Page 1

MANUFACTURING QUALITY LAWN CARE EQUIPMENT SINCE 1945

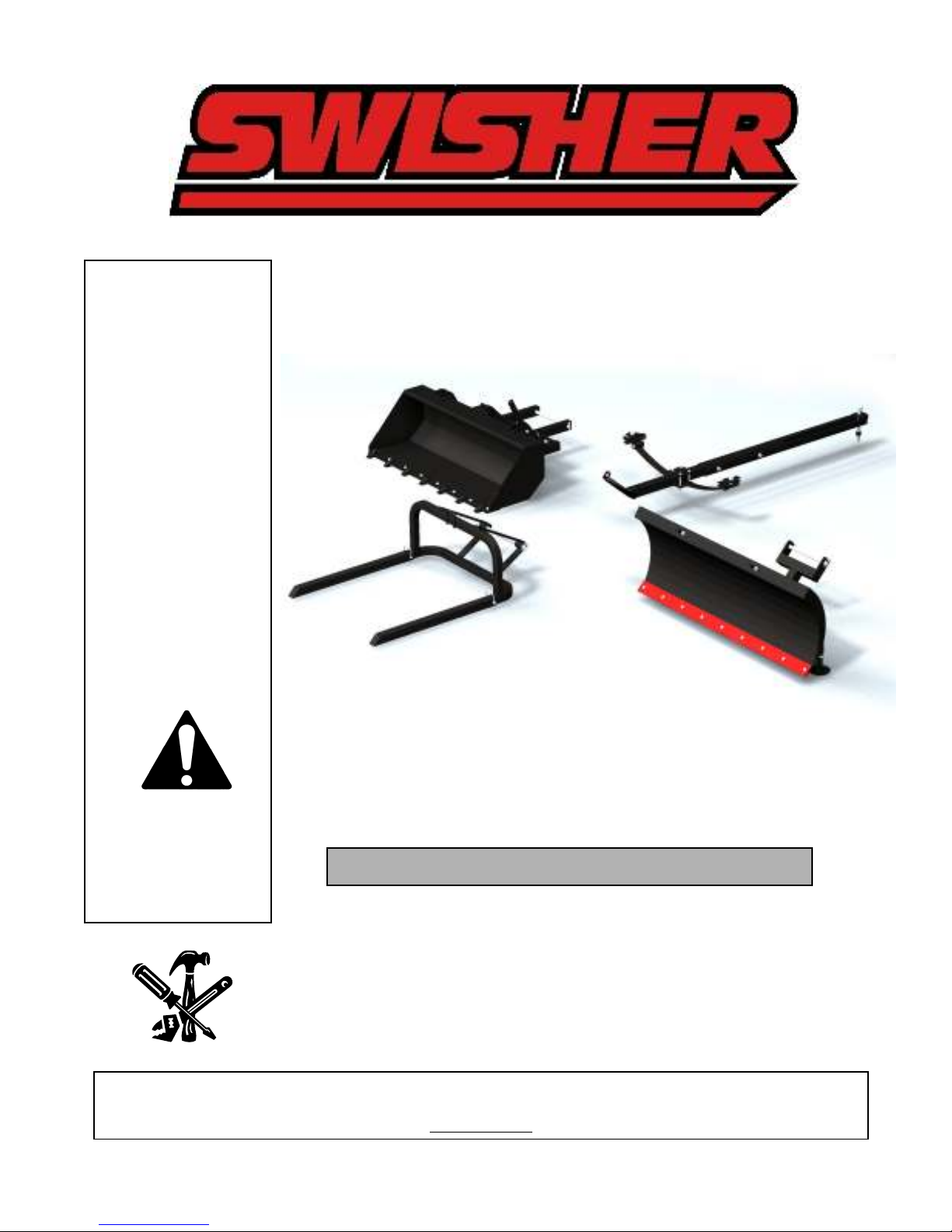

Owner’s

Manual

Plow Blade

2645

IMPORTANT

Read and follow all

Safety Precautions

and Instructions

Before Operating this

Equipment.

2643

2646

2644

2645

ATV ACCESSORIES

Sold as Separate Pieces!!!!

1602 CORPORATE DRIVE PO BOX 67 WARRENSBURG, MISSOURI 64093

2803

ASSEMBLY

OPERATION

SERVICE AND ADJUSTMENT

REPAIR PARTS

PH 660. 747. 8183 FAX 660. 747. 8650

swisherinc.com

Made In The

USA

REV. 05-270

Page 2

The manufacturer’s warranty to the original consumer purchaser is: This

ted to ninety (90) days

This warranty applies only to products which have

LIMITED WARRANTY

product is free from defects in materials and workmanship for a period

of one (1) year from the date of purchase by the original consumer

purchaser. We will repair or replace, at our discretion, parts found to be

defective due to materials or workmanship. This warranty is subject to

the following limitations and exclusions:

1) Commercial Use The warranty period for any product used for

commercial or rental is limi

from the date of original purchase.

2) Limitations

been properly assembled, adjusted, and operated

in accordance with the instructions contained

within this manual. This warranty does not apply

to any product of Swisher Mower Co., Inc., that

has been subject to alteration, misuse, abuse,

improper assembly or installation, or shipping

damage.

3) Exclusions Excluded from this warranty are normal wear,

normal adjustments, and normal maintenance.

2

Page 3

In the event you have a claim under this warranty, you must return the product

to an authorized service dealer. All transportation charges, damage, or loss

incurred during transportation of parts submitted for replacement or repair

under this warranty shall be borne by the purchaser. Should you have any

questions concerning this warranty, please contact us toll-free at

1-800-222-8183. The model number, serial number, date of purchase,

and the name of the authorized Swisher dealer from whom you purchased

the product will be needed before any warranty claim can be processed.

THIS WARRANTY DOES NOT APPLY TO ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES AND ANY IMPLIED WARRANTIES

ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN

FOR ALL EXPRESSED WARRANTIES.

Some states do not allow the limitation of consequential damages or limitations

on how long an implied warranty may last, so the above limitations or

exclusions may not apply to you. This warranty gives you specific legal rights

and you may have other rights, which vary from state-to-state. This is a limited

warranty as defined by the Magnuson-Moss Act of 1975.

3

Page 4

manual. When you see this symbol, carefully read the message that

SAFETY PRECAUTIONS

This Safety Alert Symbol indicates important messages in this

follows and be alert to the possibility of personal injury.

Read this manual completely. Failure to observe the following safety instructions

could result in serious injury or death.

• Read the manual. Learn to operate this machine safely.

• Keep the operating speed LOW!!!!!

• Allow only responsible adults who are familiar with these instructions to

operate this machine. Never allow children to operate this machine.

• Be sure the area is clear of other people before operating. Children are often

attracted to the machine and the operating activity. Never assume that

children will remain where you last saw them. Keep children under the

watchful care of another responsible adult.

• Watch for traffic when operating near or crossing roadways.

• Do not operate the attachment if it has been dropped or damaged in any

manner. Repair as necessary.

• Dress properly. Do not operate when barefoot or wearing open sandals.

• Do not operate the machine while under the influence of alcohol or drugs.

• Never tamper with safety devices. Check their proper operation regularly.

• Do not operate over 5 MPH (8KMH)

• Operate attachments up and down slopes. There is significant risk of overturns

when operating across slopes.

• Stop and inspect the equipment if you strike an object. Repair, if necessary,

before restarting.

• Never make adjustments or repairs with the engine running.

4

Page 5

ASSEMBLY, INSTALLATION and PARTS LIST

5

Page 6

TO ENSURE PROPER ASSEMBLY, CAREFULLY

FOLLOW ALL INSTRUCTIONS LISTED BELOW

REFER TO FIGURES 1 AND 2 WHILE ASSEMBLING THIS PORTION OF THE PLOW

ATTACHMENT

1. Unpack parts and make sure all are included. If they are not contact the dealer where the Swisher Plow was

purchased.

2. Locate the pivot weldment (1) and assemble to the blade (2) using two ½-13 X 2” bolts (12) two ½-13 nyloc

nuts (13) and two bushing (18) as shown. It is important to assure these two bushings are installed between the

blade and pivot to allow for the correct rotation of the pivot.

3. Assemble the tilt blocks (3) to the pivot weldment using two ½-13 X 2” bolts (12) and two ½-13 nyloc nuts (13).

4. Assemble two 3/8-16 nuts (14 ) to two eye-bolts (6). Assemble the eye-bolts into the holes at the top of the

blade. Secure with two 3/8 washers (15 ) two 3/8 -16 nuts (7). Place plastic caps (17) over the remaining

threads of the eye-bolts.

5. Attach the tilt springs (16) to the eye-bolts and to the tabs on the pivot weldment (1). See Figure 1 below.

6. Connect the skids (5) through the channels on the outer edges of the blade. Adjust their height with clevis pin

(10) and hair pin (11).

6

16

2

Attach springs here

1

Tilt Blocks set the

vertical “tilt” or rake of

5

the blade

6

Figure 1

Page 7

PLOW ATTACHMENT ASSEMBLY

8

4

10

FIGURE 2

9

5

17

2

15

7

14

6

16

1

7

13

22

28

21

13

12

11

12

18

18

13

3

13

26

See detail on

Page 8

19

21

20

ITEM

QTY.

NO.

1 1 2323TK Pivot Weldment 17 2 AS-125 Round Vinyl Cap

2 1 2312TK 50" Blade Weldment 18 8 NB-177 1/2 NR Mach. Bushing

3 2 2331TK Tilt Block 19 1 2588TK Plow Mount

4 1 2317TK Cut Edge 20 1 2642TK Plow Mount Pin

5 2 2334TK Skid 21 2 NB-506 3/16 Click Pin

6 2 NB-635 3/8-16 X 3 Turned Eye Bolt 22 1 2327TK Plow Mount Bracket

7 4 NB-182 3/8-16 Nyloc Nut 23 1 TR150W Washer

8 9 10216 5/16-18 X 3/4 Carriage Bolt 24 1 2336 Pivot Spring

9 9 NB-170 5/16-18 Serrated Flange Nut 25 4 NB-121 1/2-13 2 Way Jam Lock Nut

10 2 NB-300 Clevis Pin Std ZP 3/8 26 1 NB-131 1/2-13 X 3 Hex Bolt

11 2 NB-127 #3 Hair Pin 27 1 2310TK Plow Bracket Support

12 4 NB-509 1/2-13 X 2 Hex Bolt 28 2 NB-577 1/2-13 X 3 1/2 Hex Bolt

13 6 NB-281 1/2-13 Nyloc Nut 29 1 2319TK Lock Arm

14 2 NB-212 3/8-16 Hex Nut 30 2 NB-649 3/8-16 X 3 1/2 Hex Bolt

15 2 NB-272 3/8 SAE Washer 31 1 H9B Rope (Not Show n)

16 2 2335 Tilt Spring 32 1 H7K Knob (Not Show n)

PART

NO.

DESCRIPTION

ITEM

NO.

QTY

27

PART

NO.

DESCRIPTION

28

30

7

Page 8

TO ENSURE PROPER ASSEMBLY AND

INSTALLATION, CAREFULLY

FOLLOW ALL INSTRUCTIONS LISTED BELOW

REFER TO FIGURES 2 AND 3 WHILE ASSEMBLING AND INSTALLING THIS PORTION OF THE

PLOW ATTACHMENT

The next steps need to be done in sequence:

1. Disassemble Pivot Latch assembly from the plow mount. Lay parts down in the exact order they were removed.

Replace lock nuts (25) with lock nuts in hardware kit.

2. Slide the plow mount (19) into pivot weldment (1), secure with ½-13 X 3 1/2 bolt (28) and ½-13 nyloc nut (13).

3. Re-assemble the Pivot Latch assembly in the reverse order that it was removed in step 1. The Pivot Latch

assembly consists of the following components - lock arm (29), two bushing (18), two ½-13 lock nut (25),

Washer (23), pivot spring (24) and ½-13 X 3½ bolt (28) to plow mount (19). Make sure the tail of the pivot

spring is secured into the bent washer on plow mount, see fig 3. Note, lock arm should be able to pivot freely

after assembled.

4. Bolt plow mount bracket (22) and plow bracket support (27) to plow mount (19), as shown, using two 3/8-16 X 3

bolts (30) and two 3/8-16 nyloc nuts (7).

5. Insert ½-13 X 3 bolt (26) into plow mount bracket (22) and secure with ½-13 nyloc nut (13). Do not over tighten

as this can bend the plow mount bracket. This is where you will attach your winch or manual lift pulley, sold

separately.

6. With your Swisher ATV Accessory Mount already installed, attach the plow using plow mount pin (20) and two

3/16 click pins (21).

7. Attach red rope (31) to eyelet on lock arm (29) and loop over front of ATV so it can be reached by the operator.

8. Read Dangers on the back of the Swisher Plow and consult this manual.

9. It would be wise to become familiar with your plow using a slower speed.

10. Operating instructions are on page 9.

18

22

29

29

8

25

25

23

Tail of Spring 24

Tail of Spring 24

Figure 3

28

19

29

24

1

Top of weldment is removed for clarity.

Page 9

ADJUSTMENT AND OPERATION

PUSH YOUR PLOW AROUND!!

THE TENSION PLACED ON THE TILT SPRINGS DETERMINE THE AMOUNT OF PRESSURE

THAT MUST BE APPLIED TO THE BLADE BEFORE IT FOLDS OVER IF SOMETHING IS HIT.

ADJUST THE SPRINGS BY LOOSENING THE NUTS (7) ON THE EYEBOLTS (6) AND

ADJUSTING UNTIL THE BLADE DOES NOT FOLD OVER DURING NORMAL OPERATION

BUT WILL FOLD IF AN OBJECT IS STRUCK.

AFTER INSTALLING YOUR PLOW, SECURE THE ROPE SO IT IS ACCESSABLE WHILE

OPERATING THE ATV AND SECURELY HELD. THERE SHOULD BE A SMALL AMOUNT OF

SLACK, IN THE ROPE, TO AVOID ACCIDENTAL RELEASE OF THE LOCK ARM OR

TANGLING.

IF YOU NEED TO CHANGE THE BLADE ANGLE WHILE OPERATING, COME TO A STOP,

PULL THE ROPE AND RELEASE THE LOCK ARM. DRIVE THE PLOW INTO A SNOW BANK

AT AN ANGLE TO MOVE THE BLADE. WHEN THE PROPER ANGLE IS ACHIEVED

RELEASE THE ROPE, LOCKING THE BLADE IN PLACE

.

9

Page 10

Notes:

10

Page 11

Notes:

11

Page 12

MANUFACTURING QUALITY LAWN CARE EQUIPMENT SINCE 1945

Owner’s

Manual

Plow Blade

2645

IMPORTANT

Read and follow all

Safety Precautions

and Instructions

Before Operating this

Equipment.

ATV ACCESSORIES

WHEN ORDERING PARTS, PLEASE HAVE THE

FOLLOWING INORMATION AVAILABLE:

* PRODUCT – ________________

* SERIAL NUMBER - _______________

* MODEL NUMBER - _______________

TYPE - _______________

* PART NUMBER WITH PAINT CODE

* PART DESCRIPTION

TELEPHONE - 1-800-222-8183

FAX - 1-660-747-8650

SWISHER MOWER & MACHINE CO. INC.

SWISHER MOWER & MACHINE CO. INC.

SWISHER MOWER & MACHINE CO. INC.SWISHER MOWER & MACHINE CO. INC.

1602 CORPORATE DRIVE

P.O. BOX 67

WARRENSBURG, MO 64093

swisherinc.com

Loading...

Loading...