Page 1

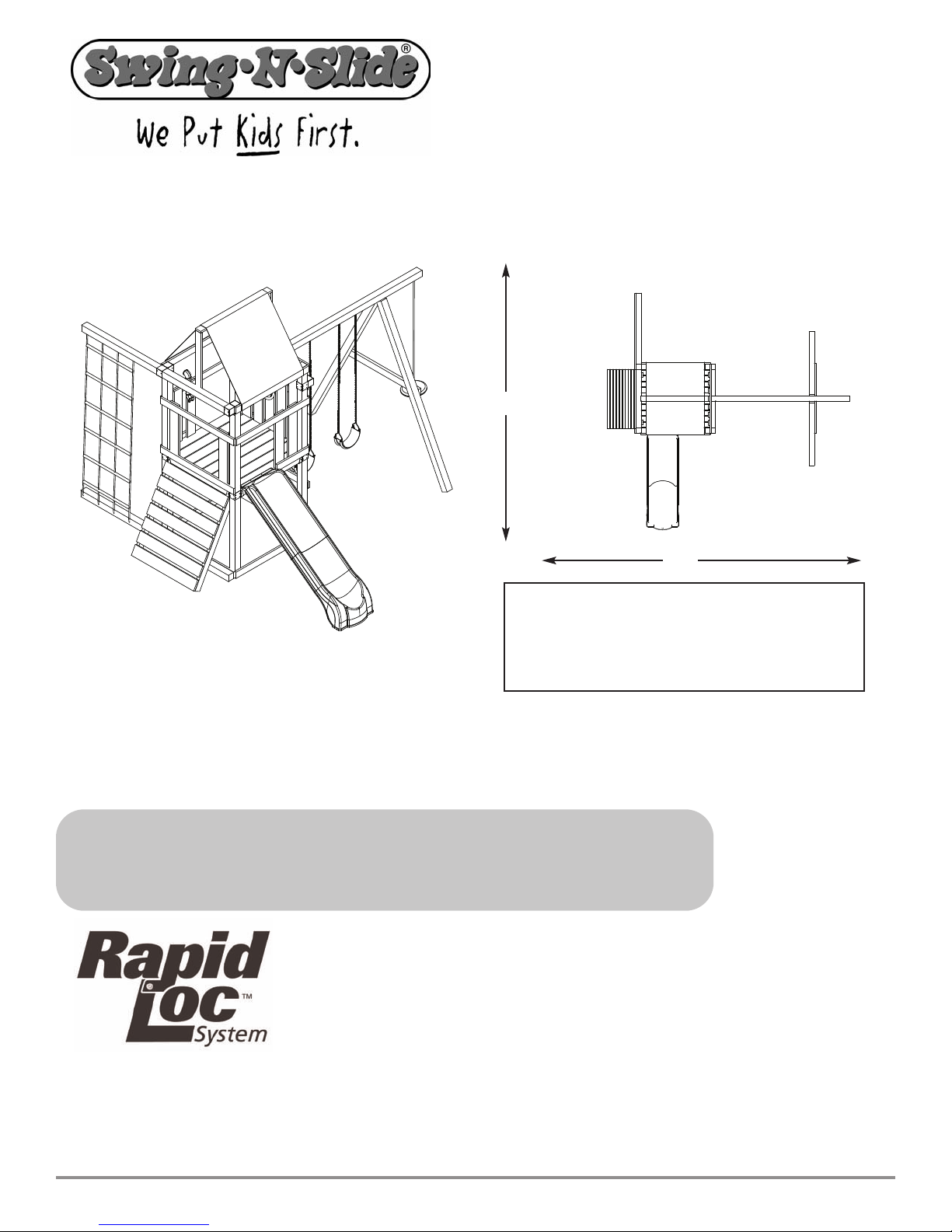

28'

26'

No. of Children: Up to 10

Min. Use Zone: 26' x 28'

Set Dim. 14'W x 14'L x 11'H

Est. Building Time: 3-6 hr.

PB 8242 - PB 8244

check out http://www.swing-n-slide.com/planupdates.htm

for updates to these instructions

For more information, visit this link:

http://www.swing-n-slide.com/

ASSEMBLY INSTRUCTIONS

Swing•N•Slide • 1212 Barberry Drive • Janesville, W

isit our web site at:

V

.swing-n-slide.com

www

or call us at

isconsin 53545

1-800-888-1232

Page 2

Safety Checklist for Swing-N-Slide Accessories

R

bserving the following statements and warnings reduces the likelihood of serious or fatal injury

O

Installation Safety – Have You:

Consulted the assembly instructions supplied with your particular model?

Noted this accessory is to be used only on Swing•N•Slide approved designs? (Do not alter its design or add/remove components.)

Made sure all hardware is tightened securely? (Supplied bolt covers must also be fastened securely.)

Using a hacksaw, cut off all protruding threaded ends of bolts and other fasteners and remove any sharp edges with

a metal file as needed?

Placed the equipment on level ground, not less than six feet (1.8 meters) from any structure or obstruction such as a fence, garage,

house, overhanging branches, laundry lines, or electrical wires?

Made sure home playground equipment is not installed over concrete, asphalt, packed earth or any other hard surface? (A fall onto

a hard surface can result in serious injury to the equipment user.)

Verified that suspended climbing ropes, chain,or cable are secured at both ends?

Consulted in assembly instructions of your particular model for minimum use zones?

Followed all anchoring and shock absorbing surfacing requirements later in this guide as they apply?

Made sure not to allow children to use equipment until it is properly installed?

Operating Safety – Have You:

Determined that on-site adult supervision is provided for children of all ages?

Warned children the following before allowing them to use the equipment?

Not to walk close to, in front of, behind or between moving items.

Not to twist swing or any other accessory chains or ropes or loop them over the top support bar since this will reduce the

strength of chain or rope.

Not to swing empty seats or other accessories.

Be sure to sit in the center of the swing seat and other accessories with full weight on the seat.

Not to attach items to the playground equipment that are not specifically designed for use with the equipment such as but not

limited to, jump ropes, clotheslines, pet leashes, cables and chain. They may cause a strangulation hazard.

Not to use equipment in a manner other than intended.

Not to get off equipment while it is in motion.

Not to climb on the equipment when it is wet.

Determined that only one child per planned occupant seat should be allowed on this set at one time.

Determined children must be dressed appropriately for play. Avoid clothing with draw strings and loose fitting clothes which

could become entangled or snagged on equipment.

Determined that suspended climbing ropes, chain, or cable cannot be looped back upon itself.

Read and understood the following warning regarding the use of two and four passenger lawn swings?

Warning: Lawn Swings are designed for use by children over two years of age. Use by children under the age of two can result

in entrapment between the seats and back areas. Never place children in a rearward facing position or with legs between the

seat and backrest because the child’s body may pass through the opening causing entrapment of the child’s head.

Safety Maintenance –

Check all nuts and bolts twice monthly during the usage season for tightness and tighten as required? (It is

ticularly important that this procedure be followed at the beginning of each season.)

par

event the deterioration of materials, r

o pr

T

use when the temperature drops below 0° F.)

Oil all metallic moving par

Check all har

necessary. It is especially important to do this at the beginning of each new season.)

Check swing seats, chains, r

, especially near the top swing hanger or at the seat connection ar

wear

sleeve or seat itself are also signs of deterioration. If any of these conditions exist, call 1-800-888-1232 to order replacement accessories.

Have You Determined to:

emove plastic swing seats and other plastic accessories and take indoors? (Do not

ts monthly during usage period?

e and equipment for sharp edges twice monthly during usage season? (Replace when

dwar

opes and cables monthly during usage season for evidence of deterioration? Severe rusting or excessive

e evidence of chain deterioration. Cracks in the pr

otective plastic

Disposal Instr

When the equipment is taken out of service, it must be disassembled and disposed of in such a way that no unreasonable hazards

will exist at the time the set is discarded.

uctions

Important!

Additional Safety Instructions for all Swing-N-Slide Playground Equipment.

Save this instr

uction sheet in the event the manufactur

er needs to be contacted.

2

Page 3

This product is intended for single family home/residential use only and not intended for use in any public setting.

According to ASTM requirements, all kits must be anchored to the ground and, if the unit has a climbing rope, the rope end must be anchored to the ground. If soil conditions

permit stakes to be pulled out easily, cementing into ground is necessary.

• To anchor the unit to the ground, use 2" x 4" x 18" (45mm x 95mm x 457mm) pressure-treated stakes. Pound stakes into ground at least 12" (305mm) at all inside corners of the

posts (including A-frame legs and climbing unit posts). Attach with four (4) 16D (3-1/2") galvanized nails per stake into each 4" x 4" (95mm x 95mm) post.

•

If the unit has a climbing rope,anchor the rope end.

• Once the unit is completely assembled and before children are allowed to play on it, proper shock-absorbing surfacing material must be installed. This may be accomplished by

using loose-fill materials at a sufficient depth. The Consumer Product Safety Commission “Handbook for Public Playground Safety” lists the following materials and required

depths that are sufficient for home/residential application. For fall height protection up to 9 ft. (2.742m) [recommended for Swing•N•Slide kits]:

Double Shredded Bark Mulch 9" (229mm)

These depths were derived from the CPSC Handbook. Swing•N•Slide has not done independent tests to determine these required depths.

When properly installed, shock absorbing material will completely cover the horizontal baseboards on climbing units. This protective surfacing must extend a minimum of 6 ft.

(1.828m) in all directions from the perimeter of the equipment or from the outermost edges of any component. For example, a slide extending beyond the platform must have

protective surfacing at least 6 ft. (1.828mm) out from both sides as well as the end. For swings, the protective surface must extend

front of the swing when the swing is in its rest position.

Placement in any public setting constitutes a misuse of this product.

MPORTANT

ADDITIONAL REQUIRED SAFETY INSTALLATION INSTRUCTIONS

LOOSE FILL MATERIAL REQUIRED (UNCOMPRESSED) DEPTH1in. (mm)

Wood Mulch 9" (229mm)

Uniform Wood Chips 12" (305mm)

Fine Sand 12" (305mm)

Fine Gravel 12" (305mm)

I

!

at least 14 ft. (6m) out from both the back and

Este producto ha sido ideado para su uso en una residencia u hogar de una sola familia y no para usarse en zonas públicas.

Según establece el ASTM, todos los equipos deben anclarse al terreno y si la unidad tiene además una cuerda de escalar, el final de la cuerda deberá anclarse al suelo. Si las

condiciones del terreno permiten que las estacas se salgan con facilidad, será entonces necesario cementarlas a la tierra.

• Para anclar la unidad a la tierra, use estacas tratadas bajo presión de 2 x 4 x 18 pulgadas (45 mm x 95 mm x 457 mm). Martillee las estacas en la tierra a una profundidad de al

menos 12 pulgadas (305 mm) en todas las esquinas internas de los postes (incluyendo las patas de la estructura A y los postes de la unidad de escalada). Sujételos con cuatro (4)

clavos galvanizados de 16D (3-1/2 pulgadas) por estaca en cada poste de 4 x 4 pulgadas (95 mm x 95 mm).

• Si la unidad tiene una cuerda de escalar, sujete el final de la cuerda.

• Una vez que la unidad esté completamente montada y antes de que se permita a los niños jugar en ella, deberá instalarse el material adecuado para la absorción de golpes. Esto

se consigue usando materiales de relleno a una profundidad suficiente. En el folleto titulado “Guía para la Seguridad en las zonas de recreo publicas” publicada por la Comisión

de Seguridad para los Productos de Consumo (CPSC por sus siglas en inglés) se citan los siguientes materiales y los requisitos necesarios para su uso en residencias y hogares

privados. Para protegerse de caídas de hasta 9 pies de altura (2,742 m), recomendado para los equipos Swing•N•Slide:

stas medidas se han sacado de la Publicación de la CPSC. Swing•N•Slide no ha realizado estudios independientes para determinar estos espesores recomendados.

E

Una vez instalado adecuadamente el material de absorción de golpes, este deberá cubrir completamente todas las bases horizontales de las unidades de escalada. Esta superficie

protectora deberá extenderse por al menos 6 pies (1,828 m) en todas las direcciones, desde el perímetro del equipo o desde los bordes externos de cualquiera de los componentes.

Por ejemplo, un tobogán que se extiende por fuera de la platafor

Para los columpios, la superficie protegida deberá extenderse al menos 14 pies (6 m) a partir de tanto la parte trasera como delantera del columpio cuando este esté en posición

inmóvil.

Ce pr

oduit est conçu uniquement pour un usage résidentiel. Il ne saurait aucunement convenir aux installations publiques.

Les normes établies par l’organisme américain ASTM spécifient que toutes les unités de jeu doivent être ancrées solidement dans le sol et que si l’unité comprend une corde

d’escalade, l’extrémité de celle-ci doit également être ancrée dans le sol. Si les piquets risquent d’être facilement délogés en raison du type de sol, il est nécessaire de les cimenter

dans le sol.

Pour ancrer l’unité dans le sol, utiliser des piquets en bois traités sous pression de 2 x 4 x 18 po

•

(45 x 95 x 457 mm). Enfoncer les piquets dans le sol à une pr

A et les poteaux des unités d’escalade). Fixer les piquets au moyen de quatre clous galvanisés 16D de 3-1/2 po (par piquet) dans chaque montant de 4 x 4 po (95 x 95 mm).

• Si l’unité comprend une corde d’escalade, ancrer l’extrémité de la corde dans le sol.

• Lorsque l’unité est entièrement assemblée, un matériau de protection amortisseur doit être installé sur le sol avant de permettre aux enfants de s’amuser. Des matériaux

particulaires d’une épaisseur suffisante peuvent être utilisés à cette fin. Le guide américain intitulé «Handbook for Public Playground Safety» rédigé par la Consumer Product

Safety Commission (CPSC) des États-Unis r

9 pieds (2,742 m) [r

ecommandation pour les unités Swing•N•Slide]:

Su uso en lugares públicos constituye una mala utilización de este producto.

INSTRUCCIONES ADICIONALES DE SEGURIDAD PARA LA INSTALACION

ERIALES DE RELLENO

MAT

Mezcla de madera 9 pulgadas (229 mm)

Mezcla de corteza de doble trituración 9 pulgadas (229 mm)

Viruta de madera uniforme 12 pulgadas (305 mm)

Arena Fina 12 pulgadas (305 mm)

Grava fina 12 pulgadas (305 mm)

’utilisation dans un endr

L

ofondeur d’au moins 12 po (305 mm) à tous les coins intérieurs des montants (y compris les montants des str

ecommande une liste de matériaux et spécifie l’épaisseur requise pour un usage résidentiel. Protection contre les chutes d’une hauteur de

¡IMPORTANTE!

SIN COMPRIMIR) DE 1 PULGADA ( 25,4 MM)DE PROFUNDIDAD

(

ma, deberá tener una superficie protegida de al menos 6 pies (1,828 m) a ambos lados así como en el extremo final.

oit public constitue un usage abusif du pr

IMPORTANT!

CONSIGNES DE SÉCURITÉ SUPPLÉMENT

AIRES

oduit.

uctur

es en

MATÉRIAUX PARTICULAIRES ÉPAISSEUR1 RECOMMANDÉE (NON COMPRIMÉE) IN. (MM)

Paillis de bois 9 po (229 mm)

Paillis d’écor

Copeaux de bois unifor

Ces valeurs sont tirées du guide de la CPSC. Les unités Swing•N•Slide n’ont pas fait l’objet d’essais indépendants afin de déter

Pour que l’installation soit adéquate, le matériau amor

l’installation sur un minimum de 6 pi (1,828 m) à partir du pourtour de l’unité ou des composants les plus éloignés. Par exemple, une glissoire qui se prolonge au-delà de la plateforme doit être entourée d’une surface de protection d’au moins 6 pi de chaque côté ainsi qu’à l’extrémité. En ce qui concerne les balançoires, la zone de protection doit couvrir au

moins 14 pi (6 m) autant devant que der

ce filamentée 9 po (229 mm)

Sable fin 12 po (305 mm)

Gravier fin

tisseur doit r

e la balançoire lorsque celle-ci est immobile.

rièr

mes

ecouvrir entiér

12 po (305 mm)

12 po (305 mm)

miner l’épaisseur r

ement la base horizontale des unités d’escalade. La surface de protection doit entourer

ecommandée des matériaux.

3

Page 4

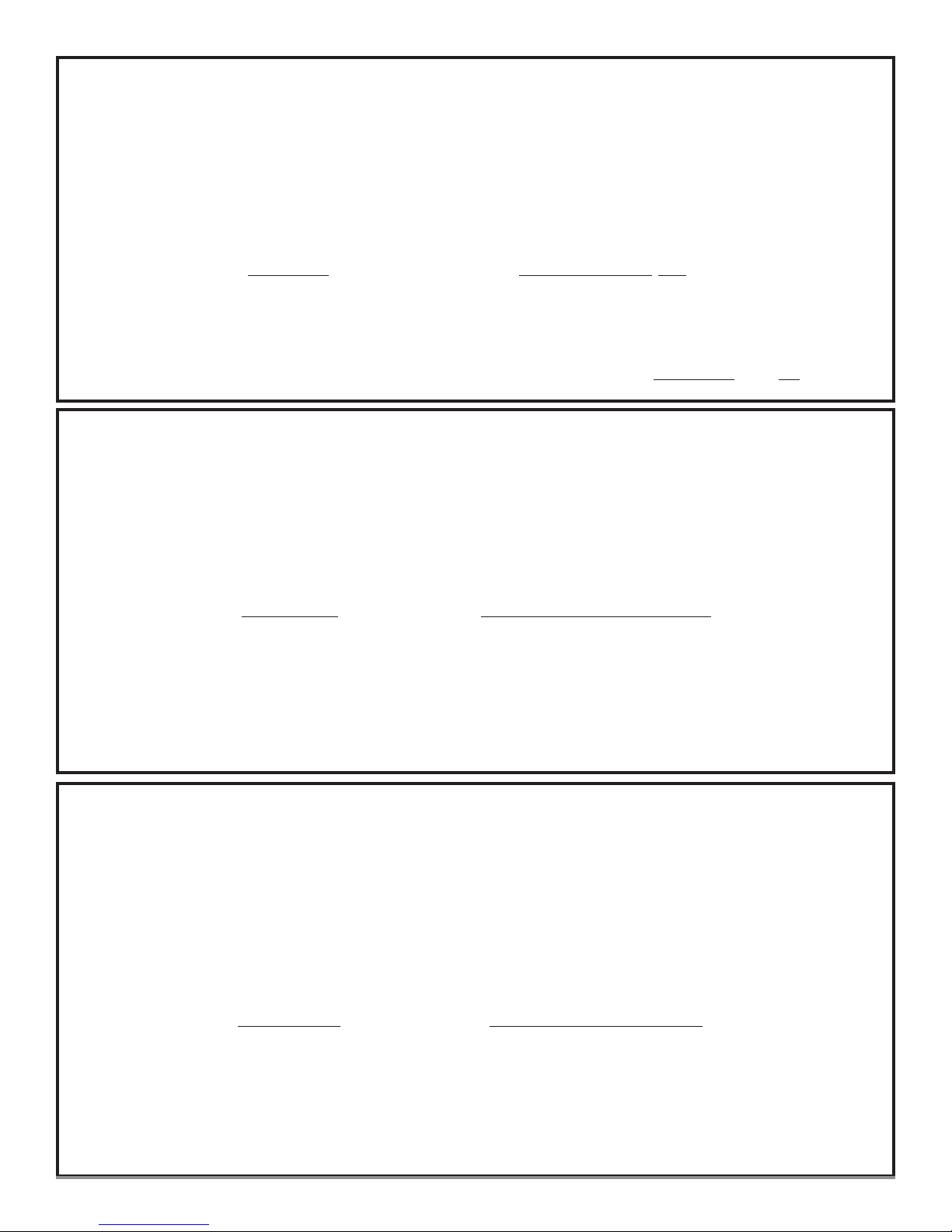

PB 8242 -PB 8244

KIT CONTENTS

TOOLS REQUIRED

ELECTRIC DRILL

TAPE MEASURE

(2) 1-3/4'' panhead screws

(2) 1/2'' panhead screws

1/2" SOCKET & WRENCH

SAFETY GLASSES

& DUST MASK

PHILLIPS BIT

(6) T- nuts

HAMMER

CARPENTER'S SQUARE

(2) 5/16'' flat washers

(105) 2" lag screw

(34) 1-1/4'' screws

(44) 1-1/2'' screws

(224) 2-1/2'' screws

(2) 3-1/2'' Bolts

(2) 1/4'' flat washers

(7) 1'' Truss Screw

4

4

(6) Tarp Washers

(4) Bottom Beam Clamps

(slotted)

Page 5

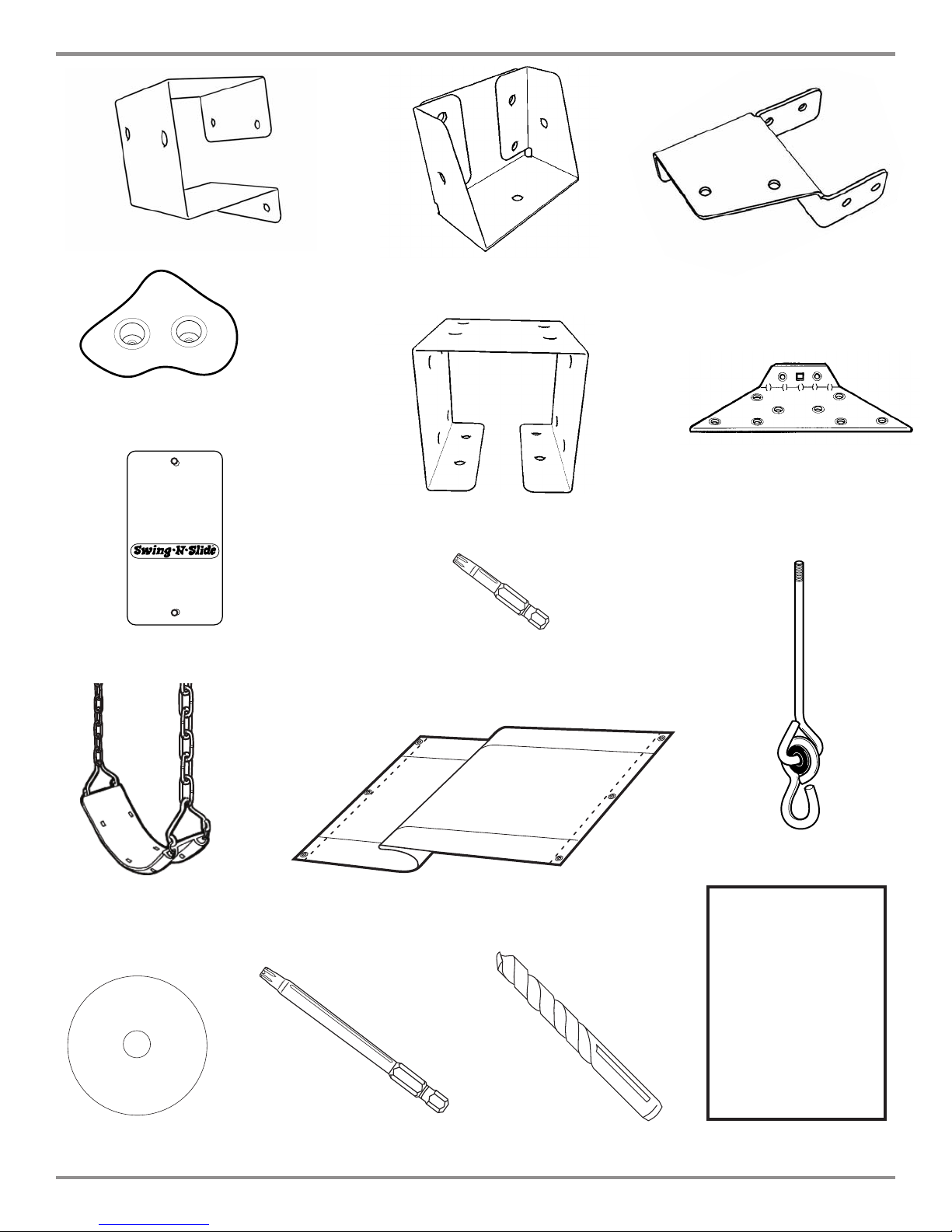

PB 8242-PB 8244

THIS PRODUCT IS

I

NTENDED FOR USE

BY CHILDREN FROM

A

GES 2-10 YEARS

For Home / Residential

Use ONLY

1212 Barberry Drive

Janesville, WI 53545

1-800-888-1232

www.swing-n-slide.com

BLACK

R

(4) Shelf-Loc

(8) Climbing Rocks

With Hardware

(1) Name Plate

(2) Split Beam bracket

(8) Cup-Loc

(2) EZ Frame Brackets

(8) Wrap-Loc

(1) T20 Torx® Bit

(2) Swing Seat

weight limit: 115 lbs.

(1) Instructional DVD

(1) T30

orx® Bit

T

(1) Canopy

5

5

3/8" DRILL

BIT (5'' Min.)

(4) Swing Hangers

PB 8242

PB 8244

Plan

(1) Plan

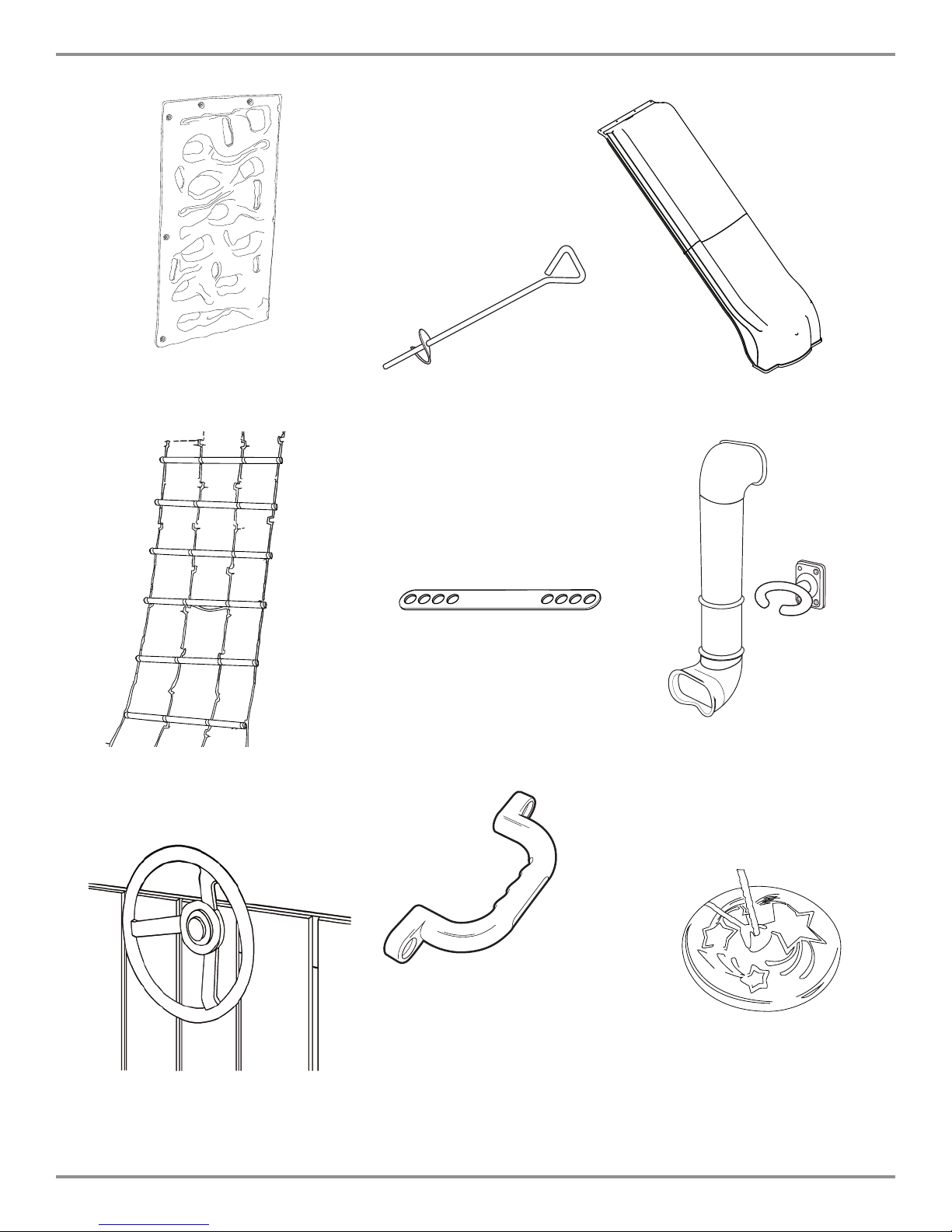

Page 6

PB 8242 -PB 8244

(1) Cliff Climber

(1) Pirate's Ladder

with hardware

(4) Anchor-It

With Hardware

(4) Anchor-It Straps

(1) Summit Slide

with hardware

(1) Periscope

With Hardware

(1) Steering Wheel

With Hardware

(1) Safety Handle

6

6

(1) Disc Swing

ith Hardware

W

Page 7

(1) 2'' x 4'' x 40-1/2''

(3) 2'' x 4'' x 47-1/2''

(2) 5/4'' x 4'' x 20-3/4''

(1) 5/4'' x 4'' x 17''

(1) 5/4'' x 4'' x 46-1/2''

(14) 5/4'' x 4'' x 47-1/2''

(6) 5/4'' x 6'' x 30''

(9) 5/4'' x 6'' x 40-1/2''

(11) 5/4'' x 6'' x 47-1/2''

(4) 4'' x 4'' x 39-3/4''

(1) 4'' x 4'' x 47-1/2''

(2) 5/4'' x 4'' x 34''

PLASTIC COATED LUMBER

(9) 4'' x 4'' x 96''

NOTE: (1) Swing Beam and (1) Accessory Board have pre-drilled holes.

PB 8242-PB 8244

Board List

7

7

Page 8

PB 8242 -PB 8244

How to select the correct fastener

Use these 3 pictorial guides to help select the correct fastener(s) for the

lumber attachment you are making. Each diagram will highlight the correct

number of fasteners to use, and where to attach them.

5/4'' Boards to 4'' x 4''

(3) 2-1/2'' screws

Apply 2 1/2" screws to the 2"x4" boards

when attaching to 4"x4" uprights.

5/4'' Boards to 5/4'' Boards

(2) 1-1/2'' screws

Use 1-3/4" screws when mounting 5/4"

boards to 5/4"x4" boards.

8

8

Page 9

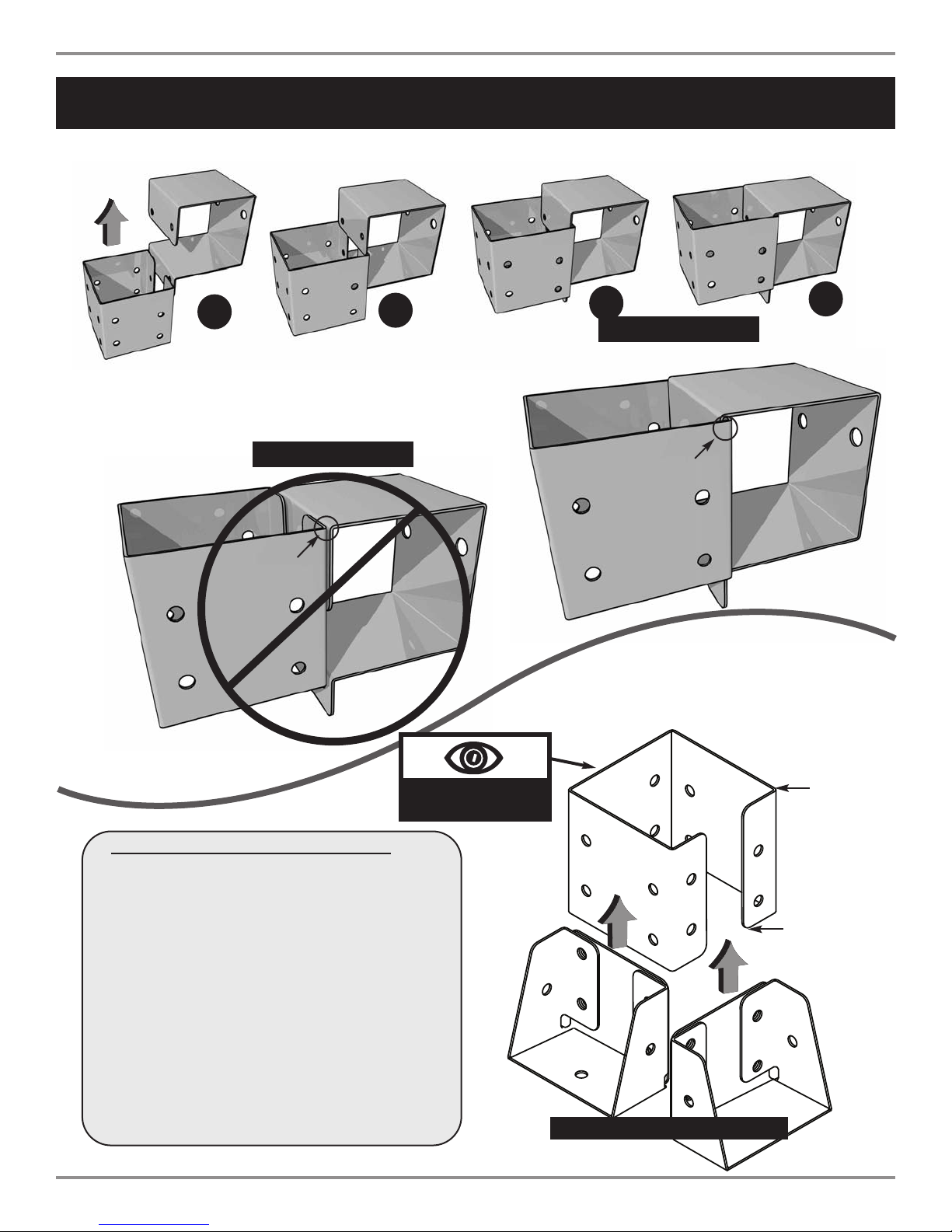

PB 8242-PB 8244

Understanding how the Bracket System Works

Shelf-Loc Bracket

Wrap-Loc

1

Example of a Shelf-Loc bracket connection.

2

3

WRONG!

rackets NOT

b

interlocked!

CORRECT!

Brackets

''clipped''

4

Look for ''TOP'' stamp on

bracket for cor

Introduction to the Bracket system

YS

A

W

AL

1.

2. Brackets ''clip'' to each other. NEVER position in

a non-interlocking position.

Use 2'' lag scr

ews on all brackets.

Example of a Cup-Loc bracket connection.

rect orientation.

Wrap-Loc

Cup-Loc

TOP

GAP

Top of bracket

Bottom of bracket

(Hole locations close to bottom)

Brackets Clip Together

9

9

Page 10

PB 8242 -PB 8244

A

BEND

WRAP

BRACKETS

TO FIT

AROUND

4'' x 4''s

AS

SHOWN

IN

A&B

B

Repeat 4x

Fig. 2

(4)

2'' lag screws

Per Bracket

43-1/4''

4'' x 4'' x 96''

REMEMBER: Brackets are inter-locking. Cup-loc will clip

and secure into the Wrap-Loc as shown below.

Fig. 1

2'' Lag screw

x 8 (4 each bracket)

A. Frame Construction

1. Measure and position brackets on (4) 4'' x 4'' x 96’’ as shown in (Fig.1),

Fig (2).

10

10

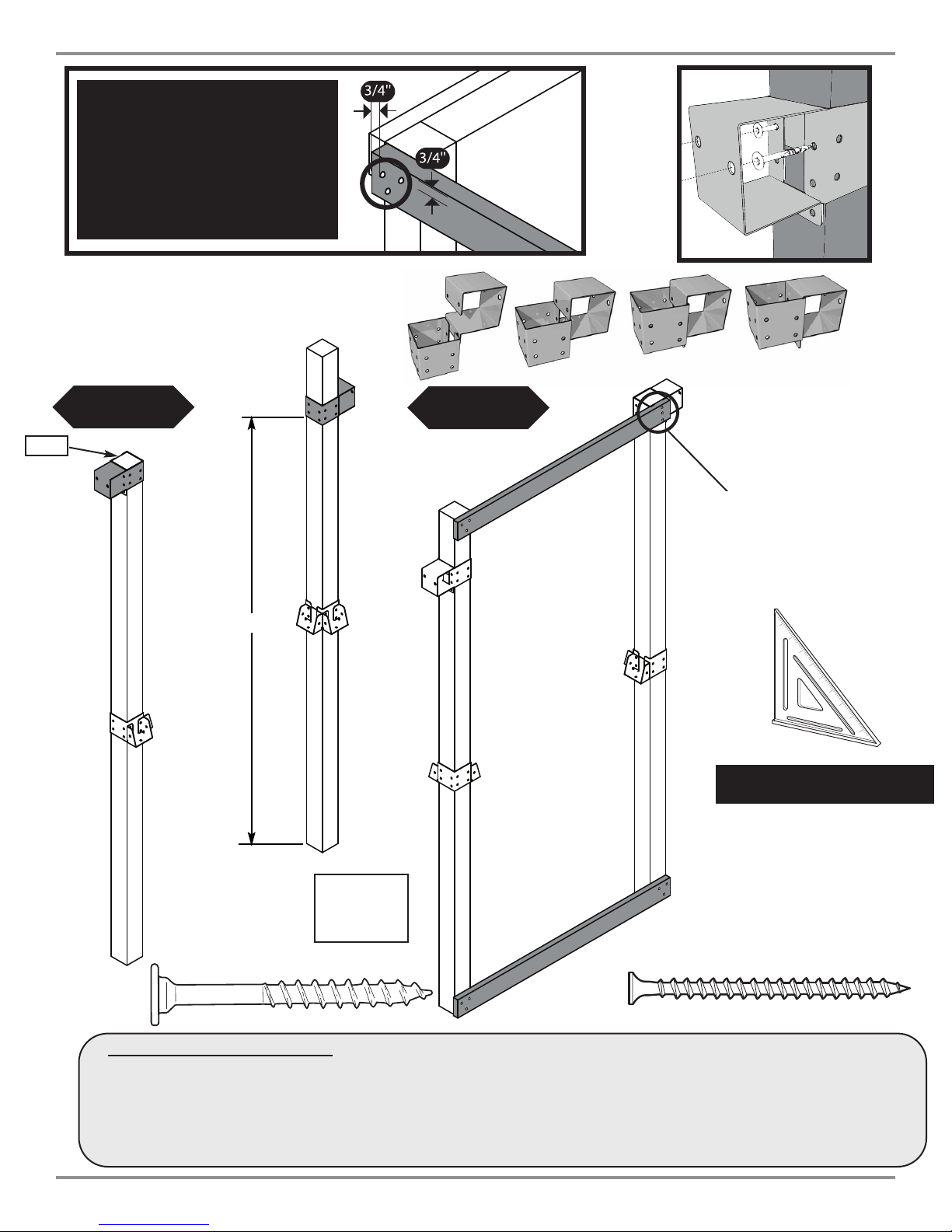

Page 11

•WARNING•

Avoid splitting your

lumber by offsetting

your screws at least

3/4’’ from edge.

Frame 1 Construction

(2)

2'' lag screws

Per Bracket

PB 8242-PB 8244

GAP

Fig. 3

82-1/2''

Fig. 4

5/4'' x 4'' x 47-1/2

''

Screws must be

vertically aligned to pass

through the gap in the

Wrap Loc Brackets.

Double check to make

sure structure is square

Frame 1

2'' Lag screw

A. Frame Construction cont.

1. Using two (2) 4'' x 4'' x 96'' fr

2. Attach upper and lower 5/4'' boar

FLIP

FRAME

OVER

om

(Fig. 2), measur

ds as shown in

(3)

Frame 1

5/4'' x 4'' x 47-1/2''

2-1/2''

screws

per joint

2-1/2'' screw

e and position brackets on 4'' x 4'' x 96’’ as shown in

(Fig. 4)

11

11

(Fig. 3).

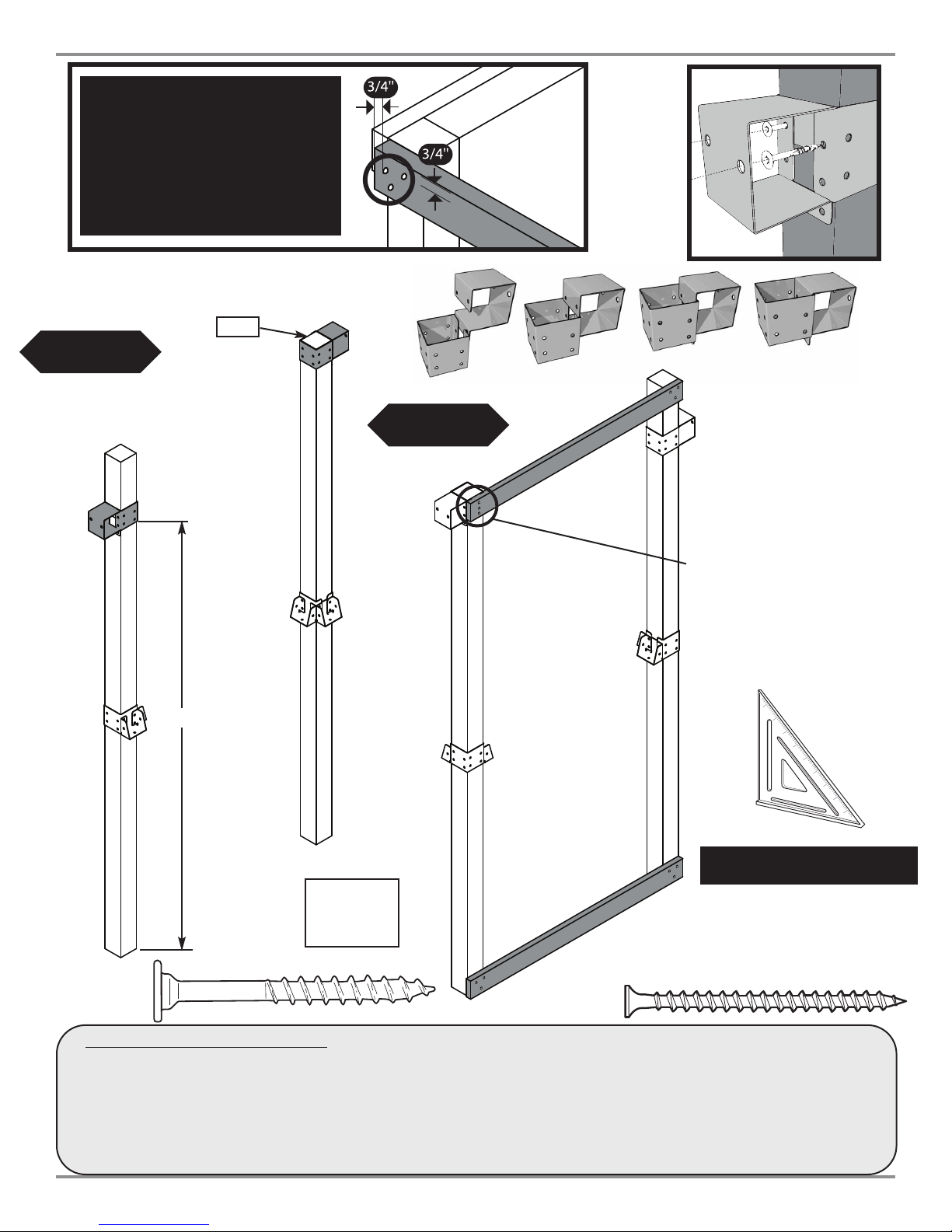

Page 12

PB 8242 -PB 8244

•WARNING•

Avoid splitting your

lumber by offsetting

your screws at least

3/4’’ from edge.

Frame 2 Construction

GAP

Fig. 5

(2)

2'' lag screws

Per Bracket

Fig. 6

82-1/2''

Frame 2

FLIP

FRAME

OVER

(3)

2

-1/2''

screws

per joint

5/4'' x 4'' x 47-1/2''

Frame 2

5/4'' x 4'' x 47-1/2''

Screws must be vertically

aligned to pass through the

gap in the Wrap Loc Brackets.

Double check to make

sure structure is square

2'' Lag screw

A. Frame 2 Construction cont.

1. Using two (2) 4'' x 4'' x 96'' from (Fig. 2), measure and position brackets on 4'' x 4'' x 96’’ as shown in (Fig.5).

2. Attach upper and lower 5/4'' boards as shown in (Fig. 6)

12

12

2-1/2'' screw

Page 13

PB 8242-PB 8244

Fig. 7

5/4'' x 4''

x 47-1/2''

(3)

2-1/2''

screws

per joint

Fig. 8

5/4'' x 4'' x 47-1/2''

Frame 1

5/4'' x 4'' x 47-1/2''

2-1/2'' screw

A. Frame Construction cont.

1. Install 5/4'' boar

2. Install Frame 2 as shown in (Fig. 8).

ds as in

(Fig. 7).

Frame 1

Double check to make

sure structure is square

(3)

2-1/2''

screws

per joint

Frame 2

13

13

Page 14

PB 8242 -PB 8244

Fig. 9

(4) 4'' x 4'' x 39-3/4''

Fig. 9a

2'' Lag screw

x 3

A. Frame Construction (cont.)

1. Install 4'' x 4'' beams as shown in (Fig. 9).

2. Install lag screws at each corner location as

shown in (Fig. 9a)

14

14

Page 15

Fig. 10

PB 8242-PB 8244

Fig. 10a

5/4'' x 6'' x 40-1/2''

(2)

2-1/2''

s

crews

per joint

5/4'' x 6'' x 40-1/2''

2'' x

4'' x 40-1/2''

19-1/2''

(

2)

2-1/2''

screws

per joint

2-1/2'' screw

B. Install Deck Boards

1. Install (2) 5/4'' x 6'' x 40-1/2'' deck boards as shown in (Fig. 10).

2. Attach 2'' x 4'' x 40-1/2'' to deck boards using 2-1/2'' screws as shown in (Fig. 10a).

15

15

Page 16

PB 8242 -PB 8244

(6) 5/4'' x 6'' x 47-1/2''

(2)

2-1/2''

s

crews

per joint

Fig. 11

B. Install Deck Boar

ds

1. Install (6) additional 5/4'' x 6'' x 47-1/2'' deck boards to structure as shown (Fig. 11).

2. Use two 2-1/2'' scr

ews at center and each end of deck boards.

Note: Screws at center will attach to center support.

2-1/2'' screw

16

16

Page 17

Fig. 12

PB 8242-PB 8244

C. Install Upper Rail Boards

5

''

x 47-1/2

'

5/4'' x 4'

0''

3

5/4'' x 4'' x 47-1/2''

(3)

2

-1/2''

screws

per joint

/4'' x 4'' x 47-1/2''

5/4'' x 4'' x 47-1/2''

1. Install 5/4'' boards as shown in (Fig 12).

Fig. 13

2-1/2'' screw

D. Install Lower Rail Boards

1. Install lower rail support as shown in (Fig 13).

17

17

(5)

2-1/2''

screws

5/4'' x 4'' x 20-3/4''

5/4'' x 4'' x 47-1/2''

5/4'' x 4'' x 47-1/2''

5/4'' x 4'' x 20-3/4''

(6)

2-1/2''

screws

per board

(5)

2-1/2''

screws

Page 18

PB 8242 -PB 8244

Tip: Flex brackets to make installation of

4'' x 4'' easier

Fig. 15

Approx. 1/4''

Fig. 16

Fig. 14

4'' x 4'' x 47-1/2''

2'' Lag screw

x 4

F. Install Accessory 4x4

1. Work 4'' x 4'' into brackets as shown in (Fig. 14)

and (Fig. 15).

2. Secure brackets (Fig. 16).

18

18

Page 19

H. Swing Beam Drill Locations

3-1/2''

10-1/2''

10-1/2''

24-1/2''

33-1/2''

47-1/2''

58''

63-1/2''

93-1/2''

14''

9''

14''

10-1/2''

5-1/2''

30''

96''

DISC SWING

MOUNTS HERE

1. Identify your Swing Beam by finding the

predrilled holes as pictured in (Fig. 17)

Tap T-nut into swing beam at locations shown.

2.

PB 8242-PB 8244

Fig. 17

19

19

Page 20

PB 8242 -PB 8244

(4) 1-1/4'' screws

Swing Hanger

Use Screwdriver to aid in tightening

Bottom Beam Clamp

t-nut

Hammer

3/8'' hole

Fig. 18

T-nut

I. Swing Hanger Assembly

ap t-nut into 3/8’

1. T

2. Place a bottom beam clamp over the swing hanger as shown in (Fig. 18)

3. Insert the swing hanger into the beam and thread it into the T-nut until it is flush or near flush with the top of the

-nut. A screwdriver may be used to twist the hanger

T

4. Use (4) 1-1/4'' screws to secure beam clamp.

5. Check hanger to ensure it does not spin.

6. Repeat for all swing hangers.

’ hole as shown in

(Fig. 18)

(Fig. 18). Orient swing hanger as shown in (Fig 18).

20

20

Page 21

Fig. XX

Fig. 19

Align the edges of the 4" x 4" legs

with the edges of EZ Frame Bracket

(8) 2-1/2’’ Screws

PB 8242-PB 8244

. A-Frame Assembly

J

ayout 4'' x 4’’s and 2'' x 4’’ as

1. L

shown in

2. Allign EZ Frame Bracket with face of

4’’ x 4’’s.

3. Secure EZ Frame Bracket with (8)

2-1/2’’ screws to 4'' x 4''s making

sure they are flush with each other.

4. Secure 2’’ x 4’’ to 4’’ x 4’’s as

shown in

Flip over and add 2nd bracket.

5.

Repeat steps 2 through 4.

(Fig. 19) and (Fig. 20).

(Fig. 20)

4" x 4" x 96'''

(4)

2-1/2'' screws

47"

2" x 4" x 47-1/2"

EZ Frame Bracket

Fig. 20

4" x 4" x 96''

(4)

2-1/2'' screws

94-1/2"

2-1/2'' screw

21

21

Page 22

PB 8242 -PB 8244

Can

til

eve

r beam

Fig. 21

T-nut

Washer

2-1/2'' screws

Hex Bolt

2-1/2'' screw

K. A-Frame Assembly cont.

1. Attach A-Frame beam to Swing Beam using (2) hex bolts and 4 screws.

2. Tighten hex bolt to flush with top of T-nut. Repeat on other bracket.

22

22

Page 23

PB 8242-PB 8244

L. Swing Beam Assembly.

1. Position Split-Brackets on 4'' x 4'' x 47-1/2''

Fig 22).

(

ith the help of others, lift A-Frame and

2.W

wing Beam Assembly and center onto unit as

S

shown in

3. Secure as shown in (Fig 23).

(Fig. 22)

Fig. 23

22''

Fig. 22

Swing Beam

View from Deck

Swing Beam

2'' Lag screw

x 8 (each bracket)

23

23

Page 24

PB 8242 -PB 8244

Fig. 24

Use 2-1/2'' screws to

secure to 5/4'' x 4'' to 4'' x 4''

(2)

1-1/2'' deck screws

per joint

(5) 5/4'' x 6'' x 47-1/2''

N. Barrier Boar

1. Install 5/4'' bar

the opening.

ds

rier boar

ds evenly spaced in

24

24

1-1/2'' screw

2-1/2'' screw

Page 25

Fig. 25

PB 8242-PB 8244

(2) 5/4'' x 6'' x 30''

(2) 5/4'' x 6'' x 30''

O. Barrier Boards cont.

(2)

1-1/2'' deck screws

p

er joint

1-1/2'' screw

2. Install 5/4'' x 30'' barrier boar

spaced in the opening. See (Fig. 25).

25

25

ds evenly

Page 26

PB 8242 -PB 8244

Fig. 26

1-1/2''

5/4'' x 6'' x 30''

5/4'' x 6'' x 30''

(

2)

1-1/2'' deck screws

per joint

1-1/2''

O. Barrier Boards cont.

3. Install 5/4'' x 30'' bar

shown in

(Fig. 26).

rier spaced to cr

eate an opening as

1-1/2'' screw

26

26

Page 27

Fig. 27

3-1/2''

60''

96''

70''

80''

90''

60''

10''

10''

10''

PB 8242-PB 8244

H. Accessory Beam Drill Locations

1. Identify your Accessory Beam by the predrilled

holes as pictured in (Fig. 27)

27

27

Page 28

PB 8242 -PB 8244

Tip: Flex brackets to make installation of

4'' x 4'' easier

Fig. 28a

Approx. 1/4''

Fig. 28

4'' x 4'' x 96''

Fig. 28b

4'' x 4'' x 96''

2'' lag screws

F. Install Accessory 4x4

ork 4'' x 4'' into brackets as shown in

1. W

(Fig. 28a).

2. Secur

e brackets

(Fig. 28b).

Note: Drill Holes in 4'' x 4''

before mounting

(4)

(Fig. 28),

2'' Lag screw

x 4

3. Attach accessory 4'' x 4'' to base board as shown

in (Fig. 28).

28

28

Page 29

Fig. 29

1. Connect 5/4'' x 4'' x 34''

to center 5/4'' x 6'' fence panel.

(2)

2-1/2'' screws

p

er joint

PB 8242-PB 8244

(3)

2-1/2'' screws

5/4'' x 4'' x 46-1/2''

5/4'' x 4'' x 34''

5/4'' x 4'' x 34''

2. Align 5/4'' x 4'' x 34''

with opposite 5/4'' x 4'' x 34''

2-1/2'' screw

S. Roof Support.

1. Install 5/4'' x 4'' boar

29

29

ds as shown in

(Fig. 29).

Page 30

PB 8242 -PB 8244

Fig. 30

T. Install Tarp.

1. Install canopy as shown in (Fig. 30)

2. Secure canopy in six locations (Fig. 30a).

30

30

Fig. 30a

1-1/4'' screw

Page 31

Fig. 31

PB 8242-PB 8244

U. Install Protective Barrier Board

1. Secure protective 5/4'' barrier board as shown in (Fig 31).

5/4'' x 4'' x 47-1/2''

30''

2-1/2'' screw

(3)

2-1/2'' screws

31

31

Page 32

PB 8242 -PB 8244

Fig. 32

(7) 5/4'' x 6'' x 40-1/2''

(2)

2

-1/2'' screws

p

er joint

Rock Wall Assembly.

(2) 2'' x 4'' x 47-1/2''

2-1/2'' screw

Fig. 32a

(3)

2-1/2'' screws

per joint

1. Assemble Rock Wall as shown in (Fig. 32). Make sure to space the 5/4'' x 6'' boards as evenly as possible.

2. Mount Rocks to wall in a pattern that will allow your child to access the deck easily. Mount rocks per attached

instructions.

3. Attach the Rock Wall to the unit as shown in (Fig. 32a).

Climbing Rock Installation

Mark locations of Climbing Rocks on the

1.

Fig. 32b

(2)"T" nuts

Climbing Wall in a pattern that will easily

allow your child to climb to the deck

. Make

sure the bolt hole locations are clear of wall

supports before drilling.

2.Drill holes through the wall at the desired

locations using a 3/8" drill bit. Install Climbing

Rocks as shown in (Fig. 32b).

3/8" Holes

3. Make sure the Climbing Wall and Climbing

Rock connections are secure before allowing

any children to play on the Climbing Wall.

(2) 1-1/2'' Hex Head Bolts

Hold (rock)

(1) Loc W

(1) Flat Washer per bolt

asher per bolt

WARNING:

Verify Rock Hardware BEFORE Drilling Holes

32

32

Page 33

PB 8242-PB 8244

Fig. 33

W. Slide Installation.

1. Assemble two piece slide by bolting

together at 11 locations using

(1) 5/16'' x 3/4'' head bolt,

(1) 5-16'' loc-nut and

(2) 5/16'' flat washers at each location.

See (Fig. 33).

2. Position slide to determine proper location

for stake.

3. Drive wood stake into ground leaving 2''

exposed.

4. Secure the slide bottom to the stake using

(2) 1-1/4'' deck screws. (Fig. 33a).

5. Attach slide to unit as shown in

(Fig. 33b).

Fig. 33a

Fig. 33b

(

2)

1-1/4'' screws

per joint

5/4'' x 4'' x 17''

2'' Above Ground

33

33

(4)

1'' Truss Screw

Use truss head screws

to secure slide to deck.

Page 34

PB 8242 -PB 8244

Fig. 33c

(5)

2'' Lag screw

W. Cliff Climber Installation.

1. Attach Cliff Climber to tower at the 5

locations where holes are drilled through

the Cliff Climber on the side & top.

2. Attach Cliff Climber to the bottom rail

through 3 holes in the bottom lip as

shown in

(Fig. 33c).

(3)

1'' Truss Screw

Use truss head screws

to secure climber to unit.

34

34

Page 35

PB 8242-PB 8244

Fig. 34

Fig. 35

NEVER

hang a swing seat by a

partial link of chain! Remove and

discard partial links.

X. Swing Seat Assembly.

. Hold the swing seat vertically and insert uncoated chains through

1

he channels on the bottom of the swing seat. Note:A coat

t

anger may be used to help pull chain through the swing seat.

h

One full link should show at each end of the seat

2. Place one covered chain onto each harness so that it fits at the top

of the V-hanger. Insert uncoated chains to bottom vinyl hooks of

V-hanger.(Fig. 36). Crimp harness end closed.

CAUTION: It is important that you crimp harness

ends completely closed before using (see Fig. 36).

Place end of harness with hooks on a hard surface and force

hooks closed with a hammer or squeeze closed with a pliers

until parts are touching.

cause deep cuts.

3. Hang the chains from the nylon bushing swing hangers. Crimp the

hook opening closed with a pliers to secure the chains to the

swing hangers

crimped and secure before using swing seat.

(Fig. 37). Make sure all connections are tightly

WARNING: Open hooks can

(Fig. 34).

Fig. 36

Fig. 37

35

35

Page 36

PB 8242 -PB 8244

Fig. 38

Anchor-It

Flat Washer

metal strap

1-1/2"

lag bolt

Anchor-It

Y. Anchor-It Installation.

Instructions for Anchoring Swing•N•Slide Activity Centers

1. Determine the final location of your activity center.

2. Place the Anchor-It stakes adjacent to the base and near the corners of your activity center (at the bottom of the

legs on swing sets) and twist the auger-style stakes into the ground until only the loop is exposed.

3. Place the metal strap through the loop of the Anchor-It stake and secure it to the unit with a lag screw and

washer as illustrated to the right. Note: Attach the strap to the unit with as little play as possible using whatever

holes in the strap that work best.

36

36

Page 37

Pirate’s Ladder

Pirate’s Ladder

Pirates Ladder.

1. Bolt Pirates Ladder to top 4'' x 4'' support at 4 locations

as shown using (4) 3/8'' loc nuts and (4) 3/8'' flat

washers (Fig. 39).

Note: Refer to (Fig. 27) for accessory arm placement.

Fig. 39a

PB 8242-PB 8244

Fig. 39

3. Using two r

Pirate's Ladder rope. Tap two staples in place

appr

4'' x 4''. Then thr

Double the rope back on itself and through the first

staple. Pull the rope tight and secure in place by

pounding staples in place. See

ope staples to secur

oximately 1'' apar

ead the r

t. Wrap the rope under the

e the bottom of each

ope thr

ough both staples.

(Fig. 39b).

2. Attach bolt covers over loc nuts at all four locations

using (2) 1-1/4'' deck screws each, as shown in

(Fig. 39a).

Fig. 39b

4'' x 4'' x 96''

1''

4. Secure end of each rope to 4'' x 4'' using supplied

rope staples.

3737

37

1''

Page 38

PB 8242 -PB 8244

Disc Swing / Safety Handle

Disc Swing / Safety Handle

INSTRUCTIONS

Attach the rope to the swing beam by slipping the eye bolt

through the hole and secure it with a 3/8" flat washer and loc

nut. Place a bolt cover over the exposed bolt end and secure it

using two 1-1/4” screws as shown in

(Fig. 1).

Fig. 1

1-1/4” screws

Bolt Cover

Loc Nut

Washer

swing beam

Fig. 2

washer

1 - 3/4

Panhead

screw

11"

Deck Surface

V. Safety Handles.

1. Mount safety handle in the Cliff Climber opening

appr

2. Refer

38

38

oximately 11'' above the deck sur

ence

(Fig. 33c) for Clif

f Climber assembly

face

(Fig. 2).

.

Page 39

NSTRUCTIONS:

I

1. Choose a desired location for the steering wheel

and drill a 3/8" diameter hole through the lumber.

NOTE: If lumber is greater than 2" in depth, you

will need to counterbore the hole appropriately.

2. Mount steering wheel to climbing unit as indicated

in (Fig. 1).

3. Snap steering wheel cap into place

(Fig. 1).

Fig. 1

PB 8242-PB 8244

Steering Wheel

Steering Wheel

Carriage Bolt

flat washer

loc nut

steering wheel cap

spacer

Periscope

Periscope

Installation Instructions:

1. Position mounting bracket in desired location as indicated.

2. Attach mounting bracket to the unit using four mounting

scr

ews provided.

3. Insert the Periscope into the mounting bracket as shown.

Note: The periscope should be inserted between the collars.

collar

collar

39

39

Page 40

Questions???...

Call our Customer Service Department

at 1-800-888-1232

© PlayCore Inc. 2007 Printed In USA LA 5596

Loading...

Loading...