Page 1

PVEL

PVEL-D

USER MANUAL IN ORIGINAL

Dok: 101504D-GB 1911

Page 2

PVEL / PVEL-D

CONTENTS

SAFETY INSTRUCTIONS ..................................... 3

OPERATION, PRECAUTIONS...............................3; 4; 5; 6

TRANSPORT, PRECAUTIONS..............................6

TECHNICAL DATA ............................................... .7

FIELD OF APPLICATION......................................8

PREPARATIONS AND OPERATING

CONDITION ...........................................................9

CONVERTER CONNECTION TO

THE SYSTEM ......................................................... 9

SPECIFIC SAFETY RULES..................................10

MAINTENANCE .................................................. 11

REGULAR MAINTENANCE .............................. 11

INSPECTION DETAIL REPAIR............................12

ELECTRIC EQUIPMENT PVEL ..........................13

FAULTY TRACING ..............................................14

EC-DECLARATION OF CONFORMITY.............15

Dok: 101504D-GB 1911

2

Page 3

PVEL / PVEL-D

SAFETY INSTRUCTIONS

To reduce the risk of serious injury or death to yourself

or others read and understand the Safety and operating instruction before installing, operating, repairing,

maintaining, or changing accessories on the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make sure

that everyone reads the Safety and operating instruction

before operating or servicing the machine.

In addition, the operator or the operator’s employer

must assess the specic risks that maybe present as a

result of each use of the machine.

Additional instructionst for the engine can be found in

the manufacturer’s engine manual.

Personal precautions and qualications

Only qualied and trained persons may operate or

maintain the machine.They must be physically able to

handle the bulk, weight, and power of the machine.

Always use your common sense and good judgement.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working

area must wear protective equipment,i ncluding at a

minimum:

• Protective helmet

• Hearing protection

• Impact resistant eye protection with side protection

OPERATION, PRECAUTIONS

DANGER Explosion hazard

If a warm machine or exhaust pipe comes into

contact with explosives, an explosion couldoccur.

During operating with certain materials, sparks

and ignition can occur. Explosions will lead to

severe injuries or death.

Never operate the machine in any explosive

environment.

Never use the machine near ammable materials,

fumes or dust.

Make sure that there are no undetected sources of

gas or explosives.

Avoid contact with the warm exhaust pipe or

the bottom of the machine.

DANGER Fire hazard

If a re starts in the machine, it can cause injury.

If possible use an ABE-class powder

extinguisher, other wise usea BE-type carbon

dioxide re extinguisher.

DANGER Fuel hazard

The fuel is ammable and fuel fumes can explode

when ignited, causing serious injury or death.

Protect your skin from contac twith the fuel.If fuel

has penetratedtheskin,consult a qualied health

professional.

Never remove the ller cap,or ll the fueltank

when the machine is hot.

• Respiratory protection when appropriate

• Protective gloves

• Proper protective boots

• Appropriate work overall or similar clothing (not loose-tting) that covers your arms and legs.

Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor reactions

and incorrect assessments can lead to severe accidents

or death.

Never use the machine when you are tired or under the

inuence of drugs, alcohol or medication.

No person who is under the inuence of drugs,alcohol

or medication may operate the machine.

Fill thef ueltank outdoors or in aclean and well

ventilated place, free from sparks and open

ames. Fill the fuel tank at least ten meters (30

feet)from the place where the machine is to be

used.

Release the ller cap slowly to let pressure escape.

Never over ll the fuel tank.

Make sure the ller cap is screwed on when the

machine is used.

Avoid spilling fuel on the machine, wipe off any

spilled fuel.

Check regularly for fuel leaks. Never use the

machine if it is leaking fuel.

Never use the machine in the proximity of ma-

terial that can generate sparks.Remove all hot

or spark-generating devices before startingthe

machine.

Dok: 101504D-GB 1911

3

Page 4

PVEL / PVEL-D

Never smoke when lling the fuel tank or when

working with the machine or servicing it.

Only store fuel in a container that is specially

constructed and approved for the purpose.

Consumed fuel and oil containers must be

taken care of and returned to the retailer.

Never use your ngers to check for uid leaks.

WARNING Unexpected movements

The machine is exposed to heavy strains during

operation.If the machine breaks or gets stuck,

there maybe sudden and unexpected movemen

that can cause injuries.

Always inspect the machine prior to use. Never

use the machine if you suspect that it is damaged.

Make sure that the handle is clean and free of

grease and oil.

Keep your feet away from the machine.

Never sit on the machine.

Never strike or abuse the machine.

Pay attention and look at what you are doing.

WARNING Dust and fume hazard

Dusts and /or fumes generated or dispersed when

using the machine may cause serious and permanent respiratory disease, illness, or other bodily

injury (forexample, silicosis or other irreversible

lung disease that can be fatal, cancer, birth defects,

and /or skin inammation). Some dusts and fumes

created by compaction work contain substances

known to cause respiratory disease, cancer, birth

defects, or other reproductive harm.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to determine

if there is dust or fumes are the air. To reduce the

risk of exposure to dust and fumes, do all of the

following:

Perform site-specic risk assessment. The risk as-

sessment should include dust and fumes created by

the use of the machine and the potential for disturbing existing dust.

Wear, maintain and correctly use respiratory protec-

tion as instructed by your employer and as required

by occupational health and safety regulations. Ther

espiratory protection must be effective for the type

of substance at issue (and if applicable, approved

by relevant governmental authority).

Work in a well ventilated area.

If the machine has an exhaust, direct the exhaust

so as to reduce disturbance of dustin a dust lled

environment.

Operate and maintain the machine as recommended

in the operating and safety instructions.

Wear washable or disposable protective clo-

thes at the worksite, and shower and change in

to clean clothes before leaving the work site to

reduce exposure of dust and fumes to your self, other

persons, cars, homes, and other areas.

Avoid eating,drinking, and using tobacco products in

areas where there is dust or fumes.

Wash your hands and face thoroughly as soon as

possible upon leaving the exposure area,and always

before eating, drinking, using tobacco products,or

making contact with other persons.

Comply with all applicable laws and regultions,

including occupational health and safety regulations.

Participate in air monitoring, medical examination

programs, and health and safety training programs

provided by your employer or trade organizations

and in accordance with occupational health and

safety regulations and recommendations. Consult

with physicians experienced in relevant occupational

medicine.

Work with your employer and trade organization

to reduce dust and fume exposure at the work site

and to reduce the risks. Effective health and safety

programs, policies and procedures for protecting

workers and others against harmful exposure to dust

and fumes should be established and mplemented

based on advice from health and safety experts.

Consult with experts.

DANGER Exhaust gas hazard

The exhaust gas from the machine’s combustion

engine contains carbon monoxide which is poisonous, and chemicals which cause cancer, birth

defects, or other reproductive harm. Inhalation of

exhaust fumes can cause serious injury, illness, or

death.

Never inhale exhaust fumes.

Ensure good ventilation (extraction of air by fan if

necessary).

Dok: 101504D-GB 1911

4

Page 5

PVEL / PVEL-D

WARNING Projectiles

Failure of the work piece, of accessories, or even

of the machine itself may generate high velocity

projectiles. During operating, splinters or other

particles from the compacted material may become

projectiles and cause personal injury by striking the

operator or other persons.To reduce these risk:

Use approved personal protective equipment and sa-

fety helmet, including impact resistant eye protection

with side protection.

Make sure that no unauthorised persons trespass into

the working zone.

Keep the work place free from foreign objects.

WARNING Rotating blades hazards

There is a risk of hands and feet getting caught by

the rotating blades when the machine is running.

This can cause personal injury.

Never place your hands or feet inside the protection

ring when the machine is running

WARNING Motions hazards

When using the machine to perform work-related

activities, you may experience discomfort in the

hands, arms, shoulders, neck, or other parts of the

body.

If numbness, persistent recurring discomfort,

burning sensation, stiffness, throbbing, tingling,

pain, clumsiness, weakened grip,whitening of the

skin, or other symptoms occurat any time, when

operating the machine or when not operating the

machine, stop operating the machine, tell your

employer and seek medical attention. Continued

use of the machine after the occurrence of any

such symptom may increase the risk of symptoms

becoming more severe and /or permanent.

Operate and maintain the machine as recommen-

ded in these instructions, to prevent an unnecessary

increase in vibration.

The following may help to reduce exposure to

vibration for the operator:

If the machine has vibration absorbing handles, keep

them in a central position, avoid pressing the handles

into the end stops.

When the percussion mechanism is activated, the

only body contact with the machine yous hould have

are your hands on the handle or handles. Avoid any

other contact, for example supporting any part of

the body against the machine or leaning onto the

machine trying to increase the feed force.

Make sure that the machine is well-maintained and

not worn out.

Adopt a comfortable posture whilst maintaining

secure footing and avoiding awkward off-balanced

postures.

Changing posture during extended tasks may help

avoid discomfort and fatigue.

In case of persistent or recurring symptoms, consult a

qualied health professional.

WARNING Vibrations hazards

Normal and proper use of the machine exposes the

operator to vibration.Regular and frequent exposure

to vibration may cause, contribute to, or aggravate

injury or disorders to the operator’sf ingers, hands,

wrists, arms, shoulders and/or nerves and blood

supply or other bodyparts, including debilitating

and/or permanent injuries or disorders that may

develop gradually over periods of weeks, months, or

years.Such injuries or disorders may include damage

to the blood circulatory system, damage to the nervous system, damage to joints, and possibly damage

to other body structures.

Immediately stop working if the machine

suddenly starts to vibrate strongly. Before resuming

the work, nd and remove the cause of the increased

vibrations.

Participate in health surveillance or monitoring,

medical exams and training programs offered by

your employer and when required by law.

When working in cold conditions wear warm

clothing and keep hands warm and dry.

See the”Noise and vibration declaration

statement”for the machine, including the declared

vibration values. This information can be found at

the end of these Safety and operating instructions.

Dok: 101504D-GB 1911

5

Page 6

PVEL / PVEL-D

WARNING Trapping hazards

There is a risk of neck ware, hair, gloves, and

clothes getting dragged into or caught by rotating

machineparts.This may cause choking, scalping,

lacerations, or death.To reduce the risk:

Never grab or touch a rotating machine part.

Avoid wearing clothing, neck ware or gloves

that may get caught.

Cover long hair with a hair net.

DANGER Electrical hazard

The machine is not electrically insulated. If the

machine comes in to contact with electricity, serious

injuries or death may result.

Never operate the machine near any electric wire or

other source of electricity.

Make sure that there are no concealed wires or other

sources of electricity in the working area.

DANGER Concealed object hazard

During operating, concealed wires and pipes

constitute a danger that can result in serious injury.

Check the composition of the material before

operating.

Watch out for concealed cables and pipes for

example electricity, telephone, water, gas, and

sewage lines.

If the machine seems to have hit a concealed object,

switch off the machine immediately.

Make sure that there is no danger before continuing.

TRANSPORT, PRECAUTIONS

WARNING Loading and unloading hazard

When the machine is lifted by a crane and similar

appliance, this can lead to injury.

Use marked lifting points.

Make sure that all lifting devices are dimensionedfor

the weight of the machine.

Never remain under or in the immediate vicinity of

the machine.

MAINTENANCE, PRECAUTIONS

WARNING Unexpected start hazard

During maintenance or when changing blades on the

machine, there is a risk that the engine backres or

that the machine unexpectedly starts. This applies

especially when the engine is hot and if the switch

is in position ON.This can result in serious personal

injury.

Always let the engine cool down.

Always turn the switch to position OFF.

Always take the cap off the spark plug.

WARNING Unexpected start hazard

Any machine modication may result in bodily

injuries to yourself or others.

Never modify the machine. Modied machines are

not covered by warranty or product liability.

Always use original parts, insertion tools, and acces-

sories.

WARNING Involuntary start

Involuntary start of the machine may cause injury.

Keep your hands away from the start and stop device

until you are ready to start the machine.

Learn how the machine is switched off in the event

of an emergency.

WARNING Noise hazard

High noise levels can cause permanent and

disablinghearing loss and other problems such as

tinnitus(ringing, buzzing, whistling, or humming in

the ears).To reduce risks and prevent an unnecessary

increase in noise levels:

Risk assessment of these hazards and implementation

of appropriate controls is essential.

Operate and maintain the machine as recommended

in these instructions.

If the machine has as ilencer, check that it is in place

and in good working condition.

Always use hearing protection.

Change damaged parts immediately.

Replace worn components in good time.

CAUTION High temperature

The machine’s engine exhaust pipe, and bottom

become hot during operation. Touching them can

lead to burns.

Never touch a hot machine.

Never touch the bottom of the machine when its hot.

Wait until the engine, exhaust pipe, and bottom of

the machine have cooled down before carrying out

maintenance work.

STORAGE, PRECAUTIONS

Keep the machine in a safe place, out of the reach

of children and locked up.

Dok: 101504D-GB 1911

6

Page 7

PVEL / PVEL-D

TECHNICAL DATA

HIGH FREQUENCY POKER WITH INTEGRATED CONVERTER

Model, standard:.........................................................................PVEL 38, 50, 58

Model with de-vibrated pistol handle:...................................PVEL-D 38, 50, 58

Motor in head, type............................................................210 V, 3phase 200 Hz

Motor winding:

Built-in thermostatic protection on

the motor winding....................Power off temperature approx. 150-160 degress

Winding isolation............................................Temperature limit on 180 degress

Converter, type:

Input from wall outlet: ................................................. .....230V, 1-phase, 50 Hz

Output to the poker head: ............................................... 210V, 3-phase, 200 Hz

Cable lenght:

PVEL / PVEL-D.....................................................................15 m / 1,5m + 20m

Hose lenght:

Standard...............................................................................................5 m / 0,5m

Special lenght are available for both PVEL and PVEL-D

WEIGHTS:

Modell Total weight

(Kg)

PVEL 38 14

PVEL 50 18

PVEL58 20

PVEL-D 38 11,5

PVEL-D 50 14,5

PVEL-D 58 16,5

Protection functions of the converter

- IP 67

- The electrical card is protected against mechanical shock.

- Internal protection against current leakage. Immediate shoutdown if leakage more than 20mA

provides total protection during use.

- Protection against short circuit for all componenst included.

- (Additional protection against leakage on the cables, 10mA.)

- Protection against interruption of any phase to the electric motor.

- Protection against overheating of the converter box

- Electro-magnetic lter compatibility prevents electromagnetic interference

Dok: 101504D-GB 1911

7

Page 8

PVEL / PVEL-D

FIELD OF APPLICATION AND USE OF CONCRETE VIBRATOR

A prerequisite for the nished oor to meet the quality requirements is to properly treat the fresh concrete.

During poker vibration, concrete is submitted to vibration which will force trapped air to the surface making

concrete homogeneous.

It is recommended that the slab be always poker vibrated if the thickness exceeds 100 mm or if the slab is

double reinforced. The next step is therefore to thoroughly compact concrete with a poker vibrator.

The poker size should be adapted to the density of reinforcement and concrete thickness. Care is required at

rails, forms and stop ends. Introduce the vibrator vertically in the concrete mass without moving it horizontally.

Do not transport concrete with a poker vibrator. This would increase the risk of over vibration.

Always start by leveling vibration. Make short pokes in order to level high spots. The concrete vibrator

should be introduced into the mass at regular intervals. The interval should be from approximately 8 times

the diameter of the poker. Duration of each insertion shall be inside 5-15 seconds. The time in vibrating the

different layers should not be big to avoid cold joints. Do not push or force the vibrator into the mass, it could

be stuck in the reinforcements.

Always remove the poker vertically with movements upwards and downwards so the concrete lls the empty

space again. Do not switch off until you stop the vibration completely. Se speed of removing is approximately

8 cm per second.

The time is shorter for a uid mass; a vibration in excess can produce segregation. It is considered the concrete

to be well vibrated when the surface around the poker is shiny and compact and there is no more air bubbles,

as well a change in the noise of the vibrator is produced. Keep a distance of 7 cm minimum from any walls or

form works.

Choose the type of vibrator adequate to the dimensions of the structure to vibrate, the distance among the

reinforcement and the slump cone. It is recommendable to have an additional concrete vibrator.

Before starting, check that the concrete vibrator is in good condition and it works correctly. Use the means of

safety and protection.

Pour the concrete in the structure avoiding high heights. Try to pour leveled the concrete. The thickness of

every layer should be less than 50 cm, The recommendation is between 30 and 50 cm.

In order to vibrate slabs, the poker has to be kept oblique so that the contact supercies with mass is bigger

and the compacting effect is better.

Do not keep the concrete vibrator out of the concrete during longer periods. Stop it during

residence in the concrete vibration. The concrete slab is working as a cooler for the

vibrator tub and if this not is respected, a break down will appear inside a shorter period

with operating lost and unnecessary cost for the owner.

Follow the maintenance instructions.

Dok: 101504D-GB 1911

8

Page 9

PVEL / PVEL-D

PREPARATIONS AND OPERATING CONDITION

For your own safety, as protection for others, and to avoid damage to the equipment, read carefully this manual

and operating guidelines.

1. Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gases or

dust.

2. Never carry or pull the tool by using the feed cable, and never for removing the outlet from the feed station.

3. Replace damaged feed cable immediately if a failure has been found.

4. Do not keep working the poker out of the concrete more than 5 minutes.

5. Do not stop the poker inside the concrete.

6. Change the wear parts to avoid damage to the internal parts. (Check wearing table for the poker)

CONVERTER CONNECTION TO THE SYSTEM

Do n The model PVEL is connected to the main 230V / 50-60Hz (single phase)

Use a residual current device (“rcd”) with a rated tripping current of 30mA for each converter. Rcd should

be installed either at the distribution board which feeds the mains supply sockets or at the xed main supply

socket. Do not plug others electric tools to the rcd where is plugged the converter.

DISCONNECTING THE EQUIPMENT.

Stop the converter by disconnecting the proper switch, and nally remove the plug from the main.

EARTH CONNECTION

To protect the user from an electrical shock, the converter should be correctly connected to earth.

The converters are equipped with three cables and their respective plugs. The adequate earth socket should be

used to connect the converters. If the socket with earth is not available, an earth adapter should be used before

connecting the plugs.

EXTENSION CABLES

Always use extension cables with earth wire and its respective plug with earth in the female and male plug.

Do not use damaged or worn out cables.

Avoid heavy loads on cables.

To determine the transversal section, follow the following procedure:

PROCEDURE TO DETERMINE THE NECESSARY TRANSVERSAL SECTION IN CABLE

EXTENSION

Do the following verications and take the highest section of cable:

1. The ohmic resistance and inductive resistance of the cable with the permitted loss of voltage of 5%,

cosphi=0.8 trough the frequency and voltage curve I.e.

Voltage nominal:……………………………….. 380 V / 50 Hz

Nominal current:............................................. ......................10 A

Cable length:................................................... ....................150 m

Entering the curve with the product: Intensity x Length=10x150=1500 Am We obtain a 2.5 mm2 section

Dok: 101504D-GB 1911

9

Page 10

PVEL / PVEL-D

2. The permitted heating of the cable according to VDE standard ( minimum transversal section table required).

I. e. For 10 A, according to table for 15 A or less, the section is of 1 mm.

Therefore, the section chosen is equal to 2.5 mm2, Always choose the highest transversal section of the two

verications.

Line

mm²

1 15 10

1,5 18 10 / 3-16 / 1-

2,5 26 20

4 34 25

6 44 35

10 61 50

16 82 63

25 108 80

SPECIFIC SAFETY RULES

For your own safety, as protection for others, and to avoid damage to the motor, read carefully the following

usage recommendations.

1. Firstly read the instruction of the converter where you are going to connect the vibrating pokers.

2. For the operation of the vibrating poker, make sure that operators have been instructed in the proper usage of

the machine

3. The vibrating poker should only be used in the specic jobs for which it has been developed and under the

instruction and safety recommendations of this manual.

4. Be sure that the parts of the poker are tight before starting working.

5. The vibrating poker plug should not be used to start or stop the equipment, use the switch.

6. Protect the electrical cable against heat, oil, or sharp edges.

7. Avoid the attening of the cable by heavy machinery which could cause breakage

8. Check the electrical cable is with the proper section and it is in good condition

9. Avoid the vibrating pokers are working in contact with hard object during a long period.

10. Disconnect the vibrating poker from the converter before doing any operation.

11. Change the external wear parts to avoid damage to the internal parts.

12. Proper protective equipment SHOULD BE USED because the acoustic pressure of this machine is 79dB

(ISO 6081) and acoustic power level is 85dB acc. to ISO 3744.

IN ADDITION, LOCAL COUNTRY ESTABLISHED ORDINANCES SHOULD BE RESPECTED.

Maximum

A

Max Fuse

A

Model

1

PVEL 38 PVEL-D 38 1,40 0,41

PVEL 50 PVEL-D 50 1,80 0,56

PVEL 58 PVEL-D 58 2,30 0,48

Hand/arm vibration hav according to ISO 5349

PVEL

Measured 2m from the poker head.

PVEL-D

Measured on the pistol handle.

10

Model

2

Effective value of

vibration in hose (m/s²)

1

Effective value of

vibration in hose (m/s²)

2

Dok: 101504D-GB 1911

Page 11

PVEL / PVEL-D

Ensure that the parts of the rod are tightened and that electrical cables and other equipment are in good condition

before starting work

When nishing the job or when taking a break, the operator should switch off, disconnect it from the electrical

system, and place it in such a way that should not fall or tip in fresh concrete.

MAINTENANCE

When replacing parts with new, use only SWEPAC original parts.

Lubricating oil, rod bottle, syntetic oil.......................Klübersynth GH 6, or similar

Volume........................................................................Tube cap volume for each diameter

REGULAR MAINTENANCE

ACCEPTED WEAR FOR DIAMETERS AND LENGTHS OF THE POKERS.

DIAMETER

(mm)

LENGHT

(mm)

MODEL

PVEL 38 36,5 (38) 365 (370)

PVEL 50 48 (50) 360 (370)

PVEL 58 56 (58) 410 (420)

The dimensions in parentheses are the original diameters and the

original lengths.

Change the hose when the minimum diameter is reached.

Change the tube tip when the minimum length is reached.

1. Every 12 months or 500 hours of working a lubrication of the bearings of the vibrating pokers is

recommended depending of the use. An expert should dismantle the vibrating poker. Clean with solvent the

bearings and check it. Fill the hole in the cap with the recommended oil. When you assemble, place the sealant

in all the threads. It is important that all the parts are tightened (600 to 800 Nm of torque) to avoid the water

does not penetrate in the head. Finally, apply two weld spots to secure the parts do not loosen.

2. Always you change the switch be sure the bolts of the switch box are tighten and the box is watertight.

3. After maintenance jobs all the parts must be assembled correctly.

4. Every 12 month or more frequently, depending on the use, it is recommended an inspection be done by an

authorized dealer.

5.Check the wear of the poker controlling the outside diameter and length of the poker. Replace the housing or

cap when the diameter or length in the least point is less than the specied in the table according to the model.

Dok: 101504D-GB 1911

11

Page 12

PVEL / PVEL-D

INSPECTION DETAIL REPAIR

1. Inspection current conpsumtion rod motor Amp.

Rod

(diameter)

Amp.

obelastad

38 1,3

50 1,5

58 1,7

60 3

2. Kontroll motstånd i motorlindning Ohm

Rod

(diameter)

Resistance

(Ohms)

38 28

50 10,6

58 8,8

65 2,6

12

Dok: 101504D-GB 1911

Page 13

PVEL / PVEL-D

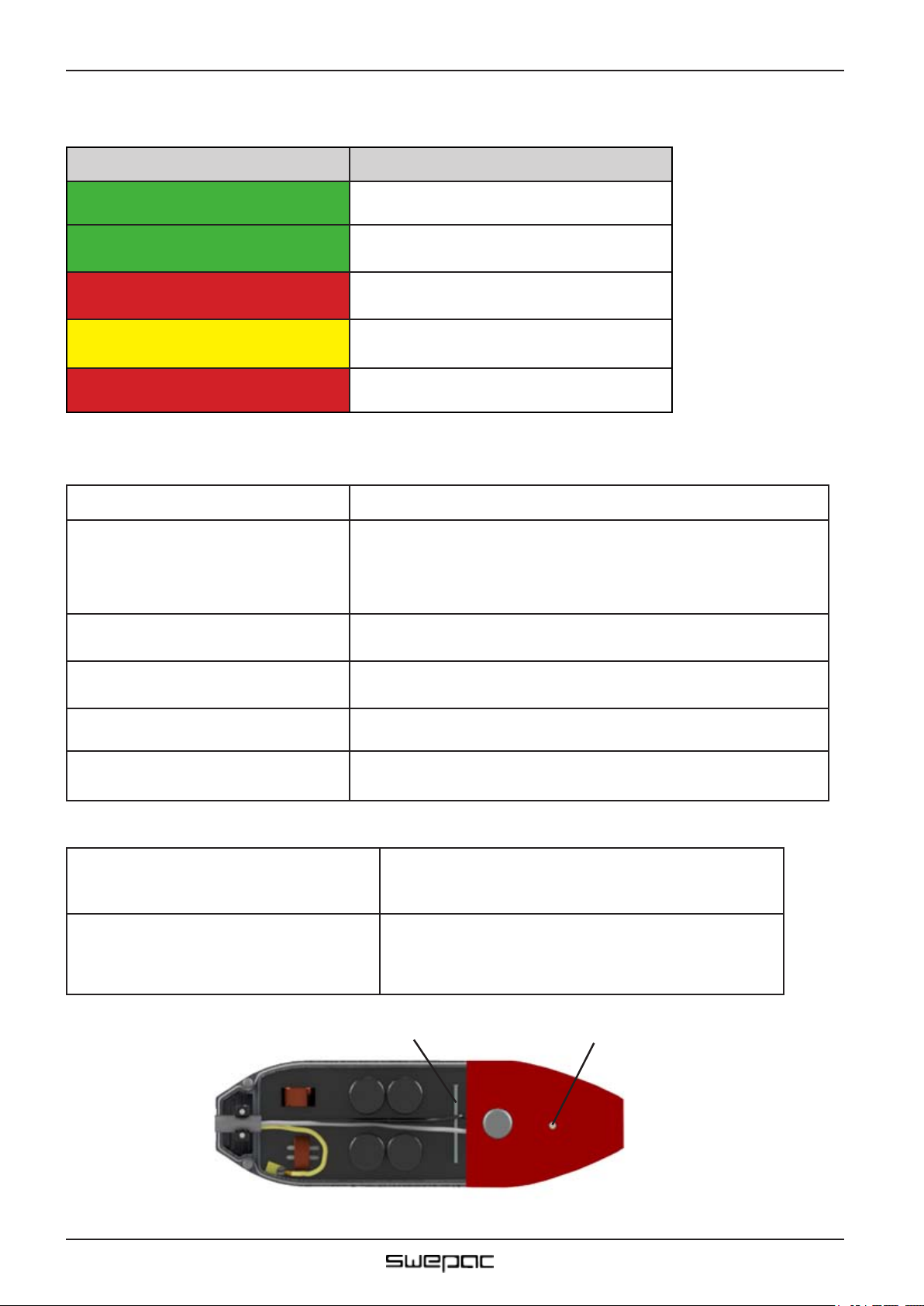

ELECTRIC EQUIPMENT PVEL

ELECTRIC WIRINGS AND ELECTRICCOMPONENTS

IDENTIFICATION LED INTERNALLY

OUTSIDE

Dok: 101504D-GB 1911

13

Page 14

TROUBLESHOOTING OUTSIDE:

LED INFORMATION

Green ashing It is connected, waiting to start

Green Normal working

Red Overcurrent / Short-circuit

Yellow Lekeage current

Red ashing Fail of a phase

TROUBLESHOOTING INTERNALLY:

PVEL / PVEL-D

PROBLEM CAUSE / SOLUTION

Not working,

green led (1) OFF

Red led (2) ON

Yellow led (3) ON

Red blue (4) ON

Led (2+3+4) ON

See if it has power

Check cord

Check plug

Converter burnt

Stator poker burnt

Converter burnt

Earth leakage current (check poker, connections)

Water inside converter or poker

Lack of phase in poker (3 phase motor)

Over temperature. (check converter’s cleanness and remove stacked

concrete and any unnecessary cover)

OTHER:

The poker is noisier

The vibrating poker works

correctly but it overheats

Bearings are not in good conditions.

Check the poker is not working out of concrete.

Verify the input voltage of the converter.

Bearings in bad conditions or without grease

14

Internal diode ramp

External diode

Dok: 101504D-GB 1911

Page 15

EC-declaration of conformity

1. Category: PokerVibrator

PVEL / PVEL-D

Manufacturer

Swepac AB

Blockvägen 3

34132 Ljungby

2. Type: PVEL / PVEL-D

The product complies with the following directives:

2006 / 42 / EG

2000 / 14 /EG

2004 / 108 / EG

EN 500-1

EN 500-4

EN 12649:2008+A1:2011

ISO 11201

ISO 5349-2:2001

Technical documentation held by:

Swepac AB, Blockvägen 3 SE-34132 Ljungby

Hans Holmlund / Product Manager

Dok: 101504D-GB 1911

15

Page 16

SWEPAC AB

Address Blockvägen 3, 341 32 Ljungby, Sweden, tel. +46 (0)372-156 00, fax +46 (0)372-837 41, E-mail mail@swepac.se,

Internet www.swepac.se

Loading...

Loading...