Page 1

OWNER’S

MANUAL

STARTING SERIAL #:

L103-335001

MODEL NO.

FT1150

IMPORTANT

Read and follow all

Safety Precautions

and Instructions

before operating this

equipment.

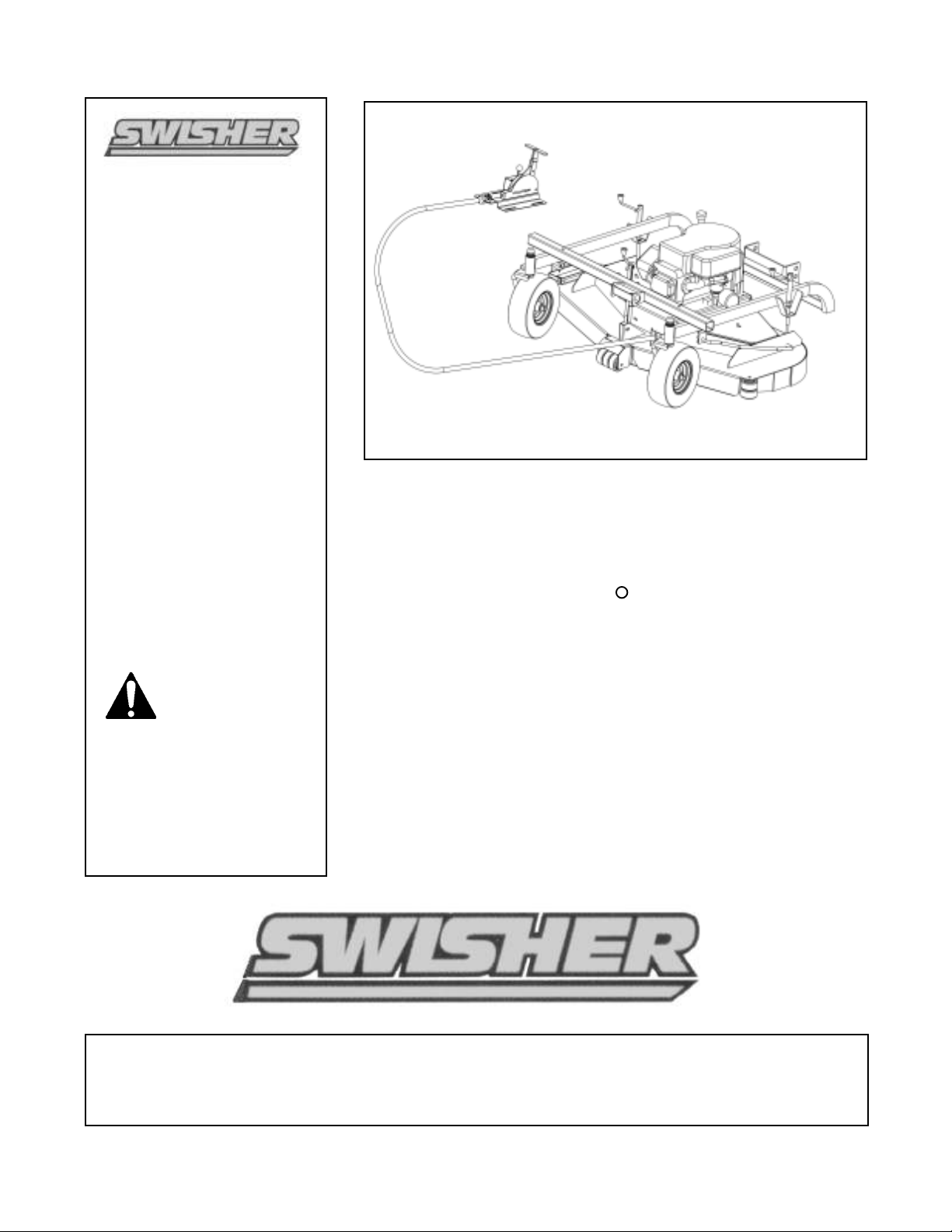

50” UNIVERSAL MOUNT

R

TRAILMOWER

For Vehicle Mounting Options See

Details On Page-16

Assembly

Operation

Service and Adjustment

Rev. 05-193

Repair Parts

1602 CORPORATE DRIVE, P.O. BOX 67, WARRENSBURG, MISSOURI 64093

PHONE 660-747-8183 FAX 660-747-8650

Manufacturing quality lawn care equipment since 1945

ONFT1150

Made In The

USA

Page 2

SAFETY PRECAUTIONS

manual. When you see this symbol, carefully read the message that

This Safety Alert Symbol indicates important messages in this

follows and be alert to the possibility of personal injury.

Read this manual completely. This machine can amputate hands, feet, and throw

objects. Failure to observe the following safety instructions could result in serious

injury or death.

• Read the manual. Learn to operate this machine safely.

• Always disconnect the spark plug wire and place the wire where it cannot contact

the spark plug, to prevent accidental starting the engine when setting up,

transporting, adjusting or making repairs.

• Keep all shields and guards in place.

• Understand the speed, steering and stability of this machine. Know the positions

and operations of all controls before you operate this machine. Check all of the

controls in a safe area before starting to work with this machine.

• Allow only responsible adults who are familiar with these instructions to operate

this machine. Never allow children to operate this machine.

• Clear the area of objects such as rocks, toys, wire, etc. that can be picked up and

thrown by the blade.

• Be sure the area is clear of other people before mowing. Be aware of the mower

discharge direction and do not point at anyone. Stop the machine if anyone enters

the mowing area. Children are often attracted to the machine and the mowing

activity. Never assume that children will remain where you last saw them.

Keep children under the watchful care of another responsible adult.

• No riders on this unit at any time.!

• Do not put hands or feet near or under rotating parts. Keep clear of the discharge

opening at all times.

• Do not mow in reverse. Always look down and behind before and while backing.

2

Page 3

•

Turn off the blades when not mowing. Before leaving the machine, turn off the

blades and stop the engine.

•

Watch for traffic when operating near or crossing roadways.

•

Do not operate the mower if it has been dropped or damaged in any manner or if

Page 4

MOWER MAINTENANCE

negligence. To receive full value from the warranty, operator must maintain unit as instructed in this

GENERAL RECOMMENDATIONS

The warranty on this trailmower does not cover items that have been subjected to operator abuse or

manual.

Some adjustments will need to be made periodically to maintain your unit properly.

All adjustments in this manual should be checked at least once each season.

BEFORE EACH USE

•

Check engine oil level on a level surface. (Check twice to insure an accurate reading.)

•

Check condition of air filter; clean and replace as necessary.

•

Check blade operation; keep blades in good condition.

•

Check for loose fasteners and tighten them as needed.

AFTER EACH USE

•

Keep blades sharp.

•

Remove fresh grass clippings with garden hose.

•

Hardened grass clippings on underside should be scraped out with a putty knife.

•

Keep fluids at proper levels.

•

Cover unit to prevent rain or other debris build-up. Definitely cover the engine.

BEFORE AND/OR AFTER EACH SEASON

•

Replace the spark plug.

•

Clean or replace the air filter.

•

A new spark plug and clean air filter assure proper air-fuel mixture and help your engine run

better and last longer.

•

Check blades and belts for wear. Replace as necessary.

STORAGE RECOMMENDATIONS

CAUTION! Do not store engine indoors or other poorly ventilated area. Keep engine away

from gas appliances where fumes could contact open flame, pilot lights, or sparks.

If engine is to be stored for 30 or more days, prepare unit as follows:

•

Drain fuel outside into an approved container.

•

Start engine properly and run until unit is out of fuel.

•

Let engine cool.

•

Remove remaining gasoline from carburetor and fuel tank to prevent gum deposits from

forming within the engine. Gum deposits can cause malfunction in the engine.

•

Store mower with blades disengaged to prevent belts from being permanently stretched.

BLADE CARE AND SERVICE

For best results cutter blades must be kept sharp. The blades can be sharpened with a few strokes of

a file or grinding wheel. Do not attempt to sharpen blades while they are on the cutter.

spark plug wire before servicing unit.

Important: Mower blades are sharp always wear gloves. [ see page 3 ]

Important: Replace blades that have been damaged or deeply nicked.

Important: Check blade and spindle hardware on a regular basis to make sure nuts are tight.

Disconnect

Only a qualified mechanic should conduct any adjustments,

disassembly or other kind of repairs.

4

Page 5

LIMITED WARRANTY

Excluded from this warranty are normal wear, normal adjustments,

this warranty, you must return the product to an authorized

service dealer. All transportation charges, damage, or loss incurred during transportation of parts

d

8183.

The model number, serial number, date of purchase, and the name of the authorized Swisher

warranty claim can be

THIS WARRANTY DOES NOT APPLY TO ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES AND ANY IMPLIED WARRANTIES ARE LIMITED TO THE SAME TIME

PERIODS STATED HEREIN FOR ALL EXPRESSED WARRANTIES. Some states do not

f consequential damages or limitations on how long an implied warranty

may last, so the above limitations or exclusions may not apply to you. This warranty gives you

is a

The manufacturer’s warranty to the original consumer purchaser is: This product is free from

defects in materials and workmanship for a period of one (1) year from the date of purchase by

the original consumer purchaser. We will repair or replace, at our discretion, parts found to be

defective due to materials or workmanship. This warranty is subject to the following limitations

and exclusions:

1) Engine Warranty All engines utilized on our products have a separate warranty

extended to them by the individual engine manufacturer. Any

engine service difficulty is the responsibility of the engine

manufacturer and in no way is Swisher Mower Co., Inc. or its

agents responsible for the engine warranty. The Briggs & Stratton

Engine Service Hot-Line is 1-800-233-3723. The Tecumseh

Engine Service Hot-Line is 1-800-558-5402.

2) Commercial Use The warranty period for any product used for commercial or rental

is limited to ninety (90) days from the date of original purchase.

3) Limitations This warranty applies only to products which have been properly

assembled, adjusted, and operated in accordance with the

instructions contained within this manual. This warranty does not

apply to any product of Swisher Mower Co., Inc., that has been

subject to alteration, misuse, abuse, improper assembly or

installation, shipping damage, or to normal wear of the product.

4) Exclusions

and normal maintenance.

In the event you have a claim under

submitted for replacement or repair under this warranty shall be borne by the purchaser. Shoul

you have any questions concerning this warranty, please contact us toll-free at 1-800-222-

dealer from whom you purchased the mower will be needed before any

processed.

allow the limitation o

specific legal rights and you may have other rights, which vary from state-to-state. This

limited warranty as defined by the Magnuson-Moss Act of 1975.

5

Page 6

OPERATING YOUR MOWER

The operation of any mower can produce foreign objects to be thrown into the

eyes, resulting in severe eye damage. Always wear certified safety glasses or

wide-vision safety goggles over spectacles before starting any cutting machine and

while operating such a machine.

The operation of any cutter produces sound waves that are damaging to the

human ear. Ear protection is recommended.

CAUTION!

Tragic accidents can occur if the operator is not alert to the presence of

children. Children are often attracted to the machine and the mowing

activity.

INTENDED USE

This trail mower is designed to produce a quality finish cut on lawns, golf courses, etc. It is not

designed to clear brush or cut saplings. Your mower be should pushed in front of or be towed

behind an ATV, a golf cart, lawn tractor, or another similar approved vehicle. It is not meant for

speeds exceeding 5 MPH. Your mower should be kept clean and worn parts replaced promptly

and properly.

of slopes, NEVER across the face. DO NOT MOW SLOPES GREATER THAN 15 DEGREES!

(SEE DIAGRAM ON PAGE 15 )

FRONT MOUNTING MOWER TO VEHICLE—[figure 9 page-16]

•

Securely attach Mount Kit to vehicle. [ As shown in kit mounting instructions ]

•

Park vehicle at rear of mower.

•

Casters should be able to rotate freely 360 degrees

•

Using clips and washers attach mower to vehicle.

•

Fix console assembly securely to vehicle using enclosed Velcro strips with adhesive.

•

Fix wire harness tubing to hitches using Velcro straps.

WARNING:

Never assume that children will remain where you last saw them.

To avoid serious injury, operate your mower up and down the face

6

Page 7

STARTING THE ENGINE

t has been measured from the

• See engine manufacturer’s instructions for the type and amount of oil and fuel used.

Engine must be level to accurately check and fill oil. Do not overfill.

• Park vehicle and mower on a level surface, set the vehicle parking brake, and disengage

blades.

• Check spark plug wire, oil, and fuel.

• Check all electrical connections.

• Make certain console assembly is secured to vehicle.

• Set engine throttle control to the “CHOKE” position.

• Turn key switch to the “START” position

• Set engine throttle at desired RPM.

STOPPING THE ENGINE

• Turn key switch to the “OFF” position.

BREAKING IN YOUR MOWER

• Set vehicle parking brake or chock wheels to prevent accidental rolling.

• Start engine.

• Engage blades.

• In a safely monitored environment, i.e. no children, allow blades to rotate and engine to

idle for 5 minutes. This breaks in the belts and the engine.

• Stop mower.

CAUTION!

SHUT OFF MOWER ENGINE AND REMOVE SPARK PLUG WIRE FROM

SPARK PLUG BEFORE MAKING ANY ADJUSTMENTS TO THE MOWER.

MOWER HEIGHT ADJUSTMENT

• Never make any adjustments while mower is running.

• The cutting range is approximately 1.5” to 4.5”. The heigh

ground to the blade tip without the engine running.

• Rotate height adjust crank handles in a clockwise direction to lift the mower deck. A

counter-clockwise direction is used to lower the mower deck.

• Make sure the height adjustment is the same at side crank handles. For best results, see

“SUGGESTED MOWING PRACTICE” section. Graduated scales are for reference

only, not the actual cutter height.

• Place crank handle in a retracted position to maintain height adjustment.

START MOWING

• Clear mowing area of debris.

• Check vehicle to mower connection.

• Start mower engine.

• Engage clutch lever.

• Begin mowing slowly.

7

Page 8

STOP MOWING

MOWER. NEVER ATTEMPT TO MAKE AN ADJUSTMENT THAT YOU ARE

NOT SURE IS CORRECT. DOING SO CAN CAUSE OTHER PROBLEMS.

• Bring vehicle to a full stop.

• Disengage clutch lever by moving lever to center position.

• Turn key switch to “OFF” position.

TRANSPORTING MOWER

• Never transport unit with engine running.

• If transporting unattached from tow vehicle, remove spark plug wire and place it where

contact with the spark plug cannot be made.

SUGGESTED MOWING PRACTICES

• Operate mower engine at full throttle to assure the best cutting performance and

maximum material discharge.

• Allow wet grass to dry. Clumps of wet grass will collect under the mowing deck.

• Mowing should be started with tow vehicle in low gear and increased only as safe

mowing conditions permit. This speed should not exceed 5 MPH.

• The average lawn should be cut to approximately 2.5” during the cool season and to over

3” during the hot months.

• For a healthier lawn and better aesthetics, your lawn should be mowed often and after

moderate growth.

• When cutting high or dense grass areas go slowly. Some areas may need to be cut twice.

The second cut should be at 90 degrees to the first, if possible.

• Never remove more than 1/3 of the grass length at any one time

GENERAL TROUBLE SHOOTING

• The mower does not cut level.

o Level deck, making sure height adjustments are equal.

o Check air pressure of all tires; make sure they are equal (about 25-30 psi).

o Check blade attachment.

• The engine will not start.

o Disengage blades, turn switch to “OFF” position, check all electrical connections,

and inspect spark plug and wire.

• Engine runs poorly.

o See engine manual.

o Check throttle adjuster.

o Replace fuel, clean fuel filter and fuel line.

IF PROBLEMS PERSIST HAVE A QUALIFIED MECHANIC SERVICE THE

8

Page 9

SAFETY AND OPERATIONAL DECALS

Replace decal immediately if damaged. Order by part number from Swisher Mower and Machine Co. Inc.

OD15-Important Decal

OD45 – Warning Decal

Decal located

On grass chute

[not shown]

OD33 – Speed Decal

OD10--BLADE ENGAGE

DECAL

OD99- ON / OFF

DECAL

OD55 – Triangle Danger Decal

OD11NO STEP DECAL

9

Page 10

FIGURE-1

5

15

14

1

DETAIL-12

12

10

11

16

6

SEE DETAIL

BELOW- # 12

4

6

FRAME ASSEMBLY

2

7

8

FIGURE 1

Item No. Description Part #

3

7

13

# 12

1 Frame Weldment 5147TK

2 Caster Weldment 5072

3 Tire & Wheel NO Tread 4.10x3.5-5 5057

4 Bearing, Flanged 3/4 ID CB58

5 3/4 Push Nut BLK Plastic NB-687

6 3/4ID X 1 1/4OD 10 GA. Washer NB-195

7 1/8 X 1 Cotter Pin NB-126

8 Sway Bar Right 3664

9 Sway Bar Left 3665

10 Stepped Hgt. Adj. Bushing 10579

11 1/2-13 X 7 3/4 Eye Bolt 10038

12 Height Adj. Assembly H7NTK

13 5/16 PAL NUT NB276

14 KNOB H7K

15 CRANK ROD ES214

16 HEIGHT ADJ. TUBE ES225

? Did You Know ?

In 1956 Swisher Mower & Machine Co. introduced the first zero turning radius riding mower.

The design of this 3-wheeled mower included safety features ahead of its time. In January 2000,

it was named one of the century’s top inventions by Popular Mechanics Magazine.

10

Page 11

FIGURE 2

5

33

See Detail

(Page 14)

32

3

12

4

8

36

14

See Detail

(Page 13)

6

20

19

31

7

15

26

34

1011

33

Not Pictured

16

35

2

17

18

14

9

1

TZ2S Spring

See Detail

(Page 13)

DECK ASSEMBLY

Item # Description Part # Item # Description Part #

1 50" Deck Weldment 5158TK 18 5/16-18 X 4 Carriage Bolt NB-101

2 Engage Cable Mount 5095TK 19 3/8 SAE Washer NB-272

3 Grass Chute Mount 6030TK 20 3/8-16 X 1 1/2 HCC GR5 Bolt NB-107

4 Grass Chute Weldment 3773TK 26 Idler Pulley OD-3.25", ID-3/8" B527

5 BELT COVER 5103TK 31 Washer NB-177

6 1/2-13 Nyloc Nut NB-281 32 Washer NB-272

7 1/2-13 Hex Nut NB-121 33 3/8-16 Nylok Nut Jam NB-182

8 Chute Spring 9100 34 Engine Idler 5115TK

9 Anti-Scalp Roller AS-001 35 Anti - Scalp Roller AS-001

10 3/8-16 Lock Nut NB-280 36 5/16 - 18 X 3/4'' Bolt NB596

11 1/2-13 X 3 HCC GR5 Bolt NB-131

12 5/16-18 X 8 1/2 HCC GR2 Bolt NB-136

14 5/16-18 Nyloc Nut NB-181

15 1/2-13 X 2 HCC GR5 ZP NB-509

16 1/2-13 Nyloc Nut NB-281

17 3/8-16 X 5 1/2 GR5 ZP NB-575

FIGURE 2

11

Page 12

Shown below

10

9

3

2

4

11

5

Console Assembly

Item No. Description Part #

68

7

1

14

1 Console Weldment 5136TK

2 Clutch Cable Clevis 9023MOD

3 T Handle 4463TK

4 Link for Console 4461TK

5 5/16-18 X 1 1/2 Torx Pan ZP NB-591

6 1/4 SAE Washer NB-274

7 1/4 X 1 1/2 Clevis Pin NB-518

8 3/32 X 3/4 Cotter Pin NB-597

9 5/16-18 Jam Nut NB-181

10 1/4-20 X 1 1/4 HCC GR5 ZP NB-560

11 1/4-20 Nylok Nut NB-180

12 Key Switch KSM

13 Throttle Cover [painted ] 5135TK

14 8 X3/8 Sheet Metal Screw NB137

15 8-32 Kep Nut NB201

16 8-32 x 1/2 Phil Truss NB197

Figure 7

Wiring Harness WHBP50

16

12

15

BELT CONFIGURATION

3752

Figure 5

(112” Belt)

13

T 39

(39” Belt)

WHBP50

(Complete Wiring

Harness)

12

Page 13

11

8

SET-UP

Figure 6

19

4

BLADE DRIVER

7

7

10

2

Center Blade

1

Driver

Configuration

18

Outer Blade

17

Driver

Configuration

3

14

23

28

20

2

9

13

12

Blade Driver Assy.

9058- 5.75” (Center Shaft)

9018- 4.25” (Outer Shafts)

22

27

10

16

5

30

15

31

26

29

Item No. Description Part #

1 Center Shaft 9054

6

24

25

33

32

21

26

2 Blade Bearing B98

3 Bearing Housing 9057TK

4 Pulley Spacer 6065PM

5 Blade Mount Plate 9008

6 17 1/2" Blade 5059

7 Blade Pulley- 5.5" 6114

8 Blade Pulley- 5" 3785

9 SP Washer Bellvl. PLN .413 X .945 X .118 NB-607

10 3/4 ID X 1 1/4 OD 18 GA Washer NB-179

11 3/4-16 Jam Nut NB-175

12 3/8-24 X 1 Bolt NB-238

13 3/8-24 X 1 Engine Bolt Locktite NB-238N

14 1/4-20 X 3/4 HCC GR5 ZP NB-250

15 1/4-20 Nylok Nut NB-180

16 3/8-16 2-Way Lock Nut NB-216

17 Housing Blade Bearing Short B99EC

18 L&R Shaft 9076

19 BELLEVILLE WASHER AS155

20 Washer B98W

Item No. Description Part #

21 Idler Bushing 6037

22 Idler Tension Spring TZ2S

23 5/16-18 X 3 1/2 Eye Bolt NB315

24 Idler Pulley OD-3.25", ID-3/8" B527

25 3/8-16 X 1 1/4 GR5 ZP NB618

26 3/8-16 Nyloc Nut NB280

27 3/8-16 X 2 1/4 HTC GR5 ZP NB693

28 5/16-18 Serrated Flange Nut NB170

29 3/8 SAE Washer NB272

30 3/8-16 Nylok Nut Jam NB207

31 3/8-16 Nut NB174

32 Idler Arm 6041TK

33 Washer 6040

13

Page 14

See Detail

10

6

MOTOR BASE ASSEMBLY

Figure 3

Item No. Description Part #

1 Motor Base 5102TK

10

9

1

2

7

3

2 Heat Shield 5094TK

3 Belt Guard 5097TK

4 Anti-Scalp Roller AS-001

5 3/8-16 X 5 1/2 GR5 ZP NB-575

6 3/8-16 Nyloc Nut NB-182

7 1/4-20 HX NUT NB-139

8 1/4-20 X 1 NB-102

9 1/4-20 Hx Nut ZP NB-134

10 5/16-18 X 2 1/2 HCC GR5 ZP NB-253

11 5/16-18 Serrated Flange Nut NB-170

8

4

5

ENGINE SET-UP

FIGURE 4

Item No. Description Part #

13 11- HP B&S Engine N/A

14 3/8-24 X 1 Engine Bolt Locktite NB-452N

15 Washer Belleville 699

16 1/4 X 1 Key Stock 9031

17 Engine Pulley- 5.5" 688

18 Engine Pulley Spacer Short 689S

19 Engine Pulley Spacer Long 689L

20 5/16-18 X 1-3/4 BOLT NB515

21 5/16 SAE Washer NB275

22 5/16-18 Flge. Nut NB170

23 Belt Guide 6000

24 Washer TR150W

25 5/16-18 Nyloc Nut NB181

21

20

22

13

25

16

18

17

24

19

15

14

23

14

Page 15

15

15

Page 16

Attachment Options

.

Attaching unit to operate in the front mount position

(Quick Switch Mount kit sold separately)

Item No. Description Part #

TM

Detail-1 , 3

1 Mount Pin 5153TK

2 3/16 Click Pin NB506

3 3/4 ID Washer NB195

FIGURE 9

Quick Switch Mount kit

Detail-1

PART# 2646

2

3

1

TM

Detail-3

PART# 9146

16

Page 17

REPAIR PARTS

Your 50’’ Trailmower has been produced with components designed specific to this

machine. Although standard V-belts, springs, bearings, blades, pulleys, hardware, etc.

look similar to parts used on other machinery, they may in some cases be made of a

different construction and/or materials.

R

? Did You Know ?

Swisher ATV Quick Switch

TM

Swisher Log Splitters

System

Swisher products pioneered tag along type residential mowers in the 1980’s with its 40’’ Trailmower.

Today, Swisher offers a full line of products which include log splitters, and a wide range of ATV

accessories.

R

17

Page 18

Notes

18

Page 19

Maintenance Log

Date Oil

Changed

Date

Changed

Belts

Date Blades

Sharpen or

Changed

Notes

18

Page 20

OWNER’S

MANUAL

Visit us at: www.swisherinc.com

50” UNIVERSAL MOUNT

TRAILMOWER

Each mower has its own model number. Each engine has its

own model number. The model number for the mower will be

found on the right hand side of the drive belt housing. The

model number for the engine will be found on the top of the

valve cover.

All mower parts listed herein may be ordered directly from

Swisher Mower & Machine Co., Inc. or your nearest Swisher

dealer.

All engine parts may be ordered from the nearest dealer of the

engine supplied with your mower

R

.

MODEL NO.

FT1150

WHEN ORDERING PARTS, PLEASE HAVE THE

FOLLOWING INFORMATION AVAILABLE:

* PRODUCT – 50” UNIVERSAL MOUNT

* SERIAL NUMBER - _______________

* MODEL NUMBER - _______________

* ENGINE MODEL NUMBER - _______________

TYPE - _______________

* PART NUMBER WITH PAINT CODE

* PART DESCRIPTION

TELEPHONE - 1-800-222-8183

FAX - 1-660-747-8650

SWISHER MOWER & MACHINE CO., INC.

1602 CORPORATE DRIVE

P.O. BOX 67

WARRENSBURG, MO 64093

SWISHER MOWER & MACHINE CO. ,INC.

PRINTED IN U.S.A.

Loading...

Loading...