Page 1

GB.TBLAMT.141001

Swegon reserves the right to alter specifications.

www.swegon.com 1

Installation Instructions for the TBLA Air Heater with

Thermo Guard frost damage protection, GOLD/SILVER C

1. General

The TBLA air heater uses hot water as the heating medium

for post-heating the supply air.

Finned-tube heat exchanger fabricated of copper tubes

and profiled aluminium fins. The headers and the pipework to the water connections are made of copper. The

male threaded pipe connections are made of brass.

Extra accessories

GOLD:

The TBVL valve set with 2(3)-way valve, actuator, connection cable with quick-fit connector, frost guard sensor

(insertion type), and T-piece (for air heaters without outlet

for an insertion sensor). See the individual instructions for

the TBVL valve set.

If you use a valve of your own, you have the option of

instead selecting a set of electrical connection components. This set contains a connection cable with quick-fit

connector, resistor and insertion or strap-on sensor.

SILVER C:

The TBVA Valve set consisting of a 2(3)-way valve including actuator can be ordered. See the instructions for

TBVA accessories. If the air heater/cooler is to be installed

outdoors or in a cold space, take into consideration the

enclosure class of the actuator and the permissible ambient temperature. If necessary, ensure that the required

protection is arranged.

2. Maintenance

Check at least twice a year whether cleaning is necessary.

Cleaning shall only be done by blowing with compressed

air against the ordinary direction of airflow, vacuum cleaning with a soft nozzle or wet cleaning with water and/or

solvent. Before you begin wet cleaning, you should cover

adjacent functional sections to protect them. After wet

cleaning, you should blow the surfaces dry with compressed air to remove every trace of cleaning solvent.

If cleaning solvent is used, this solvent must not contain

ingredients that will corrode aluminium or copper. Swegon’s cleaning agent is recommended. This cleaning agent

is sold by Swegon or Swegon Service.

While cleaning, check whether the liquid circuit needs to

be vented.

Page 2

GB.TBLAMT.141001

Swegon reserves the right to alter specifications.

2 www.swegon.com

3. Installation

For the installation of air heaters in duct systems, see the

individual instructions entitled: Installation Instructions for

Duct Accessories.

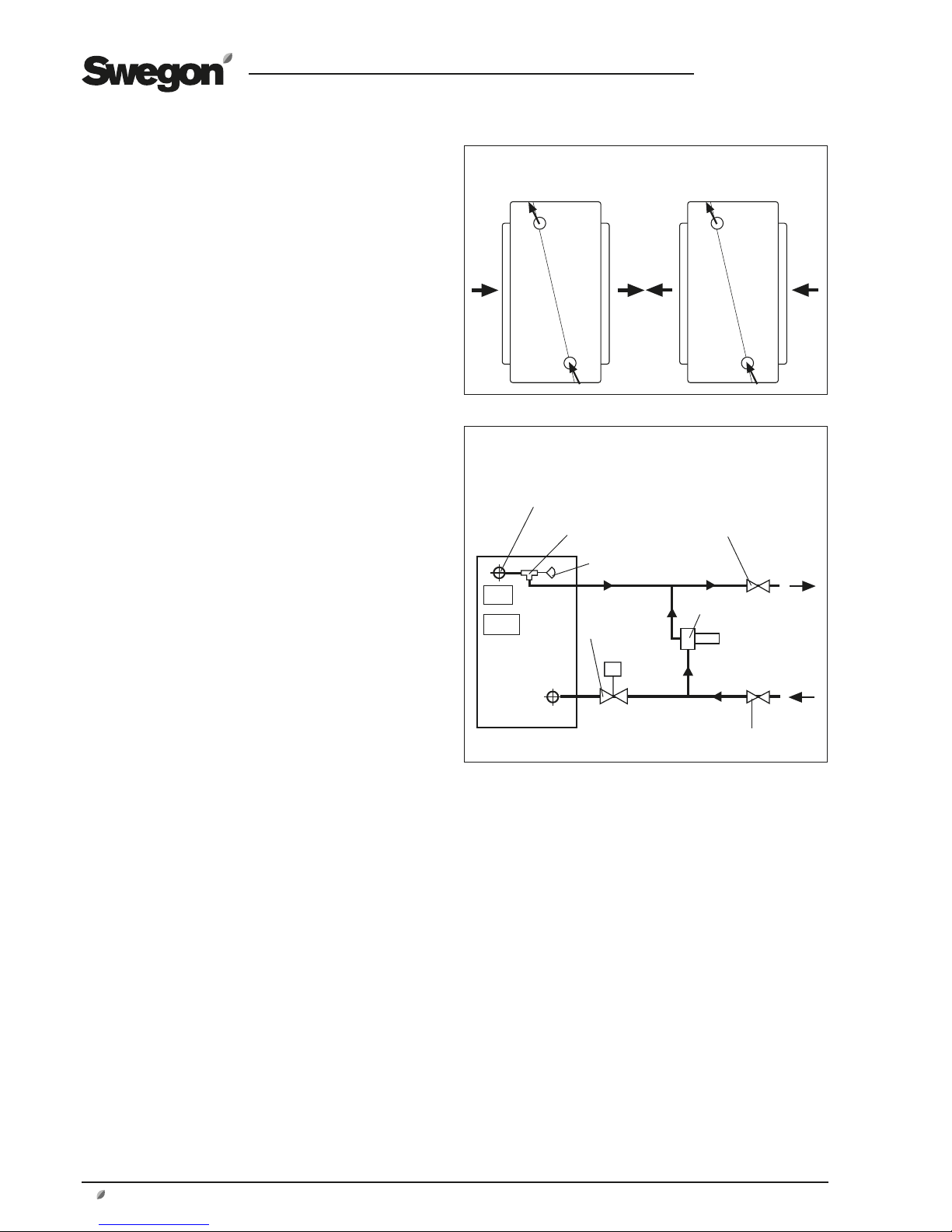

The capacity of the air heater with Thermo Guard is independent on the direction of airflow through the air heater.

See Fig. 1.

The return pipe must always be connected to the connection marked Thermo Guard. See figure. 2.

Use a pipe wrench to restrain the pipe connections of the

air heater when tightening the external pipe connections

to avoid damaging the tubes in the air heater.

Always fill the air heater with liquid from the lower connection. Vent the system before you commission it.

The supply flow temperature should be between 55-70°C.

The available pump pressure must not be higher than 25

kPa if the inlet flow temperature is higher than 65°C. If

the inlet flow temperature is between 55°C and 65°C, the

available pump pressure should be between 12–40 kPa.

If the inlet flow pressure substantially exceeds the recommended pressure, a pressure limiting device, which

reduces the pressure to the recommended level, may be

necessary.

A pressure limiting device should not be installed in ventilation systems that utilize hot water supplied from a district heating plant, since such a device could contribute to

high recirculated water temperatures.

4. Operation

Thermo Guard frost damage protection

Frost damages in the air heater most often cause the tube

bends to burst.

Research has shown that the tubes in the air stream are

the first ones to freeze. When an ice plug forms inside a

tube, it expands longitudinally along the tube and this

increases the water pressure in the bend causing it to

burst. Hence, it is not the ice itself that causes the bend

to burst, but the high water pressure in the bend brought

about by the ice inside the tube.

Thermo Guard frost-damage-protected air heaters operate

according to the principle that involves relieving abnormal

pressure rise in tube bends by draining water from the

tube bends to the return pipe of the air heater.

This enables the air heater to cope with freezing without

damage. However it is important to note that possible

valves installed in the return pipeline must not be closed

since doing so will put the Thermo Guard function out of

action.

Thermo Guard frost damage protection is the only one of

its kind on the market that offers frost damage protection

in the event of a power failure and similar service disruptions.

Fig. 1

TBLA connections with Thermo Guard

Thermo

Guard

Swegon

Thermo Guard

connection

T piece

Frost guard sensor

Shut-off valve (must not be

closed if freezing is likely –

to relieve pressure).

Pressure limiting device,

if required

Heating

water

Shut-off valve

Control

valve

Fig. 2

AB

A

5. Electrical connections

For particulars of the electrical connections of the valve

actuator and circulation pump, see the separate instructions for the TBVL/TBVA valve kit.

Loading...

Loading...