Introduction

INTRODUCTION

DEAR OWNER,

THANK YOU FOR DECIDING TO BUY ONE

OF OUR NEW CARAVANS. WE ARE SURE

YOU WILL ENJOY MANY HAPPY HOURS

IN IT AND WE HOPE THE INFORMATION

AND HINTS IN THIS HANDBOOK WILL

HEIGHTEN YOUR ENJOYMENT.

THE HANDBOOK HAS BEEN DESIGNED

TO GIVE YOU A GENERAL GUIDE TO THE

CARE, USE AND MAINTENANCE OF YOUR

CARAVAN. WHETHER YOU ARE A NEW OR

AN EXPERIENCED CARAVANNER THE

HINTS WILL HELP TO PROTECT YOUR

INVESTMENT.

THE INFORMATION CONTAINED WILL

ANSWER MOST OF YOUR QUERIES, BUT

IF THERE ARE ANY ASPECTS WHICH ARE

NOT COVERED PLEASE CONSULT YOUR

APPOINTED DEALER.

HAPPY CARAVANNING!

CONTENTS

Warranty Information

The Towing Code

Safety and Security

Services

Electrical Equipment

Fitted Equipment

Maintenance

General Data

WARRANTY

INFORMATION

Warranty and guarantee cover ................................................ 2

6 year body shell integrity guarantee...................................... 2

3 year supersure manufacturer’s guarantee .......................... 2

General terms and conditions ................................................. 3

What to do if you require assistance ...................................... 6

Annual service/inspection record............................................ 7

Annual service/inspection record stamps.............................. 8

2

All the illustrations and descriptive matter in

this handbook are intended to give a

general idea of the caravan. Changing

market and supply situations and our policy

of continuous product development may

prevent us from maintaining the exact

specifications detailed in this handbook.

We therefore reserve the right to alter

specifications as materials and conditions

demand.

Dealers are not agents of Swift Group

Limited, the manufacturer of Swift Group

caravans, and have absolutely no authority

to bind the manufacturer by any express or

implied undertaking or representation.

WARRANTY AND GUARANTEE COVER

All Swift Group caravans have a 6 year

body shell integrity guarantee and a 3 year

SuperSure manufacturer's warranty from

the date of purchase (or hire purchase),

which are subject to a chargeable annual

service, inspection and moisture survey

(“Annual Service”) being carried out at an

authorised Swift Group Service Centre.

Original VAT invoices must be retained as

proof of Annual Services being carried out.

In the unusual event that a fault develops

and you need to claim under this Warranty

and Guarantee, your first contact should

normally be made through the dealer from

whom the caravan was purchased.

In certain circumstances, arrangements can

be made to have the claim dealt with by a

different authorised Swift Group Service

Centre – see final paragraph below for

details. It is the responsibility of the

Purchaser to deliver the caravan to and

collect the caravan from the Service Centre

for all warranty work.

During the warranty period, subject to the

exclusions set out in this section of the

handbook and provided the warranty claim

is authorised by the manufacturer, Swift

Group Limited, the authorised Swift Group

Service Centre will repair (or at the option of

the manufacturer, replace) all defective

parts of the caravan at the expense of the

manufacturer. Swift Group Ltd reserves the

right to examine the caravan prior to

commencement of repairs or replacement

of parts.

6 YEAR BODY SHELL INTEGRITY

GUARANTEE (“GUARANTEE”)

The Guarantee extends to the

following items:-

Body leaks and delamination: water ingress

through any permanently sealed seam

joints or delamination of panels and floor,

being part of the original manufacturer’s

construction.

The manufacturer will honour the Guarantee

for 72 months from the date of purchase,

provided that the caravan has had an Annual

Service, within 90 days before or 60 days after

each anniversary of the original date of

purchase (or hire purchase). The sixth Annual

Service must, however, be carried out before

the expiry of the 72 month period from the

original date of purchase (or hire purchase).

Specific exclusions from the Guarantee:-

Seams and panels requiring repair must be

part of the original construction of the caravan

and must not have been tampered with or

repaired otherwise than by Swift Group Ltd or

an authorised Swift Group Service Centre.

Also see general terms and conditions.

3 YEAR SUPERSURE MANUFACTURER'S

WARRANTY (“WARRANTY”)

The manufacturer will honour the Warranty for

36 months from the date of purchase (or hire

purchase), provided that the caravan had an

Annual Service within 90 days before or 60

days after each anniversary of the original date

of purchase (or hire purchase).

The third Annual Service must, however, be

carried out before the expiry of the 36 month

period from the original date of purchase

(or hire purchase).

Warranty

Warranty

3

In the first 12 months the Warranty will

cover:-

Faults arising from a manufacturing defect but

not those which are a result of normal wear

and tear or those which relate to replacement

light bulbs.

Also not covered under the first year are faults

resulting from accidental damage or damage

caused by misuse of any component part of

the caravan.

In the years two and three the Warranty

will cover:-

1. All original components of the caravan

including permanently fitted equipment

forming part of the manufacturer's

original specification.

2. Water ingress and body delamination.

Specific exclusions from the Warranty

during years two and three:-

• Glass including heat shields,

sink lids, mirrors.

• Paintwork including all exterior paint,

heat shields, heater cases and all other

painted surfaces.

• Decals, mirror transfers, resin badges.

• GRP/ABS A frame covers, wheel spats

and skirts.

• Soft furnishings including upholstery,

curtains, pelmets.

• Carpets, lino and floor coverings

including door mats, shower mats.

• Work surfaces, tables, and flaps.

• Wallboards, ceiling boards and all other

interior décor finishes.

• Window catches, stays and

associated fittings.

• Blinds and flyscreens including door,

Heki and other rooflights.

• All hinges, catches, knobs, stays and

handles (interior and exterior).

• Replacement of bulbs, fluorescent

tubes, fuses and electrical connections

including 12n and 12s plugs, high level

brake lights and bulb contacts.

• Audio equipment including radios,

speakers, aerials and associated parts.

• Corner steadies.

• Fair wear and tear, accidental damage or

any damage caused by the misuse of

any component fitted by the

manufacturer.

• Microwave

• Routine maintenance items which are

part of the Annual Service including

brake shoes, one shot nuts, lubricants,

AKS pads, rubber gas hose, the

cleaning of the heater and fridge flues,

the replacement of gas jets, the

resealing and/or replacement of shower

room sealant, and the adjustment and

lubrication of locks.

GENERAL TERMS AND CONDITIONS

Provided that the caravan is used only for

its ordinary and intended purpose and has

not been subject to any treatment or

conditions which could not be reasonably

foreseen by Swift Group Ltd, the Warranty

and Guarantee will be honoured subject to

the following General Terms and Conditions

which apply to all three years of the

Warranty period and all six years of the

Guarantee period. The caravan is not

covered for:-

• The failure of a component for reasons

of fair wear and tear.

• Damage resulting from accidents.

• Damage resulting from freezing,

over-heating or fire.

• Misuse or abuse of the caravan or

of any component.

• Tyres, wheels and jockey wheels

• Cosmetic finishes to kitchen sinks,

cooker tops, vanity units, shower trays.

Warranty

• Normal deterioration, corrosion, intrusion of

foreign or harmful bodies, lack of servicing

or negligence of any person other than the

Swift Group Limited which causes

stoppage of or impairment to the function

of any component of the caravan.

• Replacement of parts which have reached

the end of their effective working life

because of age and/or usage.

• Cleaning or adjustment of any assemblies.

• Towing other than by private cars or 4x4

vehicles used in place of cars.

• The cost of transporting, towing or

moving the caravan by any means

(or consequential costs relating to

transportation), to or from the place

of repair, which is the responsibility of

the owner.

The Warranty and the Guarantee will be

invalidated if the caravan has been neglected,

misused, modified, used for hire or reward or

any commercial use, or has been used in

competitive events. The caravan will be

deemed to have been neglected if it has not

had an Annual Service or has otherwise not

been serviced and maintained as required by

this handbook.

The Warranty and the Guarantee only apply

to caravans purchased and used within the

UK, and for continuous journeys abroad of

no longer than 90 days per journey.

If any repairs are identified as being

necessary during an Annual Service, the

caravan must be made available to an

authorised Swift Group Service Centre

within 6 weeks for the work to be carried

out. All new caravans must be registered

with the Swift Group Ltd within 6 weeks of

purchase as new.

The benefit of this Warranty and Guarantee

may be transferred to a new owner if the

caravan is sold, provided that the caravan

has been serviced by an authorised Swift

Group Service Centre in accordance with

the requirements of this handbook, and

details of the change of ownership have

been supplied to Swift Group Ltd using the

change of ownership form set out in this

handbook. Failure to notify Swift Group Ltd

of a change of ownership within 30 days of

such a change will invalidate the Warranty

and Guarantee.

Swift Group Ltd’s liability under this

agreement shall be limited to supplying

labour and materials of a value not

exceeding £2,500 including VAT in respect

of each claim or series of claims. No liability

arises under this Warranty and Guarantee in

respect of consequential loss, costs,

damage, accidental or fire damage or any

losses incurred by accident or fire. No

liability of any kind arises under this

Warranty and Guarantee in respect of third

parties or bodily injury.

You have legal rights under UK law

governing the sale of consumer goods.

This Warranty and Guarantee does not

affect your legal rights.

The name and address of the warranty and

Guarantee provider is:-

Swift Group Limited,

Dunswell Road,

Cottingham,

East Yorkshire,

HU16 4JX.

To make a claim under this Warranty or

Guarantee, contact the Swift Group Service

Centre which supplied your caravan.

Alternatively, details of your nearest

authorised Swift Group Service Centre can

be obtained by contacting the Swift Group

Customer Care Department on 01482

875740 or enquiring on our web site:

www.swiftleisure.co.uk

4

Assistance

6

WHAT TO DO IF YOU REQUIRE ASSISTANCE

Congratulations on purchasing your new caravan. We are confident that you will enjoy

many happy holidays. However, should you have an enquiry or require assistance with a

problem, we hope that this guide will be of assistance to you.

If you have a problem, or enquiry with regards to your new caravan, please follow

these steps:

1. Check the Owners Handbook, paying particular attention to the fault finding advice at

the back of the book.

2. Contact your supplying dealer for assistance.

If you need to contact the Swift Group, please be aware of the following:

1. When contacting Swift Supercare, please quote your name, postcode and serial number

of your caravan.

2. In most instances, the Customer Care Team will involve your dealer in resolving the issue

you are experiencing.

3. If you are contacting the company by email, letter or fax, the Customer Care Team will

respond to you within five working days from the date of receiving the correspondence.

4. If you are calling the Customer Care Team, please avoid where possible, Mondays and

lunch times.

5. Please be aware that the Swift Group cannot send parts direct from the factory. In all

cases, without exception, your dealer must place the order for you.

TOURING CARAVANS - ANNUAL SERVICE/INSPECTION RECORD

In order to comply with the warranty, you must have your caravan inspected and serviced

by an authorised Swift Group Service Centre at least once per year.

It is important that the Owner’s Handbook is stamped on the appropriate page by the

authorised Swift Group Service Centre. Failure to do this will invalidate the warranty and the

transfer of the warranty on the change of ownership.

The inspection should take approximately two to four hours and will cover the areas dealt

with in the annual service check list. Any areas requiring service and/or maintenance will be

highlighted by your dealer and we recommend that you authorise any necessary work to be

carried out.

NB. It is essential, to validate the warranty, that an annual inspection be carried out by an

authorised Swift Group Service Centre covering the items listed.

1. Damp and lamination test.

2. Coupling head and breakaway cable.

3. Jockey wheel.

4. Chassis and chassis to body security.

5. Corner steadies.

6. Folding step (if fitted).

7. Tyres and tyre pressures.

8. Torque wheel nuts.

9. Brake rods and linkages.

10. Hub bearings, brakes and brake shoes.

11. Handbrake operation and

performance.

12. Suspension and shock absorbers

(if fitted).

13. 12N and 12S 7-pin plugs and cables.

14. Road lights, wiring and reflectors.

15. Internal lights and 12V DC system.

16. Water heater - gas and 230V AC

(if fitted).

17. Hob, grill and oven (if fitted).

18. Refrigerator 230V AC, 12V DC

and gas.

19. Gas system.

20. Water pump, taps and water system.

21. Mains 230V AC system.

22. Windows and fittings.

23. Smoke alarm and battery.

24. Roof lights.

25. Furniture hinges/stays etc.

26. Exterior locks and hinges.

27. Grab handle security.

28. All internal vents.

29. Oil seals.

30. Blinds and fly screens (if fitted).

7

Service/Inspection

8

ANNUAL SERVICE/INSPECTION RECORD

CARAVAN MODEL YEAR

CHASSIS NUMBER

1st SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

2nd SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

3rd SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

4th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

Service/Inspection

9

5th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

6th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

7th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

8th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

9th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

10th SERVICE

DATE:

DEALER’S STAMP

We certify that an annual service has been carried out in

accordance with the handbook.

THE

TOWING

CODE

The Caravan Towing Code .................................................... 12

Scope of the Code ............................................................... 12

Caravan Terms ........................................................................ 12

Weights ................................................................................ 12

Towing Vehicle Terms ............................................................ 13

Weights ................................................................................ 13

Measurement of Noseweight ................................................ 15

Type of Driving Licence Held ..................................................15

Glossary & Checklist .............................................................. 15

Preparing for the Road .......................................................... 18

Checklist .............................................................................. 18

Loading & Distribution ......................................................... 18

Stability ................................................................................ 19

Pre-tow Checklist ................................................................. 21

Moving Off ............................................................................... 27

Reversing ................................................................................ 28

Speed Limits ........................................................................... 28

Caravan Handling ................................................................... 28

Motorway Driving ................................................................... 28

Changing a Wheel .................................................................. 29

Jacking Points ........................................................................ 30

Stopping on a Hill ................................................................... 30

Arrival on Site ......................................................................... 30

The Towing Code

THE CARAVAN TOWING CODE

This Code of Practice contains

recommendations jointly reviewed and

agreed by the following organisations:

The National Caravan Council

The Caravan Club

The Camping and Caravanning Club

The Caravan Writers Guild

The Department for Transport

Scope of the Code

The Code applies to all trailer caravans of

maximum laden weight not exceeding

3500 kg (7,700 lbs), overall width not

exceeding 2.3m (7ft 6in approximately) and

overall length not exceeding 7m (23ft

approximately), excluding the drawbar and

coupling.

This is legally the maximum size of trailer

that can be towed by a motor vehicle with a

maximum gross weight of less than 3500 kg.

CARAVAN TERMS

Mass in Running Order:

The mass of the caravan as stated by the

caravan manufacturer, as new with standard

fixtures and fittings.

Note: Because of differences in the weight

of materials supplied for the construction of

caravans, a tolerance has been allowed for

in the Mass in Running Order weight.

Maximum User Payload:

The maximum allowable weight to be put

into the caravan whilst it is being towed. This

is made up of 3 sections:

Personal effects, optional equipment and

essential habitation equipment.

The user payload is the difference between

the Maximum Technically Permissible Laden

Mass and the Mass in Running Order.

Essential Habitation Equipment:

Those items and fluids required for safe and

proper functioning of the equipment for

habitation as defined by manufacturer of the

caravan.

Personal Effects:

Those items which a user can choose to

carry in a caravan and which are not

included as Essential Habitation Equipment

or Optional equipment.

Optional Equipment:

Items made available by the manufacturer

over and above the standard specification of

the caravan.

Maximum Technically Permissible Laden

Mass:

The maximum weight for which the caravan

is designed for normal use when being

towed on a road, laden. This mass takes into

account specific operating conditions

including factors such as the strength of

materials, loading capacity of tyres etc.

WARNING: Under no circumstances

should the maximum technically

permissible laden mass of this caravan

be exceeded.

Upgrading of maximum technically

permissible laden mass:

The standard/declared MTPLM quoted in the

specification handbook and on new caravan

weightplates maybe of lower value than the

maximum possible. If extra user payload is

required, an upgrade maybe available (model

dependant), this must be requested via your

dealer.

If required you will be issued with the

following:

(i) New weightplate giving upgrade

weight detail

(ii) New NCC Certificate (declaring the

upgraded MTPLM

(iii) Manufacturers letter confirming

the upgrade for that Vehicle

Identification Number

Note: Tyre pressures may increase

when upgrading

Nose weight:

That part of the static mass of the caravan

supported by the towing device on the rear

of the towing vehicle.

12

The Towing Code

Notes:

(i) When measuring the noseweight it is

important that the caravan is fully

loaded. Do not place extra items

indiscriminately into the caravan after

this adjustment has been made.

(ii) The caravan is intended to be towed

slightly nose heavy. The nose weight

can be adjusted by distribution of the

load within the caravan. The nose

weight should be approximately 7% of

the actual laden weight (but not greater

than the hitch capacity) and at the same

time suit the towing vehicle. See section

on Measurement of Nose Weight.

(iii) It is not recommended that you tow with

just a battery, spare wheel and gas

bottles as this may exceed the the

permitted nose weight. Additional

payload must be placed behind the axle

to compensate for this.

TOWING VEHICLE TERMS

Kerb weight (Mass of Vehicle in Running

Order):

The weight of the towing vehicle as defined

by the vehicle manufacturer. This is normally

with a full tank of fuel, with an adequate

supply of liquids incidental to the vehicles

propulsion, without driver or passengers,

without any load except loose tools and

equipment with which the vehicle is normally

provided and without any towing bracket.

Caravan to Towing Vehicle Weight Ratio:

The towing vehicle to caravan weight ratio

can be determined by calculation and is

equal to:

actual laden weight of caravan

x 100%

Kerb weight of towing vehicle

THE LAW REQUIRES THAT CARAVANS &

THEIR TOWING VEHICLES & THE LOADS

THEY CARRY MUST BE IN SUCH A

CONDITION THAT NO DANGER OR

NUISANCE IS CAUSED.

(Regulation 100 of the Road and Vehicles

[Construction and Use] Regulations 1986).

Power to weight ratio:

No hard and fast rules can be stated but,

here is a general guide.

(a) Conventional petrol engines with a

capacity up to approximately 1500 cc

should be adequate for towing a

caravan weighing around 85% of the

kerb weight of the towing vehicle.

(b) Above 1500 cc such engines should

manage a caravan weighing up to 100%

of the kerb weight of the towing vehicle

and still give adequate performance.

13

Fig. A Car/Caravan Weight Ratios

YES NO

MAYBE

85%

EQUAL

The Towing Code

Note: The towing vehicle manufacturer’s limit

is, in some cases, less than the kerb weight.

Vehicles with automatic transmission may

need an oil cooler fitting or the SAE rating of

the gearbox oil increasing when towing. The

advice of the vehicle manufacturer should be

sought.

Mass in Running Order:

Caravanners can use a public weighbridge to

establish the mass in running order.

Note: Weighbridges have varying weight

tolerance levels.

Maximum Permissible Towing Mass:

The weight defined by the vehicle

manufacturer as being the maximum that

the vehicle is designed to tow.

Train Weight (Combination Weight):

The maximum combined weight of the

towing vehicle and trailer combination as

specified by the towing vehicle manufacturer.

14

Always lower jockey wheel before entering

the caravan and then raise before measuring

again. (See Loading).

Note: The height of the towball on the

towing vehicle, when laden, is also critical.

WARNING: Do not lift the coupling head

by hand when hitching the caravan to

the car. Always raise and lower the

coupling head by winding the handle on

the jockey wheel up and down.

TYPE OF DRIVING LICENCE

HELD

In order to be able to tow a caravan a driver

must hold a Category B licence. Those car

drivers who passed their tests prior to 1

January 1997 would have automatically

obtained Category B+E. However, anyone

who passed their test after 1 january 1997

will need to take a further test in order to

obtain a Category B+E if they wish to tow a

car and caravan combination whose train

weight exceeds 3,500kg, or up to 4,250 if

the caravan is less than 750kg or if the

caravan’s Maximum Technically Permissible

Laden Mass exceeds the unladen weight of

the car.

Note: The unladen weight of a car is

normally less than the kerbside weight.

GLOSSARY & CHECKLIST

Awnings - Can consist of just a simple top

sheet but may extend to a five sided frame

tent attached to the side of the caravan.

Fire blanket - approved to BS 6575 is ideal

for dealing with ‘fat pan’ fires.

Fire extinguisher - It is strongly

recommended that a fire extinguisher is

carried in the caravan. (For suitable types

see Safety and Security).

Gas bottles - Bottled L.P. gas is the most

convenient portable source of fuel. Two

bottles are required for a constant supply.

An initial deposit is payable on each cylinder.

We recommend the use of 5kg or 6kg

Propane or 7kg Butane bottles. One position

for use and one for storage only. (For

detailed information see Services - Gas).

Jack - A suitable jack is essential (screw,

scissor, side mounted or air jack type). Many

car jacks are unsuitable.

Levellers - Levellers help level the caravan

from side to side before unhitching.

Proprietary products can be purchased from

your caravan dealer and need to be

positioned as indicated by a spirit level.

Spare Wheel - It is always advisable to carry

a spare wheel with your caravan.

MEASUREMENT OF NOSEWEIGHT

Noseweight may be measured using a

propriety brand of noseweight indicator.

Such equipment is obtainable at your

Caravan Dealer.

Note: These indicators have a varying

tolerance level.

Another simple method is to use bathroom

scales under the coupling head with a piece

of wood, fitted between the coupling head

and the scales, of such length that the

caravan floor is horizontal with the jockey

wheel raised clear of the ground. (Fig. A)

Noseweight can be adjusted simply by

distribution of weights in the caravan.

15

430mm

35mm

Fig. A Measuring Noseweight

+

-

The Towing Code

The Towing Code

16

Spirit Level -A spirit level is extremely useful

when siting the caravan.

Stabiliser -Stabilisers help to dampen the

side to side movement of the caravan. One

end fits to the car’s towing bracket and the

other end to the caravan. (See Stability)

Torque Wrench - A torque wrench is the

only way that the exact recommended

torque can be achieved for wheel nuts and

bolts. (See Preparing for the Road).

Towing Bracket - Never use cheap

alternatives, obtain one manufactured by a

reputable company complying with the

relevant standards.

Any light passenger vehicle registered in the

UK on or after August 1st 1998 (S registered

plate) will require a type approved towbar

and towball (to 94/20/EC). Failure to fit a

homologated towbar and towball could

result in a prosecution and invalidation of

your insurance cover. Always check with

your car manufacturer or towbar

manufacturer if in doubt.

Wooden Blocks - Wooden blocks typically

25cm. square and 2cm. thick are ideal for

placing under corner steadies and jockey

wheel when the ground is uneven or soft.

Water Containers - Two containers are

required, one to carry fresh water to the

caravan and one for waste water, which

needs to be disposed of properly. Several

types are available including jerry cans,

folding cans and wheeled containers.

12N & 12S Sockets - Two sockets

designated 12N and 12S are fitted to your

car to accept corresponding plugs from the

caravan. These are necessary to energise

the road lights and caravan auxiliary circuits

respectively.

12 Volt Battery - A deep cycling, heavy duty

rechargeable leisure type battery should be

purchased to provide back-up power for

lights and other electrical appliances. (See

Battery). The securing arrangements for the

battery compartment require a leisure battery

complying with EN 60095-2 in particular

those with ledges for fastening to the lower

edge of the long sides and having a

maximum height of 190mm and width of

175mm.

WARNING: Your caravan dealer should

be consulted if additional equipment is

to be fitted as strong points may or may

not be provided in the design.

Note: Fitting additional equipment will

reduce the caravan allowable payload.

17

Useful memory aid for other items.

Car

Distilled water

External mirrors

Fan belt

Fire extinguisher

Jack

Jump leads

Petrol can

Socket set

Spare bulbs

Spare keys

Spare wheel

Tool kit

Towball cover

Tow rope

Tyre pressure gauge

Warning triangle

Tyre Pump

Caravan

Awning pegs and poles

Awning ground sheet

Battery 12 volt charger

Bucket

Corner steady brace

Corner steady pads

Coupling lock

Door mat

Fire blanket

Fire extinguisher

Fresh water container

Gas cylinder

Gas regulator

Jack

Levelling boards

Mallet

Site/caravan mains lead

Spare bulbs

(Mandatory in E.C.)

Spare 12v fuses

Spare gas hose

Spare wheel

Spirit level

Toilet fluid

Waste water container

Wheel brace

Personal

After sun cream

First Aid Kit

Flannels

Hairbrush and comb

Make up. etc.

Raincoats

Toothbrush

Toothpaste

Scissors

Shampoo

Shaving kit

Shoe cleaning kit

Soap

Sun tan oil

Wellington boots

Domestic

Adhesive tape

Air freshener

Aluminium foil

Ashtrays

Bin liners

Binoculars

Bottle opener

Breadboard

Breadbin

Brush and dustpan

Butter dish

Camera and films

Carving knife

Cassette recorder

Chairs

Clock

Clothes brush

Clothes line

Coat hangers

Coffee percolator

Coolbox

Colander

Crockery

Cruet

Corkscrew

Cutlery

Dish cloth and brush

Dusters and polish

Disposable cloths

Egg cups

Electrical extension lead

Floor cloth

Fly spray

Food

Food mixer

Frying pan

Glasses

Grill pan

Jugs

Kettle

Kitchen roll

Kitchen tools

Litter bin

Matches

Measuring jug

Milk jug

Mixing bowl

Needles and thread

Oven gloves

Pegs

Piezo Gas lighter

Potato peeler

Pressure cooker

Radio

Rubbish bin

Salad shaker

Saucepans

Scissors

Sieve

Sugar bowl

Shopping bags

Sleeping bags

Tea pot

Tea strainer

Tea towels

Table cloths

Table mats

Television

Tin opener

Tissues

Toilet paper

To rc h

Towels

Toys & Games

Vacuum cleaner

Washing up bowl

Documents

Bail Bonds

(some Euro countries)

Bank and credit cards

Caravan Certificate

Cheque book

CRIS document

Driving licence

Green Card Insurance

(some Euro countries)

Maps and guides

Money

MOT Certificate

Vehicle Registration

Documents

The Towing Code

The Towing Code

18

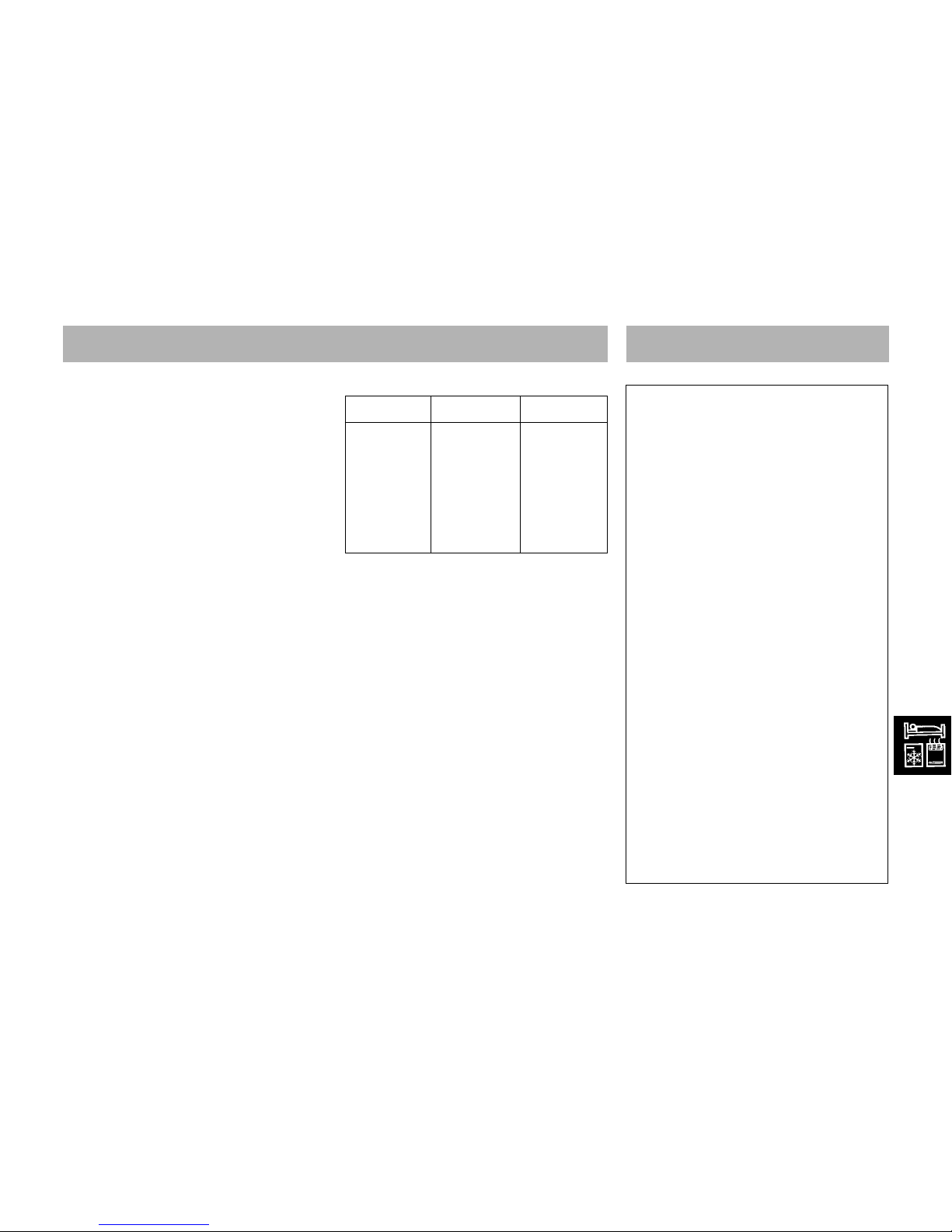

Fig. A Loading your caravan

(a)

(c)

(b)

(d)

WARNING: Turn off gas appliances

except those heating appliances

designed to function while the vehicle is

in motion.

WARNING: Do not travel with televisions

or microwaves in overhead lockers

unless the appliance was supplied fitted

to your caravan by the manufacturer.

LOADING AND DISTRIBUTION OF

WEIGHT IN THE CARAVAN

Do not exceed recommended maximum

loading for your caravan.

1. Load heavy items low down near the

floor and mainly over or just in front of

the axle(s) (Fig. A).

2. Load evenly right to left so that each

caravan wheel carries approximately the

same weight.

3. Do not load items at the extreme front or

rear since this can lead to instability due

to the ‘pendulum effect’.

4. Load remainder to give a suitable

noseweight at the towing coupling.

Check noseweight.

Note: Do not overload car boot.

Note: Please take care to ensure that you

have allowed for the masses of all items

you intend to carry in the caravan.

WARNING: All heavy and/or voluminous

items (e.g. TV, radio etc) must be stored

securely before travelling.

PREPARING FOR THE ROAD

PRE-LOAD CHECKLIST

Caution: Never enter the caravan without

first lowering the four corner steadies with

the brace provided.

BEFORE LOADING CHECK:

- loose articles are stowed securely. Do not

stow tins, bottles or heavy items in

overhead lockers prior to towing.

- all lockers and cupboard doors are

closed and secured.

- all bunks are secure.

- all rooflights are closed and secured.

- main table is stored in its transit position.

- fridge is on 12v operation and door lock

is set.

- all windows are fully closed and latched.

Never tow with windows on night setting.

Leave all curtains and blinds open to aid

rear visibility.

- gas cylinders are correctly positioned,

secured and turned off.

- battery is secure and mains connecting

cable is disconnected and stowed.

- 12v distribution panel selector switch is

set to the van position.

WARNING: The fridge will only operate

in transit when the 12V distribution panel

selector switch is in the 'VAN' position.

19

Towing vehicle’s rear suspension

It is important that the towing vehicle’s rear

suspension is not deflected excessively by

the noseweight on the tow ball. If it is

excessive the steering and stability will be

affected. (Fig. B)

The greater the towing vehicle’s tail overhang

(the distance between the rear axle and the

tow ball), the greater the effect the

noseweight will have on the towing vehicle’s

rear suspension.

After trying out the caravan it may be found

that a stiffening of the rear suspension is

necessary - but note that this may give the

towing vehicle a firmer ride when not towing.

There are a number of suspension aids

available and advice should be sought on

which to use and how to fit. It is important to

ensure that the caravan is towed either level

or slightly nose down.

If you have any doubts about the suitability

of your towbar for towing a caravan consult

the towing bracket manufacturer.

DO NOT exceed the:

• Gross Vehicle Mass (G.V.M. on car plate).

• Maximum Technically Permissible Laden

Mass (M.T.P.L.M.) on the caravan.

• Gross Vehicle Combination Mass

(Train Weight) (G.V.C.M. on car plate).

• Maximum Permissible Towing Mass.

• Vertical Static Load on the caravan

coupling.

• Maximum Vertical Load on the car towball

as specified by towing vehicle

manufacturer.

STABILITY

All our models are of a well balanced design

and should be exceptionally good towers.

Most models have an AL-KO stabiliser fitted

as standard. The common causes of poor

stability include:

(a) Worn springs or loose spring fixings on

the towing vehicle.

(b) Towing vehicle springs too soft.

(c) Insufficient noseweight.

(d) Nose of caravan is towing too high.

Fig. A Fig. B Illustration of excessive deflection of vehicle’s rear suspension

Sensible Loading:

How to apportion it

LIGHT

ITEMS

MEDIUM

ITEMS

HEAVY

ITEMS

The Towing Code

The Towing Code

20

Galvanised steel chassis

Drilling of the galvanised steel chassis will

invalidate the warranty and must not be

done.

Towball

The AL-KO stabiliser is designed to be used

with a swan neck, fixed or detachable

towball. If you use a 'bolt on type' towball

you may need to replace your towball with a

special extended neck towball.

If you have a bolt on type towball you should

ask your dealer to check clearance around

the towball to allow for the stabiliser to

articulate.

The AL-KO extended neck towball (available

from your dealer) is approved and marked

with the approval number EC94/20. Failure

to provide enough clearance around the

towball may invalidate your stabiliser

warranty.

AK160 Coupling Head

If your caravan is fitted with an AK160

coupling head the Towball must be lightly

greased.

Stabiliser Friction Pads

The AL-KO stabiliser uses 'friction pads'

inside the coupling head to clamp the

towball. These pads must be kept free from

grease and contamination from the towball.

The friction pads should last approximately

50,000km (30,000 miles) under normal use, if

correctly maintained.

Suitable towing vehicles

The caravan is manufactured for towing

behind normal road cars and is not suitable

for towing behind commercial vehicles. It is

strongly recommended that whenever a

caravan is to be towed over rough terrain,

e.g. a farmer’s field or track, great care

should be taken to ensure that no undue

stress is placed upon the caravan via the

hitch mounting, i.e. reduce speed. If in

doubt, please consult the chassis manufacturer and the towing vehicle manufacturer

who will advise. Touring caravans based on

standard AL-KO chassis can be towed by

four wheel drive off road leisure vehicles

providing the unit is used to tow in a like

manner to a conventional road-going car and

driven in the same considered manner.

Towbar manufacturers should be consulted

before towing an uncompensated twin axle

caravan.

Snaking

This is a term used to denote an unstable

car and caravan combination where the

caravan ‘weaves’ from side to side often

causing a similar swaying movement in the

car itself.

Causes:

i) Unsuitable or unbalanced outfit.

ii) Incorrect loading or weight distribution.

iii) Excessive speed especially downhill.

iv) Side winds.

v) Overtaking.

vi) Being overtaken by a large fast moving

vehicle.

vii) Erratic driving.

viii) Insufficient tyre pressures.

ix) Mixing radial and cross ply tyres.

Cures:

Cases of persistent snaking can be

alleviated by the use of a stabiliser.

On the road

If you do find your outfit snaking, try to keep

the steering wheel in a central position as far

as possible, decelerate and avoid braking if

possible.

OTHER IMPORTANT TOWING

CONSIDERATIONS THAT COULD AFFECT

STABILITY

Types of tyres fitted

The original tyres fitted by the manufacturer

are suitable for towing at maximum speed of

up to 81 mph (130 kph).

Maintenance checks should be carried out

regularly for wear and tear.

Tyre pressures must be maintained, under

inflation could lead to premature tyre failure.

Replacement tyres must be of the same size,

load and speed index.

Periodically tyres should be rotated to

equalise wear in the same manner as car

tyres.

Do not mix four ply/six ply/eight ply tyres on

the same axle.

Wheels

Caravan wheel bolts should be tightened to

a torque of 88Nm (65lb/ft) on steel wheels or

115Nm (85lb/ft) on alloy wheels and should

be checked with the use of a torque wrench

regularly. Only use a spare wheel and tyre of

the type and size provided with you caravan.

Wheel Rims

Both steel and Alloy wheel rims are the 5.5J

size incorporating a double safety hump

which conforms to European safety

standards.

If in any doubt, have your wheels checked

by a competent tyre supplier.

Hitch head load capacity

The maximum vertical static load which can

be put upon the hitch head when connected

is 100kg. Please refer to the technical data in

your handbook.

(But see also vehicle manufacturer’s weight

limits on towball loading.)

PRE-TOW CHECKLIST AND HITCH-UP

FOR AK 3004 STABILISER

Check Gas Locker, Battery Locker and

Cassette Toilet doors are secure.

Check wheelnuts, tyre pressures and tyre

conditions.

Fully raise all four corner steadies. (Fig. A).

Pick up any levelling pads or levelling boards.

Check rooflights/vents are securely closed.

Switch off gas supply and change over to

electricity if required.

Fig. B Safety Catch and HandleFig. A Winding Corner Steady

21

WARNING: If a wheel or tyre fitted to

a wheel is changed any replacement

must be of the same type of

construction and size.

Tyre tread

The law requires that tyres and pressures

must be suitable for the use to which they

are being put. The minimum tread depth of

both car and caravan tyres must be 1.6mm

throughout a continuous band comprising the

central three quarters of the breadth of tread

and around the entire circumference of the

tyre.

Tyre pressures

Towing vehicle's tyres must be at the

pressures recommended for towing or heavy

loading as stated in handbook not on tyre

wall. Towing stability may otherwise be

affected. Tyre pressures can be found on the

manufacturers plate situated adjacent to the

main exterior door and on the specification

page in your service handbook.

Note: Although the caravan may be fitted

with the same type of tyre as the towing

vehicle, the pressures specified are different.

All charts show values for cars and are

therefore not applicable for caravans.

Pressures displayed on tyre walls apply

ONLY in North America and Canada.

The Towing Code

The Towing Code

22

Fig. B Checking Secure Attachment Fig. C Connections - 7 pin PlugFig. A Handbrake

Adjust jockey wheel to lower cup on to the

ball. A click indicates it is fully engaged. Ensure

black handle has returned to its free position.

Secure caravan handbrake. (Fig. A)

Connect breakaway cable as described on

page 26.

Fig. D Hitch Head Visual Indicator

Lock the caravan exterior door.

An assistant can help in the hitching

operation by standing on the left hand side of

the drawbar (facing rear of car) and extending

an arm horizontally to indicate position of the

coupling. When reversing aim the towball of

the car directly at the caravan drawbar.

Remove towball cover and keep in car.

Adjust the jockey wheel to ensure the cup is

high enough to slide over the towball.

Release caravan handbrake.

Position cup over the ungreased towball,

release and lift forward the large red

stabiliser handle (Fig. B, page 21) lift forward

the exposed smaller black handle (Fig. B,

page 21) until it clicks up.

The hitch head is fitted with a visual indicator

to show whether or not it is properly

connected to the towball. A green band will

show immediately below the red indicator

button on the hitch head when a proper

connection has been made. (See Fig. D)

WARNING: If the green band is showing

when the hitch head is not connected

to the towball there is a fault - contact

your Dealer.

23

Ensure that the jockey wheel is fully wound

up and properly located in the slots, then

release the clamp handle, lift the whole unit

as high as possible and retighten the clamp

handle.

Note: Ensure jockey wheel locates in recess

provided. Carelessness could result in

damage to the A frame cover

Take hold of the caravan under the rubber

gaiter behind the coupling and lift to

ascertain whether the caravan is properly

attached. (Figs. B & D.)

Lock hitch if possible (see Safety and

Security, page 36).

Connect 7 pin plugs to car sockets ensuring

there is enough loose cable for cornering,

(Fig. C) ensuring they wont drag on the

ground.

Check all car and caravan roadlights are

working. Check round the caravan for

anything left behind.

Release caravan handbrake, adjust all

mirrors from driving seat and proceed.

PRE-TOW CHECKLIST AND HITCH-UP

FOR AK 160 COUPLING HEAD

Check Gas Locker, Battery Locker (if fitted)

and Cassette Toilet (if fitted) door/s are

secure.

Check wheelnuts, tyre pressures and tyre

conditions.

Fully raise all four corner steadies. (Fig. A,

Page 21).

Pick up any levelling pads or levelling boards.

Check rooflights/vents are securely closed.

Switch off gas supply and change over to

electricity if required.

Lock the caravan exterior door.

An assistant can help in the hitching

operation by standing on the left hand side

of the drawbar (facing rear of car) and

extending an arm horizontally to indicate

position of the coupling. When reversing aim

the towball of the car directly at the caravan

drawbar. Remove towball cover and keep in

car.

Adjust the jockey wheel to ensure the cup is

high enough to slide over the towball.

Release caravan handbrake.

Position cup over greased towball, release

safety catch and lift handle (Fig. B). The

hitch head is fitted with a visual indicator to

show whether or not it is properly connected

to the towball. A green band will show

immediately below the red indicator button

on the hitch head when a proper connection

has been made. (See Fig. D, Page 22)

WARNING: Serious damage will occur

unless the locking button is depressed

first and the handle lifted forward before

the caravan is lowered manually. This

prevents the noseweight being

transmitted through the locking button.

WARNING: If the green band is showing

when the hitch head is not connected

to the towball there is a fault - contact

your Dealer.

Fig. B Safety Catch and Handle

The Towing Code

The Towing Code

Fig. B Checking Secure AttachmentFig. A Handbrake

Fig. D Hitch Head Visual Indicator

24

Adjust jockey wheel to lower cup on to the

ball. A click indicates it is fully engaged. Ensure

locking button has returned to its free position.

Secure caravan handbrake. (Fig. A)

Connect breakaway cable (emergency

braking device) in the form of a noose to

suitable anchorage point on towbar. DO NOT

attach to towball. (See page 26)

Ensure that the jockey wheel is fully wound

up and properly located in the slots, then

release the clamp handle, lift the whole unit

as high as possible and retighten the clamp

handle.

Note: Ensure jockey wheel locates in recess

provided. Carelessness could result in

damage to the A frame cover.

Take hold of the caravan under the rubber

gaiter behind the coupling and lift to

ascertain whether the caravan is properly

attached. (Figs. B & D.)

Lock hitch if possible (see Safety and

Security, page 36).

Connect 7 pin plugs to car sockets ensuring

there is enough loose cable for cornering.

(Fig. C, Page 22)

Check all car and caravan roadlights are

working. Check round the caravan for

anything left behind.

Release caravan handbrake, adjust all

mirrors from driving seat and proceed.

25

ROAD LIGHTING

For your information the wiring diagram of

the 12N and 12S connectors is shown

opposite. These should be checked regularly

and if in any doubt a qualified electrician

consulted.

Some European cars may be equipped with

Volta, Jeager, West or multi-con sockets, an

adaptor or replacement sockets may be

required. If so consult your dealer or qualified

electrician.

The wiring allocations were changed in 1998

and it is important that you check the car to

caravan connections are compatible prior to

coupling up to the car.

WARNING: Always disconnect the

electrical connector between the

towing vehicle and the caravan before

connecting a low voltage supply to the

caravan (mains) and before charging

the battery (EN 1648-1).

• All road lights must be in working order.

• Lenses and reflectors must be in good

condition

• Bulbs must be of correct wattage for the

application (see Service handbook).

TERMINAL COLOUR 12N PLUG

1 YELLOW L/H INDICATOR

2 BLUE REAR FOG LAMP

3 WHITE COMMON RETURN (1-7)

4 GREEN R/H INDICATOR

5 BROWN R/H SIDE TAIL & No PLATE LIGHT

6 RED STOP LAMP

7 BLACK L/H SIDE TAIL & No PLATE LIGHT

TERMINAL COLOUR 12S PLUG

1 YELLOW REVERSING LIGHT

2 BLUE NO ALLOCATION

3 WHITE NEGATIVE PIN 4

4 GREEN CONTINUOUS POWER SUPPLY

5 BROWN NO ALLOCATION

6 RED FRIDGE

7 BLACK RETURN FOR FRIDGE

12N AND 12S VIEWED FROM REAR OF PLUG

12N (BLACK) 12S (GREY)

TUBES

PINS

PINS

STRIPS

PIN NO COLOUR DESCRIPTION

1 YELLOW LEFT FLASHER

2 BLUE FOG HAZARD LIGHT

3 WHITE EARTH FOR 1-8

4 GREEN RIGHT FLASHER

5 BROWN RIGHT TAIL LIGHT

6 RED STOP LIGHTS

7 BLACK LEFT TAIL LIGHT

8 ORANGE REVERSE LIGHTS

9 BROWN/BLUE CAR +

10 BROWN/RED FRIDGE

11 WHITE/BLACK EARTH FOR 10

12 NOT YET ALLOCATED

13 WHITE/GREEN EARTH FOR 9

PIN NO COLOUR DESCRIPTION

1 YELLOW LEFT FLASHER

2 BLUE FOG HAZARD LIGHT

3 WHITE EARTH FOR 1-8

4 GREEN RIGHT FLASHER

5 BROWN RIGHT TAIL LIGHT

6 RED STOP LIGHTS

7 BLACK LEFT TAIL LIGHT

8 ORANGE REVERSE LIGHTS

9 BROWN/BLUE CAR +

10 BROWN/RED FRIDGE

11 WHITE/BLACK EARTH FOR 10

12 NOT YET ALLOCATED

13 WHITE/GREEN EARTH FOR 9

VOLTA/JEAGER & MULTICON FEDER 13 PIN PLUGS (viewed from rear)

VOLTA/JEAGER WEST

MULTICON

FEDER 13K

The Towing Code

The Towing Code

26

WARNING: Do not cause any road

lighting to be obscured by the addition

of any options or accessories to your

caravan.

PASSENGERS

Passengers are forbidden to ride in a

caravan.

BREAKAWAY CABLES

UK law requires that all caravans are fitted

with a safety device to provide protection in

the unlikely event of separation of the main

coupling while in motion. A device referred

to as a 'breakaway cable' fulfils this

requirement and when fitted as on your

caravan is mandatory.

Purpose

To apply the caravans brakes if it becomes

separated from its towing vehicle. Having

done this, the cable assembly is designed to

part allowing the caravan to come to a halt

away from the towing vehicle.

Identification

A thin steel cable with a red plastic coating

fitted with a means of attachment for

connection to the towing vehicle. Located

directly beneath the coupling head.

Operation

In the event of the main coupling of the

caravan separating from the towing vehicle,

the cable should be able to pull tight,

without any hindrance, engaing the caravan

brakes. The breakaway cable should not

become taut during normal use.

Correct procedure for use

Regularly check the cable and clip for

damage. If in doubt contact your Swift

Group dealer.

Make sure the cable runs as straight as

possible and goes through the cable guide

fitted underneath the caravan coupling head.

Determine whether or not the towing vehicle

towbar has a designated attachment point

(i.e. a part specifically designated for a

breakaway cable).

Where a point is designated on the towbar:

• Pass the cable through the attachment

point and clip it back on itself (figure 1).

• Do not clip directly onto the designated

point (figure 2) since the clip is not

designed for use in this way.

Where there is no designated attachment

point on the towbar:

• Fixed ball: Loop the cable around the

neck of the towball in a single loop only.

See figure 3A and 3B, Page 27.

• Detachable towball: You must seek

guidance on procedure from the towing

vehicle towbar manufacturer or supplier.

Fig. 1

Fig. 2

✔

✘

27

When the breakaway cable is attached,

check to ensure:

a) that the cable cannot snag in use on the

caravan coupling head, jockey wheel,

stabiliser or accessory e.g. bumper

shield, cycle carrier etc.

b) that there is sufficient slack in the cable

to allow the towing vehicle and caravan

to articulate fully without the cable ever

becoming taut and applying the brakes.

c) that it is not slack and can drag on the

ground. If left loose, the cable may

scrape along the ground and be

weakened so that it subsequently fails to

do its job. The cable may also be caught

on an obstacle when in motion thus

engaging the caravan brakes prematurely.

Having followed this advice, should you feel

that a satisfactory coupling arrangement

cannot be achieved, consult your Swift

Group dealer or towbar supplier.

MIRRORS

The driver of the towing vehicle must have

an adequate view of the rear.

If there is no rear view through the caravan it

is essential that additional exterior towing

mirrors are fitted. This is mandatory in some

European countries and drivers can face

instant fines if extension mirrors are not fitted.

Caution: Any rear view mirror must not

project more than 200 mm outside:

a) the width of the caravan when being

towed.

b) the width of the towing vehicle when

driven solo.

Note: Any rear view mirror fitted shall be ‘e’

marked and cover the field of view as

stipulated by type approval requirements

(Regulation 33 of the Road Vehicles

[Construction and Use] Regulation 1986).

MOVING OFF

Let the clutch in smoothly.

Allow more engine speed to produce the

power to move the additional weight of the

caravan.

Reduce wear and tear on clutch and

transmission by taking extra care.

Change gears smoothly.

Try not to jerk the clutch.

Fig. 3A

Fig. 3B

The Towing Code

The Towing Code

28

Fig. A Reversing

REVERSING

When the towing vehicle is reversing, the

overrun device shaft is pushing in, applying

the brakes via the overrun lever, brake rod

system, bowden cables and the expander

mechanism.

The backwards rotation of the brake drum

causes the secondary brake shoe to collapse

cancelling out the braking effect, allowing the

trailer to move backwards. At the same time

the transmission lever swings back and

compensates for the entire travel.

When reversing up a slope or on a loose

surface the brakes may apply themselves,

Correct maintenance and set up of the

brakes will help prevent this. Incorrect

adjustment of the wheel brakes or Linkages

will result in making reversing difficult.

Proficiency at reversing can only be achieved

with practice and should be first attempted in

a large open area (Fig. A).

SPEED LIMITS

Normal road towing: 50mph

Motorways (including dual carriageways):

60mph

CARAVAN HANDLING

Allow for caravan being wider than car.

Do not bump kerb with caravan wheels.

When passing other vehicles allow more than

the normal clearance for driving solo.

Allow longer to get up speed to pass.

Allow for the outfit being twice its normal

length.

Do not suddenly swing out.

Carry out all manoeuvres as smoothly as

possible.

Use nearside wing mirror to check caravan

has cleared when overtaking.

WARNING: Take care not to foul or

ground caravan chassis whilst

traversing ramps or other obstacles.

IMPORTANT POINTS ESPECIALLY

FOR MOTORWAY DRIVING

1. Caravans may not be towed in the outside lane of a three or four lane motorway. (Reg. 12(2) of the Motorway Traffic

[England and Wales] Regulations 1982).

2. Reduce Speed:

i) In high or cross winds.

ii) Downhill.

iii) In poor visibility.

3. High sided vehicles cause air buffeting so

extra care must be taken when passing or

being passed. As much space as

possible should be given.

CHANGING A WHEEL

1. Leave caravan hitched to towing vehicle

and ensure handbrake is applied.

2. Lower corner steadies (as safety

measure) on the side that the wheel is

being changed to stabilise the caravan.

3. Use wheel brace to slacken off wheel

nuts on the wheel to be changed.

4. Position jack under the axle at the

appropriate jacking point (see fig. B)

5. Jack up the caravan until the wheel for

removal is just off the ground.

6. Remove the wheel nuts, wheel trims and

remove the wheel.

7. Fit spare wheel and reverse the above

procedure.

Ensure clean, dry mating surfaces and

clean, dry bolt/nut sealing areas.

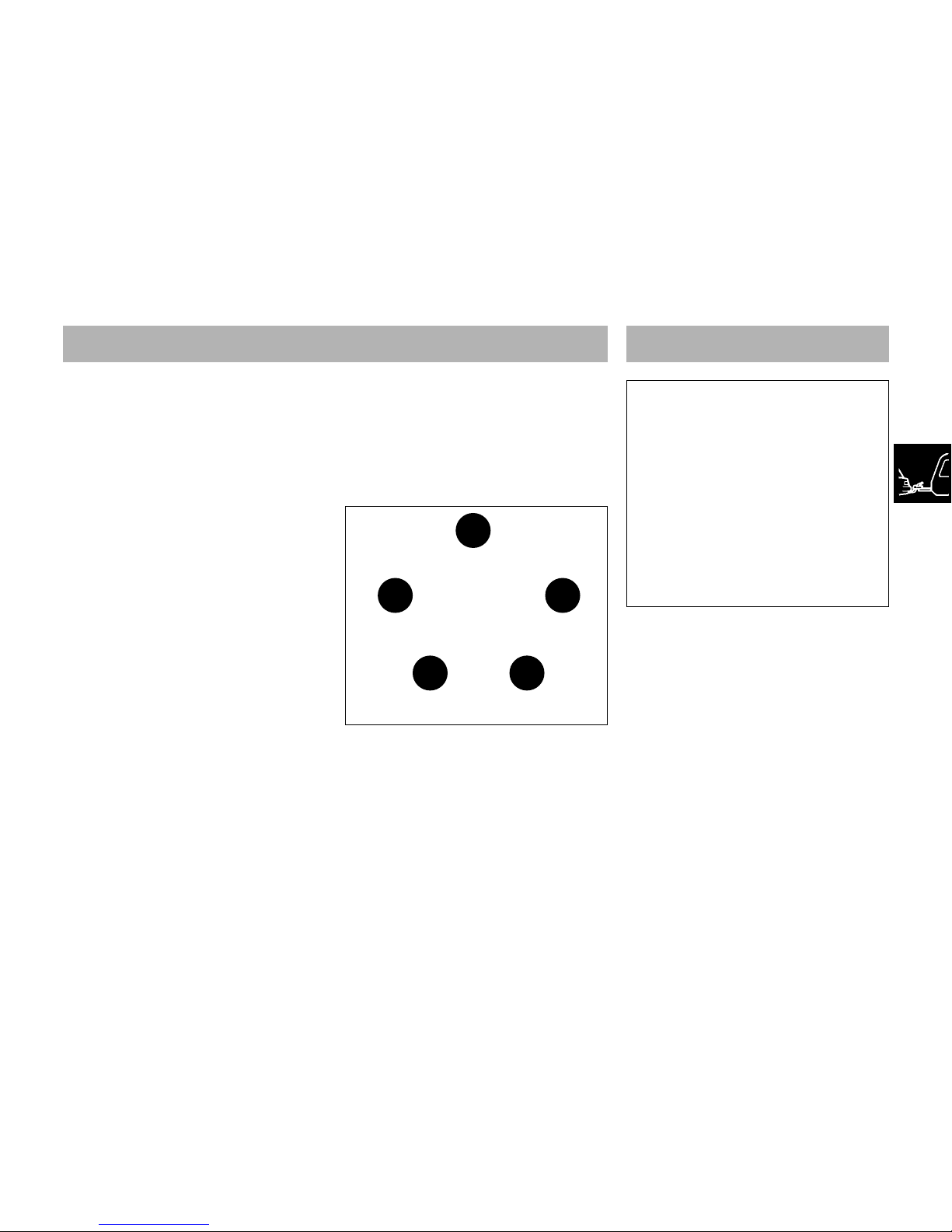

8. Tighten all five bolts, according to Fig. A,

to 88Nm (65lb/ft) for steel wheels or

115Nm (85lb/ft) for alloy wheels using a

torque wrench or have checked as soon

as possible.

Ensure the correct wheel fixings are used,

as supplied with your caravan

IMPORTANT

When a wheel has been removed and

replaced the torque of the wheel nuts should

be re-checked after approximately 15 miles

of running. (See 8 above).

WHEEL BOLT TIGHTENING

When refitting a wheel it is ESSENTIAL that

the wheel bolts are tightened to the

recommended torque figure and in the

correct sequence.

The sequences necessary to correctly carry

out this work on a 5 stud wheel is as follows:

Fig. B Side Lift Jack

Fig. A

29

1

3 4

5 2

5 Stud

The Towing Code

The Towing Code

30

JACKING POINTS

WARNING: Only jack up your caravan

when it is coupled up to the car with its

handbrake applied and in 1st gear

(engine off).

Ensure that the jack is located in the correct

position, i.e. on the jacking bracket on the

chassis for the AL-KO side mounted jack

(Fig.B). Alternatively the reinforced axle

mounting plate can be used as an alternative

but the chassis member itself MUST NEVER

be used as a jacking point.

All caravans are provided with the facility to

fit AL-KO side jacking points and although a

scissor, trolley or bottle jack may be used,

it is recommended that the side mounted

AL-KO Jacking System should be used.

STOPPING ON A HILL

Pulling off again can sometimes present a

problem. The easy solution is

(i) Carry a good sized wedge shaped piece

of wood with a rope or light chain

attached.

(ii) Attach the other end of the rope to the

nearside rear grab handle.

(iii) Place the wood behind the nearside

caravan wheel.

(iv) Carefully reverse the car slightly back

down the hill, the caravan will stop

against the wedge and turn.

(v) Drive forward since this attempt to move

up the hill will now not involve pulling the

full weight of the caravan until the car has

gained some traction.

ARRIVAL ON SITE

Note: Check and observe site regulations.

1. Selecting a pitch

Do not pitch in such a position that your

outfit will obstruct others coming in.

Try to choose an area which is dry, reasonably level and preferably with a hard base.

If you have no alternative but to pitch on a

slope ensure that, for when you leave, you

are facing down the slope.

It is good practice to chock the wheels of

the caravan when parked on a slope even

though the caravan brakes are applied.

2. Levelling the caravan

Levelling must be carried out in both

directions in order for the refrigerator and

other equipment to function correctly. This

should be done before unhitching the

caravan. Levelling boards (Fig. C) can be

used to raise one side of the caravan by

driving or reversing the caravan onto the

boards. Apply the handbrake and chock the

wheels.

The positioning of the jockey wheel can be

used to help level the caravan.

Lower the corner steadies until they are in

firm contact with the ground.

DO NOT use the steadies as a jack

they are only a means of stabilising

the caravan.

Levelling pads or boards should be used

under the steadies where the ground is soft

or uneven.

In extreme cases where it is necessary to

raise a wheel off the ground for levelling

purposes, further adequate support should

be applied so that the steadies do not take

any undue strain.

Exterior Door

To prevent distortion of the body, the

caravan must be always correctly sited and

levelled. Failure to site the caravan correctly

may prevent the exterior door from closing

properly.

Fig. C levelling Board

31

3. Unhitching

Apply the caravan handbrake.

Lower the jockey wheel to the ground.

Disconnect the breakaway cable and road

lighting plugs.

AKS3004

Release the stabiliser by lifting the red

handle. Then lift the exposed black handle

forward until it clicks up, at the same time

winding down the jockey wheel, to lift the

caravan clear of the towing vehicle.

AK160

Operate the handle by depressing the locking

button on the lever mechanism and lift the

handle upwards and forwards, at the same

time winding down the jockey wheel, to

assist in lifting the caravan clear of the

towing vehicle.

When this operation is complete, replace

towball cover and secure the 12N+12S

cables in their storage cups.

Park your vehicle alongside the caravan on

the offside.

The Towing Code

SAFETY

AND

SECURITY

Fire .......................................................................................... 34

Notice ................................................................................... 34

In Case of Fire ...................................................................... 34

Smoke Alarm......................................................................... 34

Fire Extinguishers.................................................................. 35

Children ................................................................................... 35

Ventilation .............................................................................. 35

Security ................................................................................... 36

Caravan Theft ....................................................................... 36

Chassis Number.................................................................... 36

Additional Security ............................................................... 36

Security Chips....................................................................... 36

Caravan Insurance ................................................................ 36

AL-KO secure immobiliser .................................................... 36

Safety & Security

FIRE

Important: Your attention is drawn to the

notice affixed inside the caravan advising on

fire precaution, ventilation and what to do in

case of fire.

IN CASE OF FIRE

1. Get everyone out of the caravan as

quickly as possible using whichever exit is

the quickest, including windows. Do not

stop to collect any personal items.

2. Raise the Alarm. Call the Fire Brigade.

3. Turn off the gas supply valve if it is safe to

do so.

4. Turn off the electricity supply at supply

point.

SMOKE ALARM

This is approved by The National Caravan

Council. The NCC requires that all new or

used holiday homes sold by its members are

fitted with a smoke alarm featuring an alarm

silence facility.

Maintenance

Test the smoke alarm every week, e.g. when

doing the vacuuming, by pressing the test

button for at least 10 seconds. The alarm

signal is a penetrating, rapidly pulsating

signal. The alarm sounds as long as the test

button is pressed or there is smoke in the

detector. When the alarm goes off, always

check carefully to see that there is no fire

and never remove the battery from the alarm

except when changing it!

Always test the alarm immediately after a

long period of absence. Under the test

button, there is a red control lamp which

twinkles once a minute. This shows that the

battery is correctly connected. If the alarm

does not sound when testing, the battery

must be replaced. The alarm should be

dusted and cleaned regularly with a slightly

damp cloth. In connection with annual

battery change or when required, e.g. false

alarm, clean and vacuum the alarm carefully

using a soft brush.

Removing and Replacing the Alarm

Carefully twist the alarm anti-clockwise.

Replace as diagram above.

Battery Replacement

The battery lasts approximately one year.

About a month before the battery is

completely flat, the alarm emits a short

signal once a minute, this is the signal that

the battery needs changing. The alarm works

as normal during this time.

The battery should be 9 Volt batteries GP

1604,S,A, Eveready 522,216, Duracell

MN1604. Always test the alarm after

changing the battery.

34

Test Button

Safety & Security

WARNING: Ensure that batteries are

correctly installed. Positive terminal to

positive contact (marked +), negative

terminal to negative contact. Reversing

a battery in its compartment will

immediately drain the battery and

could damage the smoke alarm.

WARNING: The electronic test button

provides a full test of the unit’s

functionality. DO NOT try to test the

alarm with a naked flame, as this may

present a potential fire hazard.

WARNING: Never use portable cooking

or heating equipment other than electric

heaters that are not of the direct radiant

type, as it is a fire and asphyxiation

hazard.

WARNING: Appliances such as cookers

must not be used for heating.

FIRE EXTINGUISHER

It is recommended that a 1kg (2lb) minimum

capacity dry powder fire extinguisher be

carried inside your caravan at all times.

When using a dry powder extinguisher it is

suggested that the caravan be evacuated

until the powder has settled, to avoid

inhalation.

A fat pan fire should not have a fire

extinguisher aimed at it. It should be

smothered with a fire blanket.

WARNING: Provide one dry powder fire

extinguisher of an approved type or

complying with ISO 7165, of at least 1kg

capacity, by the main exterior door and

a fire blanket next to the cooker.

Familiarise yourself with the instructions

on your fire extinguisher and the local

fire precaution arrangements.

ESCAPE PATHS

It is important that you do not block escape

paths to emergency exits with obstructions

or hazards.

CHILDREN

Do not leave children alone in the caravan in

any event. Keep potentially dangerous items

out of reach, as at home e.g. matches, drugs

etc.

VENTILATION

All caravans comply with BS EN 721. The

ventilation points on your caravan are fixed

points of ventilation which are required by

the European Standards.

All caravans have ventilation at high level

and low level which have been calculated to

suit the individual needs of your caravan.

High level ventilation is achieved by means

of the roof lights and washroom roof

ventilators. The low level ventilators are

positioned underneath the oven housing.

Some models with sliding doors have two

vents located underneath the sliding doors.

Under no circumstances must these vents

be blocked or obstructed.

It is advised that fixed ventilation points are

checked and cleaned (if necessary) on a

regular basis using a small brush and a

domestic vacuum cleaner.

Additional night time ventilation is obtained

by releasing the window catches and placing

them in the second groove. Note the

windows are not sealed from rain in this

position.

As the ventilation levels are calculated to suit

each models requirements there should be

no modifications made which may result in

reduced ventilation levels.

WARNING: Do not obstruct ventilation.

35

Safety & Security

Petrol/Diesel Fumes

The fitting of a tail pipe to your car exhaust

will reduce the possibility of fumes entering

your caravan through the ventilation points.

Note: Never allow modification of electrical

or LPG systems and appliances except by

qualified persons at an authorised Swift

Group dealership.

SECURITY

Caravan theft

The theft of a caravan can occur in the most

unlikely circumstances; from a motorway

service area, even from an owner’s driveway.

Secure all windows and doors when your

caravan is unoccupied even if only for a short

length of time.

Chassis number

Record your caravan chassis number which

can be found on the front offside section of

the drawbar (Fig. A) or any of the eye level

windows.

Make a note of this number in the space

provided at the front of this handbook and

make a separate note of the number to keep

safe at home.

Additional security

Consider fitting any device which might deter

or prevent intrusion by thieves.

A hitch lock cover prevents towing of the

caravan.

A wheel lock prevents towing of the caravan

and removal of the wheel.

Customers are advised to identify their

caravan with a method for subsequent

identification if other forms of identification

have been altered or removed.

Free crime prevention advice about securing

your caravan, protecting your valuables,

property marking, either at home or whilst on

site, can be obtained from the Crime

Prevention Officer through your local Police

Station.

36

Fig. A Chassis Number

SECURITY CHIPS

A special security chip is concealed within

the body of every caravan. This chip contains

the individual identity of your caravan and

can only be read by using a special decoder.

Your local police can obtain the use of a

decoder by contacting C.R.I.S. on telephone

no: 01722 411430

CARAVAN INSURANCE

It is recommended that the caravan and its

contents should be insured against theft.

It is essential to check with your car

insurance company to ensure you are

covered when towing your caravan.

AL-KO SECURE IMMOBILISER

The AL-KO immobiliser is fitted as standard

on some models, optional on others. When

fitted the 4 part kit specified below is

supplied with your caravan. Your kit will

contain : -

Part A

Box containing security components.

consisting of:

- 1off High security locking bolt

- 1off High security locking bar socket key

- 1off Barrel lock

- 2off Barrel lock keys

Safety & Security

- Instruction manuals in CD and paper

format.

- Security registration card and reference

number

Part B

Wheel specific insert assembly consisting of:

- Red coloured wheel insert lozenge

assembled with the locking bar and circlip

Part C

- 1off Wheel spanner

Part D

- Kit bag.

YOU MUST REGISTER YOUR KEY WITHIN

ONE MONTH OF THE DATE OF

PURCHASE. SHOULD YOU FAIL TO DO

THIS, YOU WILL NOT BE ABLE TO

ORDER A SPARE KEY!

- Within your AL-KO kit will find an exclusive

security number.

- Please register your card by telephoning

0870 7576788 or 0044 1926 818500.

- You will need to provide a password and

provide an answer to a prompting security

question.

- Make a note of your password and keep it

in a safe place.

- Keep your registration card safe.

- Take your registration card with you when

you are travelling with the caravan.

- Always keep your registration separate

from the lock.

SAFETY INFORMATION

- Always secure the caravan against rolling

away (chock or couple to a towing vehicle).

- Never leave Secure parts (key, adapter,

registration card) in the caravan.

- Always remove AL-KO Secure before

moving the caravan.

- After any attempt of theft has been made

on a locked AL-KO Secure, the caravan

must be inspected at an AL-KO Approved

Service Workshop.