Swi Group

Owner’s Handbook

Select Van Conversion

Issued August 2018

Part No. 1433210

CREATING SMILES FOR LIFE

A ten Haaft Company

Sat-Tech Ltd.

®

Cytrac DX

Robust construction

Less vulnerable to obstructions

Ultra low profi le

Oyster 85

Large reception range

Autoskew for optimum reception

Easy to use

Oyster V

Large reception range

Autoskew for optimum reception

Control and updates via ten Haaft App

NEW!

TOILET BOWL

WAST E-HOLDING TANK

FLUSH-

WATER TANK

PL ASTI C SURFAC ES

BLADE

SEAL

WORLD’S NO. 1

IN TOILET ADDITIVES!

www.thetford.com

DAILY USE

PERIODICAL USE

®

The only

one with the

Lifetime

Guarantee

Paint Protection Upholstery and Carpet Protection

Tel 01622 815679

Email diamondbrite@jewelultra.com

MADE IN UK

3 41 2

HOW DOES IT WORK?

You will also receive a complimentary After Care pack including the fabulous Waterless Wash, plus a range of other professional cleaning products.

www.jewelultra.com

1. EXTERIOR

• Nano-Ceramic Technology

• Fade Resistant

• Never Polish Again!

2. INTERIOR

• Easy to Clean

• Stain Resistant

• Lifetime Guarantee

®

If your paintwork was

magnified it would

reveal small pores in

the surface.

Road traffic dirt

gathers in the pores

and attacks

paintwork.

Your first Paint Protection

application cleanses and

fills pores in the vehicles

paintwork leaving a smooth

finish that cannot be

penetrated.

Your second application

bonds with the first to create

a hard protective skin. It

leaves a high lustre finish that

rain and dirt cannot penetrate.

Jewelultra Ltd. Diamondbrite House, Ewell Lane,

West Farleigh, MAIDSTONE. ME15 ONG.

From the Makers of Diamondbrite

Diamondbrite Leisure

The ultimate Paint and Upholstery Protection

for your Swift Motorhome

Diamondbrite Leisure is a two-step protection system for

your Swift Motorhome with a Lifetime Guarantee*

*Lifetime Guarantee applies for the length of time that the purchaser owns the vehicle and is non-transferable.

The only Swift Partner for Paint

and Upholstery Protection

WHAT IS CONNECT

DIRECT?

Connect Direct is an online

system which personalises each

customers experience of owning

their van conversion. The system

is now available accross the

entire range.

HOW DOES IT

WORK?

Once you have logged on and

created your prole, you will be

able to access a whole host of

information, specic to your

caravan. In addition you will be

able to have a direct line into the

retail team, with the launch of a

live chat facility.

Should a problem occur, you

will be able to report a fault to

us directly, enabling us to react

quickly and work together with

your dealer to take the problem

away from you the owner and

resolve the issue as quickly as

possible.

Product upgrades and

notications will be sent via

Connect Direct keeping you up

to date over the coming years.

This online system provides a

direct route for you into the Swift

Group, and enables us to provide

you with proactive Customer

Service support, enhancing your

experience.

Connect Direct is in addition

to the traditional methods of

contacting us.

The key benets of Connect

Direct are:

• Access to information 24/7

• Ability to report faults directly

to us

• Product upgrades and

notications

• Live chat direct into our

experienced retail team

• Upload service history

records

• Service history reminders

SERVICE

PURE

CONNECT DIRECT

LIGHTING

Create just the right

ambience onboard with easily

adjustable lighting settings.

LOCATION AND REMOTE FEATURES

Connect to your leisure vehicle from any where

to view its systems information and location.

Conveniently control and monitor selected

onboard services when away from your vehicle.

POWER

Track your energy use and

manage your batteries for

ecient use of your all

important power services.

HEATING

Activate whilst out exploring

and enjoy the warmth when

you get back.

WATER

Keep an eye on your

precious water levels so you

know in good time when to

top-up.

SUBSCRIBE FOR ONLY

£95 PER ANNUM

NOW FEATURING

THATCHAM CATEGORY 6

APPROVED

PRO-ACTIVE TRACKER

Head to the Apple or Android store and search

for ‘Swift Command’.

At the Swift Group we’re continually looking for ways to enhance your

enjoyment of the outdoors. Swift Command is a real innovation designed to

make your touring experience even more carefree.

Swift Command technology includes a smart new LCD touch screen control

panel that has enhanced control panel functions. There is also an exciting,

free downloadable ‘app’ that links to the Swift Command unit, so you can be

in control from the comfort and convenience of your mobile device.

Swift Command is now available across the entire range.

COMMAND TRACKER

BY

CONTROL

PURE

1

INTRODUCTION

Dear owner

Thank you for deciding to buy one of our new

motorhomes. We are sure you will enjoy many

happy hours in it and we hope the information

and hints in this handbook will heighten your

enjoyment.

The handbook has been designed to give

you a general guide to the care, use and

maintenance of your motorhome.

Whether you are a new or an experienced

motorhome user the hints will help to protect

your investment.

The information contained will answer most

of your queries, but if there are any aspects

which are not covered please consult your

appointed dealer.

Important - please quote the base VIN

(vehicle identification number) in all

correspondence with your dealer or

Swift Group Limited (Swift), this can be

found on the lower corner of the front

windscreen or on the Fiat plate positioned

on the front cross member within the

engine compartment.

All the illustrations and descriptive matter in

this handbook are intended to give a general

idea of the motorhome. Changing market

and supply situations may prevent us from

maintaining the exact specification details

in this handbook. We therefore reserve the

right to alter specifications as materials and

conditions demand.

Dealers are not agents of Swift Group Limited

and have absolutely no authority to bind Swift

Group Limited by any express or implied

undertaking or representation.

On-Line Handbooks

Throughout the season, specifications and

equipment details contained within this

handbook may change. Please refer to our

online handbooks (www.swiftgroup.co.uk) for

the most up-to-date version of your handbook.

Handbook Definitions

Customers should note that this handbook

contains general information for the use

and care of your product and the Technical

Handbook, which contains technical

information, weights and dimensions of your

product.

Happy touring!

Dealer Name:

Telephone Number:

E-mail:

VIN:

Sales Tel:

Service Centre Tel:

Parts Tel:

First Service Due:

INTRODUCTION

2

Swift Talk

Swift Talk is the central forum for the Swift

community online. A place for all those united

in their love of caravanning, motorhomes,

holiday homes and touring in general, to share

their experiences, meet new friends and find

out a world of information on how to enjoy

their touring lifestyle.

The site is packed full of features that actively

encourage members, not only to liaise with the

Swift Group via the forums, but also interact

with each other through publishing their own

content, uploading and sharing photos and

video, and even posting their own blogs for the

community to follow.

Swift Talk is the first place to learn about new

product launches, events and Swift Group

news, it’s also the first place customers can

go to as a quick reference to frequently asked

questions or to actively take part in the forums;

providing valuable feedback on Swift Group

products and customer service.

The online community can even be used to

create your own groups, perfect for Owners’

Clubs, dealers and exhibitors to attract new

members, publicise and build awareness for

upcoming events, rallies and shows.

Anyone who owns, uses, or is thinking of

buying a Swift Group caravan, motorhome

or holiday home, or would just like to be part

of the growing Swift community is actively

encouraged to sign up, create their own

content, and start talking!

Just visit www.swift-talk.co.uk

and become part of a unique

online experience.

SWIFT TALK

3

CONTENTS

Warranty Information ................................................................................................................. 5

The Motorhome Code ............................................................................................................. 13

Preparing for the Road ............................................................................................................ 17

En Route ................................................................................................................................. 25

Safety & Security ..................................................................................................................... 29

Arrival at Site ........................................................................................................................... 35

Connecting Services ................................................................................................................ 37

Electrical Systems ................................................................................................................... 59

Equipment Details .................................................................................................................... 89

Motorhome Care ................................................................................................................... 113

Technical Information ............................................................................................................. 127

Useful Information .................................................................................................................. 141

Index ..................................................................................................................................... 144

CONTENTS

WARRANTY INFORMATION

5

WARRANTY INFORMATION

Warranty ................................................................................................................................... 6

Supplier contacts ..................................................................................................................... 9

Service inspection .................................................................................................................. 10

WARRANTY INFORMATION

6

WARRANTY

Panel Van Conversion

Motorhome Warranty

All the illustrations and descriptive matter in

this handbook are intended to give a general

idea of the motorhome. Changing market and

supply situations and our policy of continuous

product development may prevent us from

maintaining the exact specifications detailed

in this handbook. We therefore reserve the

right to alter specifications as materials and

conditions demand.

Dealers are not agents of Swift Group Limited

("Swift") and have absolutely no authority

to bind the manufacturer by any express or

implied undertaking or representation.

Note: To register your warranty, please use

the Connect Direct Registration process,

by doing so you are agreeing that you have

had the details of the warranty and the

annual service arrangements fully explained.

This in no way affects your statutory rights

under the Consumer Rights Act.

Your panel van conversion motorhome has

three warranties:

Base Vehicle Warranty – provided by Fiat

Your vehicle is a panel van conversion

motorhome which utilises a Fiat base vehicle.

For a panel van conversion motorhome, Swift

takes a panel van as supplied by Fiat and fits

out the interior of the van for habitation. Fiat

provides a manufacturer's warranty for the

base vehicle as supplied to Swift by them.

For any issues with the base vehicle warranty

please contact your local Fiat dealer. This

Motorhome Warranty does not cover any

parts of your motorhome that are covered by

the Fiat manufacturer's warranty. Your base

vehicle warranty is subject to the terms and

conditions contained in the Fiat handbook

supplied with the base vehicle and the vehicle

must be serviced in accordance with Fiat

requirements.

SuperSure Warranty – provided by Swift

For all parts or fittings of your panel van

conversion motorhome other than the Fiat

base vehicle, Swift will repair (or at its option,

replace) any defective parts or fittings for

3 years from the date of purchase (or hire

purchase) subject to conditions, terms and

exclusions below.

Panel Van Conversion Body Shell

Warranty (“Body Shell Warranty”)

– provided by Swift

Swift will repair (or at its option, replace) any

defects with the panel van conversion to

the body shell for 3 years from the date of

purchase (or hire purchase), subject to the

conditions, terms and exclusions below.

This Motorhome Warranty does not cover any

parts of your motorhome that are covered by

the Fiat manufacturer's warranty.

Conditions for the SuperSure and

Body Shell Warranties

1. You must ensure that the habitation part

of your motorhome has an Annual Service

(see clause 2 below) within 90 days before

or 60 days after each anniversary of the

original date of purchase. In order to

preserve your SuperSure and Body Shell

Warranties the third Annual Service must,

however, be carried out before the expiry of

the 36 month period from the original date

of purchase. If you have not performed an

Annual Service then Swift will not be obliged

to perform any work under the applicable

warranty. Original VAT invoices must be

retained as proof that Annual Service have

been carried out.

2. The Annual Service on the body shell

and habitation area must be carried out

in accordance with the requirements in

this handbook. You will be responsible for

any charges made for an Annual Service.

If the Annual Service is performed by an

authorised Swift Group Service Centre then

Swift warrants that the Annual Service has

been performed correctly. If the Annual

Service is performed by an unauthorised

repairer or service centre then if the

Annual Service has not been performed in

accordance with the requirements in this

handbook and/or work has been performed

on your motorhome that is defective or

faulty, then Swift will not be obliged to

perform any work under this Warranty

WARRANTY INFORMATION

7

(insofar as it relates to defective or faulty

work or defective Annual Service).

3. All new motorhomes must be registered

with Swift within 6 weeks of purchase

as new.

4. The benefit of the SuperSure and Body Shell

Warranties may be transferred to a new

owner if the motorhome is re-sold, provided

that the motorhome has been serviced in

accordance with the requirements of this

handbook, and details of the change of

ownership have been supplied to Swift

using the change of ownership form set out

in this handbook as soon as reasonably

practicable after the change.

5. If any repairs are identified as being

necessary to the body shell or habitation

areas during an Annual Service or

otherwise, Swift will only pay for Warranty

work performed by an authorised Swift

Group Service Centre. The motorhome

must be made available to an authorised

Swift Group Service Centre within 6 weeks

of the date the repair need was identified

for the work to be carried out. The cost

of transporting, towing or moving the

motorhome by any means to or from the

place of repair is the responsibility of

the owner.

6. The SuperSure and Body Shell

Warranties only apply to motorhomes

purchased and used primarily within the

UK. Please refer to the Fiat handbook for

use of the base vehicle outside the UK.

Terms

7. The Body Shell Warranty covers any defect

with the joints and seals of the panel van

conversion. This includes body leaks,

delamination of floors, and water ingress

through any permanently sealed seam joints

which relate to the conversion of the panel

van. This Motorhome Warranty does not

cover any parts of your motorhome that are

covered by the Fiat manufacturer's warranty.

8. In the first 12 months the SuperSure

Warranty will cover any defect other than

those specified in the Exclusions below.

9. In the years 2 and 3 the SuperSure Warranty

will only cover any defect with the following

components:

• Electrical System: PSU, battery charger,

Smart Command and interior lighting units

(excluding bulbs).

• Water system: water heater, fresh water

tank, water pump, water gauges, taps

and shower head.

• Cooker: the cooker unit including grill,

oven, burners, igniter, and flame failure

device.

• Refrigerator: gas igniter, flame failure

device, door seal condenser, gas control

valve, 12v and 230v heater elements, gas

thermostat, 230v thermostat and 230v

temperature control switch.

• Cassette Toilet: the cassette toilet

(excluding seals, valves and glands).

• Heating system: thermostat, motor,

switches, control unit, gas heater, flame

failure device and igniter (exluding ducting

and fittings).

• Windows: the functionality of the opening

and closing system (stays, handles and

catches) and a warranty against the

cracking of the acrylic, Excludes fading.

• Upholstery: zips, seams and colour

fastness.

In years 2 and 3, any defect specified in the

Exclusions will not be covered.

Exclusions

10. Swift shall not be liable under the

SuperSure and Body Shell Warranties for

any defect related to or arising from the

following:

1. The failure of a component for reasons

of fair wear and tear;

2. Damage resulting from freezing, fire,

over-heating or accidents (whether

caused by the user or a third party);

3. Misuse of any component;

WARRANTY INFORMATION

8

WARRANTY & ASSISTANCE

4. Normal deterioration, corrosion,

intrusion of foreign or harmful bodies,

lack of servicing or negligence of

any person other than Swift which

causes stoppage of or impairment to

the function of any component of the

motorhome;

5. Replacement of parts which have

reached the end of their effective

working life because of age and/or

usage;

6. Cleaning or adjustment of any

assemblies;

7. Cosmetic finishes to kitchen sinks,

cooker tops, vanity units, shower trays;

and/or

8. Routine maintenance items which are

part of the annual service including

lubricants, rubber gas hose, the

cleaning of the heater and fridge

flues, the replacement of gas jets, the

resealing and/or replacement of shower

room sealant, and the adjustment and

lubrication of locks.

11. In addition to the exclusions above, in

years 2 and 3 of the SuperSure Warranty

Period, Swift Group Limited shall not be

liable under this Warranty for any defects

related to:

1. Any audio equipment

• Any microwave; and/or

• Any TV

• Television or audio equipment

12. Swift shall also not be liable under the

SuperSure, and Body Shell Warranties

if the motorhome has been neglected,

misused, modified or used for hire or

reward or if the identification marks

(chassis/VIN numbers) have been

removed or defaced. The motorhome

will be deemed to have been neglected

if it has not been serviced and maintained

as stated in this handbook or any repairs

being identified as necessary at an Annual

Service or by a Swift Group Service

Centre have not been carried out in a

reasonable time.

You have legal rights under UK law

governing the sale of consumer goods.

This Warranty does not affect your legal

rights.

The name and address of the Warranty

provider is:

Swift Group Limited, Dunswell Road,

Cottingham, East Yorkshire, HU16 4JX

To make a claim under this Warranty,

contact the Swift Group Dealer which supplied

your motorhome. Alternatively,

details of your nearest authorised Swift Group

Service Centre can be obtained by contacting

the Swift Group Customer Service Department

on 01482 875740, or enquiring on the website

www.swiftgroup.co.uk

Change of Ownership

You can transfer the remainder of any three

year 'Supersure warranty' and the three year

'Body shell' warranty, details of how to do this

can be found at the rear of this handbook.

Swift Connect Direct

You have access to an online system which is

for all Swift models. A password will be issued

to you, to enable you to interact with us.

To access the system, called 'Swift Connect

Direct', your initial log in details will be emailed

to you once your supplying dealer has

registered your ownership with us.

Please log in and create your own profile.

Should you have issues with accessing Swift

Connect Direct, please contact our Customer

Services Team.

What to do if you Require Assistance

Should you have an enquiry or require

assistance with a problem, we hope that this

guide will be of assistance to you.

Please follow these steps:

1. Check the Owners Handbook, paying

particular attention to the fault finding advice

at the back of the book.

2. Contact your supplying dealer

for assistance.

WARRANTY INFORMATION

9

If you need to contact Swift Group

Limited, please be aware of the following:

1. When contacting Swift Group, please quote

your name, postcode and VIN (Vehicle

Identification Number). This can be found at

the bottom of the front windscreen and on

the side of the sliding door. Also within the

engine bay.

2. In most instances, the Customer Service

Team will involve your dealer in resolving the

issue you are experiencing.

3. Check our website www.swiftgroup.co.uk

and enter the help and advice section

which provides answers to frequently asked

questions and how to contact us.

4. If you are contacting the company by

email, letter or fax, the Customer Service

Team will respond to you within five

working days from the date of receiving the

correspondence.

5. Please be aware that Swift Group Limited

cannot send parts direct from the factory.

In all cases, without exception, your dealer

must place the order for you.

Supplier contacts

A number of Swift Group suppliers manage

their own Technical and Warranty related

queries. Where a customer has a question

relating to a product manufactured by a

company listed below, we would advise that

the first contact should be directly with them.

Sargent Electrical Services

Unit 39, Tokenspire Business Park,

Beverley, East Yorkshire, HU17 0TB

Phone: 01482 678981

Fax: 01482 678987

E-mail: support@sargentltd.co.uk

Truma UK Ltd.

Park lane, Dove Valley Park,

South Derbyshire, DE65 5BG

Phone: 01283 586020

Fax: 01283 586029

technical@trumauk.com

Thetford Ltd.

Unit 6, Brookfields Way, Manvers,

Dearne Valley, Rotherham,

South Yorkshire, S63 5DL

Phone - 0844 997 1960

Fax - 0844 997 1961

Email - infogb@thetford.eu

Dometic (UK) Ltd

Dometic House, The Brewery,

Blandford St Mary, Dorset, DT11 9LS

Phone: 0844 626 0133

Email: technical@dometic.co.uk

https://sargentltd.co.uk

https://www.truma.com/

uk/en/home/index.php

https://www.thetford-europe.com

https://www.dometic.com

/en-gb/uk

WARRANTY INFORMATION

10

SERVICE INSPECTION

Annual service /

inspection record

In order to comply with the warranty, you must

have your motorhome inspected and serviced

in accordance with the warranty.

We highly recommend that you have your

Motorhome serviced by a Swift Group

Approved Service Centre who have direct

access to our online Customer Service

system, Connect. This system provides them

with the ability to order approved parts and

ensure that any product upgrades which

may be available for your Motorhome can

be offered to you and carried out as part of

the service. In the unfortunate event that an

issue requires attention under warranty then

a Swift Group Approved Service Centre are

able to submit a warranty claim to the Swift

Group for processing, and deal with the issue

for you from start to finish. All of our Swift

Group Approved Service Centres are provided

with up to date technical information and

have access to current repair methods giving

you peace of mind that any defect has been

repaired effectively.

It is important that the owner’s handbook

is stamped on the appropriate page by the

authorised Swift Group Service Centre.

Failure to do this will invalidate the warranty

and the transfer of the warranty on the change

of ownership.

The inspection should take approximately two

hours and will cover the areas dealt with in the

annual service check list. Any areas requiring

service and/or maintenance will be highlighted

by your dealer and we recommend that you

authorise any necessary work to be carried

out.

Just as the engine/gearbox/roadwheels need

regular servicing by your chassis dealer, so

there are components in your conversion

that need regular maintenance by your

motorhome dealer.

These include the gas and electrical systems

and the seals in the bodywork. Your dealer will

complete the record in this handbook to show

that the work has been carried out.

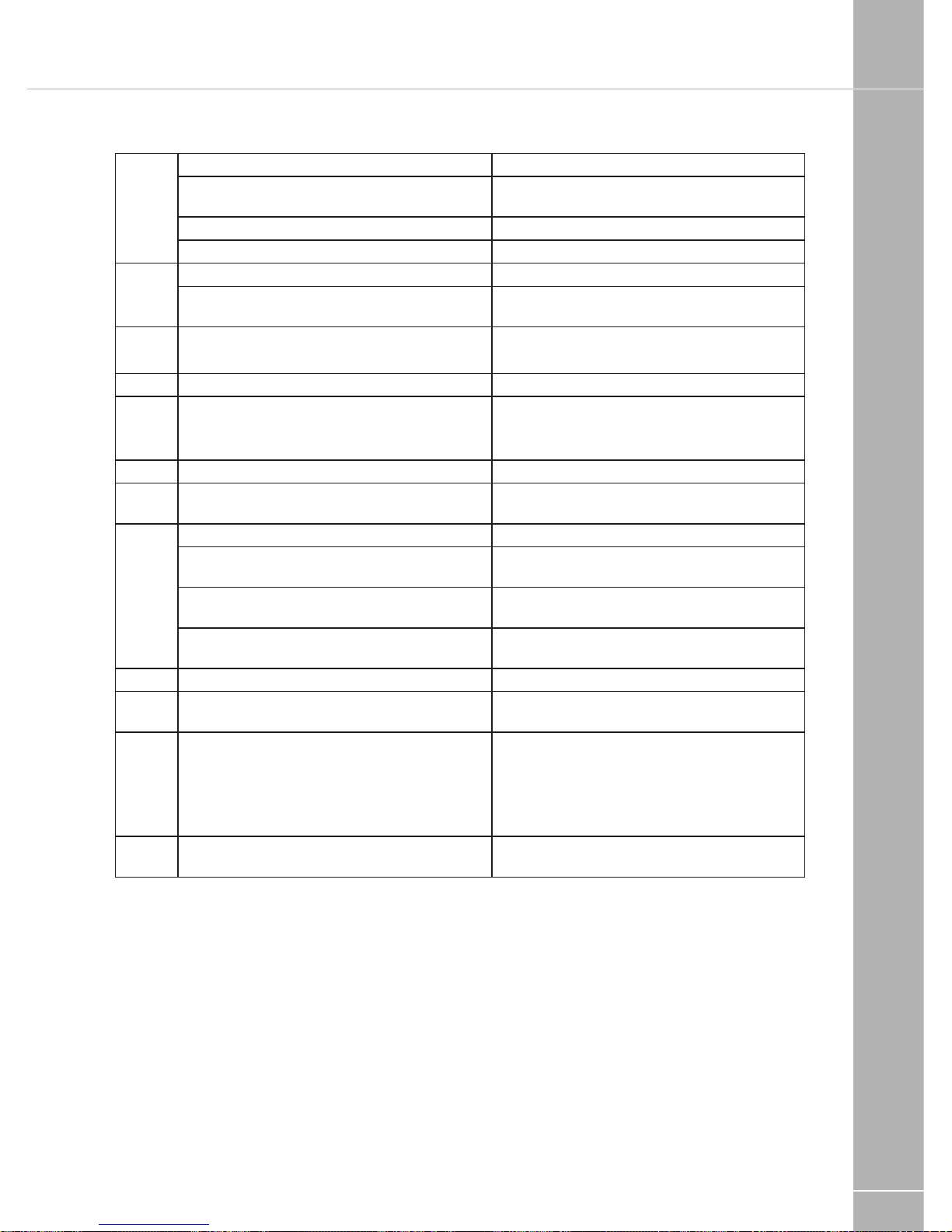

1. Damp and lamination test.

2. Chassis and chassis to body security.

3. Motorhome step.

4. Road lights, wiring and reflectors.

5. Internal lights and 12V DC system.

6. Water heater - gas and 230V AC.

7. Hob, grill and oven.

8. Refrigerator 230V AC, 12V DC and gas.

9. Gas system.

10. Water pump, taps and water system.

11. Mains 230V AC system.

12. Windows and fittings.

13. Roof lights.

14. Furniture hinges/stays etc.

15. Exterior locks and hinges.

16. All internal vents.

17. Seals.

18. Blinds and fly screens.

19. Blown air heating systems.

20. Smoke alarm and battery

21. Carbon monoxide detector and battery

WARRANTY INFORMATION

11

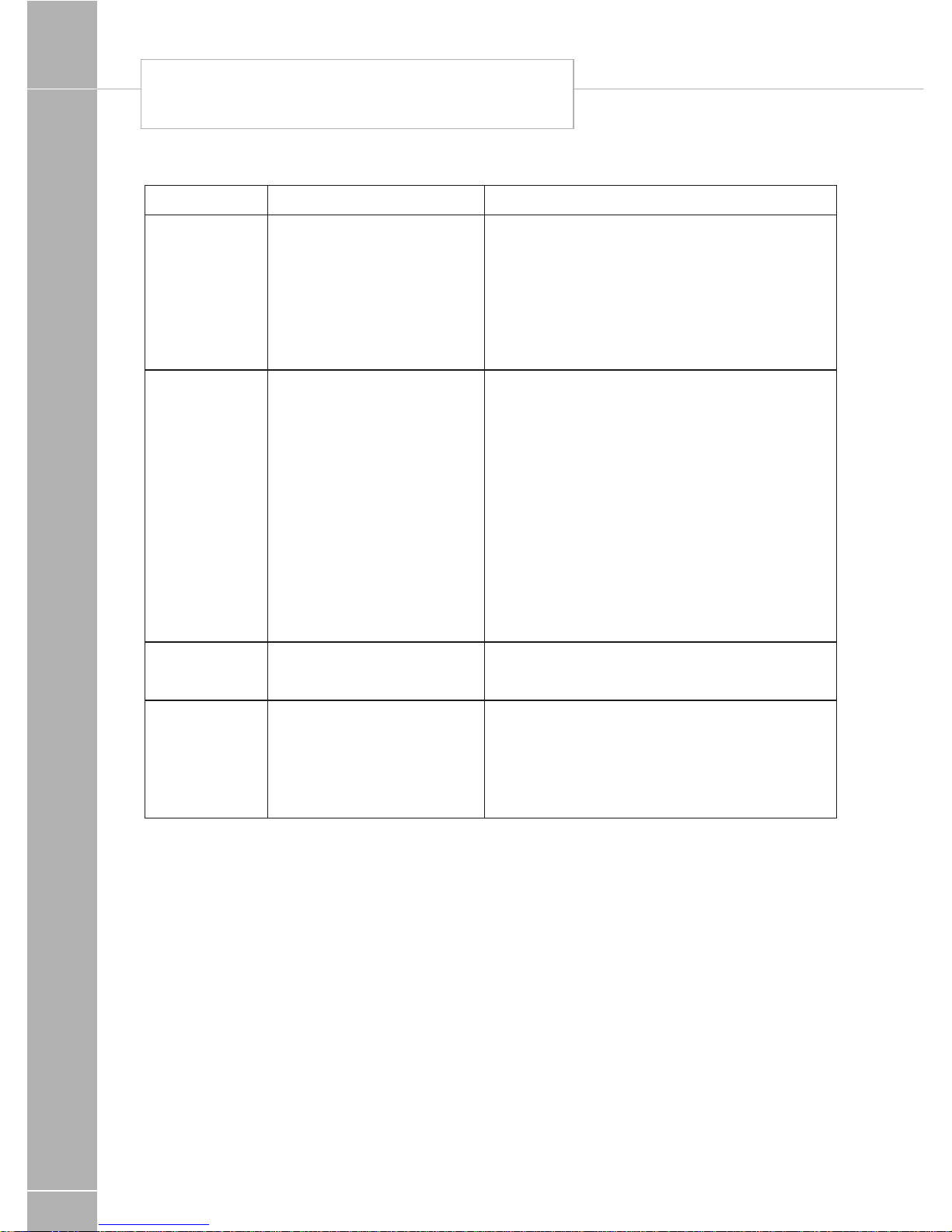

Annual service/inspection record

MOTORHOME MODEL ..................................

REGISTRATION NUMBER ..............................

CHASSIS NUMBER ........................................

REGISTRATION DATE ....................................

1st service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

2nd service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

3rd service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

4th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

5th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

6th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

WARRANTY INFORMATION

12

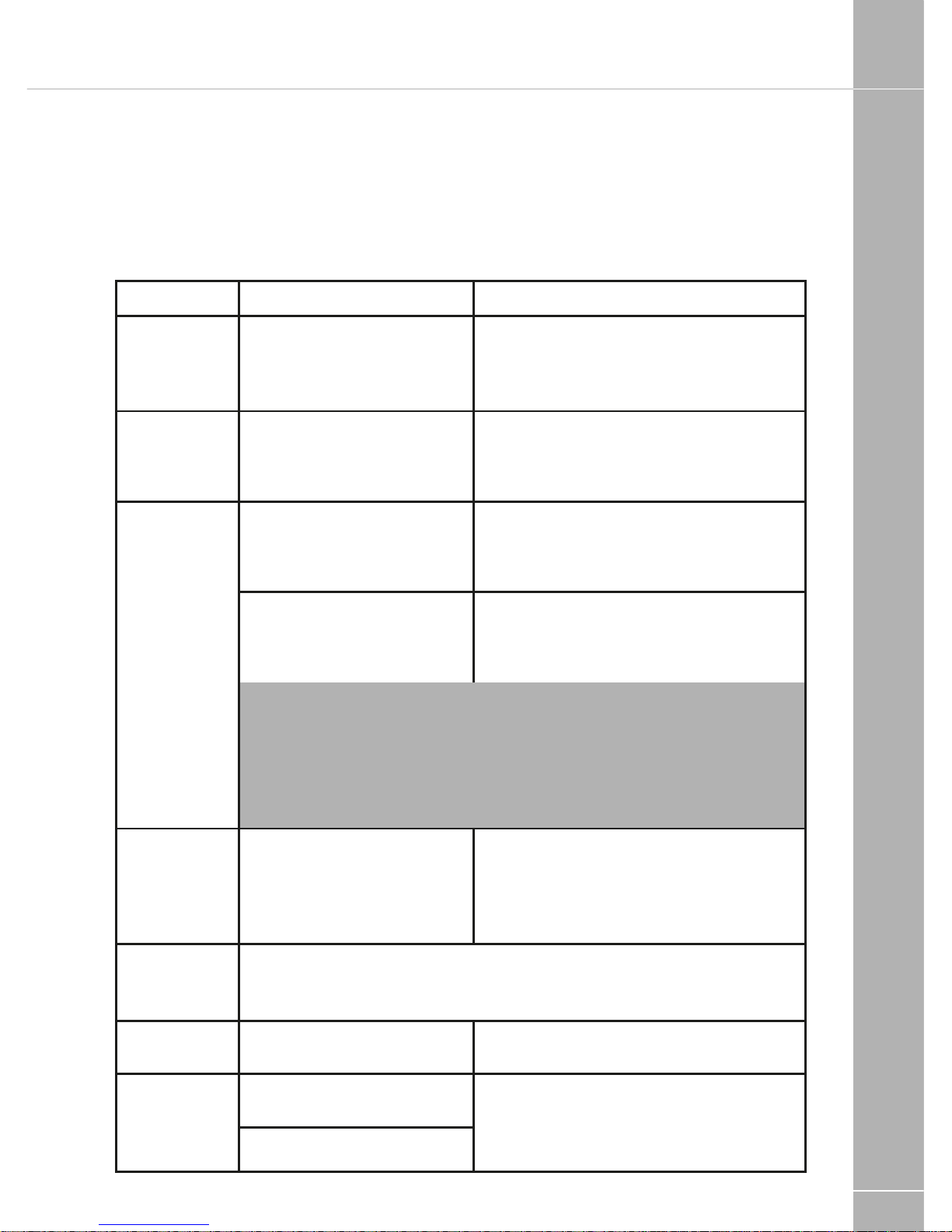

7th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

8th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

9th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

10th service

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

11th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

12th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

13th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

14th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been

carried out in accordance with the handbook.

SERVICE INSPECTION

THE MOTORHOME CODE

13

THE MOTORHOME CODE

Code of Conduct ................................................................................................................... 14

The Country Code ................................................................................................................. 16

The Coastal Code .................................................................................................................. 16

THE MOTORHOME CODE

14

CODE OF CONDUCT

Camp sites

Arrivals

Report to reception immediately on arrival.

Vehicle Movement

Keep to roadways unless otherwise directed.

Adhere to speed limits. Note that these are

generally 10 mph (remember that the stopping

distance on grass is considerably greater than

on tarmac). Only a person in possession of a

current driving licence may drive on the site.

Park correctly as advised on your pitch. Where

possible leave 20 feet of free space around

your vehicle.

Use of Site Appliances

Use the electrical mains hook-up in the correct

manner and with caution.

Ensure that all fresh water taps/connections

are turned off after use. Have care and

consideration when using all facilities (toilets

and showers etc) and leave clean and tidy.

Young children should be supervised.

Dispose of all waste water where instructed.

Empty effluent from chemical toilets where

instructed. To avoid possible damage to

sewage purification works, only approved

chemical fluids must be used. Under no

circumstances should coal tar, phenol or

caustic-based fluids be used.

Disposable nappies and similar bulky items

must not be put into chemical closet emptying

points but should be wrapped in a polythene

bag and placed in the container provided.

Place all litter in containers marked for the

purpose.

Noise

Do not make excessive noise. Children should

be restrained from making excessive noise.

Flying kites and model aircraft and the use of

items like catapults or air-guns, as well as ball

games, should not be permitted among, or

close to other vehicles.

Musical instruments, record players, radios

and televisions should not be used to the

inconvenience of other people on the site.

Open and close doors quietly. Power

generators must be adequately silenced and

used with consideration.

Dogs and other Pets

All dogs and other pets should be kept under

control. Unless permission has been granted,

no animal should be allowed loose on the site

and leads must not exceed 10ft.

No animals should be allowed in the shower/

toilet blocks. Do not let dogs foul the site.

Fire Precautions

Adhere to and take note of fire precautions

noting the whereabouts of the fire points.

! WARNING: Provide one dry powder

fire extinguisher of an approved type or

complying with EN3-7 or ISO7165, of at

least 1kg capacity, by the main exterior

door and a fire blanket next to the cooker.

Familiarise yourself with the operating

instructions on your fire extinguisher and the

local fire precaution arrangements.

When using a dry powder extinguisher it is

suggested that the motorhome be evacuated

until the powder has settled, to avoid

inhalation.

Unless permission has been granted,

barbecues should not be used.

If permission is given, consideration should be

given to the annoyance that can be caused to

other users of the site.

Open fires are not allowed.

Awnings and Tents

Awnings and tents should only be used when

permission has been obtained.

When on grass and staying for more than a

few days, the ground sheet and/or side flaps

of awnings should be periodically raised in

order to avoid damage to the ground.

THE MOTORHOME CODE

15

CODE OF CONDUCT & THE COUNTRY CODE

Departure

Leave the pitch clean and tidy.

On leaving, check out with reception paying

the required fees.

Wild Camping

Camping away from licensed sites, without the

permission from the land owner or his agents,

is not allowed in the United Kingdom.

When permission has been granted, all

aspects of this Code should be adhered to.

On no account should:

a. Litter be disposed of other than in the

receptacles provided.

b. Water be allowed to escape from the

vehicle.

c. Chemical toilets be emptied except into the

disposal places agreed with the land owner.

d. Washing or similar be hung outside the

vehicle.

Parking

Motorhomes should only be parked in

approved places.

When using the facilities of a motorhome, care

and consideration should be given to those

around them.

Driving

Before moving off, elevated rooflights and

aerials should be lowered and correctly

secured, and top hinged windows closed.

Likewise all doors and access lockers for

gas containers and chemical toilets must be

properly secured.

Exterior steps should be properly retracted

and secured. When the vehicle is in motion

it is compulsory for all front seat passengers

and rear seat passengers to wear seat belts,

where fitted. When using a motorhome on

either the public highway or private roads the

Highway Code should be complied with and

full consideration given to other road users.

In the event of a motorhome travelling

slowly the driver of the motorhome should,

where possible, pull over in order to let other

traffic pass.

! WARNING: When travelling, refuelling

or on a ferry ensure the gas system is fully

isolated at source.

Handbooks (Chassis & Converter)

Before using a motorhome all aspects of

the handbooks, produced by the chassis

manufacturer and the converter, must be read

and adhered to.

The separate chassis manufacturer handbook

refers to your motorhome chassis and base

vehicle including care and maintenance.

Link to Fiat handbook

THE MOTORHOME CODE

16

THE COASTAL CODE

Environment

Care and consideration should be taken to

protect the environment.

Observe the Country and Coastal Codes

shown below.

The country code

Enjoy the countryside but respect its life

and work. More people than ever before

are exploring the countryside, interested

in farming, plant life, bird watching or just

observing the general wildlife. Whatever your

interest, there is a lot to learn, but please

observe the following code:

1. Guard against all risk of fires. Hay and

heathland catch alight easily and once

ablaze are very difficult to put out.

Remember: fire spreads quickly.

2. Fasten all gates.

3. Keep your dog under proper control.

4. Keep to the paths across farm land.

5. Avoid damaging fences, hedges and walls.

6. Leave no litter.

7. Safeguard water supplies.

8. Protect wildlife, wild plants and trees.

9. Go carefully on country roads.

10. Respect the life of the countryside.

The coastal code

As our coastlines are increasingly used

for recreation and education, the following

suggestions are made to enable us to

enjoy our inheritance and preserve it

for posterity.

DO NOT trample about, or move rocks

unnecessarily.

DO NOT frighten seals or seabirds.

DO NOT spill detergents, solvents or fuel from

boats as these can kill marine life.

Live molluscs and crustaceans need not

be collected as souvenirs - dead shells can

usually be found.

Shellfish can take years to grow and fines

can be imposed for not observing national

regulations.

DO NOT pull up seaweeds unnecessarily.

Make your visit instructive - not destructive.

Look at material - don’t remove it. Take notes

and photographs, not specimens.

Observe by-laws and be considerate to others.

National Trust property and Country Parks

have regulations to protect the wildlife. Follow

these and the Country and Coastal Codes.

PREPARING FOR THE ROAD

17

PREPARING FOR THE ROAD

Before Moving Off ................................................................................................................... 18

Motorhome Terms .................................................................................................................. 18

Loading of Vehicle .................................................................................................................. 19

Large Storage Areas ............................................................................................................... 20

Tyres ....................................................................................................................................... 20

Dedicated Travelling Passenger Seats .................................................................................... 20

Seat belts & legislation ............................................................................................................ 21

Child seats ............................................................................................................................. 21

Airbag ..................................................................................................................................... 22

Three Point Seat Belts ............................................................................................................. 22

Driving Licence ....................................................................................................................... 22

Vehicle Classifications ............................................................................................................. 22

Advice on towing .................................................................................................................... 22

European touring .................................................................................................................... 23

PREPARING FOR THE ROAD

18

BEFORE MOVING OFF & MOTORHOME TERMS

Before moving off check:

• Gas cylinders are correctly positioned,

secured and turned off unless using

en-route heating.

• All gas operated appliances have been

isolated except en route heating where fitted

and in use.

• Loose articles including luton ladder are

stowed securely. Do not stow tins, bottles or

heavy items in overhead lockers.

• All lockers and cupboard doors are closed

and secured.

• Tables are stored or locked in their

transit position.

• Fridge is on 12V operation and door lock

is set.

• 230V mains input socket flap is

securely closed.

• All drain valves are closed.

• Tyre pressures

• Exterior roof rack ladder is raised

and secured (where fitted).

• All windows/doors/rooflights are closed

and secured.

• Exterior step (where fitted) is retracted /

folded in.

Special attention must be taken to ensure all

top hinged windows as well as rooflights are

closed when in transit. All units should be fully

closed and latched to prevent damage. The

motorhome rear and side sliding door should

also be locked.

! WARNING: Large and/or voluminous

items should be stored securely before

travelling.

Motorhome terms

Mass in running order

The mass of the motorhome equipped to

the motorhome manufacturers standard

specification, as stated by the manufacturer.

The MRO comprises the ex-works weight of

the motorhome, including the driver, 90% fuel

capacity, 1 x LPG gas cylinder @10kg and

standard fixtures & fittings in compliance with

European Regulation No. 1230/2012 (Masses

& Dimensions)

Note: The mass of the motorhome in

running order contains provision for the

masses of liquids, gas etc. (see Mass in

Running Order in the Technical Section).

Part of this provision can also be utilised as

additional payload, if for example, you wish

to travel with no gas cylinders.

Note: If you travel with water in the fresh

water tank or waste tank, the payload will be

reduced accordingly.

Note: Quoted MRO is subject to tolerance,

due to weight variation of materials used in

Motorhome construction.

Maximum User Payload:

The maximum allowable weight to be put into

the motorhome whilst it is being driven. This

is made up of 4 sections: Personal effects,

conventional load, optional equipment and

essential habitation equipment.

The Maximum User Payload is the difference

between the Maximum Technically Permissible

Laden Mass and the Mass in Running Order.

Personal Effects:

Those items which a user can choose to carry

in a motorhome and which are not included

as Essential Habitation Equipment or Optional

equipment.

Conventional Load:

A mass allowance for each designated

passenger seat.

PREPARING FOR THE ROAD

19

LOADING OF VEHICLE

Optional Equipment:

Items made available by the manufacturer over

and above the standard specification of the

motorhome.

Essential Habitation:

A mass allowance for liquids in systems not

accounted for within the MRO.

Maximum Technically Permissible

Laden Mass:

The maximum weight for which the

motorhome is designed for normal use when

being driven on a road, laden. This mass takes

into account specific operating conditions

including factors such as the strength of

materials, loading capacity of tyres etc.

! WARNING: Under no circumstances

should the Maximum Technically

Permissible Laden Mass of this motorhome

be exceeded.

Nose weight on towed trailers:

The static mass of the trailer towing device on

the rear of the towing vehicle.

When measuring the noseweight it is important

that the trailer is loaded.

The trailer is intended to be towed slightly

nose heavy. The nose weight can be adjusted

by distribution of the load. The nose weight

should be approximately 7% of the actual

laden weight (but not greater than the hitch

capacity) and at the same time suit the

motorhome requirements. See ‘Advice on

Towing’ page 22.

Loading of vehicle

! WARNING: Loads must not be

exceeded. The driver is responsible for

arranging the loads so that they comply with

the technical weight limits of the specific

motorhome model.

See specification handbook.

Correct weight distribution is an important

factor in ensuring your vehicle is well balanced

and easy to drive. It is therefore necessary to

load your motorhome carefully making sure all

heavy articles are evenly distributed and are

preferably placed in the lower lockers or bed

boxes.

! WARNING: Do not travel with televisions

or microwaves in overhead lockers unless

the appliance was supplied fitted to your

motorhome by the manufacturer.

Although it is essential to ensure that the

total weight of your motorhome does not

exceed the stipulated Maximum Technically

Permissible Laden Mass, (MTPLM), it is

important to remember that the front and rear

axles also have individual maximum weights

which must not be exceeded.

To ensure adequate road holding the load

on the front axle, under all conditions,

must not be less than 40% or more than

70% of the total weight.

Ensure you distribute the payload equally on

each side of the vehicle to avoid an imbalance.

PREPARING FOR THE ROAD

20

TYRES & PASSENGER SEATING

These weights, together with the MTPLM, can

be found on the statutory plate affixed to the

forward edge side sliding door.

! WARNING: Turn off all gas appliances

while the vehicle is in motion. If a en-route

heating system is fitted isolate all appliances

except the heater.

! WARNING: Please take care to

ensure you have allowed for the masses

of all the items you intend to carry in your

motorhome e.g. passengers, optional

equipment, essential habitational equipment

and personal effects such as clothing,

food, pets, bicycles, sailboards and sports

equipment etc.

Large storage areas

The large storage areas provided in some

motorhome layouts are designed solely for

the purpose of carrying personal possessions,

these areas must not be used:

• As a habitation area (eg living, sleeping or

cooking).

• To carry passengers, animals or livestock.

• For the installation (or use) of any LPG gas

operated appliances (unless supplied fitted

by the manufacturer).

• For carrying LPG gas cylinders.

• To carry any flammable liquids, unless

properly stored, sealed and secured.

• For the operation of an electrical generator.

• In such a way that the load exceeds the

MTPLM, and/or minimum and maximum

axle loads.

Care must be taken to ensure that exterior

doors are closed, locked and that all

possessions are properly stored and secured

before setting off on any journey.

Tyres

If a wheel or tyre is changed any

replacement must be of the same type

of construction and size.

The law requires that the tyres and pressures

must be suitable for the use to which they

are being put. The minimum tread depth

must be 1.6mm throughout a continuous

band comprising the centre three-quarters

of the breadth of the tread and around the

circumference of the tyre.

Please refer to base vehicle manufacturer’s

handbook for tyre pressure information.

This may also be displayed in the driver’s or

passenger's door aperture.

The motorhome tyre pressure noted in the

Technical book are the pressures stated by

Fiat for your vehicle calculated in a fully laden

condition. If you are not running fully laden,

reduced pressures could be used but please

seek clarification from the tyre manufacturer.

Dedicated travelling passenger

seating

Seat belts are fitted to all travelling seats.

Travelling seats are

designated by the

manufacturer and vary

according to the layout

you have purchased. Each

seat is homologated i.e.

tested to all relevant safety

requirements. NEVER

travel in or attempt to

install a seatbelt to a non-designated seat.

! WARNING: Side facing seats are

designed for habitational use only, not for

when the vehicle is in motion.

Fig. 1

PREPARING FOR THE ROAD

21

Seat belts and legislation

Designated driver and passenger seats are

fitted with seat belts and MUST be worn when

travelling.

All children up to 135cm (4'5") in height, or 12

years of age, whichever is reached first must

use a child car seat or booster seat suitable for

their age and weight.

Children over 135cm (4'5") in height or aged

12 years and over must wear a seat belt.

Note: It is the legal responsibility of the

driver To ensure children aged up to 14

years old are suitably restrained.

For passengers aged 14 and over, it is their

responsibility (not the driver) that a seat belt

is worn.

Seat belts are fitted for your safety and must

be worn unless a ‘Certificate of Exemption

from Compulsory Seat Belt Wearing’ is held.

This Certificate must be produced if asked for

by the Police – seat belt offences can result in

a fine.

Child seats

Choosing/Buying

Go to a reputable retailer such as Halford's,

Mothercare, John Lewis etc. Most reputable

retailers will have trained child seat advisers

on site and will offer a fitting service. Ask the

advisor to fit various seats to the vehicle. Once

a correctly fitted seat has been installed, satisfy

yourself on it's suitability for your child and the

vehicle before buying as it is important to use a

correctly fitting seat in your motorhome.

! WARNING: The child seat you use in

your car may not be suitable for mounting

on a motorhome seat.

Choose the right seat for your child's height

and weight.

Height-based seats

Height-based seats are known as ‘i-Size’

seats. They must be rear-facing until your child

is over 15 months old. Your child can use a

forward-facing child car seat when they’re over

15 months old.

You must check the seat to make sure it’s

suitable for the height of your child.

Only EU-approved height-based child car

seats can be used in the UK. These have

a label showing a capital ‘E’ in a circle and

‘R129’.

Weight-based seats

The seat your child can use (and the way they

must be restrained in it) depends on their

weight.

Only EU-approved weight-based child car

seats can be used in the UK. These have a

label showing a capital ‘E’ in a circle and ‘ECE

R44’.

You may be able to choose from more than

one type of seat in the group for your child’s

weight.

For more information visit www.gov.uk

Never fit or use a second hand car seat.

It could have been damaged and may

not meet modern standards. The fitting

instructions may also be missing.

Positioning/Fitting

Dependant upon the child seat type, the most

suitable position for the child seat to be fitted

may be the front passenger seat of the cab

(NOTE airbag advice below) or the window

seat of the forward facing rear seat, the isle

seat in the rear is NOT a recommended

position, advice should always be taken from

the retailer on the suitability and security of the

seat in the motorhome. Read and follow the

child seat manufacturer's instructions for fitting

the seat.

All Swift motorhomes are fitted with inertia reel

seat belts, however, the child seat must be

tight in the adult seat. Push all your weight into

PREPARING FOR THE ROAD

22

the child seat as you tighten the belt.

Keep a copy of the child seat fitting instruction

in the motorhome for easy reference.

Any doubts, ask an advisor to show you how

to correctly install the seat.

Airbag

Never fit a rear facing child restraint in a seat

with an active airbag in front of it.

Forward-facing child restraints should be

positioned as far back from the airbag as

possible. Check the base vehicle handbook.

Three point seat belts

This section refers to the seat belts located in

the habitation area of your motorhome.

Fastening the seat belt:

Insert tongue into buckle; a positive ‘click’

indicates correct assembly.

Releasing the seat belt:

Press the red release button, the tongue will

be ejected from the buckle.

• The belt is designed for use by one person

and must not be put around a child seated

on a person’s lap.

• The belt is suitable for restraining most child

seats and boosters.

• The belt should at all times be adjusted and

used in accordance with the instructions. No

excessive slackness should be present.

• Once installed the diagonal should pass

across the centre of the shoulder and the

buckle should lie just on or below the hip.

• Avoid twisting the webbing during use.

Webbing must not be allowed to chafe

against sharp edges.

• Do not make alterations or additions to the

belt.

• Belts that have been cut, frayed, damaged or

stressed through impact should be replaced.

After impact the motorhome anchorage

points should also be checked.

• To clean use warm soapy water only.

• Periodic inspection of the installation will

ensure reliability of the seat belt.

Driving licence

Licences issued to drivers who passed their

car driving test before 1st January 1997

include categories B+E and C1+E which gives

them entitlement to drive motor vehicles up to

7500kg MTPLM.

Drivers who passed their test on or after this

date have category B entitlement only, which

restricts the entitlement to motor vehicles

with up to 8 passenger seats and an MTPLM

of up to 3500kg with trailers up to 750kg

MTPLM (4250kg combined) or larger trailers

providing the combination of the trailer and

towing vehicle does not exceed 3500kg and

the MTPLM of the trailer does not exceed the

unladen weight of the towing vehicle.

Drivers who passed their test on or after

the 1st January 1997 will need to take an

additional test(s) to gain the B+E and C1+E

entitlement.

Vehicle classifications

Motorhomes up to 3500kg MTPLM are P/LGV

(Private Light Goods Vehicles), motorhomes

with an MTPLM over 3500kg and up to

7500kg are P/HGV (Private Heavy Goods

Vehicles). These are used for vehicle excise

duty (road tax) classifications.

Advice on Towing

The towing capability of each motorhome

differs depending on the specific chassis and

engine types, (see ‘Towing Capabilities Table’

in your specification section).

This table takes account of the maximum front

and rear axle loadings as well as the minimum

front axle loading in two conditions, MRO and

MTPLM condition.

Towing in these, and any other condition

requires sensible loading and distribution of

payloads to ensure the requirements of the

towing capability table are met.

When towing, the demands on both the

vehicle and driver increase. A trailer reduces

manoeuvrability, the ability to climb hills,

acceleration and braking capacity and makes

the vehicle handle and corner differently. It will

also increase the fuel consumption of

the vehicle.

THREE POINT SEAT BELTS

VEHICLE CLASSIFICATIONS & ADVICE ON TOWING

PREPARING FOR THE ROAD

23

Always brake in good time. Special care must

be taken when descending gradients. Change

down before going down a steep hill so the

engine can act as a brake. Ensure that the

towing vehicle tyre pressures are correct and

adjusted for full load conditions and that the

trailer tyre pressures are as recommended by

the trailer manufacturer. Regularly check the

operation of trailer brakes and lights.

For maximum stability, when loading the trailer

ensure that the loads are properly secured

during transit. Position loads so that most of

the weight is placed close to the floor and,

where possible, immediately above or close

to the axle(s). Where the load can be divided

between trailer and tow vehicle, loading

more weight into the vehicle will generally

improve the stability of the combination.

After loading the trailer, check that the nose

weight and axle loads are in accordance

with the manufacturer’s recommendations,

also check the rear and front axle loads on

the motorhome. When calculating the laden

weight of the trailer, remember to include the

weight of the trailer PLUS THE LOAD.

Note: Towing regulations vary from country

to country. It is very important to ensure

that national regulations governing towing

weights and speed limits are observed

(refer to the relevant national motoring

organisation for information). The stated

maximum permissible towing weights refer

to the vehicle’s design limitations and NOT

to any specific territorial restrictions.

Notes:

1. Do not exceed the motorhome gross vehicle

train weight.

2. Do not exceed the maximum front & rear

axle loads on the motorhome.

3. Ensure the motorhome front axle load is

never less than 40% or more than 70% of

the total weight.

4. Motorhomes with an MTPLM up to 3500kg

which have European Type approval can

only be fitted with a type approved towbar

complying to 94/20/EC or UN ECE R55.

5. The limit for towing an un-braked trailer

is 750kg (based on VIN plate not actual

weight), this applies to a towed car.

6. A car dolly with a car with a GVW over

750kg in place is considered as two

trailers, these are legal for use for recovery

but under the Road Traffic Regulations

Act 1984 the combination is limited to 40

mph on motorways and dual carriageways

and 20 mph elsewhere. A car dolly is not

legal for transportation (there is a very

specific difference between recovery and

transportation. Recovery is defined as the

removal of a broken down vehicle to a place

of safety).

7. The maximum permitted vehicle combination

length is 18.75m, however any combination

must ensure compliance with the turning

circle requirements of Construction and Use

regulations 1986 & 97/27/EC.

Note: Not all motorhomes are suitable for

towing and may not have sufficient payload to

permit towing. If in doubt, consult your dealer.

European Touring

Please note there are a number of

requirements placed on a driver when driving

on European roads. Carrying a warning

triangle, high visibility jacket, first aid kit

and spare bulb is now compulsory in many

EU states but some EU countries are now

introducing further regulations such as carrying

a breathalyser kit and not being able to use

satellite navigation systems with speed camera

warnings.

We would advise customers to check on the

many web-sites available to ensure you are

carrying the correct equipment when touring in

those EU countries.

EUROPEAN TOURING

EN ROUTE

25

EN ROUTE

Fix & Go tyre repair kit ............................................................................................................ 26

Cruise Control ........................................................................................................................ 28

Parking Sensors ..................................................................................................................... 28

Fix & Go Repair Kit (if fitted)

CAUTION: Before use please read the user

instructions supplied with your Fit & Go

repair kit.

(For more details see Fiat user Manual)

If a spare wheel is not fitted within the

specification of your vehicle, then a Fix & Go

kit is supplied.

The Fix & Go automatic quick tyre repair kit

is positioned at the front of the vehicle

passenger compartment and includes Fig. A:

Fig.A

• Bottle A containing sealer and fitted with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible to

the driver (on the instrument panel) after

fixing the tyre;

• Instruction brochure (see fig. B), to be used

for prompt and correct use of the quick

tyre repair kit and then to be handed to the

personnel charged with handling the tyre

treated with the tyre repair kit;

• A compressor D complete with pressure

gauge and connectors; a pair of protective

gloves located in the side compartment of

the compressor;

• Adaptors for inflating different elements

CAUTION: Give the instruction booklet to

the tyre repair workshop personnel.

CAUTION: Punctures on the sides of the

tyre cannot be repaired. Do not use the

quick tyre repair kit if the damage is due to

running with flat tyre.

CAUTION: If the wheel rim has been

damaged (bent so as to cause air to leak),

the wheel cannot be repaired. Do not

remove the foreign body (screws or nails)

from the tyre.

CAUTION: Punctures caused by foreign

bodies can be repaired if the damage does

not exceed 4 mm on the tread and on the

shoulder of the tyre.

Fig.B

Important Information:

The sealing fluid of the quick tyre repair kit is

effective at external temperatures of between

-20 °C and +50 °C. The sealant has an expiry

date.

CAUTION: The bottle contains ethylene

glycol. It contains latex that might cause

allergic reactions. It is harmful if swallowed.

It is irritant for the eyes. It may cause

sensitisation if inhaled or on contact.

Avoid contact with eyes, skin and clothes.

In the event of contact, wash immediately

with plenty of water. Do not induce vomiting

if swallowed. Rinse your mouth and drink

plenty of water. Call a doctor immediately.

Keep out of the reach of children.

The product must not be used by

asthmatics. Do not breathe in the vapours

during insertion and suction. Call a doctor

immediately if allergic reactions are noted.

Store the bottle in its proper compartment,

away from sources of heat. The sealant has

an expiry date. Replace the bottle

EN ROUTE

26

FIX AND GO

EN ROUTE

27

INFLATION PROCEDURE

Inflation Procedure

CAUTION: Wear the protective gloves

provided together with the quick tyre repair

kit.

CAUTION: Affix the adhesive label in an

easy-to-see position for the driver as a

reminder that the tyre has been treated with

the quick tyre repair kit. Drive carefully,

particularly on bends. Do not exceed 80

km/h. Do not accelerate or brake suddenly.

CAUTION: If the pressure falls below 3

bars, do not drive any further: the Fix &

Go automatic quick tyre repair kit cannot

guarantee proper hold because the tyre is

too much damaged. Contact a Fiat

Dealership.

CAUTION: You must inform the dealership

that the tyre has been repaired using the

quick tyre repair kit. Give the booklet to the

personnel who will be handling the tyre

treated with the repair kit.

CAUTION: If different tyres from the ones

supplied with the vehicle are used, it may

not be possible to carry out the repair. If the

tyres are replaced, it is advisable to use

those approved by the manufacturer.

Consult a Fiat Dealership.

• Pull the handbrake. Unscrew the tyre valve

cap, take out the filler hose A (Fig. C) and

tighten the ring nut B on the tyre valve;

• Insert the plug E (Fig. E) in the nearest 12V

power socket and start the engine.

Turn the selector D (Fig. D) anti-clockwise

to the repair position. Activate the kit by

pressing the on/off switch. Inflate the tyre

to the pressure specified in the "Inflation

pressure" paragraph, in the "Technical Data"

chapter;

For a more accurate reading, it is advisable to

check the pressure reading on the pressure

gauge F (Fig. D) with the compressor off and

without moving the centre selector from the

repair position

F

ig C

F

ig D

• If after 10 minutes it is still impossible to

reach at least 3 bar, release the transparent

filler pipe from the valve and take out the

12 V plug, then move the vehicle forwards

by about 10 metres in order to distribute

the sealing fluid inside the tyre evenly, then

repeat the inflation operation;

• If after this operation you still cannot reach at

least 3 bar after 10 minutes, do not resume

driving because the tyre is too damaged and

the quick tyre repair kit cannot guarantee

suitable sealing. Contact a Fiat Dealership;

• If the tyre reaches the pressure specified

in “Inflation pressure” paragraph in the

"Technical Data" section of the Fiat user

manual start driving immediately;

EN ROUTE

28

FIX AND GO /

CRUISE CONTROL / PARKING SENSORS

F

ig E

• after having driven for about 10 minutes,

stop and recheck the tyre pressure;

remember to apply the handbrake;

• If a pressure value of at least 3 bar is

detected, inflate to the correct pressure,

resume driving and drive with care to nearest

Fiat Dealership.

Bottle Replacement Procedure

To replace the bottle, proceeds follows:

Fig. F

• press button A (Fig. F) to release the part;

• fit the new bottle and press until it is

automatically engaged.

CAUTION: Punctures caused by foreign

bodies can be repaired if the damage does

not exceed 4 mm on the tread and on the

shoulder of the tyre.

CAUTION: Replace the bottle containing

the sealant after the expiry date. Dispose of

the bottle and the sealant properly.

Have the sealing fluid and the bottle

disposed of in compliance with national and

local regulations.

Cruise Control

The driver of the vehicle should always

remain seated and in control of the vehicle

when the cruise control has been engaged.

Never leave the driving seat for any reason

when the vehicle is underway.

Parking sensors

Parking sensors are fitted to some vehicles.

Please use the information provided. Use the

sensors as a guide only. It is the responsibility

of the driver to ensure it is safe to reverse the

vehicle.

SAFETY & SECURITY

29

SAFETY & SECURITY

Fire ........................................................................................................................................ 30

Smoke Alarm Operation ........................................................................................................ 30

Fire Extinguisher ..................................................................................................................... 30

Escape Paths ......................................................................................................................... 30

Children ................................................................................................................................. 30

Ventilation .............................................................................................................................. 31

CO Alarm .............................................................................................................................. 31

Security ................................................................................................................................. 31

Vehicle Identification Number ................................................................................................. 31

Swift Command Tracker by Sargent ...................................................................................... 32

VIN CHIP™ ........................................................................................................................... 33

SAFETY & SECURITY

30

FIRE AND FIRE ALARM

Fire

Note: Your attention is drawn to the notice

affixed inside the wardrobe advising on fire

precaution, ventilation and what to do in

case of fire.

In case of fire

1. Get everyone out of the motorhome as

quickly as possible using whichever exit is

the quickest, including windows. Do not

stop to collect any personal items.

2. Raise the Alarm. Call the Fire Brigade.

3. Turn off the gas supply valve if it is safe to

do so.

4. Turn off the electricity supply at

supply point.

Smoke Alarm Operation

Your motorhome is fitted with a Fire Angel SB1

smoke alarm. Please read the user instructions

for the smoke alarm, which are available at the

following location:

http://fireangel.co.uk/products/sb1-t

If you are unable to view the documents on

line, please contact the supplier, your dealer or

Swift for an electronic or paper copy.

! WARNING: Never use portable cooking

or heating equipment other than electric

heaters that are not of the direct radiant

type, as it is a fire and asphyxiation hazard.

! WARNING: Appliances such as cookers

must not be used for heating.

Fire Extinguisher

It is recommended that a dry powder fire

extinguisher be carried inside your motorhome

at all times.

When using a dry powder extinguisher it is

suggested that the motorhome be evacuated

until the powder has settled, to avoid

inhalation.

A fat pan fire should not have a fire

extinguisher aimed at it. It should be

smothered with a fire blanket.

! WARNING: Provide one dry powder

fire extinguisher of an approved type or

complying with EN3-7 or ISO 7165, of at

least 1kg capacity, by the main exterior door

and a fire blanket next to the cooker.

Familiarise yourself with the instructions

on your fire extinguisher and the local fire

precaution arrangements.

Escape paths

It is important that you do not block escape

paths to emergency exits with obstructions

or hazards.

Children

Do not leave children alone in the motorhome

in any event. Keep potentially dangerous items

out of reach, as at home e.g. matches and

drugs etc.

SAFETY & SECURITY

31

VENTILATION AND SECURITY

Ventilation

All motorhomes comply with BS EN 721. The

ventilation points on your motorhome are fixed

points of ventilation which are required by the

European Standards.

All motorhomes have ventilation at high level

and low level which have been calculated to

suit the individual needs of your motorhome.

High level ventilation is achieved by means of

the roof lights and washroom roof ventilators

(where applicable). The low level ventilators

are positioned in the front fascias of furniture in

van conversions.

Under no circumstances must these vents be

blocked or obstructed in any manner as this

could lead to insufficient fresh air. In this case

the confined atmosphere becomes depleted of

oxygen which could lead to dangerous levels

of carbon dioxide (CO2) build up, leading up to

the risk of asphyxiation.

The risk of carbon (CO) build up, which is

a colourless, odourless and tasteless gas,

will also be reduce with ventilation. Carbon

monoxide is produced from incomplete

combustion and should the CO detector

be activated the cause of the incomplete

combustion must be investigated prior to

reusing the appliance in question.

It is advised that fixed ventilation points

are checked and cleaned (if necessary) on

a regular basis using a small brush and a

domestic vacuum cleaner.

Additional night time ventilation is obtained

by releasing the window catches and placing

them in the second groove. Note the windows

are not sealed from rain in this position.

As the ventilation levels are calculated to suit

each model requirements, no modifications

should be made which may result in reduced

ventilation levels.

! WARNING: Do not obstruct ventilation.

CO alarm

Your motorhome is fitted with a Fireangel CO9D Carbon Monoxide Alarm. Please read the

instructions for the alarm, which are available

at the following location:

http://fireangel.co.uk/wp-content/

uploads/2015/07/CO-9D%20Manual.pdf

If you are unable to view the documents on

line, please contact the supplier, your dealer or

Swift for an electronic or paper copy.

Security

Motorhome Theft:

The theft of a motorhome can occur in

the most unlikely circumstances; from a

motorway service area or even an owner's

driveway. Secure all windows and doors

when your motorhome is unoccupied even if

only for a short length of time.

VIN

(Vehicle identification Number)

Record your motorhome VIN which can be

found on the lower edge of the base vehicle

front windscreen and the plate located on the

front cross member under the bonnet.

Make a note of these numbers in the space

provided at the front of this handbook and

make a separate note of the numbers to keep

safe at home.

SAFETY & SECURITY

32

SWIFT COMMAND TRACKER

Additional security

Consider fitting any device which might deter

intrusion by thieves. Customers are advised

to identify their motorhome with a method

for subsequent identification if other forms of

identification have been altered or removed.

Free crime prevention advice about securing

your motorhome, protecting your valuables,

property marking either at home or whilst

on site, can be obtained from the Crime

Prevention Officer through your local Police

station.

Swift Command Tracker

by Sargent

A Swift Command Tracker is built in to your

vehicle and forms part of the Swift Command

system.

The unit is Thatcham Category 6 certified and

is monitored by an approved monitoring centre

which operates 24 hours a day 7 days a week

and provides European coverage and direct

police liaison.

This system is ready for use, all you need to

do is purchase a tracking subscription by

visiting www.swiftcommand.co.uk or calling

Sargent on 01482 881655.