Page 1

F 80A

USER MANUAL IN ORIGINAL

Doc: 101516-GB 1810

Page 2

2

F 80A

Doc: 101516-GB 1810

USE

SWEPAC F 80A

is used to pack freshly laid asphalt on pavements and garage

approaches, in connection with roadworks, etc. The machine is

designed to pack small asphalt areas and is particularly suitable

for additional works and repair works. The compact design with

an articulated control handle makes the machine very easy to

manoeuvre. The machine is also suitable for packing sand and

gravel in thin layers.

USE ......................................................................... 2

STANDARDS ......................................................... 3

SIGNS ..................................................................... 4

TECHNICAL DATA ................................................ 5

FUNCTION .............................................................5

TECHNICAL DESCRIPTION ................................ 6

DAILY CHECKS ..................................................... 7

BEFORE STARTING THE ENGINE .....................8

STARTING ..............................................................8

AFTER STARTING ................................................. 8

STOPPING .............................................................. 8

WATER TANK..........................................................9

TRANSPORTATIONS........................................... 10

NOTES..................................................11; 12; 13; 14

EC-DECLARATION OF CONFORMITY.............15

CONTENTS

Page 3

3

F 80A

Doc: 101516-GB 1810

As the sound pressure level at the operator’s ears

exceeds

80 dB (A), ear protectors must be used during operation!

Hand/arm vibrations

The vibration acceleration was measured in accordance

with the ISO 5349 standard during operation on a

graveled surface. The measurement values were

translated into the maximum daily exposure time

for regular usage. For additional information about

vibrations, please confer the regulation AFS 2005:15

from the Swedish Work Environment Authority,

effective July 1st 2005.

Measurement uncertainty ± 0.3 m/s2 in 95% of the

measurements.

Exhaust emissions

F 80Ameet the requirements for exhaust emissions in

acoordance with EU directive 2002/88 Euro2

STANDARDS

Noise

Measurement in accordance with the standard EN 5004 Rev. 1:1998, Annex C:

Measurement uncertainty ± 0.5 dB (A) in 95% of the

measurements.

In accordance with the conditions in Directive 2000/14/

EC, Annex VI, the following values are reported:

F 80A

Sound pressure levelat the operator’s

ears, LpA

90dB (A) LpA

Permitted sound

power level, L

WA

108 dB (A)

Guaranteed sound

power level, L

WA

105 dB (A)

F 80A

Hand/armvibrations, m/s

2

4,6

The maximum daily

exposure time

2,4 h

Page 4

4

F 80A

1 2 3

7 6

4

5

8

MACHINERY

9

Doc: 101516-GB 1810

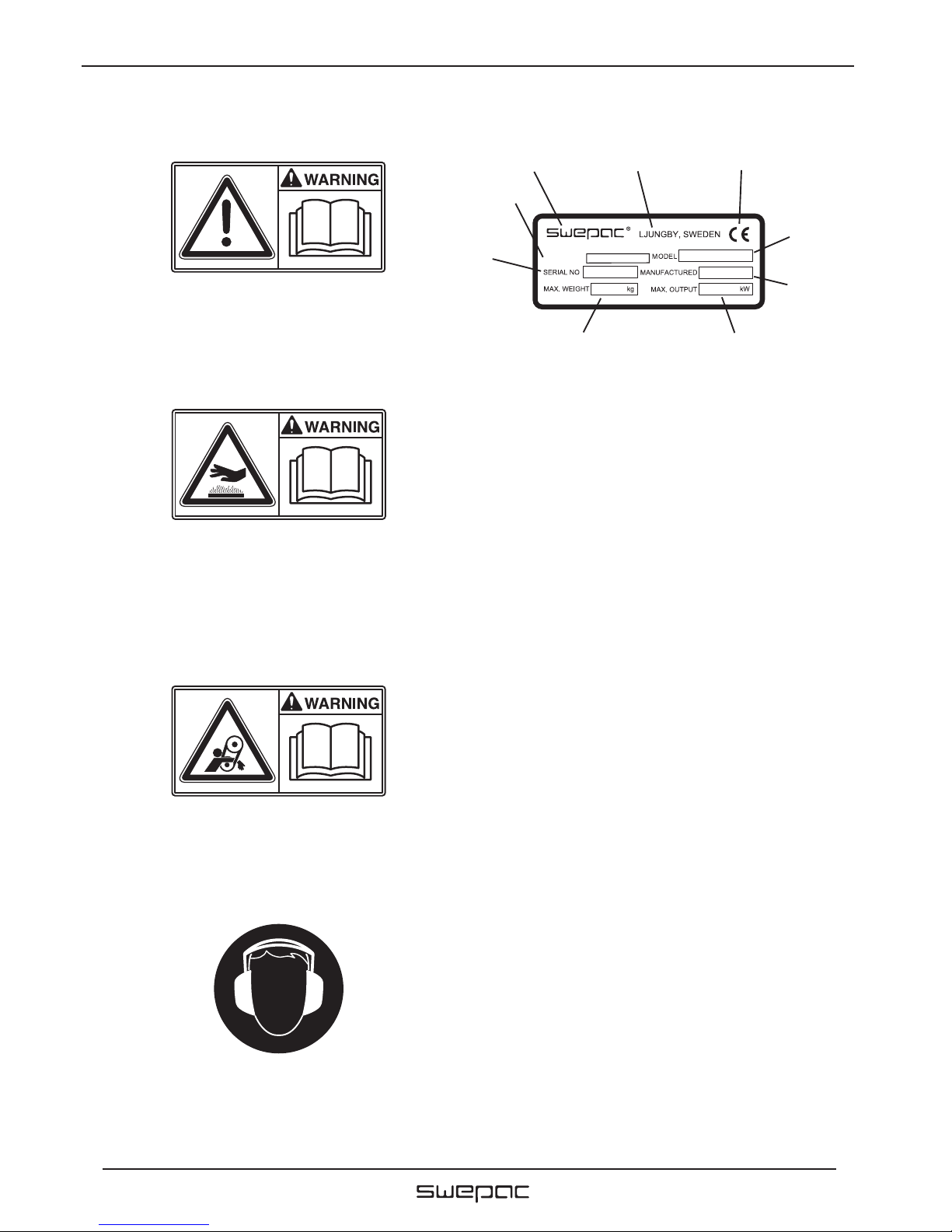

SIGNS

Warning signs Machine Signs

Before use, carefully read the manual and its safety instructions so that you can handle the machine safely. Ensure that

the manual is always accessible.

Belt drive: Keep hands, tools and other objects away from

the belt drive when the machine is on to avoid injury and

damage. See the safety instructions in the manual.

As the sound pressure level at the operator’s ears exceeds 80

dB (A), ear protectors must be used when working with the

machine to prevent hearing damage.

Engine, silencer: to avoid burns or discomfort, do not touch

hot engine parts when the engine is on or when the machine

has recently been used.

1. Manufacturer

2. Place, country of manufacture.

3. CE mark.

4. Model name.

5. Year of manufacture.

6. Max. engine power.

7. Max. weight.

8. Serial number.

9. Machine type

Page 5

5

F 80A

Doc: 101516-GB 1810

TECHNICAL DATA FUNCTION

The machine consists of a base plate with a vibration element

and an upper part cushioned from the base plate.

The upper part include even carrying handle. The lifting eye

include even an water tank bracket.

The power is transmitted from the petrol engine to the vibration

element via a V-belt. To adjust the V-belt loosen the four screws

which holds the upper part to the base plate and pull whole the

upper part backward to the operator.

The engine is tted with an integrated centrifugal clutch. On

account of the direction of rotation and the position of the

vibration element at the front end of the base plate, the

vibrator moves forward under its own power.

The machine’s vibration element stops when the throttle is

switched to idle.

Work with the machine in daylight or other adequate lighting.

All other use is discouraged.

Transport wheels are accessories.

FUEL AND OIL RECOMMENDATIONS

Fuel ..............................Unleaded petrol or alkylate

Engine oil .....................SAE10W-30

Engine oil change: rst oil change after 20 hours then every

100 hours of operation

F 80A

Net weight .................................80 kg

Base plate, w x l .......................430 x 580 mm

Permitted inclination ................18°

Speed .........................................appr 25 m/min

Centrifugal force .......................14 000N

Vibration frequency ..................93 Hz

Drive engine ..............................Honda GX 160

Engine power ............................4,0 kW

Engine RPM ..............................3600 RPM

Fuel tank volume .......................2,5 liter

Fuel type ....................................Unleaded petrol or alkylatet

Water tank volume....................11 Liter

Page 6

6

F 80A

1

2

3

9

4

6

7

8

5

10

Doc: 101516-GB 1810

1. Handle

2. Protective cover

3. Petrol engine

4. Engine plate

5. Centrifugal clutch

6. V-belt

7. Rubber damper

8. Vibration element / Base plate

9. Water tank

10. Lifting eye / Water tank bracket

TECHNICAL DESCRIPTION

Page 7

7

F 80A

1

2

3

1

2

Doc: 101516-GB 1810

DAILY CHECKS

Fuel Check

Check that there is fuel in the tank. Top up if necessary.

Engine Oil Level Check

Check the oil level in the crankcase every day. The oil

must reach the edge of the lling hole when the machine is

on a level surface.

Air Filter Check

The air lter must be checked at least once every working week.

When working in dusty conditions, check daily.

1. Paper element

2. Foam plastic element

Cleaning the air lter

1. Remove the foam plastic element and the

paper element and check that they are

undamaged. Replace damaged parts.

2. Wash the foam plastic element in liquid with

a high ashpoint and let it dry properly. Dip in

engine oil and squeeze dry.

3. Strike the paper element against a hard object

a few times to loosen any dirt.

Oil/Fuel Leakage

Check every day that the engine is not leaking oil

or fuel. If a leak is discovered, the machine may

not be operated until the fault has been remedied.

See also the separate engine instructions!

V-belt Drive

Check the tension and condition of the V-belt regularly.

Adjustment of V-belt tension

Loosen the screws (pos 1) that hold the engine plate.

Loosen the screws (pos 2) holding the cover.

Remove the cover.

Tension the V-belt by pulling the handle on the side of the

engine plate.

Tighten the screws.

Ret the cover.

Rubber Dampers

Check the condition of the rubber dampers (pos 3)

regularly. Replace damaged dampers.

Polyuretan Pad

A polyuretan pad is used for stone paving work to protect

against stones and ground clinker.

Note! Options

Page 8

8

F 80A

Doc: 101516-GB 1810

Oil level

Off

On

Engine power switch

Off On

Fuel cock

Active Not active

Choke

Full RPM

Idle

Throttle lever

BEFORE STARTING THE ENGINE

See Daily Checks on page 8.

STARTING

Switch the engine power switch to “on”. Open the fuel

crane.

See that the lever is in idle speed position.

Active the choke. If the engine is cold, active the choke

completely. Do not use the choke if the engine is warm or if

the air temperature is high.

Start by pulling the starting handle. Pull it rst until the

mechanism engages. Then pull it hard and fast.

AFTER STARTING

Switch the throttle lever to idle.

Open the choke gradually.

Run the engine warm for around 1-5 minutes.

STOPPING

Switch the engine to idle and let it run for a few minutes.

Switch the engine power switch to “off”.

Close the fuel crane.

Page 9

9

F 80A

1

2

Doc: 101516-GB 1810

Push the water tank from

upside down.

The water tank for the F 80A is removable. To mount the water tank do this steps:

Push the water tank down with the side lock pos. 1 open. The rear part of the water

tank´s should be placed in the holder on the bracket.

Make sure that the water tank hangs rmly in the holder, release the side lock and

check that the pin of the side lock hits the hole on the bracket.

MOUNT THE WATER TANK

Start the water supply for asphalt work

Open the water trap pos. 2 by turning it counterclockwise from the

operator´s hole.

Open

Closed

Page 10

10

F 80A

Doc: 101516-GB 1810

TRANSPORTATION

It is easy to remove the handle without tools, and the boot

of a standard car is sufcient to transport the machine.

Lifting by hand

Remove the handle by pushing it forward and pull apart the

shafts so that the fastening tabs release.

Stir the handle slightly sideways so that the handle release.

Caution!The machine must be lifted by 2 persons!

Lift by means of the handle on the back and the front edge

of the machine.

Lifting with crane

Tilt the handle forward.

Fit a lifting sling to the lifting eye and thread the lifting

sling between the shafts of the handle, see illustration

below.

Transport locking

Secure the machine with straps according to illustration

during transportation

Note! Secure it by the base plate and not the rubbercushioned upper part.

Page 11

11

F 80A

Doc: 101516-GB 1810

NOTES

Page 12

12

F 80A

Doc: 101516-GB 1810

NOTES

Page 13

13

F 80A

Doc: 101516-GB 1810

NOTES

Page 14

14

F 80A

Doc: 101516-GB 1810

NOTES

Page 15

15

F 80A

Doc: 101516-GB 1810

EC-declaration of conformity

Manufacturer

Swepac AB

Blockvägen 3

34132 Ljungby

1. Category: Vibratory plate

2. Type: F80A

3. Engine power: F80A 4,0 kW

The product complies with the following directives:

2006 / 42 / EG

2000 / 14 /EG

2004 / 108 / EG

EN 500-1

EN 500-4

Technical documentation held by:

Swepac AB, Blockvägen 3 SE-34132 Ljungby

Tomas Johansson / Product Engineer

Page 16

SWEPAC AB

Address Blockvägen 3, 341 32 Ljungby, Sweden, tel. +46 (0)372-156 00, fax +46 (0)372-837 41, E-mail mail@swepac.se,

Internet www.swepac.se

Loading...

Loading...