Page 1

Packing list

Parts Qty Parts Qty

Thermoelectric Heat Sink assembly 1 6-32 Hex Lock-Nuts (for

motherboard)

Snap-rivets (f or 80mm fan) 4 Black fiber washers (f or

motherboard)

Spring assembly – pre-installed 4 2 pole euro-style wire

connector

Standoffs 4 Thermal grease – Arctic

Alumina

.220x.046 Nylon spacers (for motherboard) 4 Motherboard gaskets 2

Preamble:

4

10

1

1

This product is intended for expert users only. Please consult with a qualified technician for installation. Improper installation may result in damage

to your components.

their installation.

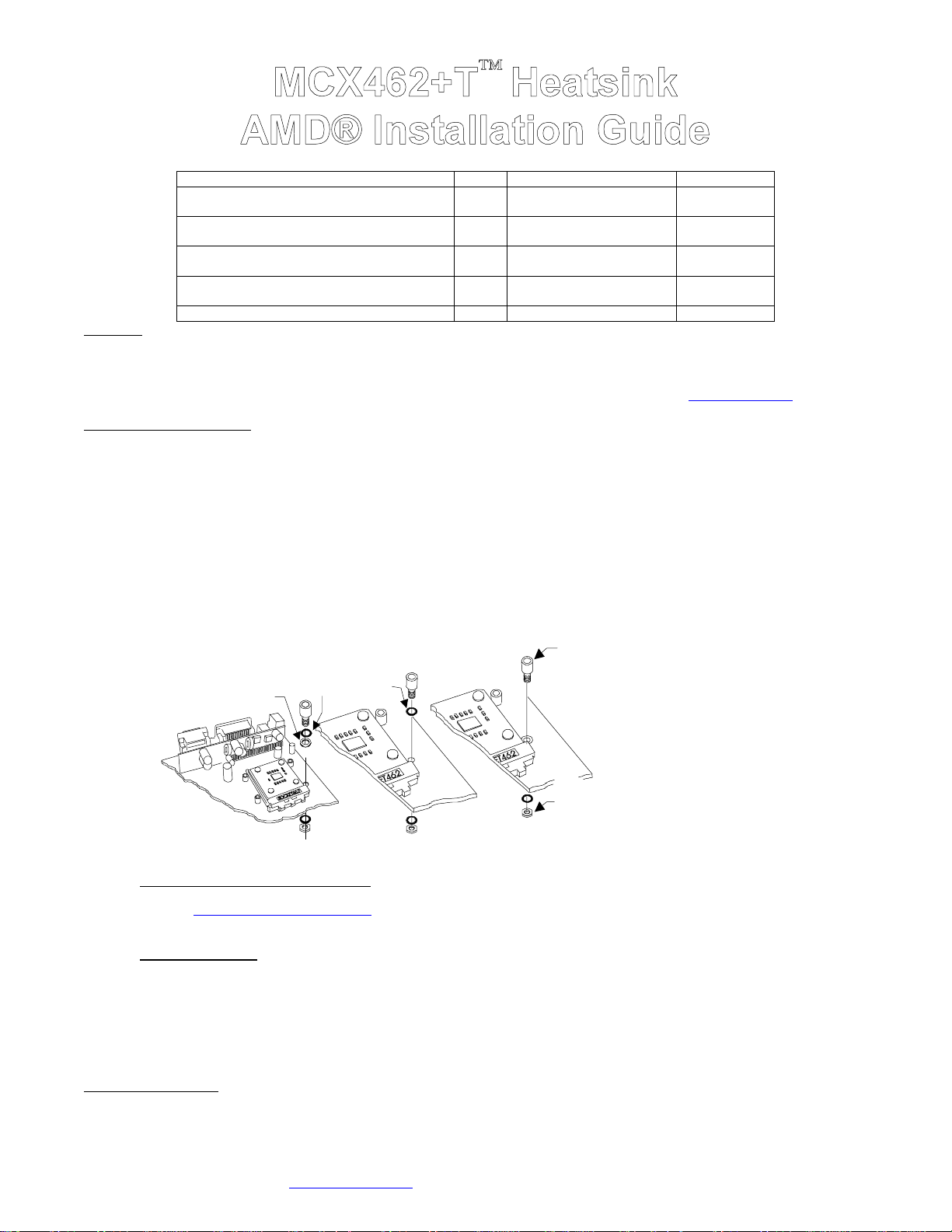

I. Preparing the motherboard

1. You must uninstall your MB prior to installing the MCX462+ heat sink.

2. Install standoffs in MB

Determine which standoff washers to use, depending on the mounting holes sizes of your particular MB model:

• Large holes .230”(5.8mm) diameter, use in the following order: standoff, black fiber washer, .220x.046 Nylon spacers (fits inside the

• Small grounded holes .150”(3.8mm) diameter (you can recognize grounding by a silver ring around the holes), use in the following

• Small holes, NOT grounded (bare c ircuit board): you must us e black fiber washers, or damage to the MB may occ ur: us e in the

Swiftech assumes no liability whatsoever, expressed or implied, for the use of these products, nor

The following instructions are subject to change without notice. Please visit our web site at www.swiftnets.com for updates.

MB hole), then on the other side of the MB, black fiber washer, and lock-nut.

order: standoff directly to the MB (black fiber washer is NOT necessary), then on the other side of the MB, black fiber washer, and locknut.

following order: standoff, black fiber washer, then on the other side of the MB, black fiber washer, and lock-nut.

MB with

small grounded

holes, no washer

necessary on

this side

Standoff

MB with

large holes

Use .220x.046

nylon spacer

MB with

small

non-grounded

must use

fiber washer

holes

(fit inside the hole)

Ins tall standoff in each one of the

four holes surrounding the socket.

Keep the standoff & washer centered

over the MB holes, and secure with

hex lock nuts on backside of the MB.

Hex lock-nut

to back side of

the MB

Figure 1

• Fill-up the socket with dielectric grease:

the CPU. Dielectric grease is used to prevent condensation where parts are exposed to cold. We use Luberex (available on our web site

under the liquid cooling accessories section

Fill-up the socket center cavity (grease is to be level with the upper surface of the socket), and coat the socket pinholes with greas e.

Spread the grease with your finger so that it will penetrate inside the pinholes.

• Insert the processor

make sure that the processor is completely inserted into the socket. Apply paper-thin coat of thermal compound to processor core,

using a razor blade, or a credit card, held between thumb and index at a 45° angle. It is critical to ascertain that the entire core is covered

with a uniform coat of thermal compound. Thermal performance will dramatically decrease if any portion of the core is not covered by

thermal compound.

• Remove the peel-of f paper back of the motherboard gas ket, and install it as shown Fig. 2, s ticky side towards the motherboard.

• Apply the provided neoprene stic ker to the bac k of the motherboard as shown in Fig. 2

3. Install the MB inside the case..

II. Heat sink Installation

Copyright Swiftech 2002 – All rights reserved – Last revision date: Sep 11, 2002

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

into the socket. Since there is grease inside the socket, some hydraulic pressure lift may occur: for this reason,

Do not confuse dielectric grease with the provided thermal compound that is only used for

), but any similar product can be us ed, as long as it clearly s tates “ good dielectric properties ”.

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-8769

Information subject to change without notice

Page 1

Page 2

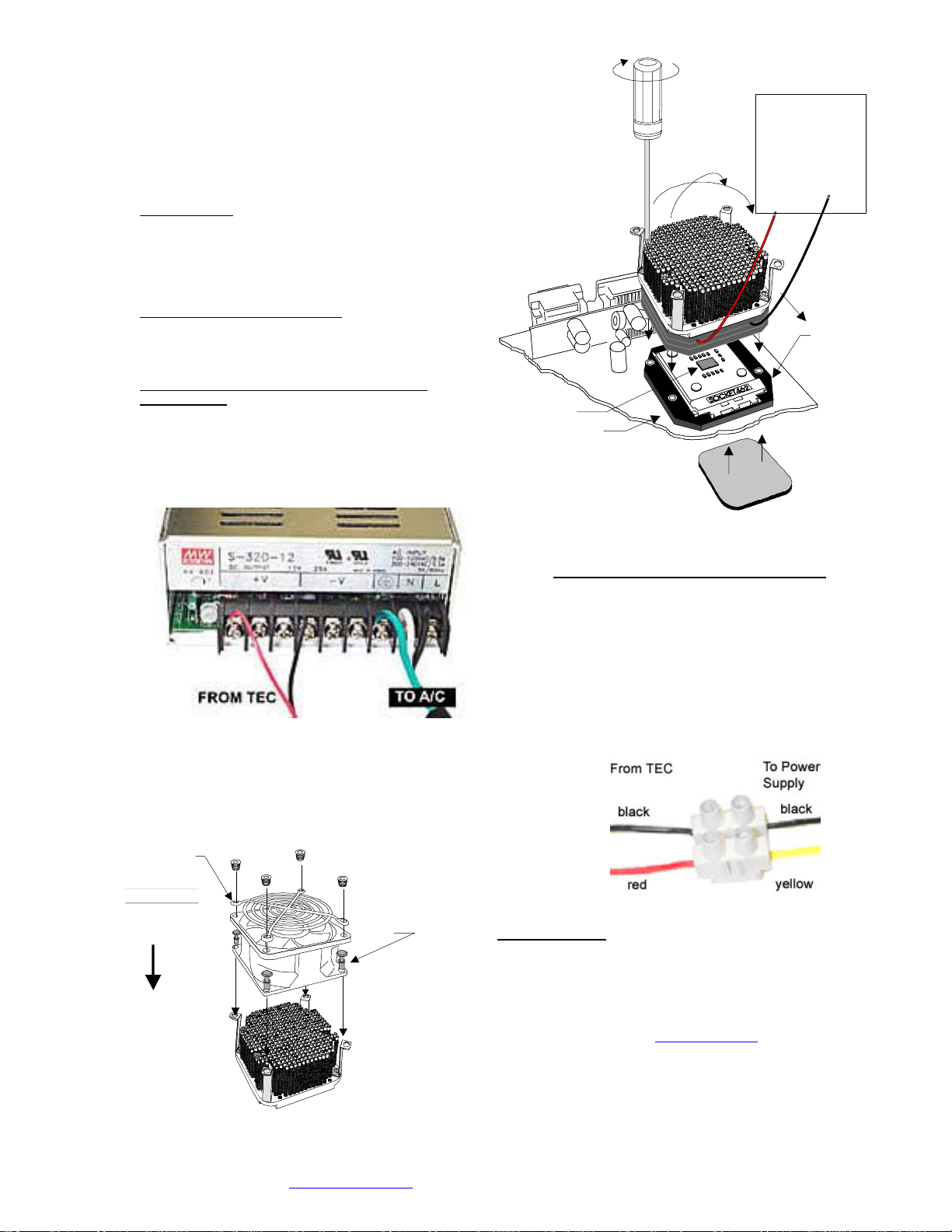

1. The case should be laying flat on a table.Install the

MCX462+T heatsink onto the CPU as shown in f ig. 2,

heats ink step s ide over the soc ket’s cam box. T ighten the

mounting screws in a crisscross pattern. Important note: Due

to wide variations in gasket thickness tolerances, we

suggest that you uninstall the heatsink once following the initial

assembly, just to verify that you have good contact between

cold plate and CPU. Inspect the grease imprint that the CPU

left on the copper plate: it should be perfectly even!

2. Fan installation:

! Use provided snap-rivets as shown in fig. 4 to secure fan to

heats ink.

! Recommended fans

Minimum 68cfm 80mm fans, such as but not limited to Delta

FFB0812SHE, FFB0812EHE, or Vantec 84cfm Tornado.

3. Thermoelectric module installation

! IMPORTANT WARNING: Solder joints of the wires to the

thermoelec tric module are extremely fragile. Bending the wires

at their root will break the solder joint, with no possible repair.

Swiftech will not honor the warranty for broken wires.

! Connection to a dedicated auxiliary power supply

(recommended):

# The TEC module is provided with “bare wires” to facilitate

installation with screw type terminals. We recommend the

“Meanwell S320-12” power supply, available on our website

in the liquid cooling accessories section. Connect red wire

from TEC module to the +V terminal, and black wire to the

–V terminal as shown in figure 3 below:

# Minimum requirements for a dedicated power supply: 20A

@ +12 V.

# If adjustable voltage is available: s etting the voltage higher

than +12V is not recommended. Lower voltage, can be

safely used, down to 9 volts.

:

Figure 3

Fan guard

and fan sold

Separately

TO POWER

Crisscros

tightening

pattern

SUPPLY

(min 20A at 12V)

Connect

Red wire

to +12 VDC

CPU core

MB gasket

Neoprene sticker

to back of MB

Figure 2

! Connection to an ATX computer power supply:

# Important Warning: to connect the MCX462+T cooler

to your computer power supply, you must carefully

consider the existing requirements of other devices

connected on the +12V line. Connecting to an

underpowered unit will definitely damage the power

supply.

#

Minimum requirements for an ATX computer power

supply: 28A at +12V in a typical setup.

#

Only use the provided euro-style wire connector

shown in fig 4 below. Connect red wire from TEC

module to +12V of P/S (Yellow wire), and black wire to

black wire:

Connect

black wire

to - VDC

Step side

This way

over

cam box

Direction of

the fan flow

(fan label

facing down)

Figure 4

Provided

Snap rivets

here

Copyright Swiftech 2002 – All rights reserved – Last revision date: Sep 11, 2002

Rouchon Industries, Inc., dba Swiftech – 1703 E. 28

E Mail: Swiftech @swiftnets.com – URL: http://www.swiftnets.com

th

Street, Signal Hill, CA 90755 – Tel. 562-595-8009 – Fax 562-595-8769

Figure 5

III. Final inspection

Now that the heat sink is installed, startup your computer, go into the

BIO S and obs erve the CPU temperature. Under normal ambient

temperature conditions, the proc essor temperature s hould never

exceed 55° C (130 ° F). If it does, shut down the computer

immediately, and review your entire installation. T roubleshooting help

is available on our web site at www.swiftnets.com

customer support at 562-595-8009.

DISCLAIMER: Swiftech assumes no liability whatsoever,

expressed or implied, for the use of these products.

, or by calling

Page 2

Information subject to change without notice

Loading...

Loading...