Page 1

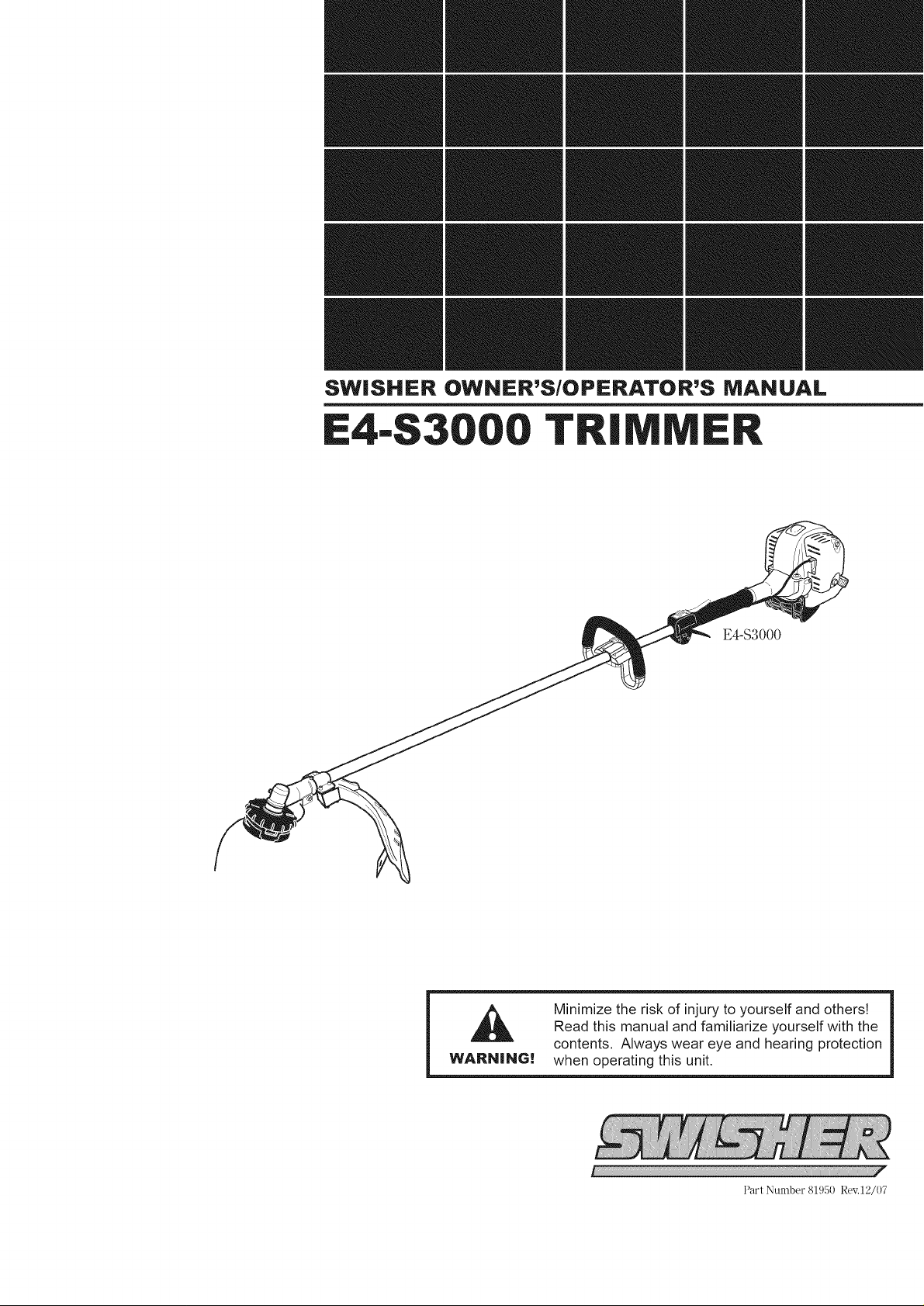

SWISH ER OWNER'S/OPERATOR'S MAN UAL

E4--$3000 FR|MMER

E4-$3000

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with the

contents. Always wear eye and hearing protection

when operating this unit.

Part Number 81950 Rev.12/07

Page 2

introduction

Attention Statements

The Swisher E4-$3000 hand held power

equipment has been designed and built to

deliver superior performance and reliability

without compromise to quality, comfort,

safety or durability.

Swisher engines represent the leading edge

of high-performance engine technology, deliv-

ering exceptionally high power with remarkably

low displacement and weight. As an owner!op-

eratoL you'll soon discover for yourself why

Swisher is simply in a class by itseli!.

The information contained in this owner's/

operator's manual describes units avail-

able at the time of publication.

Swisher reserves the right to make

changes to products without prior notice, and

without obligation to make alterations to units

previously manufactured.

_ WARN|NG!

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

Contents

I_6E

Attention Statements ................................. 2

Safety Information ...................................... 3

Safety Labels ............................................... 4

Product Description ................................... 5

Specifications .............................................. 5

Assembly and Adjustments ....................... 6

Engine Fuel ................................................. 9

Starting the Engine .................................... 9

Stopping the Engine ................................ 10

Adjusting Engine Idle .............................. 10

Checking Unit Condition ......................... 11

Shoulder Strap .......................................... 11

Cutting Grass with a Trimmer Head ...... 11

Maintenance ............................................. 12

Throughout this manual are special "atten-

tion statements".

_WARN|NG!

A statement preceded by the trian-

gular attention symbol and the word

"WARNING" contains information that

should be acted upon to prevent seri-

ous bodily injury.

CAUT|ON!

A statement preceded by the word

"CAUTION" contains information that

should be acted upon to prevent me-

chanical damage.

A statement preceded by the word

"IMPORTANT" is one that possesses

special significance.

A statement preceded by the word "NOTE"

contains information that is handy to know

and may make your job easier.

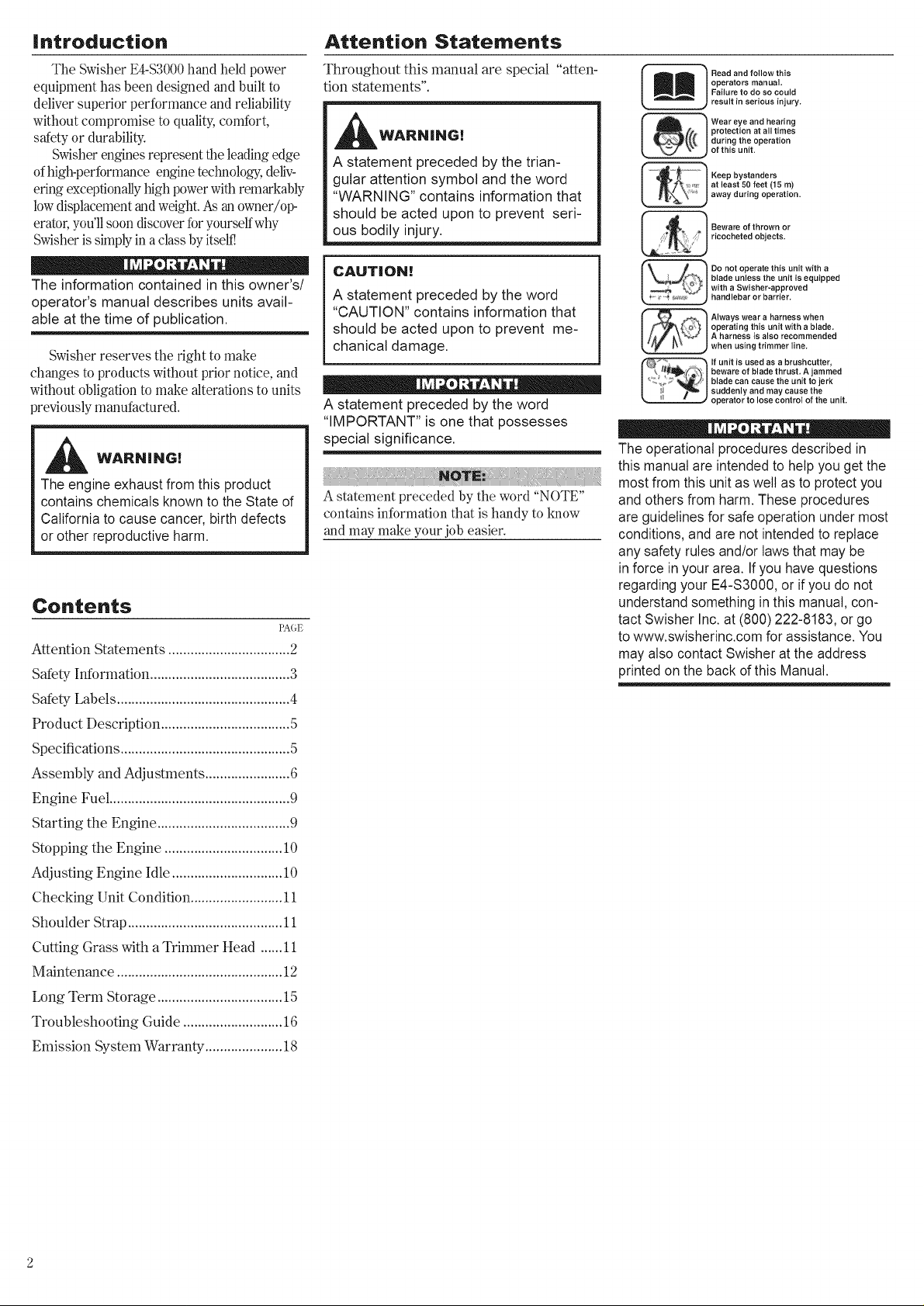

operators manual,

Failure to do so could

Read and follow this

result in serious injury.

protection at all times

during the operation

Wear eye and hearing

of this unit.

Keep bystanders

at least 50 feet (15 m)

away during operation.

_ eware of thrown or

_ lways wear a harness when

ricocheted objects.

blade unless the unit is equipped

with a Swisher-approved

Do not operate this unit with a

handlebar or barrier.

operating this unit with a blade,

A harness is also recommended

when using trimmer line.

lf unit is used as a brushcutter,

beware of blade thrust, A jammed

blade can cause the unit to jerk

suddenly and may cause the

operator to lose control of the unit.

" 0 " '

The operational procedures described in

this manual are intended to help you get the

most from this unit as well as to protect you

and others from harm. These procedures

are guidelines for safe operation under most

conditions, and are not intended to replace

any safety rules and/or laws that may be

in force in your area. If you have questions

regarding your E4-$3000, or if you do not

understand something in this manual, con-

tact Swisher Inc. at (800) 222-8183, or go

to www.swisherinc.com for assistance. You

may also contact Swisher at the address

printed on the back of this Manual.

Long Term Storage .................................. 15

Troubleshooting Guide ........................... 16

Emission System Warranty ..................... 18

Page 3

General Safety Instructions

Work Safely

Swisher trimmers operate at very high

speeds and can do serious damage or

injury if they are misused or abused. Never

allow a person without la_ainingor insh_uction to

operate this unit!

lk WARNING!

Never make unauthorized attachment

installations. Do not use attachments

not approved by Swisher for use on

this unit.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

Never operate power equipment of

any kind if you are tired or if you are

under the influence of alcohol, drugs,

medication or any other substance that

could affect your ability or judgement.

_ WARN|NG!

Use Good Judgment

ALWAYS wear eye protection to shield

against thrown objects.

NEVER run the engine when transport-

ing the unit.

NEVER run the engine indoorsg Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

ALWAYS use the proper cutting tool

for the job.

ALWAYS stop the engine immediately

if it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly

installed parts or attachments.

NEVER extend trimming line beyond

the length specified for your unit.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegeta-

tion, mud, etc.

ALWAYS hold the unit firmly with

both hands when cutting or trimming,

and maintain control at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any mainte-

nance work.

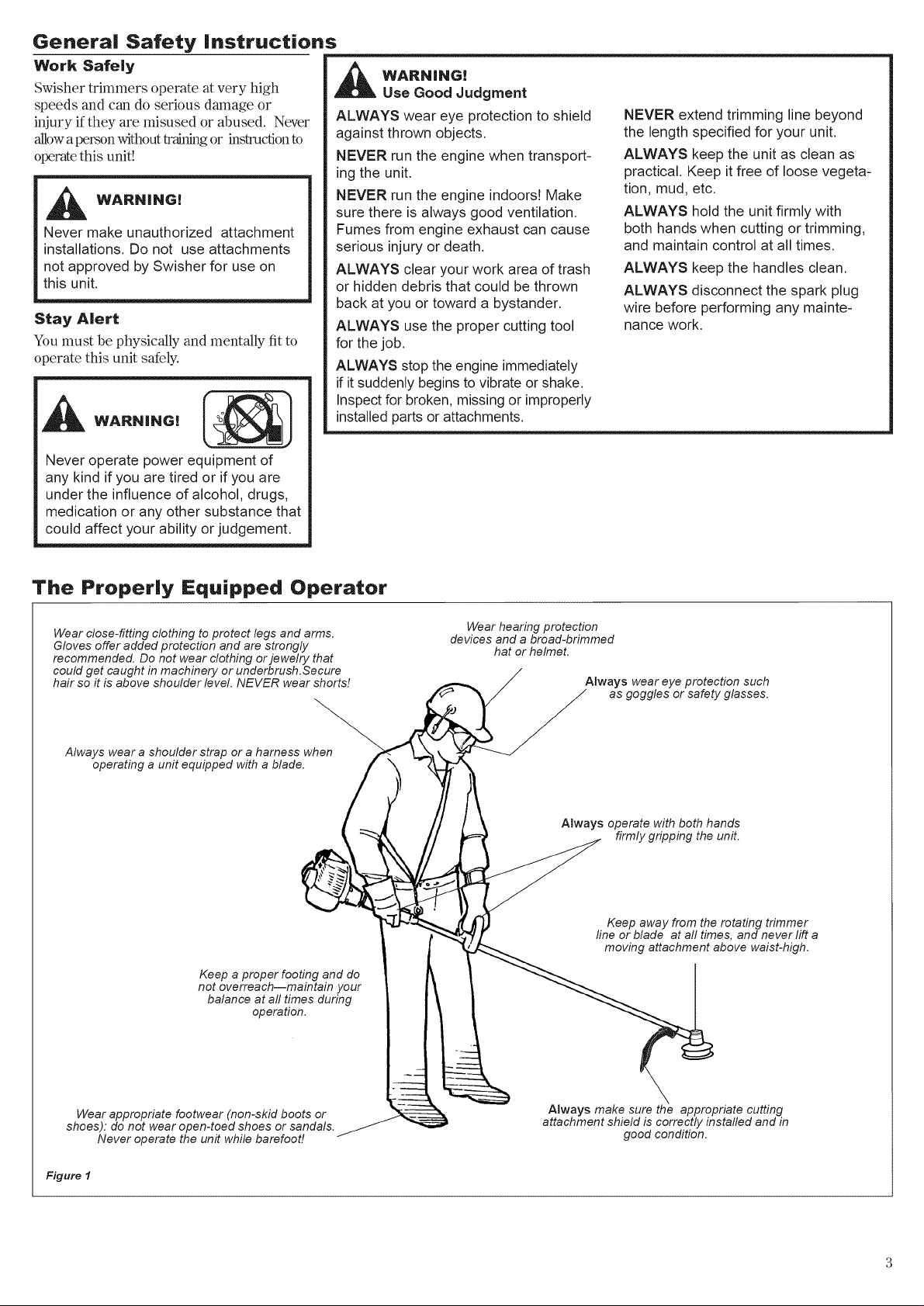

The Properly Equipped Operator

Wear close-fitting clothing to protect legs and arms.

Gloves offer added protection and are strongly

recommended. Do not wear clothing or jewelry that

could get caught in machinery or underbrush.Secura

hair so it is above shoulder level. NEVER wear shorts]

Always wear a shoulder strap or a harness when

operating a unit equipped with a blade.

Keep a proper footing and do

not overreach--maintain your

balance at all times during

operation.

Wear hearing protection

devices and a broad-brimmed

hat or helmet.

Always wear eye protection such

Always operate with both hands

as goggles or safety glasses.

firmly gripping the unit.

Keep away from the rotating trimmer

line or blade at all times, and never lift a

moving attachment above waist-high.

Wear appropriate footwear (non-skid boots or

shoes): do not wear open-toed shoes or sandals.

Never operate the unit while barefoot]

Figure I

Always make sure the appropriate cutting

attachment shield is correctly installed and in

good condition.

Page 4

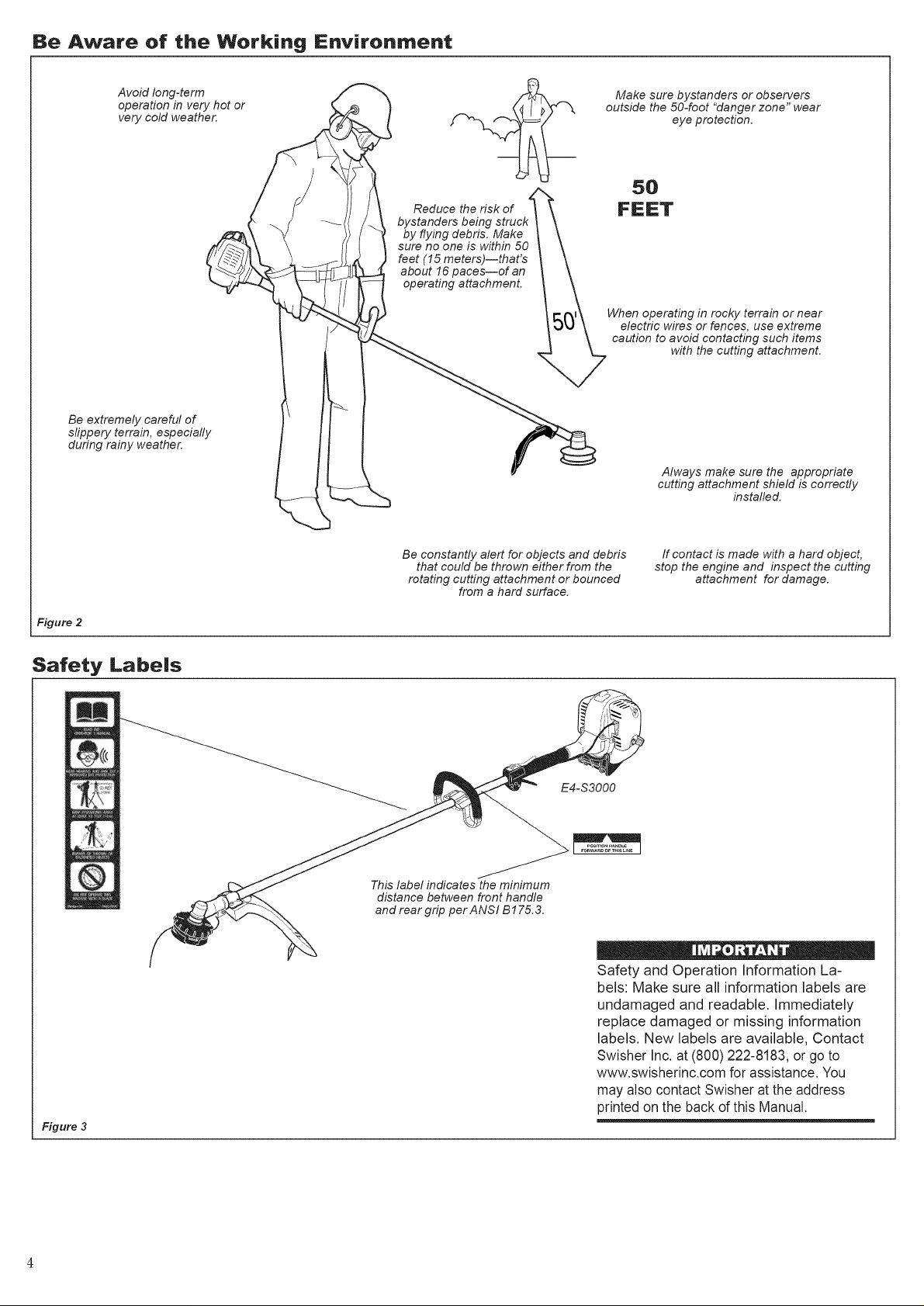

Be Aware of the Working Environment

Avoid long-term

operation in very hot or

very cold weather.

Be extremely careful of

slippery terrain, especially

during rainy weather.

Reduce the risk of

bystanders being

by flying debris. Make

sure no one is within 50

feet (15 meters)--that's

about 16 paces--of an

operating attachment.

Make sure bystanders or observers

outside the 50-foot "danger zone" wear

eye protection.

50

FEET

When operating in rocky terrain or near

electric wires or fences, use extreme

caution to avoid contacting such items

with the cutting attachment.

Always make sure the appropriate

cutting attachment shield is correctly

installed.

Figure 2

Safety Labe|s

Figure 3

Be constantly alert for objects and debris

that could be thrown either from the

rotating cutting attachment or bounced

This label indicates the minimum

distance between front handle

and rear grip perANSI B175.3.

from a hard surface.

If contact is made with a hard object,

stop the engine and inspect the cutting

attachment for damage.

E4-S3000

Safety and Operation Information La-

bels: Make sure all information labels are

undamaged and readable. Immediately

replace damaged or missing information

labels. New labels are available, Contact

Swisher Inc. at (800) 222-8183, or go to

www.swisherinc.com for assistance. You

may also contact Swisher at the address

printed on the back of this Manual.

Page 5

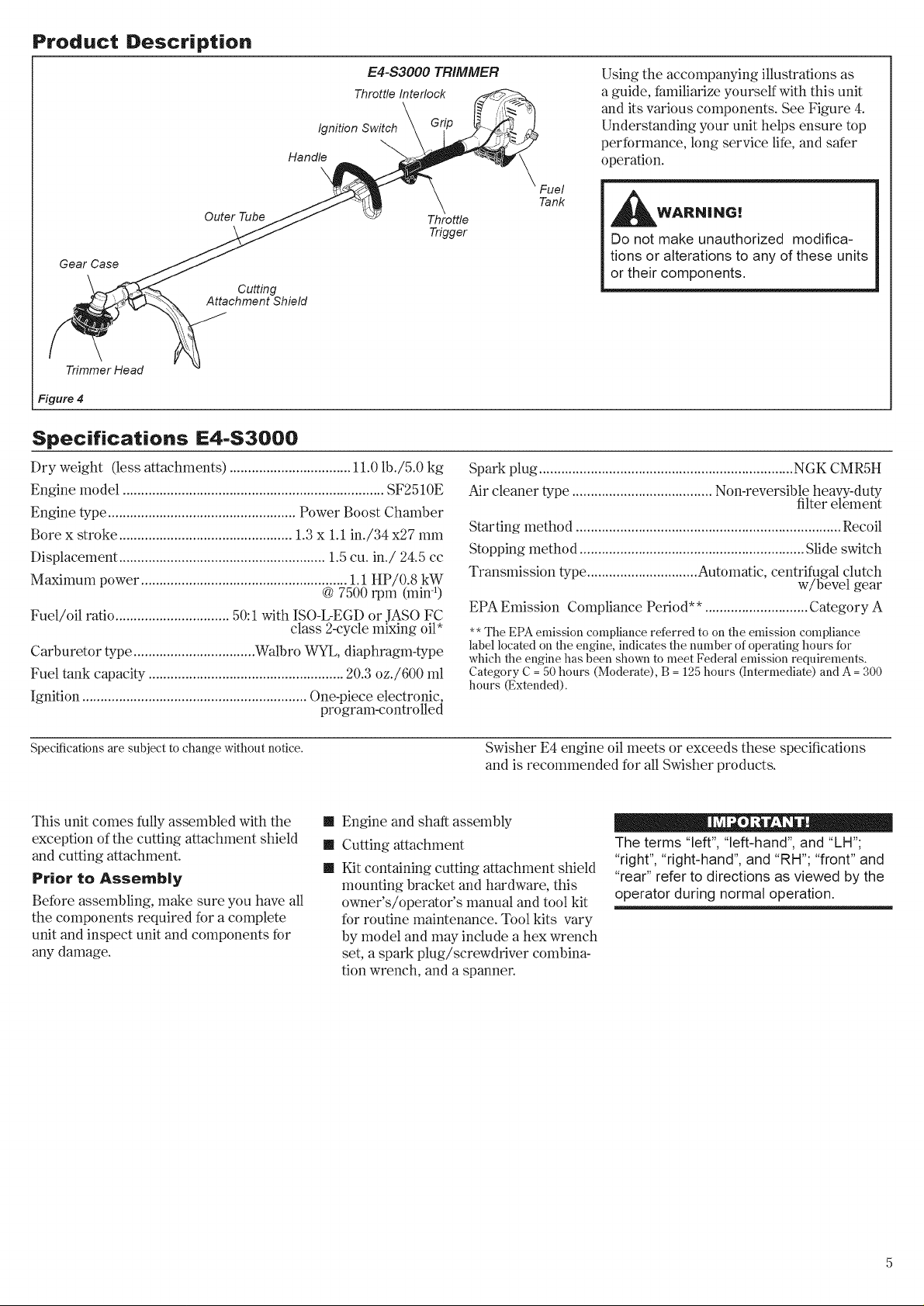

Product Description

E4-$3000 TRIMMER

Throttle Interlock

Ignition Switch

Handle

Gear Case

Trimmer Head

Figure 4

Outer Tube

Cutting

Attachment Shield

Throttle

Trigger

Specifications E4-$3000

Dry weight (less attachments) ..................................... lb./5.0 kg

Engine model ....................................................................... SF2510E

Engine type ................................................... Power Boost Chamber

Bore x stroke ............................................... 1.3 x 1.1 in./34 x27 mm

Displacement ........................................................ 1.5 cu. in./24.5 cc

Maximum power ........................................................ 1.1 HP/0.8 kW

Fuel/oil ratio ............................... 50:1 with ISO-L-EGD or JASO FC

Carburetor type ................................. Walbro WYL, diaphragm-type

Fuel tank capacity ..................................................... 20.3 oz./600 ml

Ignition ............................................................. One-piece electronic,

@ 7500 rpm (mill -1)

class 2-cycle mixing oil*

program-controlled

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. See Figure 4.

Understanding your unit helps ensure top

performance, long service life, and safer

operation.

Fuel

Tank

WARN|NG!

Do not make unauthorized modifica-

tions or alterations to any of these units

or their components,

Spark plug ..................................................................... NGK CMR5H

Air cleaner type ...................................... Non-reversible heavy-duty

filter element

Starting method ........................................................................ Recoil

Stopping method ............................................................. Slide switch

Transmission type .............................. Automatic, centrifugal clutch

w/bevel gear

EPA Emission Compliance Period** ............................ Category A

** The EPA emission compliance referred to on the emission compliance

label located on the engine, indicates the number of operating hours for

which the engine has been shown to meet Federal emission requirements.

Category C = 50 hours (Moderate), B = 125 hours (Intermediate) and A = 300

hours (Extended).

Specifications are subject to change without notice. Swisher E4 engine oil meets or exceeds these specifications

and is recommended for all Swisher products.

This unit comes fully assembled with the

exception of the cutting attachment shield

and cutting attachment.

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete

unit and inspect unit and components for

any damage.

m

Engine and shaft assembly

m

Cutting attachment

m

Kit containing cutting attachment shield

mounting bracket and hardware, this

owner's/operator's manual and tool kit

for routine maintenance. Tool kits vary

by model and may include a hex wrench

set, a spark plug/screwdriver combina-

The terms "left", "left-hand", and "LH";

"right", "right-hand", and "RH"; "front" and

"rear" refer to directions as viewed by the

operator during normal operation,

tion wrench, and a spanner.

Page 6

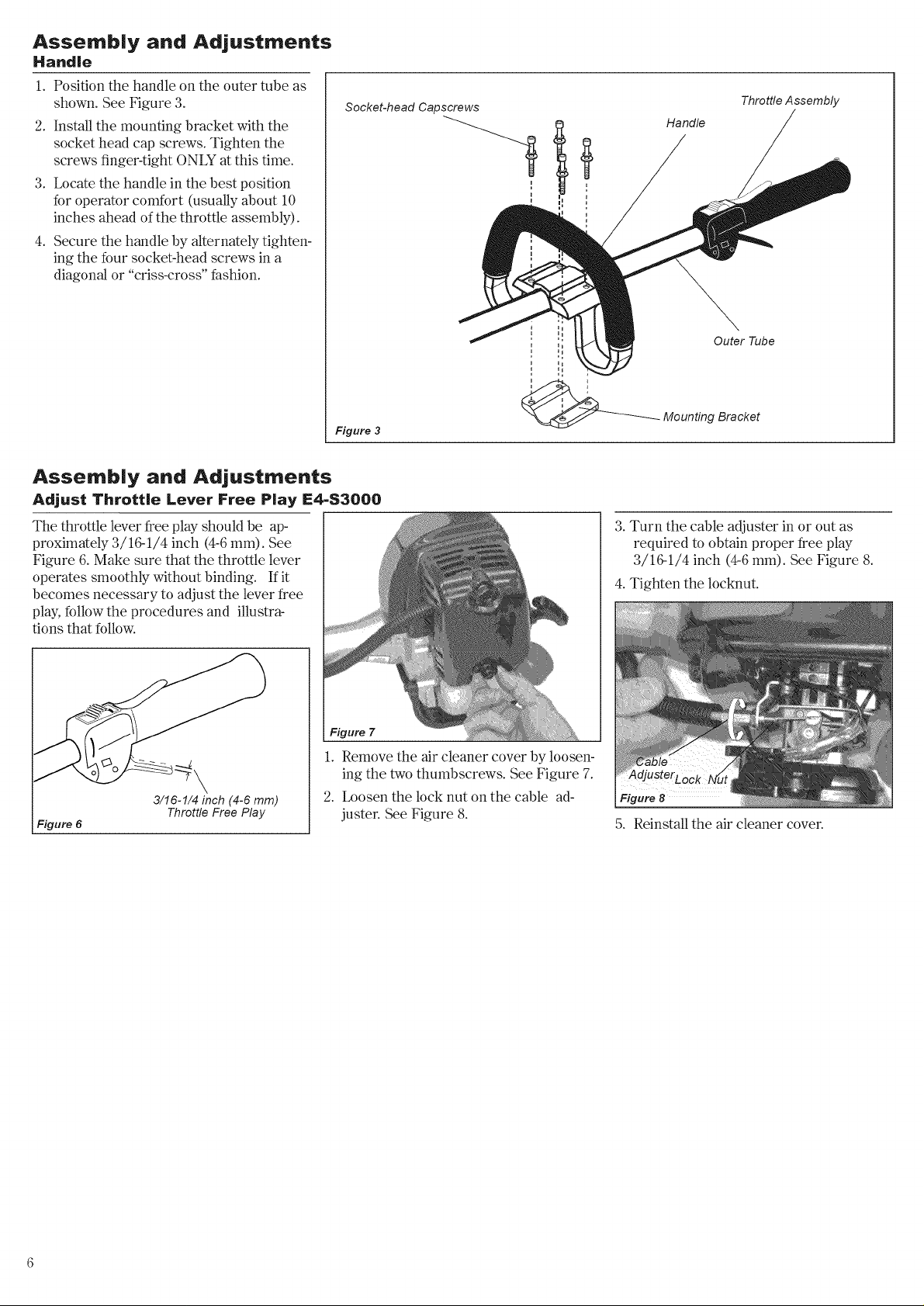

Assemb|y and Adjustments

Handle

1. Position the handle on the outer tube as

shown. See Figure 3.

Socket-head Capscrews

2. Install the mounting bracket with the

socket head cap screws. Tighten the

screws finger-tight ONLY at this time.

3. Ix)care the handle in the best position

for operator comfort (usually about 10

inches ahead of the throttle assembly).

4. Secure the handle by alternately tighten-

ing the four socket-head screws in a

diagonal or "criss-cross" fashion.

Figure 3

Assembly and Adjustments

Adjust Throttle Lever Free Play E4-$3000

The throttle lever free play should be ap-

proximately 3/161/4 inch (4-6 mm). See

Figure 6. Make sure that the throttle lever

operates smoothly without binding. If it

becomes necessary to adjust the lever free

play, follow the procedures and illustra-

tions that follow.

Handle

"" Outer Tube

ij

q

_ Mounting Bracket

3. Turn the cable adjuster in or out as

required to obtain proper free play

3/161/4 inch (4-6 mm). See Figure 8.

4. Tighten the locknut.

Throttle Assembly

Figure 6

3/16-1/4 inch (4-6 mm)

Throttle Free Play

Figure 7

1. Remove the air cleaner cover by loosen-

ing the two thumbscrews. See Figure 7.

2. Loosen the lock nut on the cable ad-

juster. See Figure 8.

Figure 8

5. Reinstall the air cleaner cover.

Page 7

Assembly and Adjustments

Cutting Attachment Shield

Head Cap __

Screw

Outer

Tube

Bracket __-_-i

Shim __

Line Cutter

Shim

Figure 9A

Retaining Mounting Plate

Nut

Figure 9

I

Cutting

Attachment

Install the Cutting Attachment Shield E4-$3000

1. Insert the cutting attachment shield

between the outer tube and the cutting

attachment mounting plate. See Figure 9.

2. Fit the two shims and the bracket over

the outer tube and loosely install the

four socket-head screws. See Figure 9.

3. Tighten the four socket-head cap screws

to secure the cutting attachment shield.

It may be necessary to loosen the retaining

nut and clamp screw to adjust cutting attach-

ment shield mounting plate.

E4-$3000

Cutting

Attachment

Shield

Nuts

Scre ws

WARN|NG!

NEVER operate the unit without the

cutting attachment shield installed

and tightly secured!

CAUT|ON!

Make sure the clamp screw and re-

taining nut are securely tightened

before tightening the four socket-head

cap screws.

To Change Position of Line Cutter,

The line cutter can be positioned in 2

positions to obtain different line length for

cutting.

1. Remove the 2 hex screws with a 4mm

hex wrench. See Figure 9A.

2. Rotate line cutter. See Figure 9A.

3. Reinstall the two hex screws and

tighten them securely.

_IL WARN|NG!

The line cutter is very sharp. Wear

gloves to protect your hands when

handling.

Be careful to not lose the 2 nuts in the cutting

attachment shield, they are not captured.

Page 8

Install the Trimmer Head

_ WARNING!

machine should NEVER be oper-

ated with blade-type attachments.

1. Turn the trimmer over so that the gearcase

output shaft faces UR See Figure 5.

2. Remove and discard the plastic retain-

ing plug.

3. Position the tool holder as shown, and

slide the holder onto the output shaft.

See Figure 5.

4. Rotate the tool holder and shaft until the

notch in the holder aligns with the notch

on the gearcase flange, and use the long

end of the hex wrench to lock the output

shaft in position. See Figure 6.

5. While holding the hex wrench, thread

the trimmer head onto the output shaft,

turning counter-clockwise.

A standard grass trimmer

Tool holder

Position

attachment

so that the

gearcase

Output shaft

/igure $

6. Using hand pressure only, tighten the

trimmer head firmly on the gearshadt.

See Figure 6.

7. Remove the hex wrench.

output shaft

faces UP

Turn trimmer head

COUNTERCLOCKWISE to tighten

Figure 6

The trimmer head has a left-hand thread.

Turn the trimmer head counter-clockwise

m install.

Mixing Fuel

CAUTION[

Never use any type of gasoline con-

taining more than 10% alcohol by vol-

ume! Some types of gasoline contain

alcohol as an oxygenate. Oxygenated

gasoline may cause increased operat-

ing temperatures. Under certain con-

ditions, alcohol-based gasoline may

also reduce the lubricating qualities of

some 2-cycle mixing oils. Generic oils

and some outboard oils may not be

intended for use in high-performance

engines, and should never be used in

your Swisher engine.

Filling the Fuel Tank

,_ WARNING!

NEVER smoke or light fires near the

engine.

ALWAYS stop the engine and allow

it to cool before refueling. Avoid over-

filling and wipe off any fuel that may

have spilled.

ALWAYS inspect the unit for fuel

leaks before each use. During each

refill, check that no fuel leaks from

around the fuel cap and/or fuel tank.

Minimize the Risk of Fire

CAUTION[

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FC

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

m Use only fresh, clean unleaded gasoline

with a pump octane of 87 or higher.

m Mix all fuel with a 2-cycle aipcooled mix-

ing oil that meets or exceeds ISO-L-EGD

and/or JASO FC classified oils at 50:1

gasoline/oil ratio.

If fuel leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYS move the unit at least 10

feet (3 meters) away from a fuel stor-

age area or other readily flammable

materials before starting the engine.

NEVER place flammable material

close to the engine muffler.

NEVER operate the engine without

the muffler and spark arrester screen

in place.

Examples of 50:1 mixing quantities

m 1 gallon ofgasoline to 2.6 oz. mixing oil

m 5 liters ofgasoline to 100 ml. mixing oil

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than 30

days and Swisher E4 Engine Oil with fuel

stabilizer is not used, it should first be treated

with a fuel stabilizer such as STA-BIL TM.

Swisher E4 Engine Oil is a registered JASO

FC classified oil and also meets or exceeds

ISO-L-EGD performance requirements.

Swisher E4 engine oil is recommended for

use in all Swisher low emissions engines and

also includes a fuel stabilizer.

1. Place the trimmer on a fiat, level surface.

2. Clear any dirt or other debris from

around the fuel filler cap.

3. Remove the fuel cap, and fill the tank

with clean, fresh fuel.

4. Reinstall the fuel filler cap and tighten

firmly.

Page 9

Starting the Engine

,_ WARNING!

The cutting attachment may

rotate when the engine is started!

Engine ignition is controlled by a two position switch mounted on the throttle housing labeled, "1"for ON or START and "O" for OFF or STOP.

Slide the ignition switch to the "ON" posi-

tion. See Figure 6.

_ WARNING!

out the tool assembly and cutting

attachments installed to the engine.

Failure to do so could damage the

engine and increase unexpected risk

to the operator and any bystander.

Never start the engine with-

Set the choke lever to the "CLOSED" posi-

tion if engine is cold.

_h_ ARN|NG!

Never start the engine from

the operating position.

When the engine starts, slowly move the

choke lever to the "OPEN" position. See

Figure 10. (If the engine stops aster the

Ignition Switch

Button

Figure 6

ON

Throttle

Trigger

initial start, close the choke and restart.)

Set the throttle lever to the "fast idle";

Squeeze the throttle lever toward the

hand grip on the shast tube.

Depress and hold the throttle lock but-

ton.

While depressing the throttle lock button,

release the throttle lever. See Figure 6.

Press the primer bulb until fuel can be seen

flowing in the transparent return tube.

Return Tube__

• tll" *

The primer system only pushes fuel

through the carburetor. Repeatedly

pressing the primer bulb will not flood the

engine with fuel.

Figure 8

While holding the outer tube firmly with

your left hand, use your other hand to

slowly pull the recoil starter handle until

resistance is felt, then pull quickly to

start the engine.

Make sure the cutting

attachment is clear of

obstructions!

Figure 9

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

Figure 10

If the engine fails to start after several at-

tempts with the choke in the closed posi-

tion, the engine may be flooded with fuel.

If flooding is suspected, move the choke

lever to open position and repeatedly pull

the recoil starter to remove the excess

fuel and start the engine. If the engine still

fails to start, See the section "Starting a

Flooded Engine" for instructions.

When the Engine Starts...

[]

After the engine starts, allow the

engine to warm up at idle 2 or 3 min-

utes before operating the unit.

[]

After the engine is warm, pick up the

unit and clip on the shoulder strap.

[]

Advancing the throttle makes the cut-

ting attachment turn faster; releasing

the throttle permits the attachment to

stop turning. If the cutting attachment

continues to rotate when the engine

returns to idle, carburetor idle speed

should be adjusted (see "Adjusting

Engine Idle").

Page 10

Stopping the Engine

OFF

Idle the engine briefly before stopping

(about 2 minutes), then slide the ignition

switch to the "O" (Engine OFF) position.

ure 21

E4-$3000

Adjusting Engine |die

__lJ

Figure 22 Idle

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutting attachment.

|die Speed Adjustment

WARNING!

The cutting attachment must NEVER

rotate at engine idle! If the idle speed

cannot be adjusted by the procedure

described here, return the trimmer to

your Swisher dealer for inspection,

1. Place the trimmer on the ground, then

start the engine, and then allow it to idle

2-3 minutes until warm.

2. Ifthe attachment rotates when the

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise. See Figure 22.

3. Ifa tachometer is available, the engine idle

speed should be final adjusted to 3,000

(_+300)RPM (min-1).

4. Carburetor fuel mixture adjustments are

preset at factory and cannot be serviced

in the field.

Checking Unit Condition

NEVER operate the unit with the cut-

ting attachment shield or other protective

devices removed!

WARN|NG!

A cutting attachment shield or other

protective device is no guarantee

of protection against ricochet. YOU

MUST ALWAYS GUARD AGAINST

FLYING DEBRIS!

Use only authorized Swisher parts and

accessories with your Swisher trimmer. Do

not make modifications to this unit without

written approval from Swisher, Inc.

ALWAYS make sure the cutting attach-

ment is properly installed and firmly tight-

ened before operation.

NEVER use a cracked or warped cutting

attachment: replace it with a serviceable

one.

ALWAYS make sure the cutting attach-

ment fits properly into the appropriate

attachment holder. If a properly installed at-

tachment vibrates, replace the attachment

with new one and re-check.

ALWAYS stop the engine immediately and

check for damage if you strike a foreign

object or if the unit becomes tangled. Do not

operate with broken or damaged equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could dam-

age the engine.

NEVER operate a unit with worn or dam-

aged fasteners or attachment holders.

10

Page 11

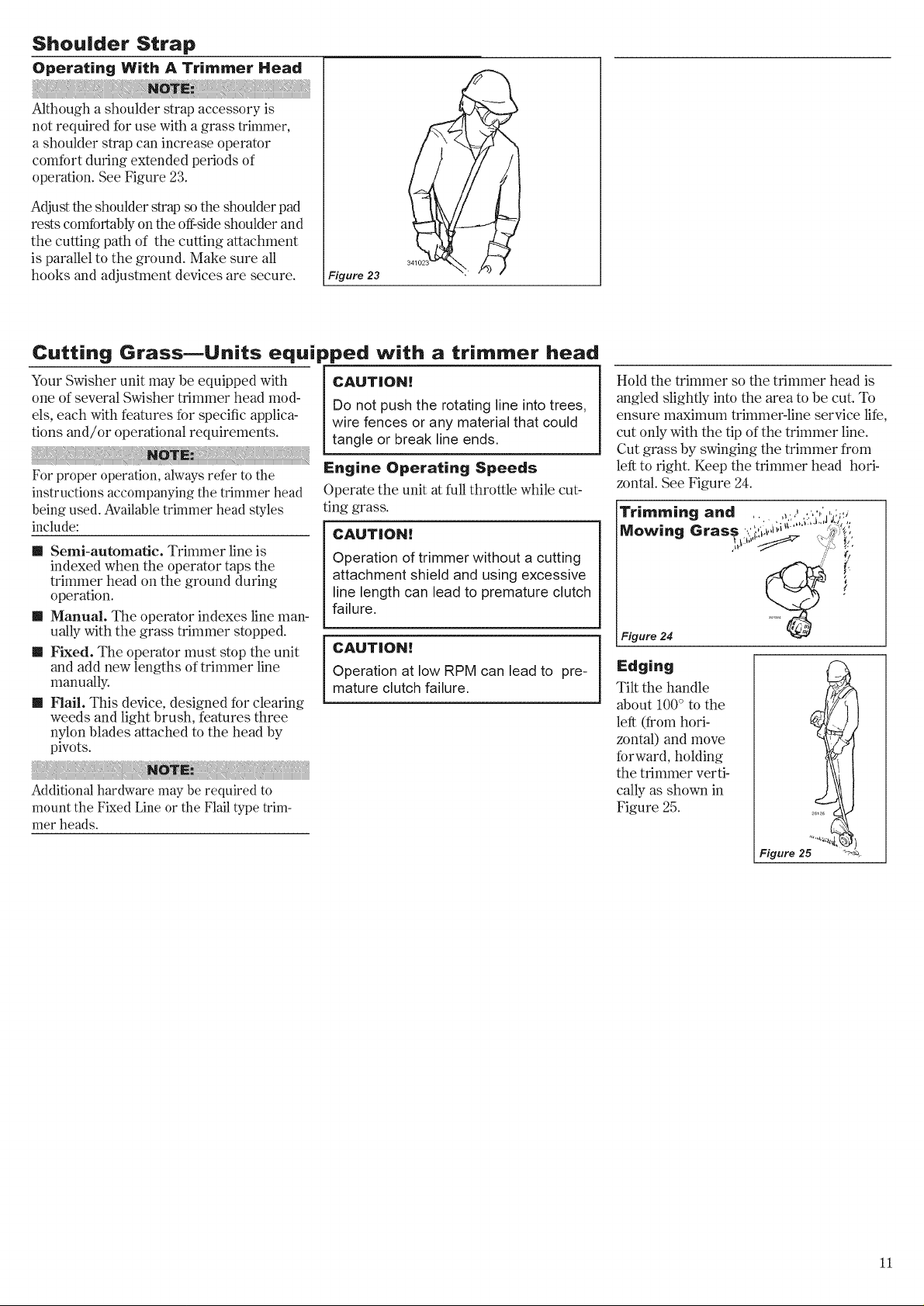

Shoulder Strap

Operating With A Trimmer Head

Although a shoulder strap accessory is

not required for use with a grass trimmer,

a shoulder strap can increase operator

comfort during extended periods of

operation. See Figure 23.

Adjust the shoulder strap so the shoulder pad

rests comfortably on the off-side shoulder and

the cutting path of the cutting attachment

is parallel to the ground. Make sure all

hooks and adjustment devices are secure.

Figure 23

b

1

Cutting GrassmUnits equipped with a trimmer head

Your Swisher unit may be equipped with

one of several Swisher trimmer head mod-

els, each with features for specific applica-

tions and/or operational requirements.

For proper operation, always refer to the

instructions accompanying the trimmer head

being used. Available trimmer head styles

include:

m Semi-automatic. Trimmer line is

indexed when the operator taps the

trimmer head on the ground during

operation.

m Manual. The operator indexes line man-

ually with the grass trimmer stopped.

m Fixed. The operator must stop the unit

and add new lengths of trimmer line

manually.

m Nail. This device, designed for clearing

weeds and light brush, features three

nylon blades attached to the head by

pivots.

Additional hardware may be required to

mount the Fixed Line or the Flail type trim-

mer heads.

CAUT|ON!

Do not push the rotating line into trees,

wire fences or any material that could

tangle or break line ends.

Engine Operating Speeds

Operate the unit at full throttle while cut-

ting grass.

CAUTION!

Operation of trimmer without a cutting

attachment shield and using excessive

line length can lead to premature clutch

failure.

CAUTION!

Operation at low RPM can lead to pre-

mature clutch failure.

Hold the trimmer so the trimmer head is

angled slightly into the area to be cut. To

ensure maximum trimmer-line service life,

cut only with the tip of the trimmer line.

Cut grass by swinging the trimmer from

left to right. Keep the trimmer head hori-

zontal. See Figure 24.

Figure 24

Edging

Tilt the handle

about 100° to the

left (from hori-

zontal) and move

forward, holding

the trimmer verti-

cally as shown in

Figure 25.

Figure 25

11

Page 12

General Maintenance

MAINTENANCE, REPLACEMENT OR

RE-PAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE PER-

FORMED BYANY REPAIR ESTABLISH-

MENT OR INDIVIDUAL; HOWEVER,

WARRANTY REPAIRS MUST BE PER-

FORMED BYA DEALER OR SERVICE

CENTER AUTHORIZED BY SWISHER.

THE USE OF PARTS THATARE NOT

EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS OF

THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

Air Filter

The E4 engine that powers your Swisher mod-

el is a hybrid 4-stroke engine. As a hybrid,

the engine is lubricated by oil mixed with

the gasoline and air from the carburetor that

moves through and around the internal parts

Daily Maintenance

Prior to each work day, perform the

following:

m Remove dirt or debris from the engine,

check the cooling fins and air cleaner for

clogging and clean them as necessary.

I 0-Hour Maintenance

(more frequently in dusty conditions)

1. Remove the air cleaner cover by loosening

the two thumbscrews. See Figure 28A.

2. Remove and inspect the pre-filter. Ifthe

pre-filter is torn or otherwise damaged,

replace it with a new one. See Figure 28B.

3. Clean the pre-filter with soap and water.

Let dry before reinstalling.

4. Inspect the air cleaner element. If the

element is damaged or distorted, replace

it with a new one.

5.Tap filter gently on a hard surface to dis-

lodge debris from element or use com-

pressed air from the inside to blow debris

out and away from the air cleaner element.

Direct the air stream at the inside face of

the filter only!

_IkWARN| NG!

Before performing any maintenance,

repair or cleaning work on the unit,

make sure the engine and cutting at-

tachment are completely stopped. Dis-

connect the spark plug wire before per-

forming service or maintenance work.

WARNING!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury.

ofthe engine ina similar way that a 2-stroke

engine is lubricated. Without the heavy duty

2-stage air filter equipped on all E4 engines,

dust and dirt could also move through the en-

gine, decreasing engine life, increasing valve

m Carefully remove any accumulation of

dirt or debris from the muffler or the

fuel tank. Dirt build-up in these areas

could cause engine overheating, induce

premature weal', or create a fire hazard.

Unscrew

Fasteners

Figure 28,4

6. Install the air cleaner element, pre-filter

and cover in the reverse order of removal.

Using non-standard replacement parts could

invalidate your Swisher warranty.

Muffler

This unit must never be operated with a faulty

or missing spark arrester or muffler. Make

sure the muffler is well secured and in good

condition. A worn or damaged muffler is a

fire hazard and may also cause hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

wear and the need for more frequent valve ad-

justments. To keep your E4 engine strong and

reliable, Swisher recommends that you check

and service the air filter as instructed in the

10-Hour Maintenance section that follows.

m Check for loose or missing screws or

components. Make sure the cutting at-

tachment is securely fastened.

m Check the entire unit for leaking fuel or

grease.

Pre-Filter

Air Cleaner

Element

Figure 28B

CAUTION!

Neveroperate the unit ifthe air cleaner

assembly is damaged or missing!

12

Page 13

10/15-Hour Maintenance

Clean the spark plug

0.024-0.028 inch

(0.6-0. 7 mm)

Figure 29

and check the gap at

the electrode.

50-hour Maintenance

Every 50 hours of operation

(more frequently in dusty or

dirty conditions):

II Remove and clean the cylinder cover

and clean grass and dirt from the

cylinder fins.

II Remove the cutting attachment, cutting

attachment holder and gear shaft collal:

Remove the filler plug from the side of

the gear case and press new grease into

the gear case until old grease is pushed

out. Use only lithium-base grease. See

Figure 30.

II Lubricate main shaft splines.

II Use a hooked wire to extract the fuel filter

from inside the fuel tank. See Figure 31.

Remove and replace the filter element.

CAUT|ON!

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be dam-

aged easily.

Figure 30

New

Grease

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.024 - 0.028

inch (0.6 - 0.7 ram). If the spark plug must

be replaced, use only an NGK CMR5H or

equivalent resistor type spark plug of the

correct heat range. See Figure 29.

The NGK CMR5H also meets the require-

ments for electro magnetic compliance (EMC).

Gear

Shaft

Collar C_

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine's internal parts,

Old

Grease

Before reinstalling the new filter element,

inspect the condition of all the fuel system

components (fuel pick-up line, fuel return

line, tank vent line, tank vent, fuel cap and

fuel tank). If damage, splitting or deteriora-

tion is noted, the unit should be removed

from service until it can be inspected or

repaired by a Swisher-trained service

technician.

13

Page 14

139/150-Hour Maintenance

Maintenance after first 139-hours, then every 150-hours thereafter.

Combustion chamber should be decar-

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Swisher-trained

service technician.

Valve Adjustment

1. Remove cylinder cover, rocker arm cover,

and spark plug. Rotate the crankshaft

while observing the piston through the

spark plug opening. When the piston

is at the top of the compression stroke

(TDC), the valves can be adjusted.

CAUT|ON!

II Performing a valve adjustment

incorrectly may cause hard starting

and/or can damage the engine.

II If you are unfamiliar with this engine

or uncomfortable with this proce-

dure, consult with an authorized

Swisher servicing dealer.

m Replace the spark plug annually: Use

only NGK CMR5H or equivalent resis-

tor type spark plug of the correct heat

range. Set spark plug electrode gap to

0.024-0.028 inch (0.6 -0.7 mm).

2. Ix)osen adjuster locknut so that the 2.5

mm Allen socket head adjustment screw

can turn freely.

3. Insert 0.10 mm (0.004") feeler gauge

between valve stem tip and rocker arm.

4. Turn adjustment screw (clockwise =

tighter, counter-clockwise = looser) until

feeler gauge is almost snug. Back off

just enough to allow gauge to slip out

with limited resistance.

5.

While holding the adjustment screw in

place with the Allen driver, tighten the

locknut with a wrench.

The NGK CMRSHalsomeets the requirements

forelectro magnetic compliance _MC).

6. Turn engine over several times, and re-

turnthe to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change

as a result of tightening the locknut.

Readjust as necessary.

7. Replace rocker arm cover gasket to as-

sure proper sealing and install cover.

If a new gasket is not available and/or the

old gasket is not damaged, the old gasket

may be reused. Never use cracked or

damaged gaskets!

Spark Attester Screen Maintenance

Ifthe engine becomes sluggish and low on pow-

er, check and clean the spark arrester screen.

WARN|NG!

Neveroperatethe unitwith a damaged

or missing muffleror spark arrester!

Operatingwith a missingor damaged

spark arresterisa fire hazardand

couldalsodamageyourhearing.

These instructions refer to Figure 32.

1. With a 3 rrnn hex wrench remove the 3

engine cover screws and the engine cover.

2. With a 4 mm hex wrench remove the 3

muffler bolts and the muffler.

3. With a small flat bladed screwdriver

remove the 2 screws holding the spark

arrester screen and cover to the muffler.

4. Remove the screen and clean it with a

stiff bristle brush.

5. Inspect the cylinder exhaust port for any

carbon buildup.

6. Reassemble the spark arrester, muffler

and engine cover in the reverse order of

disassembly.

Engine Cover_

Figure 32

Scre ws i

I

i

I

I

I

with an authorized E4 Swisher servicing

dealer. Contact Swisher Inc. at (800) 222-8183,

or go to www.swisherinc.com for assistance.

If you note excessive carbon buildup, consult

Muffler

Muffler /

Gasket

_2 Muffler Bolts

........._a /

Screen

Spark Arrester

Cover

Cover

Screws

14

Page 15

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following proce-

dures to prepare it for storage:

II Clean external parts thoroughly.

II Drain all the fuel from the fuel tank.

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL TM, if

Swisher E4 Engine Oil with fuel stabilizer

is not used.

Speed-Feeff375LoadingInstructionsPIN78890-28000

Align

Alinear

Aligner

Allineare

Austrichten \

\

CAUT|ON!

Gasoline stored in the carburetor for

extended periods can cause hard start-

ing and could also lead to increased

service and maintenance cost.

Remove the remaining fuel from the fuel

lines and carburetor.

1. Prime the primer bulb until no more fuel

is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps 1 and 2 until the engine will

no longer start.

II Remove the spark plug and pour about

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3 times

so oil will evenly coat the interior of the

engine. Reinstall the spark plug.

II Before storing the unit, repair or replace

any worn or damaged parts.

II Remove the air cleaner element from the

carburetor and clean it thoroughly with

soap and water. Let dry and reassemble

the element.

m Store the unit in a clean, dust-free area.

I0

No. Part Number

1 78890-11330

2 78890-11380

3 78890-11310

4 28820-07350

5 78890-11320

6 28820-07340

7 28820-07380

8 17500-23600

9 28820-09310

10 78890-25310

Part Name

SPOOLLH

BUSHING

KNOB

CORE

EYELETCARRIER

EYELET

CAP

SPRING

COVER

STUD,7MM LH

5"(127cm)

4

Descripcien

CARRETELH

BUJE

PERILLA

BASECENTRAL

SOPORTEDEBOQUILLAS

BOQUILLAS

TAPA

RESORTE

TAPA

PERNO,7MM LH

Nora de la piece

BOBINE LH

BAGUE

POIGNEE

MOYEU

CORP DE POULIE

PASSE-CABLE

CAPUCHON

RESSORT

COUVERCLE

BOULON, 7 MM LH

5 4TM

1 _@_2

Denominazione

BOBINALH

BOCCOLA

MANOPOLA

PARTEINTERNA

SUPPORTODELL'OCCHIELLO

OCCHIELLO

CAPPELLO

GRUPPOMOLLA

COPERCHIO

BULLONE,7MM

Beschreibung

SPULELH

REDUZIERRING

DREHSCHEIBE

KERNSTOCK

FENSTERELEMENT

FENSTER

VERSCHLUSSAUFBAU

FEDER

DECKEL

SCHRAUBBOLZEN,7 MM

Qty.

1

1

1

1

1

2

1

1

1

1

15

Page 16

Troub|eshootin Guide

What To Check

Does the engine crank?

YES 1

Good compression?

YES

Does the tank contain

fresh fuel of the proper

grade?

YES Jr

Is fuel visible and moving [NO J Check for clogged fuel filter and/or vent.

in the return line when _ Priming pump not flmctioning properly.priming?

YES

Is there spark at the spark

plug wire terminal?

YES J_

Check the spark plug.

Possible Cause

Flnkt in the crankcase.

_ aulty recoil starter.

Internal damage.

INO I Ix)ose spark plug.

Excess wear on cylinder, piston, rings.

/ Valves not seating.

NO I Fuelincorrect, stale or contaminated;

V_ mixture incorrect.

INO IThe ignition switch is in "O" {OFF)

position.

I I Shorted ignition ground.

[ Faulty ignition unit.

If the plug is wet, excess fuel may be in

the cylinder.

Tile plug is fouled or improperly gapped.

Tile plug is damaged internally or of the

wrong size.

Remedy

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Tighten and re-test.

Refill with flesh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled nlixing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 5(}:1gasoline/oil ratio.

Replace fl_el filter or vent as required; restart.

Consult with an authorized servicing dealer.

Move switch to 'T' (ON) position and restart.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Crank the engine with the plug removed,

reinstall the plug, and restart.

Clean and regap the plug to 0.024 -0.028

inch (0.6 - (1.7ram). Restart.

Replace the plug with an NGK CMR5H or

equivalent resistor type spark plug of the

correct heat range. Set spark plug electrode

gall to (/.024-(/.028 inch (0.6-(/.7 ram).

What To Check

Is tile engine overheating? [ _

Engine is rough at all I ,

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Engine is knocking. ]_

/

Possible Cause

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty

or damaged.

Carbon deposits on the piston or in

the muffler.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm.

Valve clearance set incorrectly.

Overheating condition.

Improper fuel.

Remedy

Shorten trimmer line. Cut at a slower rate.

Consult with an authorized servicing dealer.

Refill with flesh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled mLxing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 50:1 gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing dealer.

Service the air cleaner element.

Tighten or replace.

Repair or replace filter and/or fuel line.

Replace the fuel. See page 10.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

See above.

Check fuel octane rating; check for presence of

alcohol in the fuel (pg. 10). Refuel as necessary.

Carbon deposits in the combustion

chamber.

Valve clearance set incorrectly.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

16

Page 17

Troubleshooting Guide (continued)

Symptom

Poor acceleration.

Engine stops abruptly.

[Engine difficult to shut off._

Possible Cause

Clogged air filter,

Clogged fuel filter,

Lean fuel/air mixture.

Idle speed set too low.

Switch turned off.

Fuel tank empty,

Clogged fuel filter,

Water in the fuel,

Shorted spark plug or loose terminal,

Ignition failure.

Piston seizure.

Ground (stop) wire is disconnected or

switch is defective.

Overheating due to incorrect spark plug.

Remedy

Clean tile air filter.

Replace tile fuel filter.

Consult with an authorized servicing dealer.

Adjust: 3,000 (±300) RPM (mind).

Reset tile switch and restart.

Refuel. See page 10.

Replace fuel filter.

[)rain; replace with clean fuel. See page 10.

Clean and replace spark plug, tighten

tile terminal.

Replace tile ignition unit.

Consult with an authorized servicing dealer.

Test and replace as required.

Idle engine until cool.

Clean and regap tile plug to 0.024- 0.028

inch (0.6- 0.7 ram). Correct plug: NGK CMR5H

or equivalent resistor type spark plug of tile

correct range.

Overheated engine.

Top ofengine isgettingdirty and oily.

_ Valve cover is leaking.

Cutting attachment

rotates at engine idle.

Broken clutch spring or worn clutch

spring boss.

_ Engine idle too high.

Loose attachment holder.

[ Engine will not idle down. ]-----,,+ Engine idle set t°° higlL

Symptom

I Excessive vibration.

Engine has an air leak.

Possible Cause

Warped or damaged cutting attachment.

Loose gearcase.

Bent main shaft/worn or damaged

bushings.

Trhnmer line not wound properly on spool. Rewind trhnmer line.

Cutting attachment will

not rotate.

Shaft not installed in powerhead or

gearcase.

Idle engine until cool.

Consult with an authorized servicing dealer.

Set idle: 3,000 (±300) RPM (rain-l).

Replace spring/shoes as required, check

idle speed.

Inspect and re-tighten holders securely.

Set idle: 3,000 (±300) RPM (rain-l).

Consult with an authorized servicing dealer.

Remedy

Inspect and replace attachment as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Broken shaft.

Damaged gearcase.

17

Page 18

NOTES

18

Page 19

NOTES

19

Page 20

Emission System Warranty Statement (Administered by Shindaiwa Corporation)

Your Warranty Rights and Obligations

The California Air Resources Board, the U.S. Environmental

Protection Agency and Shindaiwa Corporation are pleased to

explain the exhaust and evaporative emission control system war-

ranty on your new small off-road (non-road) engine.

In California, new small off-road engines must be designed,

built, and equipped to meet the State's stringent anti-smog stan-

dards. In other states, new 1997 and later non-road engines must

meet the Federal EPA's stringent anti-smog standards.

Shindaiwa Corporation must warrant the emission control system

on your small off-road engine for the periods of time listed below,

provided there has been no abuse, neglect, or improper mainte-

nance of your small off-road engine.

Your engine exhaust and evaporative emission control system

includes parts such as the carburetol; fuel tank, the ignition sys-

tem and, ifequipped, the catalytic converter. These components

are specifically listed below.

Where a warrantable condition exists, Shindaiwa Corporation

will repair your small off-road engine at no cost to you including

diagnosis, parts, and labol:

Manufacturer's Warranty Coverage

When sold within the U.S., this engine's emission control sys-

tem is warranted %r a period of two (2) years from the date this

product is first delivered to the original retail purchaser.

During the warranty period, Shindaiwa Corporation will, at

their option, repair or replace any defective emission-related com-

ponent on this engine. During the original Warranty Period, these

Warranty Rights are automatically transferable to subsequent

owners of this product.

What is Covered by this Warranty

1. Carburetor Internal Components

m Throttle Valve, Needle, Jet, Metering Diaphragm

2. Fuel Tank

3. Ignition System Components

m Ignition Coil

m Flywheel Rotor

4. Catalytic Converter (iforiginally equipped)

The emission control system for your particular Shindaiwa

Corporation engine may also include certain related hoses and

connectors.

Owners Warranty Responsibilities

As the small off-road engine owner, you are responsible for the

performance of the required maintenance listed in this owners

manual. Shindaiwa Corporation recommends that you retain all

receipts covering maintenance on your small off-road engine, but

Shindaiwa Corporation cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all sched-

uled maintenance.

As the small off-road engine owner, you should be aware, how-

ever, that Shindaiwa Corporation may deny you warranty cover-

age ifyour small off-road engine or a part has failed due to abuse,

neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your small off-road engine to

an authorized Shindaiwa Corporation Dealer as soon as a problem

exists. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a Shindaiwa Corporation cus-

tomer service representative or your local Shindaiwa Dealer.

Consequential Damages

In the event that other component parts of this product are dam-

aged by the failure of a warranted part, Shindaiwa Corporation will

repair or replace such component parts at no charge to you.

What is Not Covered

Failures caused by abuse, neglect, or improper maintenance

procedures.

m Failures caused by the use of modified or non-approved parts or

attachments.

This Warranty is Administered by',

Shindaiwa Corporation

11975 SW Herman Road

Tualatin, OR 97062

(503) 692-3070

Swisher Part Number 81950

RO. Box 67 Revision 12/2007

Warrensburg, MO 64093

Loading...

Loading...