Page 1

SWISHER OWNER'S/OPERATOR'S MANUAL

WARN|N6!

Minimize the risk of injury to yourself and others! Read this manual

and familiarize yourself with the contents, Always wear eye and hear-

ing protection when operating this unit,

l : :: f"

Part Number 81955 Rev, 10/07

Page 2

Introduction

The Swisher E4-HT3000 Hedge Trimmer

has been designed and built to deliver

superior performance and reliability with-

out compromise to quality, comfort, or

durability.

Swisher high performance engines repre-

sent the leading edge of air-cooled engine

technology, delivering exceptionally high

power at remarkable low displacement and

weight. As an owner/operator, you'll soon

discover for yourself why Swisher is simply

in a class by itself!

The information contained in this manual

describes units available at the time of

publication. While every attempt has been

made to give you the very latest informa-

tion about your Swisher product, there

may be some differences between your

E4-HT3000 hedge trimmer and what is

described here.

Swisher Inc. reserves the fight to make

changes to products without prior notifica-

tion, and without obligation to make akera-

tions to units previously manufactured.

WARN|NG!

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth de-

fects or other reproductive harm.

Attention Statements

_ WARN|NG!

A statement preceded by the trian-

gular Attention Symbol and the word

"WARNING" contains information that

should be acted upon to prevent seri-

ous bodily injury.

CAUT|ON!

A statement preceded by the word

"CAUTION" contains information that

should be acted upon to avoid damag-

ing your unit.

A statement preceded by the word IM-

PORTANT is one that possesses special

significance.

A statement preceded by tile word "NOTE"

contains information that is handy to know

and may make your job easier.

Read and follow this

operators manual.

Failure to do so could

result in serious injury.

Wear eye and hearing

protection at all times

during the operation of

this unit.

The blades are SHARP!

Handle with care.

Keep hands clear of the

cutter blades when

starting the engine.

The operational procedures described in

this manual are intended to help you get

the most from your unit, and to protect you

and others from harm. These procedures

are guidelines for safe operation under

most conditions, and are not intended to

replace any safety rules and/or laws that

may be in force in your area. If you have

questions regarding your E4-HT3000

hedge trimmer, or if you do not understand

something in this manual, contact Swisher

Inc. at (800) 222-8183, or go to www.

swisherinc.com for assistance.

Contents _A_;I;

Introduction ................................................... 2

Attention Statements ..................................... 2

General Safety Instructions .......................... 3

Safety and Equipment Labels ....................... 4

Specifications ................................................. 4

Unit Descfiption ............................................ 5

Mixing Fuel .................................................... 5

Filling the Fuel Tank ..................................... 5

Starting the Engine ....................................... 6

Adjusting Engine Idle .................................... 7

Stopping the Engine ...................................... 7

Maintenance and Adjustments ..................... 8

Spark Arrester Screen Maintenance .......... 11

Long Term Storage ...................................... 11

Troubleshooting Guide ............................... 12

Emission System Warranty Statement ......... 15

Page 3

Genera| Safety instructions

Work Safely

Swisher hedge trimmers operate at very

high speeds and can do serious damage or

injury if they are misused or abused. Never

allow a peJ_on without training or instruction

to operate your unit!

_ WARNING!

Never make unauthorized attachment

installations.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

equipment of any kind if you are tired

or if you are under the influence of al-

cohol, drugs, medication or any other

substance that could affect your ability

or judgement.

_ WARNING!

Minimize the Risk of Fire!

NEVER smoke or light fires near the

engine.

ALWAYS stop the engine and allow it

to cool before refueling. Avoid overfill-

ing and wipe off any fuel that may have

spilled.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily flammable materials before

starting the engine.

NEVER place flammable material close

to the engine muffler.

NEVER run the engine without the spark

arrester screen in place.

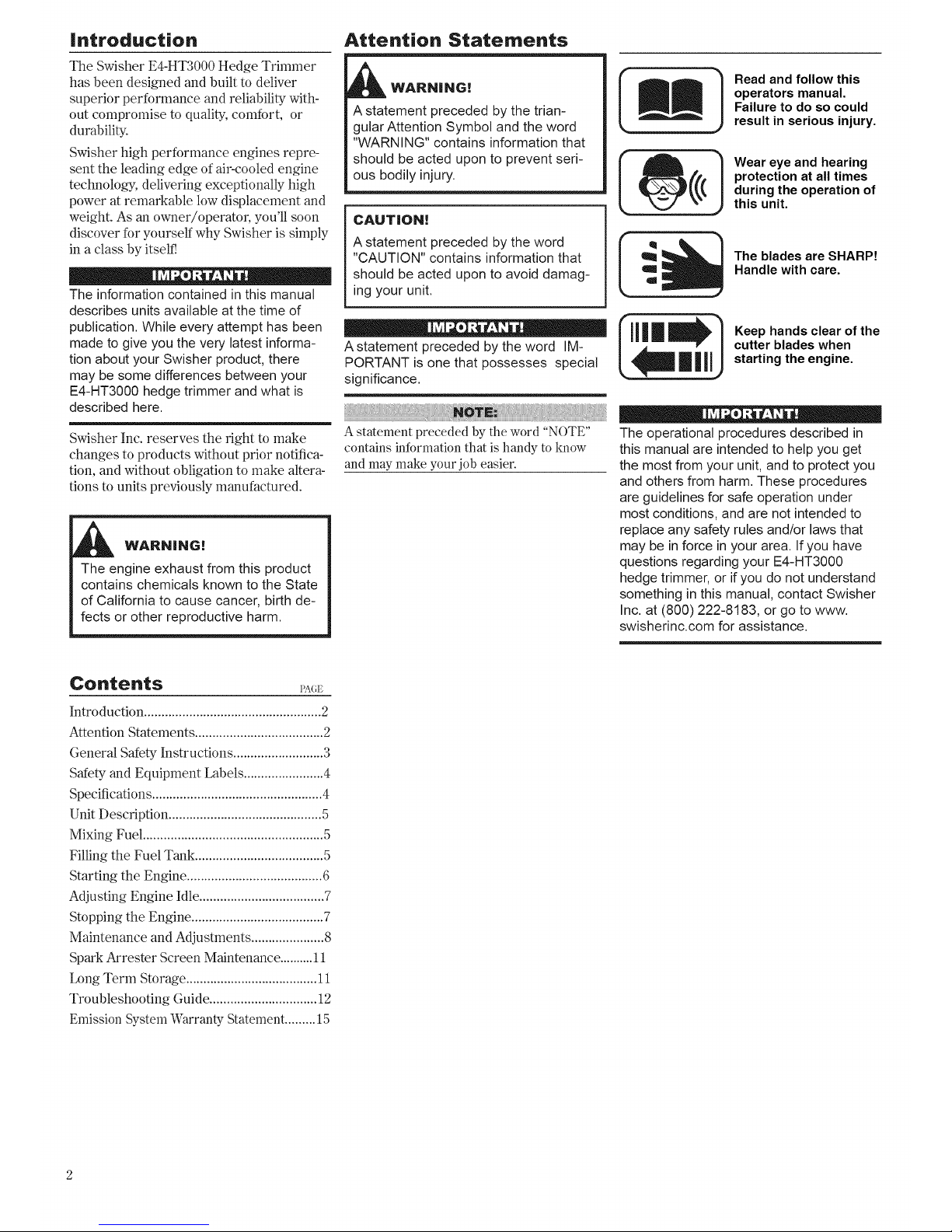

WORK SAFEL

ALWAYS wear close-fitting clothing. Gloves offer

added protection and am strongly recommended. Do

not wear clothing or jewehy that eould get caught in

machinery.

NEVER allow children to use the

unit. Avoid operating near bystand-

ers.

ALWAYS wear eye, eaJ, and

hand protection while operat-

ing this unit!

ALWAYS operate

with both hands firmly

gripping the uniL

ALWAYS stop the

engine b@re removing

branches or debris from

the cutters! Never allow

the cutters to contact

buildings or other hard

objects!

NEVER operate this unit

if the salty guard has been

removed or damaged!

ALWAYS stop the engine and

install the blade cover before

moving to another work site,

and maintain a firm footing

while operating or earJying

the trimmer.

NEVER cut metal objects or

wire with the blade.

USE EXTREME CA UTION

when operating near,rices or

electric wiring.

Figure I

AVOID using or storing this

unit in a wet environment.

Water on the cutters may enter

the gearcase and damage your

unit.

AVOID cutting large or extremely

"woody" branches. Doing so can

shorten cutter life, and may also

damage the gearcase.

ALWAYS ke@ p_vper footing and do not ove_

reach. Maintain your balance at all times

during operation.

ALWAYS wear eye protection to shield

against thrown objects.

ALWAYS protect yourself from haz-

ards such as thorny brush and flying

debris by wearing gloves and close

fitting clothing that covers arms and

legs. Never wear shorts. Don't wear

loose clothing or items such as jewelry

that could get caught in machinery or

underbrush. Secure long hair so it is

above shoulder level.

NEVER run the engine when transport-

ing the unit,

_ WARN|NG[

Use Good Judgment

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

ALWAYS use the proper cutting tool for

the job.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improp-

erly installed parts or attachments.

ALWAYS hold the unit firmly with both

hands when cutting or trimming, and

maintain control at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any mainte-

nance work.

Inspect front and rear handles for dam-

aged or loose attachments before use.

NEVER operate a hedge trimmer with

damaged or loose handles

Page 4

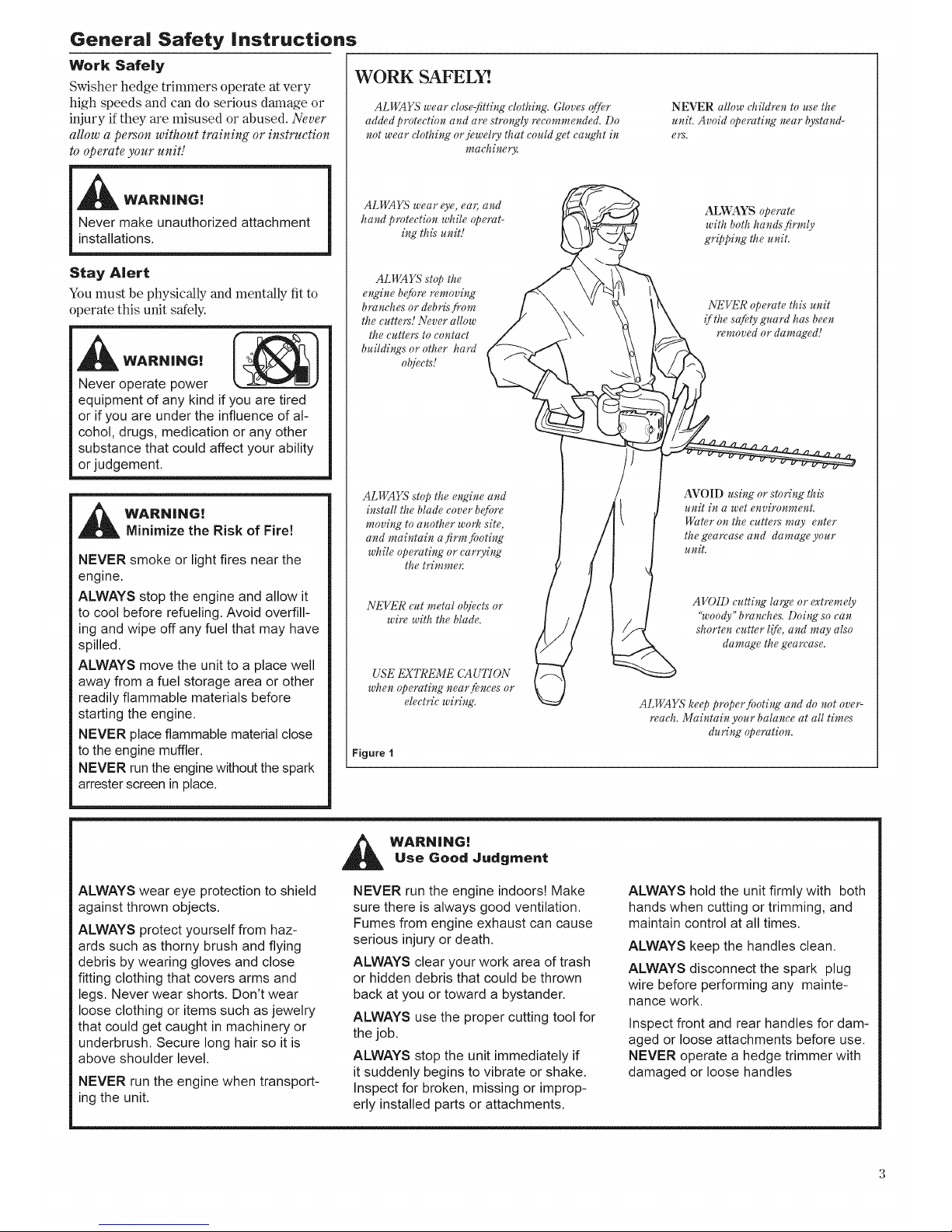

Safety Equipment and Labels

ON-OFF Switch

Throttle Interlock

Protector

Figure 2

Caution Label

• Q . ,

Caution,Danger,Warning,andOperationInformation

Labels:Makesureall informationlabelsare undam-

aged andreadable. Immediatelyreplacedamagedor

missinginformationlabels.Newlabelsareavailable,

contactSwisherInc. at (800)222-8183,or go to www.

swisherinc.com.

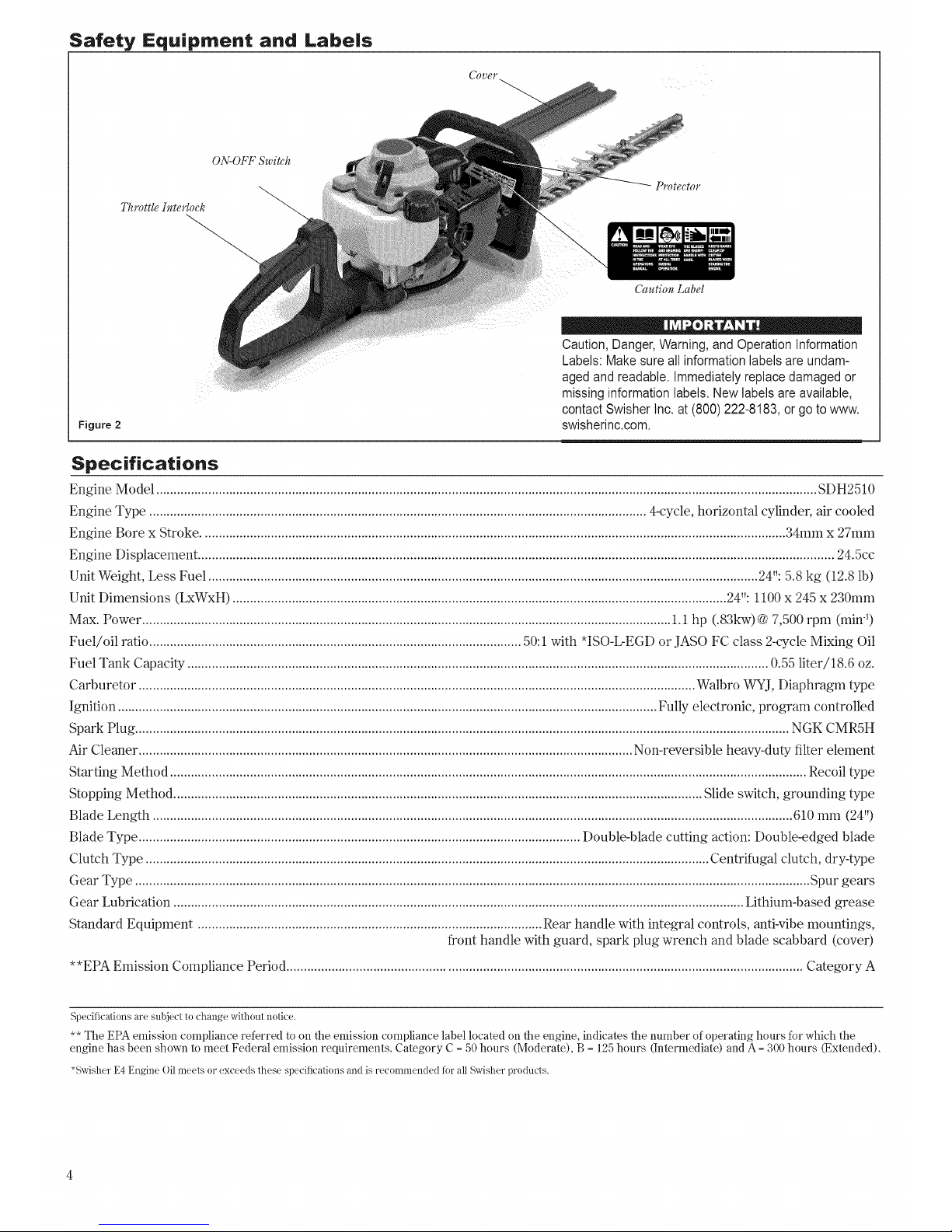

Specifications

Engine Model .............................................................................................................................................................................................. SDH2510

Engine Type ............................................................................................................................................... 4-cycle, horizontal cylinder, air cooled

Engine Bore x Stroke ........................................................................................................................................................................ 34mm x 27mm

Engine Displacement ....................................................................................................................................................................................... 24.5cc

Unit Weight, Less Fuel .............................................................................................................................................................. 24": 5.8 kg (12.8 lb)

Unit Dimensions (LxWxH) .............................................................................................................................................. 24": 1100 x 245 x 230mm

Max. Power ........................................................................................................................................................ 1.1 hp (.83kw)@ 7,500 rpm (min-1)

Fuel/oil ratio ........................................................................................................... 50:1with *ISO-L-EGD or JASO FC class 2-cycle Mixing Oil

Fuel Tank Capacity ....................................................................................................................................................................... 0.55 liter/18.6 oz.

Carburetor ................................................................................................................................................................ Walbro WYJ, Diaphragm type

Ignition ........................................................................................................................................................... Fully electronic, program controlled

Span Plug ............................................................................................................................................................................................ NGK CMR5H

Air Cleaner .............................................................................................................................................. Non-reversible heavy-duty filter element

Starting Method ....................................................................................................................................................................................... Recoil type

Stopping Method ........................................................................................................................................................ Slide switch, grounding type

Blade Length ........................................................................................................................................................................................ 610 mm (24")

Blade Type ............................................................................................................................... Double-blade cutting action: Double-edged blade

Clutch Type .................................................................................................................................................................. Centrifugal clutch, dry-type

Gear Type .................................................................................................................................................................................................. Spur gears

Gear Lubrication .................................................................................................................................................................... Lithium-based grease

Standard Equipment ................................................................................................... Rear handle with integral controls, anti-vibe mountings,

front handle with guard, spark plug wrench and blade scabbard (cover)

**EPA Emission Compliance Period .................................................................................................................................................... Category A

Specifications are subject to change without notice.

** The EPA emission compliance referred to on the emission compliance label located on tile engine, indicates tile number of operating hours for which the

engine has been shown to meet Federal emission requirements. Category C = 50 hours (Moderate), B = 125 hours (Intermediate) and A = 300 hours (Extended).

*Swisher E4 Engine Oillneets or exceeds these specifications and is recomrnended for all Swisher products.

Page 5

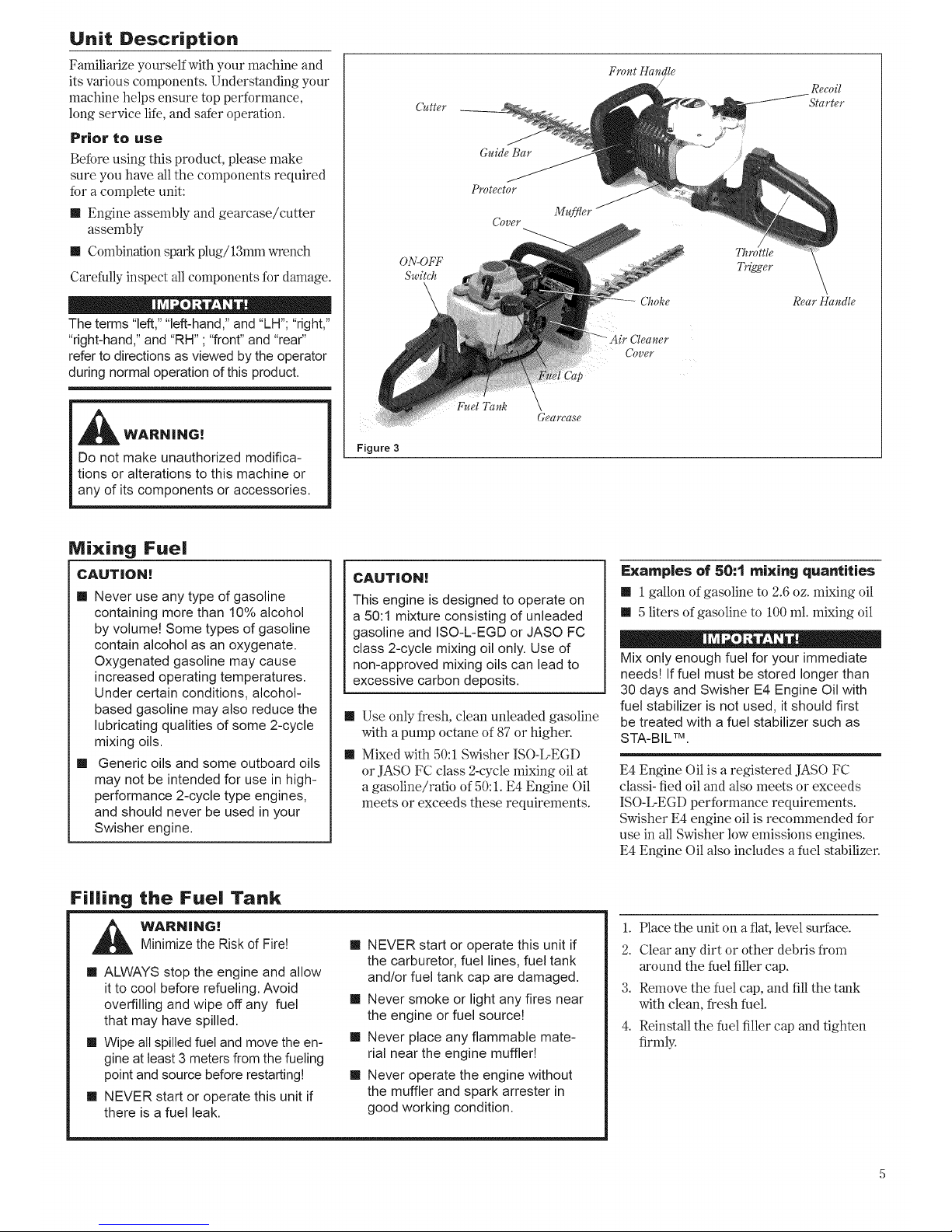

Unit Description

Familiarize yourself with your machine and

its various components. Understanding your

machine helps ensure top performance,

long service life, and safer operation.

Prior to use

Before using this product, please make

sure you have all the components required

Mr a complete unit:

[[ Engine assembly and gearcase/cutter

assembly

1[ Combination spark plug/13mm wrench

Carefully inspect all components for damage.

The terms "left," "left-hand," and "LH"; "right,"

"right-hand," and "RH" ; "front" and "rear"

refer to directions as viewed by the operator

during normal operation of this product.

_ WARNING!

Do not make unauthorized modifica-

tions or alterations to this machine or

any of its components or accessories,

Figure 3

Cutter

ON-OFF

Switch

\

Front Handle

/

Guide Bar

Protector

Cover

Choke

Cleaner

Cover

Throttle

Trigger

Fuel Tank

Gearease

Recoil

Starter

Rear Handle

Mixing Fuel

CAUTION!

m Never use any type of gasoline

containing more than 10% alcohol

by volume! Some types of gasoline

contain alcohol as an oxygenate.

Oxygenated gasoline may cause

increased operating temperatures.

Under certain conditions, alcohol-

based gasoline may also reduce the

lubricating qualities of some 2-cycle

mixing oils.

II Generic oils and some outboard oils

may not be intended for use in high-

performance 2-cycle type engines,

and should never be used in your

Swisher engine,

CAUTION[

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FC

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

1[ Use only fresh, clean unleaded gasoline

with a pump octane of 87 or higher.

m Mixed with 50:1 Swisher ISO-L-EGD

or JASO FC class 2-cycle mixing oil at

a gasoline/ratio of 50:1. E4 Engine Oil

meets or exceeds these requirements.

Examples of 50:1 mixing quantities

II 1 gallon of gasoline to 2.6oz. mixing oil

!! 5 liters of gasoline to 100 mL mixing oil

Mix only enough fuel for your immediate

needsg If fuel must be stored longer than

30 days and Swisher E4 Engine Oil with

fuel stabilizer is not used, it should first

be treated with a fuel stabilizer such as

STA-BIL TM.

E4 Engine Oil is a registered JASO FC

classi- fled oil and also meets or exceeds

ISO-L-EGD performance requirements.

Swisher E4 engine oil is recommended for

use in all Swisher low emissions engines.

E4 Engine Oil also includes a fuel stabilizer.

Filling the Fuel Tank

i_k WARNING!Minimize the Risk of Fire!

m ALWAYS stop the engine and allow

it to cool before refueling. Avoid

overfilling and wipe off any fuel

that may have spilled.

m Wipe all spilled fuel and move the en-

gine at least 3 meters from the fueling

point and source before restarting!

m NEVER start or operate this unit if

there is a fuel leak.

II NEVER start or operate this unit if

the carburetor, fuel lines, fuel tank

and/or fuel tank cap are damaged,

II Never smoke or light any fires near

the engine or fuel sourceg

II Never place any flammable mate-

rial near the engine muffle!!

II Never operate the engine without

the muffler and spark arrester in

good working condition,

1. Place the unit on a fiat, level surface.

2. Clear any dirt or other debris from

around the fuel filler cap.

3. Remove the fuel cap, and fill the tank

with clean, fresh fuel.

4. Reinstall the fuel filler cap and tighten

firmly.

Page 6

Starting Procedure

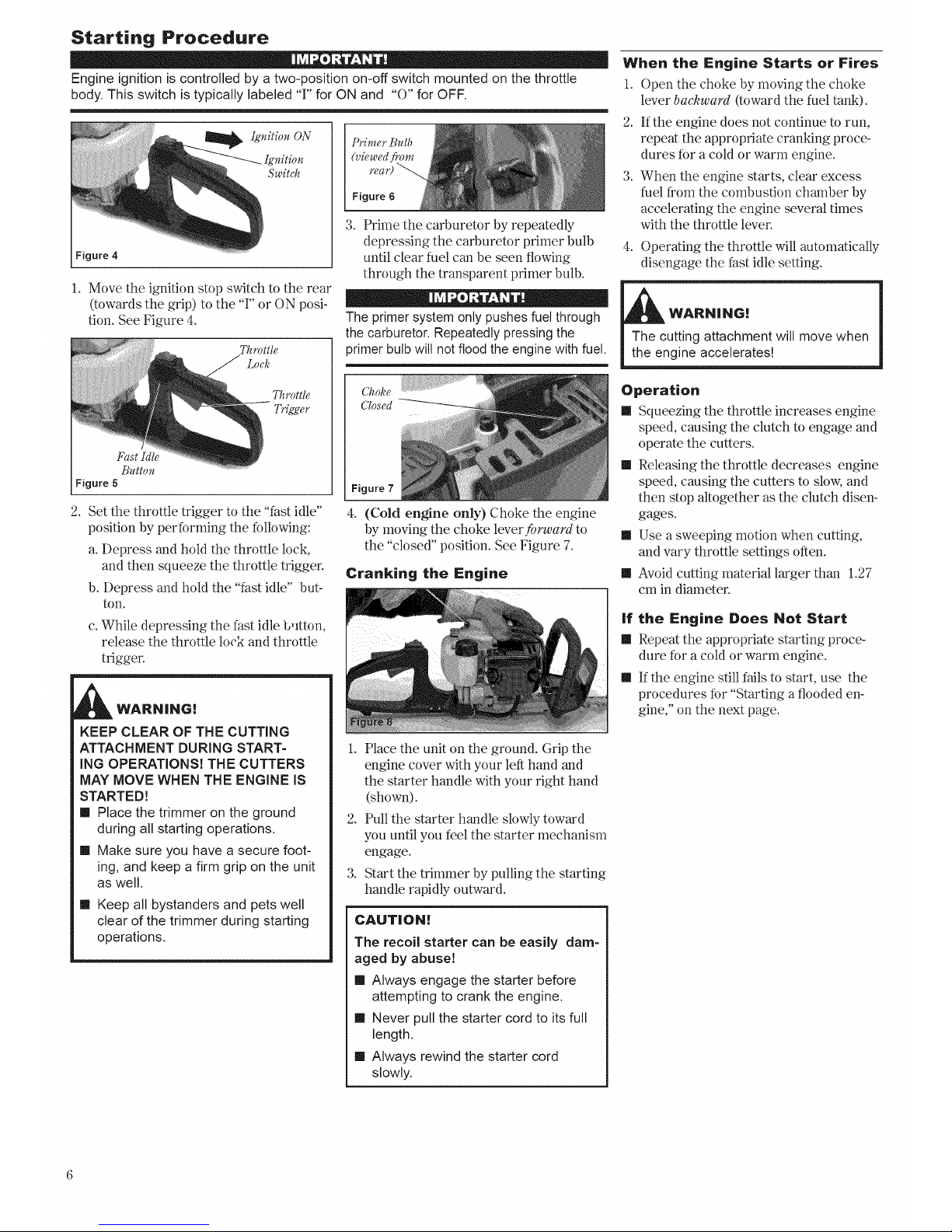

Engine ignition is controlled by a two-position on-off switch mounted on the throttle

body. This switch is typically labeled "F' for ON and "0" for OFF.

_ Iguitiou ON

Switch

Figure 4

1. Move the ignition stop switch to the rear

(towards the grip) to the 'T' or ON posi-

tion. See Figure 4.

Throttle

Lock

Throttle

Trigger

Fast Idle

Button

Figure 5

Primer Bulb

Figure 6

3. Prime the carburetor by repeatedly

depressing the carburetor primer bulb

until clear fuel can he seen flowing

through the transparent primer bulb.

The primersystem only pushes fuel through

the carburetor.Repeatedly pressing the

primer bulb will notflood the engine with fuel.

2. Set the throttle trigger to the "fast idle"

position by performing the following:

a. Depress and hold the throttle lock,

and then squeeze the throttle trigger.

b. Depress and hold the "fast idle" but-

ton.

4. (Cold engine only) Choke the engine

by moving the choke lever forward to

the "closed" position. See Figure 7.

Cranking the Engine

c. While depressing the fast idle button ...............

release the throttle lock and throttle

trigger.

KEEP CLEAR OF THE CUTTING

ATTACHMENT DURING START=

ING OPERATIONS! THE CUTTERS

MAY MOVE WHEN THE ENGINE iS

STARTED)

m Place the trimmer on the ground

during all starting operations.

m Make sure you have a secure foot-

ing, and keep a firm grip on the unit

as well.

m Keep all bystanders and pets well

clear of the trimmer during starting

operations.

1. Place the unit on the ground. Grip the

engine cover with your left hand and

the starter handle with your right hand

(shown).

2. Pull the starter handle slowly toward

you until you feel the starter mechanism

engage.

3. Start the trimmer by pulling the starting

handle rapidly outward.

CAUTION!

The recoil starter can be easily dam-

aged by abuse[

m Always engage the starter before

attempting to crank the engine.

m Never pull the starter cord to its full

length.

m Always rewind the starter cord

slowly.

When the Engine Starts or Fires

1. Open the choke by moving the choke

lever backward (toward the fuel tank).

2. If the engine does not continue to run,

repeat the appropriate cranking proce-

dures for a cold or warm engine.

3. When the engine starts, clear excess

fuel from the combustion chamber by

accelerating the engine several times

with the throttle lever.

4. Operating the throttle will automatically

disengage the fast idle setting.

WARN|NG[

Operation

m Squeezing the throttle increases engine

speed, causing the clutch to engage and

operate the cutters.

m Releasing the throttle decreases engine

speed, causing the cutters to slow, and

then stop altogether as the clutch disen-

gages.

m Use a sweeping motion when cutting,

and vary throttle settings often.

m Avoid cutting material larger than 1.27

cm in diameter.

if the Engine Does Not Start

m Repeat the appropriate starting proce-

dure for a cold or warm engine.

m If the engine still fails to start, use the

procedures for "Starting a flooded en-

gine," on the next page.

Page 7

Starting a Flooded Engine

WARN|NG!

Burn danger from hot engine! Allow en-

gine to cool before removing cylinder

cover.

1. Disconnect the spark plug lead, and

then use the spark plug wrench to

loosen and remove the spark plug.

2. If the spark plug is fouled or is soaked

with fuel, clean or replace the plug as

necessary. For spark plug specifcations

and gapping procedure, see page 9.

3. With the spark plug removed, crank the

engine several times to clear excess fuel

from the combustion chamber.

4. Replace the spark plug and tighten it

firmly with the spark plug wrench. If a

torque wrench is available, torque the

spark plug to 170-190 kg cm.

5. Repeat the starting procedures for a

warm engine.

CAUTION

Incorrect spark plug installation can

damage the engine!

6. If the engine still fails to start or fire,

refer to the Foubleshooting chart at the

end of this manual.

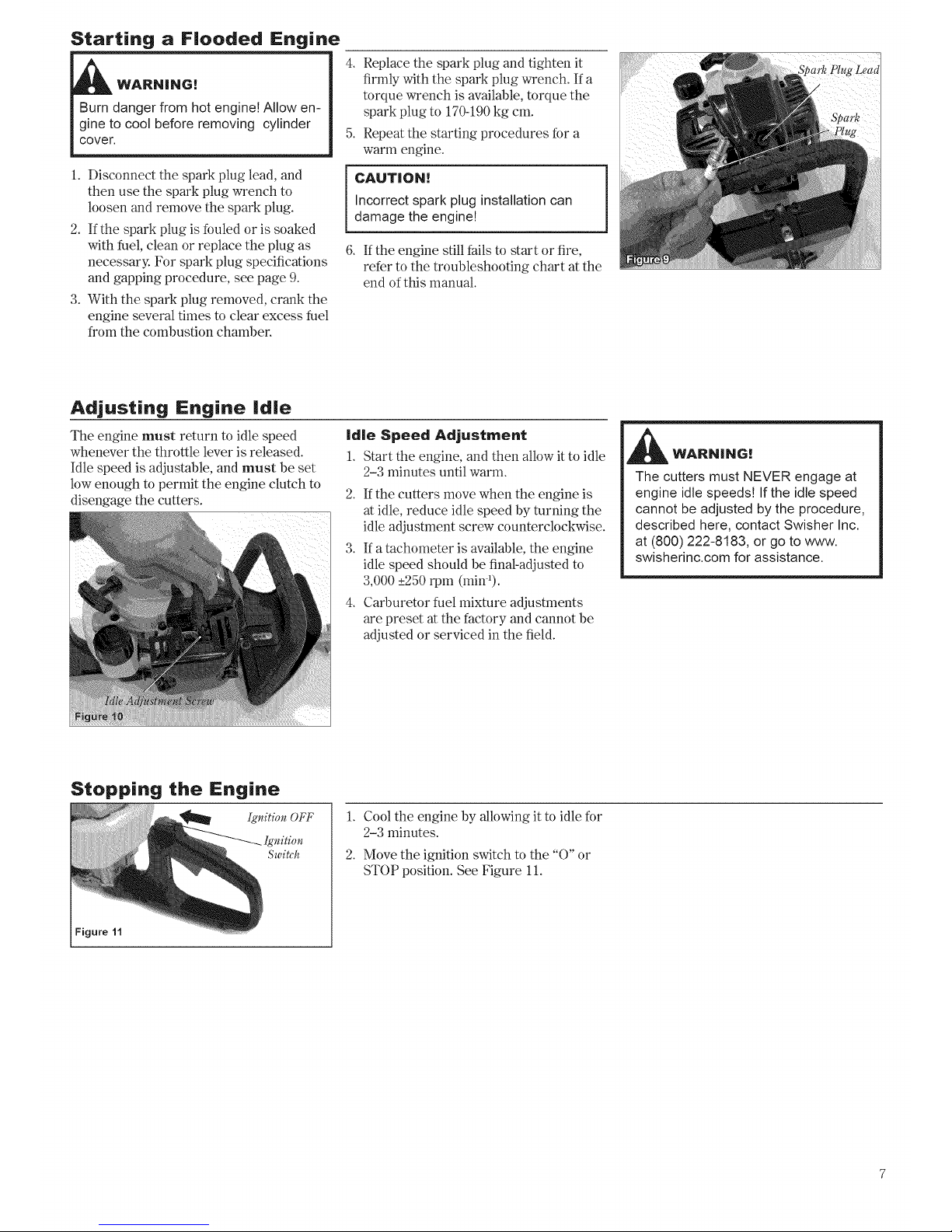

Adjusting Engine idle

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutters.

|d|e Speed Adjustment

1. Start the engine, and then allow it to idle

2-3 minutes until warm.

2. If the cutters move when the engine is

at idle, reduce idle speed by turning the

idle adjustment screw counterclockwise.

3. If a tachometer is available, the engine

idle speed should be final-adjusted to

3,000 _+250rpm (rain-l).

4. Carburetor fuel mixture adjustments

are preset at the factory and cannot be

adjusted or serviced in the field.

_ WARN|N6!

The cutters must NEVER engage at

engine idle speeds! Ifthe idle speed

cannot be adjusted by the procedure,

described here, contact Swisher Inc.

at (800) 222-8183, or go to www.

swisherinc.com for assistance.

Figure 11

1.

2.

Cool the engine by allowing it to idle for

2-3 minutes.

Move the ignition switch to the "O" or

STOP position. See Figure 11.

Page 8

Maintenance and Adjustments

General Maintenance

MAINTENANCE, REPLACEMENT OR

RE-PAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE PER-

FORMED BY ANY REPAIR ESTABLISH-

MENT OR INDIVIDUAL; HOWEVER,

WARRANTY REPAIRS MUST BE PER-

FORMED BYA DEALER OR SERVICE

CENTER AUTHORIZED BY SWISHER.

THE USE OF PARTS THATARE NOT

EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS OF

THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE

OUTCOME OFA WARRANTY CLAIM.

WARNING[

Beforeperformingany maintenance,

repairor cleaningwork on the unit,

make surethe engineandcuttingat-

tachmentare completelystopped. Dis-

connectthespark plug wire beforeper-

formingserviceor maintenancework.

_likWARi\l i i\lG!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury.

Using non-standard replacement parts could

invalidate your Swisher warranty.

Muffler

This unit must never be operated with a faulty

or missing spark arrester or muffler. Make

sure the muffler is well secured and in good

condition. Aworn or damaged muffler is a

fire hazard and may also cause hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

Air Filter

The E4 engine that powers your Swisher mod-

el is a hybrid 4-stroke engine. As a hybrid,

the engine is lubricated by oil mixed with

the gasoline and air from the carburetor that

moves through and around the internal parts

of the engine in a similar way that a 2-stroke

engine is lubricated. Without the heavy duty

2-stage air filter equipped on all E4 engines,

dust and dirt could also move through the en-

gine, decreasing engine life, increasing valve

wear and the need for more frequent valve ad-

justments. To keep your E4 engine strong and

reliable, Swisher recommends that you check

and service the air flter as instructed in the

10-HourMaintenance section that follows.

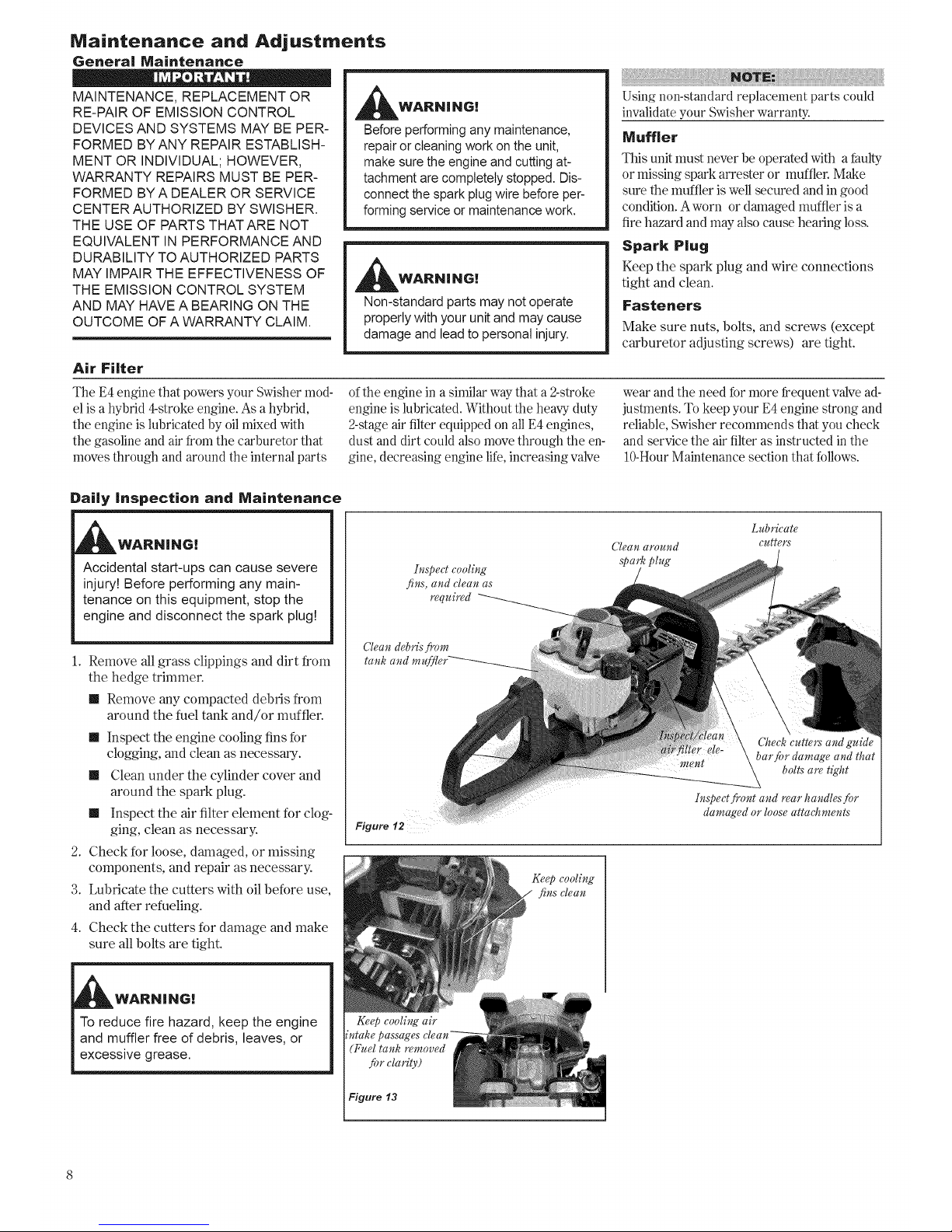

Daily Inspection and Maintenance

_WARN|NG!

Accidental start-ups can cause severe

injury! Before performing any main-

tenance on this equipment, stop the

engine and disconnect the spark plug!

1. Remove all grass clippings and dirt from

the hedge trimmer.

m Remove any compacted debris from

around the fuel tank and/or muffler.

m Inspect the engine cooling fins for

clogging, and clean as necessary.

m Clean under the cylinder cover and

around the spark plug.

m Inspect the air filter element for clog-

ging, clean as necessary.

2. Check for loose, damaged, or missing

components, and repair as necessary.

3. Lubricate the cutters with oil before use,

and after refueling.

4. Check the cutters for damage and make

sure all bolts are tight.

WARNING!

Iuspect cooling

fins, and clean as

required

Cleau aYouud

spark plug

Clean debrisfrom

tank and mu

Figure 12

bolts are tight

Iuspect fivut and rear handles for

damaged or loose attaehments

Ke@ cooling air

intake passages

_Fuel tank removed

fi) r elarity)

Figure 13

Page 9

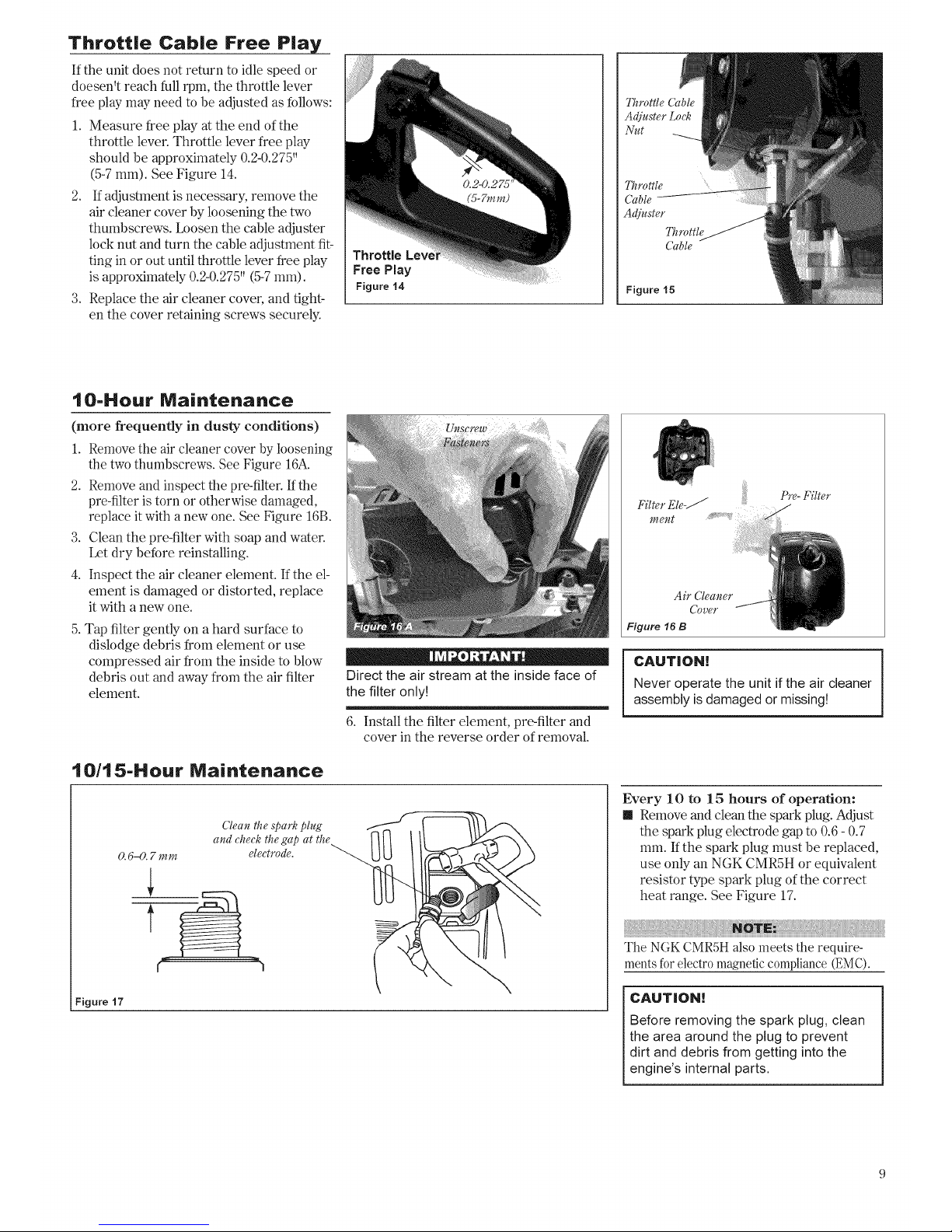

Throttle Cab|e Free P|ay

If the unit does not return to idle speed or

doesen_t reach full rpm, the throttle lever

free play may need to be adjusted as follows:

1. Measure free play at the end of the

throttle lever. Throttle lever free play

should be approximately 0.2-0.275"

(5-7 mm). See Figure 14.

2. If adjustment is necessary, remove the

air cleaner cover by loosening the two

thumbscrews. Loosen the cable adjuster

lock nut and turn the cable adjustment fit-

ting in or out until throttle lever free play

is approximately 0.2-0.275" (5-7 mm).

3. Replace the air cleaner cover, and tight-

en the cover retaining screws securely.

Throttle

Free Play

Figure 14

Throttle

Cable

I O-Hour Maintenance

(more frequently in dusty conditions)

1. Remove the air cleaner cover by loosening

the two thumbscrews. See Figure 16A.

2. Remove and inspect the pre-filter. If the

pre-filter is torn or otherwise damaged,

replace it with a new one. See Figure 16B.

3. Clean the pre-filter with soap and water.

Let dry before reinstalling.

4. Inspect the air cleaner element. If the el-

ement is damaged or distorted, replace

it with a new one.

5. Tap filter gently on a hard surface to

dislodge debris from element or use

compressed air from the inside to blow

debris out and away from the air filter

element.

10/15-Hour Maintenance

Direct the air stream at the inside face of

the filter only!

6. Install the filter element, pre-filter and

cover in the reverse order of removal.

O.6-0. 7 mm

Clean the spark plug

and check the gap at the

electrode.

f

Figure 17

Pre- Filter

Filter Ele-J

Air Cleaner

Cover

Figure 16 B

CAUTION!

Never operate the unit if the air cleaner

assembly is damaged or missing!

Every 10 to 15 hours of operation:

m Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.6 - 0.7

mm. If the spark plug must be replaced,

use only an NGK CMR5H or equivalent

resistor type spark plug ofthe correct

heat range. See Figure 17.

The NGK CMR5H also meets the require-

ments for electro magnetic compliance (EMC).

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine's internal parts.

Page 10

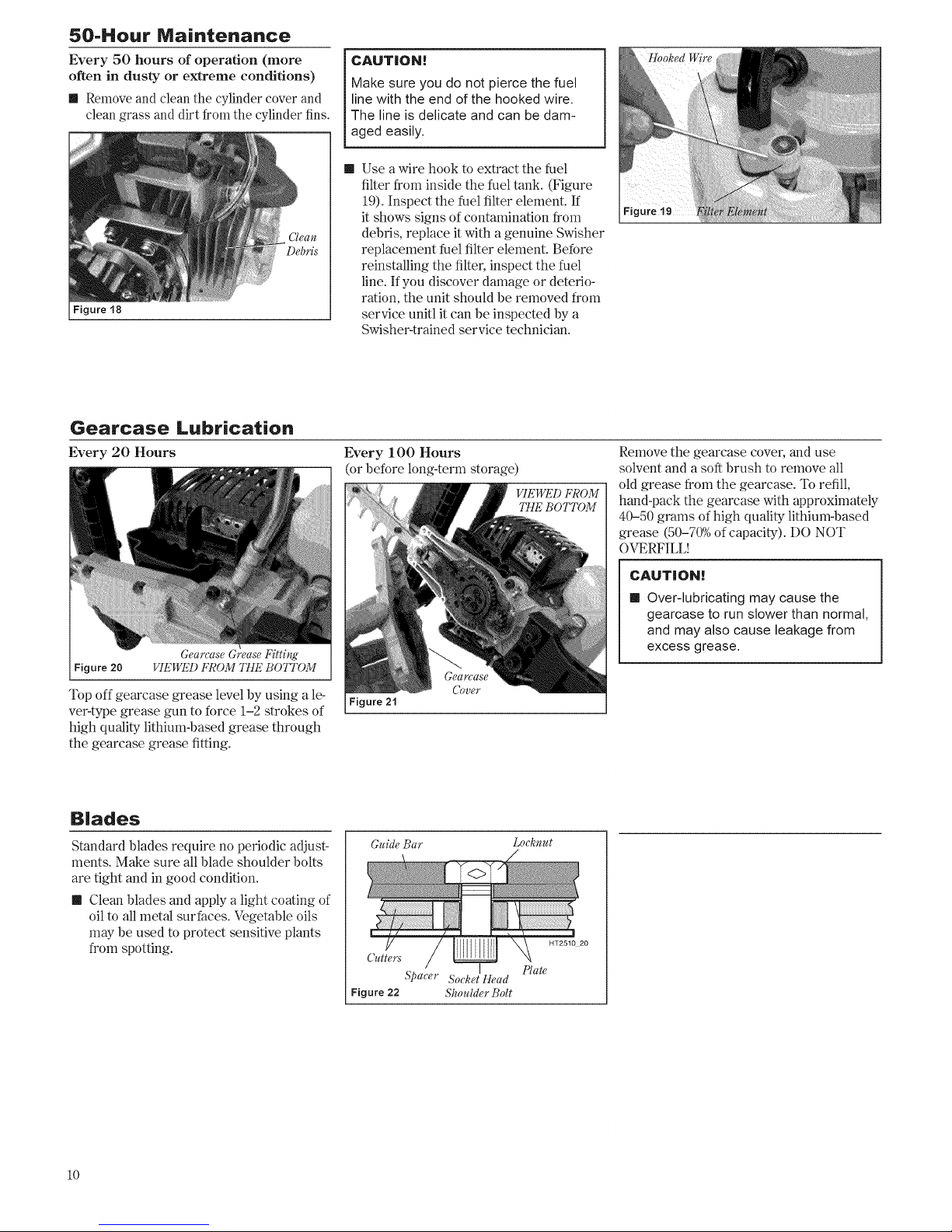

50-Hour Maintenance

Every 50 hours of operation (more

often in dusty or extreme conditions)

Remove and clean the cylinder cover and

clean grass and dirt from the cylinder fins.

Debris

Figure 18

CAUTION[

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be dam-

aged easily.

II Use a wire hook to extract the fuel

filter from inside the fuel tank. (Figure

19). Inspect the fuel filter element. If

it shows signs of contamination from

debris, replace it with a genuine Swisher

replacement fuel filter element. Before

reinstalling the filter, inspect the fuel

line. If you discover damage or deterio-

ration, the unit should be removed from

service unitl it can be inspected by a

Swisher-trained service technician.

Gearcase Lubrication

Every 20 Hours

Figure 20

Gearcase Grease Fitting

VIEWED FROM THE BOTTOM

Top off gearcase grease level by using a le-

ver-type grease gun to force 1-2 strokes of

high quality lithium-based grease through

the gearcase grease fitting.

Every 100 Hours

(or before long-term storage)

VIEWED FROM

THE BOTTOM

Figure 21

Gearcase

Cover

Remove the gearcase cover, and use

solvent and a soft brush to remove all

old grease from the gearcase. To refill,

hand-pack the gearcase with approximately

40-50 grams of high quality lithium-based

grease (50-70% of capacity). DO NOT

OVERFILL!

CAUTION[

II Over-lubricating may cause the

gearcase to run slower than normal,

and may also cause leakage from

excess grease.

Blades

Standard blades require no periodic adjust-

ments. Make sure all blade shoulder bolts

are tight and in good condition.

m Clean blades and apply a light coating of

oil to all metal surfaces. Vegetable oils

may be used to protect sensitive plants

from spotting.

Guide Bar

Locknut

Cutters

Spacer Socket Head

Figure 22 Shoulder Bolt

Plate

10

Page 11

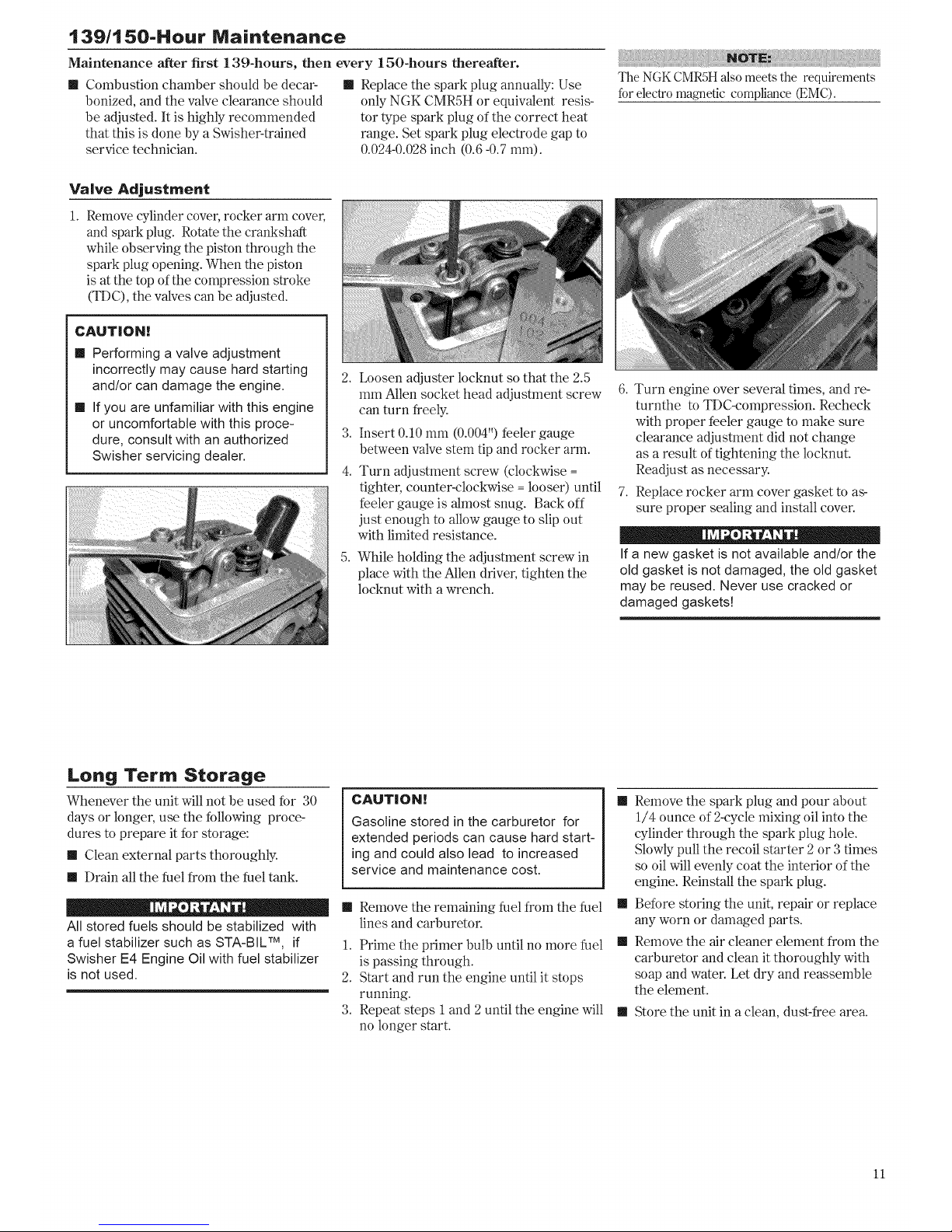

139/150-Hour Maintenance

Maintenance after first 139-hours, then every 150-hours thereafter.

m Combustion chamber should be decar- m Replace the spark plug annually: Use

bonized, and the valve clearance should only NGK CMR5H or equivalent resis-

be adjusted. It is highly recommended tor type spark plug of the correct heat

that this is done by a Swisher-trained range. Set spark plug electrode gap m

service technician. 0.024-0.028 inch (0.6 -0.7 mm).

The NGK CMRSH also meets the requirements

for electro magnetic compliance _MC).

Valve Adjustment

1. Remove cylinder cover, rocker arm cover,

and spark plug. Rotate the crankshaft

while observing the piston through the

spark plug opening. When the piston

is at the top of the compression stroke

(TDC), the valves can be adjusted.

CAUT|ON!

II Performing a valve adjustment

incorrectly may cause hard starting

and/or can damage the engine.

II If you are unfamiliar with this engine

or uncomfortable with this proce-

dure, consult with an authorized

Swisher servicing dealer.

2. L_)osen adjuster locknut so that the 2.5

mm Allen socket head adjustment screw

can turn freely.

3. Insert 0.10 mm (0.004") feeler gauge

between valve stem tip and rocker arm.

4. Turn adjustment screw (clockwise =

tighter, counter-clockwise = looser) until

feeler gauge is almost snug. Back off

just enough to allow gauge to slip out

with limited resistance.

5.

While holding the adjustment screw in

place with the Allen driver, tighten the

locknut with a wrench.

6. Turn engine over several times, and re-

turnthe to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change

as a result of tightening the locknut.

Readjust as necessary.

7. Replace rocker arm cover gasket to as-

sure proper sealing and install cover.

If a new gasket is not available and/or the

old gasket is not damaged, the old gasket

may be reused. Never use cracked or

damaged gaskets!

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following proce-

dures to prepare it for storage:

1[ Clean external parts thoroughly.

1[ Drain all the fuel from the fuel tank.

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL TM, if

Swisher E4 Engine Oil with fuel stabilizer

is not used.

CAUT|ON!

Gasoline stored in the carburetor for

extended periods can cause hard start-

ing and could also lead to increased

service and maintenance cost.

1[ Remove the remaining fuel from the fuel

lines and carburetor.

1. Prime the primer bulb until no more fuel

is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps 1 and 2 until the engine will

no longer start.

1[ Remove the spark plug and pour about

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3 times

so oil will evenly coat the interior of the

engine. Reinstall the spark plug.

1[ Before storing the unit, repair or replace

any worn or damaged parts.

1[ Remove the air cleaner element from the

carburetor and clean it thoroughly with

soap and water. Let dry and reassemble

the element.

11 Store the unit in a clean, dust-free area.

11

Page 12

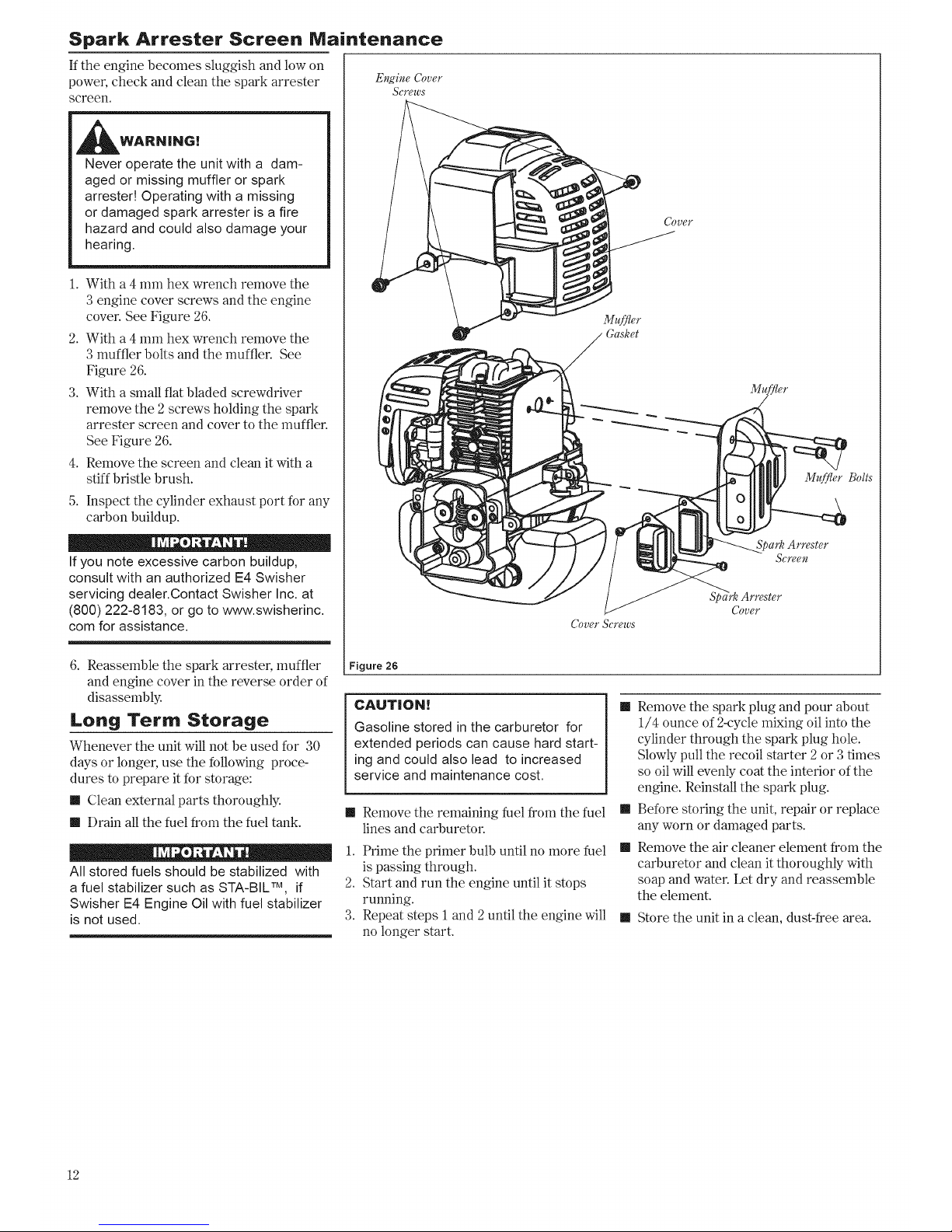

Spark Arrester Screen

If the engine becomes sluggish and low on

power, check and clean the spark arrester

screen.

_1 WARNING!

Never operate the unit with a dam-

aged or missing muffler or spark

arrested Operating with a missing

or damaged spark arrester is a fire

hazard and could also damage your

hearing,

1. With a 4 mm hex wrench remove the

3 engine cover screws and the engine

cover. See Figure 26.

2. With a 4 mm hex wrench remove the

3 muffler bolts and the muffler. See

Figure 26.

3. With a small flat bladed screwdriver

remove the 2 screws holding the spark

arrester screen and cover to the muffler.

See Figure 26.

4. Remove the screen and clean it with a

stiff bristle brush.

5. Inspect the cylinder exhaust port for any

carbon buildup.

If you note excessive carbon buildup,

consult with an authorized E4 Swisher

servicing dealer.Contact Swisher Inc. at

(800) 222-8183, or go to www.swisherinc.

corn for assistance.

6. Reassemble the spark arrester, muffler

and engine cover in the reverse order of

disassembly.

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following proce-

dures to prepare it for storage:

II Clean external parts thoroughly.

II Drain all the fuel from the fuel tank.

Maintenance

Engine Cover

Screws

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL TM, if

Swisher E4 Engine Oil with fuel stabilizer

is not used.

Muffler

Gasket

Cover Screws

Figure 26

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard start-

ing and could also lead to increased

service and maintenance cost.

II Remove the remaining fuel from the fuel

lines and carburetoc

1. Prime the primer bulb until no more fuel

is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps i and 2 until the engine will

no longer start.

(]ouey

Muffler Bolts

Spark Arrester

Screen

Spark Arrester

Cover

II Remove the spark plug and pour about

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3 times

so oil will evenly coat the interior of the

engine. Reinstall the spark plug.

II Before storing the unit, repair or replace

any worn or damaged parts.

II Remove the air cleaner element from the

carburetor and clean it thoroughly with

soap and water. Let dry and reassemble

the element.

II Store the unit in a clean, dust-free area.

12

Page 13

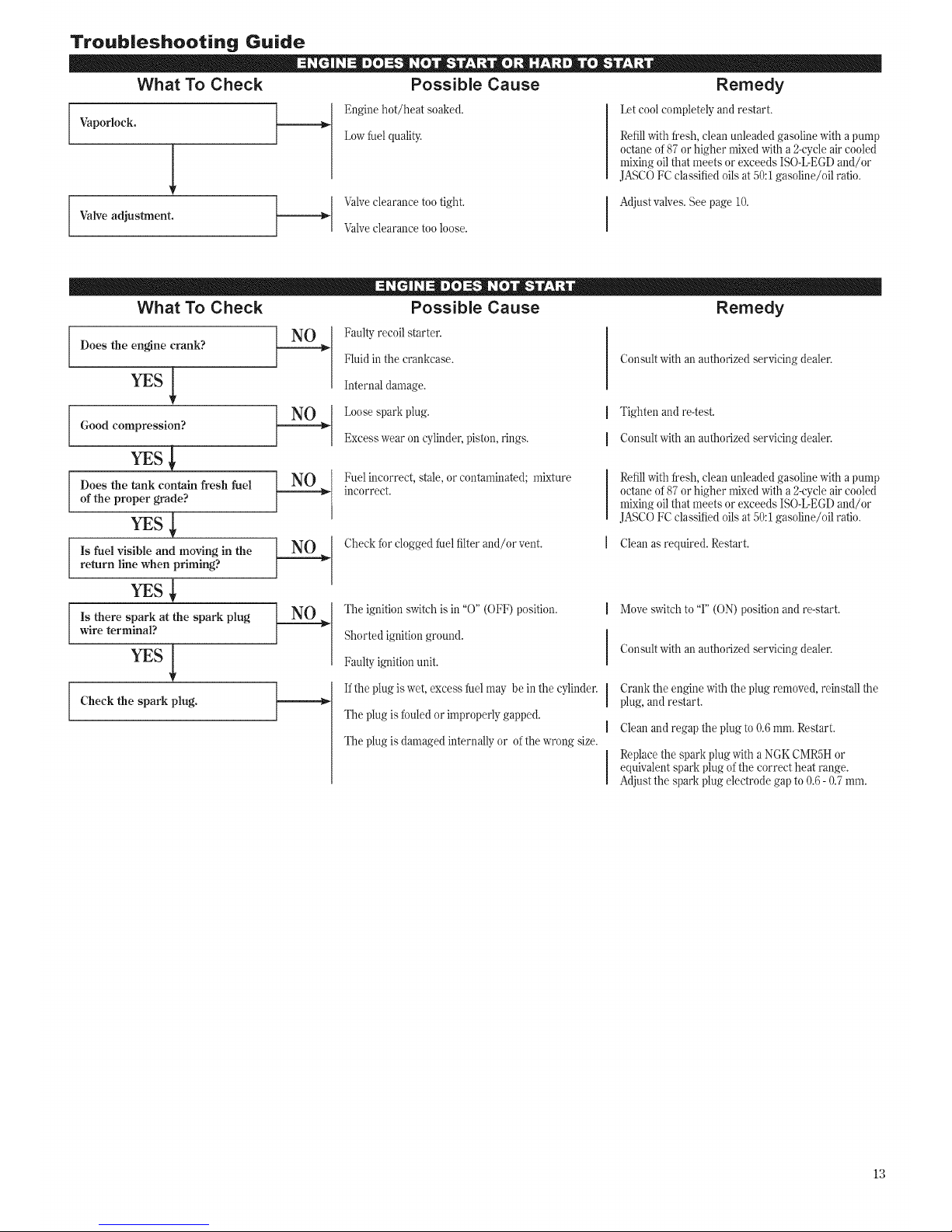

Troubleshooting Guide

What To Check Possible Cause Remedy

Vaporlock.

1

Valve adjustment.

Engine hot/heat soaked.

Lowfuel quality.

Valveclearance too tight.

Valveclearance too loose.

Let cool completely and restart.

Refill with fresh, clean unleaded gasoline with a pump

octane of87 or higher mixed with a 2-cycle air cooled

mixing oil that meets or exceeds ISO-L-EGDand/or

JASCOFC classified oils at 50:1gasoline/oil ratio.

Adjust valves. See page 10.

What To Check Possible Cause Remedy

Does the engine crank?

YEs

Good compression?

YEs

Does the tank contain fresh fuel

of the proper grade?

YEs

Is fuel visible and moving in the

return line when priming?

YEs

Is there spark at the spark plug

wire terminal?

Check the spark plug.

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Loosespark plug.

Excess wear on cylinder, piston, rings.

Fuel incorrect, stale, or contaminated; mixture

incorrect.

Check for clogged fuel filter and/or vent.

The ignition switch is in "O" (OFF) position.

Shorted ignition ground.

Faulty ignition unit.

Ifthe plug is wet, excess fuel may be in the cylinder.

The plug is fouled or improperly gapped.

The plug is damaged internally or ofthe wrong size.

Consult with an authorized servicing dealer.

I Tighten and re-test.

I Consult with an authorized servicing dealer.

Refill with fresh, clean unleaded gasoline with a pump

octane of87 or higher mixed with a 2-cycle air cooled

mixing oil that meets or exceeds ISO-L-EGDand/or

JASCOFC classified oils at 50:1gasoline/oil ratio.

Clean as required. Restart.

Move switch to "I" (ON) position and re-start.

Consult with an authorized servicing dealer.

Crank the engine with the plug removed, reinstall the

plug, and restart.

Clean and regap the plug to 0.6mm. Restart.

Replace the spark plug with a NGKCMR5H or

equivalent spark plug of the correct heat range.

Adjust the spark plug electrode gap to 0.6- 0.7 ram.

13

Page 14

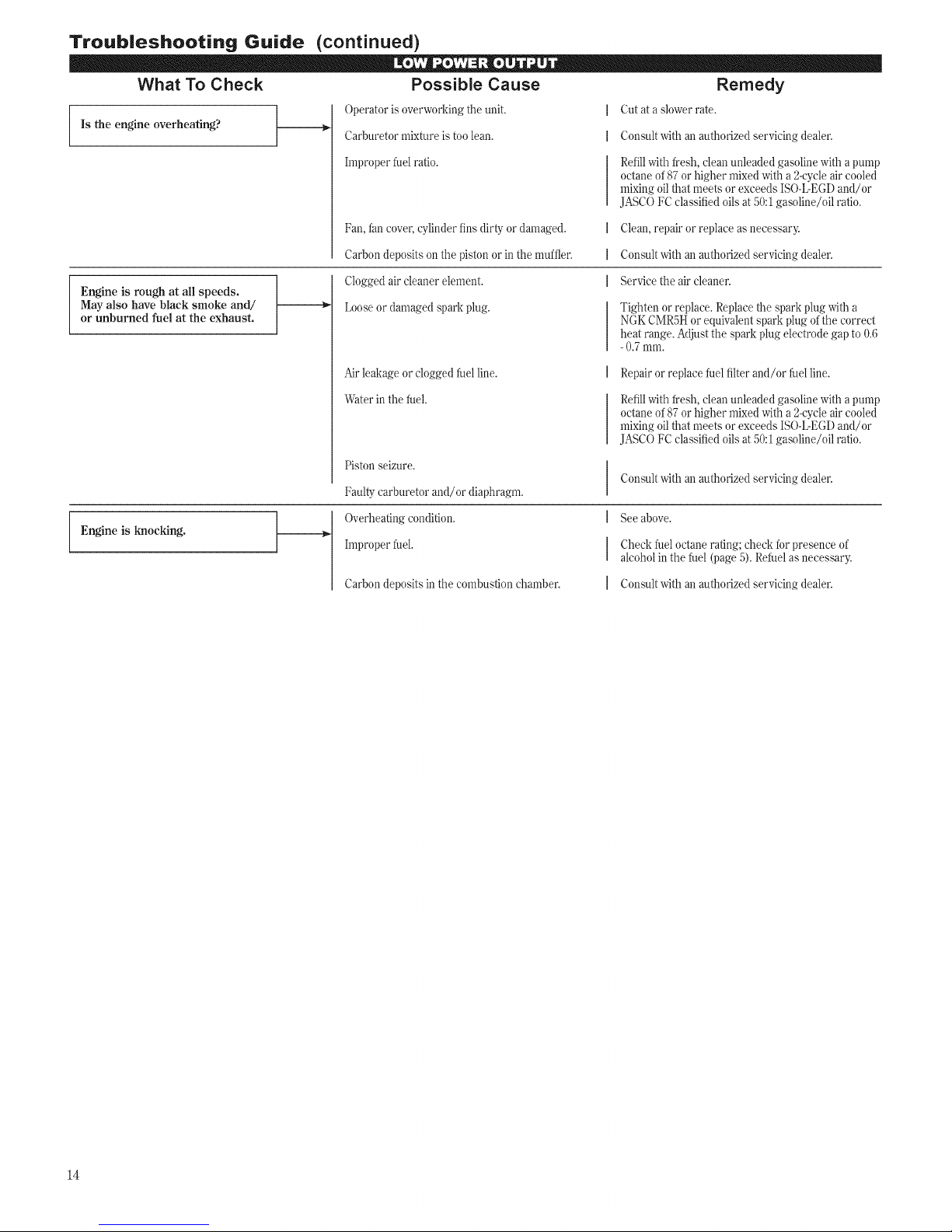

Troubleshooting Guide (continued)

Possible Cause

Operator is overworking the unit.

Carburetor mixture is too lean,

Improper fuel ratio.

What To Check

Is the engine overheating?

Fan, fan cover, cylinder fins dirty or damaged.

Carbon deposits on the piston or in the mufflen

Clogged air cleaner element.

Loose or damaged spark plug.

Engine is rough at all speeds.

May also have black smoke and/

or unburned fuel at the exhaust.

Air leakage or clogged fuel line.

Water in the fuel.

Piston seizure.

Remedy

Cut at a slower rate.

Consult with an authorized servicing dealer.

Refill with fresh, clean unleaded gasoline with a pump

octane of 87 or higher mixed with a 2-cycle air cooled

mixing oil that meets or exceeds ISO-L-EGD and/or

JASCO FC classified oils at 50:1 gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing dealer.

Service the air cleaner.

Tighten or replace. Replace the spark plug with a

NGK CMR5H or equivalent spark plug of the correct

heat range. Adjust the spark plug electrode gap to 0.6

-0.7 mm.

Repair or replace fuel filter and/or fuel line.

Refill with fresh, clean unleaded gasoline with a pump

octane of87 or higher mixed with a 2-cycleair cooled

mixing oil that meets or exceeds ISO-L-EGDand/or

JASCOFC classified oils at 50:1gasoline/oil ratio.

Engine is knocking.

Faulty carburetor and/or diaphragm.

Overheating condition.

Improper fuel.

Carbon deposits in the combustion chamber.

Consult with an authorized servicing dealer.

See above.

Check fuel octane rating; check for presence of

alcohol in the fuel (page 5). Refuel as necessarg

Consult with an authorized servicing dealer.

14

Page 15

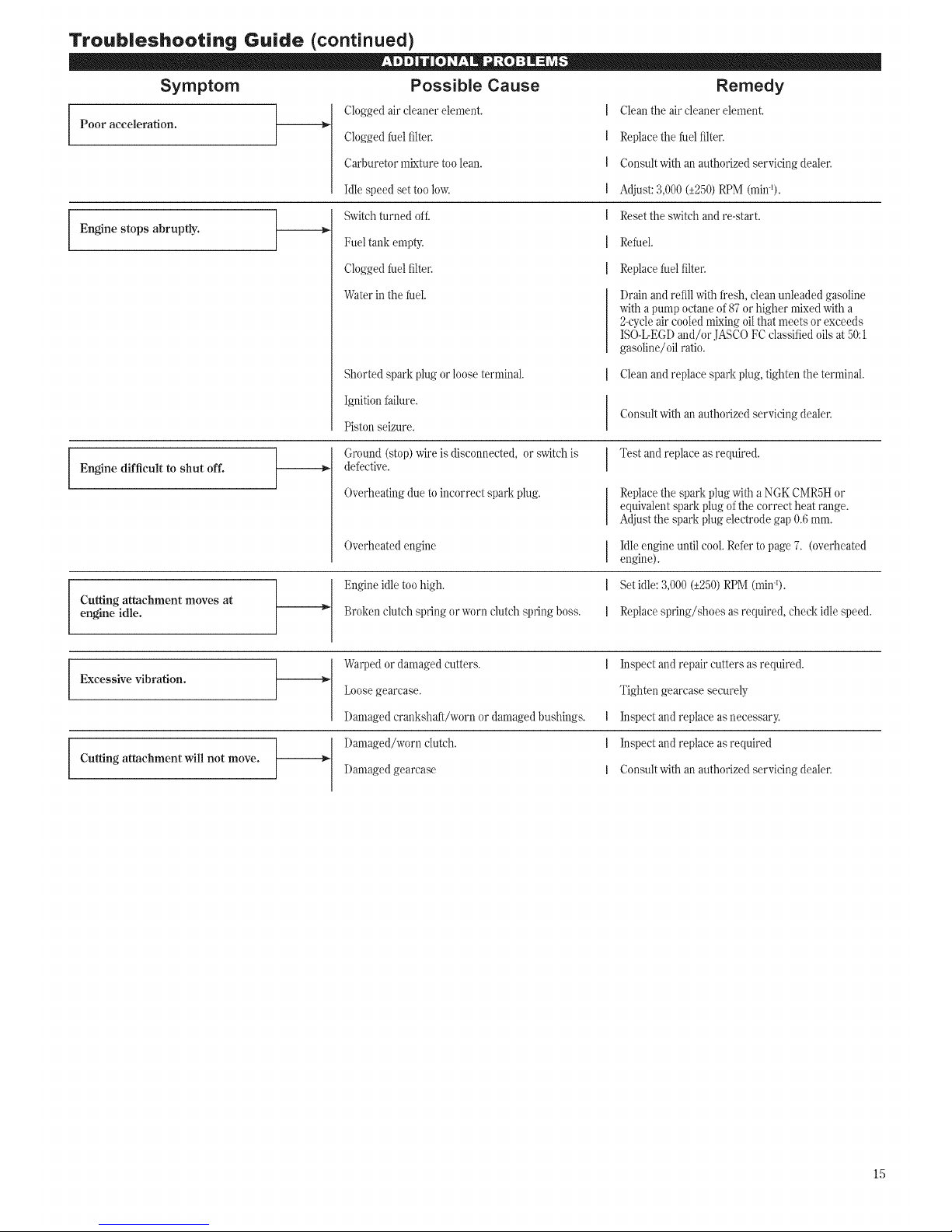

Troubleshooting Guide (continued)

Symptom Possible Cause Remedy

Clogged air cleaner element. Clean the air cleaner element.

Poor acceleration.

Engine stops abruptly.

Engine difficult to shut off.

Clogged fuel filter.

Carburetor mixture too lean.

Idle speed set too low.

Switchturned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Cutting attachment moves at

engine idle.

Replacethe fuel filter.

Consult with an authorized servicing dealer.

Adjust:3,000 (_+250)RPM (min%

Reset the switch and re-start.

Refuel.

Replacefuel filter.

[)rain and refill with fresh, clean unleaded gasoline

with a pump octane of 87 or higher mixed with a

2-cycleair cooled mixing oilthat meets or exceeds

ISO-L-EGDand/or JASCO FCclassified oils at 50:1

gasoline/oil ratio.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Ground (stop) wire is disconnected, or switch is

defective.

Overheating due to incorrect spark plug.

Overheated engine

Engine idle too high.

Broken clutch spring or worn clutch spring boss.

Clean and replace spark plug, tighten the terminal.

Consult with an authorized servicing dealer.

Test and replace as required.

Replacethe spark plug with a NGK CMR5Hor

equivalent spark plug of the correct heat range.

Adjust the spark plug electrode gap 0.6 mm.

Idle engine until cool. Refer to page 7. (overheated

engine).

Set idle: 3,000 (_+250)RPM (min%

Replace spring/shoes as required, check idle speed.

Excessive vibration.

Cutting attachment will not move.

Warped or damaged cutters.

L_osegearcase.

Damaged crankshaft/worn or damaged bushings.

Damaged/worn clutch.

Damaged gearcase

Inspect and repair cutters as required.

Tighten gearcase securely

Inspect and replace as necessary.

Inspect and replace as required

Consult with an authorized servicing dealer.

15

Page 16

Emission System Warranty Statement (Administered by Shindaiwa inc.)

Your Warranty Rights and

Obligations

The California Air Resources Board, the U.S. Environmental

Protection Agency and Shindaiwa Corporation are pleased to

explain the exhaust and evaporative emission control system

warranty on your new small off-road (non-road) engine.

In California, new small off-road engines must be designed,

built, and equipped to meet the State's stringent anti-smog stan-

dards. In other states, new 1997 and later non-road engines must

meet the Federal EPA's stringent anti-smog standards.

Shindaiwa Corporation must warrant the emission control sys-

tem on your small off-road engine for the periods of time listed

below, provided there has been no abuse, neglect, or improper

maintenance of your small off-road engine.

Your engine exhaust and evaporative emission control system

includes parts such as the carburetol; fuel tank, the ignition sys-

tem and, if equipped, the catalytic converter. These components

are specifically listed below.

Where a warrantable condition exists, Shindaiwa Corporation

will repair your small off-road engine at no cost to you including

diagnosis, parts, and labol:

Manufacturer's Warranty

Coverage

When sold within the U.S., this engine's emission control

system is warranted for a period of two (2) years from the date

this product is first delivered to the original retail purchaser.

During the warranty period, Shindaiwa Corporation will, at

their option, repair or replace any defective emission-related

component on this engine. During the original Warranty Period,

these Warranty Rights are automatically transferable to subse-

quent owners of this product.

What is Covered by this

Warranty

1. Carburetor Internal Components

m Throttle Valve, Needle, Jet, Metering Diaphragm

2. Fuel Tank

3. Ignition System Components

m Ignition Coil

m Flywheel Rotor

4. Catalytic Converter (if originally equipped)

The emission control system for your particular Shindaiwa

engine may also include certain related hoses and connectors.

Owners Warranty

Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in this own-

ers manual. Shindaiwa Corporation recommends that you retain

all receipts covering maintenance on your small off-road engine,

but Shindaiwa Corporation cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of

all scheduled maintenance.

As the small off-road engine owner, you should be aware,

however, that Shindaiwa Corporation may deny you warranty

coverage if your small off-road engine or a part has failed due to

abuse, neglect, improper maintenance, or unapproved modifica-

tions.

You are responsible for presenting your small off-road engine

to an authorized Shindaiwa Dealer as soon as a problem ex-

ists. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights

and responsibilities, you should contact a Shindaiwa customer

service representative at (503) 692-3070 or your local Shindaiwa

Dealer.

Consequential Damages

In the event that other component parts of this product are

damaged by the failure of a warranted part, Shindaiwa Corpora-

tion will repair or replace such component parts at no charge to

you.

What is Not Covered

m Failures caused by abuse, neglect, or improper

maintenance procedures.

II Failures caused by the use of modified or non-approved parts

or attachments.

This Warranty is Administered by:

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, OR 97062

(503) 692-3070

Swisher

EO. Box 67

Warrensburg, MO 64093

Part Number 81953

Revision 12/2007

16

Page 17

SWISHER MANUAL DEL PROPiETAR|O/OPERADOR

CORTADORA DE SETOS E4-

F4-HT3000

iADVERTENC|A!

Minimize el riesgo de accidentes contra usted u otras personas. Lea

este manual y familiaricese con sus contenidos. Siempre utilice pro-

tecci6n para los ojos y oidos cuando la maquina sea usada.

Ndlnero de Parte 81955 Revisado 10/07

Page 18

introducci6n

La cortadora de setos Swisher Sefie E4-

HT3000 ha sido disefiada y construida para

suministrar rendimiento superior y seguri-

dad sin comprometer calidad, comodidad o

durabilidad.

Los motores de alto rendimiento Swisher

representan la tecnologia lider en momres

de enfriados por aire, de cilindrada y peso

notablemente bajos que desarrollan suma

)otencia. Como duefio/operafio, usted muy

)ronto descubfirfi pot que Swisher, simple-

nente, es la unica en su clase.

!La informaci6n contenida en este manual

describe las maquinas disponibles en el

momento de publicacidn! Aunque todo es-

fuerzo sea hecho para proveerle la mas

reciente informaci6n sobre su producto

Swisher, podria haber algunas diferencias

entre su cortadora de setos E4-HT3000 y

las descritas en este manual.

Swisher se reserva el derecho de hacer cam-

bios a sus productos sin notificaci6n previa y

sin obligaci6n alguna de hacer alteraciones a

maquinas previamente fabricadas.

_I_IADVERTENC|A!

Las emisiones tiberadas por este pro-

ducto contienen substancias quimicas

queen el estado de California son con-

sideradas como causantes de cancer,

defectos congenitos u otros efectos

nocivos a la reproducci6n humana.

Co_er_i_o IL_(;INA

Introducci6n ....................................... 2

Advertencias de Segufidad ..................... 2

Introducciones Generales de Segufidad .... 3

Equipo de Segufidad y Etiquetas .............. 4

Especificaciones ............................................. 4

Descfipci6n de la Unidad ....................... 5

Combustible ................................................... 5

Llenado del tanque de combustible ............. 5

Instrucciones de arranque ...................... 6

Ajuste de la Marcha Minima ........................ 7

Parada Normal del Motor. ........................ 7

Mantenimiento y Ajustes ........................ 8

Mantenimiento de la Maya Guarda Chis-

pas ......................................... 11

Almacenamiento .......................................... 11

Guia de diagnostico ............................ 12

Declaraciones del sistema de emisidn ...... 15

Advertencias de Seguridad

_ iADVERTENCIA!

Una declaraci6n precedida por el sim-

bolo triangular de advertencia y la pa-

labra [ADVERTENClA! contiene infor-

maci6n o procedimientos que se deben

cumplir para prevenir lesiones graves.

IPRECAUC|(_N!

Una declaraci6n precedida por la pa-

labra [PRECAUCION! contiene infor-

maci6n o procedimientos que se deben

cumplir para evitar da_ar la maquina.

[Una declaraci6n precedida por la palabra

11MPORTANTE ! denota informaci6n esen-

cial o especial.

Todo texto precedido por la palabra "NOTA"

contiene informacidn prfictica que puede

facilitar su trabajo.

Lea y siga las recomendaciones

en este manual. De no hacerlo

Io podria sufrir lesiones graves.

Use proteccion para los ojos

aprovada pot la norma ANSI Z87.1

v proteccion para los oidos en

todo momento que esta operando

esta maquina.

Manipule con mucho cuidado.

las cuchillos estan bien afiladas.

Maintenga ambas manos

distanciadas de las cuchillas

al encender y operar esta maquina

La intenci6n de los procedimientos op-

eracionates descritos en este manual es

ayudarle a obtener el mas alto rendimiento

posible de su maquina y proteger a usted

y otras personas de sufrir lesiones graves.

Estos procedimientos son pautas opera-

tivas para operaciones seguras bajo la

mayoria de condiciones y no tienen el

prop6sito de substituir las normas vigentes

en su area. Si usted tiene alguna pre-

gunta en relaci6n a su cortadora de setos

E4-HT3000 o no entiende algo en este

manual, su distribuidor Swisher estara

muy contento en atenderlo. Tambien pu-

ede ponerse en contacto con Swisher Inc.

en la direcci6n impresa al inverso de este

manual.

sP2

Page 19

|nstrucciones Genera|es de Seguridad

Trabaje con cuidado

Cortadoras de setos operan en aItas ve]o-

cidades y pueden causar dafios o lesiones

sefias si son malusadas o abusadas. Nunca

permita que una persona sin entrenamiento

o instrucci6n opere esta unidad !

iADVERTENC|A!

Nunca instale accesorios de corte no

autorizados.

Mantengase Alerta

Debe de estar fisica y mentalmente en opti-

mas condiciones para operar esta m_tquina

con seguridad.

RTENCIA!

No opere esta

cansado, enfermo o ha consumido be-

bidas que contienen alcohol, drogas o

medicamentos.

iADVERTENC|A!

Disminuya El Riesgo de Incendios.

NUNCA fume ni encienda fuegos cerca

del motor.

8[EMPRE pare el motor y permita

que se enfrie antes de votver a Ilenar

el tanque. Evite sobre Ilenar el

tanque y limpie cualquier derrame de

combustible.

SiEMPRE Inspeccione la maquina pot

perdidas de combustible, antes de cada

uso. Durante cada Ilenado, verifique po-

sibles perdidas alrededor de la tapa o

tanque de combustible. Si existen per-

didas de combustible evidentes, pare

inmediatamente de utilizar la maquina.

Perdidas de combustible deben de set

reparadas antes de cada uso.

SIEMPRE aleje la maquina del area de

combustible o de otros materiales in-

flamabtes antes de arrancar el motor.

NUNCA cotoque materiates inflamables

cerca del silenciador de la maquina.

NUNCA opere el motor sin la malla del

guardachispas en su lugar.

TRABAJE CON CUIDADO!

Use siempre _pa cefiida al eue@o. Useguantes de

trabajo para incrementar el nivel de proteeci6n.

No use ropa o joyas que pudieran enredarse en la

mdquina. Cercibrese de que el eabello no le pase de

los hombros.

SIEMPRE use protecci6n

para los ojos, los oidos y las

manos euando trabaja con esta

mdquina.

SIEMPRE detenga

la marcha del motor

antes de retirar ra-

mas o residuos de las

cuchillas. Nunca per-

mita que las cuchillas

hagan contacto con

edifieaeiones u otros

objetos s61idos.

iADVERTENC|A!

Inspeccione el frente y la parte de atras

de los mangos asegur&ndose que no

haya piezas dafiadas o flojas. NUNCA

opere un corta setos con mangos da-

fiados o sueltos.

NUNCA permita que nifios usen

estd mdquina. Evite usarla eerca de

transe_ntes.

NUNCA @ere esta

mdquina a velocidad

m_xima sin carga.

NUNCA opere esta md-

quina si el protector para

la mano estd quebrado.

SIEMPRE detenga la marcha

del motor e instale la vaina

protectora en las cuchillas antes

de llevarla a otra drea de traba-

joy mantenga su balance sobre

el suelo mientras trabaje o lleva

la recortadora a mano.

EVITE usar o guardar esta

mdquina en sitios h_medos. E1

d@fsito de agua en las euchil-

las podria penetrar en la caja de

engranaje y daiTar su mdquina.

NUNCA corte objetos metdli-

cos o alambre.

EJERCER EXTREMA

CA UTELA euando trabaje

en la prfximidad de cemas o

alambrados electricos.

Figura I

SIEMPRE mant_ngase parado

sobre tierra firme y no sobre

extienda el euerpo. Mantenga

su equilibrio en todo momento

que est_ operando la mdquina.

EVITE cortar ramas grandes o demasiado _'lefiosas', De

Io contrario, podria acortar la vida _til de las euehillas

y/o daiTar la eaja de engranajes.

iADVERTENC|A! Use Buen Juicio

81EMPRE use protecci6n para los ojos tal

como lentes de seguridad para protegerse

de objetos lanzados.

Use ropa de su talla para protejer su

piernas y brazos. Los guantes siempre

proveen protecci6n adicional y son alta-

mente recomendados. No use ropa holgada

o joyas que puedan atascarse en la maqui-

na o en la vegetaci6n. Amarrese el cabello

largo de tal forma que este sobre el nivel de

los hombros.

NUNCA opere el motor cuando transporte

la unidad.

NUNCA opere el motor en el interior!

Cerciorese que siempre haya buena ven-

tilaci6n. El humo o gases del escape del

motor pueden causar serias lesiones o la

muerte.

SIEIVlPRE pare el motor inmediatamente

si repentinamente empieza a vibrar.

lnspeccione el accesorio de corte por

partes quebradas, faltantes o instaladas

incorrectamente.

81EMPRE sujete la maquina firmemente

con ambas manos cuando corte o recorte, y

mantenga el control en todo momento.

81EMPRE mantenga los mangos limpios.

SP_3

Page 20

Equipo de Seguridad y Etiquetas

Cubierta para

cuchillas

Trabador del gatillo

de

lnterruptor de

marcha

Protector

Etiqueta de Precaucion

Etiquetas de Cuidado, Peligro, Advertencia e lnformaci6n

de Funcionamiento: Asegurese de que todas las etiquetas

de informaci6n no esten dafiadas y que sean legibles.

Reemplace inmediatamente cualquier etiqueta de

informacion que falte o que este dafiada. Puede obtener

etiquetas nuevas de su agente local autorizado Swisher.

Figura 2

Especificaciones

Nombre del Modelo ........................................................................................................................................ E4-HT3000

Modelo del Motor ........................................................................................................................................ SDH2510

Tipo de Motor ...................................................................................................................... 4-tiempos, cilindro horizontal, refligerado

Difimetro x Carrera .................................................................................................................................. 34mm x 27mm

Cilindrada ........................................................................................................................................................ 24.5cc

Peso de la unidad, sin gasolina ................................................................................................... DH2510-24:5.8 kg (12.8 lb)

Dimensiones de la unidad (L x An x A1)............................................................................... DH2510-24:1100 x 245 x 230mm

Velocidad del Motor a Potencia Mfixima ................................................................................ 1.1 hp (.83kw) @ 7,500 rpm (rain-0

Proporcidn de Combustible ................................................................. 50:1 con ISO-L-EGD o JASO FC aceite de mezcla de motor 2 tiempos

Capacidad del Depdsito de Combustible ......................................................................................... 0.55 liter!18.6 oz.

Carburador ................................................................................................................................ Walbro WYJ, Tipo Diapragma

Sistema de Encendido ......................................................................................... Totalmente electrdnico, controlado pot transistor

Bujia ....................................................................................................................................................... NGK CMR5H

Filtro de Aire ....................................................................................................................... Elemento no reversible de uso pesado

M6todo de Arranque ................................................................................................................................. Retrfictil

M6todo de Parada ............................................................................................................. Interruptor, corredizo de pu esta a tierra

Largo de la cuchilla ............................................................................................................................ DH2510-24: 610mm

Clase de cuchilla .............................................................................................................. Cuchilla doble de accidn de corte: Cuchilla doble

Tipo de embrague ........................................................................................................................ Embrague centrifugo, Tipo seco

Tipo de caja de engranaje .................................................................................................................... Engranaje cilindrico

Lubricaci6n de la caja de engranajes ...................................................................................................... Grasa de litio

Equipo esNndar. .......................................................................................................... Controles en el mango posterior, montajes de Anti-vibracidn,

mango delantero con protector, llave de bujias y cobertor de la cuchilla

** Periodo de emisiones requerido por la EPA.................................................................................................. Categoria A

**El periodo de emisiones requerido por la EPA se refiere a la etiqueta localizada en el motol; Esta indica el ndmero de horas de operacidn en los que ha llenado

los estfindares de emisiones requeridas por el gobierno federal.

Categoria C = 50 horas (Moderado), B = 125 horas (Intermedio) y A = 300 horas (Extendido

o sobrepasa las especificaciones yes recomendado para todos los productos Swisher.

Especificaciones sjuetas a cambio sin previo aviso.

sP4

Page 21

Descripcion de |a Unidad

Familiaricese con al mfiquinay sus diversos

componentes. E1conocimiento de su mfiquina le

ayudarfia grantizar un rendimiento superior, una

vNa utfl prolongada y un manejo mils seguro.

Antes de usarla

Antes de comenzar el ensamblaje de este pro-

ducto, cercidrese de tenet todos los componentes

necesarios para ensamblar una mfiquinacompleta:

m Motor con caja de engranaje/cuchfllas

m Llave de bujia/llave de 13mm y destor-

nillador pequefio.

Inspeccione con cuidado todos los componen-

tes para comprobar que ninguno est6 dafiado.

Los terminos "izquierda", "mano izqui-

erda" y "MI" (en ingles, "LH"), "derecha",

"mano derecha" y "MD" (en ingles, "RH"),

"delantero" y "trasero", indican direcciones

desde el punto de vista del usuario duran-

te la utilizacidn normal de este producto.

i_ iADVERTENC|A!

No realice modificaciones o alteracio-

nes, que no esten autoizadas, en esta

maquina o en alguno de sus compo-

nentes o accesorios.

lnterruptor

de Mareha

Figura 3

Cuehillas

Mango Delantero

/

. J

Bastzdor de

Cuehillas

ProtectSr

Protector

Para las

Silenciador

Combustible

del Es-

h'angulador

Filtro de Aire

_do de

Combustible

de En-

granajes

Gatillo de

Aceleracibn

Arra_zcador

Mango Trasero

Combustible

iPRECAUC|ON!

[] Algunos tipos de gasolina contienen

alcohol como oxigenante. Combustible

oxigenante prodria Ilegar a causar tem-

peraturas elevadas durante la operacidn

de la maquina. Bajo ciertas condiciones,

combustible con base de gasolina po-

dria tambien reducir las cualidades de la

lubricaci6n de algunos aceites mezclas

para motores de 2-tiempos.

[] Nunca utilice ningOn tipo de gasolina

con mas de 10% de alcohol por volu-

men !Aceites genericos no deberian

ser utilizados para alto rendimiento en

motores de 2-tiempos, y nunca deben

ser utilizados en motores Swisher.

iPRECAUCiON!

Este motor esta certificado para funcionar

[?nicamente con una mezcla de combustible

compuesta de gasolina sin plomo y aceite

de mezclar para motores de 2 tiempos tSO-

L-EGD o JASO FC a proporcidn de 50:1.

m Utilice gasolina sin plomo nueva y lim-

pia, La gasolina debe tener un grado de

Octano de 87 o mils alto.

m Mezcle combustible con aceite mezcla

para motor de 2 tiemos enfriado por air

que cumplan o excedan ISO-L-EGD y/o

JASO JC a proporcidn de 50:1.

Ejemplos de cantidades de mezcJa 50:1

II 1 galdn de gasotina por 2.6 oz. de aceite

II 5 litros de gasolina por 100 ml. aceite

Mezcleel combustible necesario para uso inme-

diato. Si tiene que almacenar combustible por

mas de 30 d'as agregele acete con adtvo

estabilizador como por ejemplo STA-BILTM,

es un aceite registrado JASO FC que

cumple con los requerimientos ISO-L-EGDpara

major rendimiento. Swisher one es recomen-

dado para ser utflizadoen forma conjunta con las

mfiquinas de bajas emisiones. Swisher tambi6n

incluye un estabilizador de combustible.

Lienado del Tanque de Combustible

iADVERTENCIA!

iDisminuya el riesgo de incendios!

[] DETENGAe[ motorantes de volvera [[enar

el tanque.

[] SlEMPREdeje que el equipo se enfrie

antesde cargar combustible.

[] SlEMPREaguardeel combustibleen un

envaseapropiado para [iquidos inflamables.

[] Limpietodoel combustiblederramado y

alejeel equipo pot Iomenos3 metros (10

pies)de[sector de [[enadode combustible

antesde volver a arrancar[o!

[]

[]

NUNCAarranqueuopere esta unidadsi

existe una perdida de combustible.

NUNCAarranqueuopere esta unidadsi

el carburador,[as [ineasde combustible,el

tanquede combustible y/o[atapa de[tanque

de combustible estandafiados.

[] NUNCAfume o enciendafuego cercade[

equipo o los combustibles.

[] NUNCAco[oquemater|ales inflamables

cercade[ silenciadorde[ motor.

[] NUNCAopere el motor sin el silenciador y

el guardachispasen su posicioncorrecta y

funcionandoadecuadamente.

1. Ponga la cortadora de setos E4-HT3000

en el suelo o sobre una superficie plana.

2. Limpie el polvo y los desechos de cortes

de la superficie de la tapa de llenado de

combustible.

3. Remueva lentamente la tapa de lIenado y

llene el tanque con combustible nuevo y

limpio. ;NO SE EXCEDA AL LLENAR!

4. Reinstale la tapa de llenado y apri6tela

firmemente.

SP_5

Page 22

|nstrucciones de Arranque

• Q - ,

El sistema de encendido Io controla un

interruptor deslizante de dos contactos. El

rotulo STOP aparece grabado en el tope

del bot6n del interruptor.

Figura 4

1. Deslice el botdn del interruptor hacia la

posicidn I (encendido). Consulte Figura

4.

Seguro del gatillo

de aceleracibn

Gatillo de

Bot6n tra-

bador

Figura 5

2. Trabe el gatillo de aceleracidn en la

posicidn de marcha acelerada segun las

siguientes instrucciones.

a. Optima el gatillo de aceleracidn y el

seguro del gatillo de aceleracidn a la

misma vez.

b. Oprima el bot6n trabador y lenta-

mente suelte el gatillo y el seguro del

gatillo de aceleraci6n a la misma vez.

& iADVERTENCIA!

iMantenga las manos y el cuerpo aleja-

dos de las cuchillas en todo momennto)

Las cuchillas se moveran al arrancar el

motor.

m Ponga la cortadora de setos sobre

el suelo durante todas las operacio-

nes de arranque.

m Cercidrese de estar en posicidn

firme sobre el suelo y sujete la m&-

quina firmemente.

m Mantenga a todos los nifos, tran-

seentes y animales domesticos

alejados de la cortadora de setos

durante todas las fases de oper-

acidn.

Labombade cebado solamenteempuja

combustiblea traves del carburador.Presion-

ando repetidamentela bombadecebadono

ahogarael motorcon combustible.

Estrangulador

Figura 7

4,

(Motor frlo)

Mueva la leva del estrangulador hacia

adelante ("closed") para cebar el momc

Consulte Figura 7.

Arranque de| Motor

Bomba de cebado

(vista posterior)

Figura 6

,

Oprima la bomba de cebado varias

veces basra que sienta resistencia y vea

combustible fluir por la bomba. Consulte

Figura 18.

5,

Ponga la mfiquina en el suelo. Sujete el

motor por la cubierta con la mano izqui-

erda y con la mano derecha, empufie el

mango del arrancadoc Consulte Figura

8.

6. Jale el mango del arrancador lenta-

mente hacia afuera hasta que sienta el

mecanismo de arranque engranm:

7. Jale el mango del arrancador rfipidam-

ente hacia aJ'uera para arrancar el motol:

iPRECAUCI(_N!

El arrancador le durara mas si se

opera de acuerdo a las siguientes

recomendaciones.

m Siempre engrane el arrancador al

comenzar el arranque del motor.

m Nunca extienda la cuerda del ar-

rancador hasta el tope.

m Permita que la cuerda vuelva enrol-

lar en el arrancador.

Cuando el Motor Enciende o

|ntenta Encender,

1. Mueva la palanca del estrangulador

hacia atrfis para abrir el estrangulador.

2. Despu6s que el motor arranca accione

el acelerador vafias veces para eliminar

el exceso de combustible de la cfimara

de combustidn.

3. Si el motor se para, repita los proced-

imientos aplicables para el arranque de

un motor frio o un motor caliente.

iADVERTENC|A(

Las cuchillas se mueven al acelerar

el motor, Mantenga las manos y el cu-

erpo distanciados de las cuchillas.

Operacibn

m A1instante que el operafio oprime el ga-

tillo de aceleracion, la marcha del motor

se acelera. La aceleraci6n de la marcha

del motor causa que el embrague

acople con la caja de engranajes, la cual

acciona el movimiento de las cuchillas.

m La desaceleracidn de la marcha del

motor es inmediata al instante que el op-

erario libera el gatillo de aceleracidn. La

marcha del motor vuelve a caer en mar-

cha minima y causa que el embrague

se desacople de la caja de engranajes,

la cual detiene el movimiento de las

cuchillas.

m [x)s cortes se deben de llevar a cabo

con movimientos de lado a lado (cortes

laterales) o de arriba abajo (cortes ver-

ticales) variando la marcha del motor de

acuerdo a la clase de seto que corta.

m Siempre se debe de evitar cortar setos

que tienen mils de 1,3 cm de difimetro.

Si el Motor no Enciende

m Repita las instrucciones aplicables para

el arranque de un motor frio o caliente.

m Consulte las instrucciones "Arranque de

un motor ahogado."

SP_6

Page 23

Arranque de un Motor Ahogado

iADVERTENC|A!

[Riesgo de quemadura por el motor

caliente. Permita que el motor enfrie

antes de retirar la cubierta del cilindro.

1. Desconecte la bujia dirige, y entonces

utiliza la llave inglesa de bujia para aJ_lo-

jar y quitar la bujia.

4. Reemplace la bujia y lo aprieta firme-

mente con la llave inglesa de bujia.

Si una llave inglesa del momento de

torsidn estfi disponible, el momento de

torsidn la bujia a 170-190 kg cm.

iPRECAUC|6N!

La instalacidn incorrecta de la bujia

puede dafiar el motor.

2. Si la bujia se fouled o es empapada con

el combustible, limpia o reemplaza el

tapdn como sea necesario. Para espe-

cificaciones de bujia y procedimiento de

gapping, vea pfigina 9.

3. Con la bujia quitada, acodar el motor

para vaciar varias veces el combustible

del exceso de la camara de combustidn.

5. Repita los procedimientos que empiezan

para un motor tibio.

6. Si el motor falla todavia empezar o despe-

dil; referirse al grS_ico de la localizacidn

de fallas a fnes de este manual.

Ajuste de la Marcha Minima

La velocidad del motor debe de volver a

marcha minima en todo momento que el

gatillo de aceleracidn se libera. La marcha

minima es regulable y se ajusta, de acuerdo

alas especificaciones del moto]; para que el

motor permita que el embrague centrifugo

se desacople de los engranajes.

Para Ajustar la Marcha Minima:

1. Arranque el motor y permita que opere

pot dos o tres minutos para que alcance

la temperatura normal de operacidn.

2. Si las cuchillas se mueven con el motor

operando en marcha minima, gire el

tornillo de ajuste de marcha minima en

sentido contrario a la manecillas del re-

loj hasta que las cuchillas de detengan.

3. Si tiene disponible un medidor de revo-

luciones para motores de dos tiempos

(tac6metro), ajuste la velocidad de mar-

cha minima a 3000 -+250 RPM (min-1).

4. [x_s tornillos de ajustar la mezcla del

carburador tienen calibracidn de ffibrica

y no se pueden ajustar.

_ IADVERTENCIA!

Las cuchillas NUNCA deben moverse

cuando el motor esta operando en

marcha minima. Si la marcha minima

no se puede ajustar de acuardo alas

instrucciones proveidas, consulte con

su distribuidor Swisher o centro de

reparaci6n autorizado.

Parada Normal del Motor

Parada (0)

lnterruptor

de rnarcha

Figura 11

1. Permita que el opere en marcha minima

por dos o tres minutos para que la tem-

peratura del motor se estabilice.

2. Mueva el bot6n del interruptor a la

posici6n O (apagado). Consulte Figura

11.

SP7

Page 24

Mantenimiento y Ajustes

CUALQUIER ESTABLECIMIENTO 0 TI_C-

NICO CAPACITADO PODRA LLEVAR A

CABO EL MANTENIMIENTO, REEMPLAZO

O REPARACION DE LOS DISPOSITIVOS Y

SISTEMAS DE CONTROL DE EMISIONES;

NO OBSTANTE LO ANTERIOR, LAS REPA-

RACIONES CUBIERTAS POR LA GARANTIA

LAS DEBERA LLEVARA CABO UN DISTRI-

BUIDOR O CENTRO DE SERVICIO AUTOR-

IZADO POR CORPORACION Swisher EL USO

DE REFACCIONES QUE NO SEAN EQUIVA-

LENTES EN DESEMPEIqO Y DURABILIDAD A

LAS REFACCIONES AUTORIZADAS PODRiA

AFECTAR LA EFICACIA DEL SISTEMA DE

CONTROL DE EMISIONES. ASIMISMO,

PODRIAAFECTAR LA RESPUESTA DADAA

CUALQUIER SOLICITUD DE COBERTURA

DE GARANTiA.

iADVERTERClA!

Un arranque accidental puede causar

lesiones graves. Antes de Ilevar a

cabo cualquier tarea de mantenimien-

to a este equipo, detenga la marcha

del motor y desconecte la bujia.

1. Limpie todos los residuos de corte y

sucio de la cortadora de setos.

m Limpie los residuos de corte

acumulados alrededor del tanque

de combustible y el silenciador.

m Inspeccione las aletas de enfriamiento

del motor y lflnpielas si es necesario.

m Limpie la superficie interior de la

cubierta del motor y el {_rea alrededor

de la bujia.

m Inspeccione el elemento del filtro de

aire y lflnpielo segdn sea necesario.

|.specci6n y mantenimiento diario

Limpiar alrededor

de la bujia

impecciom

las aletas de

enfriamienyo

Limpie los residuos

del tanque y el

silenciado_

LubHque las

cuchillas

Figura 12

IADVERTENCIA!

Para reducir el riesgo de incendios,

mantenga las superficies del motor y

el silenciador libres de residuos, hojas

o exceso de grasa.

2. Inspeccione en bt]squeda de componentes

flojos, dafiados o faltantes, y lleve a cabo

reparaciones necesarias.

3. Lubrique las cuchillas con aceite de ma-

quinaria de grado fino antes de usar y cada

vez que llena el tanque de combustible.

4. Revisar las cuchillas y asegurarse que

todas las tuercas estfin apretadas.

barra no estdn dafiadas y los

pernos estdn apretados

inspeccione el frente y el trasero de los

mangos asegurdndose que no haya piezas

da_adas o flojas.

Manteuga

eufi@miento

limpias.

Manteuga la entrada

de aire limpia