Page 1

Swiftech Inc., 1703 E. 28

th

St., Signal Hill, CA 90755 T. (562) 595-8009 F. (562) 595-8769

Parts list

Parts QTY PARTS QTY

MCW5000-64™ assembly 1 Aluminum tension limiter 2

6-32 x 1 ¾ Philips screw 2 Springs 2

Nylon shoulder washers 2 Arctic Alumina Thermal compound 1

This product is intended for expert users. Please consult with a qualified technician for installation. Improper installation may result in

damage to your components. Swiftech assumes no liability whatsoever, expressed or implied, for the use of these products, nor their

installation. The following instructions are subject to change without notice. Please visit our web site at www.swiftnets.com

updates.

1. Before you install the MCW5000-64™ water-block:

Tube inserts 4 Nylon spacers 2

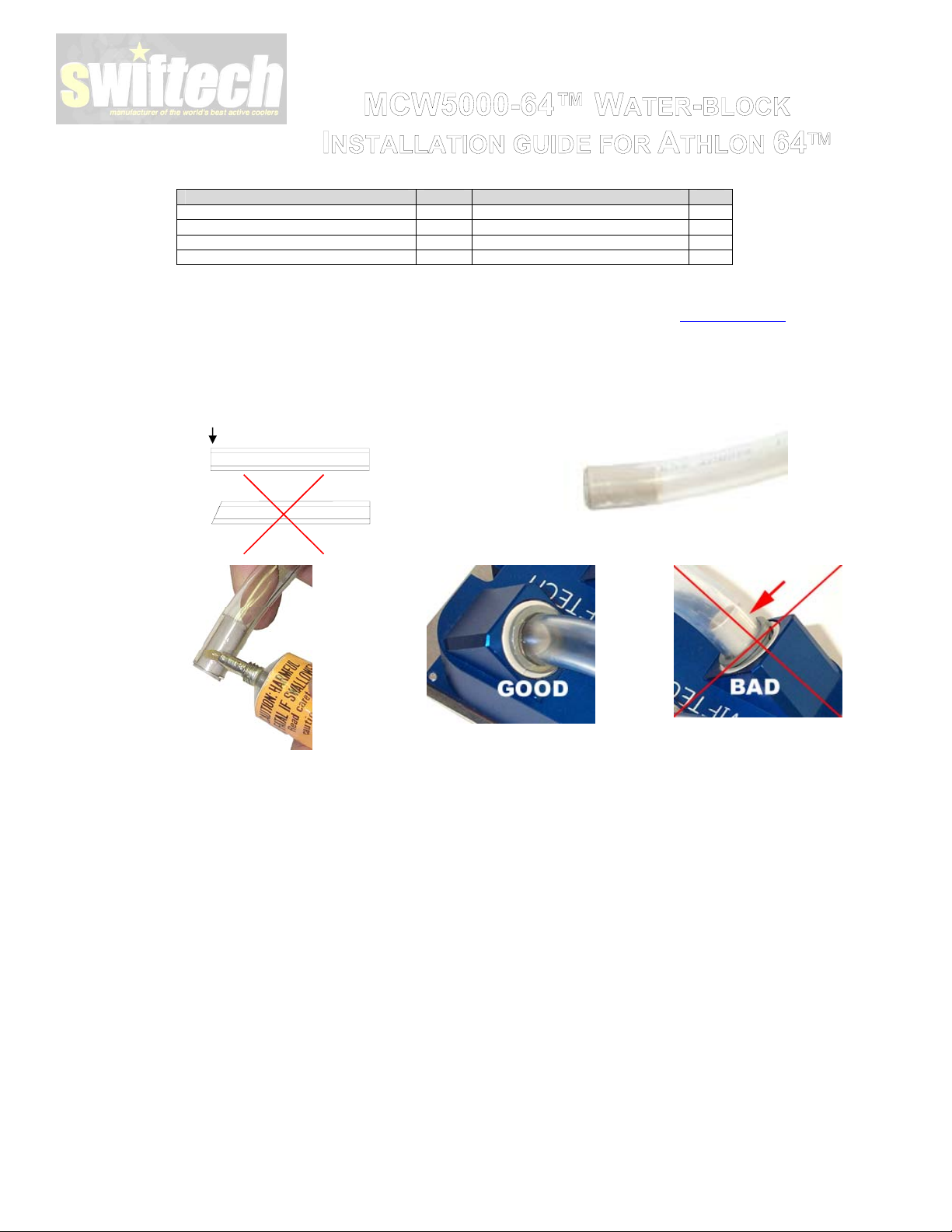

a. Prepare two pieces of tubing of sufficient length to connect

to the rest of your circuit. The cuts must be square as shown in

figure 1 or leaks may occur:

b. Install the provided plastic tube inserts at each end of the tubes,

as shown in figure 2: these inserts are absolutely imperative when

using any kind of soft tubing, such as vynil, ClearFlex, Taigon, etc...

Square cut

for

Figure 1

Figure 3

c. Spread a little bit of grease or simple

liquid soap around the tubing. It helps pushing

the tubes in, particularly with Clearflex tubing,

which features a very “sticky” surface.

2. Preparing your Motherboard

Remove the existing heat sink

Carefully clean the CPU.

Lightly coat the CPU with the provided thermal compound. Only a paper-thin coat is necessary. It should be applied

using preferably a razor blade, or a credit card, held between thumb and index at a 45-degree angle.

3. MCW5000-64™ water-block installation diagram

Method 1: The MCW5000-64 water-block bolts onto AMD’s validated plastic retention frame with two screw

spring assemblies. Please use the retention frame provided by your motherboard vendor. Remove the two

existing screws that hold the frame in place, place the water-block assembly onto the CPU, and use these two

holes to bolt down the spring assemblies, as shown in figure 6, page 2. Each spring assembly features an

aluminum spacer acting as a tension limiter. It’s main purpose is to guarantee that each springs is compressed

to the exact same amount of tension (35lbs each).

Method 2: It is also possible to install the MCW5000-64 without the stock plastic retention frame.

However, you MUST then use the nylon spacers provided with your accessories package as shown in figure 7,

page 2. These are necessary to replace the stock plastic retention frame and to provide support to the entire

assembly.

Figure 2

Figure 4

d. Fully insert both tubes into the fittings. The tip of the plastic tube inserts should

be flush with the inlet and outlet openings, as shown in figure 4 above. Inserting the

tubes requires a firm push, accompanied by a twisting motion.

Figure 5

Page 1 of 2

Page 2

A

Installation with stock plastic retention frame

CPU

Motherboard

6x32 philips screw

Nylon shoulder washer

Spring

Aluminum

tension limiter

SocketSocket

Plastic retention

frame

Installation without retention frame

CPU

Motherboard

6-32 Philips s crew

Nylon shoulder

washer

Spring

luminum

tension limiter

Nylon spacer

Figure 7

Figure 6

4. Connecting the water-block(s) to the cooling circuit.

FAQS:

Inlet and outlet are interchangeable.

In Multi-Processor environments, optimal water-block performance will be achieved by connecting them in series (outlet

of one connected to the inlet of the other).

Recommended coolant: distilled water+ algaecides & corrosion inhibitors are mandatory (automotive antifreeze).

5. Final inspection

Once the installation is completed, it is always a good idea to test the circuit for leaks, prior to powering up the computer.

Troubleshooting help is available on our web site at www.swiftnets.com

, or by calling customer support at 562-595-8009.

Note concerning removal of the tubing: Push in collet squarely against face of fitting, using swiftech’s tube removal tool,

or a wrench of approximately the same opening diameter as the tube (1/2” +). With the collet firmly held against the face of the fitting,

the tube can be safely pulled out. Do not attempt to pull the tube out without pushing squarely against the collet. This may result in

damaging the fitting.

Page 2 of 2

Loading...

Loading...