Page 1

MANUFACTURING QUALITY LAWN CARE EQUIPMENT SINCE 1945

Owner’s

Manual

GC-14

IMPORTANT

Read and follow all

Safety Precautions

and Instructions

Before Operating this

Equipment.

14 Cubic Ft.

Garden Cart

1602 CORPORATE DRIVE, PO BOX 67, WARRENSBURG, MISSOURI 64093

11621 REV. 05-269

Made In CHINA

PH 660. 747. 8183 FAX 660. 747. 8650

swisherinc.com

Page 2

RULES FOR SAFE OPERATION

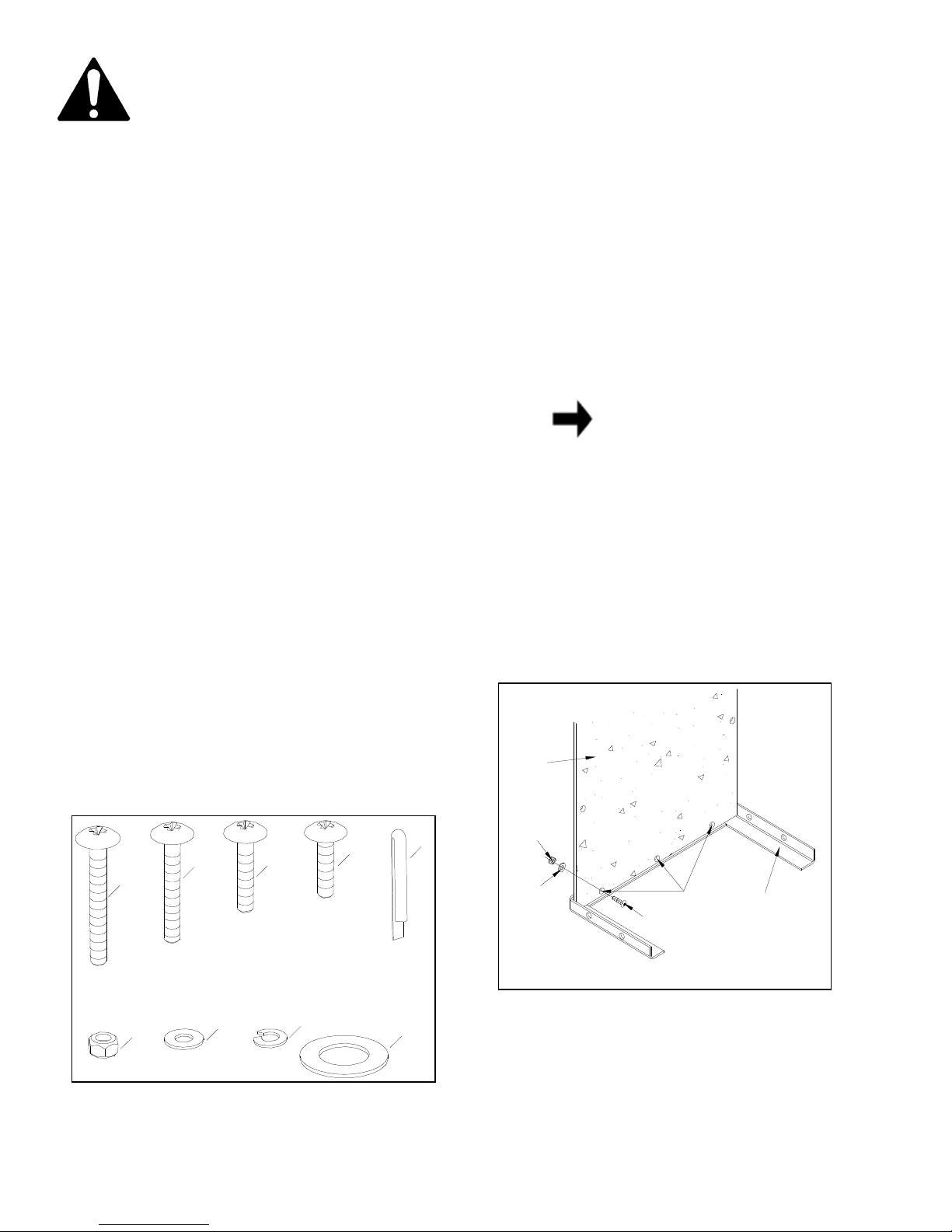

package with parts as shown in the chart below

ASSEMBLY INSTRUCTIONS

Preventing accidents is the responsibility of every TOOLS REQUIRED

equipment operator. The following general safety (1) Screw Driver

precautions must be fully understood and followed (1) Pliers

by every operator. (1)10mm Wrench

1. Do not at any time carry passengers in this cart. It

is designed for carrying materials only and not When assembling your cart, place the heads of all

intended to carry passengers. screws to the inside and hex nuts with flat washers

2. Be careful on any grade (hill) and stay off of steep to the outside.

grades.

3. Use caution when loading cart to avoid tipping. 1. Lay the front angle assembly down (flat) on floor

4. Avoid large holes and ditches when transporting and stand the bottom panel in position as shown in

loads. figure 2.

Your Farm/Yard Cart carton contains a hardware

NOTE

The bottom panel has one galvanized

and in figure 1.

edge; this is the rear. The front edge

has three holes. See figure 2.

Contents of Hardware Pack: (See figure 1)

REF. QTY. DESCRIPTION

A 6 Screws,M6X50 2. Line up three holes in bottom panel with holes in

B 2 Screws,M6X40 front angle assembly. Start three M6X25 screws

C 8 Screws,M6X30 through bottom panel, then through angle. Secure

D 21 Screws,M6X25 screws with flat washers and hex nuts.

E 4 Cotter Pins

Finger tight at this time.

See figure 2.

F 37 Hex Nuts,M6

G 33 Flat Washer,Ф6

H 4 Lock Washer,Ф6

I 4 Large Flat Washer

BOTTOM

PANEL

HARDWARE REFERENCE CHART

B

A

M6X40

C

M6X25

M6X30

D

E

M6

HEX

NUT

Ф

6

FLAT

WASHER

M6X25

SCREW

THREE

HOLES

FRONT

EDGE

Make only

FRONT

ANGLE

ASSEMBLY

M6X50

F

G

H

FIGURE 1

I

FIGURE 2

2

Page 3

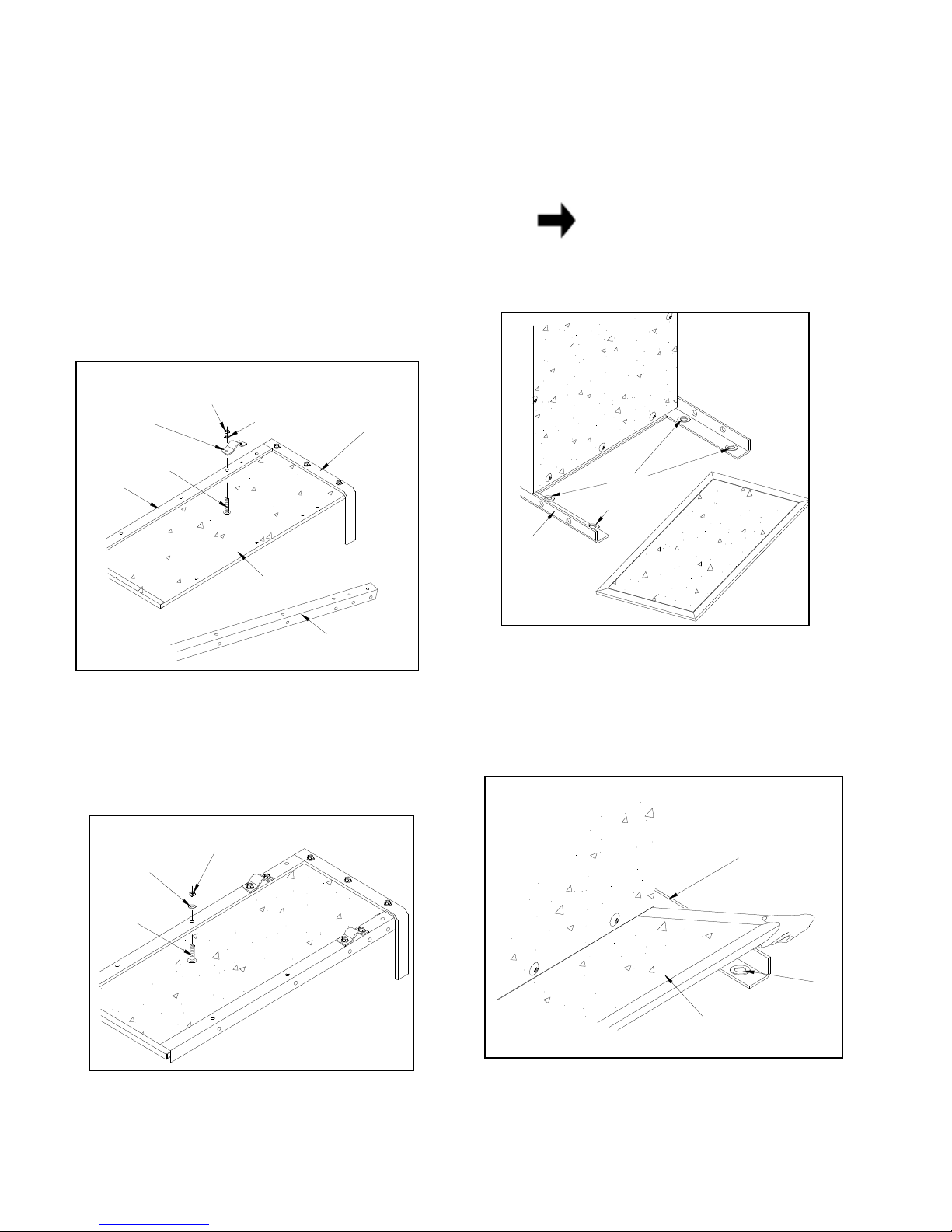

3. Turn the front angle assembly and bottom panel 7. Stand the cart on end with the front angle assemupside down as shown in figure 3. bly down on the floor. Temporarily place the four

large flat washers (axle washers) on

4. Lay each side angle on the bottom panel so that the inside of front angle assembly. See figure 5.

the two holes (for the axle clamp) are closer to the

front angle assembly. See figure 3.

NOTE

These washers act as shims and are

5. Secure both axle clamps to the side angles and

the bottom panel using four M6X30 screws,

lock washers and hex nuts.

until the axle is assembled. See figure 3.

tight

M6

HEX

NUT

SIDE

ANGLE

AXLE

CLAMP

M6X30

SCREW

Make only finger

Ф

6

LOCK

WASHER

FRONT

ANGLE

ASS'Y

just for assembly purposes. You will

remove them later to use on axle.

BOTTOM

PANEL

LARGE

FLAT

WASHER

FRONT

ANGLE

BOTTOM

PANEL

SIDE

ANGLE

ASS'Y

FIGURE 5

8. Lay the front panel down onto the front angle

FIGURE 3

assembly, on top of the four large washers.

6. Assemble four M6X25 screws, flat washers and See figure 6.

hex nuts to the side angles and bottom panel

using the holes on each side of the axle clamps.

Tighten the four nuts.

Ф

6

FLAT

WASHER

M6X25

SCREW

See figure 4.

M6

HEX

NUT

FRONT

PANEL

FRONT

PANEL

FRONT

ANGLE

ASS'Y

LARGE

FLAT

WASHER

FIGURE 4 FIGURE 6

3

Page 4

9.Position a Side Panel againist a Side Angle,resting

WASHERS

FRONT

HOLE

it down on top of the front panel. Place a support

strap on the outside of the side angle and start a

M6X30 screw through the

second hole

side panel, the side angle and the support strap.

Secure with a flat washer and hex nut.

finger tight at this time.

See figure 7.

10. Start a M6X30 screw through the top hole in the

side panel. the front angle assembly and the support strap. Secure with a flat washer and hex nut.

Make only finger tight at this time.

11. Repeat steps 9 and 10 for the other side panel.

Ф

6

FLAT

WASHER

M6

HEX

NUT

SIDE

15. Lay the cart down the floor so that the sides are

ANGLE

SECOND

FRONT

HOLE

M6X25

SCREW

M6X30

SCREW

SIDE

PANEL

in the

Make only

See figure 7.

M6X30

SCREW

SIDE

ANGLE

FRONT

HOLE

BOTTOM

HOLE

M6

HEX

NUT

SIDE

PANEL

Ф

6

FLAT

WASHER

M6X25

SCREW

FRONT

PANEL

FRONT

ANGLE

ASSEMBLY

FIGURE 8

in the normal upright position. remove the front

panel by sliding it up, then remove the four large

washers you used for shims. See figure 9.

SUPPORT

STRAP

M6

HEX

NUT

Ф

6

FLAT

WASHER

Top

Hole

SUPPORT

STRAP

FRONT

PANEL

ANGLE

ASS'Y

FIGURE 7

12. Start one M6X25 screw through the bottom hole

in the side panel and the front angle assembly.

Start another M6X25 screw through the front hole

in the side panel and the side angle. Secure with

two flat washers and two hex nuts,

finger tight at this time.

see figure 8.

13. Repeat step 12 for the other side panel.

14.

Tighten

all nuts and screws securely at this time,

except for nuts and screws in axle clamps. See

figure 8.

making only

SIDE

PANEL

(4) LARGE

FLAT

USED AS

SHIMS

CART

SIDE

PANEL

FRONT

PANEL

FIGURE 9

4

Page 5

16. Turn the cart upside down. Place the handle tube 17. Insert a M6X25 screw through the hole at the rear

NUT AND

on the bottom of the cart as shown in figure 10. of each side panel and the hole at the rear of each

Place the four tube clamps over the handle tube, side angle. Secure with Ф6 flat washers and M6

with the longer leg of each tube clamp to the

outside.

Secure the four tube clamps over the See figure 11.

hex nuts,

making only finger tight at this time.

handle tube using eight M6X25 screws, eight flat

washers and eight hex nuts. Make only finger tight 18. Place the tube caps on the ends of the "W"

until all eight screws are in place and then

securely.

See figure 10.

tighten

shaped leg tube. See figure 11.

19. With the cart still upside down, assemble the leg

tube to the bottom of the cart. Line up the two

NOTE

The length of the handle tube can be

adjusted by sliding the tube in or out

before tightening the four clamps. see

figure 10. tight at this time.

holes in the center of the leg tube with the holes in

the bottom of the cart. Secure the leg tube to the

bottom of the cart with two M6X50 screws, Ф6

flat washers and M6 hex nuts.

Make only finger

See figure 11.

BOTTOM

PANEL

FIGURE 10

SIDE

PANEL

HANDLE

TUBLE

TUBE CLAMPS

M6X25 SCREW

M6 HEX

NUT AND

Ф

6 FLAT

WASHER

20. Attach the leg tube to the side panels with four M6

x50 screw, Ф6 flat washers and M6 hex nuts.

Make only finger tight at this time. See figure 11.

21. Fasten the support straps to the leg tube with two

M6X40 screws,Ф6 flat washers and M6

hex nuts. See figure 11.

22. At this time tighten securely all screws and nuts

assembled in figure 11.

HANDLE

TUBE

LEG

TUBE

M6X40

SCREW

M6X25

SCREW

M6X50

SCREW

M6 HEX

NUT AND

Ф

6 FLAT

WASHER

SUPPORT

STRAP

FIGURE 11

5

SIDE PANEL

M6 HEX

Ф

6 FLAT

WASHER

Page 6

23. Slide the axle through the axle clamps. See

MAINTENANCE

figure 12.

1. Grease or oil wheel bearings occasionally. Use

24. Assemble a cotter pin to the inner hole at one automotive wheel bearing type grease or 20 weight

end of the axle. Spread ends to lock into position. oil.

Place a large flat washer, a wheel

and then another large flat washer onto the axle. 2. Periodically retighten all screws, especially after

Secure the wheel with a cotter pin assembled to heavy use.

the outer hole at the end of the axle. Repeat step

of 400lbs.

Do not exceed load capacity rating

for other wheel. See figure 12.

3. Clean cart thoroughly after each use.

25. Center the wheels and axle side to side.

Tighten

the four nuts on the axle clamps. 4. Store indoors during severe weather.

AXLE

LARGE

FLAT

WASHER

5. Apply light coat of varnish to all wood surfaces

annually.

6. Use glossy black enamel spray paint to touch up

WHEEL

COTTER

PIN

scratched or worn painted metal surfaces.

COTTER

PIN

LARGE

FLAT

WASHER

FIGURE 12

26. Turn cart right side up, so that it rests on its

wheels.

27. Place front panel in guides to complete assembly.

28. Your cart is now ready to use.

RECOMMENDED TIRE PRESSURE

80-85 PSI

MAXIMUM TIRE PRESSURE 85 PSI (600KPa)

6

Page 7

14 CU.FT. FARM/YARD CART

7

Page 8

MANUFACTURING QUALITY LAWN CARE EQUIPMENT SINCE 1945

Owner’s

Manual

GC-14

IMPORTANT

Read and follow all

Safety Precautions

and Instructions

Before Operating this

Equipment.

ATV & LAWN ACCESSORIES

WHEN ORDERING PARTS, PLEASE HAVE THE

FOLLOWING INORMATION AVAILABLE:

* PRODUCT – ________________

* SERIAL NUMBER - _______________

* MODEL NUMBER - _______________

TYPE - _______________

* PART NUMBER WITH PAINT CODE

* PART DESCRIPTION

TELEPHONE - 1-800-222-8183

FAX - 1-660-747-8650

SWISHER MOWER & MACHINE CO. INC.

SWISHER MOWER & MACHINE CO. INC.

SWISHER MOWER & MACHINE CO. INC.SWISHER MOWER & MACHINE CO. INC.

1602 CORPORATE DRIVE

P.O. BOX 67

WARRENSBURG, MO 64093

swisherinc.com

Loading...

Loading...