Page 1

STACK-AND-SHRED200X&200XL

™

SHREDDERS

start here

démarrez ici

empieza aquí

comece aqui

Page 2

2min

1

2

Page 3

3

4

5

6

7

**

Page 4

Page 5

STACK-AND-SHRED200X&200XL

SHREDDERS

English instruction manual 6

Francais manuel d’utilisation 14

Español manual de instrucciones 22

Português manual de instruções 30

™

Page 6

English

autofeed technology

The Stack and Shred 200X/200XL has been designed to automatically shred up to 200 sheets

from the auto-feed chamber and up to 7 sheets through the manual feed slot. The auto-feed

mechanism has been designed to handle paper fastened with staples and paper clips and to only

pull a few sheets of paper into the cutting mechanism to minimise the risk of paper jams.

To guard against injury, the following basic safety precautions must be observed in the set-up of this

product.

• Ensure the machine is plugged into an easily accessible power outlet, and ensure the cable is not

likely to trip up a passer by.

• Any attempt to repair this unit by unqualied personnel will invalidate the warranty. Please return to

supplier.

• Unplug your shredder before moving it or when it is not in use for an extended period of time.

• Do not operate with a damaged power supply cord or plug, after it malfunctions, or after it has been

damaged in any manner.

• Do not overload electrical outlets beyond capacity as this can result in re or electrical shock.

• The socket-outlet should be installed near the equipment and shall be easily accessible.

• Do not alter the attachment plug. The plug is congured for the appropriate electrical supply.

• Do not use near water.

• Do not use aerosol dusters or cleaners.

• Do NOT spray anything into the shredder.

• Do NOT load the autofeed chamber with junk mail, magazines, bound documents etc.

Although this shredder has been designed to comply with UL 60950-1 EN 60950-1 safety standards

including the “probe accessibility tests”, do not operate the shredder near children or pets.

6 register this product online at www.accobrands.com

Page 7

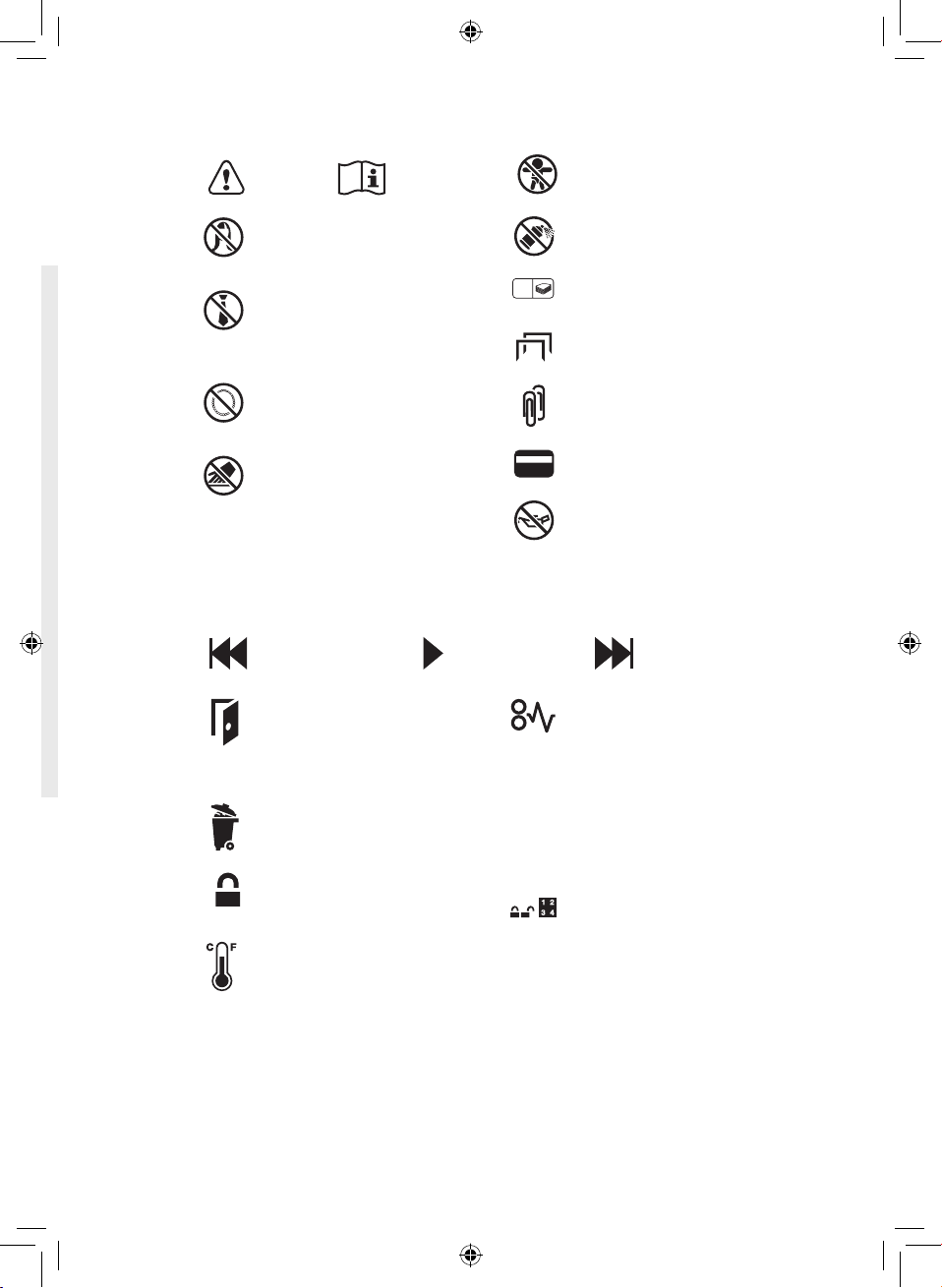

warning symbols

Safety First

English

This means keep children away

from shredder.

This means you should be careful

because long hair can become

entangled in the cutting head.

This means be careful of ties and

other loose clothing which could

become entangled in the cutting

head.

This means be careful of loose

jewellery which could become

entangeld in the cutting head.

This means don’t reach into the

feed opening of the cutting head.

control panel and indicators

Auto

Paper Loading Door/Bin Door

Open indicator –

This means either:

• Loading door is open

• Bin is open

Bin Full indicator – This means the

bin is full.

Lock indicator – This means the

paper loading door is locked (during

shredding).

Cool Down indicator – This means

the machine is cooling down.

This means no aerosols.

Sheet capacity of manual feed

7

entry slot.

This means the shredder can

accept small staples.

This means the shredder can

accept small paperclips.

This means the shredder can

accept credit cards.

This means no oil lubrication,

use Swingline oil sheets only.

Continuous Jam BoostReverse

Paper jam indicator – This means

there is a paper jam in the auto feed

chamber.

If this symbol is ashing the

shredder is attempting to clear a

paper jam automatically.

If this symbol is permanently

illuminated red please follow the

instructions under ‘Rare Occasion

of Jamming’.

Loading Door Locking

Mechanism – PIN Password

Buttons – Enter a four digit code

to lock the loading door during

shredding.

STACK-AND-SHRED 200X&200XL™ SHREDDERS 7

Page 8

English

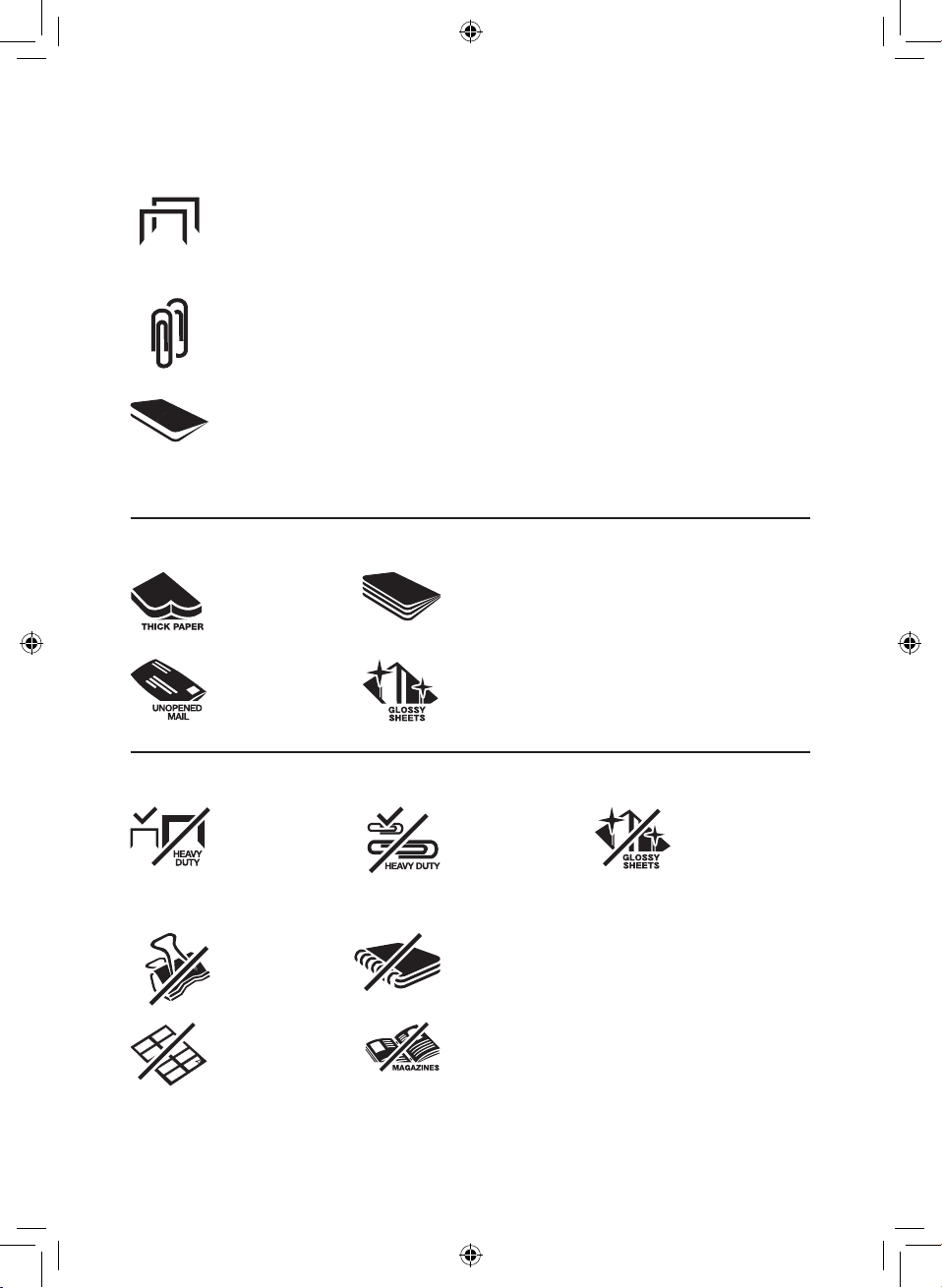

Stack and Shred 200X/200XL shredding capability

Stack and Shred 200X/200XL CAN shred the following:

• 200 sheets

• Stapled paper, 25mm within the corner

• 26/6 and 24/6 or smaller staples

• Small sized paper loaded centrally

• 200 sheets

• Paper clip paper, 25mm within the corner (200XL through manual feed slot ONLY)

• Capable of shredding small/medium paper clips (max. wire thickness = 0.9 mm)

• >80/100gsm paper (through manual feed slot ONLY)

• A3 folded in half max. 2 sheets

• 200 sheets

• 80 gsm paper

- Letter and Legal

- A3 single sheet folded in half to make A4

Stack and Shred 200X/200XL CAN shred (through the manual feed slot):

Thick paper or

card.

Unopened mail

(e.g. junk mail).

Multiple folded

sheets (e.g. A3

sheets folded in

half).

Glossy paper or

a sheet covered

with print on both

sides.

Stack and Shred 200X/200XL CANNOT shred the following:

Heavy duty

staples. Check

the staple leg

length is not

greater than

6mm.

Bulldog clips

Adhesive labels.

8 register this product online at www.accobrands.com

Large clips.

Check the length

of the paperclip

is not longer than

32mm.

Bound

documents

Magazines or

other documents

bound by multiple

staples or clips.

Plastic sheets,

laminated

documents,

plastic folders.

Page 9

bin or loading door open safety function

As a safety precaution, if the bin or loading door is opened during shredding, the shredder

will stop and the bin full indicator will illuminate ( ).

intelligent help

1 In the unlikely event of the shredder jamming, the Stack and Shred 200X & 200XL will stop

shredding, and the jam icon will blink in orange.

2 The shredder will illuminate the FWD (

necessary to clear the jam.

3 If the jam cannot be intelligentally cleared, the jam icon (

point open the auto feed chamber to clear any jammed material.

) and REV (

) buttons in the sequence

) will illuminate in red. At this

automatic jam clearance

Intelligent Jam Clearance: In the unlikely event of the shredder jamming, the Stack and Shred

200X & 200XL will automatically reverse and forward the engine three times to clear a jam.

During this operation the Paper Jam indicator will ash (

).

** 200XL only

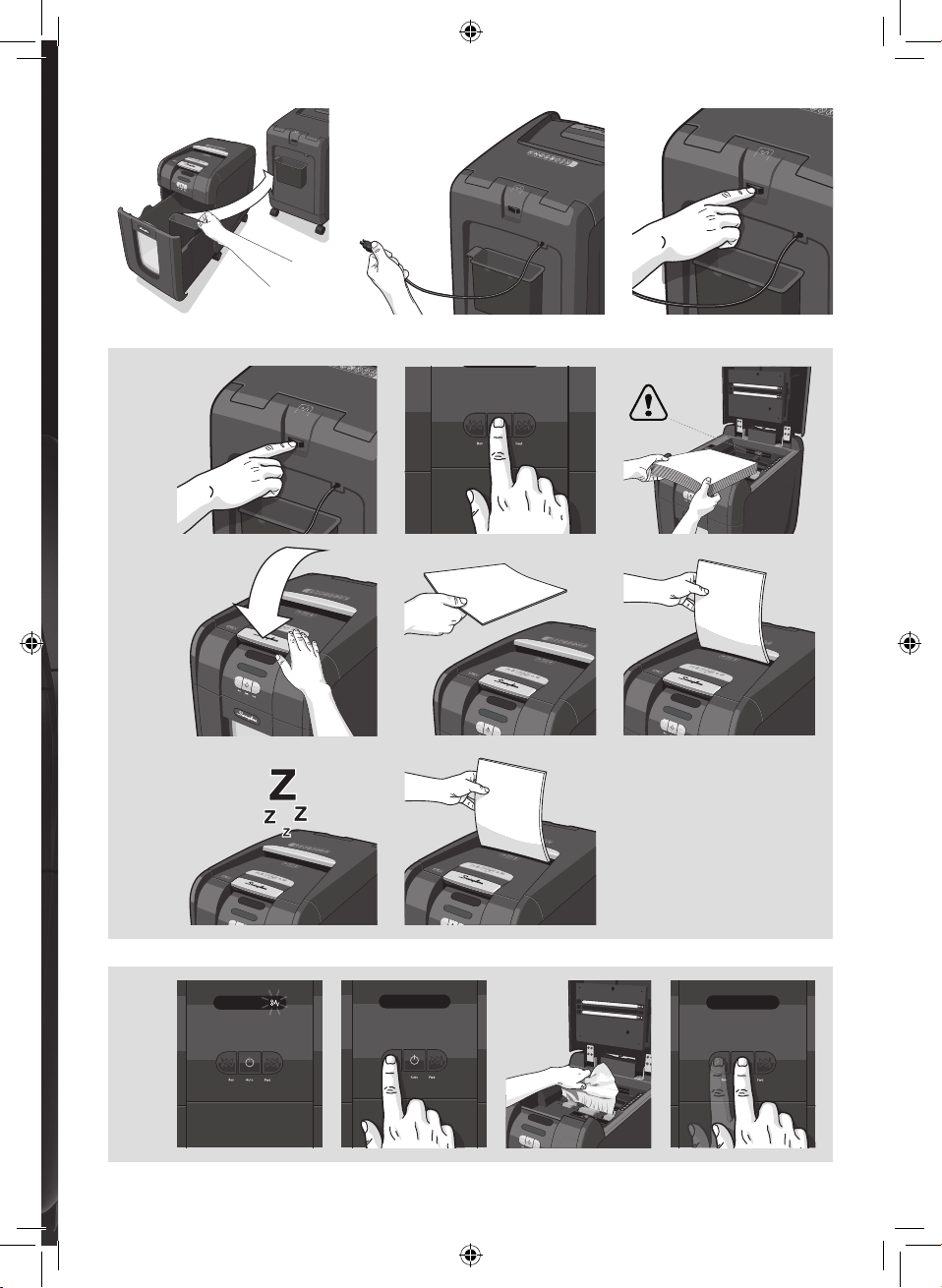

locking the paper loading door

For additional security the paper loading door can be locked during the shredding of condential

material.

To lock shredder:

1

Place documents in tray. Close paper loading door.

2 Press any 4 digits. REMEMBER YOUR CODE!

Shredder unlocks automatically when:

• 4 digit code is re-entered.

• Shredding is complete.

• Shredder is inactive for 30 minutes (but documents remain in tray)

English

STACK-AND-SHRED 200X&200XL™ SHREDDERS 9

Page 10

English

1. operation

1 Unpack the product.

2 Connect the shredder to mains supply.

3 Ensure the ON/OFF button on the back of the machine is in the ON position, which will

illuminate the blue standby symbol (

4 To commence shredding, press the Auto button (

You are now ready to shred.

5 To load the shredder, simply lift the loading door handle to open the loading door and insert

documents. You can open the door further to 90 degrees for easier access if required Load up

to 200 sheets at a time into the feed chamber. Do not ll above the 200 MAX level, this could

damage the shredder.

6 The shredder will start the shredding cycle automatically ONLY after closing the loading door.

If there is still paper in the Autofeed chamber after rst attempt open and reclose the paper

loading door a second time.

200XL only

Attention: If required you can now lock the loading door by entering a 4 digit code (see Locking

the Paper Loading Door section).

7 If you only have up to 7 sheets to shred, you can use the manual feed slot, provided the auto

feed chamber is empty.

8 Insert paper to be shredded into the feed area. The shredder will detect the paper and start

automatically.

9 If the shredder is left in auto mode for more than 2 minutes without being used, the shredder will

automatically turn back to standby mode in order to save power.

10 The shredder will automatically ‘wake up’ from sleep mode when paper is inserted into the

shred mouth or you open the loading door. There is no need to press the Auto button (

).

), which sets the shredder into auto mode.

).

2. reverse function

1 Should you wish to reverse paper out whilst shredding, a reverse button (

your convenience.

2 Reverse the paper out then turn the machine o using the ON/OFF switch at the rear of the

shredder. Remove the paper from the manual feed slot (if being used) or open the loading door,

remove the remaining stack of paper, then pull the jammed paper free of the cutting mechanism.

3 To resume shredding, turn the shredder on using the ON/OFF switch at the rear of the shredder.

Return the switch to the auto position (

10 register this product online at www.accobrands.com

).

) has been tted for

Page 11

English

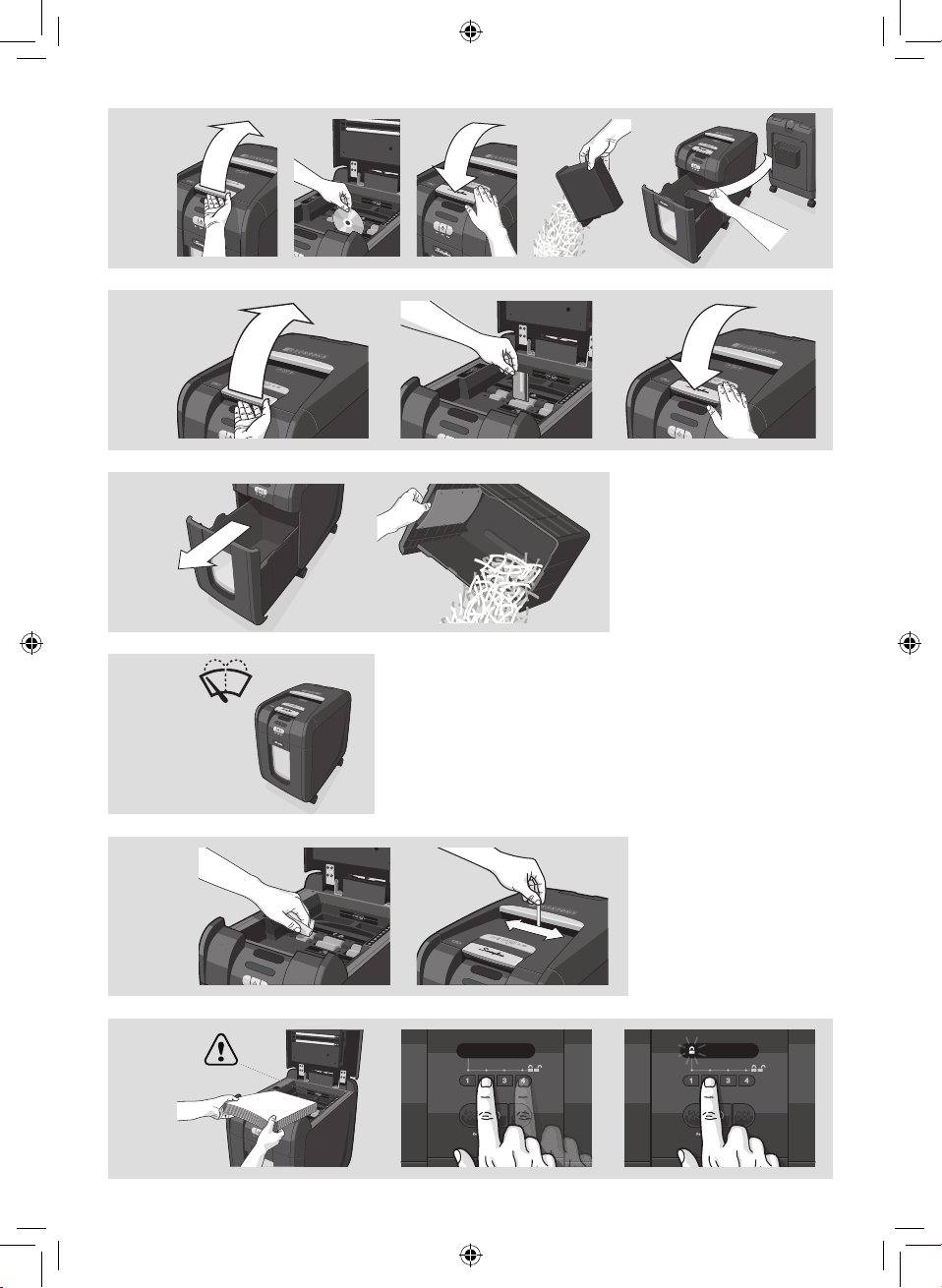

3. CD/DVD shredding

A separate CD/DVD tray is provided to collect the shredded CD/DVD shards, ensure that this is

correctly mounted onto the bin before shredding.

1 Lift up the paper loading door.

2 Always insert CDs/DVDs in the CD/DVD slot. Only shred one CD/DVD at a time.

3 Close the paper loading door.

4 Empty the CD/DVD bin after 8 CDs/DVDs to avoid waste spilling over into the paper waste bin.

5 Remove the CD/DVD tray before recommencing to shred paper.

4. credit card shredding

1 Lift up the paper loading door.

2 Insert the credit card into the roller as shown. Only shred one credit card at a time.

3 Close the paper loading door.

Swingline encourages customers to recycle shredded paper.

Please note that shredded paper cannot be recycled if mixed with credit card shards.

If recycling, please separate shredded paper and credit cards.

5. bin full

The shredder will not function when the bin is full and the bin full symbol ( ) is illuminated.

You should empty the bin.

• Pull open the bin slowly to empty.

• Push the empty bin back into place and press the auto button to resume shredding.

over heating

If the Stack and Shred 200X & 200XL is used continuously for over 10 minutes the shredder may

overheat and the cool down indicator will ash red (

When the shredder is ready to be used the thermometer symbol will no longer illuminate. If the

shredder needs to cool down while shredding, no action is needed. The shredder will automatically

restart shredding paper once it has cooled down after periods of continuous use. All you need to do

is ensure paper is loaded into the chamber and the bin is empty when the machine is cooling down.

). Please allow the shredder to cool down.

6. self-cleaning cutters

After emptying and replacing a full bin, the shredder will run in forward for 4 seconds, stop for

2 seconds and then reverse for 4 seconds to clear away any remaining paper from the cutter

mechanism. This unique ‘self-cleaning’ mechanism is additional jam prevention technology

from Swingline.

STACK-AND-SHRED 200X&200XL™ SHREDDERS 11

Page 12

English

lubrication of the shredder

Only use oil sheets to lubricate. ACCO Brands accepts no liability for product performance or

safety when other types of lubricants are used on any part(s) of this machine. Insert the oil sheet

into the manual feed slot and NOT in the auto-feed chamber. Using an oil sheet in the auto-feed

chamber will contaminate the feed rollers preventing the auto-feed mechanism shredding. Follow

the maintenance instructions if the rollers become contaminated. Do not directly oil the shredder.

7. maintenance

The rollers on the auto-feed mechanism may become dirty over time, please wipe clean with a dry

cloth to maintain maximum product performance.

The auto-start infra-red sensor, located in the paper feed entry-slot, can occasionally become

covered in paper-dust causing the shredder to run despite no paper being fed into the machine.

Switch the shredder o at the rear of the machine and carefully clean the sensor using a cotton-

swab.

service

We recommend these machines are serviced every 6 to 12 months by a Swingline service

engineer – see back of this booklet for the contact details of your local service centre and for

enquiries about maintenance contracts.

shredder accessories

We recommend that a paper waste sack for

recycling shredded paper is used on all models.

Accessory Part Number Box Quantity

Recycling Waste

Sack

Plastic Waste

Sack

1765031

1765016

20 sacks

100 sacks

FCC CLASS B NOTICE

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try to If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment o and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

CANADA CLASS B NOTICE

This Class B digital apparatus complies with Canadian ICES-003

MODIFICATIONS

Any modications made to this device may void the authority granted to the user by the FCC and/or by Industry Canada to operate this equipment.

ACCO is a registered trademark of ACCO Brands.

Copyright © 2013 ACCO Brands. All rights reserved.

Issue August 2013

Fusion is a registered trademark of ACCO Brands.

12 register this product online at www.accobrands.com

Page 13

English

technical specifications

Swingline Stack and Shred 200X/200XL

Sheet capacity:

Manual feed slot

Sheet capacity:

Autofeed chamber

Duty Cycle 10 min ON / 40 min OFF

Run time from cold 14 minutes

Volts / Hz 120V / 60Hz

Amperage 1.2 Amps

Motor Watts 270 Watts

7 sheets (80gsm)

200 sheets (80gsm)

Limited Warranty

Limited 2 year Cutter Warranty for Stack and Shred 200X/200XL Shredder and Limited 2 Year Warranty for all other Parts

ACCO Brands USA LLC, Four Corporate Drive, Lake Zurich, IL 60047-8997 (in Canada, ACCO Brands Canada Inc., 5 Precidio Court, Brampton,

ON L6S 6B7; and in Mexico, ACCO Mexicana, S.A. de C.V. Av. Circuito Industrial Norte #6 Parque Industrial Lerma 52000, Lerma Edo. De México)

(each, respectively, “ACCO Brands”) warrants to the original purchaser that the cutters of this Swingline™ Stack and Shred 200X/200XL Shredder

are free from defects in workmanship and material under normal use and service for a period of 2 years after purchase and all other parts are free

from defects in workmanship and material under normal use and service for a period of 2 years after purchase.

ACCO Brands’ obligation under this warranty is limited to replacement or repair, at ACCO Brands’ option, of any warranted part found defective by

ACCO Brands without charge for material or labor. Any replacement, at ACCO Brands’ option, may be the same product or a substantially similar

product that may contain remanufactured or refurbished parts. This warranty shall be void in the following circumstances:

(i) if the product has been misused,

(ii) if the product has been damaged by negligence or accident, or

(iii) if the product has been altered by anyone other than ACCO Brands or ACCO Brands’ authorized agents.

For warranty execution, please call:

1-800-541-0094 in the USA

1-800-263-1063 in Canada

01-(55)-1500-5700 / 5778 in Mexico

Or go to www.swingline.com.

TO THE EXTENT ALLOWED BY APPLICABLE LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESSED WARRANTIES.

REPRESENTATIONS OR PROMISES INCONSISTENT WITH OR IN ADDITION TO THIS WARRANTY ARE UNAUTHORIZED AND SHALL NOT

BE BINDING ON ACCO BRANDS. TO THE EXTENT PERMITTED BY APPLICABLE LAWS, ANY IMPLIED WARRANTIES (IF APPLICABLE)

ARE LIMITED IN DURATION TO THE DURATION OF THIS WARRANTY. SOME STATES AND JURISDICTIONS DO NOT ALLOW LIMITATIONS

ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. TO THE EXTENT PERMITTED

BY APPLICABLE LAW, IN NO EVENT SHALL ACCO BRANDS BE LIABLE FOR ANY SPECIAL, INCIDENTAL, PUNITIVE, EXEMPLARY,

CONSEQUENTIAL OR SIMILAR DAMAGES, WHETHER OR NOT FORSEEABLE. SOME STATES AND JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF SPECIAL, INCIDENTAL, PUNITIVE, EXEMLARY, CONSEQUENTIAL, OR SIMILAR DAMAGES, SO THE

ABOVE EXCLUSION OR LIMITATION MAY NOT APPLY TO YOU.

FOR CONSUMERS WHO HAVE THE BENEFIT OF CONSUMER PROTECTION LAWS OR REGULATIONS IN THEIR JURISDICTION OF

PURCHASE OR, IF DIFFERENT, IN THEIR JURISDICTION OF RESIDENCE, THE BENEFITS CONFERRED BY THIS WARRANTY ARE IN

ADDITION TO ALL RIGHTS AND REMEDIES CONVEYED BY SUCH CONSUMER PROTECTION LAWS AND REGULATIONS.

To the extent permitted by law, this warranty is not transferable and will automatically terminate if the original product purchaser sells or otherwise

disposes of the product.

This warranty gives you specic legal rights. Other rights, which vary from jurisdiction to jurisdiction, may exist. In addition some jurisdictions do

not allow (i) the exclusion of certain warranties, (ii) limitations on how long an implied warranty lasts and/or (iii) the exclusion or limitation of certain

types of costs and/or damages, so the above limitations may not apply.

STACK-AND-SHRED 200X&200XL™ SHREDDERS 13

Page 14

Français

technologie d’auto-alimentation

Le Stack and Shred 200X / 200XL a été conçu pour détruire automatiquement jusqu’à 200 feuilles

placées dans le compartiment d’auto-alimentation et jusqu’à 7 feuilles par le biais de la fente

d’alimentation manuelle. Le mécanisme d’auto-alimentation a été conçu pour détruire les feuilles

attachées avec une agrafe et un trombone et pour n’introduire que quelques feuilles de papier à la

fois sur le mécanisme de coupe an de réduire les risques de bourrage.

Pour vous protéger contre les accidents, veuillez observer les consignes de sécurité de base

suivantes lors de l’installation de l’appareil.

• Branchez le destructeur dans une prise de courant facile d’accès, en veillant à ce que personne ne

puisse trébucher sur le l.

• La garantie sera annulée en cas de tentative de réparation par du personnel non qualié. En cas de

problème, renvoyez l’appareil au fournisseur.

• Débranchez l’appareil avant de le déplacer ou en cas d’inutilisation prolongée.

• N’utilisez PAS l’appareil en cas d’endommagement de la che ou du cordon d’alimentation, après

un mauvais fonctionnement ou après un endommagement quelconque.

• Ne surchargez PAS les prises électriques au-delà de leur capacité, au risque de causer un incendie

ou de subir un choc électrique.

• L’appareil doit être installé à proximité d’une prise de courant facilement accessible.

• Ne modiez PAS la che. La che est congurée pour une alimentation électrique déterminée.

• N’utilisez PAS l’appareil près de l’eau.

• N’utilisez PAS de bombe aérosol dépoussiérante ou nettoyante.

• Ne pulvérisez AUCUN produit dans le destructeur.

• Ne mettez PAS, entre autres, d’imprimés publicitaires sous enveloppe, de revues ni de documents

reliés dans le compartiment d’auto-alimentation.

Bien que ce destructeur ait été conçu conformément aux normes de sécurité UL 60950-1

EN 60950-1, intégrant les « essais d’accessibilité à l’aide de sondes », n’utilisez jamais le

destructeur à proximité d’enfants ou d’animaux domestiques.

14 enregistrez ce produit en ligne à www.accoeurope.com

Page 15

symboles d’avertissement

Français

La sécurité d’abord

Faites preuve de diligence si vous

avez les cheveux longs car ils

pourraient s’emmêler dans le bloc

de coupe.

Attention aux cravates et autres

vêtements amples qui pourraient

être happés par le bloc de coupe.

Attention aux bijoux qui pourraient

être happés par le bloc de coupe.

Ne mettez pas la main dans la

fente d’alimentation pour saisir des

feuilles.

Gardez le destructeur hors de

portée des enfants.

N’utilisez pas de bombes aérosols.

Capacité de destruction de la fente

7

d’alimentation manuelle.

Le destructeur peut accepter de

petites agrafes.

Le destructeur peut accepter de

petits trombones.

Le destructeur peut détruire les

cartes bancaires.

N’utilisez pas de lubriant

liquide, mais uniquement des

feuilles lubriantes Swingline.

panneau de contrôle et indicateurs du destructeur

Mode automatique

Indicateur Corbeille/Couvercle

de compartiment ouvert –

Il avertit que :

• le couvercle du compartiment

est ouvert

• la corbeille est ouverte

Indicateur corbeille pleine – Il

avertit que la corbeille est pleine

Indicateur de verrouillage – Il

indique que le couvercle du

compartiment est verrouillé

(pendant la destruction).

Indicateur de refroidissement – La

machine est en train de se refroidir.

Indicateur de bourrage – Il

indique l’existence d’un bourrage

de papier dans le compartiment

d’auto-alimentation.

Ce symbole se met à clignoter

lorsque le destructeur essaye

d’éliminer un bourrage

automatiquement.

Si ce symbole reste allumé en

rouge en permanence, veuillez

suivre les instructions données à la

section « Rares cas de bourrage »

Mécanisme de verrouillage du

couvercle du compartiment

– Touches de saisie de code

PIN Saisissez - un code à quatre

chires pour verrouiller le couvercle

du compartiment pendant la

destruction.

Marche avant en continu Marche arrière

STACK-AND-SHRED 200X&200XL™ DESTRUCTEURS 15

Page 16

Français

capacité de destruction de le

Stack and Shred 200X / 200XL

Le Stack and Shred 200X / 200XL PEUT détruire ce qui suit :

• 200 feuilles

• Feuilles agrafées à 25 mm du coin au plus

• Agrafes 26/6 et 24/6 ou plus petites

• Feuilles petit format chargées centralement

• 200 feuilles

• Feuilles avec trombone, à 25 mm du coin au plus

(200XL uniquement via la fente d’alimentation manuelle)

• Trombones petits/moyens (épaisseur maxi du l = 0,9 mm)

• Papier > 80 / 100 g/m

• Feuille A3 pliée en deux – 2 feuilles maxi

• 200 feuilles de papier imprimées d’un côté

• Papier de 80 g/m

- Letter et Legal

- Une seule feuille A3 pliée en deux au format A4

Le Stack and Shred 200X / 200XL PEUT détruire ce qui suit

(uniquement via la fente d’alimentation manuelle) :

Papier épais ou

carton

2

(uniquement via la fente d’alimentation manuelle)

2

Plusieurs feuilles

pliées (p. ex. des

feuilles A3 pliées

en deux)

Du courrier sous

enveloppe

Papier brillant

ou une feuille

imprimée recto/

verso

Le Stack and Shred 200X / 200XL NE PEUT PAS détruire ce qui suit :

Agrafes grande

capacité. Vériez

que l’agrafe ne

fait pas plus de

6 mm de haut.

Pinces

double clip

Étiquettes

adhésives

16 enregistrez ce produit en ligne à www.accoeurope.com

Gros trombones.

Vériez que le

trombone ne

fait pas plus de

32 mm de long

Documents

reliés

Revues ou autres

documents

reliés à l’aide de

plusieurs agrafes

ou trombones

Feuilles en

plastique,

documents

plastiés,

dossiers en

plastique

Page 17

Français

fonction d’arrêt automatique en cas de corbeille

ou couvercle ouvert

Par mesure de sécurité, si la corbeille ou le couvercle du compartiment est ouvert pendant

la destruction, le destructeur s’arrête de fonctionner et l’indicateur s’allume ( ).

rares cas de bourrage

1 Dans le cas improbable de bourrage, le Stack and Shred 200X / 200XL s’arrête de détruire les

documents, et l’icône de bourrage se met à clignoter en orange.

2 La touche de déblocage par marche avant en continu (

(

) s’allument. Appuyez alors, tour à tour, sur la touche allumée jusqu’à l’élimination du

bourrage.

3 S’il est impossible d’éliminer le bourrage ainsi, l’icône de bourrage (

ce moment-là, ouvrez le compartiment d’auto-alimentation an d’enlever les feuilles provoquant

le bourrage.

) et la touche marche arrière

) s’allume en rouge. À

elimination de bourrage automatique

Dans le cas peu probable d’un bourrage, le Stack and Shred 200X / 200XL met automatiquement

le mécanisme de coupe en marche arrière puis avant à trois reprises an de dégager le papier.

L’indicateur de bourrage de papier clignote pendant cette procédure (

).

** 200XL

mécanisme de verrouillage du couvercle

du compartiment

Pour accroître la sécurité, le couvercle du compartiment peut être verrouillé pendant la destruction

de documents condentiels.

Comment verrouiller le destructeur :

1 Placez les documents dans le bac du compartiment papier. Fermez le couvercle du

compartiment.

2 Saisissez 4 chires de votre choix. N’OUBLIEZ PAS CE CODE !

Le destructeur se déverrouille automatiquement dans les cas suivants :

• à la saisie du code à 4 chires

• si la destruction est terminée

• si le destructeur est inactif pendant 30 min (mais que les documents sont toujours dans le

compartiment)

STACK-AND-SHRED 200X&200XL™ DESTRUCTEURS 17

Page 18

Français

1. fonctionnement

1 Déballez l’appareil.

2 Branchez le destructeur à une prise secteur.

3 Vériez que le commutateur marche/arrêt situé à l’arrière de l’appareil est en position de

marche (

4 Pour démarrer la destruction automatique, appuyez sur la touche centrale de mode

automatique (

automatique s’allume. Vous pouvez maintenant commencer à détruire vos documents.

5 Pour ouvrir le couvercle et charger le destructeur, soulevez simplement la poignée du couvercle

du compartiment et insérez les documents. Vous pouvez ouvrir le couvercle à un angle de 90

degrés pour faciliter la manipulation si besoin est. Chargez jusqu’à 200 feuilles à la fois dans le

compartiment d’auto-alimentation. Ne dépassez PAS le niveau MAXIMUM de 200 feuilles au

risque d’endommager le destructeur.

6 Le destructeur se mettra automatiquement à fonctionner UNIQUEMENT si vous avez fermé

le couvercle du compartiment. S’il reste encore du papier dans le compartiment d’auto-

alimentation après la première tentative de destruction, ouvrez et fermez le couvercle du

compartiment une seconde fois.

200XL

Attention ! Si besoin est, vous pouvez maintenant verrouiller le couvercle du compartiment en

saisissant un code à 4 chires (voir la section « Verrouillage du couvercle du compartiment »).

7 Si vous ne voulez détruire que jusqu’à 7 feuilles, vous pouvez utiliser la fente d’alimentation

manuelle à condition que le compartiment d’auto-alimentation soit vide.

8 Insérez les feuilles à détruire dans la fente d’alimentation manuelle. Le destructeur détecte le

papier et lance automatiquement la destruction.

9 Si le destructeur est laissé en mode automatique pendant plus de 2 minutes sans servir, il se

met automatiquement en mode de veille an d’économiser de l’énergie.

10 À l’alimentation de papier dans la fente d’insertion ou à l’ouverture du couvercle du

compartiment, le destructeur passe automatiquement du mode de veille au mode de

fonctionnement. Il est inutile d’appuyer sur la touche de mode automatique (

).

), auquel cas le symbole de mise en veille bleu sur la touche de mode

).

2. fonction marche arrière

1 Si, lors de la destruction de papier, vous souhaitez faire ressortir les feuilles par l’avant, utilisez

la touche marche arrière ( ) mise à votre disposition à cet eet.

2 Faites ressortir le papier par l’avant, puis mettez le destructeur hors tension à l’aide du

commutateur marche/arrêt situé à l’arrière de l’appareil. Retirez le papier de la fente

d’alimentation manuelle (en cas d’utilisation) ou ouvrez le couvercle du compartiment et retirez

les feuilles restantes, puis enlevez le papier du mécanisme de coupe.

3 Pour reprendre la destruction, mettez l’appareil sous tension à l’aide du commutateur marche/

arrêt situé à l’arrière de l’appareil et appuyez sur la touche de mode automatique (

18 enregistrez ce produit en ligne à www.accoeurope.com

).

Page 19

Français

3. destruction de CD/DVD

Le destructeur est doté d’un bac à déchets de CD / DVD séparé pour récupérer les morceaux de

CD / DVD détruits. Vériez que le bac est bien installé sur le cadre de support de sac à déchets

avant la destruction.

1 Soulevez le couvercle du compartiment.

2 Insérez toujours les CD / DVD dans la fente d’alimentation pourCD / DVD. Ne détruisez qu’un

seul CD / DVD à la fois.

3 Fermez le couvercle du compartiment.

4 Videz le bac à déchets de CD / DVD après la destruction de 8 CD / DVD pour éviter que les

déchets retombent dans la corbeille à papier.

5 Retirez le bac à déchets de CD / DVD avant de relancer la destruction de papier, et rangez-le

sur le côté de l’appareil selon l’illustration.

4. destruction de cartes bancaires

Le Stack and Shred 200X / 200XL peut détruire les cartes bancaires. Appuyez sur la touche de

mode automatique, puis :

1 Soulevez le couvercle du compartiment papier.

2 Insérez la carte bancaire dans les rouleaux selon l’illustration. Ne détruisez qu’une seule carte

bancaire à la fois.

3 Fermez le couvercle du compartiment.

Swingline encourage ses clients à recycler le papier déchiqueté.

Veuillez noter que le papier déchiqueté ne peut pas être recyclé s’il est mélangé à des

morceaux de carte bancaire. Pour le recyclage, veuillez séparer le papier déchiqueté et les

morceaux de carte bancaire.

5. corbeille pleine

Le destructeur ne fonctionne pas si la corbeille est pleine, auquel cas le symbole corbeille pleine

( ) s’allume. Vous devez alors vider la corbeille.

• Ouvrez la porte et sortez le cadre de support de sac en le faisant glisser.

• Retirez avec soin le sac à déchets du cadre.

surchauffe

En cas d’utilisation continue de le Stack and Shred 200X / 200XL pendant plus de 10 minutes,

le destructeur risque de surchauer, auquel cas l’indicateur de refroidissement rouge, situé sous

le symbole du thermomètre (

le destructeur peut être de nouveau utilisé, le symbole à thermomètre s’éteint. S’il a besoin

de se refroidir en cours de destruction, votre intervention est inutile. En eet, il recommence

automatiquement la destruction du papier dès qu’il s’est refroidi après une période d’utilisation

continue. Il vous sut de vérier que le papier est chargé dans le compartiment d’auto-alimentation

et que la corbeille est vide pendant que l’appareil se refroidit.

), s’allumera. Veuillez alors laisser l’appareil se refroidir. Lorsque

STACK-AND-SHRED 200X&200XL™ DESTRUCTEURS 19

Page 20

Français

6. lames auto-nettoyantes

Après le vidage et la remise en place de la corbeille, le destructeur fonctionne en marche arrière

pendant 4 secondes, s’arrête pendant 2 secondes puis se met en marche avant pendant 4

secondes pour dégager tout déchet de papier du mécanisme de coupe. Cette fonction « d’autonettoyage » unique vient complémenter la technologie anti-bourrage de Swingline.

lubrification de la déchiqueteuse

Utilisez uniquement des feuilles lubriantes à cet eet. ACCO Brands décline toute responsabilité

concernant la sécurité ou la performance du produit lorsque d’autres types de lubriant sont

utilisés sur un ou plusieurs composants de cet appareil. Insérez la feuille lubriante dans la fente

d’alimentation manuelle et NON PAS dans le compartiment d’alimentation automatique. L’utilisation

d’une feuille lubriante dans le compartiment d’alimentation automatique peut contaminer

les rouleaux d’alimentation et empêcher le déchiquetage par le mécanisme d’alimentation

automatique. Si les rouleaux deviennent contaminés, reportez-vous aux instructions d’entretien. Ne

faites pas directerment de péreolw la moulinette.

7. maintenance

Les rouleaux du mécanisme d’auto-alimentation peuvent se salir au cours du temps. Veuillez les

essuyer avec un linge sec an d’optimiser la performance de l’appareil.

Lorsque le capteur à infrarouges de démarrage automatique, situé dans la fente d’alimentation,

est recouvert de poussière de papier, ce qui arrive parfois, le destructeur continue de fonctionner

même sans papier. Éteignez alors le destructeur à l’aide du commutateur marche/arrêt situé à

l’arrière de l’appareil et nettoyez avec soin le capteur avec un coton tige.

révision

Nous conseillons de faire réviser ces appareils tous les 6 à 12 mois par un réparateur Swingline –

voir les coordonnées de contact de votre centre de révision local au dos de ce livret.

accessoires du destructeur

Nous vous conseillons d’utiliser, avec tous les

modèles, un sac à déchets papier pour recycler

les particules de papier.

Accessorio Numero parte Quantità in una

Sac à déchets à

recycler

Sac à déchets en

plastique

1765031

1765016

confezione

20

100

AVIS FCC CLASSE B

Note : Cet équipement a été testé et s’avère être conforme aux restrictions établies pour un dispositif numérique Classe B, conformément à la section

15 de la Règlementation FCC. Ces restrictions ont été conçues pour fournir une protection raisonnable contre les interférences nuisibles dans une

installation résidentielle. Cet équipement produit, utilise et peut émettre une énergie radiofréquence nuisible aux communications radio et peut causer

une interférence s’il n’est pas installé et utilisé conformément aux instructions. Cependant, il n’y a pas de garantie qu’une interférence ne surviendra

pas dans une installation spécique. Si cet équipement cause eectivement une interférence nuisible à la réception radio ou télévisuelle, ce qui peut

être déterminé en allumant et en éteignant successivement l’équipement, il est recommandé à l’utilisateur de tenter de corriger l’interférence en

prenant une ou plusieurs des mesures suivantes:

Réorienter ou déplacer l’antenne réceptrice.

Augmenter la distance entre l’équipement et le récepteur.

Brancher l’équipement sur une prise de courant sur un circuit diérent de celui sur lequel le récepteur est connecté.

Pour obtenir de l’aide, s’adresser au concessionnaire ou consulter un technicien spécialisé dans les téléviseurs.

AVIS CANADA, CLASSE B

Cet appareil numérique de classe B est conforme à la norme NMB-003 du Canada.

MODIFICATIONS

Toute modication apportée à cet appareil peut entraîner l’annulation du droit accordé à l’utilisateur par la FCC et/ou par Industrie Canada de faire

fonctionner cet équipement.

ACCO est une marque de commerce déposée d’ACCO Brands.

Copyright © 2013 ACCO Brands. Tous droits réservés.

Numéro Août 2013

Fusion est une marque de commerce déposée d’ACCO Brands.

20 enregistrez ce produit en ligne à www.accoeurope.com

Page 21

Français

spécifications

Swingline Stack and Shred 200X / 200XL

Capacité de destruction

Fente d’alimentation

manuelle

Capacité de destruction

Compartiment

d’auto-alimentation

Cycle de fonctionnement 10 min marche / 40 min arrêt

Durée de fonctionnement

initiale après démarrage

à froid

Volts/Hz 120V / 60Hz

Ampérage 1,2 A

Puissance du moteur 270 watts

7 feuilles (80 g/m

200 feuilles (80 g/m

14 minutes

2

)

2

)

Garantie limitée

Garantie limitée de 2 ans sur les couteaux de la déchiqueteuse Stack-and-Shred 200X / 200XL et limitée de 2 ans de garantie pour toutes

les autres parties

ACCO Brands USA LLC, Four Corporate Drive, Lake Zurich, IL 60047-8997 (au Canada, ACCO Brands Canada inc., 5 Precidio Court, Brampton, ON

L6S 6B7; et au Mexique, ACCO Mexicana, S.A. de V.V. Av. Circuito Industrial Norte #6 Parque Industrial Lerma 52000, Lerma Edo. De Mexico) (chacun,

respectivement, «ACCO Brands») garantit à l’acheteur initial que les lames de cette déchiqueteuse Swingline™ Stack-and-Shred 200X / 200XL sont

exemptes de défauts de fabrication et de main-d’œuvre dans des conditions d’utilisation et d’entretien normales pour une période de (1) ans.

L’obligation d’ACCO Brands envers cette garantie est limitée au remplacement ou à la réparation, au choix d’ACCO Brands, dans le cas ou n’importe

quelle pièce garantie serait trouvée défectueuse par ACCO Brands, et ce, sans frais de matériel ou de main-d’œuvre. ACCO Brands se réserve le droit

de remplacer le produit défectueux par un autre produit identique ou par un équivalent qui peut contenir des pièces réusinées ou remises à neuf. La

garantie sera nulle et non avenue dans les circonstances suivantes :

(i) si le produit a été utilisé abusivement;

(ii) si le produit a été endommagé par négligence ou accidentellement ou

(iii) si le produit a été modié par une personne autre qu’un employé ou un agent autorisé d’ACCO Brands.

Pour prestation de la garantie, veuillez composer le :

1-800-541-0094 aux É.U.

1-800263-1063 au Canada

01-(55)-1500-5700 / 5778 au Mexique

Ou allez sur le site www.swingline.com.

DANS LA MESURE AUTORISÉE PAR LA LOI APPLICABLE, LA PRÉSENTGARANTIE REMPLACE TOUTES LES AUTRES GARANTIES

EXPRESSES, TOUTES REPRÉSENTATIONS OU PROMESSES CONTRADICTOIRES AVEC, OU AJOUTÉES À CETTE GARANTIE NE SONT

PAS AUTORISÉES ET NE SONT PAS RELIÉES À ACCO BRANDS. DANS LA MESURE AUTORISÉE PAR LES LOIS APPLICABLES, LA

DURÉE DE TOUTE GARANTIE IMPLICITE (SI APPLICABLE ) SE LIMITE À LA DURÉE DE LA PRÉSENTE GARANTIE. CERTAINS ÉTATS ET

CERTAINES JURIDICTIONS N’AUTORISENT PAS LES LIMITATIONS PORTANT SUR LA DURÉE D’UNE GARANTIE IMPLICITE, DE SORTE QUE

LES LIMITATIONS CI-DESSUS PEUVENT NE PAS VOUS ÊTRE APPLICABLES. DANS LA MESURE AUTORISÉE PAR LA LOI APPLICABLE,

ACCO BRANDS NE SERAIT, EN AUCUN CAS, ÊTRE TENU RESPONSABLE DE TOUS DOMMAGES SPÉCIAUX, ACCESSOIRES, PUNITIFS,

EXEMPLAIRES, CONSÉCUTIFS OU SIMILAIRES, QU’ILS SOIENT PRÉVISIBLES OU NON. CERTAINS ÉTATS ET CERTAINES JURIDICTIONS NE

PERMETTENT PAS L’EXCLUSION OU LA LIMITATION DES DOMMAGES SPÉCIAUX, ACCCESSOIRES, PUNITIFS, EXEMPLAIRES, CONSÉCUTIFS

OU SIMILAIRES DE SORTE QUE LES EXCLUSIONS OU LIMITATIONS CI-DESSUS PEUVENT NE PAS VOUS ÊTRE APPLICABLES.

POUR LES CONSOMMATEURS BÉNÉFICIANT DE LOIS OU DE RÉGLEMENTATIONS EN MATIÈRE DE PROTECTION DES CONSOMMATEURS

DANS LEUR JURIDICTION D’ACHAT, OU, SI ELLE EST DIFFÉRENTE, DANS LEUR JURIDICTION DE RÉSIDENCE, LES AVANTAGES CONFÉRÉS

PAR CETTE GARANTIE S’AJOUTENT À TOUS LES DROITS ET RECOURS FOURNIS PAR LESDITES LOIS ET RÉGLEMENTATIONS EN MATIÈRE

DE PROTECTION DES CONSOMMATEURS.

Dans la mesure autorisée par la loi applicable, cette garantie n’est pas transférable et devient automatiquement nulle si l’acheteur original du produit

vend ou aliène de quelque autre manière le produit.

Cette garantie vous donne des droits légaux spéciques auxquels peuvent s’ajouter d’autres droits variant selon les juridictions. De plus, certaines

juridictions n’autorisent pas (i) l’exclusion de certaines garanties [ii), les limitations portant sur la durée d’une garantie implicite et/ou l’exclusion ou la

limitation de certains coûts et/ou dommages, de sorte que les limitations ci-dessus peuvent ne pas vous être applicables.

STACK-AND-SHRED 200X&200XL™ DESTRUCTEURS 21

Page 22

Español

tecnología de entrada automática

La destructora Stack and Shred 200X/200XL se ha diseñado con el n de que destruya

automáticamente hasta 200 hojas desde el compartimento de entrada automática y hasta 7

hojas desde la ranura de entrada para alimentación manual. El diseño del mecanismo de entrada

automática tiene como nalidad manipular papel sujeto con grapas o clips de papel y tirar solo

de unas cuantas hojas de papel a la vez hacia las cuchillas para reducir el riesgo de que se

produzcan atascos de papel.

Para protegerse de lesiones, al congurar este producto, debe seguir las siguientes precauciones

básicas de seguridad.

• Compruebe que la máquina se ha enchufado a una toma de alimentación de fácil acceso y que no

es probable que alguien que pase tropiece con el cable.

• Cualquier intento de reparar esta unidad por parte de personal no cualicado invalidará la garantía.

Devuélvala al proveedor.

• Desenchufe la destructora de papel si la va a mover o no la va a usar durante un período de tiempo

prolongado.

• NO utilice la destructora si el cable o la toma de corriente están dañados, la unidad no funciona

correctamente o ha sufrido cualquier daño.

• NO supere la capacidad de las tomas eléctricas ya que esto podría provocar un incendio o una

descarga eléctrica.

• La toma de alimentación debe estar instalada cerca de la unidad y debe ser de fácil acceso.

• NO modique el enchufe. Viene congurado para la corriente eléctrica adecuada.

• NO use la unidad cerca del agua.

• NO use productos para limpiar o quitar el polvo con aerosol.

• NO pulverice ningún producto sobre la destructora de papel.

• NO llene el compartimento de entrada automática de correo basura sin abrir, revistas, documentos

encuadernados, etc.

Aunque esta destructora se ha diseñado con la nalidad de que cumpla con la norma de seguridad

UL 60950-1 EN 60950-1, incluidas las “pruebas de accesibilidad con sondas”, no la utilice cerca de

niños o mascotas.

22 registre este producto en línea en www.accoeurope.com

Page 23

símbolos de advertencia

Español

La seguridad es lo

más importante

Este símbolo signica que debe

tener cuidado porque el cabello

largo puede quedar atrapado en el

mecanismo de corte.

Este símbolo signica que debe

tener cuidado con las corbatas o

cualquier otra prenda suelta que

pudiera quedar atrapada en el

mecanismo de corte.

Este símbolo signica que debe

tener cuidado con las joyas sueltas

que pudieran quedar atrapadas en

el mecanismo de corte.

Este símbolo signica que no debe

meter la mano en la ranura de

entrada del mecanismo de corte.

7

panel de control e indicadores

Automático

Tapa de carga/recipiente abierto.

Puede signicar:

• La tapa de carga de papel está

abierta

• El recipiente para recortes está

abierto

Indicador de recipiente de

recortes lleno: signica que el

recipiente está lleno

Indicador de bloqueo: signica

que la tapa de carga de papel está

bloqueada (durante la destrucción

de documentos)

Indicador de enfriamiento:

signica que la máquina se está

enfriando.

Este símbolo signica que debe

mantener a los niños alejados de la

destructora.

Este símbolo signica que no debe

pulverizar aerosoles sobre la máquina.

Capacidad de hojas para la ranura de

entrada de alimentación manual.

Este símbolo signica que la destructora

puede aceptar grapas pequeñas.

Este símbolo signica que la destructora

puede aceptar clips de papel pequeños.

Este símbolo signica que la destructora

puede aceptar tarjetas de crédito.

Este símbolo signica que no debe

usar aceite lubricante, utilice solo

hojas lubricantes Swingline.

Avance continuoRetroceso

Indicador de atasco de papel

- signica que hay un atasco de

papel en el compartimento de

entrada automática.

Si parpadea este símbolo, la

destructora está intentando eliminar

un atasco automáticamente.

Si este símbolo aparece iluminado

en rojo de forma permanente, siga

las instrucciones del apartado

Ocasiones excepcionales de

atasco.

Mecanismo de bloqueo de

la tapa de carga de papel:

botones para la introducción

de contraseña: Introduzca un

código de cuatro dígitos para

bloquear la tapa de carga durante la

destrucción de documentos

STACK-AND-SHRED 200X&200XL™ DESTRUCTORAS DE PAPEL 23

Page 24

Español

capacidad de destrucción de la destructora

Stack and Shred 200X/200XL

La destructora Stack and Shred 200X/200XL PUEDE destruir lo siguiente:

• 200 hojas

• Papel grapado, las grapas deben estar a menos de 25 mm de la esquina

• Grapas de tamaño 26/6 y 24/6 o inferior

• El papel de tamaño pequeño debe centrarse

• 200 hojas

• Papel con clips de papel, el clip debe estar a menos de 25 mm de la esquina

(200XL por la ranura de entrada para alimentación manual)

• Clips de papel pequeños/medianos (grosor máximo del alambre = 0,9 mm)

• Papel de más de 80/100 g/m

• Papel A3 doblado por la mitad: 2 hojas como máximo

• 200 hojas de papel, impreso por una cara

• Papel de 80 g/m

- Letter y Legal

- Una sola hoja de tamaño A3, doblada por la mitad para convertirla en A4

2

La destructora Stack and Shred 200X/200XL PUEDE destruir lo

siguiente (por la ranura de entrada para alimentación manual):

Papel grueso o

cartulina

2

(por la ranura de entrada para alimentación manual)

Varias hojas dobladas

(por ejemplo, hojas de tamaño

A3 dobladas por la mitad)

Cartas sin abrir

Papel satinado u

hojas impresas

por ambas caras

La destructora Stack and Shred 200X/200XL NO PUEDE destruir

lo siguiente:

Grapas de

gran tamaño.

Compruebe que

la longitud de pata

de la grapa no sea

superior a 6 mm.

Broches

aprietapapel

Etiquetas

adhesivas

24 registre este producto en línea en www.accoeurope.com

Clips de gran

tamaño. Compruebe

que la longitud del

clip de papel no

sea superior a los

32 mm.

Documentos

encuadernados

Revistas u otros

documentos

encuadernados con

varias grapas o clips.

Hojas de plástico,

documentos

plasticados,

carpetas de

plástico

Page 25

Español

función de seguridad de recipiente para recortes

o tapa de carga de papel abiertos

Como medida de seguridad, si se abre el recipiente para recortes o la tapa de carga de papel

mientras la destructora está en funcionamiento, esta se detendrá y se iluminará el indicador ( ).

ocasiones excepcionales de atasco

1 En el caso poco probable de que la destructora Stack and Shred 200X/200XL se atasque,

dejará de destruir documentos y el icono de atasco de papel parpadeará en color naranja.

2 Para eliminar el atasco, se iluminarán el botón de eliminación de atasco, modo de avance

continuo (

3 Si el atasco no se puede eliminar de esta forma, se iluminará el icono de atasco (

rojo. Llegado a este punto, abra el compartimento de entrada automática para eliminar el papel

atascado.

) y el botón de retroceso (

) en la secuencia necesaria.

)en color

eliminación automática de atascos

En el caso poco probable de que se atasque la destructora Stack and Shred 200X/200XL, las

cuchillas funcionarán automáticamente en modo retroceso y avance tres veces para eliminar el

papel atascado. Durante esta operación parpadeará el indicador de atasco de papel (

).

mecanismo de bloqueo de la tapa de carga de papel

Para una mayor seguridad, se puede bloquear la tapa de carga de papel durante la destrucción de

material condencial.

Para bloquear la destructora:

1 Coloque los documentos en la bandeja. Cierre la tapa de carga de papel.

2 Pulse 4 dígitos cualquiera. RECUERDE EL CÓDIGO QUE HA INTRODUCIDO.

La destructora se desbloquea automáticamente:

• Si se vuelve a introducir el código de 4 dígitos.

• Al nalizar la destrucción

• Si la destructora lleva 30 minutos sin actividad (pero sigue habiendo documentos en la bandeja)

STACK-AND-SHRED 200X&200XL™ DESTRUCTORAS DE PAPEL 25

Page 26

Español

1. funcionamiento

1 Desembale el producto.

2 Conecte la destructora a la corriente eléctrica.

3 Compruebe que el interruptor de encendido/apagado en la parte posterior de la destructora

está en la posición de encendido (

4 Para comenzar a destruir documentos, pulse el botón central Auto (

encienda el símbolo del modo de espera azul en el botón Auto y que la destructora pase al

modo automático. Ahora ya puede destruir documentos.

5 Para cargar el papel, levante el tirador de la tapa de carga de papel para abrir la tapa de

carga de papel e inserte los documentos. Si fuera necesario, puede abrir la tapa hasta los

90 grados para que el acceso sea más fácil. Cargue un máximo de 200 hojas a la vez en el

compartimento de entrada automática. No supere el número MÁXIMO de 200, puesto que esto

podría dañar la destructora.

6 La destructora SOLO empezará a destruir documentos automáticamente cuando se haya

cerrado la tapa de carga.Si tras el primer intento, todavía queda papel en el compartimento de

entrada automática, abra y cierre la tapa de carga una segunda vez.

200XL

Atención: si fuera necesario, puede introducir un código de 4 dígitos para bloquear la tapa de

carga (vea el apartado Bloqueo de la tapa de carga de papel).

7 Si solo tiene que destruir un máximo de 7 hojas, puede usar la ranura de entrada para

alimentación manual, siempre que el compartimento de entrada automática esté vacío.

8 Introduzca el papel que se va a destruir en la ranura de entrada para alimentación manual. La

destructora detecta el papel y empieza a funcionar automáticamente.

9 Si la destructora permanece sin utilizarse durante más de 2 minutos en modo automático,

volverá automáticamente al modo de espera para ahorrar energía.

10 Cuando se inserte papel en la ranura de entrada de papel o abra la tapa de carga, la

destructora se reactivará del modo de suspensión. No es necesario pulsar el botón Auto (

).

), que hará que se

).

2. función de retroceso

1 Si, mientras que destruye un documento, desea hacer que retroceda el papel para extraerlo, se

ha incorporado un botón de retroceso (

2 Use la función de retroceso para extraer el papel y, a continuación, apague la destructora con

el botón de encendido/apagado situado en la parte posterior. Extraiga el papel de la ranura de

entrada para alimentación manual (si la está usando) o abra la tapa de carga de papel, extraiga

la pila de papel restante y tire del papel atascado para sacarlo de las cuchillas.

3 Para seguir destruyendo documentos, encienda la destructora con el interruptor de encendido/

apagado situado en la parte posterior y pulse el botón Auto (

26 registre este producto en línea en www.accoeurope.com

) para su comodidad.

).

Page 27

Español

3. destrucción de discos CD/DVD

Se suministra una bandeja independiente para recoger los restos de los CD/DVD destruidos.

Antes de empezar a destruir discos CD/DVD, compruebe que está colocada correctamente sobre

el bastidor para bolsas de residuos.

1 Levante la tapa de carga de papel.

2 Introduzca siempre los CD/DVD en la ranura para CD/DVD. Destruya solo un CD/DVD en cada

ocasión.

3 Cierre la tapa de carga de papel.

4 Vacíe la bandeja para discos CD/DVD cuando haya destruido 8 discos CD/DVD. Así evitará que

los residuos caigan en el recipiente para recortes de papel.

5 Antes de empezar a destruir el papel, quite la bandeja para discos CD/DVD y guárdela en el

lateral de la destructora tal y como se muestra.

4. destrucción de tarjetas de crédito

La destructora Stack and Shred 200X/200XL puede destruir tarjetas de crédito. Pulse el botón

Auto de la destructora y, a continuación:

1 Levante la tapa de carga de papel.

2 Introduzca la tarjeta de crédito en los cilindros tal y como se muestra. Destruya solo una tarjeta

de crédito en cada ocasión.

3 Cierre la tapa de carga de papel.

Swingline anima a sus clientes a reciclar el papel triturado.

Tenga en cuenta que el papel triturado no se puede reciclar si se mezcla con los restos de

tarjetas de crédito. Si va a reciclar, separe los recortes de papel y tarjetas de crédito.

5. recipiente para recortes lleno

Cuando el recipiente para recortes está lleno y se enciende el símbolo de recipiente lleno ( ),

la destructora deja de funcionar. Debe vaciar el recipiente para recortes.

• Abra la puerta y extraiga el bastidor para bolsas de residuos.

• Saque cuidadosamente la bolsa del bastidor.

sobrecalentamiento

Si se utiliza la destructora Stack and Shred 200X/200XL de forma continua durante más de

10 minutos, podría sobrecalentarse y se encendería el indicador rojo de enfriamiento situado

debajo del símbolo del termómetro (

apagará cuando la destructora esté lista para su uso. Si la destructora debe enfriarse mientras

está funcionando, no tiene que hacer nada. Tras períodos de uso continuo, la destructora volverá

a empezar a triturar papel automáticamente una vez que se haya enfriado. Lo único que tiene

que hacer mientras se enfría la máquina es asegurarse de que se ha cargado el papel en el

compartimento de entrada automática y que el recipiente para recortes está vacío.

STACK-AND-SHRED 200X&200XL™ DESTRUCTORAS DE PAPEL 27

). Deje que se enfríe. El símbolo del termómetro se

Page 28

Español

6. limpieza automática de las cuchillas

Una vez que se haya vaciado y vuelto a colocar el recipiente, la destructora funcionará en modo

retroceso durante 4 segundos, se detendrá durante 2 segundos y funcionará en modo de avance

durante 4 segundos para eliminar los restos de papel de las cuchillas. Este mecanismo de “limpieza

automática” exclusivo se añade a la tecnología antiatascos de Swingline.

lubricación de la trituradora

Utilice únicamente hojas lubricantes para lubricar. ACCO Brands no acepta ninguna responsabilidad por la

seguridad o el rendimiento del producto cuando se utilizan otros tipos de lubricantes para cualquier pieza

de esta máquina. Inserte la hoja lubricante en la ranura de alimentación manual, y NO en la cámara de

alimentación automática. El uso de una hoja lubricante en la cámara de alimentación automática contaminará

los rodillos de alimentación, lo que impedirá que el mecanismo de alimentación automática triture. Siga las

instrucciones de mantenimiento, si los rodillos se contaminan. No haga directamente del aceite la desbradora.

mantenimiento

Los cilindros del mecanismo de entrada automática se pueden ensuciar con el tiempo. Para que el

producto siga teniendo un rendimiento óptimo, límpielos con un paño seco.

El sensor de inicio automático por infrarrojos, situado en la ranura de entrada, puede quedar cubierto

de polvo de papel de vez en cuando, lo que hará que la destructora siga funcionando aunque no se

coloque papel en la máquina. Apague la destructora con el interruptor situado en la parte posterior y

limpie el sensor con cuidado con un bastoncito de algodón.

servicio

Recomendamos que un ingeniero de servicio de Swingline realice una revisión de estas máquinas cada 6-12

meses. En la contraportada de este folleto encontrará los datos de contacto de su centro de servicio local.

accesorios para las destructoras

Se recomienda utilizar una bolsa de papel

para residuos en todos los modelos para

reciclar el papel destruido.

Accesorio N.º de pieza Nº de unidades

Bolsa para

residuos reciclable

Bolsas de plástico

para residuos

1765031

1765016

de la caja

20

100

AVISO DE LA FCC (COMISIÓN FEDERAL DE

COMUNICACIONES DE EE.UU.) CLASE B

Nota: Este equipo fue probado y se comprobó que cumple con los límites correspondientes a un dispositivo digital clase B, según la Parte 15 de las

Reglamentaciones de la FCC. Estos límites están diseñados para proporcionar una razonable protección contra las interferencias perjudiciales en una

instalación residencial. . Este equipo genera, usa y puede irradiar energía de radiofrecuencia y, si no se instala y usa de acuerdo con las instrucciones,

puede causar interferencias perjudiciales a las comunicaciones de radio. No obstante, no existe garantía de que no se produzcan interferencias

en una instalación en particular. Si este equipo causa interferencias perjudiciales a la recepción de radio o televisión, lo que puede comprobarse

encendiendo y apagando el equipo, se recomienda alusuario intentar corregir la interferencia mediante una o más de las siguientes medidas:

Reorientar o cambiar de posición la antena receptora.

Aumentar la separación entre el equipo y el receptor.

Conectar el equipo a un tomacorriente de un circuito diferente al que está conectado el receptor.

Consultar a un distribuidor o a un técnico experimentado de radio/TV para obtener asistencia.

CLASE B (CANADÁ)

Este equipo digital de Clase B cumple con las normas de ICES-003 de Canadá.

MODIFICACIONES

Cualquier modicación que se le realice a este dispositivo puede invalidar la autorización otorgada al usuario por la FCC o Industry Canada para

operar este equipo.

ACCO es una marca registrada de ACCO Brands.

Copyright © 2013 ACCO Brands. Todos los derechos reservados.

Fusion es una marca registrada de ACCO Brands.

Número Augusto 2013

28 registre este producto en línea en www.accoeurope.com

Page 29

Español

datos técnicos

Swingline Stack and Shred 200X/200XL

Capacidad de hojas

Ranura de entrada para

alimentación manual

Capacidad de hojas

Compartimento de

entrada automática

Ciclo de trabajo 10 min en funcionamiento/

Tiempo de

funcionamiento desde

inicio en frío

Voltios/Hz 120V / 60Hz

Amperaje 1,2 amperios

Potencia del motor 270 vatios

7 hojas (80 g/m

200 hojas (80 g/m

40 min en espera

14 minutos

2

)

2

)

Garantía limitada

Garantía limitada de las cuchillas de corte 2 años por Stack and Shred 200X/200XL y limitada 2 años de garantía para todas las demás

partes

ACCO Brands USA LLC, Four Corporate Drive, Lake Zurich, IL 60047-8997, ACCO Brands Canada Inc., 5 Precidio Court, Brampton, ON L6S-6B7,

ACCO MEXICANA S.A. DE C.V Circuito de la Industria Norte No. 6 Parque Industria Lerma, Lerma Edo. de México C.P. 52000 México. (cada una,

respectivamente, “ACCO Brands”) garantizan al comprador original de este producto que este producto de ACCO Brands (excepto las cuchillas) está

libre de defectos de mano de obra y material por un período de 2 años.

La obligación de ACCO Brands bajo esta garantía se limita al reemplazo o la reparación, a la sola opción de ACCO Brands, de cualquier

pieza garantizada que ACCO Brands determine que está defectuosa, sin cargo por material o mano de obra. Cualquier reemplazo puede ser,

a la sola opción de ACCO Brands, por el mismo producto o un producto sustancialmente similar que puede contener piezas reconstruidas o

reacondicionadas. Esta garantía no será válida en cualquiera de las siguientes circunstancias:

(i) si el producto se usó incorrectamente,

(ii) si el producto se dañó por negligencia o accidente,

(iii) si el producto fue alterado por cualquier persona que no pertenezca a ACCO Brands o sus agentes autorizados.

Para reclamar la garantía por favor llame al:

1-800-541-0094 en los Estados Unidos de América

1-800-263-1063 en Canadá

01-(55)-1500-5700 / 5778 en México

O visite www.swingline.com.

CONFORME LO PERMITAN LAS LEYES APLICABLES, ESTA GARANTÍA REEMPLAZA CUALQUIER OTRA GARANTÍA VERBAL O ESCRITA.

NO ESTÁ AUTORIZADA NINGUNA REPRESENTACIÓN O PROMESA ADICIONAL QUE NO SEA CONSISTENTE CON ESTA GARANTÍA Y

NO REPRESENTARÁ OBLIGACIÓN LEGAL ALGUNA PARA ACCO BRANDS. HASTA DONDE LO PERMITEN LAS LEYES APLICABLES, LA

DURACIÓN DE CUALQUIER GARANTÍA IMPLÍCITA (SI CORRESPONDIERA) ESTÁ LIMITADA A LA DURACIÓN DE ESTA GARANTÍA. ALGUNOS

ESTADOS Y JURISDICCIONES NO PERMITEN LIMITACIONES EN RELACIÓN AL TIEMPO DE DURACIÓN DE UNA GARANTÍA IMPLÍCITA,

POR LO TANTO, LA LIMITACIÓN ANTERIOR PUEDE NO SER APLICABLE EN SU CASO. HASTA DONDE LAS LEYES APLICABLES LO

PERMITAN, EN NINGÚN CASO ACCO BRANDS ASUME RESPONSABILIDAD LEGAL POR DAÑOS ESPECIALES, INCIDENTALES, PUNITIVOS,

EJEMPLARES, CONSECUENTES O SIMILARES YA SEAN PREDECIBLES O NO. ALGUNOS ESTADOS Y JURISDICCIONES NO PERMITEN LA

EXCLUSIÓN O LIMITACIÓN DE LOS DAÑOS Y PERJUICIOS ESPECIALES, INCIDENTALES, PUNITIVOS, EJEMPLARES, CONSECUENTES O

SIMILARES, DE MODO QUE LA EXCLUSIÓN O LIMITACIÓN PRECEDENTE PUEDE NO SER APLICABLE A SU CASO.

PARA LOS CONSUMIDORES QUE CUENTAN CON EL BENEFICIO DE LEYES O REGULACIONES DE PROTECCIÓN AL CONSUMIDOR EN LA

JURISDICCIÓN DONDE SE EFECTUÓ LA COMPRA O SI LAS LEYES SON DIFERENTES Y APLICAN A LA JURISDICCIÓN DE RESIDENCIA,

LOS BENEFICIOS OTORGADOS POR ESTA GARANTÍA SON ADICIONALES A TODOS LOS DEMÁS DERECHOS Y COMPENSACIONES QUE

MARCAN TALES LEYES Y REGULACIONES DE PROTECCIÓN AL CONSUMIDOR.

Conforme a lo permitido por ley, esta garantía no es transferible y termina automáticamente si el comprador original del producto vende o se deshace

de dicho producto de cualquier otra manera.

Esta garantía le otorga derechos legales especícos. Pueden existir otros derechos, que varían según la jurisdicción. Además, ciertas jurisdicciones

no permiten (i) la exclusión de ciertas garantías, (ii) las limitaciones de la duración de las garantías implícitas y/o (iii) la exclusión o limitación de

ciertos tipos de costos y/o daños y perjuicios de modo que las limitaciones precedentes pueden no ser aplicables.

STACK-AND-SHRED 200X&200XL™ DESTRUCTORAS DE PAPEL 29

Page 30

Português

tecnologia de alimentação automática

A destruidora Stack and Shred 200X/200XL foi concebida para destruir automaticamente até 200 folhas

introduzidas no compartimento de alimentação automática e até 7 folhas introduzidas na ranhura de

entrada de alimentação manual. O mecanismo de alimentação automática foi concebido para se poder

usar papel preso com agrafos e clipes, assim como para se introduzir apenas algumas folhas de papel

de cada vez no mecanismo de corte, para minimizar o risco de encravamento do papel.

Para evitar ferimentos, deve respeitar as seguintes precauções de segurança básicas durante a

instalação deste produto.

• Certique-se de que a máquina está ligada a uma tomada facilmente acessível e que o cabo não

está colocado de maneira a fazer tropeçar alguém.

• Qualquer reparação desta destruidora de papel efectuada por pessoal não qualicado anulará a

garantia. Por favor, devolva a máquina ao fornecedor.

• Retire a cha da tomada da máquina antes de a movimentar ou se a não for utilizar por um período

de tempo prolongado.

• NÃO utilizar a máquina se o cabo ou a cha estiverem danicados, depois de uma falha de

funcionamento da máquina ou se esta tiver sido danicada de algum modo.

• NÃO sobrecarregar as tomadas eléctricas para além da sua capacidade, pois isto pode causar um

incêndio ou choque eléctrico.

• A tomada deve ser instalada junto do equipamento e estar facilmente acessível.

• NÃO alterar a cha. A cha fornecida está congurada para a fonte de alimentação apropriada.

• NÃO utilizar junto de água.

• NÃO utilizar aerossóis de limpeza ou para remoção de pó.

• NÃO pulverizar nenhum produto para o interior da destruidora de papel.

• NÃO colocar correio não solicitado não aberto, revistas, documentos encadernados etc., no

compartimento de alimentação automática.

Embora esta destruidora tenha sido concebida em conformidade com as normas de segurança

UL 60950-1 EN 60950-1, incluindo os “testes de segurança dos dedos em peças móveis”, não utilize

a máquina junto de crianças ou animais de estimação.

30 registe este produto on-line em www.accoeurope.com

Page 31

símbolos de advertência

Português

Segurança Acima de Tudo

Este símbolo signica que deve ter

cuidado para não deixar prender o

cabelo comprido na cabeça de corte.

Este símbolo signica que deve

ter cuidado com gravatas e outro

vestuário solto, porque podem car

presos na cabeça de corte.

Este símbolo signica que deve ter

cuidado com artigos de joalharia

soltos, porque podem car presos na

cabeça de corte.

Este símbolo signica que não deve

introduzir a mão na abertura de

entrada da cabeça de corte.

7

painel de controlo e indicadores

Auto

Indicador de porta do

compartimento de alimentação

automática/recipiente de aparas

aberto – Isto indica uma das

seguintes situações:

• A porta do compartimento de

alimentação está aberta

• O recipiente de aparas está aberto

Indicador de recipiente de

aparas cheio – Isto indica que o

recipiente está cheio

Indicador de bloqueio - Isto

indica que a porta do

compartimento de alimentação

automática está travada (durante

a operação de corte)

Indicador de arrefecimento –

Isto indica que a máquina está a

arrefecer

Este símbolo signica que deve

manter as crianças afastadas da

destruidora.

Este símbolo signica que não deve

pulverizar a máquina com aerossóis.

Capacidade de corte da ranhura de

entrada de alimentação manual.

Este símbolo signica que a destruidora

de papel aceita agrafos pequenos.

Este símbolo signica que a destruidora

de papel aceita clipes pequenos.

Este símbolo signica que a destruidora

de papel aceita cartões de crédito.

Este símbolo signica que não deve

usar óleos lubricantes; usar apenas

as folhas lubricantes Swingline.

Avanço ContínuoInverter

Indicador de encravamento do

papel – Isto indica que o papel está

encravado no compartimento de

alimentação automática

Se este símbolo piscar, a destruidora

está a tentar desencravar o papel

automaticamente.

Se este símbolo estiver

permanentemente aceso a vermelho,

siga as instruções sob o título: “Casos

Raros de Encravamento”.

Mecanismo de Bloqueio da

Porta do Compartimento de

Alimentação Automática –

Botões de Introdução da Senha

(PIN): Introduza um código de

quatro dígitos para bloquear a porta

do compartimento de alimentação

automática durante a operação de

corte

STACK-AND-SHRED 200X&200XL™ DESTRUIDORA DE PAPEL 31

Page 32

Português

capacidade de corte da destruidora Stack

and Shred 200X/200XL

A destruidora Stack and Shred 200X/200XL PODE ser usada para

cortar o seguinte:

• 200 folhas

• Papel agrafado com o agrafo a uma distância não superior a 25 mm do canto do papel

• Agrafos 26/6 e 24/6 ou mais pequenos

• Papel pequeno introduzido centralmente

• 200 folhas

• Papel preso com clipe colocado a uma distância não superior a 25 mm do canto

do papel (200XL APENAS pela ranhura de entrada de alimentação manual)

• Clipes de papel pequenos/médios (espessura máxima do arame = 0,9 mm)

• Papel com gramagem >80/100 g/m²

(APENAS pela ranhura de entrada de alimentação manual)

• Papel A3 dobrado ao meio – no máximo 2 folhas

• 200 folhas de papel impressas de um lado apenas

• Papel de 80 g/m²

- Letter e Legal

- Uma única folha A3, dobrada ao meio para formar A4

A destruidora Stack and Shred 200X/200XL PODE ser usada para cortar

o seguinte (APENAS pela ranhura de entrada de alimentação manual):

Papel espesso

ou cartão

Várias folhas dobradas

(por ex. folhas A3

dobradas ao meio)

Correio não

aberto

Papel brilhante ou

folha impressa em

ambos os lados

A destruidora Stack and Shred 200X/200XL NÃO destrói o seguinte:

Agrafos grandes.

Verique que o

comprimento da

perna do agrafo

não é superior a

6 mm.

Molas

Etiquetas

adesivas

32 registe este produto on-line em www.accoeurope.com

Clipes grandes.

Verique que o

comprimento do

clipe de papel não

é superior a 32 mm

Documentos

encadernados

Revistas ou outros

documentos presos

com vários agrafos

ou clipes

Folhas de

plástico,

documentos

plasticados,

pastas de

plástico

Page 33

Português

função de segurança de recipiente aberto

ou porta do compartimento de alimentação

automática aberta

Como medida de precaução, se abrir o recipiente de aparas ou a porta do compartimento de

alimentação automática durante a operação de corte, a destruidora pára de funcionar e a luz

indicadora acende ( ).

casos raros de encravamento

1 No caso (pouco provável) de a máquina encravar, a destruidora Stack and Shred 200X/200XL

pára de funcionar e o ícone Encravamento do Papel pisca com luz cor de laranja.

2 O botão de desencravamento em modo Avanço Contínuo (

destruidora acendem na sequência necessária para desbloquear o papel.

3 Se o encravamento não puder ser eliminado seguindo a sequência indicada pela máquina, o

ícone Encravamento do Papel (

alimentação automática para retirar o papel encravado.

) acende a vermelho. Nesta altura, abra o compartimento de

) e o botão Inverter (

) da

desencravamento automático

No caso pouco provável de a máquina encravar, a destruidora Stack and Shred 200X/200XL

inverte e avança automaticamente o mecanismo de corte três vezes, para desencravar o papel.

Durante esta operação o indicador de encravamento do papel pisca (

).

mecanismo de bloqueio da porta do compartimento

de alimentação automática

Para maior segurança, pode bloquear a porta do compartimento de alimentação automática

enquanto destrói documentos condenciais.

Para bloquear a destruidora:

1 Coloque os documentos no tabuleiro. Feche a porta do compartimento de alimentação

automática.

2 Prima 4 dígitos quaisquer. MEMORIZE O CÓDIGO!

A destruidora de papel ca automaticamente desbloqueada quando:

• Voltar a introduzir o código de 4 dígitos.

• A operação de destruição de papel terminar.

• A destruidora estiver inactiva durante 30 minutos (mas os documentos permanecerem no

tabuleiro).

STACK-AND-SHRED 200X&200XL™ DESTRUIDORA DE PAPEL 33

Page 34

Português

1. funcionamento

1 Desembale a máquina.

2 Ligue a máquina à fonte de alimentação.

3 Verique que o botão LIGAR/DESLIGAR na traseira da máquina está na posição “ON” (Ligada)

(

).

4 Para começar a destruir o papel, prima o botão central Auto (

de Standby do botão Auto e activa o modo Automático da destruidora. Agora está pronto a

destruir o papel.

5 Para carregar a destruidora, basta levantar o puxador da porta do compartimento de

alimentação para abrir a porta e introduzir os documentos. Pode abrir a porta mais de 90

graus para facilitar a entrada do papel, se necessário. Introduza até 200 folhas de cada vez no

compartimento. Não encha acima do nível 200 MAX, porque isto pode danicar a destruidora.

6 A destruidora de papel começa automaticamente o ciclo de corte APENAS depois de fechar a

porta do compartimento de alimentação automática. Se ainda houver papel no compartimento

de alimentação automática após a primeira tentativa de destruir o papel, abra e feche a porta

do compartimento de alimentação outra vez.

200XL

Atenção: Se necessário, pode bloquear a porta agora introduzindo o código de 4 dígitos

(consultar a secção Como Bloquear a Porta do Compartimento de Alimentação Automática).

7 Se tiver apenas até 7 folhas para destruir, pode usar a ranhura de entrada de alimentação

manual, desde que o compartimento de alimentação automática esteja vazio.

8 Introduza o papel a destruir na ranhura de entrada de alimentação manual. A máquina detecta

o papel e começa a funcionar automaticamente.

9 Se deixar a destruidora em modo Automático durante mais de 2 minutos sem a utilizar, ela

volta automaticamente a modo Standby para economizar energia.

10 A destruidora de papel “sai” automaticamente do modo Inactivo quando se introduz papel na

entrada do papel, ou quando se abre a porta do compartimento. Não é necessário premir o

botão Auto (

).

). Isto acende o símbolo azul

2. função inverter

1 Para inverter o percurso do papel para o retirar da máquina enquanto destrói um documento,

existe um botão Inverter (

2 Inverta o percurso do papel e em seguida desligue a máquina no interruptor LIGAR/DESLIGAR

da traseira da máquina. Retire o papel da ranhura de entrada de alimentação manual (se estiver

a ser usada) ou abra a porta do compartimento de alimentação, retire a pilha de papel restante e

seguidamente puxe o papel encravado para o retirar do mecanismo de corte.

3 Para continuar a destruir o papel, ligue a máquina no interruptor LIGAR/DESLIGAR da traseira da

máquina e prima o botão Auto (

34 registe este produto on-line em www.accoeurope.com

).

).

Page 35

Português

3. destruição dos CD/DVD

Existe um tabuleiro separado para recolher os resíduos dos CD/DVD. Certique-se de que aquele

está correctamente montado na armação padrão de suporte dos sacos de resíduos antes de

destruir os CD/DVD.

1 Abra a porta do compartimento.

2 Introduza sempre os CD/DVD na ranhura dos CD/DVD. Só pode destruir um CD/DVD de cada

vez.

3 Feche a porta do compartimento.

4 Esvazie o tabuleiro de resíduos dos CD/DVD depois de destruir 8 CD/DVD para evitar que eles

se misturem com as aparas de papel.

5 Retire o tabuleiro de resíduos dos CD/DVD antes de voltar a destruir papel e guarde-o na parte

lateral da destruidora, como indicado.

4. destruição de cartões de crédito

A destruidora Stack and Shred 200X/200XL destrói cartões de crédito. Prima o botão Auto da

destruidora e em seguida:

1 Abra a porta do compartimento.

2 Introduza o cartão de crédito nos roletes, como se indica. Introduza apenas um cartão de cada vez.

3 Feche a porta do compartimento.

A Swingline sugere que os seus clientes reciclem as aparas de papel.

Note que as aparas de papel não podem ser recicladas se estiverem misturadas com os

resíduos de cartıes de crédito. Se quiser reciclar, separe as aparas de papel dos resíduos

de cartıes de crédito.

5. recipiente cheio

A destruidora não funciona se o recipiente estiver cheio e o símbolo de recipiente cheio ( )

estiver iluminado. Deve esvaziar o recipiente de aparas de papel.