Page 1

Packing list

Parts Qty Parts Qty

Heat Sink 1 Springs 4

Fan 1 .230x.096 Nylon spacers 8

Fan guard 1 .220x.046 Nylon spacers 4

6-32 x 2” screws (for fan) 4 Nylon 6-32 Hex nuts 4

6-32 x 1 ½” screws (for HS) 4 Black fiber washers 8

Standoffs 4 Thermal grease 1

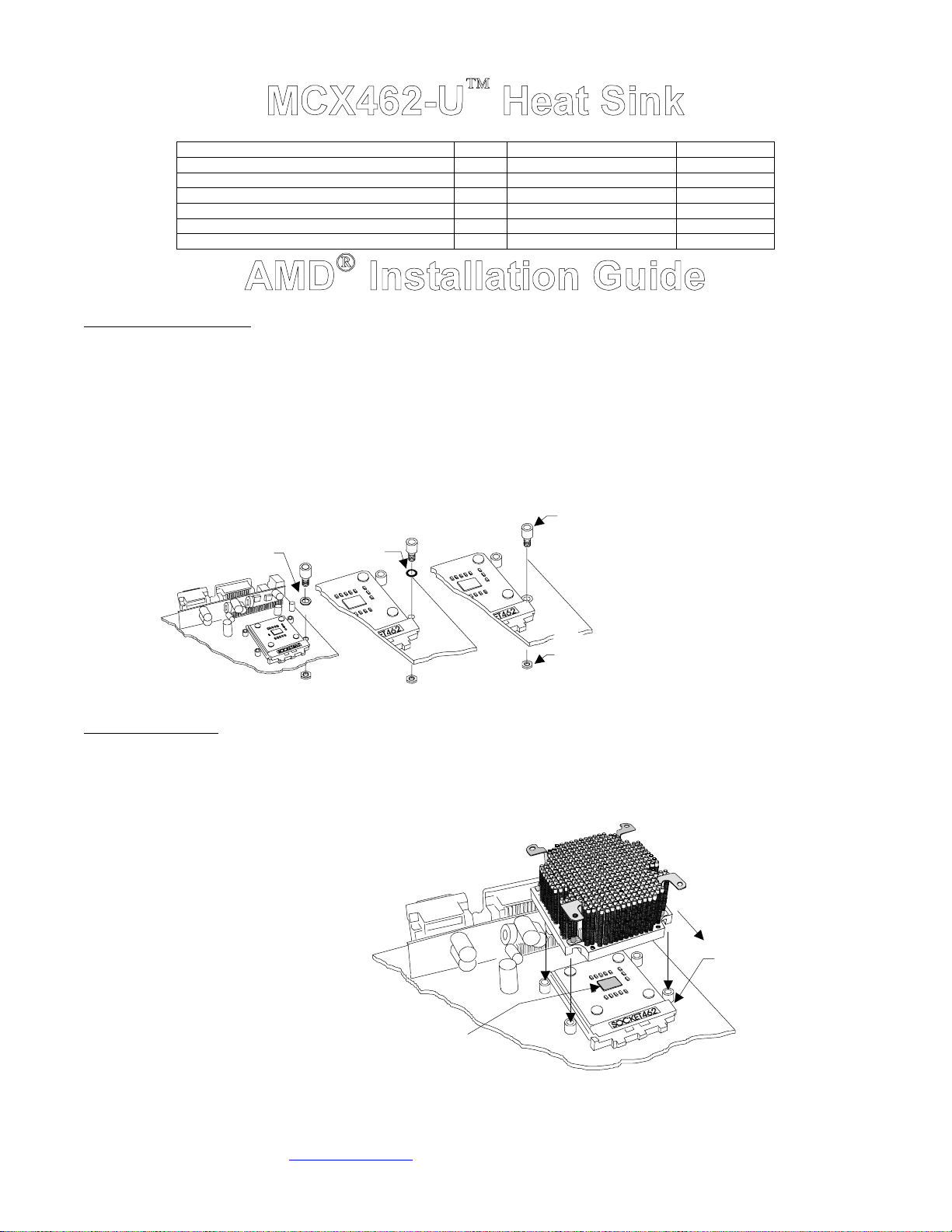

I. Preparing the motherboard

1. You must uninstall your MB prior to installing the MCX462-U heat sink.

2. Install standoffs in MB

Determine which standoff washers to use, depending on your MB mounting holes:

• Large holes .230”(5.8mm) diameter : use .220x.046 Nylon spacers. The washers fit inside the MB hole.

• Small grounded holes .150”(3.8mm) diameter: you can recognize grounding by a silver ring around the holes; no washers

needed nor neces sary.

• Small holes, NOT grounded (bare c ircuit board): you must us e black fiber washers, or damage t o the MB may occ ur.

MB with

MB with

large holes

Use .220x.046

nylon spacer

MB with

small holes,

NOT grounded

Use black

Fiber washer

small holes,

grounded

No washer

necessary

Standoff

(fit inside the hole)

Nylon, hex nut

on back side of

the MB

3. Re-install the MB inside the case.

II. Heat sink Installation

1. The case should be laying flat on a table.

2. Insert the processor into the socket, and lightly coat the processor core with high quality thermal compound. Only a paper thin coat is

necessary. It should be applied using preferably a razor blade, or a credit card, held between thumb and index at a 45 degree angle. It is

critical to ascertain that the entire core is covered with a uniform coat of thermal compound. Thermal performance will dramatically

decrease if any portion of the core is not covered by thermal compound. We recommend Arctic Silver or similar high end compound for

superior thermal conductivity.

3. Place the bare MCX462-U heat sink

over the CPU as shown in the pic ture to

the right. The step side should be

located over the socket’s cam box. Keep

the heat sink mounting holes lined up

with the standoffs.

Ins tall standoff in each one of the

four holes surrounding the socket.

Keep the standoff & washer centered

over the MB holes, and secure with

nylon hex nuts on backside of the

MB. If you are going to

assemble/disas semble the heat sink

frequently, we recommend finishing

the installation by putting a drop of

“Crazy Glue “ at the junction between

standoff & MB, and between nylon

hex nut & MB. This will lock the

standoff onto the MB, and further

prevent it from spinning lose during

frequent assembly and disassembly

operations .

Step side

CPU core

Copyright Swiftech 2001 – All rights reserved – Last revision date: Oct. 2001

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

th

Street, Signal Hill, CA 90806 – Tel. 562-595-8009 – Fax 562-595-8769

This way

over cam box

Page 1

Information subject to change without notice

Page 2

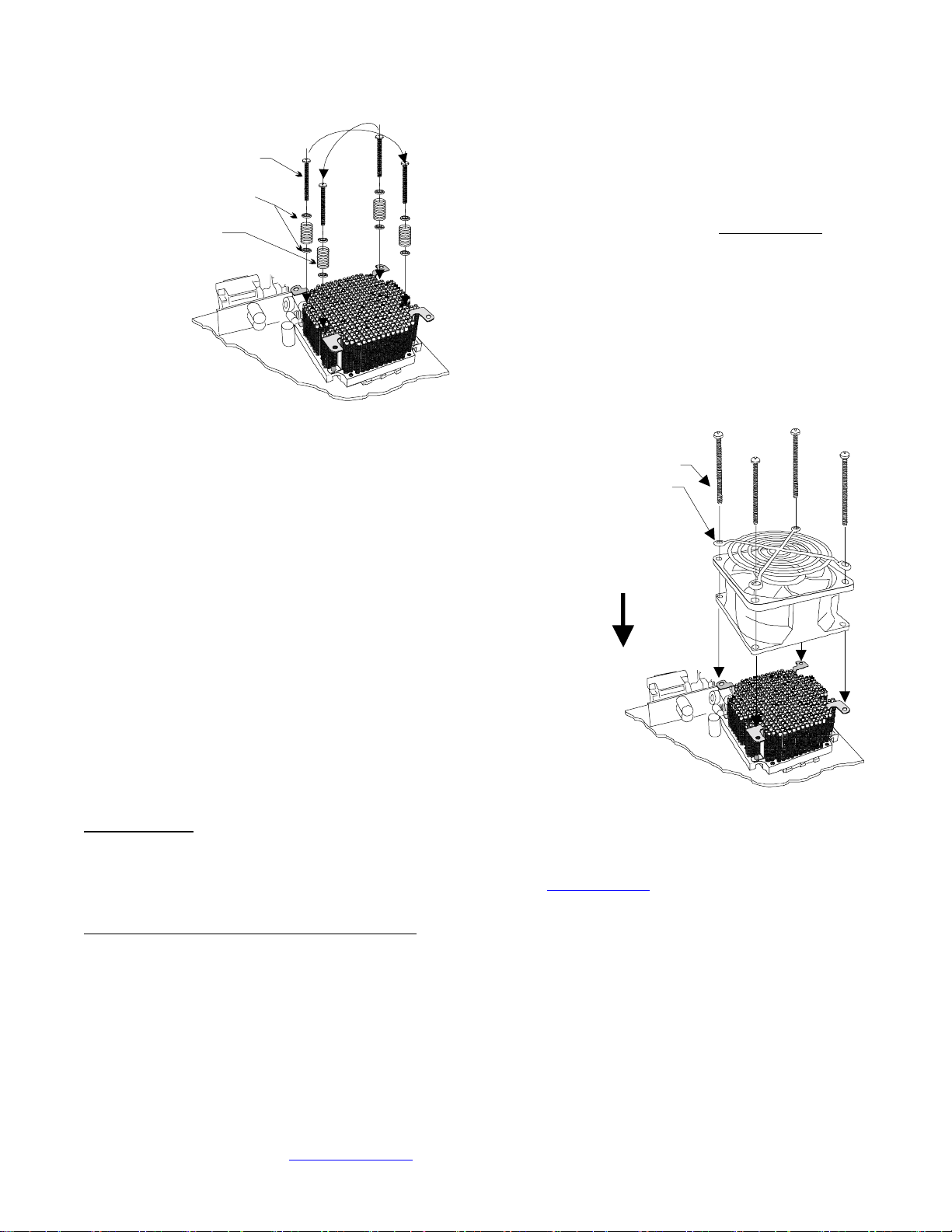

Crisscros

tightening

pattern

6-32 x 1 ½“

Philips screw

.230x.096

Nylon spacers

Spring

5. Fan Installation: Place the f an over the heat sink. The airflow should

be blowing down (fan label facing down). Place the fan guard over the

fan. Tighten the four 6-32 x 2” screws. The fan is equipped with two

connectors: a four pin molex connector which must be connected to

the power supply, and a 3 pin single wire connector which connects to

the MB fan sensor header.

6. Optional fan rheostat: a rheostat model # RH070 is sold separately,

and allows to adjust the fan speed. It connects between the fan power

connector and the power supply connector. Please consult your

distributor if you wish to purchase this item. Reducing the fan speed

reduces fan noise up to 9 dBA. It also reduces thermal performance,

and will affect overclocking performance accordingly. It is however

perf ectly appropriate f or non overclocked processor s.

4. Prepare 4 assemblies compos ed of (1) 1 ½”

screw, (2) .230x.096 Nylon spacers, and (1) spring

as shown in the picture to the left. Drop each

assembly in the heat sink mounting holes. While

gently press ing at the center of the heat sink, start

tightening the screws gradually in a crisscross

pattern until you feel that they reach the bottom of

the standoff. A “finger-tight” lock is sufficient.

Over tightening may result in stripping the nylon hex

nut. Conversely, adjustments such as tightening the

screws only partially are strictly prohibited

attempts will result in improper contact between the

CPU core and the heat sink, and result in CPU

overheating.

. Such

6-32 x 2“

Philips screw

Fan guard

Direction of

the flow

(fan label

facing down)

III. Final inspection

Now that the heat sink is installed, s tartup your computer, go into the BIOS and observe the C PU temperature. Under normal ambient

temperature c onditions, the processor temperature should never exc eed 55° C (130 ° F). If it does, shut down the computer immediately, and

review your entir e installation. Troubleshooting help is available on our web sit e at www.swiftnets.com

595-8009.

Uninstall note: CPU removal f rom some soc ket motherboar ds

Once in place, the standoffs may slightly interfere with CPU removal in some motherboards:

Depending on the manufacturers, sockets use either a plastic locking arm, or a metal locking arm. Sockets using a plastic locking arm require that

the arm be slightly pried open at the center in order to release it from its retaining tab. This can easily be done by inserting a thin screwdriver in

between the socket body and the arm’s mid-section, and by slightly twisting the screwdriver in either direction, while pulling on the arm. This will

slightly arch the mid-sec tion of the arm, and release it f rom its locking tab.

DISCLAIMER: Swiftech assumes no liability whatsoever, expressed or implied, for the use of these products.

Copyright Swiftech 2001 – All rights reserved – Last revision date: Oct. 2001

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

, or by calling customer support at 562-

th

Street, Signal Hill, CA 90806 – Tel. 562-595-8009 – Fax 562-595-8769

Information subject to change without notice

Page 2

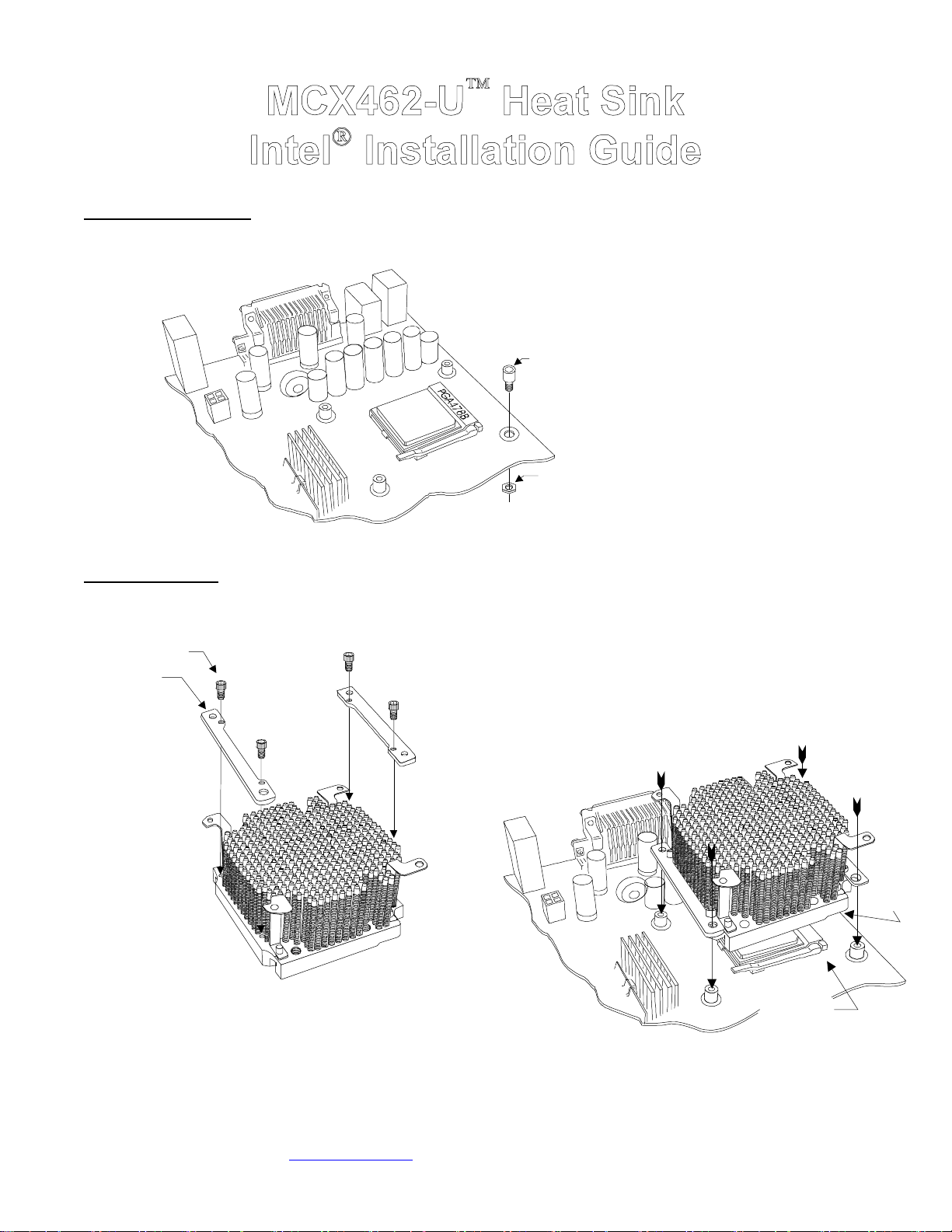

Page 3

I. Preparing the motherboard

4. You must uninstall your M B prior to installing the MCX462-U heat sink.

5. Install standoffs in MB.

6. Re-install the MB inside the case.

II. Heat sink Installation

1. Install the two mounting brackets ont o the heat

4-40 x 1/4“

socket screw

sink, using the provided 4-40 x 1/4” socket screws:

Bracket

Do not install, or remove (if already

installed) Intel stock retention

mechanism (black plas tic f rame).

Ins tall standoff in each one of the four

holes surrounding the socket. Keep the

Standoff

Nylon, hex nut

on back side of

the MB

3. Insert the processor into the socket, and lightly coat the process or core

with high quality thermal compound. Only a paper thin coat is necessary.

It s hould be applied using preferably a razor blade, or a credit card, held

between thumb and index at a 45 degree angle. It is critical to ascertain that

the entire core is covered with a uniform coat of thermal compound. Thermal

performance will dramatically decrease if any portion of the core is not

covered by thermal compound. W e recommend Arctic Silver or similar high

end compound for superior thermal conductivity.

4. Place the bare MCX462-U heat sink over the CPU as s hown in the

pic ture below. T he s tep side should be located over the s ocket’s c am box.

Keep the heat sink mounting holes lined up with the standoffs.

standof f centered over the MB holes, and

secure with nylon hex nuts on backside of

the MB. If you are going to

assemble/disassemble the heat sink

frequently, we recommend finishing the

installation by putting a drop of “Crazy Glue

“ at the junction between standoff & MB,

and between nylon hex nut & MB. This will

lock the standoff onto the MB, and further

prevent it from spinning lose during

frequent assembly and disassembly

operations .

2. For the next step, the cas e should be laying flat on a

table

Copyright Swiftech 2001 – All rights reserved – Last revision date: Oct. 2001

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

th

Street, Signal Hill, CA 90806 – Tel. 562-595-8009 – Fax 562-595-8769

Socket

cam box

Page 3

Information subject to change without notice

Step

side

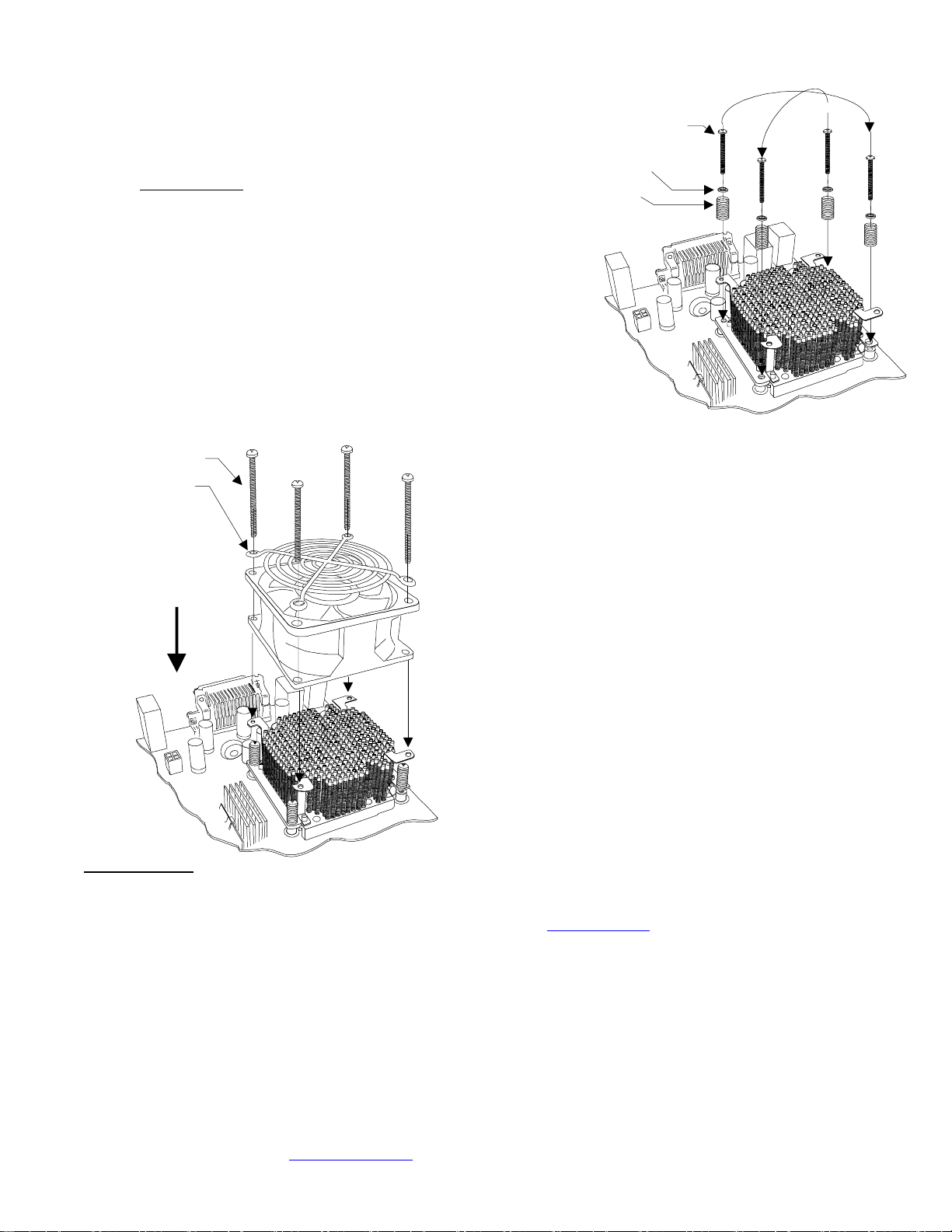

Page 4

5. Prepare 4 assemblies compos ed of a 1 ½ ” s crew, 2 nylon flat washers,

and 1 spring as shown in the picture to the right. Drop each assembly in

the bracket mounting holes. While gently pressing at the center of the heat

sink, start tightening the screws gradually in a crisscross pattern until you

feel that they reach the bottom of the standoff. A “finger-tight” lock is

sufficient. Over tightening may result in stripping the nylon hex nut.

Conversely, adjustments such as tightening the screws only partially ar e

strictly prohibited

the CPU core and the heat sink, and result in CPU overheating.

. Such attempts will result in improper contact between

Criscross tightening pattern

6-32 x 1 ½“

Philips screw

Nylon flat

washer

Spring

6-32 x 1 5/8“

Philips screw

Fan guard

Direction of

the flow

(fan label

facing down)

III. Final inspection

Now that the heat sink is installed, s tartup your computer, go into the BIOS and observe the C PU temperature. Under normal ambient

temperature c onditions, the processor temperature should never exc eed 55° C (130 ° F). If it does, shut down the computer immediately, and

review your entir e installation. Troubleshooting help is available on our web sit e at www.swiftnets.com

595-8009.

DISCLAIMER: Swiftech assumes no liability whatsoever, expressed or implied, for the use of these products.

6. Fan Installation: Place the f an over the heat sink. The airflow should be

blowing down (fan label facing down). Place the fan guard over the fan.

Tighten the four 6-32 x 1 5/8” screws. The fan is equipped with two

connectors: a four pin molex connector which must be connected to the

power supply, and a 3 pin single wire connector which connects to the MB

fan sensor header.

7. Optional fan rheostat: a rheostat model # RH070 is sold separately, and

allows to adjust the fan speed. It connects between the fan power

connector and the power supply connector. Please consult your distributor

if you wish to purchase this item. Reducing the fan speed reduces fan

noise up to 9 dBA. It also reduces thermal performance, and will affect

overclocking performance ac cordingly. It is however perfectly appropr iate

for non over clocked pr ocessors .

, or by calling customer support at 562-

Copyright Swiftech 2001 – All rights reserved – Last revision date: Oct. 2001

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

th

Street, Signal Hill, CA 90806 – Tel. 562-595-8009 – Fax 562-595-8769

Page 4

Information subject to change without notice

Loading...

Loading...