Page 1

Visit us at www.swisherinc.com

OWNER’S

Self-Propelled

MANUAL

MODEL NO.

STARTING SERIAL # L215-335001

STP67522BS

IMPORTANT

Read and follow all

Safety Precautions

and Instructions

before operating this

equipment.

Easy Glide

Assembly

Operation

Service and

Adjustment

Repair Parts

1602 CORPORATE DRIVE, WARRENSBURG MISSOURI 64093

19129 REV 15-335

Made In The

USA

of US and Global Parts

SWISHER ACQUISITION INC.

PHONE 660-747-8183 FAX 660-747-8650

Page 2

LIMITED WARRANTY

The manufacturer’s warranty to the original consumer purchaser is: This product is free from defects in

materials and workmanship for a period of two (2) years from the date of purchase by the original consumer

purchaser. We will repair or replace, at our discretion, parts found to be defective due to materials or

workmanship. This warranty is subject to the following limitations and exclusions:

1) Engine Warranty All engines utilized on our products have a separate warranty extended

to them by the individual engine manufacturer. Any engine service

difficulty is the responsibility of the engine manufacturer and in no way

is Swisher or its agents responsible for the engine warranty. The Briggs

& Stratton Engine Service Hot Line is 1-800-233-3723.

2) Commercial Use This product is not intended for commercial use and carries no

commercial warranty.

3) Limitation This warranty applies only to products which have been properly

assembled, adjusted, and operated in accordance with the instructions

contained within this manual. This warranty does not apply to any

product of Swisher that has been subject to alteration, misuse, abuse,

improper assembly or installation, shipping damage, or to normal wear

of the product.

4) Exclusions Excluded from this warranty are normal wear, normal adjustments, and

normal maintenance.

In the event you have a claim under this warranty, you must return the product to an authorized

service dealer. All transportation charges, damage, or loss incurred during transportation of parts

submitted for replacement or repair under this warranty shall be borne by the purchaser. Should

you have any questions concerning this warranty, please contact us toll-free at 1-800-222-8183.

The model number, serial number, date of purchase, and the name of the authorized Swisher dealer

from whom you purchased the trimmer will be needed before any warranty claim can be processed.

THIS WARRANTY DOES NOT APPLY TO ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES AND ANY IMPLIED WARRANTIES ARE LIMITED TO THE SAME TIME

PERIODS STATED HEREIN FOR ALL EXPRESSED WARRANTIES. Some states do not allow

the limitation of consequential damages or limitations on how long an implied warranty may last,

so the above limitations or exclusions may not apply to you. This warranty gives you specific legal

rights and you may have other rights, which vary from state-to-state. This is a limited warranty as

defined by the Magnuson-Moss Act of 1975.

2

Page 3

tructions, to operate

Safety Instructions

This Safety Alert Symbol indicates important messages in this

manual. When you see this symbol, carefully read the message that

follows and be alert to the possibility of personal injury.

• Read, understand and follow all instructions in the manual and on the trimmer

before starting.

• Read this manual carefully. Become familiar with the controls and how to

operate the unit properly.

• Only allow responsible adults, who are familiar with the ins

the unit.

• Clear the area of objects such as rocks, toys, etc. that could be thrown by the

unit.

• Be sure the area is clear of other people before trimming. Stop the unit if

anyone enters the area.

• Be aware of the direction of the trimmer discharge and do not direct it at

anyone. Do not direct trimmer discharge at breakable objects, such as

windows, etc.

• Do not operate trimmer without all guards and shields in place.

• Never leave the machine running unattended.

• Trim only in daylight or good artificial light.

• Do not operate the trimmer while under the influence of alcohol or drugs.

• Watch for traffic when operating near roadways.

• Use the trimmer as the manufacturer intended and as described in the

manual.

• Do not operate trimmer if it has been dropped or damaged in any manner.

Always have the damage repaired before operating.

• Always wear safety glasses or eye shields when using the trimmer.

• Dress properly. Do not operate the trimmer when barefoot or wearing open

sandals. Wear only solid shoes for good traction when trimming. Wear a long

sleeved shirt or jacket and long pants. Do not trim in shorts.

• Keep your eyes and mind on your trimmer and the area being trimmed. Do

not let other interests distract you.

• Do not put hands and feet near or under rotating parts.

• Before cleaning, inspecting or repairing your trimmer, stop the engine and

disconnect the spark plug wire and keep it away from the spark plug to

prevent accidental starting.

• Do not operate the trimmer if it vibrates abnormally. Excessive vibration is a

sign of damage. Stop the engine and safely check for damage and repair as

required.

• Do not operate the trimmer in wet grass, where good footing may not be

possible. Walk, never run.

• Stop the trimmer when crossing gravel drives, etc.

3

Page 4

Slopes are a major factor related to loss of control and slip accidents,

Slope Operation

•

•

Use extra care when approaching blind corners, shrubs, trees or other objects

which can result in severe injury. All slopes require extra caution. If you

feel uneasy on it do not trim it.

DO: Trim across the face of a slope and not up and down.

• DO: Remove objects such as rocks, tree limbs, etc.

• DO: Watch for holes, ruts or bumps. Tall grass can hide obstacles.

• DO NOT: Mow near drop-offs, ditches or embankments. The operator could

lose footing or balance.

• DO NOT: Trim excessively steep slopes.

• DO NOT: Trim on wet grass. Reduced footing could cause slipping.

Keep children out of the area and under the watchful care of another

responsible adult.

Be alert and turn the machine off if children enter the area.

•

Before and when backing, look behind and down for small children.

•

Never allow children to operate this machine.

•

•

that may obstruct vision.

Children

• Use extra care handling gasoline and other fuels. They are flammable and

vapors are explosive.

• Use only an approved container for fuel.

• Never remove gas cap or add fuel with the engine running.

• Allow engine to cool before refueling. Do not smoke while refueling.

• Never refuel the machine indoors.

• Never store the machine or fuel container where there is an open flame, such

as a water heater.

• Never run a machine inside a closed area.

• Keep nuts and bolts tight and equipment in good condition.

• Never tamper with safety devices.

• Keep machine free of grass, leaves or other debris build up. Clean oil or fuel

spillage. Allow machine to cool before storing.

• Stop and inspect the equipment if you strike an object. Repair if necessary

before restarting.

• Never make repairs or adjustments with the engine running.

Service

4

Page 5

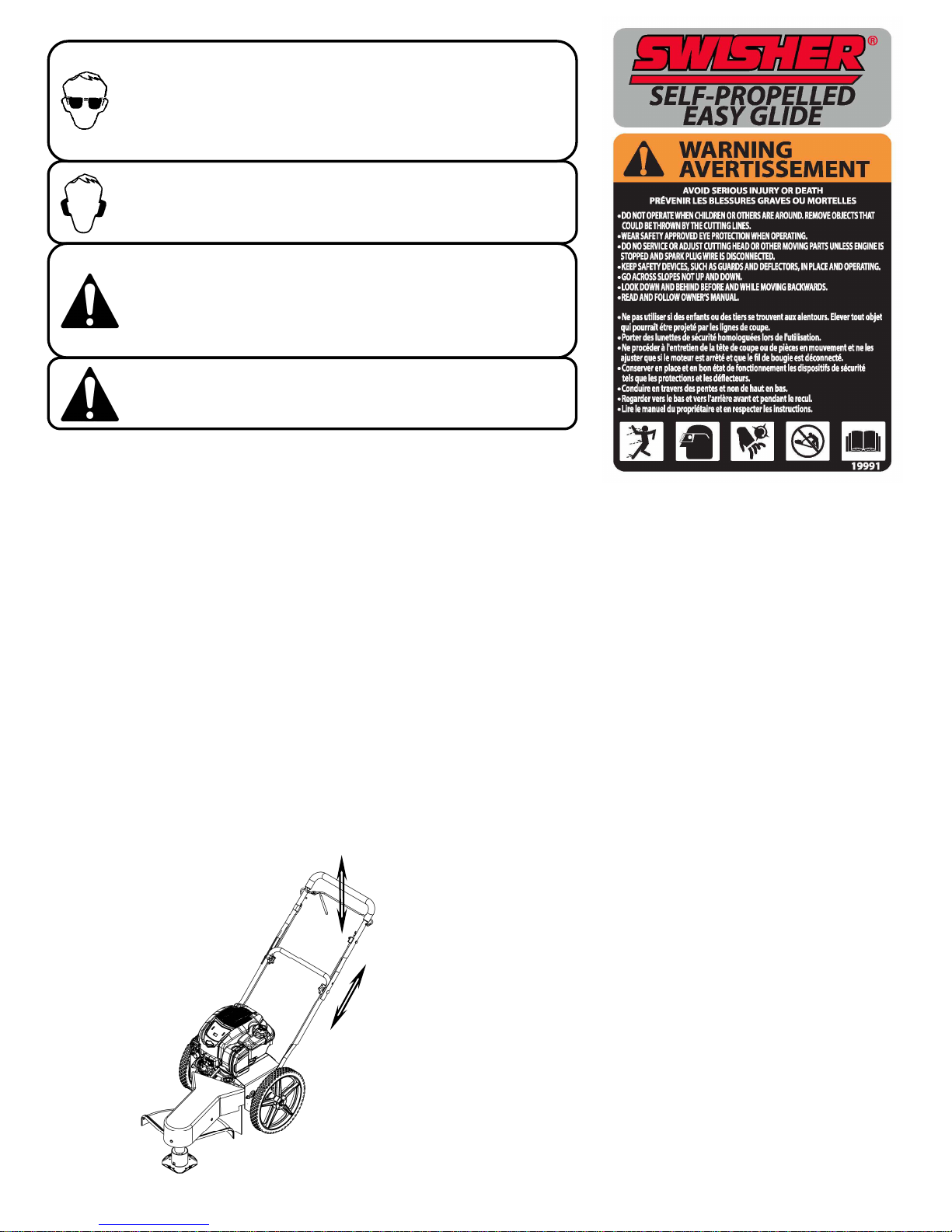

The operation of any mower can encounter foreign

hardware removed in previous step. Snug, but

objects to be thrown into the eyes, resulting in severe eye

damage. Always wear certified safety glasses or widevision safety goggles over spectacles before starting any

cutting machine and while operating such a machine.

The operation of any mower produces sound waves that

are damaging to the human ear. Ear protection is

recommended.

CAUTION!

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw them.

Do not operate the trimmer if it vibrates abnormally. Excessive

vibration is a sign of damage. Stop the engine and safely

check for damage and repair as required.

Warning Decal

19991

Contents of Box:

• Trimmer

Parts bag containing:

• Manual

• Engine manual

• Safety goggles

• Bottle of engine oil

• Trimmer line

• Hex wrench

Assembly

Tools Required:

• ½” Wrench

Installation of handles:

1. Remove loose fasteners from trimmer frame

handle holes.

2. Pivot lower handle up and align holes in

handle with holes on trimmer frame. Install

do not tighten bolts.

3. Attach upper handle to lower handle using

knobs and fasteners provided with lower

handle.

4. Adjust handles for comfortable operation.

5. Tighten all bolts.

Handles may be adjusted up and down and in and out

for comfortable operation.

Handle Adjustment

5

Page 6

Preparing Unit For First Use

• Fill engine crankcase with oil. A 20oz. bottle has been provided with this unit. A new unit

requires 18-20oz. DO NOT OVERFILL.

• Fill the engine fuel tank with gasoline. GASOLINE SHOULD BE ADDED OUTSIDE IN A

WELL-VENTILATED AREA.

• Check to ensure string has been installed properly. A diagram is provided just above the trimmer

head for proper installation.

• Refer to engine manufacture’s manual for oil and fuel specifications.

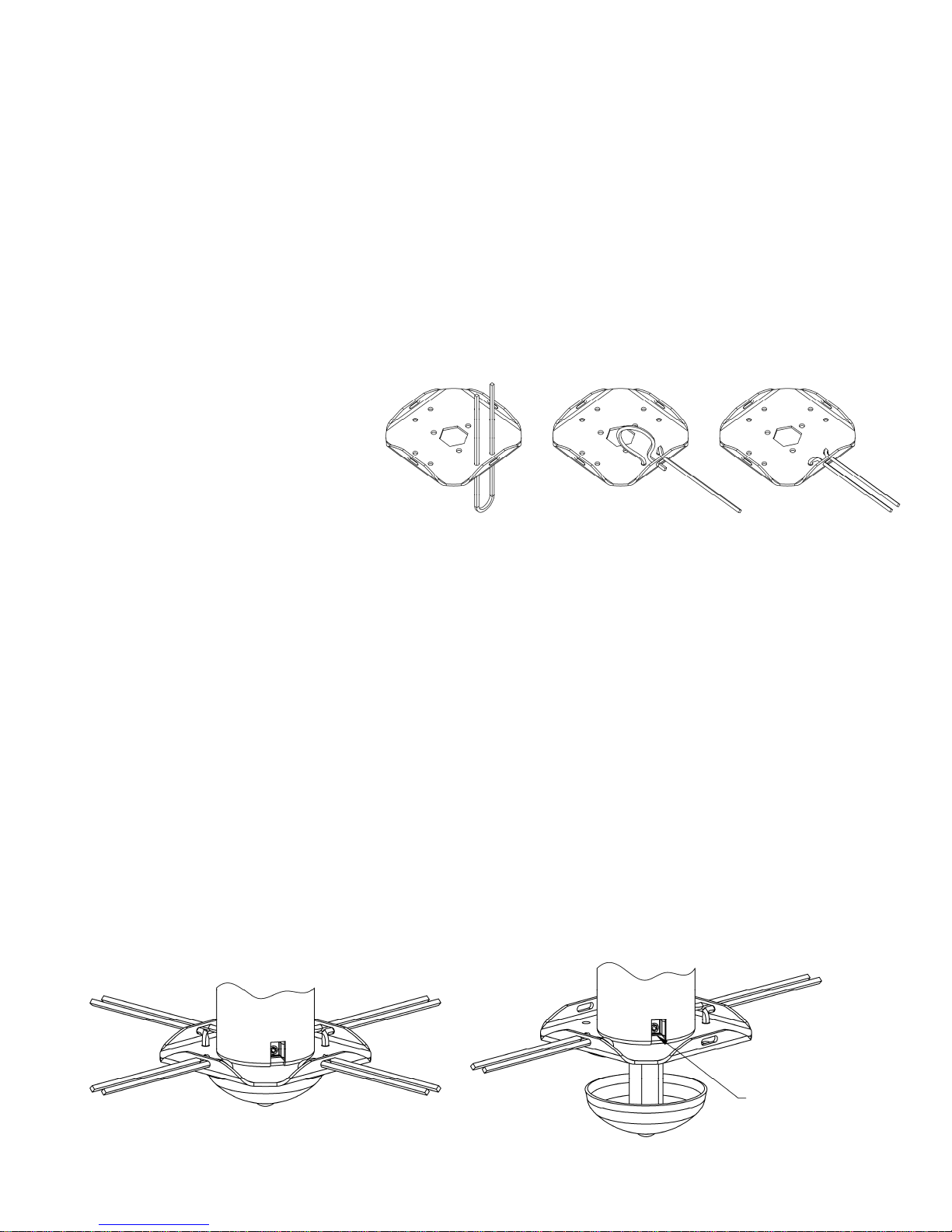

Installing Trimmer Line

Important! Use the proper length of line. Using a line too long for the unit will cause

stalling and unacceptable operation.

Use 18” Trimmer Line

Part Number P3618

• Loosely fold trimmer line in half.

• Insert line through the bottom holes of the cutting disc (Step 1).

• Bring ends around and through the slot in the cutting disc flange (Step 2).

• Pull ends to tighten loop (Step 3).

Step 1

Step 3Step 2

Trimmer Line Positions

Trimmer line attachment positions:

• Trimmer is equipped with 4 trimmer line attachment points.

• When mowing with trimmer, the 4 trimmer line configuration is recommended for a more consistent,

even cut.

• When trimming tall or thick vegetation, the 2 trimmer line configuration is recommended for improved

To adjust cutting height:

1. Loosen set screw using hex wrench provided.

2. Slide cutting head up or down to desired cutting height.

3. Tighten set screw.

4. Any cutting height may be used with either trimmer line configuration.

performance.

Set Screw

4 Trimmer line Configuration

Shown set at Low cutting height

2 Trimmer line Configuration

Shown set at High cutting height

6

Page 7

Operation

•

Important! To ensure proper operation, clean the engine and trimmer regularly. Remove any build up

of chaff from the top of the engine. During operation debris may get wrapped around trimmer head.

Prolonged use in this condition may result in excessive wear and part failures. Periodically turn off trimmer

and remove debris.

To start the trimmer:

1. Remove any built up debris from engine and trimmer head.

2. Move throttle control to “FAST”.

3. Firmly grasp rope handle and pull out slowly until resistance is felt. Then pull back rapidly with a

full arm stroke.

4. When engine starts, leave throttle control at “FAST”. Throttle control must be set in the fast

position for maximum performance.

5. Engage trimming head.

6. Begin trimming.

To engage/disengage trimmer head:

• Engage: Bring control bail into contact with the upper handle and grip it together with the handle.

If trimmer head does not fully engage, see belt adjustment section.

• Disengage: Release control bail. Trimmer head should stop within a few seconds. If it does not,

To engage/disengage transmission:

• Engage: Bring transmission engagement lever into contact with the upper handle and grip it

• Disengage: Release transmission engagement lever.

To stop the trimmer:

1. Release the control bail.

2. Move throttle control lever on engine to “SLOW” for a few seconds then move to “STOP”.

see belt adjustment section.

together with the handle.

Important!

For safest operation, make sure debris is directed away from you and others.

Troubleshooting

• If engine will not start, remove and check air filter to make sure filter and

carburetor are clean.

Trimming Tips

Do not lift the trimmer head when trimming. Let the head rest lightly touching the ground.

• Keep an eye on the length of the trimmer line. As the line gets shorter they become less effective at

cutting and will take longer to trim properly. Replace the line as necessary (see Installing Trimmer Line).

• Do not trim wet grass.

• Use caution when trimming slopes.

• Use the proper length of line. Using a line too long for the unit will cause stalling and

7

Page 8

Trimmer Maintenance

WARNING

–

ALWAYS STOP ENGINE AND DISCONNECT SPARK PLUG

e belts may need to be adjusted using the following instructions. Indications that the belts

.

Make sure your trimmer is in safe working condition by keeping the following guidelines in mind every time you

use your trimmer.

• Keep trimmer in good operating condition and keep all guards and shields in place. DO NOT operate this

trimmer if any of the shields and guards are missing.

• Check all fasteners for secure fit to keep equipment in safe working order. Make adjustments as necessary.

• To reduce fire hazards, keep engine free of grass, leaves or excessive grease.

• DO NOT operate trimmer with a damaged or missing muffler. DO NOT tamper with exhaust system; this may

cause a fire hazard.

• DO NOT operate engine if air cleaner or the cover over the carburetor air intake is missing. Removal of these

parts could create a fire hazard.

• Before cleaning, making adjustments or repairing the trimmer, STOP engine, disconnect spark plug wire and

allow engine to cool.

• Handle gasoline with care. DO NOT smoke or use open flame near gasoline. Use only approved gasoline

containers. Never fuel or run trimmer in poorly ventilated areas, such as a garage or utility building.

• Always replace fuel tank cap. Be sure to clean up any spilled gasoline.

• Do not change the engine governor settings or over-speed the engine; severe injury or damage may result.

• Never store mower with gasoline in the tank inside a building where fumes may reach an open flame or spark.

Always allow engine to cool before storing.

NEVER ADD GASOLINE TO A HOT ENGINE – ALLOW ENGINE TO

COOL BEFORE ADDING GASOLINE.

WIRE BEFORE PERFORMING ANY ADJUSTMENTS OR SERVICE.

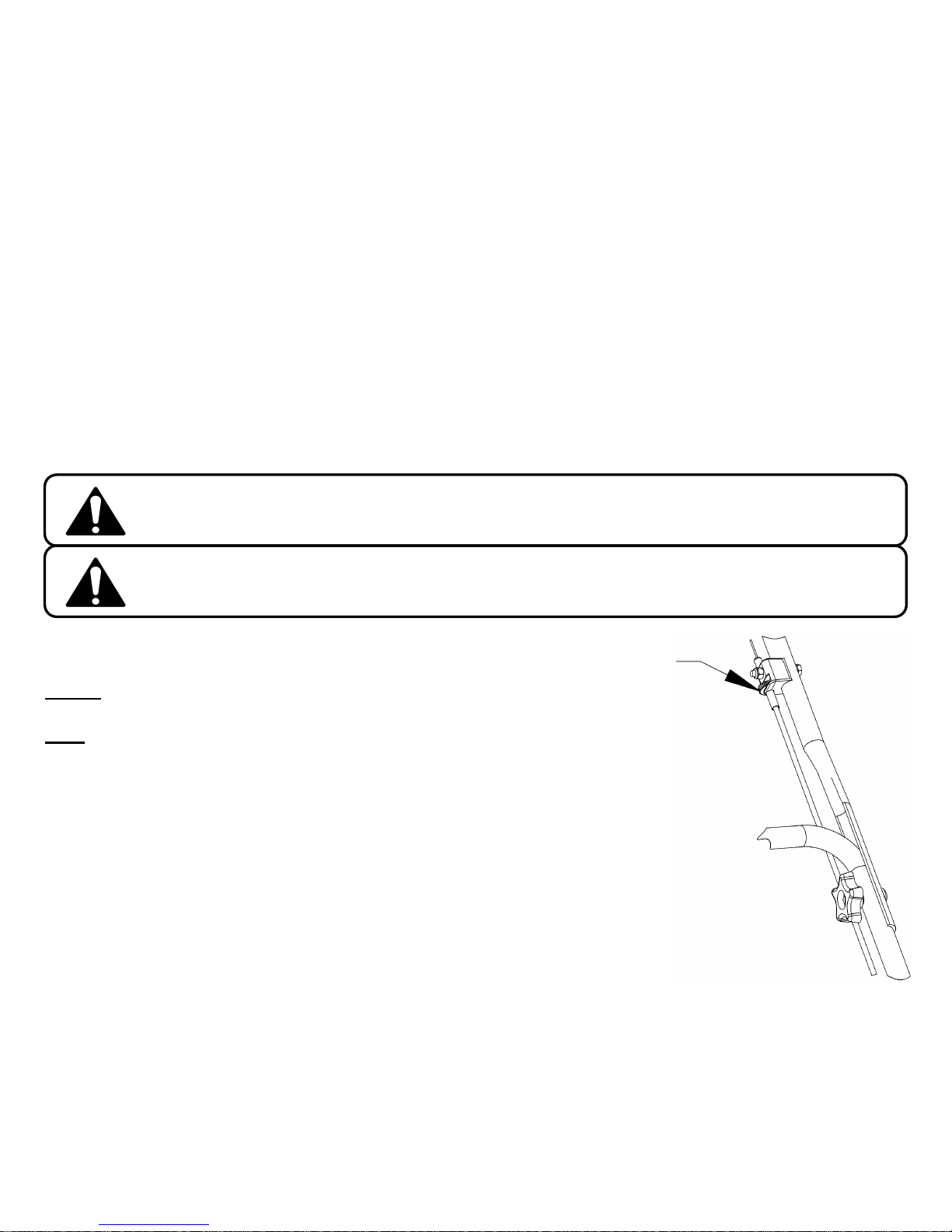

Thumb wheel

Engine

• Refer to the engine service manual provided with this unit.

Belts

• Occasionally check the belts for wear. A worn belt should be replaced.

Belt Adjustment

During the first few hours of operation all belts go through a “break-in period” after which

th

need to be adjusted include:

• Loss of power at the trimming head causing the head to spin unusually slow or stop.

• Excessive wear on belt due to slipping.

• The belt that powers the transmission is designed to be under constant tension and

needs no further adjustment.

• The belts used to engage/disengage the trimmer head can be adjusted using the

following instructions:

1. Locate the thumb wheel adjuster on the control cable (see illustration).

2. Release control bail to disengage trimmer head.

3. Rotate thumb wheel a few turns counterclockwise

4. Re-engage trimmer head.

5. If trimmer head has not returned to normal operation, repeat steps 2-4.

(from normal operating position).

Important!

Excessive force should NOT be required to fully engage control bail.

Do not over tighten cable adjuster. This may cause the cable to break

8

Page 9

Belt Replacement

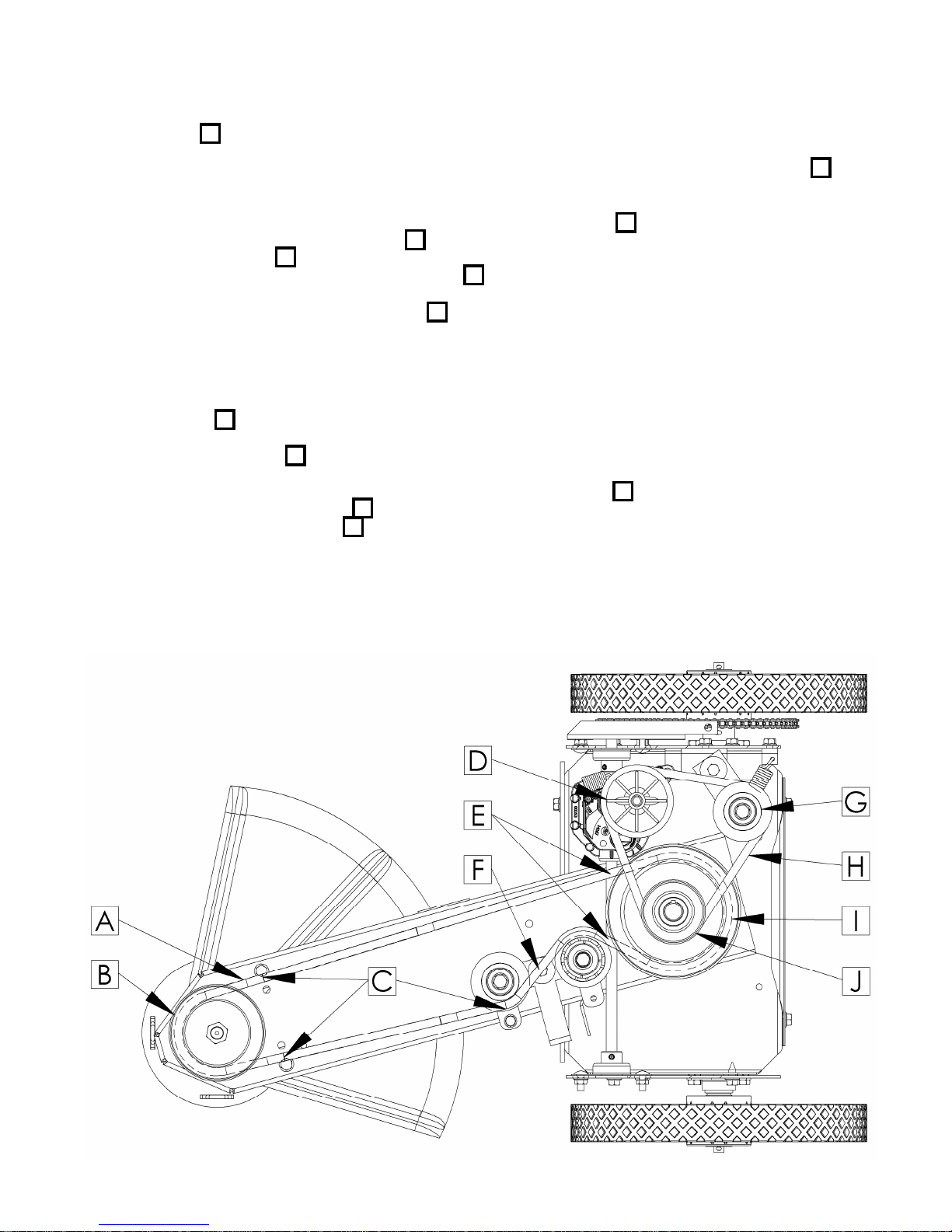

Head Engagement Belt A Replacement

1. Remove front belt cover.

2. Loosen or remove fasteners used to attach engine to allow engine to shift. Slide or tilt engine so lower engine pulley I moves

away from transmission, creating a gap to allow belt to be removed.

3. Remove old belt.

4. Install new belt by first routing belt under the engine and around lower engine pulley I .

5. Then route belt between two idler pulleys as shown F .

6. Install belt around front pulley B .

7. Ensure that belt is correctly installed between the belt guides C and adjacent pulley.

8. Ensure that belt is correctly installed in the grove of each pulley.

9. Ensure that belt is over the top of the transmission axle E .

10. Tighten or reinstall fasteners used to attach engine.

11. If belt tension had previously been adjusted, reset thumb wheel adjuster by rotating wheel clockwise as far as adjuster will allow

(see illustration in belt adjustment instructions). If head does not properly engage refer to belt adjustment instructions.

12. Reinstall front belt cover.

Transmission Power Belt H Replacement

1. Remove front belt cover.

2. Remove Head Engagement Belt A per instructions above.

3. Remove old belt.

4. Install new belt by first routing belt under the engine and around upper engine pulley J .

5. Then route belt around transmission pulley D .

6. Finally route belt around rear idler pulley G . The idler pulley is spring loaded, making it difficult to finish belt installation. To

ease belt installation push idler pulley toward transmission pulley while wrapping belt around idler pulley. CAUTION – Pinch

Hazard: Ensure that you do not get any part of your body between the belt and the pulleys as this may cause injury.

7. Reinstall Head Engagement Belt per instructions above.

8. Reinstall front belt cover.

9

Page 10

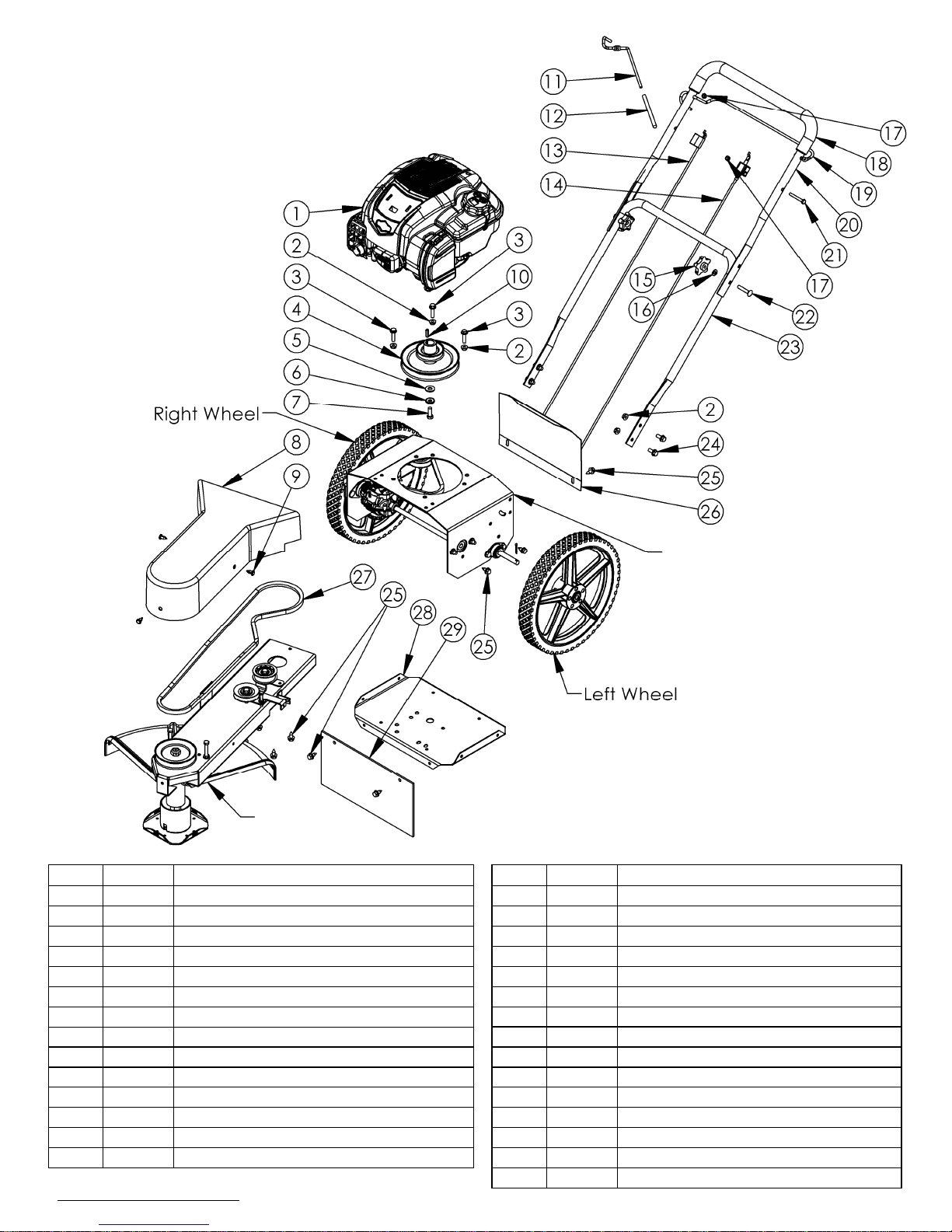

Assembly

See Detail

Page 11

Item # Part # Description Item # Part # Description

1 N/A Engine - Briggs & Stratton 15 2030 Knob - Black Plastic

2 NB170 Nut - Serrated Flange 5/16-18 16 NB275 Washer - SAE Flat 5/16

3 NB253 Bolt - Serrated Flange, 5/16-18 X 1 1/4 17 NB180 Nut - Nyloc 1/4-20

4 19018 Pulley - Double Drive, Trimmer 18 19561 Grip - Handle, Anti-Vibration

5 NB271 Washer - USS Flat 3/8, ZY Carbn Stl 19 19005 Bail - Trimmer

6 NB607 Washer - SP Bellville 20 19017* Handle - Top, SP Trimmer

7 NB238N Bolt - HHC 3/8-24 X 1 21 NB218 Bolt - 1/4-20 X 2 HCC GR5 ZY

8 2019 Guard - Belt 22 NB587 Bolt - Carriage, 5/16-18 X 1 3/4

9 19135 Clip - Panel 23 10399* Handle - Lower

10 9030 Key Stock - 3/16 X 1 24 NB596 Bolt - Serrated Flange, 5/16-18 X 3/4

11 19027 Lever - Transmission Engagement 25 26X249 Screw - .312-18 X .75

12 19823 Grip - STP Lever 26 19016* Cover - Rear, SP Trimmer

13 19101 Cable - Transmission Control; STP 27 19034 Belt - 60", Trimmer

14 19006 Cable - Control, Trimmer 28 2006* Base - Lower Motor

When ordering replacement parts

* USE PAINT CODE: TK=BLACK

See Detail

Page 12

29 19004 Shield - Rubber

10

Page 11

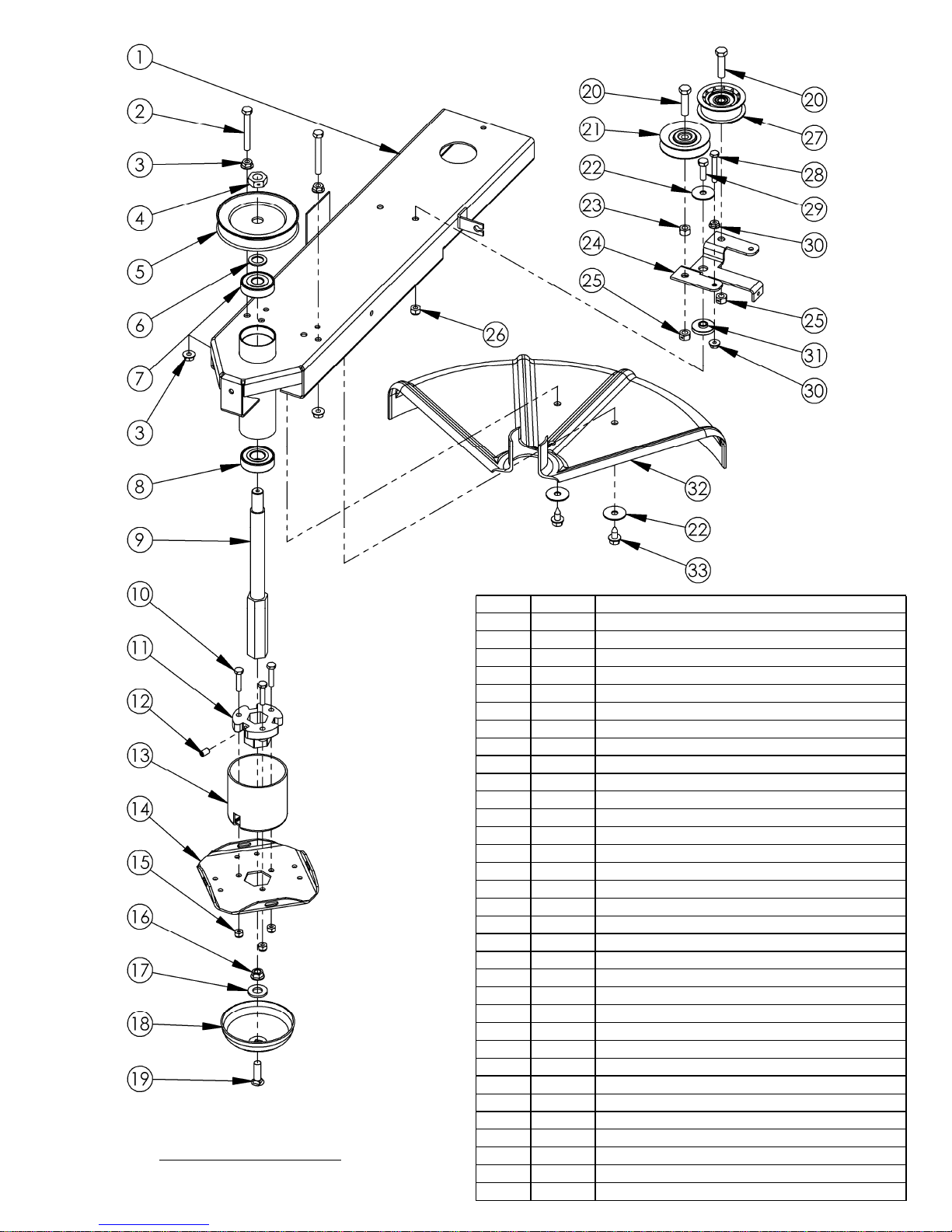

Trimmer Head Assembly

ITEM #

PART #

DESCRIPTION

1

18999*

Weldment - Trimmer Neck, Standard

2

NB138

Bolt - 5/16-18 X 2 1/2 HCC GR5 ZY

3

NB170

Nut - Serr Flange 5/16-18 ZY Case Hrd

4

NB595

Nut - Lock Jam, 5/8-11 2 Way

5

2049

Pulley - Blade 4.5"

6

NB149

Washer - 5/8 ID X 1 OD 14 GA ZY

7

B985/8

Bearing - Trimmer

8

19123

Bearing - 20mm ID, Steel Seal

9

19009

Shaft - Cutting Head, Standard

10

NB560

Bolt - 1/4-20 X 1 1/4 HCC GR5 ZY

11

19011

Hub - Cutting Head, PM

12

NB312

Screw - Set 5/16-18 X 1/2 With Loctite

13

19010

Guard - Shaft, Trimmer

14

19837*

Disc - Cutting Head

15

NB180

Nut - Nyloc 1/4-20

16

NB779

Nut - Serr Flange, Hex ZY 3/8-16

17

18823

Washer - Flat, 1/2"ID-12GA ASTM A325; ZY

18

19012*

Cutting Guide - Trimmer

19

10501

3/8 X 1-1/4 Carriage Bolt

20

NB107

Bolt - 3/8-16 X 1 1/2 HCC GR5 ZY

21

T30V

Pulley - Idler Clutch, 2 3/4 OD

22

NB579

Washer - Fender, 5/16 X 1 1/4 OD ZY GR2

23

NB212

Nut - HNC, 3/8-16 GR2 ZY

24

19014*

Idler Arm - STP Trimmer

25

NB280

Nut - 2 Way Lock 3/8-16 ZY & Wax Gr A

26

NB181

Nut - Nyloc 5/16-18 ZY

27

19108

Pulley - Backside Idler, 2.25" OD 3/8"

28

NB278

Bolt - 1/4-20 X 1 3/4 GR2 ZY

29

NB501

Bolt - 5/16-18 X 1 HCC GR5 ZY

30

NB524

Nut - Serr Flange, 1/4-20 Grade 5 ZY

31

16823

Bushing - Shoulder 3/8, ZT60

32

2042

Guard - String

33

26X249

Screw - .312-18 X .75

When ordering replacement parts

* USE PAINT CODE: TK=BLACK

11

Page 12

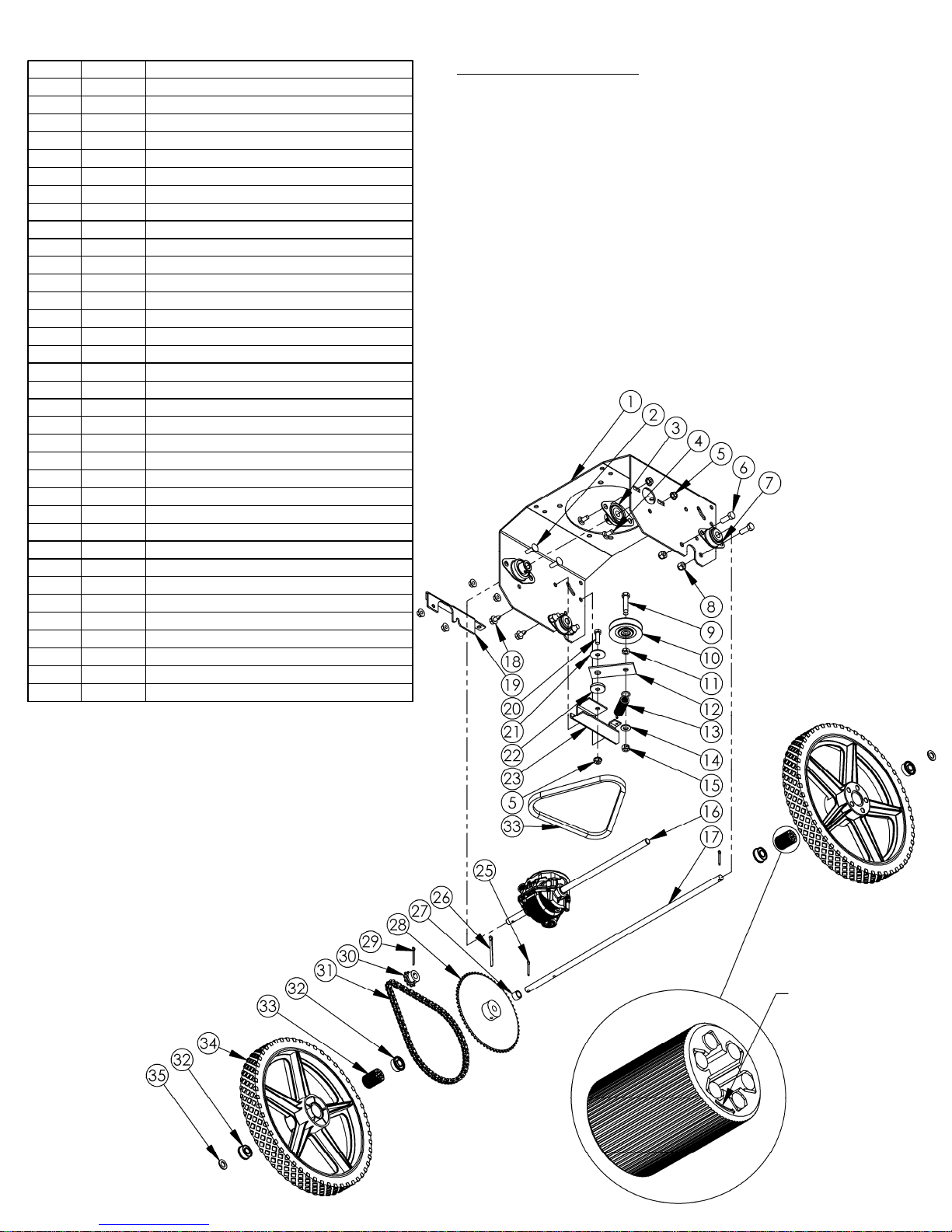

Drive Train Assembly

ITEM # PART # DESCRIPTION

1 19015* Motor Base - Upper, STP Trimmer

2 10197 Bolt - Carriage 5/16-18X1 GR5 ZY

3 19019 Bearing - 1/2" Flange Mounted

4 10216 Bolt - Carriage 5/16-18X3/4 GR5 ZY

5 NB170 Nut - Serr Flange 5/16-18 ZY

6 NB604 Bolt - 3/8-16 X 1 GR5 ZY

7 4005 Bearing - Side Flange

8 NB182 Nut - Nyloc 3/8-16 ZY

9 NB107 Bolt - 3/8-16 X 1 1/2 HCC GR5 ZY

10 T30V Pulley - Idler Clutch, 2 3/4 OD

11 NB174 Nut - Jam 3/8-16 ZY Grade 2

12 19024* Idler Arm - Transmission

13 7821 Latch Spring

14 NB272 Washer - SAE Flat 3/8 ZY

15 NB280 Nut - 2 Way Lock 3/8-16 ZY

16 19020 Transmission - String Trimmer

17 19025 Axle - Self-Propelled Trimmer

18 26X249 Screw - .312-18 x .75

19 19087* Guard - Chain; Trimmer

20 NB501 Bolt - 5/16-18 X 1 HCC GR5 ZY

21 NB579 Washer - Fender, 5/16 X 1 1/4 OD ZY

22 16823 Bushing - Shoulder 3/8, ZT60

23 19023* Bracket - Idler Arm, SP Trimmer

24 19053 Belt - 24", SP Trimmer

25 NB126 Pin - Cotter, 1/8 X 1

26 19036 Pin - Cotter, 3/16 X 2.25; ZP

27 690369 Spacer - 1/2" TO 17 MM

28 19022 Sprocket - No. 35, 60 Teeth; 1/2" Bore

29 19035 Pin - Cotter, 1/8 X 1-1/2; ZP

30 19021 Sprocket - No. 35, 10 Teeth; 1/2" Bore

31 19044 Chain - ANSI #35, 70 Link Loop

32 MWB Bearing - Wheel, 1 1/8"OD X 1/2"ID

33 19045*** Clutch - Wheel, 1.125 OD X 0.5 ID

34 19026** Wheel - 14", 1/2" Bearings; Trimmer

35 NB177 Washer - Mach 1/2 NR 14 GA

When ordering replacement parts

* Use paint code: TK=Black

** Wheels include two bearings. Use part # MWB when replacing bearings only.

Note: Optional wheel kits are available that include the bearings and wheel clutch

installed. Order part # 19085 for left wheel kit and part # 19086 for right wheel kit.

*** Wheel clutch must be installed in the correct orientation in order to operate

properly. Wheel clutch is installed correctly when wheels spin freely while

trimmer is moving forward without the engine running (wheels will have resistance

when trimmer is moving backward). One of the wheel bearings may need to be

removed prior to installing the wheel clutch. The wheel clutch has an arrow on the

side to indicate the “free-wheel” direction. Ensure clutch is orientated so the freewheel direction corresponds to direction the wheel will rotate while trimmer is

moving forward and press the clutch into the center of the wheel (interference fit).

Then replace the wheel bearing and install the wheel on the axle.

Important!Rotate wheel in free-wheel direction while mounting on axle

(spin and push at the same time). Ensure both wheel bearings remain fully

seated in wheel during wheel installation and operation. Failure to do so may

cause damage to wheel clutch.

Arrow on clutch

shows direction

wheel spins freely

when installed.

12

Page 13

OWNER’S

MANUAL

Visit us at: www.swisherinc.com

MODEL NO.

STP67522BS

Each trimmer has its own model number. Each engine has its

own model number. The model number for the trimmer will be

found on the left hand side of the motor base. The model

number for the engine will be found on the top of the blower

fan housing.

All trimmer parts listed herein may be ordered directly from

Swisher or your nearest Swisher dealer.

All engine parts may be ordered from the nearest dealer of the

engine supplied with your mower.

WHEN ORDERING PARTS, PLEASE HAVE THE

FOLLOWING INFORMATION AVAILABLE:

* PRODUCT – TRIMMER

* SERIAL NUMBER - _______________

* MODEL NUMBER - _______________

* ENGINE MODEL NUMBER - _______________

TYPE - _______________

* PART NUMBER WITH PAINT CODE

* PART DESCRIPTION

TELEPHONE - 1-800-222-8183

FAX - 1-660-747-8650

SWISHER ACQUISITION INC.

1602 CORPORATE DRIVE

WARRENSBURG, MO 64093

Changing your landscape since 1945.

13

Page 14

Visítenos en www.swisherinc.com

MANUAL DEL

Self-Propelled

PROPIETARIO

Número del modelo

Del número de serie

L215-335001

STP67522BS

IMPORTANTE

Lea y siga todas las

advertencias e instrucciones

sobre seguridad antes de

poner en funcionamiento

este equipo.

Easy Glide

Ensamblaje

Funcionamiento

Servicio y ajuste

Piezas para

reparación

1602 CORPORATE DRIVE, WARRENSBURG MISSOURI 64093

TELÉFONO 660-747-8183 FAX 660-747-8650

19129 REV 15-335

Hecho en

EE.UU.

de Estados Unidos y partes mundial

SWISHER ACQUISITION INC.

Page 15

GARANTÍA LIMITADA

La garantía que el fabricante otorga al comprador original es: Este producto está libre de defectos en los

materiales y la mano de obra por un periodo de dos (2) años desde la fecha de compra por parte del

comprador consumidor original. Repararemos o cambiaremos, a nuestra discreción, las partes que se

determine estén defectuosas debido a los materiales o a la mano de obra. Esta garantía está sujeta a las

siguientes limitaciones y exclusiones:

1) Garantía del motor Todos los motores que se utilizan en nuestros productos poseen una

garantía separada que las extiende el fabricante a cada motor.

Cualquier problema en el funcionamiento del motor es

responsabilidad del fabricante del motor y de ninguna manera

Swisher o sus agentes son responsables por la garantía del motor. El

teléfono de atención de Briggs & Stratton Engine Service Hot Line es

1-800-233-3723.

2) Uso Comercial Este producto no ha sido diseñado para uso comercial y no posee

garantía comercial.

3) Limitación Esta garantía se aplica sólo a los productos que se han ensamblado,

ajustado y operados correctamente de acuerdo con las instrucciones

contenidas en este manual. Esta garantía no se aplica a ningún

producto de Swisher que ha sido objeto de modificaciones, mal uso,

abuso, ensamblaje o instalación incorrectos, daños en el embarque, o

a un desgaste normal del producto.

4) Exclusiones Están excluidos de esta garantía el desgaste normal, los ajustes

normales y el mantenimiento normal.

En caso de que usted tenga un reclamo amparado por esta garantía, debe regresar el producto a un

representante de servicio autorizado. Todos los cargos de transporte, daños o pérdida que se produzcan

durante el transporte de las piezas suministradas para el cambio o reparación bajo esta garantía los

cubrirá el comprador. Si tiene preguntas relacionadas con esta garantía, por favor llámenos al número

gratis 1-800-222-8183. Antes de procesar cualquier reclamo cubierto por la garantía, necesitamos saber

el número del modelo, el número del serial y el nombre del distribuidor Swisher autorizado en donde

usted compró la podadora.

ESTA GARANTÍA NO SE APLICA A DAÑOS INCIDENTALES O CONSECUENCIALES Y

CUALQUIERA DE LAS GARANTÍAS IMPLÍCITAS SE LIMITAN AL MISMO PERIODO DE

TIEMPO ESTABLECIDO AQUÍ, PARA TODAS LAS GARANTÍAS EXPRESAS. Algunos estados

no permiten la limitación de los daños consecuenciales o las limitaciones en la duración de una garantía

implícita, así que las limitaciones o las exclusiones de arriba es posible que no apliquen para usted. Esta

garantía le otorga derechos legales específicos y usted puede tener otros derechos, los cuales varían de

un estado a otro. Esta es una garantía limitada de acuerdo a como se ha definido en la ley MagnusonMoss Act de 1975.

2

Page 16

Limpie el área de objetos tales como rocas, juguetes, etc., que pudieran ser arrojados

Pare el motor y revise cuidadosamente el daño y repárelo como sea necesario.

Instrucciones sobre seguridad

Este símbolo de alerta de seguridad indica mensajes importantes en

este manual. Cuando vea este símbolo, lea cuidadosamente el mensaje

que sigue y esté alerta a la posibilidad de lesiones personales

• Lea, comprenda y siga todas las instrucciones del manual y sobre la orilladora antes

de encenderla

• Lea cuidadosamente este manual. Familiarícese con los controles y cómo operar

correctamente la unidad.

• Sólo permita que los adultos responsables, que estén familiarizados con las

instrucciones operen la unidad.

•

por la unidad.

• Asegúrese de que no haya otras personas antes de hacer recortes. Detenga la

unidad si alguien entra al área.

• Esté alerta sobre la dirección de la descarga de la orilladora y no la dirija hacia nadie.

• No dirija la descarga de la orilladora hacia objetos rompibles, tales como ventanas,

etc.

• No ponga en funcionamiento la orilladora sin que tenga colocadas todas las

protecciones y pantallas.

• Nunca deje la máquina funcionando sin supervisión.

• Pode sólo bajo la luz del día o con buena luz artificial.

• No opere la orilladora mientras esté bajo la influencia del alcohol o de drogas.

• Tenga cuidado con el tráfico cuando esté operando cerca de vías de comunicación.

• Use la orilladora de acuerdo a lo proyectado por el fabricante y como se describe en

el manual.

• No ponga a funcionar la orilladora si se ha caído o está dañada de alguna forma.

Siempre haga que reparen los daños antes de ponerla a funcionar.

• Siempre use gafas de seguridad o protectores para los ojos cuando use la orilladora.

• Vístase adecuadamente. No opera la orilladora cuando esté descalzo o cuando use

sandalias abiertas. Use sólo zapatos sólidos para una buena tracción cuando esté

rebajando. Use camisas manga larga o chaquetas, también use pantalones largos.

No pode usando pantalones cortos.

• Mantenga los ojos y la mente en su orilladora y en el área que está podando.

• No permita que otros intereses lo distraigan.

• No coloque las manos y los pies cerca o debajo de las piezas rotatorias.

• Antes de limpiarla inspeccione o repare la orilladora, pare el motor y desconecte el

cable de la bujía y manténgalo lejos de la bujía para evitar un arranque accidental.

• No opere la orilladora si vibra anormalmente. La vibración excesiva es una señal de

daño.

• No ponga a funcionar la orilladora sobre grama húmeda, donde no sea posible una

pisada firme. Camine, nunca corra.

• Detenga la orilladora cuando cruce sobre sendas de grava, etc.

3

Page 17

Las pendientes son un factor principal relacionado

con

la p

érdida de

Funcionamiento en pendiente

•

•

control y de accidentes por resbalones, los cuales pueden ocasionar

lesiones graves. Todas las pendientes exigen mayor precaución. Si se

siente incómodo en una pendiente no realice la poda.

SÍ: Pode a través de la cara de una pendiente y no arriba y abajo

• SÍ: Quite los objetos tales como rocas, ramas de árboles, etc.

• SÍ: Esté pendiente de los agujeros, los surcos o los topes. El césped alto puede

esconder los obstáculos.

• NO: Pode cerca de declives, zanjas o terraplenes. El operador podría perder

apoyo o balance.

• NO: Pode en exceso las pendientes pronunciadas

• NO: Pode sobre el césped húmedo. La pisada sin apoyo podría ocasionar

resbalones.

Mantenga a los niños fuera del área y bajo la supervisión de otro adulto

responsable.

• Esté alerta y apague la máquina si los niños entran al área.

Niños

• Antes y cuando repase, observe hacia atrás y hacia abajo si hay niños.

• Nunca permita que los niños pongan a funcionar esta máquina.

• Tenga mayor cuidado cuando se aproxime a las esquinas ciegas, arbustos, árboles

o hacia otros objetos que puedan obstruir la visión.

Servicio

• Tenga mucho cuidado cuando manipule gasolina y otros combustibles. Son

inflamables y sus gases son explosivos.

• Use sólo un recipiente aprobado para el combustible.

• Nunca quite la tapa de la gasolina o añada combustible con el motor encendido.

• Permita que el motor se enfríe antes de agregarle más combustible. No fume.

• Nunca recargue de combustible la máquina en ambientes interiores.

• Nunca almacene la máquina o el recipiente de combustible donde haya una llama

abierta, tal como un calentador de agua.

• Nunca ponga a funcionar una máquina en un área cerrada.

• Mantenga las tuercas y los pernos roscados apretados y el equipo en buena

condición.

• Nunca interfiera los dispositivos de seguridad

• Mantenga la máquina libre de grama, hojas o de otras partículas. Limpie los

derrames de aceite y de combustible. Permita que la máquina se enfríe antes de

almacenarla.

• Detenga e inspeccione el equipo si golpea un objeto. Repárelo, si es necesario,

antes de volverlo a encender.

• Nunca haga reparaciones o ajustes con el motor encendido.

4

Page 18

Cuando está en funcionamiento, cualquier cortadora puede

Déle vuelta hacia arriba a los mangos y alinee el agujero

Los mangos se pueden ajustar hacia arriba y hacia abajo y hacia

chocar con objetos extraños que podrían ser lanzados a los ojos,

lo que podría causar lesiones graves. Siempre use lentes de

seguridad certificados o gafas de seguridad de visión amplia

sobre los anteojos, antes de fijar la vista en cualquier maquina

cortadora y mientras esté operando tal máquina.

El funcionamiento de cualquier cortadora produce ondas sonoras

que pueden dañar el oído humano. Se recomienda protección para

los oídos.

¡PRECAUCIÓN!

Pueden ocurrir accidentes trágicos si el operador no está alerta a la

presencia de los niños. Los niños, a menudo, se sienten atraídos por

las máquinas y por la actividad de podar. Nunca asuma que los

niños se quedarán donde usted los vióanteriormente.

No opere la orilladora si vibra anormalmente. La vibración excesiva

es una señal de daño. Pare el motor y revise con cuidado el daño y

repárelo como sea necesario.

Etiqueta de advertencia

19991

Las cajas contienen:

• Orilladora

Contenido de las piezas en bolsas:

• Manual

• Manual del motor

• Gafas de seguridad

• Botella de aceite de motor

• Línea cortadora

• llave hexagonal

Ensamblaje

Herramientas necesarias:

• Llave de 12,7 mm

Instalación de los mangos:

1. Quite los sujetadores sueltos de los mangos inferiores.

2.

inferior de los mangos con el agujero del marco de la

orilladora. Instale los accesorios que se quitaron en el

paso anterior. Ajuste, pero no apriete los pernos

roscados.

3. Enganche la empuñadura superior a la empuñadura

inferior con los botones y sujetadores incluidos con la

empuñadura inferior.

4. Ajuste los mangos para que funcionen cómodamente.

5. Apriete todos los pernos roscados.

adentro y hacia fuera para proporcionar un funcionamiento

cómodo.

Ajuste del mango

5

Page 19

Preparación de la unidad para uso por primera vez

• Llene el cárter del motor con aceite. Con esta unidad se ha suministrado un 20oz envase con

aceite. Una nueva unidad requiere 18-20oz. NO LO SOBRELLENE.

• Llene el tanque de combustible del motor con gasolina. LA GASOLINA DEBE

AGREGARSE EN EL EXTERIOR, EN UN ÁREA BIEN VENTILADA.

• Inspeccione para estar seguro de que la cuerda se ha instalado correctamente. Para realizar una

instalación correcta, se ha proporcionado un diagrama, y está exactamente arriba de el cabezal

de corte.

• Consulte el manual del fabricante del motor para especificaciones de combustible y aceite.

Instalación de la línea recortadora

¡Importante!

para la unidad, ocasionará atascamientos y mal funcionamiento.

Usan una cuerda de 45,7 cm

Compre la línea pre cortada P3618

• Doble con holgura la línea cortadora a la mitad.

• Inserte la línea a través de los agujeros inferiores del disco (Paso 1).

• Llevar extremos alrededor ya través de la ranura en la brida de disco (Paso 2).

• Hale los extremos para apretar el lazo (Paso 3).

Use la longitud adecuada de la línea. El uso de una línea demasiado larga

Paso 1

Paso 2 Paso 3

Posiciones del hilo de la bordeadora

Posiciones de ajuste del hilo de la bordeadora:

• La bordeadora cuenta con 4 puntos de ajuste del hilo.

• Para segar con la bordeadora, se recomienda utilizar la configuración con 4 hilos para

obtener un corte más parejo y uniforme.

• Para recortar vegetación larga o densa, se recomienda utilizar la configuración con 2 hilos,

para un mejor rendimiento.

Para ajustar la altura del corte:

1. Afloje el tornillo de fijación con la llave de cabeza hexagonal incluida.

2. Deslice el cabezal de corte hacia arriba o abajo, hasta la altura de corte deseada.

3. Apriete el tornillo de fijación.

4. Puede utilizarse cualquier altura de corte con cualquier configuración de hilos.

Configuración con 4 hilos

Se ilustra ajustada a una altura de corte baja

Tornillo

de fijación

Configuración con 2 hilos

6

Se ilustra ajustada a una altura de corte alta

Page 20

Operación

Importante: Para garantizar la correcta operación, limpie el motor y la bordeadora periódicamente.

Retire los restos acumulados en la parte superior del motor. Durante la operación, los residuos pueden

enroscarse en el cabezal de la bordeadora. El uso prolongado en este estado puede provocar un desgaste

excesivo y daños en las piezas. Apague la bordeadora y retire los residuos periódicamente.

Para arrancar la bordeadora:

1. Retire los residuos acumulados en el motor y el cabezal de la bordeadora.

2. Coloque el control del acelerador en la posición “FAST” (Rápido).

3. Sujete firmemente la empuñadura de la soga y jale lentamente hasta sentir resistencia. Luego, jale

rápidamente con una brazada completa.

4. Una vez que el motor arranque, deje el control del acelerador en la posición “FAST”. El control

del acelerador debe estar en la posición rápida para un máximo rendimiento.

5. Conecte el cabezal de corte.

6. Comience a recortar.

Para conectar/desconectar el cabezal de la bordeadora:

• Conexión: Jale el gancho de control hasta que haga contacto con la empuñadura superior y sujételo

junto con la empuñadura. Si el cabezal de la bordeadora no se conecta completamente, consulte la

sección de ajuste de la correa.

• Desconexión: Libere el gancho de control. El cabezal de la bordeadora debería detenerse en unos

segundos. De lo contrario, consulte la sección de ajuste de la correa.

Para activar/desactivar la transmisión:

• Activación: Jale la palanca de activación de la transmisión hasta que haga contacto con la

empuñadura superior y sujétela junto con la empuñadura.

• Desactivación: Libera la palanca de activación de la transmisión.

Para detener la bordeadora:

1. Libere el gancho de control.

2. Coloque la palanca de control del acelerador en la posición “SLOW” (Lento) durante unos

segundos y, luego, colóquela en la posición “STOP” (Detención).

Importante: Para una operación más segura, verifique que los residuos no salgan despedidos en

su dirección ni la de otras personas.

Solucion de problemas

• Si no se arranque el motor, quitar el filtro de aire para asegurarse que el

filtro y el carburador estan limpios.

Consejos para podar

• No levante la cabeza recortadora cuando esté podando. Deje que la cabeza descanse levemente,

tocando la tierra.

• Mantenga un ojo sobre la longitud de la línea recortadora. A medida que la línea se hace más corta

también se hace menos efectiva para cortar y llevará más tiempo para podar adecuadamente. Cambie

la línea cuando sea necesario. (Vea la instalación de la línea recortadora).

• No pode la grama húmeda.

• Tenga cuidado cuando recorte en pendientes.

• Use la longitud apropiada de la línea. El uso de una línea demasiado larga para la unidad, ocasionará

atascamientos y mal funcionamiento.

7

Page 21

ADVERTENCIA

-

SIEMPRE PARE EL MOTOR Y DESCONECTE EL CABLE

Mantenimiento de la orilladora

Las correa utilizadas para conectar/desconectar el cabezal de la bordeadora pueden ajustarse conforme a

Asegúrese de que la orilladora esté en buenas condiciones de trabajo, teniendo en mente las siguientes indicaciones

cada vez que use su orilladora.

• Mantenga la orilladora en buenas condiciones de funcionamiento y conserve todos los protectores y pantallas

en su lugar. NO opere esta orilladora si falta alguna de las pantallas o protectores.

• Revise que todos los sujetadores estén adaptados para mantener el equipo en una disposición segura de trabajo.

Haga los ajustes que sean necesarios.

• A fin de reducir los peligros de incendio, mantenga el motor libre de grama, hojas o de grasa excesiva.

• NO funcione la orilladora con un silenciador dañado o faltante.

• NO intervenga el sistema de escape; esto podría causar un peligroso incendio.

• NO funcione el motor si falta el purificador de aire o la cubierta colocada sobre la toma de aire del carburador.

La remoción de estas piezas podría crear un incendio peligroso.

• Antes de limpiar, hacer ajustes o reparaciones a la orilladora, PARE el motor, desconecte el cable de la bujía y

deje que el motor se enfríe.

• Manipule la gasolina con cuidado. NO fume o use gasolina cerca de llamas abiertas. Utilice sólo contenedores

de gasolina aprobados.

• Nunca añada combustible o arranque la orilladora en áreas poco ventiladas, tales como garajes o edificios de

servicios.

• Siempre vuelva a colocar la tapa al tanque de combustible. Asegúrese de limpiar cualquier gasolina derramada.

• No cambie los ajustes del gobernador del motor o le dé más velocidad al motor; se pueden originar lesiones o

daños graves.

• Nunca almacene la orilladora, con gasolina en el tanque, dentro de un edificio donde los gases puedan alcanzar

una llama abierta o chispas.

• Siempre permita que el motor se enfríe antes de almacenarlo.

NUNCA AÑADA GASOLINA A UN MOTOR CALIENTE – PERMITA QUE

EL MOTOR SE ENFRÍE ANTES DE AÑADIRLE GASOLINA.

DE LA BUJÍA ANTES DE EFECTUAR CUALQUIER AJUSTE O SERVICIO.

Motor

• Consulte el manual de servicio del motor incluido con este producto.

Correas

• Cada tanto, revise la correas para verificar que no presente desgaste.

Si está desgastada, reemplácela.

Ajuste de la correa

Durante las primeras horas de operación, todas las correas atraviesan un período de “rodaje”,

tras el cual muchas deben ajustarse conforme a las siguientes instrucciones. Algunas señales

que indican que las correas deben ajustarse son las siguientes:

• Pérdida de potencia del cabezal de corte, que hace que el cabezal gire inusualmente

lento o se detenga.

Ruedecilla

• Desgaste excesivo de la correa debido al deslizamiento.

• La correa que acciona la transmisión está diseñada para estar tensa constantemente y no debe ajustarse

más.

•

las siguientes instrucciones:

1. Ubique la ruedecilla de ajuste del cable de control (consulte la ilustración).

2. Libere el gancho de control para desconectar el cabezal de la bordeadora.

3. Gire la ruedecilla unas vueltas en sentido antihorario (desde la posición de operación normal).

4. Vuelva a conectar el cabezal de la bordeadora.

5. Si el cabezal de la bordeadora no funciona normalmente, repita los pasos 2 a 4.

Importante: No apriete excesivamente la ruedecilla de ajuste del cable. Puede provocar la rotura

del cable. NO debería necesitarse fuerza excesiva para accionar completamente el gancho de control.

8

Page 22

Reemplazo de la correa

Reemplazo de la correa de accionamiento del cabezal A

1. Retire la cubierta de la correa delantera.

2. Afloje o retire los sujetadores utilizados para enganchar el motor y permitir su movimiento. Deslice o incline el

motor de manera que la polea inferior del motor I se aleje de la transmisión y se genere un espacio que

permita retirar la correa.

3. Retire la correa desgastada.

4. Instale la nueva correa pasándola primero por debajo del motor y alrededor de la polea inferior del motor I .

5. Luego, pásela entre las dos poleas locas, como se ilustra en F .

6. Instale la correa alrededor de la polea delantera B .

7. Asegúrese de que la correa esté bien instalada entre las guías de la correa C y la polea adyacente.

8. Asegúrese de que la correa esté bien instalada en la ranura de cada polea.

9. Asegúrese de que la correa está encima de la parte superior del eje de la transmisión E .

10. Apriete o vuelva a colocar los sujetadores utilizados para enganchar el motor.

11. En caso de haberse ajustado previamente la tensión de la correa, restablezca la ruedecilla de ajuste girándola en

sentido horario hasta donde lo permita (consulte la ilustración de las instrucciones de ajuste de la correa). Si el

cabezal no se conecta correctamente, consulte las instrucciones de ajuste de la correa.

12. Vuelva a colocar la cubierta de la correa delantera.

Reemplazo de la correa de potencia de la transmisiónH

1. Retire la cubierta de la correa delantera.

2. Retire la correa de accionamiento del cabezal A conforme a las instrucciones anteriores.

3. Retire la correa desgastada.

4. Instale la nueva correa pasándola primero por debajo del motor y alrededor de la polea superior del motor J .

5. Luego, pase la correa alrededor de la polea de transmisión D .

6. Por último, pase la correa alrededor de la polea loca G . La polea loca es accionada por resorte, lo que puede

dificultar la última parte de la instalación de la correa. Para facilitar la instalación de la correa, empuje la polea

loca hacia la polea de transmisión mientras coloca la correa alrededor de la polea loca.

Peligro de pellizco:

Asegúrese de que ninguna parte de su cuerpo quede entre la correa y las poleas, ya que se

pueden provocar lesiones.

7. Vuelva a colocar la correa de accionamiento del cabezal conforme a las instrucciones anteriores.

8. Vuelva a colocar la cubierta de la correa delantera.

PRECAUCIÓN.

9

Page 23

Rueda derecha

elemento

pieza

elemento

pieza

Montaje

Ver detalle

Ver detalle

Página 12

Página 12

Rueda izquierda

Ver detalle

Página 11

N.º del

1 N/D Motor - Briggs & Stratton 15 2030 Perilla - Plástico negro

2 NB170 Tuerca - Acanalada 5/16-18 16 NB275 Arandela - Plana SAE 5/16

3 NB253 Perno - Acanalado, 5/16-18x1 1/4 17 NB180 Tuerca - Nyloc 1/4-20

4 19018 Polea - Accionamiento doble, bordeadora 18 19561 Apretón - Manilla, antivibraciones

5 NB271 Arandela - Plana USS 3/8, acero al carbono ZY 19 19005 Gancho - Bordeadora

6 NB607 Arandela - Belleville SP 20 19017* Empuñadura - Superior, bordeadora SP

7 NB238N Perno - HHC 3/8-24 X 1 21 NB218 Perno - 1/4-20 X 2 HCC GR5 ZY

8 2019 Protector - Correa 22 NB587 Perno - Cabeza de hongo, 5/16-18 X 1 3/4

9 19135 Sujeción - Panel 23 10399* Empuñadura - Inferior

10 9030 Chaveta - 3/16 X 1 24 NB596 Perno - Acanalado, 5/16-18 X 3/4

11 19027 Palanca - Activación de la transmisión 25 26X249 Tornillo - 0.312-18 X 0.75

12 19823 Palanca Apretón 26 19016* Cubierta - Posterior, bordeadora SP

13 19101 Cable - Control de transmisión; STP 27 19034 Correa - 60 in, bordeadora

14 19006 Cable - Control, bordeadora 28 2006* Base - Motor inferior

N.º de

Descripción

N.º del

29 19004 Protección - Caucho

N.º de

Descripción

Para realizar pedidos de repuestos

* USE EL CÓDIGO DE PINTURA: TK=NEGRO

10

Page 24

Montaje del cabezal de la bordeadora

N.º del

elemento

Para realizar pedidos de repuestos

* USE EL CÓDIGO DE PINTURA:

TK=NEGRO

N.º de

pieza

1 18999* Pieza soldada - Cuello de la bordeadora, estándar

2 NB138 Perno - 5/16-18 X 2 1/2 HCC GR5 ZY

3 NB170 Tuerca - Acanalada 5/16-18 ZY Carcasa Hrd

4 NB595 Tuerca - Obstrucción, 5/8-11, reversible

5 2049 Polea - Álabe de 4.5 in

6 NB149 Arandela - 5/8 de diám. int. X 1, 14 de diám ext. GA ZY

7 B985/8 Rodamiento - Bordeadora

8 19123 Rodamiento - 20 mm de diám. int, sello de acero

9 19009 Árbol - Cabezal de corte, estándar

10 NB560 Perno - 1/4-20 X 1 1/4 HCC GR5 ZY

11 19011 Buje - Cabezal de corte, PM

12 NB312 Tornillo - Fijación 5/16-18 X 1/2 con Loctite

13 19010 Protector - Árbol, bordeadora

14 19837* Disco del cabezal de corte

15 NB180 Tuerca - Nyloc 1/4-20

16 NB779 Tuerca - Acanalada, hex. ZY 3/8-16

17 18823 Arandela - Plana, 1/2 in de diám int.-12GA ASTM A325; ZY

18 19012* Guía de corte - Bordeadora

19 10501 Perno de cabeza de hongo de 3/8 X 1-1/4

20 NB107 Perno - 3/8-16 X 1 1/2 HCC GR5 ZY

21 T30V Polea - Embrague de polea loca, 2 3/4 de diám. ext.

22 NB579 Arandela - Defensa, 5/16 X 1 1/4 de diám. ext. ZY GR2

23 NB212 Tuerca - HNC, 3/8-16 GR2 ZY

24 19014* Brazo secundario libre - Bordeadora STP

25 NB280 Tuerca - Reversible de bloqueo 3/8-16 ZY y cera Gr A

26 NB181 Tuerca - Nyloc 5/16-18 ZY

27 19108 Polea - Polea loca de la parte posterior, 2.25 in 3/8 in de diám. ext.

28 NB278 Perno - 1/4-20 X 1 3/4 GR2 ZY

29 NB501 Perno - 5/16-18 X 1 HCC GR5 ZY

30 NB524 Tuerca - Acanalada, 1/4-20 grado 5 ZY

31 16823 Casquillo - Arcén 3/8, ZT60

32 2042 Protector - Hilo

33 26X249 Tornillo - 0.312-18 X 0.75

DESCRIPCIÓN

11

Page 25

elemento

pieza

DESCRIPCIÓN

3

19019

Rodamiento - 1/2 in, montado sobre una base

6

NB604

Perno - 3/8-16 X 1 GR5 ZY

9

NB107

Perno - 3/8-16 X 1 1/2 HCC GR5 ZY

10

T30V

12

19024*

Brazo secundario libre - Transmisión

15

NB280

Tuerca - Reversible de bloqueo 3/8-16 ZY

18

26X249

Tornillo - 0.312-18 X 0.75

21

NB579

Arandela - Defensa, 5/16 X 1 1/4 de diám. ext.

24

19053

Correa - 24 in, bordeadora SP

27

690369

Separador - 1/2 in a 17 mm

28

19022

30

19021

Rueda dentada - N.º 35, 10 dientes; orificio de

1/2 in de diám. int.

34

19026**

Rueda - 14 in, rodamientos de 1/2 in;

Montaje del sistema de tracción

N.º del

11 NB174 Tuerca - Obstrucción 3/8-16 ZY Grado 2

13 7821 Resorte sujetador

14 NB272 Arandela - Plana SAE 3/8 ZY

16 19020 Transmisión - Bordeadora de hilo

17 19025 Eje - Bordeadora autopropulsada

19 19087* Protector - Cadena, bordeadora

20 NB501 Perno - 5/16-18 X 1 HCC GR5 ZY

22 16823 Casquillo - Arcén 3/8, ZT60

23 19023* Ménsula - Brazo secundario libre, bordeadora

25 NB126 Pasador- De aletas, 1/8 X 1

26 19036 Pasador- De aletas, 3/16 X 2.25; ZP

N.º de

1 19015* Base del motor - Superior, bordeadora STP

2 10197 Perno - Cabeza de hongo 5/16-18X1 GR5 ZY

4 10216 Perno - Cabeza de hongo 5/16-18X3/4 GR5 ZY

5 NB170 Tuerca - Acanalada 5/16-18 ZY

7 4005 Rodamiento - Brida lateral

8 NB182 Tuerca - Nyloc 3/8-16 ZY

Polea - Embrague de polea loca, 2 3/4 de

Para realizar pedidos de repuestos

* Use el código de pintura: TK=Negro

** Las ruedes incluyen dos rodamientos. Utilice el número de pieza MWB para

reemplazar solo los rodamientos.

Nota: Se ofrecen conjuntos de ruedas opcionales que vienen con los rodamientos y el

embrague de rueda instalado. Solicite el número de pieza 19085 si necesita el conjunto

de la rueda izquierda y el número de pieza 19086 para el conjunto de rueda derecha.

*** El embrague de rueda debe instalarse con la orientación correcta para que funcione

bien. Si el embrague de rueda está bien instalado, las ruedas giran libremente cuando

la bordeadora avanza con el motor apagado (las ruedas tendrán resistencia cuando la

bordeadora retrocede). Es posible que deba retirar el rodamiento de una de las ruedas

antes de instalar el embrague de rueda. El embrague de rueda posee una flecha en el

lateral para indicar la dirección de “rueda libre”. Asegúrese de que el embrague esté

orientado de manera tal que la dirección de rueda libre coincida con la dirección en la

que deberá girar la rueda cuando la bordeadora avance, y presione el embrague para

introducirlo en el centro de la rueda (ajuste con apriete). Luego, reemplace el

rodamiento de la rueda e instale la rueda en el eje.

Importante:Rote la rueda en la dirección de rueda libre durante el montaje

del eje (gire y empuje al mismo tiempo). Asegúrese de que los rodamientos de

ambas ruedas permanezcan completamente fijados durante la instalación de las

ruedas y la operación. De no hacerlo, podría dañarse el embrague de rueda.

Rueda dentada - N.º 35, 60 dientes; orificio de

29 19035 Pasador- De aletas, 1/8 X 1-1/2; ZP

31 19044 Cadena - ANSI 35, 70 eslabones cerrados

32 MWB

33 19045***

35 NB177 Arandela - Mach 1/2 NR 14 GA

Rodamiento - Rueda, 1 1/8 in de diám. ext. X

Embrague - Rueda, 1.125 de diám. ext. X 0.5

de diám. int.

La flecha del

embrague indica la

dirección en la que

la rueda gira

libremente cuando

está instalada.

12

Page 26

MANUAL DEL

PROPIETARIO

Visítenos en www.swisherinc.com

NÚMERO DEL

MODELO

STP67522BS

Cada orilladora tiene su propio número de modelo. Cada motor

tiene su propio número de modelo. El número de modelo de la

orilladora se encuentra en el lado izquierdo de la base del

motor. El número de modelo del motor se encuentra en la parte

superior de la caja del ventilador soplador.

Todas las piezas de la orilladora listadas aquí se pueden

ordenar directamente a Swisher o al distribuidor Swisher más

cercano.

Todas las piezas del motor suministrado con su podadora se

pueden ordenar al distribuidor del motor más cercano.

CUANDO ORDENE LAS PIEZAS, POR FAVOR

TENGA DISPONIBLE LA SIGUIENTE INFORMACIÓN:

* PRODUCTO-ORILLADORA

* NÚMERO DE SERIE- _______________

* NÚMERO DEL MODELO- _______________

* NÚMERO DE MODELO DEL MOTOR- _______________

TIPO - _______________

* NÚMERO DE LA PIEZA CON CÓDIGO DE LA PINTURA

* DESCRPCIÓN DE LA PIEZA

TELÉFONO - 1-800-222-8183

FAX - 1-660-747-8650

SWISHER ACQUISITION INC.

1602 CORPORATE DRIVE

WARRENSBURG, MO 64093

Modificando su paisaje desde 1945.

13

Page 27

Rendez-nous visite à : www.swisherinc.com

MANUEL DU

Self-Propelled

PROPRIÉTAIRE

Numéro de modèle

A partir du no de série L215-335001

STP67522BS

IMPORTANT

Avant de mettre en marche

cet équipement, lire le

présent manuel et suivre

toutes les directives de

sécurité indiquées.

Easy Glide

Assemblage

Utilisation

Réglage et entretien

Pièces de rechange

1602 CORPORATE DRIVE, WARRENSBURG MISSOURI 64093

TÉLÉPHONE 660-747-8183 TÉLÉCOPIEUR 660-747-8650

19129 REV 15-335

Fabriqué aux

ÉTATS-UNIS

des États-Unis et Pièces mondiaux

SWISHER ACQUISITION INC.

Page 28

GARANTIE LIMITÉE

Garantie du fabricant au consommateur acheteur original : Ce produit est garanti au consommateur acheteur

d'origine contre toute défectuosité de matériel et de main d'œuvre sur une période de deux (2) ans de la date

d'achat. Nous réparerons ou remplacerons, selon notre décision, les pièces trouvées défectueuses pour cause

de défaut de matériel ou de main-d'œuvre. La présente garantie est sujette aux limites et exclusions

suivantes :

1) Garantie du moteur Tous les moteurs utilisés dans nos produits sont couverts par une

garantie séparée attribuée par leurs fabricants individuels. Tout

problème à ce niveau est la responsabilité du fabricant et d'aucune façon

Swisher ou ses agents représentants ne pourront être tenus responsables

des problèmes sous garantie des moteurs. Ligne d'assistance pour

moteurs Briggs & Stratton : 1-800-233-3723.

2) Usage commercial Cet équipement n'est pas prévu pour usage commercial et n'est couvert

d'aucune garantie dans ce cas.

3) Limites La présente garantie s'applique seulement aux équipements adéquatement

assemblés, réglés et utilisés selon les directives comprises dans le

présent manuel. La présente garantie ne s'applique à aucun équipement

qui a été assujetti à toute modification, mauvaise utilisation, abus,

assemblage ou installation inadéquat, endommagement de transit ou à

l'usure normale du produit.

4) Exclusions Sont exclus de la présente garantie, l'usure. les réglages et l'entretien

normaux.

Pour toute réclamation de garantie, l'équipement ou la pièce défectueuse devra être retourné à un

concessionnaire de service autorisé. Toute responsabilité de perte dommages et frais d'expédition relatifs

aux retours pour réparation ou remplacements sous garantie demeureront à la charge du propriétaire. Pour

toute question relative à la présente garantie, veuillez communiquer avec nous au numéro sans frais 1-800222-8183. Pour pouvoir appliquer la garantie, les numéros de modèle et de série, la date d'achat et le nom

du dépositaire Swisher autorité duquel l'équipement a été acheté seront requis.

LA PRÉSENTE GARANTIE NE S'APPLIQUE À AUCUN DOMMAGE D'INCIDENCE OU DE

CONSÉQUENCE ET TOUTE GARANTIE DE MARCHANDISAGE IMPLICITE SERA LIMITÉE À LA

MÊME DURÉE QUE CELLE INDIQUÉE AUX PRÉSENTES, ET CE POUR TOUTE GARANTIE

EXPRIMÉE DE FAÇON EXPRESSE. Certains États ou provinces ne permettent pas d'exception des

dommages de conséquence ou de limite à la période de validité des garanties implicites, alors les limites et

exclusions ci-dessus peuvent ne pas s'appliquer dans votre cas. La présente garantie vous donne des droits

particuliers et il se peut que vous ayez d'autres droits qui varient d'un État ou d'une province à l'autre. La

présente est une garantie limitée tel que défini par la loi américaine Magnuson-Moss de 1975.

2

Page 29

Directives de sécurité

Ce symbole d'alerte de sécurité indique d'importants messages tout

au long du présent manuel. Lorsque rencontré, lisez attentivement

le message indiqué et demeurez sur vos gardes pour éviter toute

blessure possible.

3

Page 30

Utilisation sur des pentes

•

•

RECOMMANDATION : évoluer d'un côté à l'autre de la pente et non de haut en bas.

• RECOMMANDATION : retirer les objets tel que caillous, branches d'arbres, etc. avant de

commencer.

• RECOMMANDATION : prendre garde aux dépressions, monticules ou décompositions

organiques. Les hautes herbes peuvent cacher des obstacles.

• CONTRE-INDICATION : travailler près des fossés, remblais ou précipices ou autres

zones à fort risque de perdre pied ou l'équilibre.

• CONTRE-INDICATION : travailles sur des pentes abruptes

• CONTRE-INDICATION : travailler sur du gazon mouillé pour cause de danger de glisser.

Enfants

Gardez les enfants hors de la zone de travail et sous la surveillance d'un autre adulte

responsable.

• Demeurez alerte et arrêtez la machine si des enfants s'introduisent dans la zone de

travail.

• Avant de reculer et lorsque vous y procédez, regardez vers le sol derrière vous au cas

d'approche de petits enfants.

• Ne jamais laisser d'enfants faire fonctionner cette machine.

• Redoublez de prudence à l'approche d'aires hors de vue tel les coins de mur, derrière

les broussailles ou les arbres ou autre objets obstruant la vue.

Entretien

• Redoublez de prudents lors de l'utilisation d'essence ou autres carburants. Ceux-ci sont

inflammables et leurs émanations sont explosives.

• Ne les conservez que dans des contenants approuvés pour le carburant.

• Ne jamais retirer le bouchon du réservoir d'essence lorsque le moteur est en marche.

• Laissez refroidir le moteur avant de faire le plein d'essence. Ne pas fumer en faisant le plein

d'essence.

• Ne jamais faire le plein d'essence de la machine à l'intérieur.

• Ne jamais entreposer la machine ou un contenant d'essence près d'une flamme ou source

d'étincelles (chauffe-eau au gaz, outils électriques ou autres).

• Ne jamais faire fonctionner la machine dans un lieu clos.

• Gardez tous les écrous et boulons serrés et l'équipement en bon état.

• Ne jamais désaffecter les dispositifs de sécurité.

• Gardez la machine libre de toute accumulation de gazon, de feuilles ou d'autres débris.

Nettoyez les déversements d'essence et d'huile. - Laissez refroidir le moteur avant de faire le

plein d'essence.

• Si vous frappez un obstacle, arrêtez et inspectez la machine. Faites les réparations

nécessaires avant de redémarrer.

• Ne jamais faire de réglage ou réparation lorsque le moteur est en marche.

4

Page 31

La lame rotative de toute tondeuse peut venir en contact avec des

llerie retirée à l'étape précédente.

objets étrangers pouvant être projetés dans les yeux causant de graves

blessures. Avant de démarrer et durant le fonctionnement de toute

machine de tonte, portez toujours des lunettes de sécurité ou coquilles

par dessus vos verres de prescription qui sont homologuées pour

protéger tous les angles d'arrivée de particules.

Le fonctionnement de toute tondeuse produit une pression sonore

dommageable à l'ouïe humaine. Protection auditive recommandée.

MISE EN GARDE!

Un accident tragique peut se produire si l'opérateur n'est pas alerte en

présence d'enfants. Les machines et les activités engendrées sont

souvent une source d'intérêt pour les enfants. N'assumez jamais que

les enfants demeureront où vous les avez vus la minute précédente.

Ne vous servez pas du coupe-bordure s'il vibre de façon exagérée.

Ceci serait l'indication d'une pièce endommagée. Arrêtez le moteur et,

en prenant les précautions nécessaires, vérifiez les dommages et

effectuez les réparations requises.

Attention décalque

19991

Contenu de la boîte:

• Coupe-bordure

Sac de pièces comprenant:

• Manuel

• Manuel du moteur

• Coquilles de

protection oculaire

• Contenant d'huile

moteur

• Fil de coupe

• Clé hexagonale

Assemblage

Outils requis:

• Clé ½ po (13 mm)

Installation de la poignée:

1. Retirez les attaches lâches de la partie inférieure de la

poignée.

2. Faites pivoter la poignée vers le haut et alignez son

trou inférieur au trou du bâti du coupe- bordure.

Réinstallez la quincai

Seulement serrer les boulons légèrement à la main.

3. Fixer la poignée supérieure à la partie inférieure du

manche à l'aide des boutons et attaches fournies avec

la poignée inférieure.

4. Réglez la position de la poignée pour pour travailler

confortablement.

5. Serrez tous les boulons.

Pour un positionnement ergonomique, l'angle et la longueur

de la poignée sont réglables.

Réglage de la poignée

5

Page 32

Préparation pour la première utilisation

N

• Remplissez le carter du moteur d'huile. Un 20oz. contenant d'huile est fourni avec cette machine.

Une nouvelle unité nécessite 18-20oz. NE PAS EXCÉDER LE NIVEAU REQUIS.

• Remplissez le réservoir à essence. LE REMPLISSAGE DOIT ÊTRE FAIT À L'EXTÉRIEUR OU

DANS UN ENDROIT BIEN AÉRÉ.

• Confirmez que l'installation du fil est conforme au schéma apposé juste au-dessus la tête de coupe.

• Reportez-vous au manuel du fabricant de moteur pour les spécifications d'huile et de carburant.

Installation du fil de coupe

Important! Gardez le fil à une longueur adéquate. Un fil trop long causera un fonctionnement erratique

et le calage du moteur.

Utilisez un fil de 46 cm (18 po)

o

de pièce de fil pré-dimensionné P3618

• Repliez le fil de coupe en deux de façon lâche.

• Insérez ligne à travers les trous inférieurs du disque (Étape 1).

• Ramener les extrémités autour et à travers la fente dans la bride de disque (Étape 2).

• Tirez les bouts pour serrer le fil (Étape 3).

Étape 1

Étape 2

Étape 3

Positions des fils du taille-bordure

Positions des fixations des fils du taille-bordure

• Le taille-bordure est équipé de 4 points de fixation des fils.

• En coupant avec le taille-bordure, la configuration à 4 lignes de coupe est recommandée pour une

coupe plus cohérente et régulière.

• Lorsque vous coupez une végétation haute ou épaisse, la configuration à 2 lignes de coupe est

recommandée pour des performances améliorées.

Pour ajuster la hauteur de coupe :

1. Desserrez la vis de réglage à l'aide de la clé hexagonale fournie.

2. Faites glisser la tête de coupe vers le haut ou vers le bas selon la hauteur de coupe désirée.

3. Serrez la vis de réglage.

4. Toute hauteur de coupe est activable avec une des configurations de ligne de coupe.

Placez la vis

de réglage

Configuration de coupe à 4 lignes

Ensemble montré à une hauteur

de coupe peu élevés

Configuration de coupe à 2 lignes

Ensemble montré à une hauteur de

6

coupe élevée

Page 33

Fonctionnement

Important !

Pour assurer un bon fonctionnement, nettoyez régulièrement le moteur et le taille-bordure.

Retirez toute accumulation de paille du haut du moteur. Au cours de l'opération, des débris peuvent venir

s'enrouler autour de la tête de coupe. Une utilisation prolongée dans cet état peut entraîner une usure

excessive et des défaillance de la pièce. Périodiquement, éteignez le taille-bordure et retirez les débris.

Pour démarrer le taille-bordure :

1. Retirez tout débris accumulés du moteur et de la tête de coupe.

2. Déplacez la manette de commande sur « FAST » (rapide).

3. Saisissez fermement la poignée de corde et tirez lentement jusqu'à ce qu'une résistance se fasse sentir.

[X]Puis tirez rapidement de tout le bras.

4. Lorsque le moteur démarre, laissez manette sur « FAST ». La commande des gaz doit être définie en

position rapide pour des performances maximales.

5. Engagez la tête de coupe.

6. Commencez la coupe.

Engager/dégager la tête de coupe :

• Engager : Amenez l'étrier de contrôle en contact avec la poignée supérieure et saisissez-le en même

temps que la poignée. Si la tête de coupe ne s'engage pas complètement, reportez-vous à la section

Réglage de la courroie.

• Désengager : Relâchez l'étrier de contrôle. La tête de coupe doit s'arrêter en quelques secondes. Si la

Pour engager/désengager la transmission :

• Engager : Amenez le levier d'engagement de la transmission en contact avec la poignée supérieure et

• Désengager : Libérez le levier d'engagement de transmission.

Pour arrêter le taille-bordure :

1. Relâchez l'étrier de contrôle.

2. Placez le levier de commande de gaz sur le moteur à « SLOW » (lent) pendant quelques secondes, puis

tête de coupe ne se désengage pas complètement, reportez-vous à la section Réglage de la courroie.

saisissez-le en même temps que la poignée.

passer à « STOP » (arrêt).

Important! Pour un fonctionnement sûr, assurez-vous que es débris sont dirigés loin de vous et des

autres.

Dépannage

• Si le moteur ne démarre pas, retirez le filtre à air pour inspection et vous assurer

qu'il est propre, ainsi que carburateur

Conseils pour coupe-bordure

• Ne pas soulever la tête du coupe-bordure lors du travail. Laissez-la reposer légèrement contre le

sol.

• Gardez un œil sur la longueur du fil de coupe. Lorsque celui-ci devient plus court son efficacité est

réduite et il sera plus long de faire une bonne coupe. Au besoin, replacer le fil à une bonne longueur

(se référer à Installation du fil de coupe).

• Ne pas utiliser sur gazon mouillé.

• Pour le travail en pente, redoublez de prudence.

• Gardez le fil à une longueur adéquate. Un fil trop long causera une coupe inégale et le calage du

moteur.

7

Page 34

Entretien du coupe-bordure

AVERTISSEMENT

–

TOUJOURS ARRÊTER LE MOTEUR ET DÉCONNECTER LE

NE JAMAIS FAIRE LE PLEIN D'ESSENCE LORSQUE LE MOTEUR EST

Assurez-vous que votre coupe-bordure est en bonne condition de marche en suivant les directives ci-dessous en tête.

• Garder le coupe-bordure en bon état de marche et tous les écrans et gardes en place. NE PAS faire fonctionner le

coupe-bordure si l'un ou l'autre des écrans ou gardes est absent.

• Vérifiez le serrage de tous les écrous et boulons pour conserver l'équipement dans un état de marche sécuritaire.

Faites les réglages requis.

• Gardez le moteur libre de paillettes d'herbe, de feuilles ou d'excès de graisse pour prévenir tout danger d'incendie.

• NE PAS faire fonctionner le coupe-bordure si son silencieux est endommagé ou absent. NE PAS modifier le

système d'échappement, ceci pourrait créer un risque d'incendie.

• NE PAS faire fonctionner le moteur si le filtre ou le couvercle au-dessus du carburateur est absent. Le retrait des

ces pièces pourrait créer un danger d'incendie.

• ARRÊTER le moteur, débrancher la bougie et laisser refroidir le moteur avant de faire tout réglage ou réparation

du coupe-bordure.

• Manipulez l'essence avec précautions. NE PAS fumer ou utiliser de chalumeau ou outils pouvant créer des

étincelles près du contenant/réservoir d'essence. - N'utilisez que des contenants approuvés. Ne jamais faire

fonctionner un coupe-bordure dans un endroit sans aération adéquate tel un garage ou édifice d'entretien.

• Ne retirer le bouchon du réservoir que pour le remplissage. Assurez-vous de nettoyer tout déversement d'essence.

• Ne pas faire fonctionner le moteur à un régime excessif ou changer le réglage du gouverneur de vitesse, ceci

pourrait conduire à un bris mécanique ou des blessures graves.

• Ne jamais entreposer le coupe-gazon avec de l'essence dans le réservoir à l'intérieur d'un édifice où la possibilité

d'émanations pourraient atteindre un pilote de brûleur à gaz allumé ou une source d'étincelles. - Laissez toujours

refroidir le moteur avant de la remiser.

CHAUD – LAISSER REFROIDIR LE MOTEUR AVANT LE REMPLISSAGE

FIL DE BOUGIE AVANT DE FAIRE TOUT RÉGLAGE OU ENTRETIEN

Moteur

• Se référer au manuel d'entretien moteur fourni avec cet équipement.

Courroies

• Vérifiez occasionnellement la courroie pour usure. Une courroies usée doit être remplacée.

Réglage de la courroie

Pendant les premières heures de fonctionnement toutes les courroies traversent une « période de

rodage », après quoi les courroies doivent être ajustées en se référant aux instructions suivantes.

Les indications en faveur de l'ajustement des courroies incluent :

• La perte de puissance de la tête de coupe, causant une rotation anormale de la tête ou un

ralentissement.

• Une usure excessive de la courroie en raison du glissement.

• La courroie qui alimente la transmission est conçue pour être sous une tension constante et ne

nécessité aucun autre réglage.

• Les courroie utilisées pour engager/désengager la tête de coupe peuvent être ajustées en vous

référant aux instructions suivantes:

1. Localiser l'ajusteur de molette sur la câble de commande (voir illustration).

2. Sortez l'étrier de contrôle pour dégager la tête de coupe.

3. Faites pivoter la molette de quelques tours dans le sens des aiguilles d'une montre (à partir

de la position normale de fonctionnement).

4. Ré-engagez la tête de coupe.

5. Si la tête de coupe n'est pas revenue à son fonctionnement normal, répétez les étapes 2 à 4.

Molette !

Important ! Ne serrez pas trop les réglage du câble d'ajustement. Cela peut entraîner la cassure

du câble. Une force excessive ne doit PAS être nécessaire pour engager complètement l'étrier.

8

Page 35

Remplacement de la courroie

Remplacement de la courroie d'engagement de la tête A

1. Retirez le carter de la courroie avant.

2. Desserrez ou retirez les éléments de fixation utilisés pour attacher le moteur afin de permettre le déplacement du

moteur. Faites glisser ou inclinez le moteur de sorte que la poulie moteur inférieure I s'éloigne de la transmission, en

créant un écart pour permettre à la courroie d'être retirée.

3. Retirez l'ancienne courroie.

4. Installez la nouvelle courroie en passant tout d'abord la courroie sous le moteur puis autour de la poulie moteur

inférieure I .

5. Puis passez la courroie entre les deux poulies de renvoi comme indiqué en F .

6. Installer la courroie autour de la poulie avant B .

7. Veillez à ce que cette courroie soit correctement installée entre les guides-sangles C et la poulie adjacente.

8. Veillez à ce que cette courroie soit correctement installée dans le sillon de chaque poulie.

9. Veillez à ce que la courroie soit au-dessus de l'axe de transmission E .

10. Serrez ou réinstaller les fixations pour fixer le moteur.

11. Si la tension de la courroie avait précédemment été ajustée, réinitialisez la molette d'ajustement en faisant pivoter la

molette dans le sens des aiguilles d'une montre autant que le dispositif de réglage le permettra (reportez-vous

l'illustration dans les instructions de Réglage de courroie). Si la tête ne s'engage pas correctement, reportez-vous aux

instructions de Réglage de courroie.

12. Réinstaller le carter de la courroie avant.

Remplacement de la courroie H de transmission de puissance

1. Retirez le carter de la courroie avant.

2. Retirez la courroie A d'engagement de la tête selon les instructions fournies ci-dessus.

3. Retirez l'ancienne courroie.

4. Installez la nouvelle courroie en passant tout d'abord la courroie sous le moteur puis autour de la poulie moteur

supérieure J .

5. Ensuite, passez la courroie autour de la poulie de transmission D .

6. Pour terminer, passez la courroie autour de poulie arrière G . La poulie est à ressort, ce qui rend difficile de terminer

l'installation de la courroie. Pour faciliter l'installation, poussez la poulie vers la poulie de transmission tout en

enveloppant la courroie autour de de la poulie. ATTENTION – risque de pincement : Veillez à ne pas exposer une

partie du corps entre la courroie et les poulies, car cela pourrait causer des blessures.

7. Réinstaller la courroie d'engagement de la tête selon les instructions fournies ci-dessus.

8. Réinstaller le carter de la courroie avant.

9

Page 36

Ensemble[Assemblage]

Roue droite

Voir détail

Page 12

Roue gauche

Voir détail