rear adjustment nut while making

sure the cable bulkhead does not spin. Pliers

may be needed to keep the bulkhead from

spinning.

Make small adjustments approximately

an ⅛” to a ¼”.

•Tighten the front adjustment nut once all

adjustments are made.

•Re-engage the brake to check if the adjustments

were enough to fully engage the brakes. If not

repeat the previous steps until the wheels can no

longer spin more than 10° while brakes are set to

engaged.

5

2

4

1. Cable(s)

1a. Cable Bulkhead

2. Front Adjustment Nut

3. Rear Adjustment Nut

4. Mount Plate

5. Brake/Bypass Arm

Front Rear

WARNING

When it is necessary to raise the mower for

any repair or service, use jack stands to

provide adequate support. DO NOT rely on

hydraulic or mechanical jacks.

3

1a

1

18

18

Page 19

SERVICE & ADJUSTMENTS

Deck Belt Routing & Replacement

For replacement belt part number refer to Replacement Parts Quick Reference Chart in this manual.

Removal

Disconnect spark plug wire.

Apply parking brake.

Lower the deck to its lowest position.

Remove the belt covers.

Disconnect tension idler(s).

Roll the belt over the top of the deck pulleys.

To remove the Deck Idler belt the Engine-to-Deck

belt will need to be removed first.

1. Engine-to-Deck belt

2. Deck idler belt

3. Deck pulleys

4. Inside deck idler

5. Backside deck idler

6. Engine-to-Deck belt idler tensioner

7. Deck idler tensioner

8. Engine Clutch

Replacement

nstall new belt by placing it around the deck pulleys. Refer to routing diagram below.

I

The belt will be loose at this time.

Tightly secure the belt tension back to its original position.

Reinstall the belt covers.

Check for sufficient tension on all belts.

Reconnect the spark plug.

Front of Unit (Top View)

6 33

5

8

Rotation

19

19

24

7

1

Page 20

SERVICE & ADJUSTMENTS

Hydro Belt Routing & Replacement

For replacement belt part number refer to Replacement Parts Quick Reference Chart in this manual.

Removal

Disconnect spark plug wire.

Apply parking brake.

Remove both hydro fan covers (18691TK).

Disconnect wiring from electric clutch.

Remove clutch stop (18667TK).

Remove the engine-to-deck belt.

Loosen the tension on the idler spring.

If loosening the spring is not enough, disconnect the

idler spring from eyebolt completely.

Remove belt from the engine pulley and from the hydro pulleys.

1. Left side hydro

2. Right side hydro

3. Hydro belt

4. Engine pulley / Clutch

5. Pivoting idler

6. Idler spring

7. Idler eyebolt

8. Inside stationary idler

9. Large backside stationary idler

10. Small backside stationary idler

11. Clutch stop

Replacement

nstall new belt by placing it around the hydro pulleys first, then around the idler pulleys and engine

I

pulley. Refer to routing diagram below.

The belt will be loose at this time.

Tightly secure the belt tension back to its original position.

Reinstall the engine-to-deck belt.

Reconnect wiring to the electric clutch.

Reattach the clutch stop in the groove of the clutch.

Reattach the hydro fan covers.

Check for sufficient tension on all belts.

Reconnect spark plug wire.

6

7

5

3

1

10

Rear of Unit (Bottom View)

Rotation

4

11

8

2

9

20

20

Page 21

SERVICE & ADJUSTMENTS

Seat Adjustment

The Swisher ZTR2760BS, ZTR2460BS & ZTR2460KA are equipped with a 4” range sliding

seat.

Release the tension on the seat adjustment lever by pushing the grey tip lever to the left.

SEE FEATURES section in this manual.

Using your own weight, slide the seat to the desired position.

Release the lever and be certain you feel the seat slide lock into place.

PTO Clutch Adjustment

Please visit www.ogura-clutch.com/files/pdfIMP/PTOinstallation.pdf to view maintenance,

adjustment and installation instructions.

Hydro Expansion Tank Oil Levels

The Swisher ZTR2760BS, ZTR2460BS & ZTR2460KA are equipped with two hydrostatic

transmission expansion tanks to allow for oil expansion during regular use. These are located

directly behind the seat and in front of the engine.

Oil levels in both expansion tanks (when oil is cold or at ambient temperature) should always

be kept at the “full cold” line. Note: Oil levels could rise above this line once the oil has been

used and has increased in temperature. Wait until oil has cooled back to the ambient

temperature before checking the oil levels. See image below for reference.

If oil level in either tank is below the “full cold” line please remove the cap and add *oil to the

tank until it reaches the “full cold” line.

*Only use SAE 20w-50 engine oil; preferably with the following specifications:

•Viscosity Rating: 162 @ 40°C / 18.1 @100°C

•13cSt & 9cSt min @ 110°C

•API Classification: SL

Using another type of oil may void the warranty.

Cap

Above

Expansion Tank

21

21

Full Cold Line

Below

Page 22

WIRING HARNESS

RIGHT WIRING

HARNESS P/N

18692

22

22

Page 23

WIRING HARNESS

LEFT WIRING

HARNESS P/N

18693

23

23

Page 24

WIRING HARNESS

WIRING HARNESS

P/N 18806

(Kawasaki Engines Only)

24

24

Page 25

PARTS BREAKDOWN

Item # Part # Description Qty.

1 18705TK Weldment - Frame, Rear; Txt Blk 1

2 18923TK Weldment - Front Frame, HD; Txt Blk 1

3 18860 Kit - ROPS, Fully Assembled, Txt Blk 1

4 18737TK Wrap - Engine; Txt Blk 1

5 B98 Bearing 4

6 18581 Plug - Finishing, 1 x 3 x .083 Tube 2

7 18629 Plug - Finishing, 3/4 x 3/4 x .120 Tube 4

8 18635 Bolt - Carriage 5/16-18 x 6; GR5, Full Thrd 4

9 18589 Bolt - Hex, 1/2-13 x 6 1/4; GR8, ZP 4

10 NB177 Washer - Mach 1/2 NR 14 GA. 16

11 12669 Bolt - 1/2-13 x 3 1/4; GR8, ZY 4

12 NB121 Nut - 2-Way Jam Lock, 1/2-13, ZY 8

13 26X249 Screw - 5/16-18 X 3/4 7

14 NB515 Bolt - Serr Flange 5/16-18 x 1 3/4; GR5, ZY 8

15 NB170 Nut - Serr Flange 5/16-18 ; Case Hrd, ZY 8

16 18928TK Plate - Seat Base Support, Txt Blk 2

Notes:

Torque settings for bolt number 9

should be set at 25 ft./lbs.

Torque settings for bolt number 11

should be set at 75 ft./lbs.

25

25

Page 26

PARTS BREAKDOWN

HYDRO DETAIL

3 18858TK Weldment - Hydro Link Support; Txt Blk 1 24 18674TK Plate - Idler; Txt Blk 1

4 NB515 Bolt - Serr Flange, 5/16-18 x 1 3/4; GR5, ZY 2 25 6037 Bushing - Idler 1

5 18580 Bolt - Serr Flange, 5/16-18 x 3; GR5, ZP 4 26 NB198 Bolt - HCC, 3/8-16 x 2; GR5, ZY 1

6 NB275 Wahser - SAE Flat, 5/16; ZY 8 27 7509 Pulley - Idler, 2 3/4 OD x 3/8 ID 1

7 NB181 Nut - Nyloc, 5/16-18; ZY 9 28 18714TK W eldment - Idler Pulley Offset; Txt Blk 1

8 18664TK Plate - Hydro Control; Txt Blk 2 29 NB596 Bolt - Serr Flange, 5/16-18 x 3/4; GR5, ZY 2

9 NB780 Bolt - Serr Flange, 3/8-16 x 3/4; GR5, ZY 2 30 NB170 Nut - Serr Flange, 5/16-18; Case Hard, ZY 2

10 NB690 Bolt - Serr Flange, 1/4-20 x 3/4; GR5, ZY 2 31 B27 Pulley - Idler, 2.16 OD x 3/8 ID 1

11 NB779 Nut - Serr Flange, 3/8-16; ZY 4 32 NB221 Bolt - HCC, 3/8-16 x 2 1/2; GR5, ZY 2

12 NB524 Nut - Serr Flange, 1/4-20: GR5, ZY 2 33 NB107 Bolt - HCC, 3/8-16 x 1 1/2; GR5, ZY 1

13 18811 Belt - Hydro; 1/2 x 80 1/4" 1 34 26X263 Screw - Hex .25-20 x 0.59 2

14 26X249 Screw - .313-18 x .75 2 35 NB579 W asher - Fender, 5/16 x 1 1/4; GR2, ZY 1

15 18938TK Bracket - Bulkhead Cable Mount; Txt Blk 1 36 NB231 Bolt - HTC, 3/8-16 x 2; GR5, ZY 2

16 17465 Spring - Extension, Hydro Release, ZT 4 18950TK Bracket - Brake Cable, Left; Txt Blk 1

17 18952TK Plate - Brake Spring Return, Txt Blk 2 18949TK Bracket - Brake Cable, Right; Txt Blk 1

18 6040Z Washer - Idler, 3/8: ZP 3 38 NB315 Eyebolt - 5/16-18 x 3; w/ Gap, ZY 1

19 18607 Pulley - Backside Idler, 5" 1 39 7821 Spring - Latch 1

20 NB272 Washer - SAE Flat, 3/8; Carbon Steel, ZY 7 18941TK Mount - Bypass cable, Left; Txt Blk (Left) 1

21 NB182 Nut - Nyloc, 3/8-16; ZY 5 18940TK Mount - Bypass cable, Left; Txt Blk (Right) 1

26

26

37

40

Page 27

PARTS BREAKDOWN

Engine shown may not be

the actual engine used. It

is for reference only.

Notes:

Torque settings for bolt number 12

should be set at 20 ft./lbs.

Item # Part # Description Qty. Item # Part # Description Qty.

14398 Engine - 27HP B&S (ZTR2760BS & CA) 1 19 NB180 Nut - Nyloc, 1/4-20 4

1

18729 Engine - 24HP Kawasaki (ZTR2460KA & CA) 1 20 18696TK Bracket - Hydro Expansion Tank; Txt Blk 2

14391 Muffler - B&S V-Twin (for BS) 1 21 26X249 Screw - 5/16-18 x 3/4 20

2

18730 Muffler - Kawasaki (for KA) 1 22 1002004 Solenoid - 3 Pole 1

226462 Deflector - Muffler, B&S (for BS) 1 23 18709TK W eldment - Contnmnt. Rocker Shaft; Txt Blk 4

3

18853 Deflector - Muffler Turn Down, 90° (for KA) 1 24 18614TK Plate - Deck Lift Pedal; Txt Blk 1

NB783 Screw - 10-16 x 3/4 (for BS) 1 25 NB596 Bolt - Serr Flange, 5/16-18 x 3/4; GR5, ZY 3

4

18876 Clamp - Muffler (for KA) 1 26 18706TK Weldment - Rocker Shaft, Front; Txt Blk 1

NB253 Bolt - Serr Flange, 5/16-18 x 1 1/4; (for BS) 4 27 18700TK Weldment - Rocker Shaft, Rear; Txt Blk 1

5

NB618 Bolt - 3/8-16 x 1 1/4; GR5, ZY (for KA) 4 28 NB779 Nut - Serr Flange, 3/8-16; ZY 4

NB170 Nut - Serr Flange, 5/16-18; (for BS) 9 29 NB780 Bolt - Serr Flange, 3/8-16 x 3/4; GR5, ZY 4

6

NB711 Washer - Split Lock, 3/8; Medium (for KA) 4 30 18592 Weldment - Deck Height Stop Rod 1

7 9031 Key Stock - 1/4 x 1"; Under Size, Plain Fin. 1 31 NB184 Washer - 3/4ID x 1 1/4 OD x 10 GA. 2

8 18585 Pulley - Engine 1 32 NB126 Pin - Cotter, ⅛ x 1"; Carbon Steel, Ext Prng 2

9 18632 Clutch - Ogura, 1" Shaft 1 33 2335 Spring - Tilt 2

10 18631 Bushing - Clutch, Ogura 1 34 18650TK Plate - Drag Link Capture; Txt Blk 2

11 10291 Washer - Bellville, 1/2 x 1 1/4 x 10GA; GR2 1 35 NB690 Bolt - Serr Flange, 1/4-20 x 3/4; GR5, ZY 8

12 NB705 Bolt - HCF, 7/16-20 x 3 1/4"; GR5, ZY 1 36 NB524 Nut - Serr Flange, 1/4-20: GR5, ZY 8

13 18691TK Cover - Hydro Fan; Txt Blk 2 37 NB651 Pin - Ball Lock, 1/2 x 2 1/2 1

14 NB114 Bolt - TCS, 1/4-20 x 1/2; Unslot, GR2, ZY 8 38 18602 Pin - Clevis 1/2 OD x 1-33/64 1

15 AS161 Hose - bulk, Oil Drain 2.5" x2 39 NB127 Pin - Hair, #39; Std, ZY 1

16 NB250 Bolt - 1/4-20 x 3/4; GR5, ZY 4 40 18667TK Bracket - Clutch Stop, Ogura; Txt Blk 1

17 NB274 Washer - SAE Flat, 1/4; ZY 4 41 10216 Bolt - Carriage, 5/16-18 x 3/4; GR5, ZY 2

18 17015 Tank Expansion - Hydro Resivoir (71328) 2 42 18883 Spacer - Clutch Stop 1

27

27

Page 28

PARTS BREAKDOWN

HANDLE DETAIL

Notes:

-Item number 23 (two places) attaches

to item number 8 from Page 26 using

item numbers 29 & 30.

BRAKE DETAIL

28

28

Page 29

Item #

PARTS BREAKDOWN

Part # Description Qty.

1 18742 Seat - High Back; w/ Seat Slide, Armrest 1

2 18679TK Base - Seat; Txt Blk 1

3 NB513 Bolt - HCC, 5/16-18 x 4; GR5, Zy 2

4 NB275 Washer - SAE Flat, 5/16; ZY 6

5 NB170 Nut - Serr Flange, 5/16-18; Case Hard, ZY 15

6 NB207 Nut - Jam, Nyloc 3/8-16 ZY 2

7 NB181 Nut - Nyloc, 5/16-18; ZY 5

8 18582 Gas Tank - 4 Gallon, ZT 2

9 18686TK Strap - Tank Hold Down; Txt Blk 2

10 NB110 Bolt - Carriage, 5/16-18 x 2 1/4; GR2, ZY 2

11 18713TK Weldment - Tank & Seat Mount; Txt Blk 1

12 NB515 Bolt - Serr Flange 5/16-18 x 1 3/4; GR5, ZY 8

13 18931TK Weldment - Brake Arm, Txt Blk 1

14 26X249 Screw - 5/16-18 x 3/4 22

15 18951TK Weldment - Bypass Arm, Txt Blk 1

16 18936TK Weldment - Brake Mount Bracket 1

17 18945 Switch - 2 Pole, NC/NO 1

18 18933TK Plate - Swivel lock, Txt Blk 2

19 NB503 Bolt - HCC, 5/16-18 x 1 3/4; GR5, ZP 1

20 14029 Bushing 2

21 NB180 Nut - Nyloc, 1/4-20 3

22 17465 Spring - Extension, Hydro Release, ZT 2

23 NB264 Linkage - Ball, Left; Moridge # 265616 2

24 NB265 Nut - Jam, 5/16-24; Left-Hand Thrd; GR2, ZY 2

25 18627 Linkage - 5/16-24 x 1; LHT & RHT 2

26 NB190 Nut - Jam, 5/16-24; GR2, ZY 2

27 NB263 Linkage - Ball, Right; Moridge # 265615 2

28 18723 Damper - AVM, ZT 2

29 NB159 Washer - Split Lock, 5/16; Medium Duty, ZY 4

30 NB215 Nut - Hex, 5/16-24; GR2, ZY 4

31 18710TK Weldment - Handle Mount, Right; Txt Blk 1

32 3609 Spring - Tapered 3

33 18685TK Bracket - Damper Mount, Right; Txt Blk (Hidden) 1

34 18687TK Bracket - Damper Mount, Left; Txt Blk (Hidden) 1

35 NB583 Bolt - Carriage, 1/4-20 x 1 1/2; GR2, ZY 1

36 18680TK Bracket - Seat Swivel; Txt Blk 1

37 18937 W asher - Wave, 1/2 ID x 1 OD x .087 2

38 10548 Bolt - Serr Flange, 5/16-18 x 1; GR5, ZY 1

39 009X58 Bolt - Shoulder, 3/8-16 2

40 NB177 Washer - Mach, 1/2 x 14 GA; NR 2

41 18711TK Weldment - Handle Mount, Left; Txt Blk 1

42 18712TK Weldment - Handle; Txt Blk 2

43 MWB Bearing - Wheel, 1 ⅛" OD x 1/2" ID 4

44 18852 Plug - Plastic, 7/8 OD x 11 GA Tube; Blk 2

45 18807 Grip - Hand Conforming, Right 1

46 18808 Grip - Hand Conforming, Left 1

47 NB688 Nut - Nyloc Jam, 1/2-13; ZY 2

48 NB574 Bolt - 1/4-20 x 3; GR2, ZP 1

49 2077 Pivot - Handle Grip 2

50 18942 Cable - Brake w/ Junction Box (Not Shown) 1

51 18943 Cable - Bypass w/ Junction Box (Not Shown) 1

29

29

Page 30

PARTS BREAKDOWN

Notes:

-Item number 37 (four places) attaches to item

number 26 & 27 from Page 27.

-Item number 3 attaches to item number 2 from Page

25 using item numbers 34, 35 & 36 from Page 27.

INSDIE IDLER DETAIL

30

30

OUTSDIE IDLER DETAIL

Page 31

Item #

PARTS BREAKDOWN

Part # Description Qty.

1 18701TK Weldment - 60" deck; Txt Blk 1

2 18786TK Bracket - Deck Stabilizer: Txt Blk 2

3 18601 Tod - Drag Link Bar 1

4 NB596 Bolt - Serr Flange, 5/16-18 x 3/4; GR5, ZY 17

5 NB170 Nut - Serr Flange, 5/16-18; Case Hard, ZY 19

6 NB178 Washer - 5/8" ID x 1" OD x 10 GA; ZY 2

7 NB126 Pin - Cotter, ⅛ x 1"; Carbon Steel, Ext Prng 2

8 18383TK Bracket - Middle Toller; Txt Blk 1

9 3511 Gauge - Wheel 3

10 18874 Washer - UHMW, 2" OD x 3/8" ID x .188" 8

11 NB132 Bolt - Hex, 1/2-13 x 4; GR5 1

12 15779TK Bracket - Left Wheel; Txt Blk 1

13 NB707 Bolt - Carriage, 3/8-16 x 4; Full Thread, GR2 1

14 18637 Belt - Deck Idler, 1/2" x 55" 1

15 AS001 Roller - Anti-Scalp, 3/8 ID 2

16 NB577 Bolt - 1/2-13 x 3 1/2; GR5, ZY 2

17 NB121 Nut - Jam Lock, 1/2-13; 2-way, GR A 5

18 NB272 Washer - SAE Flat, 3/8; Carbon Steel, ZY 20

19 NB182 Nut - Nyloc, 3/8-16; ZY 14

20 15780TK Bracket - Anti-Scalp; Txt Blk 1

21 18652TK Bracket - Grass Chute; Txt BLk 1

22 18604 Rubber - Grass Chute 1

23 10501 Bolt - Carriage, 3/8-16 x 1 1/4; GR5, ZY 7

24 18702TK Weldment - Grass Chute; Txt Blk 1

25 18654TK Bracket - Grass Chute Mount; Txt Blk 1

26 26X249 Screw - 5/16-18 x 3/4 2

27 18595 Rod - Deck, Grass Chute; ZP 1

28 166X34 Spring - Torsion 1

29 NB117 Nut - Push, 5/16; ZP 2

30 NB181 Nut - Nyloc, 5/16-18; ZY 1

31 NB275 Washer - SAE Flat, 5/16; ZY 1

32 18622 Bolt - Spade, 5/16-18; ZY 1

33 18532 Nut - Clip, 10-24 4

34 18531 Washer - Bent, 1/4" ID x 18 GA; Belt Cover 4

35 024203 Screw - Phillips Truss Head, 10-34; ZP 4

36 18621 Cover - Deck Belt, Short 2

37 18722 Chain - Deck Hanger, Six Links 4

38 18597 Bolt - Hook, 3/8-16 4

39 NB618 Bolt - 3/8-16 x 1 1/4; GR5, ZY 3

40 6040Z Washer - Idler, ZP 9

41 18875 Spacer - UHMW, 7/8" Sq. x 3/8" ID x .200" 4

42 18707TK Weldment - deck Idler, Backside; Txt Blk 1

43 18613 Pulley - 4 1/2" OD x 2 1/2" 1

44 NB164HT Wahser - 1 x 1 1/2 x 10 GA; Hardened 1

45 18708TK Weldment - Deck Idler, Inside; Txt Blk 1

46 NB207 Nut - Nyloc Jam, 3/8-16; ZY 7

47 18605 Spring - Extension, Idler; ZP 1

48 3622 Pulley - V, Idler; 3.54 OD x 3/8 ID 1

49 4422 Spring - Idler Tension, Bent Leg 1

50 NB779 Nut - Serr Flange, 3/8-16; ZY 1

51 NB210Z Nut - HNC, 5/16-18; GR2, ZY 2

52 18746 Belt - Engine to Deck, 1/2 x 126, Gates 1

31

31

Page 32

PARTS BREAKDOWN

CENTER BLADE DRIVER

Note:

Torques for bolt numbers 10 & 11

should be set at 35 ft./lbs.

Torque settings for nut number 1

should be set at 35 ft./lbs.

LEFT BLADE DRIVER

Item # Part # Description Qty. Item # Part # Description Qty.

1 NB175 Nut - Jam, 3/4-16; GR2 3 10 NB238 Bolt - 3/8-24 x 1; GR5, ZY 6

2 AS155 Washer - Belleville, 3/4 x 1 1/2 x .098 3 11 NB238N Bolt - HHc, 3/8-24 x 1; GR5, Nyloc 3

3 B4104TK Pulley - Blade 4 1/2"; Txt Blk 4 12 NB607 Washer - SP Belleville, .413 x .945 x .118 3

4 NB179 3/4 ID X 1 1/4 OD 18 GA Washer 7 13 NB216 Nut - Two Way Lock, 3/8-24; GR A, ZY 6

5 B98 Bearing - Blade 6 14 NB596 Bolt - Serr Flange, 5/16-18 x 3/4; GR5 12

6 9077 Shaft - Blade 5", Long Shoulder 1 15 NB170 Nut - Serr Flange, 5/16-18; Case Hard, ZY 12

7 10539TK Blade Driver; Txt Blk 3 16 12823 Spacer - 3/4 ID x 1, Powder Metal 1

8 9008 Plate - Blade Mount 3 17 9078 Shaft - Blade 6", Long Shoulder 2

9 3293 Blade - 20.5" Mulching 3 18 18620 Spacer - Pulley, Deck Idler 1

32

32

RIGHT BLADE DRIVER

Page 33

PARTS BREAKDOWN

Item # Part # Description Qty. Item # Part # Description Qty.

1 18610 Fender - Left 1 18 18717 Spacer - Fender 13

2 18578TK Panel - Control, Left; Txt Blk 1 19 18609 Fender - Right 1

3 18743 Screw - Rolok, 5/16-18 x 1; STD, ZY 8 20 18639TK Panel - Control, Right; Txt Blk 1

4 3706 Clip - Timmerman, 5/16-18 6 21 18606 Cable - Control, Engine Choke 66" 1

5 17635 Hour Meter - LCD 1 22 NB711 Washer - Split Lock, 3/8; Medium, ZY 1

6 3605 Switch - PTO 1 23 NB456 Nut - HNF, 3/8-24; GR2, ZY 1

7 18636 Switch - Starter 1 24 18745 Adapter - 12V Power Plug 1

8 1001542 Holder - GA, Beverage 1 25 4226 Cable - Throttle 1

9 18221 Cap, Fuel - 2.5 Gallon, Carb Sealed 2 26 4226K Knob - T, for Throttle Cable 1

10 EBAT230 Battery - 12V (8U1L) 1 27 26X263 Screw - 1/4-20 x 1/2 2

11 18698TK Strap - Battery Hold Down; Txt Blk 1 28 3623 Switch - Key 1

12 NB622 Bolt - Serr Flange, 5/16-18 x 2 1/4; GR5, ZY 1 29 9087 Nut - Key Switch 1

13 NB690 Bolt - Serr Flange, 1/4-20 x 3/4; GR5, ZY 2 30 9088 Washer - Lock, Key Switch 1

14 NB524 Nut - Serr Flange, 1/4-20; GR5, ZY 2 31 18588 Floor Pan - ZT 1

15 18697TK Cover - Battery, Fender; Txt Blk 1 32 NB780 Bolt - Serr Flange, 3/8-16 x 3/4; GR5, ZY 1

16 18802 Screw - Thumb w/ Shoulder, 5/16-18 x 3/4 1 33 18603B Bar - Foot Pedal, Black Oxide 1

17 26X249 Screw - 5/16-18 x 3/4 4 34 18743 Screw - Thread Cut, 5/16-18 x 1; Black Oxide 9

33

33

Page 34

PARTS BREAKDOWN

Notes:

-Torque specs for lug nuts number 2 should be

set at 40 ft./lbs.

-Nut number 10 should not be fastened tightly. It

should only be tight enough to engage the Nyloc

nut but also allow the caster (#4) to spin freely.

There should be no up and down axial

movement in the caster once fastened.

-Bolt & nut numbers 5 & 6 should also not be

fastened tightly. They should be tight enough

that the bolt has no axial movement side to side

but also allow the wheel (#3) to spin freely.

Item # Part # Description Qty. Item # Part # Description Qty.

1 18784 Tire/Wheel - 20 x 10-10; Spoked, Blk 2 7 B98 Bearing - Blade 4

2 2203LN Nut - Lug, Wheel Hub, 1/2-20; GR5, ZY 8 8 NB195 Washer - 13/16 x 1 1/4 x ⅛; Mild, ZY 4

3 18785 Tire/Wheel - 12/600 x 6-4Ply; Smooth, Blk 2 9 17X195 Washer - Flat 2

4 18886TK W eldment - Caster, 1/2"; Txt Blk 2 10 NB313 Nut - Myloc Jam, 3/4-10 2

5 14430 Bolt - HCC, 5/8-11 x 8; GR8, ZY 2 11 094618 Cap - Hub 2

6 NB595 Nut - 2-way Jam Lock, 5/8-11; GR A 2

34

34

Page 35

TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Engine Will

Not Start

Engine Hard

To Start

1. Out of fuel.

2. Engine flooded.

3. Bad spark plug.

4. Dirty air filter.

5. Dirty fuel filter.

6. Water in fuel.

7. Loose or damaged wiring.

8. Carburetor out of adjustment.

9. Engine valves out of adjustment.

10. Extreme cold conditions.

1. Bad spark plug.

2. Dirty air filter.

3. Dirty fuel filter.

4. Weak or dead battery.

5. Carburetor out of adjustment.

6. Engine valves out of adjustment.

7. Loose or damaged wiring.

8. Stale or dirty fuel.

1. Fill fuel tank.

2. Wait several minutes before attempting to

restart.

3. Replace spark plug.

4. Clean or replace air filter.

5. Replace fuel filter.

6. Drain fuel tank & carburetor, refill tank with

fresh gas and replace fuel filter.

7. Check all wiring.

8. See Engine Manual.

9. Contact an authorized service center.

10. See Engine Manual.

1. Replace spark plug.

2. Clean or replace air filter.

3. Replace fuel filter.

4. Recharge or replace battery.

5. See Engine Manual.

6. Contact an authorized service center.

7. Check all wiring.

8. Drain fuel tank & refill with fresh gasoline.

Engine Will

Not Turn Over

Engine Clicks

but Will Not

Start

Unit Does Not

Travel in a

Straight Line

Excessive

Vibration

1. Brake not engaged.

2. PTO engaged.

3. Weak or dead battery.

4. Blown fuse.

5. Corroded battery terminals.

6. Loose or damaged wiring.

7. Faulty ignition switch.

8. Faulty solenoid.

9. Faulty operator presence switch/switches.

1. Weak or dead battery.

2. Corroded battery terminals.

3. Loose or damaged wiring.

4. Faulty solenoid.

1. Incorrect tire pressure.

2. Rear wheels rotating at different speeds.

1. Worn, bent or loose blade.

2. Bent blade driver.

3. Loose/damaged part or parts.

4. Faulty blade driver assembly.

1. Engage Brake.

2. Push PTO switch down to disengage.

3. Recharge or replace battery.

4. Replace fuse.

5. Clean battery terminals – See Battery

section of this manual.

6. Check all wiring.

7. Check/replace ignition switch.

8. Check/replace solenoid.

9. Contact an authorized service center.

1. Recharge or replace battery.

2. Clean battery terminals – See Battery.

section of this manual.

3. Check all wiring.

4. Check/replace solenoid.

1. Check tire pressure (See Specifications).

2. Return-to-Neutral assembly may need

adjustments.

3. Contact an authorized service center.

1. Replace blade. Tighten blade bolt.

2. Replace blade driver.

3. Tighten loose part or parts. Replace

damaged parts.

4. Replace blade driver assembly.

35

35

Page 36

TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Loss of

Power

Engine

Backfires

When Turning

Engine OFF

1. Cutting too much grass/ too fast.

2. Buildup of grass, leaves and trash under

deck.

3. Dirty air filter.

4. Low oil level/dirty oil.

5. Faulty spark plug.

6. Dirty fuel filter.

7. Stale or dirty fuel.

8. Water in fuel.

9. Spark plug wire loose.

10. Dirty engine air screen/fins.

11. Dirty/clogged muffler.

12. Loose or damaged wiring.

13. Carburetor out of adjustment.

14. Engine valves out of adjustment.

15. Loose drive belt.

1. Engine throttle control not set at “SLOW”

position for 30 seconds before stopping

engine.

1. Set in High Cut (position 1)/reduce speed.

2. Clean underside of mower deck.

3. Clean or replace air filter.

4. Check oil level/change oil.

5. Clean and re-gap or change plug.

6. Replace fuel filter.

7. Drain fuel tank & refill tank with fresh gas.

8. Drain fuel tank & carburetor, refill tank with

fresh gas and replace fuel filter.

9. Connect and tighten spark plug wire.

10. Clean engine air screen/fins.

11. Clean/replace muffler.

12. Check all wiring.

13. See Engine Manual.

14. Contact an authorized service center.

15. Adjust idler/replace belt.

1. Move throttle control to “SLOW” position and

allow to idle for 30 seconds before stopping

engine.

Poor Cut -

Uneven

Battery Will

Not Charge

Loss of

Drive

1. Worn, bent or loose blade.

2. Mower deck not level.

3. Buildup of debris under deck.

4. Bent deck.

5. Faulty blade driver assembly.

1. Bad battery.

2. Poor cable connections.

3. Faulty solenoid.

1. Bypass linkages in the disengaged position.

2. Hydro belt worn, damaged, or broken.

3. Idler spring loose or broken.

4. Low transmission fluid level

1. Replace blade. Tighten blade bolt.

2. Possible damaged or bent components.

3. Clean underside of mower deck.

4. Replace deck.

5. Replace blade driver assembly.

1. Replace battery.

2. Check/clean all connections. See section in

this manual.

3. Replace solenoid.

1. Make sure that the bypass handle is in the drive

or disengaged position. Refer to page 16

2. Replace Hydro belt.

3. Replace Idler spring.

4. Add specified transmission fluid. Refer to page 21

36

36

Page 37

MOWER IDENTIFICATION

Mower Identification

Each mower has its own model number. Each

engine has its own model number. The model

number for the mower will be found behind the

seat. The model number for the engine will be

found on the top of the blower fan housing.

All mower parts listed herein may be ordered

directly from Swisher or your nearest Swisher

dealer. All engine parts may be ordered from

the nearest dealer of the engine supplied with

your mower.

WHEN ORDERING PARTS, PLEASE HAVE THE

FOLLOWING INORMATION AVAILABLE:

•Date Purchased ____________________

Unauthorized Replacement Parts

Use only Swisher replacement parts. The

replacement of any part on this unit with

anything other than Swisher authorized

replacement part may adversely affect the

performance, durability and safety of this unit

and may void the warranty. Swisher

disclaims liability for any claims or damages,

whether warranty, property damage, personal

injury or death arising out of the use of

unauthorized replacement parts.

•Purchased From____________________

•PRODUCT – \ ZTR2760BS \ ZTR2760BS-CA \ ZTR2460KA \ ZTR2460KA-CA

\ ZTR2460BS \ ZTR2460BS-CA

•SERIAL NUMBER - _______________

•ENGINE MODEL NUMBER - _______________

•TYPE - _______________

•PART NUMBER WITH PAINT CODE__________________

•PART DESCRIPTION______________________________

S.A.I.

1602 CORPORATE DRIVE

WARRENSBURG, MO 64093

www.swisherinc.com

TELEPHONE - 1-800-222-8183

FAX - 1-660-747-3160

cust.serv@swisherinc.com

37

37

Page 38

REPLACEMENT PARTS

Quick Reference

Part DescriptionSwisher Part #

Belt – Hydro, ½ x 80 ¼18811

Belt – Engine to Deck ½ x 12618746

Belt – Deck Idler, ½ x 5518637

Tire/Wheel – 20 x 10-10, Spoked18784

Tire/Wheel – 12/600 x 6-4 Ply18785

Blade – 20 ½” Mulching 3293

Fuse – 10 AmpAS069

Blade – Driver Assembly (Right)10540

12824

Blade – Driver Assembly (Center

& Left)

CAUTION

Use extreme care when working on machinery.

Before performing any maintenance, turn off engine, allow the unit to cool and

remove the key. Disconnect spark plug wire.

Set Parking Brake by pulling up on both arms until locked into the “engaged”

position.

Do not wear watch or jewelry. Do not wear loose fitting clothes. Observe all

common safety practices with tools.

SEE PAGE 16 FOR BRAKE OPERATION INSTRUCTIONS.

38

38

Page 39

NOTES

39

39

Page 40

SWISHER HISTORY

Back before electricity came to rural Missouri Max Swisher was producing lawn

mowers from his mother’s chicken house. Max never liked to mow grass. He

installed a gearbox on his family’s lawn mower creating a self-propelled unit. By tying

one end of a rope to the mower and the other end to a tree in the center of the yard

the mower circled the tree, shortening the rope and guiding the mower in concentric

circles. Max enjoyed relaxing under a shade tree while his invention did all the work.

Max had designed his first self-propelled rotary lawn mower to do his dirty work for

him. Neighbors noticed his new invention and began asking him to make more.

Today, over 65 years later, Swisher is still producing innovative lawn and garden and

ATV/UTV equipment designed to give us all more “relaxing in the shade” time.

Swisher products have been featured nationally on television programs such as

Regis and Kathie Lee and seen in publications like ATV Magazine

Popular Mechanics Magazine and others. In January 2000 Popular Mechanics

Magazine named Max’s zero turning radius riding mower one of the 20thcentury’s top

household inventions.

Swisher offers value and function in its products to meet your grounds maintenance

needs.

, Country Journal,

CELEBRATING OVER 65 YEARS OF INNOVATION

SINCE 1945

40

40

Loading...

Loading...