CREATING SMILES FOR LIFE

Swi Group

Owner’s Handbook

Basecamp

Issued July 2017

Luxury

you deserve

WHEREVER YOU ARE

Truma Aventa

Experience the ultimate comfort of Automatic Climate

Control (ACC) by upgrading your Swift caravan with the

Truma Aventa Air Conditioner.

Your vehicles heating system and the Truma Aventa work

perfectly together to keep you cosy in the winter and cool

in the summer.

Set your preferred temperature just once and let the ACC

system keep you in ultimate comfort.

www.trumauk.com

Upgrade to even more

comfort on the move

Duvalay luxury

sleeping bags

& portable toppers

Luxury mattresses &

beds for your home

Truma Aventa

Upgrade to even more

comfort on the move

Experience the ultimate comfort of Automatic Climate

Control (ACC) by upgrading your Swift caravan with the

Truma Aventa Air Conditioner.

Your vehicles heating system and the Truma Aventa work

perfectly together to keep you cosy in the winter and cool

in the summer.

Set your preferred temperature just once and let the ACC

system keep you in ultimate comfort.

www.trumauk.com

®

The only Swift Partner for Paint

and Upholstery Protection

The only

one with the

Lifetime

Guarantee

Paint Protection Upholstery and Carpet Protection

From the Makers of Diamondbrite

Diamondbrite Leisure

The ultimate Paint and Upholstery Protection

for your Swift Basecamp

Diamondbrite Leisure is a two-step protection system for

your Swift Basecamp with a Lifetime Guarantee*

1. EXTERIOR

• Nano-Ceramic Technology

• Fade Resistant

• Never Polish Again!

2. INTERIOR

• Easy to Clean

• Stain Resistant

• Lifetime Guarantee

HOW DOES IT WORK?

If your paintwork was

magnified it would

reveal small pores in

the surface.

You will also receive a complimentary After Care pack including the fabulous Waterless Wash, plus a range of other professional cleaning products.

Jewelultra Ltd. Diamondbrite House, Ewell Lane,

West Farleigh, MAIDSTONE. ME15 ONG.

Tel 01622 815679

Email diamondbrite@jewelultra.com

Road traffic dirt

gathers in the pores

and attacks

paintwork.

Your first Paint Protection

application cleanses and

3 41 2

fills pores in the vehicles

paintwork leaving a smooth

finish that cannot be

penetrated.

Your second application

bonds with the first to create

a hard protective skin. It

leaves a high lustre finish that

rain and dirt cannot penetrate.

®

www.jewelultra.com

MADE IN UK

*Lifetime Guarantee applies for the length of time that the purchaser owns the vehicle and is non-transferable.

INTRODUCTION

INTRODUCTION

Dear owner

Thank you for deciding to buy one of our

new caravans.

We are sure you will enjoy many happy hours

in it and we hope the information and hints in

this handbook will heighten your enjoyment.

The handbook has been designed to give

you a general guide to the care, use and

maintenance of your caravan. Whether you

are a new or an experienced caravanner the

hints will help to protect your investment.

The information contained will answer most

of your queries, but if there are any aspects

which are not covered please consult your

appointed dealer. We would suggest you

make a note of your dealers name and

contact information below.

Dealer Name:

Telephone Number:

Throughout the season, specifications and

equipment details contained within this

handbook may change. Please refer to our

online handbooks (www.swiftgroup.co.uk)

for the most up-to-date version of your

handbook.

Customers should note that there are two

handbooks, the User Handbook which

contains general information for the use

and care of your product and the Technical

Handbook, which contains technical

information, weights and dimensions of

your product.

First Service Due:

Dealer Contact Sales:

E-mail:

Serial Number:

Dealer Contact Parts:

Dealer Contact Service:

1

SWIFT TALK

CONTENTS

I chat on

Talk

t

wi

S

SwiftTalk

Social Network for Caravan and Motorhome enthusiasts

www.swift-talk.co.uk

f

Swift Talk

Swift Talk is the central forum for the Swift

community online. A place for all those united

in their love of caravanning, motorhomes,

holiday homes and touring in general, to share

their experiences, meet new friends and find

out a world of information on how to enjoy

their touring lifestyle.

The site is packed full of features that actively

encourage members, not only to liaise with the

Swift Group via the forums, but also interact

with each other through publishing their own

content, uploading and sharing photos and

video, and even posting their own blogs for the

community to follow.

Swift Talk is the first place to learn about new

product launches, events and Swift Group

news, it’s also the first place customers can

go to as a quick reference to frequently asked

questions or to actively take part in the forums;

providing valuable feedback on Swift Group

products and customer service.

2

The online community can even be used to

create your own groups, perfect for Owners’

Clubs, dealers and exhibitors to attract new

members, publicise and build awareness

for upcoming events, rallies and shows.

Anyone who owns, uses, or is thinking of

buying a Swift Group caravan, motorhome

or holiday home, or would just like to be part

of the growing Swift community is actively

encouraged to sign up, create their own

content, and start talking!

Just visit www.swift-talk.co.uk

and become part of a unique

online experience.

CONTENTS

Warranty .................................................................................................................................... 5

Towing code .............................................................................................................................. 8

Safety & security ...................................................................................................................... 32

Services .................................................................................................................................. 38

Electrics ................................................................................................................................... 58

Fitted equipment ..................................................................................................................... 90

Maintenance .......................................................................................................................... 112

Useful information .................................................................................................................. 148

Index ...................................................................................................................................... 155

CONTENTS

3

Back to main menu

WARRANTY INFORMATION

Supplier contacts ....................................................................................................................... 6

To view the warranty details for your vehicle please follow the link:

WARRANTY INFORMATION

5

Back to section menu

WARRANTY

Supplier contacts

A number of Swift Group suppliers manage their own Technical and Warranty related queries.

Where a customer has a question relating to a product manufactured by a company listed below,

we would advise that the first contact should be directly with them.

WARRANTY INFORMATION

Sargent Electrical Services

Unit 39, Tokenspire Business Park,

Beverley, East Yorkshire, HU17 0TB

Phone: 01482 678981

Fax: 01482 678987

E-mail: support@sargentltd.co.uk

AL-KO Kober Limited

South Warwickshire Business Park

Kineton Road, Southam,

Warwickshire, CV47 0AL

Fax: 01926 818562

Email: mail@al-ko.co.uk

Truma UK Ltd.

Park lane, Dove Valley Park,

South Derbyshire, DE65 5BG

Phone: 01283 586020

Fax: 01283 586029

technical@trumauk.com

Thetford Ltd.

Unit 6, Brookfields Way, Manvers,

Dearne Valley, Rotherham,

South Yorkshire, S63 5DL

Phone - 0844 997 1960

Fax - 0844 997 1961

Email - infogb@thetford.eu

Alde International (UK) Ltd

Huxley Close, Park Farm South,

Wellingborough, Northants, NN8 6AB

Phone: 01933 677765

Fax: 01933 674975

Email: info@alde.co.uk

Dometic (UK) Ltd

Dometic House, The Brewery,

Blandford St Mary, Dorset, DT11 9LS

Phone: 0844 626 0133

Email: technical@dometic.co.uk

Whale

2 Enterprise Road, Bangor,

Co. Down, Northern Ireland BT19 7TA

Phone: 0845 217 2933

Email: info@whalepumps.com

https://sargentltd.co.uk

http://www.al-ko.co.uk

https://www.truma.com/

uk/en/home/index.php

https://www.thetford-europe.com

www.alde.co.uk

https://www.dometic.com

/en-gb/uk

http://whalepumps.com/

home.aspx

6

Back to main menu

TOWING CODE

Caravan towing code .............................................................................................................. 8

Caravan terms ........................................................................................................................ 8

Towing vehicle terms .............................................................................................................. 10

Measurement of nose weight .................................................................................................. 10

Type of driving licence held ..................................................................................................... 11

Glossary & checklist ............................................................................................................... 11

Useful memory aid .................................................................................................................. 13

Preparing for the road ............................................................................................................. 14

Tyre Maintenance ................................................................................................................... 17

The Tyre Law .......................................................................................................................... 18

Hitching up for AK160 ............................................................................................................. 18

Pre tow check list ................................................................................................................... 20

13 Pin Socket ......................................................................................................................... 21

Towcar electrics ....................................................................................................................... 22

Breakaway Cables .................................................................................................................. 23

Mirrors .................................................................................................................................... 25

Moving off .............................................................................................................................. 25

Reversing ............................................................................................................................... 25

Speed limits ............................................................................................................................ 25

Caravan handling .................................................................................................................... 26

Motorway driving .................................................................................................................... 26

Spare wheel ........................................................................................................................... 26

Changing a wheel ................................................................................................................... 27

Wheel Bolt tightening .............................................................................................................. 27

Jacking points ........................................................................................................................ 27

Stopping on a hill .................................................................................................................... 28

Arrival on site .......................................................................................................................... 28

Exterior Door .......................................................................................................................... 29

TOWING CODE

7

TOWING CODE

Back to section menu

Caravan towing code

This Code of Practice contains

recommendations jointly reviewed and

agreed by the following organisations:

The National Caravan Council

TOWING CODE

The Caravan Club

The Camping and Caravanning Club

The Caravan Writers Guild

The Department for Transport

Scope of the Code

The Code applies to all trailer caravans of

maximum laden weight not exceeding 3500 kg

(7,700 lbs), overall width not exceeding 2.3m

(7ft 6in approximately) and overall length not

exceeding 7m (23ft approximately), excluding

the drawbar and coupling.

This is legally the maximum size of trailer

that can be towed by a motor vehicle with a

maximum gross weight of less than 3500 kg.

Caravan terms

Empty Weight

The empty weight of the caravan includes

all loose items supplied by Swift e.g. Electric

hook cable, kit bag, entrance step, portable

waste tank and central heating fluid

(where applicable).

Mass in Running Order:

The mass of the caravan equipped to the

caravan manufacturer, standard specification.

The MRO comprises the empty weight of the

caravan and includes an allowance for gas.

Note: The mass of the caravan in running

order contains provision for the masses

of liquids, gas etc. (see Mass in Running

Order in the Technical Handbook). Part

of this provision can also be utilised as

additional payload, if for example, you wish

to travel with no gas cylinders.

Maximum User Payload:

The maximum allowable weight to be put into

the caravan whilst it is being towed.

This is made up of the personal effects and the

optional equipment payloads.

The user payload is the difference between the

Maximum Technically Permissible Laden Mass

8

and the Mass in Running Order.

The Mass in Running Order + Personal Effects

+ Optional Equipment = Maximum Technical

Permissible Mass or MRO + PE + OE =

MTPLM

Personal Effects

Those items which a user can choose to carry

in a caravan.

Note: The Personal effects payload includes

an allowance of 20kg for a leisure battery.

Optional Equipment

Items made available by the manufacturer over

and above the standard specification of the

caravan for factory fitted options.

Maximum Technically Permissible Laden

Mass (Lower Limit):

The fully laden mass of the caravan in the

manufacturers standard specification which

is stated in the publications, technical

handbooks, brochures and weight plate and

used for car matching.

Maximum Technically Permissible Mass

(Upper Limit):

The mass takes into account specific

operating conditions including factors such as

the strength of materials, loading capacity of

tyres, etc.

Payload Definition

The method of calculating the Mass in Running

Order (MRO) and user payload figures are in

line with European Vehicle Directives.

Allowances for essential equipment is

now contained within the MRO of the

caravan and as per NCC code of Practise

(CoP) 304.

This includes the following;

LPG 1 x cylinder = 10kg

The MRO is calculated with the fresh water

tank empty.

Back to section menu

TOWING CODE

Note: If you travel with water in the fresh

water tank, the payload will be reduced

accordingly.

The leisure battery is considered to be

included in the personal effects and an

allowance of 20kg has been made for this.

Items fitted at the point of manufacturer (wheel

locks, hook-up cable, plastic steps, waste

containers, etc.) are included within the vehicle

MRO.

! WARNING: Under no circumstances

should the maximum technically permissible

laden mass (MTPLM) be exceeded.

Upgrading of maximum technically

permissible laden mass:

The lower (or standard) MTPLM is quoted in

the Technical Handbook, in brochures and on

the caravan weight plate. However, in some

cases it may be possible to increase this

to a higher (upper) MTPLM. (See Technical

Handbook for details).

If extra user payload is required, an upgrade

maybe available (model dependant), this

must be requested via your dealer and is

chargeable.

If required you will be issued with the following:

(i) New weight plate giving upgrade weight

details.

(ii) New NCC certificate (declaring the

upgraded MTPLM)

(iii) Manufacturers letter confirming the upgrade

for that Vehicle Identification Number.

Note: Tyre pressures may increase when

upgrading the MTPLM.

Nose weight:

The vertical weight transferred to the towing

vehicle through the coupling head.

Notes:

(i) When measuring the noseweight it is

important that the caravan is fully loaded.

Do not place extra items indiscriminately into

the caravan after this adjustment has been

made.

(ii) The caravan is intended to be towed

slightly nose heavy. The nose weight can

be adjusted by distribution of the load

within the caravan. The nose weight

should be approximately 5%-7% of the

actual laden weight (but not greater than

the hitch capacity) and at the same time

suit the towing vehicle. See section on

Measurement of Nose Weight.

(iii) It is not recommended that you tow with

just a battery, spare wheel and gas bottles

as this may exceed the permitted nose

weight. Additional payload must be placed

behind the axle to compensate for this.

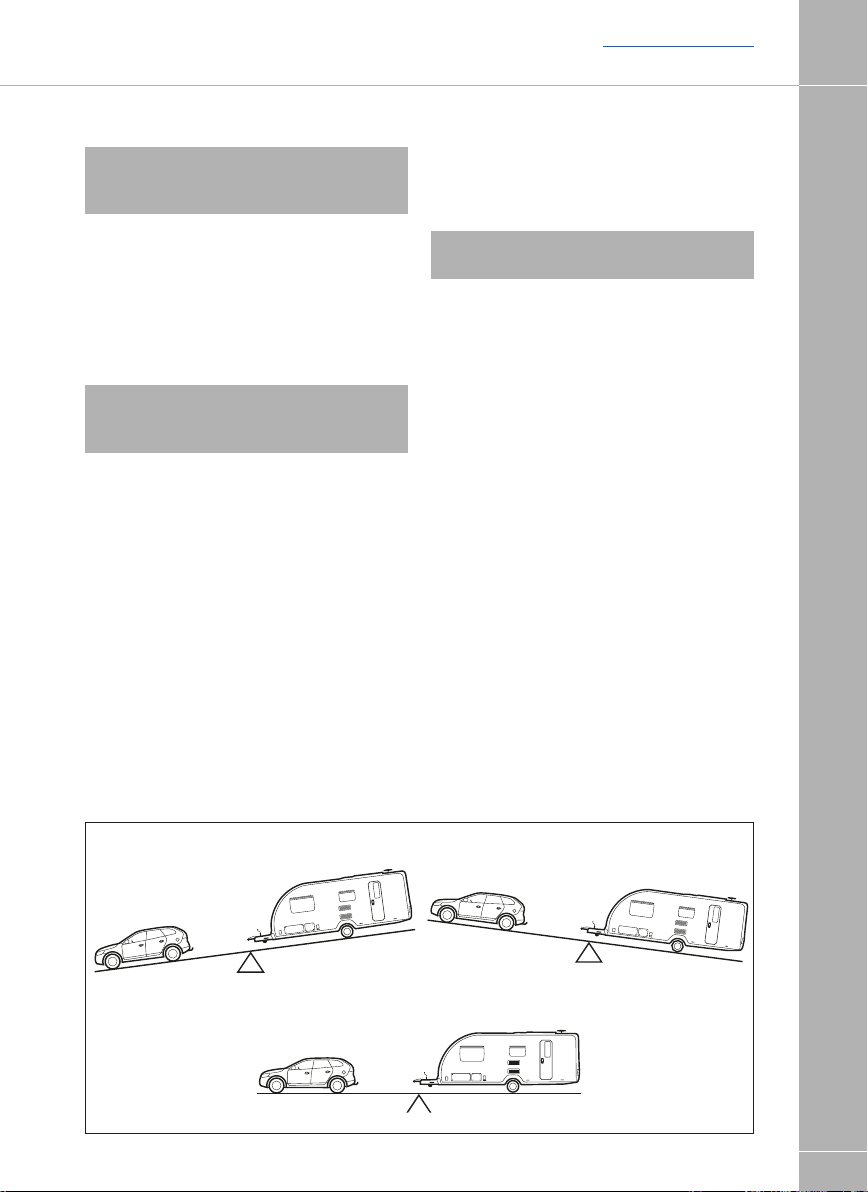

Fig. A Car/Caravan

weight ratios

YES NO

85%

MAYBE

Equal

9

TOWING VEHICLE TERMS

Back to section menu

Towing vehicle terms

Kerb weight

(Mass of Vehicle in Running Order):

The weight of the towing vehicle as defined by

the vehicle manufacturer. This is normally with

TOWING CODE

a full tank of fuel, with an adequate supply of

liquids incidental to the vehicles propulsion,

without driver or passengers, without any load

except loose tools and equipment with which

the vehicle is normally provided and without

any towing bracket.

Caravan to Towing Vehicle Weight Ratio:

The towing vehicle to caravan weight ratio can

be determined by calculation and is equal to:

Actual laden weight of caravan

Kerb weight of towing vehicle

The law requires that caravans & their towing

vehicles & the loads they carry must be in

such a condition that no danger or nuisance

is caused.

(Regulation 100 of the Road and Vehicles

[Construction and Use] Regulations 1986).

Note: The towing vehicle manufacturer’s

limit is, in some cases, less than the kerb

weight.

Measurement of nose weight

Nose weight may be measured using a

propriety brand of nose weight indicator.

Such equipment is obtainable at your

Caravan Dealer.

Note: These indicators have a varying

tolerance level and may not be accurate.

Another simple method is to use bathroom

scales under the coupling head with a piece of

wood, fitted between the coupling head and

the scales, of such length that the caravan

floor is horizontal with the jockey wheel raised

clear of the ground. (Fig. A)

x 100%

LEVEL

430mm

±35mm

GROUND LINE

Fig. A Measuring nose weight

10

Mass in Running Order:

Caravanners can use a public weigh bridge to

establish the mass in running order.

Note: Weigh bridges have varying weight

tolerance levels.

Maximum Permissible Towing Mass:

The weight defined by the vehicle

manufacturer as being the maximum that the

vehicle is designed to tow at.

Train Weight (Combination Weight):

The maximum combined weight of the towing

vehicle and trailer combination as specified by

the towing vehicle manufacturer.

Nose weight can be adjusted simply by

distribution of weights in the caravan.

Always lower jockey wheel before entering

the caravan and then raise before measuring

again. (See Loading).

Note: The height of the towball on the

towing vehicle, when laden, is also critical.

! WARNING: Do not lift the coupling head

by hand when hitching the caravan to the

car. Always raise and lower the coupling

head by winding the handle on the jockey

wheel up and down.

Back to section menu

DRIVING LICENCE / GLOSSARY AND CHECKLIST

TOWING CODE

Driving licence

If you passed your car test before 1st January

1997 you are generally entitled to drive a

vehicle and trailer combination up to 8,250kg

maximum authorised mass (MAM). This is

the weight of a vehicle or trailer including the

maximum load that can be carried safely when

it’s being used on the road.

You can also drive a minibus with a trailer over

750kg MAM.

If you passed your driving test after 1st

January 1997 and have an ordinary category

B (car) licence, you can:

• Drive a vehicle up to 3,500kg MAM towing a

trailer of up to 750kg MAM

• Tow a trailer over 750kg MAM as long as

the combined MAM of the trailer and towing

vehicle is no more than 3,500kg

For anything heavier you need to take a

category B+E driving test.

From 19th January 2013, drivers passing a

category B (car) test can tow:

• Small trailers weighing no more than 750kg

• A trailer over 750kg as long as the combined

weight of the trailer and towing vehicle is no

more than 3,500kg MAM

If you want to tow a trailer weighing more

than 750kg, when the combined weight of

the towing vehicle and trailer is more than

3,500kg, you’ll have to pass a further test

and get B+E entitlement on your licence.

Glossary & checklist

Awnings - Can consist of just a simple top

sheet but may extend to a five sided frame

tent attached to the side of the caravan.

Fire blanket - approved to BS 6575 is ideal

for dealing with ‘fat pan’ fires.

Fire extinguisher - It is strongly

recommended that a fire extinguisher is carried

in the caravan. (For suitable types see Safety

and Security).

Gas bottles - Bottled L.P. gas is the most

convenient portable source of fuel. Ideally, two

bottles are required for a constant supply.

An initial deposit is payable on each cylinder.

We recommend the use of 6kg Calor Light

Propane bottles. One position for use and one

for storage only. (For detailed information see

Services - Gas).

Jack - A suitable jack is essential (screw,

scissor, side mounted or air jack type).

Many car jacks are unsuitable. Ensure the

lifting capacity of the jack is suitable for your

caravan.

Levellers - Levellers help level the caravan

from side to side before unhitching. Proprietary

products can be purchased from your caravan

dealer and need to be positioned as indicated

by a spirit level.

Spare Wheel - It is always advisable to carry

a spare wheel with your caravan.

Spirit Level - A spirit level is extremely useful

when siting the caravan.

Stabiliser - Stabilisers help to dampen the

side to side movement of the caravan.

Torque Wrench - A torque wrench is the only

way that the exact recommended torque can

be achieved for wheel nuts and bolts. (See

Preparing for the Road).

11

GLOSSARY AND CHECKLIST

Back to section menu

Towing Bracket - Never use cheap

alternatives, obtain one manufactured by

a reputable company complying with the

relevant standards.

Any light passenger vehicle registered in the

TOWING CODE

UK on or after August 1st 1998 will require a

type approved towbar and towball

(to 94/20/EC or UN ECE R55).

Failure to fit a homologated towbar and

towball could result in a prosecution and

invalidation of your insurance cover.

Always check with your car manufacturer or

towbar manufacturer if in doubt.

Wooden Blocks - Wooden blocks typically

25cm square and 2cm thick are ideal for

placing under corner steadies and jockey

wheel when the ground is uneven or soft.

Water Containers - Two containers are

required, one to carry fresh water to the

caravan and one for waste water, which needs

to be disposed of properly. Several types

are available including jerry cans, Aquarolls,

wastemaster, etc .

13 Pin Socket - One socket fitted to the

car to accept corresponding plugs from the

caravan this energises the road lights and

caravan auxiliary circuits.

12 Volt Battery - A deep cycling, heavy duty

rechargeable leisure type battery should be

purchased to provide back-up power for

lights and other electrical appliances. (See

Battery). The securing arrangements for the

battery compartment require a leisure battery

complying with EN 60095-2 in particular those

with ledges for fastening to the lower edge

of the long sides. The maximum battery size

that can be fitted is 225mm high, (including

terminals) x 175mm deep x 353mm wide.

The depth and width dimensions include the

rim around the bottom used for securing the

battery.

! WARNING: Your caravan dealer should

be consulted if additional equipment is to be

fitted as strong points may or may not be

provided in the design.

Caravan motor movers

The design and fitment of a caravan motor

mover shall be in accordance with the NCC

Code of Practice 305 and you should ensure

you receive a signed installation certificate of

compliance from the installer.

Failure to do so may invalidate your

warranty.

Note: Fitting additional equipment, such

as a motor mover will reduce the caravan

allowable payload.

Note: The fitting of a motor mover

may require a larger capacity battery fitting.

Note: If a towing cover is fitted, care should

be taken not to obscure lights, reflectors

and protect against rubbing or damaging

the bodywork.

12

Note: Check first that the battery will fit

within the battery box and can be secured

before purchasing.

Back to section menu

USEFUL ITEMS

TOWING CODE

Useful memory aid

Car

External mirrors

Fire extinguisher

Jack

Petrol can

Spare bulbs

Spare keys

Spare wheel

Tool kit

Towball cover

Tyre pressure gauge

Warning triangle

Tyre pump

Hi-Vis tabard(s)

Breathalyser kit (some Euro

countries)

Headlight stickers (Beam

deflectors)

Caravan

Awning pegs and poles

Awning ground sheet

Bucket

Corner steady brace

Corner steady pads

Coupling lock

Door mat

Fire blanket

Fire extinguisher

Fresh water container

Gas cylinders

Jack

Levelling boards

Mallet

Site/caravan mains lead

Spare bulbs (Mandatory in E.C.)

Spare 12v fuses

Spare high pressure gas hose

Spare wheel

Spirit level

Toilet fluid

Waste water container

Wheel brace

Personal

After sun cream

First Aid Kit

Flannels

Hairbrush and comb

Make up. etc.

Raincoats

Toothbrush

Toothpaste

Scissors

Shampoo

Shaving kit

Shoe cleaning kit

Soap

Sun tan oil

Wellington boots

Domestic

Adhesive tape

Air freshener

Aluminium foil

Ashtrays

Bedding

Bin liners

Binoculars

Bottle opener

Breadboard

Brush and dustpan

Butter dish

Camera

Carving knife

Chairs

Clock

Clothes brush

Clothes line

Coat hangers

Coolbox

Colander

Crockery

Cruet

Corkscrew

Cutlery

Dish cloth and brush

Dusters and polish

Disposable cloths

Egg cups

Floor cloth

Fly spray

Food

Food mixer

Frying pan

Glasses

Grill pan

Jugs

Kettle

Kitchen roll

Kitchen tools

Matches

Measuring jug

Milk jug

Mixing bowl

Needles and thread

Oven gloves

Pegs

Piezo Gas lighter

Potato peeler

Radio

Rubbish bin

Saucepans

Scissors

Sieve

Sugar bowl

Shopping bags

Sleeping bags

Tea pot

Tea strainer

Tea towels

Table cloths

Table mats

Television

Tin opener

Tissues

Toilet paper

Torch

Towels

Toys & Games

Vacuum cleaner

Washing up bowl

Documents

Bank and credit cards

Caravan Certificate

Cheque book

CRIS document

Driving licence

Green Card

Insurance (some Euro

countries)

Maps and guides

Money

MOT Certificate

Vehicle Registration

Documents

Gadgets

Mobile phone & charger

13

PREPARING FOR THE ROAD

Back to section menu

Preparing for the road

Pre-load checklist

! WARNING: Never enter the caravan

without first lowering the four corner

TOWING CODE

steadies with the brace provided.

Before loading check:

- loose articles are stowed securely.

Do not stow tins, bottles or heavy items in

overhead lockers prior to towing.

- all lockers and cupboard doors are closed

and secured, including the bathroom door.

- all bunks are secure.

- ensure shower door is secure

- all rooflights are closed and secured.

- main table is stored in its transit position.

- television aerial is lowered and locked

where applicable

- fridge is on 12V operation and door lock

is set.

- all windows and service doors are fully

closed and latched. Never tow with windows

on night setting. Leave all curtains and blinds

open to aid rear visibility.

- gas cylinders are correctly positioned,

secured and turned off, unless using en route

heating.

- battery is secure and mains connecting cable

is disconnected and stowed.

- Ensure control panel settings are correct

for 12v fridge operation. See control panel

instructions for detail.

- Exterior door is closed and locked

! WARNING: Always disconnect the

electrical connector between the towing

vehicle and the caravan before connecting a

LV supply to the caravan.

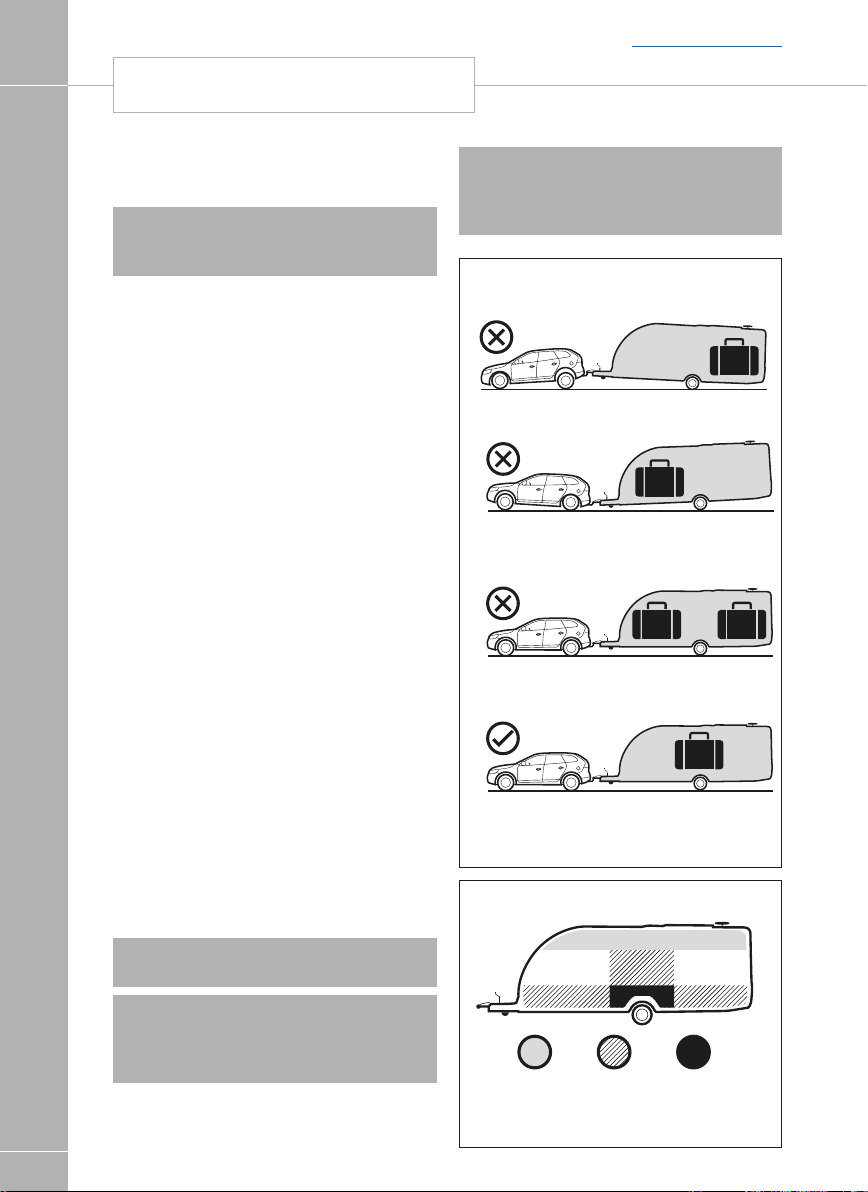

(a)

(b)

(c)

(d)

Fig. A Loading your caravan

14

! WARNING: Turn off gas appliances

except en route heating (if fitted).

! WARNING: Do not travel with televisions

or microwaves in overhead lockers unless

the appliance was supplied fitted to your

caravan by the manufacturer.

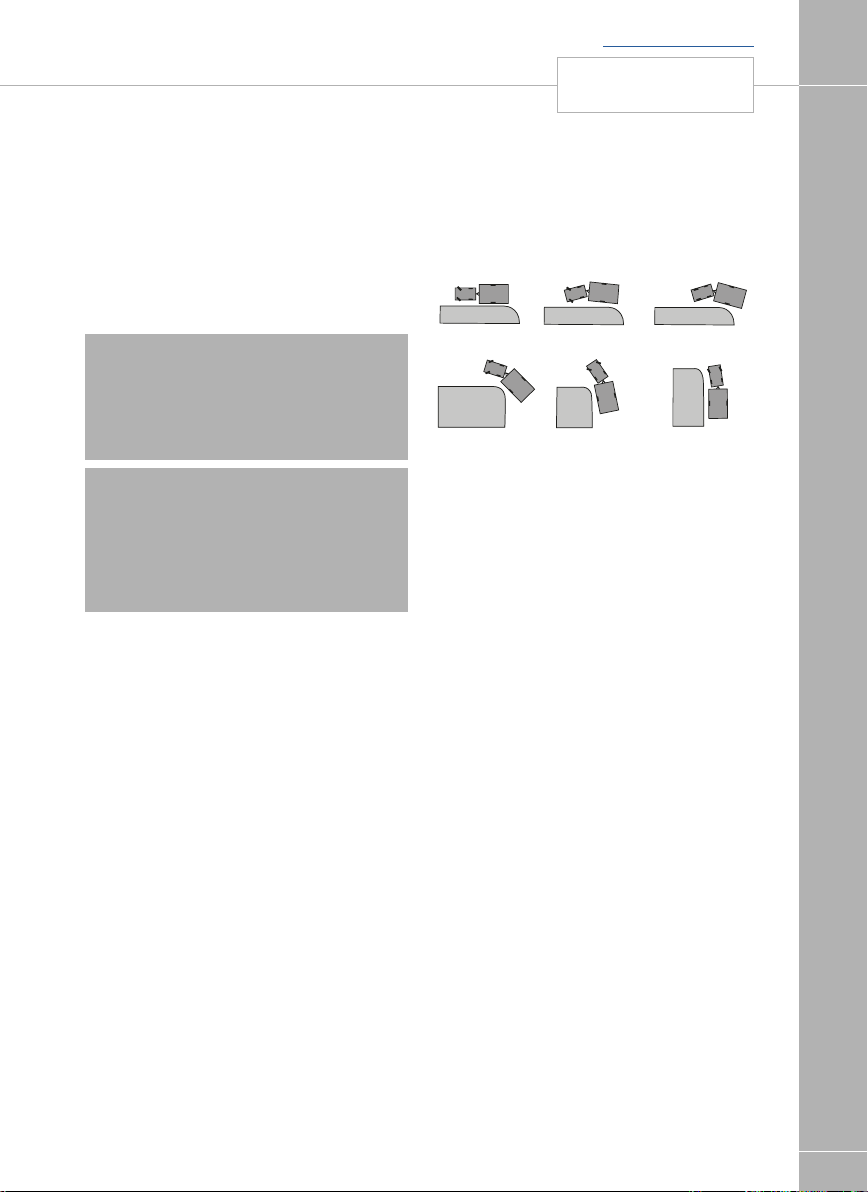

Light Medium Heavy

Fig. A Sensible loading

Back to section menu

TOWING CODE

How to apportion it

1. Load heavy items low down near the floor

and mainly over or just in front of the axle(s)

(Fig. A).

2. Load evenly right to left so that each

caravan wheel carries approximately the

same weight.

3. Do not load items at the extreme front or

rear since this can lead to instability due to

the ‘pendulum effect’.

4. Load remainder to give a suitable nose

weight at the towing coupling.

Check nose weight.

Note: Do not overload car boot.

! WARNING: All heavy and/or voluminous

items (e.g. TV, radio etc) must be stored

securely before travelling.

! WARNING: Please take care to

ensure that you have allowed for the

masses of all items you intend to carry

in the caravan. e.g. optional equipment,

and personal effects such as clothing, food,

pets, bicycles, sailboards, sports equipment

etc.

! WARNING: under no circumstances

should the MTPLM of this caravan be

exceeded

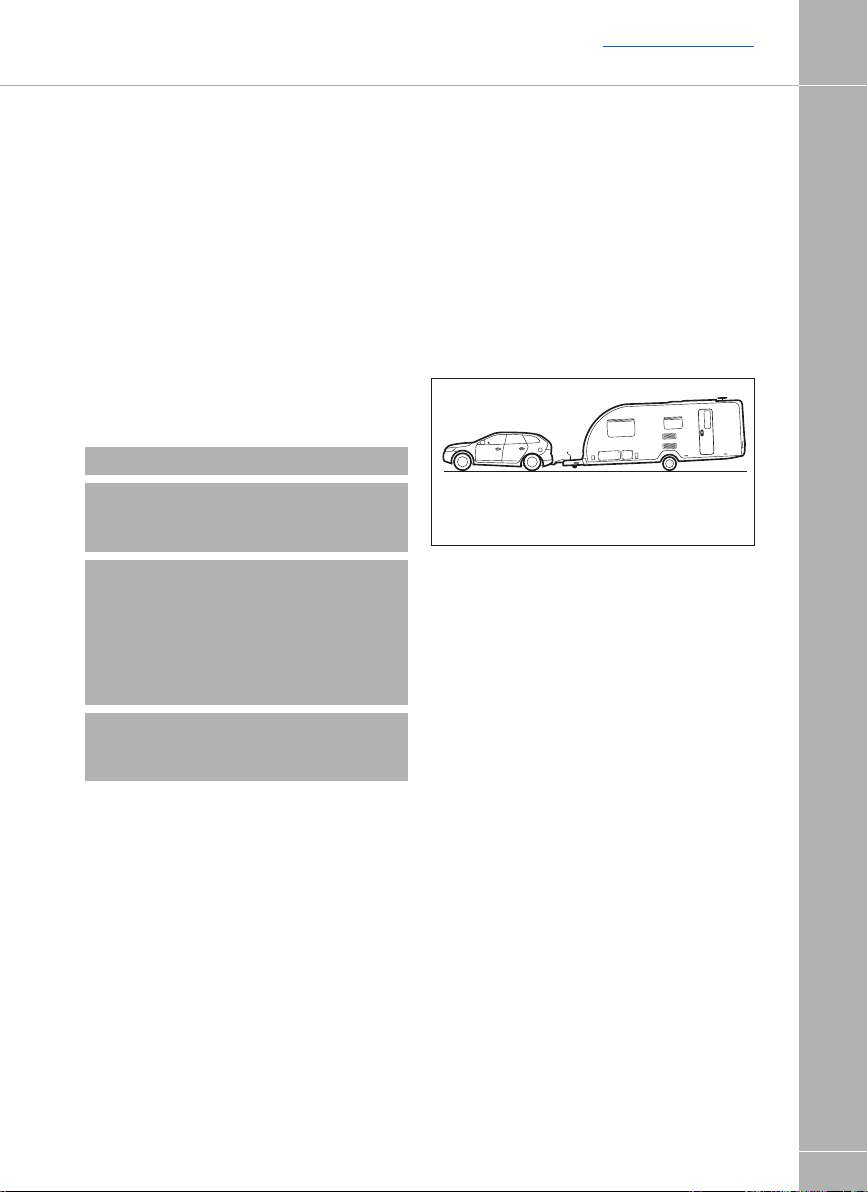

Towing vehicle’s rear suspension

It is important that the towing vehicle’s rear

suspension is not deflected excessively by the

nose weight on the tow ball. If it is excessive

the steering and stability will be affected.

(Fig. B)

The greater the towing vehicle’s tail overhang

(the distance between the rear axle and the

tow ball), the greater the effect the nose

weight will have on the towing vehicle’s rear

suspension.

Fig. B Illustration of excessive deflection

of vehicle’s rear suspension

After trying out the caravan it may be found

that a stiffening of the rear suspension is

necessary - but note that this may give the

towing vehicle a firmer ride when not towing.

There are a number of suspension aids

available and advice should be sought on

which to use and how to fit. It is important to

ensure that the caravan is towed either level or

slightly nose down.

If you have any doubts about the suitability of

your towbar for towing a caravan consult the

towing bracket manufacturer.

Do not exceed the:

• Gross Vehicle Mass (G.V.M. on car plate).

• Maximum Technically Permissible Laden

Mass (M.T.P.L.M.) on the caravan.

• Gross Vehicle Combination Mass (Train

Weight) (G.V.C.M. on car plate).

• Maximum Permissible Towing Mass.

• Vertical Static Load on the

caravan coupling (noseweight).

• Maximum Vertical Load on the car towball

as specified by towing vehicle manufacturer

(noseweight).

• Driving licence limitations

15

STABILITY

Back to section menu

Stability

All our models are of a well balanced design

and should be exceptionally good towers.

The common causes of poor stability include:

a. Worn springs or loose spring fixings on the

TOWING CODE

towing vehicle.

b. Towing vehicle springs too soft.

c Insufficient nose weight.

d Nose of caravan is towing too high or to low.

e Unsuitable towing vehicle.

Galvanised steel chassis

Drilling of the galvanised steel chassis will

invalidate the warranty and must not be done.

Suitable towing vehicles

The caravan is manufactured for towing behind

normal road cars and is not suitable for towing

behind commercial vehicles.

It is strongly recommended that whenever

a caravan is to be towed over rough terrain,

e.g. a field or track, great care should be

taken to ensure that no undue stress is placed

upon the caravan via the hitch mounting, i.e.

reduce speed. If in doubt, please consult the

chassis manufacturer and the towing vehicle

manufacturer who will advise.

Touring caravans based on standard AL-KO

chassis can be towed by four wheel drive off

road leisure vehicles providing the unit is used

to tow in a like manner to a conventional roadgoing car and driven in the same considered

manner.

Towbar manufacturers should be consulted

before towing an uncompensated twin axle

caravan.

Snaking

This is a term used to denote an unstable car

and caravan combination where the caravan

‘weaves’ from side to side often causing a

similar swaying movement in the car itself.

Causes:

1. Unsuitable or unbalanced outfit.

2. Incorrect loading or weight distribution.

3. Excessive speed especially downhill.

4. Side winds.

5. Overtaking.

6. Being overtaken by a large fast

moving vehicle.

7. Erratic driving.

8. Incorrect tyre pressures, car and caravan

9. Incorrect vehicle towball height

10. Worn hitch head or towball

Cures

Cases of persistent snaking can be alleviated

by the use of a stabiliser.

On the road

If you do find your outfit snaking, try to keep

the steering wheel in a central position as far

as possible, decelerate and avoid braking if

possible.

16

Back to section menu

TOWING CODE

Types of tyres fitted

The original tyres fitted by the manufacturer are

suitable for towing at a maximum speed of up

to 81 mph (130 kph).

Tyres

Caravan manufacturers choose the type,

size, profile, load carrying capacities and

speed ratings to match the design masses

of their vehicles, adjusting the tyre pressures

to suit. Only change the type of tyres on your

caravan on expert advice from the caravan

manufacturer, or tyre manufacturer.

Tyre maintenance

Tread depth

Pay special attention to the amount of tread

remaining on your tyres, and measure them

regularly. Always replace tyres before they

reach the minimum legal limit of 1.6mm.

Periodically tyres should be rotated to equalise

wear in the same manner as car tyres.

Pressures

The caravan manufacturers plate (fixed

adjacent to exterior door) and Technical

handbook contains information about caravan

loading and the required adjustments to

tyre pressures, which should be followed for

safety (these pressures relate only to the tyres

originally fitted to the caravan). Tyre pressures

should always be checked and corrected prior

to each journey. It is vital that tyre pressures

are maintained at the levels recommended by

the manufacturer to ensure maximum tyre life,

safety and handling characteristics.

Please also remember to check your spare

tyre pressure as it can be easily overlooked.

Over or under-inflating tyres is likely to

seriously impair their performance and may

compromise the safe use of the vehicle.

Over-inflation increases overall tyre diameter,

decreases the amount of tread in contact with

the road, decreases sidewall flexibility and

affects road-adhesion.

Under-inflation decreases overall tyre diameter,

increases sidewall flexing, generates higher

tyre operating temperatures and difficult

vehicle handling characteristics. Running an

under-inflated tyre may cause premature tyre

failure. Both over and under-inflation adversely

affect tyre life.

Tread

Keep tyre treads clean of stones and other

foreign bodies, and check regularly for

damage to the tread and sidewalls. It is vitally

important that any damage is checked out

by a tyre expert and any necessary repairs or

replacements are carried out immediately.

Tyre valves

Check tyre valves carefully. Ensure the caps

are in place free from dirt/ debris and that there

is no evidence of cracking or damage to the

valve stem.

Tyre Ageing

Rubber compounds used in tyres contain

chemicals that help to slow down the natural

aging process of untreated rubber. However,

tyres do deteriorate with age, which increases

the risk of tyre failure, and there are many ways

in which this can be spotted:

• Cracking/crazing on the side wall of the tyre,

caused by its flexing

• Distortion of tyre tread

• Deformation of the carcass of the tyre

There will also be a deterioration of the ride

quality caused by vibrations through the

tyre. This may signify the tyres performance

has been affected by age and should be

investigated as soon as possible

Note: It is recommended that tyres are

replaced after 5 years from the date of first

inflation. The date of first inflation is normally

within a few days of the date of manufacture

of the vehicle they are fitted to, and this

date can be determined from the gas and

/ or electrical certificate supplied with the

caravan.

We recommend that tyres that are over 5

years old (from first inflation) are inspected

and passed as fit for use by a qualified

technician. It is possible that in the event of

a tyre failure, an insurer may not cover any

losses incurred if the tyre is over 5 years

(from first inflation) and was not inspected

no more than 12 months prior to the

incident.

17

THE TYRE LAW

Back to section menu

Tyres that display signs of aging should be

removed and not put to further use.

The effects of aging can be brought about

prematurely in several conditions. Tyres fitted

as spare wheels may age prematurely. If

tyres on caravans are not in regular use they

TOWING CODE

should be inspected before every journey,

several cleaning products may also harm the

chemicals in the rubber. However, the age of

a tyre will affect its safety and increase the risk

of failure, and you should inspect tyres for the

signs of aging regularly.

Note: The use of some motor movers

can damage or increase wear on the tyres

prematurely.

The tyre law

Note: Sales literature/ Technical Handbooks

publish recommended tyre pressures for the

MTPLM only (fully laden condition). It is not

possible to publish tyre pressures for any

other load condition other than the MTPLM.

Tyre types

It is illegal to mix tyres of a different

construction on the same axle.

Note: Although the caravan may be fitted

with the same type of tyre as the towing

vehicle, the pressures specified are different.

All charts show values for cars and are

therefore not applicable for caravans.

Pressures displayed on tyre walls apply ONLY

in North America and Canada.

Wheels

Caravan wheel bolts supplied with your

caravan should be tightened to a torque of

88Nm (65lb/ft) on steel wheels or 130Nm

(96lb/ft) on alloy wheels and should be

checked with the use of a torque wrench

regularly. Only use a spare wheel and tyre of

the type and size provided with you caravan.

Note: Please remember to check the wheel

bolt torque setting regularly.

Wheel rims

Two sizes of wheel rims are used 5.5J x 14

and 6J x 15, the rim sizes are the same for

both steel and alloy rim, incorporating a double

safety hump which conforms to European

safety standards. Check the size on your

caravan before replacing a rim.

Hitch head load capacity

The maximum vertical static load which can

be put upon the hitch head when connected

is 100kg. Please refer to the technical data

in your handbook. (But see also vehicle

manufacturer’s weight limits on towball

loading.)

Hitching-up

An assistant can help in the hitching operation

by standing on the left hand side of the

drawbar (facing rear of car) and extending

an arm horizontally to indicate position of the

coupling. When reversing aim the towball

of the car directly at the caravan drawbar.

Remove towball cover and keep in car.

Adjust the jockey wheel to ensure the hitch

head is high enough to slide over the towball.

! WARNING: Do not lift the coupling head

by hand when hitching the caravan to the

car. Always raise and lower the coupling

head by winding the handle on the jockey

wheel up and down.

18

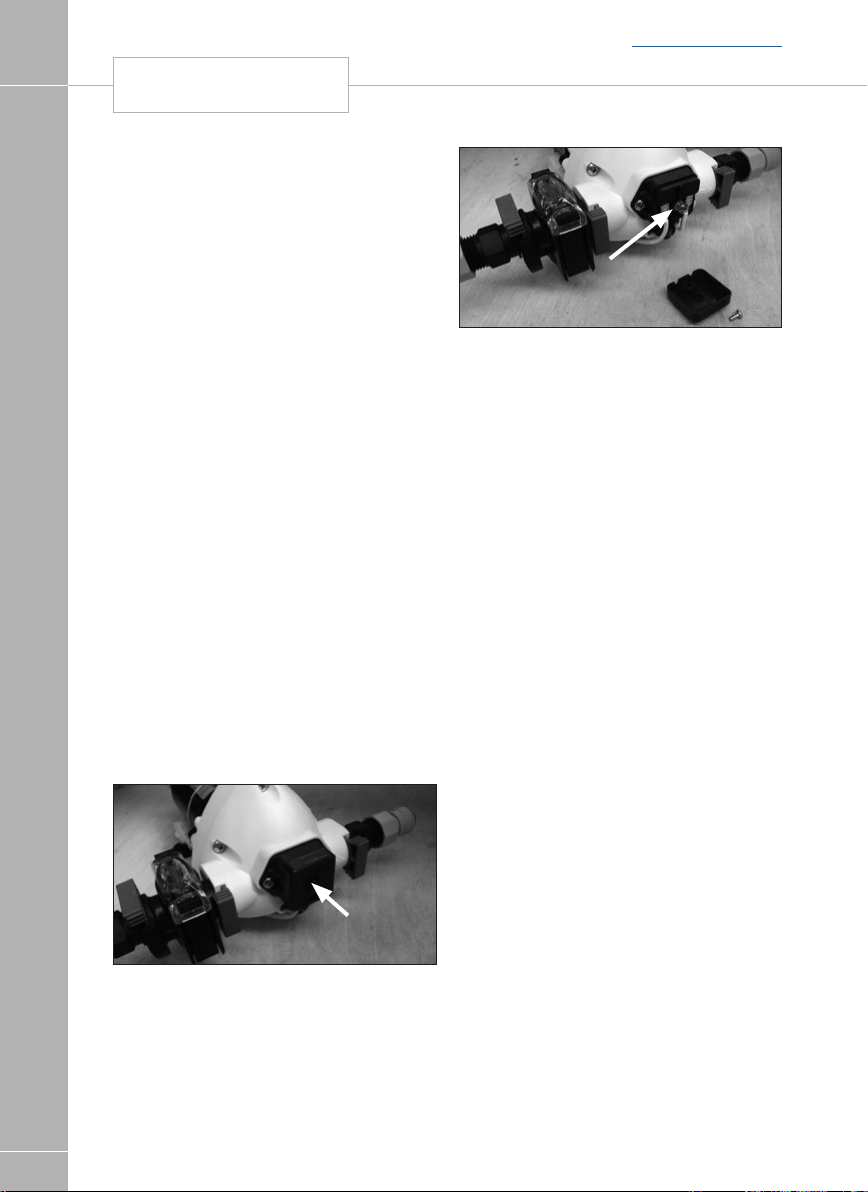

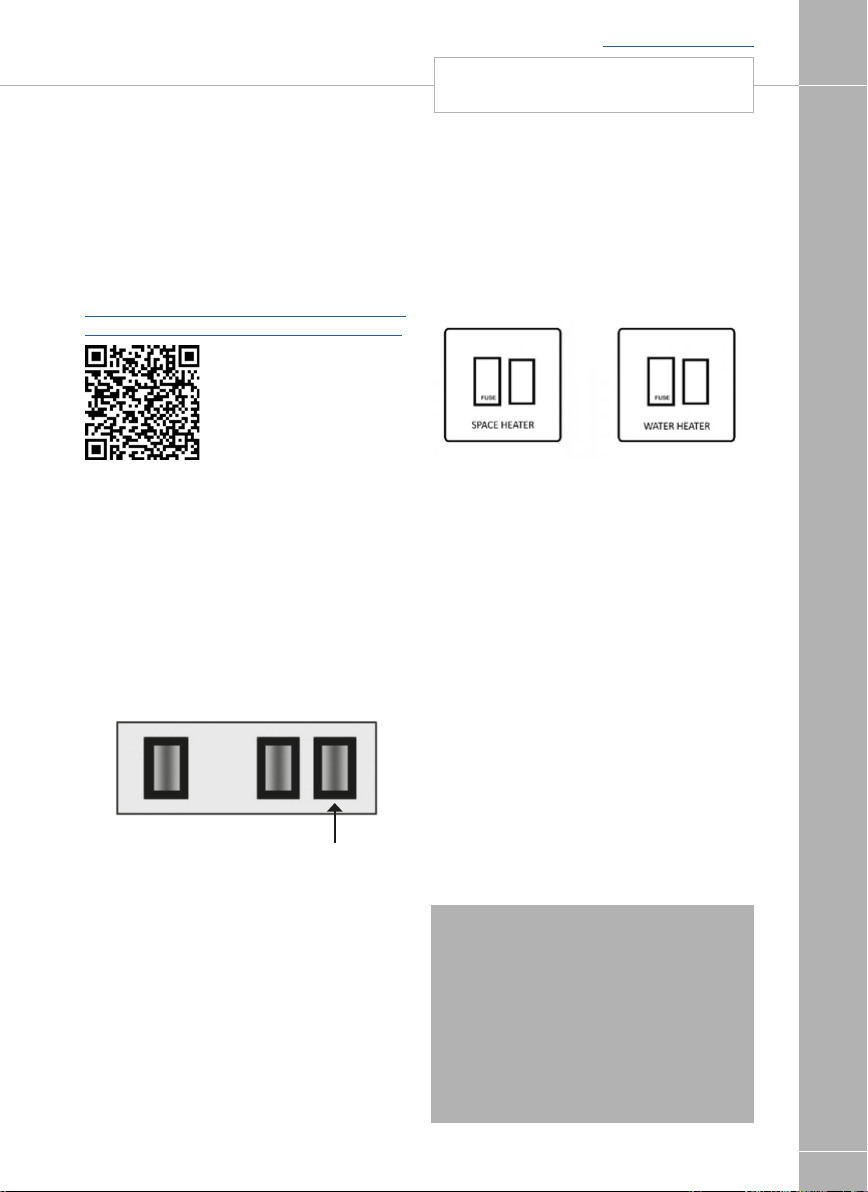

AK160 Type Hitch head

Fig. A

Open the locking mechanism by pulling the

coupling handle upward in the direction of the

arrow (Fig.A item 1). The handle will remain

in the open position until the hitch head is

positioned onto the towball.

Release the caravan handbrake and

manoeuvre the hitch head over the greased

towball and re-apply the handbrake. Using

the jockey wheel winding handle, lower the

hitch head carefully onto the towball. The

pressure of the towball within the hitch head

will release the locking tongue with an audible

click and the coupling handle should drop

down. For safety check that the coupling

handle is fully down by pushing the handle

down manually. When the hitch head is

correctly coupled to the tow ball the green

collar of the locking display button will be

visible. (Fig A item 2). If the green collar is

not visible it is not safe to tow the caravan.

Contact your dealer for advice.

Back to section menu

HITCHING-UP

TOWING CODE

19

PRE-TOW CHECK LIST

Back to section menu

Pre-Tow Check List

Check gas locker, battery locker and cassette

toilet doors are secure.

Check wheelnuts, tyre pressures and tyre

conditions.

TOWING CODE

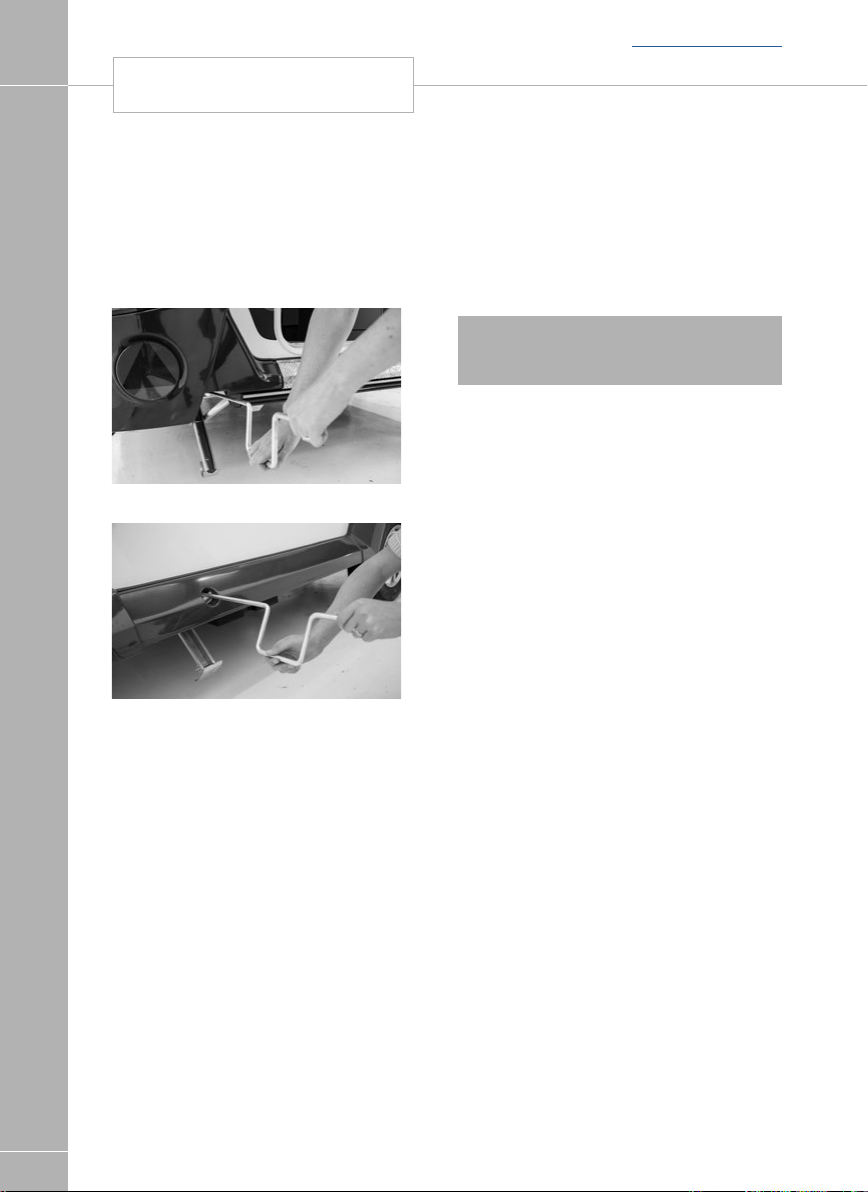

Fully raise all four corner steadies. (Fig. E & F).

Fig. E

Fig. F

Pick up any levelling pads or levelling boards.

Check windows/rooflights/vents are securely

closed.

Ensure television aerial is lowered (where

applicable).

Switch off gas supply and change fridge to

12V operation.

Lock the caravan exterior door.

Check all car and caravan roadlights are

working.

Check round the caravan for anything left

behind.

Fit extending mirrors

Release caravan handbrake, adjust all mirrors

from driving seat and proceed.

• All road lights must be in working order.

• Lenses and reflectors must be in good

condition

• Bulbs must be of correct wattage for the

application (see Service handbook).

! WARNING: Do not cause any road

lighting to be obstructed by the addition of

any options or accessories to your caravan.

20

13 Pin socket

Please be aware that some car manufacturers

and towbar manufacturers do not wire up all

13 pins as standard, unless requested.

Back to section menu

13 PIN SOCKET

TOWING CODE

21

TOW CAR ELECTRICS

Back to section menu

Tow Car Electrics

In all cases, The Swift Group assumes that the

tow car harness and electrics have been fitted

with the specific requirement of connection to

a caravan, which may contain AL-KO trailer

control (ATC), a 12V powered fridge and

TOWING CODE

charging circuits.

Most modern retro-fit towbars contain a relay,

located somewhere within the boot of the

tow car, which may have a selectable power

output for the fridge supply.

If a customer is experiencing issues with the

fridge supply it is possible the relay requires

adjustment and they should contact their tow

vehicle electrics installer or an auto electrician

to verify the installation.

LED Road Lighting

Your caravan maybe fitted with LED road

lighting, including the directional indicators and

stop lamps. LEDs consume very little power,

offer excellent light output and longevity when

compared to traditional tungsten bulbs.

Some more advanced tow cars are fitted

with Vehicle Light Monitoring Systems {VLM},

where the car monitors the condition of the

trailer/caravan road lights and advises the

driver of any bulb failures. To do this, some

tow cars expect to see a load on the caravan

lighting circuit similar to a tungsten bulb while

others may send a pulse of energy to each

light to confirm that the resistance of a bulb is

present.

The result of the above is that some tow cars

may incorrectly advise the driver of a bulb

failure, due to the use of LED lights while

others may flash or pulse the lights during use.

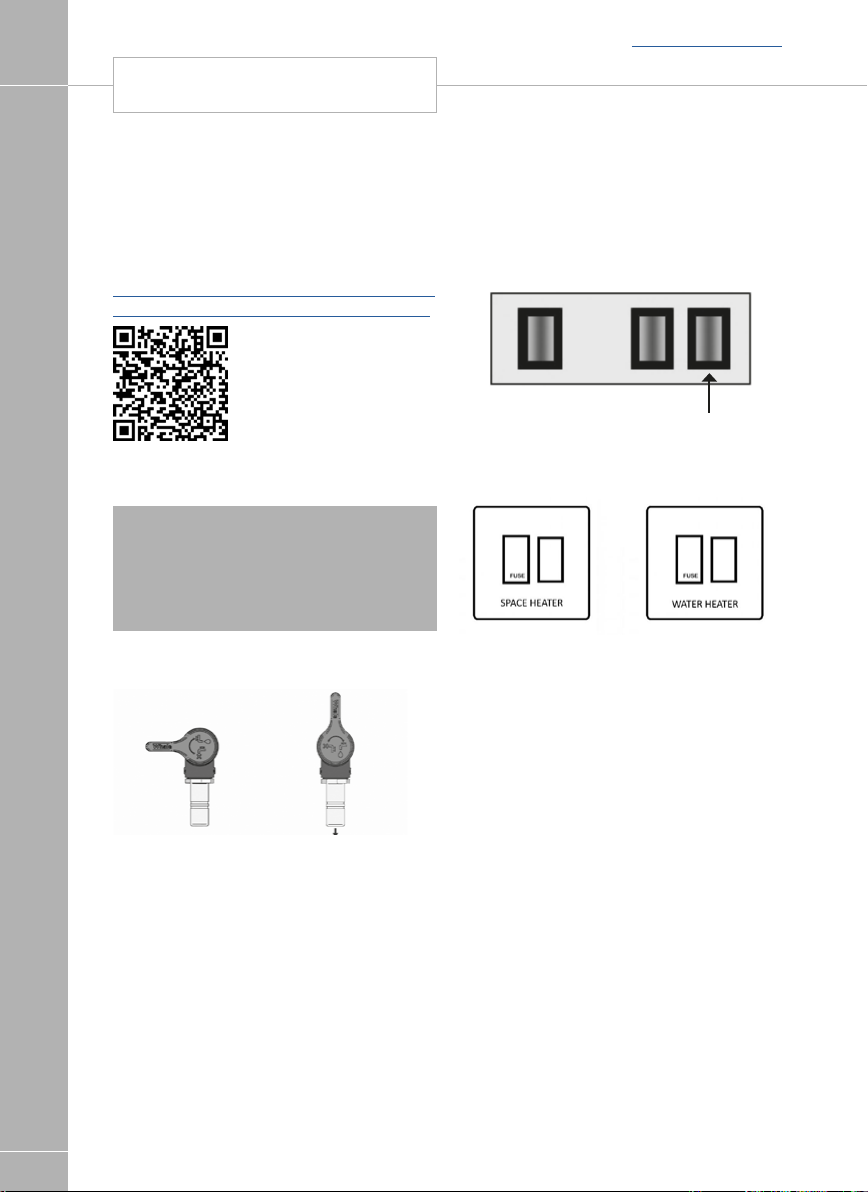

Recognising this, The Swift Group have

developed an additional towing fusebox,

which when connected to the existing towing

fusebox and is used to assist the towcar in

recognising the VLM System. Depending on

the type of car and system used the fusebox

maybe model specific.

The secondary fusebox is chargeable and

available through any Swift Group Dealer.

Note: This will change updates will be

required.

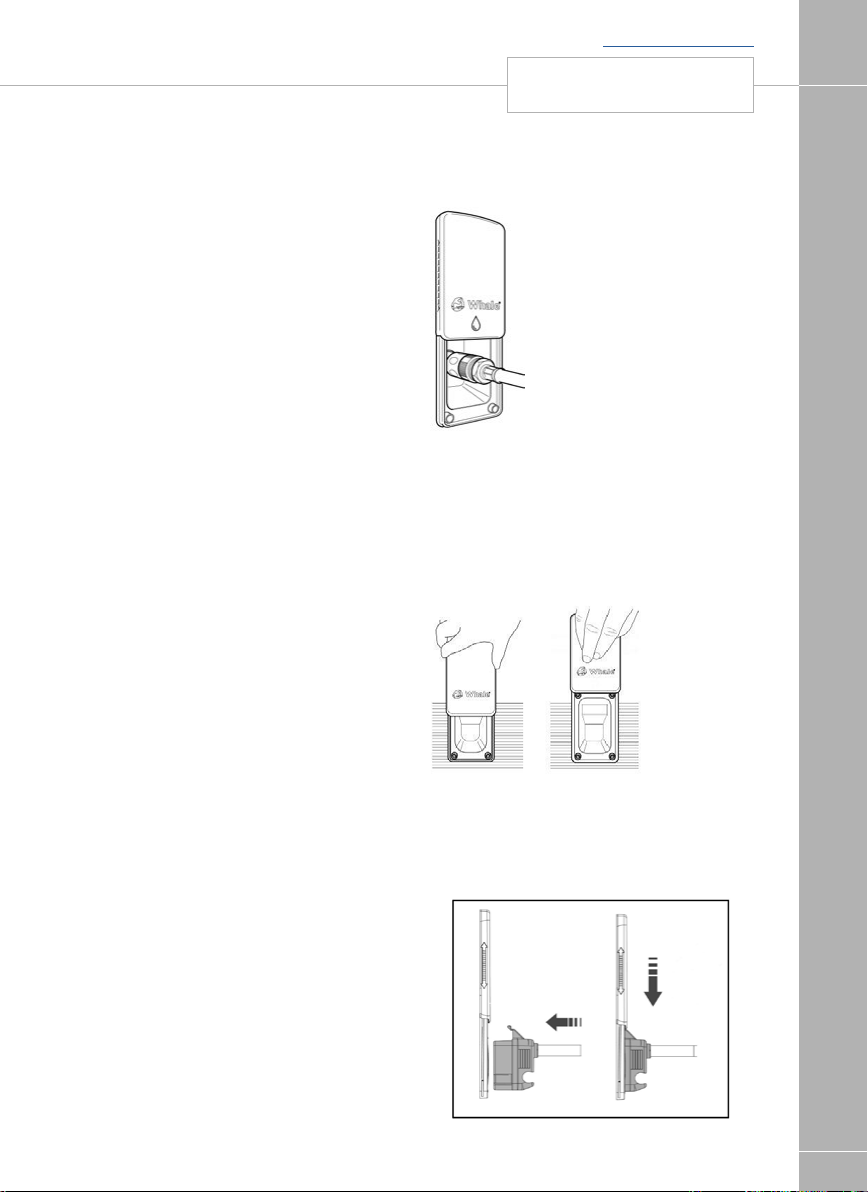

Caravan 13 Pin Connection - care advice

All caravans since 2008 have been supplied

with a 13 pin plug to connect to the towcar.

The 13 pin plug has an inner ring assembly

that is independent from the outer body.

Plug Inner Ring (containing

male pin terminals) - fitted to

Plug Outer Body with locating

groove and hood - fitted to

Socket Body (containing

female socket terminals) -

the caravan

the caravan

fitted to the car

Under normal circumstances the inner ring and

the outer body will be locked in one position

(see fig 1).

Fig 1

When the plug is first inserted in the socket

body ensure that the locating protrusion (key)

matches the groove (keyway) in the socket

body. The outer body can then be rotated a

full 90 degrees clockwise until a click is felt

or heard, at this point the cover flap can be

allowed to fall over the circular surface of the

plug top.

To remove the plug it is important to rotate the

outer body a full 90 degrees anti-clockwise,

again until a click is heard or felt before

withdrawing the plug from the socket. This will

ensure that the inner and outer parts of the

plug are returned to a locked condition.

22

Back to section menu

BREAKAWAY CABLE

TOWING CODE

WARNING: If the connector is not fully rotated

anti-clockwise prior to removing it from the

socket it is possible that the inner ring will

become ‘floating’ and may result in a condition

where the protrusion will be incorrectly aligned

(see fig 2 & 3).

Fig 2

Fig 3

If this situation does occur then it can be

corrected by inserting the edge of the

protrusion on the plug into the groove in the

socket (see Fig 4) and rotating the plug body

anti-clockwise until a click is felt. This process

will re-establish the lock between the inner and

outer parts allowing the correct insertion of the

plug into the socket.

Fig 4

Note: Customers should note that the

towbar and towcar electrical socket will

be checked as part of the standard MOT

regulations, under directive 2009/40/EC.

This not only applies to tow cars but also

all Motorhomes fitted with a tow bar and

socket. Inappropriate repair or modification

to either maybe deemed a failure of the

vehicle if it is likely to affect the road

worthiness of the vehicle.

Passengers

Passengers are forbidden to ride in a caravan.

Breakaway cables

UK law requires that all caravans are fitted

with a safety device to provide protection in

the unlikely event of separation of the main

coupling while in motion. A device referred to

as a ‘breakaway cable’ fulfils this requirement

and when fitted as on your caravan is

mandatory.

Purpose

To apply the caravans brakes if it becomes

separated from its towing vehicle. Having done

this, the cable assembly is designed to part

allowing the caravan to come to a halt away

from the towing vehicle.

Construction

A thin steel cable with a red plastic coating

fitted with a means of attachment for

connection to the towing vehicle. Located

directly beneath the coupling head.

Operation

In the event of the main coupling of the

caravan separating from the towing vehicle,

the cable should be able to pull tight, without

any hindrance, engaging the caravan brakes.

The breakaway cable should not become taut

during normal driving.

Correct procedure for use

Regularly check the cable and clip for damage.

If in doubt contact your Swift Group dealer.

Make sure the cable runs as straight as

possible and goes through the cable guide

fitted underneath the caravan coupling head.

23

BREAKAWAY CABLE

Determine whether or not the towing vehicle

towbar has a designated attachment point

(i.e. a part specifically designated for a

breakaway cable).

Where a point is designated on the towbar:

• Either pass the cable through the attachment

TOWING CODE

point and clip it back on itself (Fig 1)

or attach it directly to the designated point

(Fig 2).

Fig. 1

Fig. 2

Where there is no designated attachment point

on the towbar:

• Fixed ball: Loop the cable around the neck

of the towball in a single loop only. See figure

3A and 3B.

Back to section menu

Fig. 3a

Fig. 3b

In some instances it may be possible

to attach the cable assembly either to a

permanent part of the towbar structure, as

long as this meets the approval of the towbar

manufacturer/supplier, or to an accessory sold

for the specific purpose of breakaway cable

attachment. For vehicles fitted with detachable

towbars, guidance must be sought from the

towbar manufacture/supplier on the correct

method for attaching the breakaway cable.

When the breakaway cable is attached it must

not snag in use on the trailer coupling head,

jockey heel or any accessories, e.g. a stabliser,

bumper shield, cycle carrier, etc. There should

also be sufficient slack in the cable to allow

the towing vehicle and trailer to articulate fully

without applying tension to the cable which

could otherwise cause the trailer brakes to be

inadvertently applied.

The cable must not be allowed to drag on the

ground. If there is too much slack, the cable

might drag on the ground and be weakened

so that it has insufficient strength to apply the

brakes in the event of the trailer becoming

detached when in motion. Excess slack may

also lead to the cable being caught on an

obstacle when in motion, leading to inadvertent application of the trailer brakes. Care must

be also taken to ensure that the cable cannot

be entangled with the electrical cables.

24

Back to section menu

MOVING OFF

TOWING CODE

Mirrors

The driver of the towing vehicle must have an

adequate view of the rear.

If there is no rear view through the caravan it is

essential that additional exterior towing mirrors

are fitted. This is mandatory in some European

countries and drivers can face instant fines if

extension mirrors are not fitted.

! WARNING: Any rear view mirror must

not project more than 250 mm outside:

a. the width of the caravan when being

towed.

b. the width of the towing vehicle when

driven solo.

Note: Any rear view mirror fitted shall be

‘e’ marked and cover the field of view as

stipulated by type approval requirements

(Community Directive 2003/97 or 2005/27

or ECE Regulation 46.02 or Regulation 33

of the Road Vehicles (Construction & Use

Regulation 1986).

Moving off

Let the clutch in smoothly.

Allow more engine speed to produce the

power to move the additional weight of the

caravan.

Reduce wear and tear on clutch and

transmission by taking extra care.

Change gears smoothly.

Try not to jerk the clutch.

Reversing

When the towing vehicle is reversing, the

overrun device shaft is pushing in, applying the

brakes via the overrun lever, brake rod system,

bowden cables and the expander mechanism.

Fig. A Reversing

The backwards rotation of the brake drum

causes the secondary brake shoe to collapse

cancelling out the braking effect, allowing the

caravan to move backwards. At the same

time the transmission lever swings back and

compensates for the entire travel.

When reversing up a slope or on a loose

surface the brakes may apply themselves,

Correct maintenance and set up of the brakes

will help prevent this. Incorrect adjustment

of the wheel brakes or linkages will result in

making reversing difficult.

Proficiency at reversing can only be achieved

with practice and should be first attempted in

a large open area (Fig. A).

Speed limits

Single carriageways: 50mph

Motorways (including dual carriageways):

60mph

25

CARAVAN HANDLING

Back to section menu

Caravan handling

Allow for caravan being wider than car.

Do not bump kerb with caravan wheels.

When passing other vehicles allow more than

the normal clearance for driving solo.

TOWING CODE

Allow longer to build up speed to pass.

Allow for the outfit being twice its

normal length.

Do not suddenly swing out.

Carry out all manoeuvres as smoothly

as possible.

Use nearside wing mirror to check caravan has

cleared when overtaking.

! WARNING: Take care not to foul or

ground caravan chassis whilst traversing

ramps or other obstacles.

Motorway driving

Important points

1. Caravans may not be towed in the out- side

lane of a three or four lane motorway. (Reg.

12(2) of the Motorway Traffic [England and

Wales] Regulations 1982).

2. Reduce Speed:

a. In high or cross winds

b. Downhill

c. In poor visibility

3. High sided vehicles cause air buffeting so

extra care must be taken when passing or

being passed. As much space as possible

should be given.

Spare wheel

The spare wheel is located in the gas locker at

the front of the caravan.

Note: The side-lift jack (when fitted) has a

maximum lifting height of 375mm and the

scissor jack a maximum lifting height of

340mm.

26

Back to section menu

CHANGING A WHEEL

TOWING CODE

Changing a wheel

1. Leave caravan hitched to towing vehicle and

ensure that the caravan and towing vehicle

handbrakes are applied.

2. Lower corner steadies (as safety measure)

on the side that is being jacked up.

3. Remove wheel trims (if fitted).

4. Use wheel brace to slacken off wheel nuts

on the wheel to be changed.

5. Position jack under the axle at the

appropriate jacking point

(see Fig. B, page 34)

6. Jack up the caravan until the wheel for

removal is just off the ground.

7. Remove the wheel nuts and remove

the wheel.

8. Fit spare wheel and reverse the above

procedure. Ensure clean, dry mating

surfaces and clean, dry bolt/nut sealing

areas.

9. Ensure the spare wheel is free from damage

and distortion

10. Tighten all five bolts, according to

Fig. A, to 88Nm (65lb/ft) for steel wheels

or 130Nm (96lb/ft) for alloy wheels using a

torque wrench or have checked as soon as

possible. Ensure the correct wheel fixings

are used, as supplied with your caravan.

! WARNING: When a wheel has been

removed and replaced the torque of the

wheel nuts should be re-checked after

approximately 50 miles.

Wheel bolt tightening

When refitting a wheel it is ESSENTIAL that the

wheel bolts are tightened to the recommended

torque figure and in the correct sequence.

The sequences necessary to correctly carry

out this work on a 5 stud wheel is as follows:

1

3

5 Stud

5

Fig. A

Please note the correct torque settings.

4

2

Jacking points

! WARNING: Only jack up your caravan

when it is coupled up to the car with its

handbrake applied and in 1st gear

(engine off).

Ensure that the jack is located in the correct

position, i.e. on the jacking bracket on the

chassis for the AL-KO side mounted jack

(Fig.B). Alternatively the reinforced axle

mounting plate can be used but the chassis

member itself MUST NEVER be used as a

jacking point.

All caravans are provided with the facility to

fit AL-KO side jacking points and although a

scissor, trolley or bottle jack may be used.

Ensure the lifting capacity of your jack is

suitable for your caravan.

Note: Only use a suitable wheel brace to

loosen and tighten the wheel bolts. Do

not use the corner steady brace for this

application.

27

STOPPING ON A HILL

TOWING CODE

Fig. B Side lift jack

Stopping on a hill

Pulling off again can sometimes present a

problem. The easy solution is

1. Carry a good sized wedge shaped piece of

wood with a rope or light

chain attached.

2. Attach the other end of the rope to the

nearside rear grab handle.

3. Place the wood behind the nearside

caravan wheel.

4. Carefully reverse the car slightly back down

the hill, the caravan will stop against the

wedge and turn.

5. Drive forward since this attempt to move

up the hill will now not involve pulling the

full weight of the caravan until the car has

gained some traction.

6. When reaching the top of the hill retrieve

the wedge.

Arrival on site

Note: Check and observe site regulations.

Manoeuvring your caravan by hand

Back to section menu

1. Selecting a pitch

Do not pitch in such a position that your outfit

will obstruct others coming in.

Try to choose an area which is dry, reasonably level and preferably with a hard base.

If you have no alternative but to pitch on a

slope ensure that, for when you leave, you are

facing down the slope.

Ensure sufficient space is left at the rear of the

caravan (4m) for the awning

It is good practice to chock the wheels of the

caravan when parked on a slope even though

the caravan brakes are applied.

2. Levelling the caravan

Levelling must be carried out in both directions

in order for the refrigerator and other

equipment to function correctly. This should be

done before unhitching the caravan. Levelling

boards (Fig. C) can be used to raise one side

of the caravan by driving or reversing the

caravan onto the boards. Apply the handbrake

and chock the wheels.

The positioning of the jockey wheel can be

used to help level the caravan.

Lower the corner steadies until they are in firm

contact with the ground.

! WARNING: DO NOT use the steadies

as a jack they are only a means of stabilising

the caravan.

Levelling pads or boards should be used

under the steadies where the ground is soft or

uneven.

In extreme cases where it is necessary to raise

a wheel off the ground for levelling purposes,

further adequate support should be applied so

that the steadies do not take any undue strain.

28

Note: Care must be taken when

manoeuvring your caravan into position.

Pressure placed on unsupported parts

of front and rear GRP panels may cause

surface damage/ cracks to appear. Use the

grab handles provided.

Fig. C Levelling board

Exterior door

To prevent distortion of the body, the caravan

must be always correctly sited and levelled.

Failure to site the caravan correctly may

prevent the exterior door from closing properly.

3. Unhitching

Before applying the handbrake ensure the

hitch is fully extended and not compressed

behind the tow vehicle otherwise the hitch will

not release from the tow ball.

Apply the caravan handbrake.

Lower the jockey wheel to the ground.

Disconnect the breakaway cable and road

lighting plugs.

AK160

Lift the coupling handle to release the locking

tongue (fig A page 24), whilst simultaneously

winding down the jockey wheel, to lift the

caravan hitch head clear of the tow ball.

Back to section menu

UNHITCHING

TOWING CODE

29

Back to main menu

SAFETY AND SECURITY

Fire .......................................................................................................................................... 32

SI 601 Smoke Alarm Operation ............................................................................................... 32

Fire extinguisher ....................................................................................................................... 32

Escape paths .......................................................................................................................... 32

Children ................................................................................................................................... 32

CO Alarm - Fireangel CO-9X Carbo Monoxide Alarm operation ................................................ 32

Ventilation ................................................................................................................................ 33

Security ................................................................................................................................... 33

Swift Command tracker ............................................................................................................ 34

AL-KO Secure immobiliser ........................................................................................................ 35

Mobile Alarm System ............................................................................................................... 36

SAFETY AND SECURITY

31

FIRE / SMOKE ALARM / CO ALARM

Back to section menu

Fire

Important: Your attention is drawn to the

notice affixed inside the caravan wardrobe

advising on fire precaution, ventilation and

what to do in case of fire.

In case of fire

1. Get everyone out of the caravan as quickly

as possible using whichever exit is the

quickest, including windows. Do not stop to

SAFETY AND SECURITY

collect any personal items.

2. Raise the Alarm. Call the Fire Brigade.

3. Turn off the gas supply valve if it is safe to

do so.

4. Turn off the electricity supply at

supply point.

Smoke Alarm operation

Your caravan is fitted with a Fire Angel S0-601

smoke alarm. Please read the user instructions

for the smoke alarm, which are available at the

following location:

http://fireangel.co.uk/wp-content/

uploads/2015/07/SO-601%20Manual.pdf

If you are unable to view the documents on

line, please contact the supplier, your dealer or

Swift for an electronic or paper copy.

Fire Extinguisher

It is recommended that a dry powder fire

extinguisher be carried inside your caravan at

all times.

When using a dry powder extinguisher it is

suggested that the caravan be evacuated until

the powder has settled, to avoid inhalation.

A fat pan fire should not have a fire

extinguisher aimed at it. It should be

smothered with a fire blanket.

! WARNING: Provide one dry powder

fire extinguisher of an approved type or

complying with EN 3-7 or ISO7165, of at

least 1kg capacity, by the main exterior door

and a fire blanket next to the cooker.

Familiarise yourself with the instructions

on your fire extinguisher and the local fire

precaution arrangements.

Escape paths

It is important that you do not block escape

paths to emergency exits with obstructions

or hazards.

Children

Do not leave children alone in the caravan

in any event. Keep potentially dangerous

items out of reach, as at home e.g. matches,

medicine etc.

CO alarm

Fireangel CO-9D Carbon Monoxide Alarm

Your caravan is fitted with a Fireangel CO-9D

Carbon Monoxide Alarm . Please read the

instructions for the alarm, which are available

at the following location:

http://fireangel.co.uk/wp-content/

uploads/2015/07/CO-9D%20Manual.pdf

32

If you are unable to view the documents on

line, please contact the supplier, your dealer or

Swift for an electronic or paper copy.

Back to section menu

VENTILATION / SECURITY

SAFETY AND SECURITY

Ventilation

All caravans comply with BS EN 721.

The ventilation points on your caravan are fixed

points of ventilation which are required by the

European Standards.

All caravans have ventilation at high level and

low level which have been calculated to suit

the individual needs of your caravan.

High level ventilation is achieved by means of

the roof lights and washroom roof ventilators.

The low level ventilators are positioned

underneath the oven housing.

Under no circumstances must these vents be

blocked or obstructed in any manner as this

could lead to insufficient fresh air. In this case

the confined atmosphere becomes depleted of

oxygen which could lead to dangerous levels

of carbon dioxide (CO2) build up leading to risk

of asphyxiation.

The risks of carbon monoxide (CO) build

up, which is a colourless, odourless and

tasteless gas, will also be reduced with

ventilation. Carbon monoxide is produced

from incomplete combustion and should the

CO detector be activated the cause of the

incomplete combustion must be investigated

prior to reusing the appliance in question.

It is advised that fixed ventilation points

are checked and cleaned (if necessary) on

a regular basis using a small brush and a

domestic vacuum cleaner.

Additional night time ventilation is obtained

by releasing the window catches and placing

them in the second groove. Note the windows

are not sealed from rain in this position.

As the ventilation levels are calculated to suit

each models requirements there should be

no modifications made which may result in

reduced ventilation levels.

! WARNING: Do not obstruct ventilation

Petrol/Diesel Fumes

The fitting of a tail pipe extension to your

car exhaust will reduce the possibility of

fumes entering your caravan through the

ventilation points.

Security

Caravan theft

The theft of a caravan can occur in the most

unlikely circumstances; from a motorway

service area, even from an owner’s driveway.

Secure all windows and doors when your

caravan is unoccupied even if only for a short

length of time.

Security chips

A special security chip is concealed within

the body of every caravan. This chip contains

the individual identity of your caravan and can

only be read using a special decoder by police

officers.

Chassis number

Your 17 digit serial number chassis number

can be found on your windows and on the

offside chassis member of the drawbar. It is

also stated on the manufacturers weight plate

next to the doorway.

Make a note of this number in the space

provided at the front of this handbook and

make a separate note of the number to keep

safe at home.

Additional security

Consider fitting any device which might deter

or prevent intrusion by thieves.

A hitch lock cover prevents towing of

the caravan.

A wheel lock prevents towing of the caravan

and removal of the wheel.

Customers are advised to identify their caravan

with a method for subsequent identification if

other forms of identification have been altered

or removed.

Free crime prevention advice about securing

your caravan, protecting your valuables,

property marking, either at home or whilst

on site, can be obtained from the Crime

Prevention Officer through your local

Police Station.

33

SWIFT COMMAND TRACKER

Back to section menu

Caravan insurance

It is recommended that the caravan and its

contents should be insured against theft.

It is essential to check with your car insurance

company to ensure you are covered when

towing your caravan.

Swift Command Tracker

by Sargent

A Swift Command Tracker is built in to your

SAFETY AND SECURITY

vehicle and forms part of the Swift Command

system.

The unit is Thatcham Category 6 certified and

is monitored by an approved monitoring centre

which operates 24 hours a day 7 days a week

and provides European coverage and direct

police liaison.

This system is ready for use, all you need to

do is purchase a tracking subscription by

visiting www.swiftcommand.co.uk or calling

Sargent on 01482 881655.

The subscription cost is £95 per year

including VAT.

For more information please visit

www.swiftcommand.co.uk

Operation

The Swift Command Tracker is easy to

operate as it is controlled by the vehicle

systems.

In a caravan the tracker is armed when the

Stinger 310 / 350 Alarm System is armed. It is

disarmed when the alarm is disarmed.

If the caravan doesn’t have an alarm system

fitted, a simple numeric keypad is used to arm

/ disarm the tracker. Enter your code followed

by the ON button to arm the tracker.

Enter your code followed by the OFF button to

disarm the tracker.

Event of a Theft

If the vehicle is moved whilst the tracker is

armed the geo-fence monitoring will trigger a

theft event.

In addition to the above, in a caravan with the

Stinger 310 / 350 Alarm System fitted, if the

alarm is triggered by internal movement or

caravan tilting the alarm monitoring will also

trigger a theft event.

The monitoring station will now contact you

to confirm the theft or false alarm. You will

be required to confirm your identity against

the information you provided when you

subscribed.

If a genuine theft is confirmed the monitoring

station will liaise with the police and keep you

informed of progress.

Note; during a theft event to comply with

legislation you will not be able to manually

locate your vehicle using the Swift Command

locate feature.

Contact

Before contacting any of the following please

ensure you know your caravan serial number.

For caravans this is the last 10 digits if the

CRIS number (like SWG0123456).

The Swift Command Tracker monitoring

station can be contacted on 0345 6027302.

The stations operates 24 yours a day 7 days

a week.

Sargent customer support can be contacted

on 01482 678981 or via support@

swiftcommand.co.uk

Telephone lines are manned during normal

office hours.

Swift customer support can be contacted on

01482 875740 during normal office hours.

34

cont...

Back to section menu

AL-KO SECURE IMMOBILISER

SAFETY AND SECURITY

Precautions

The Swift Command Tracker monitors the