Page 1

Guide to the GOLD version F functions,

Reversible heat pump, RX/HC

GB.FUNKRXHC.180907

1. General

RX/HC is a complete reversible heat pump, fully integrated

in the GOLD air handling unit.

There are three options to defrost the coils

in the exhaust air:

Option 1. Reversing the media circuit.

Option 2. Reversing the media circuit +

electric air heater

Option 3. Reversing the media circuit +

air recirculation section RX/HC

1.1 Installation

See the separate installation and maintenance instructions

to install RX/HC.

See the separate installation instructions to install the air

recirculation section RX/HC, if used.

2. Material specification

Air handling unit with integrated

reversible heat pump GOLD RX/HC

For defrosting according to option 2 (see section 1):

Electric air heater for defrosting. Installed in GOLD RX/HC

from the factory.

For defrosting according to option 3 (see section 1):

Air recirculation section RX/HC for defrosting.

We reserve the right to alter specifications.

www.swegon.com 1

Page 2

3. Function

3

25%%%

25%

100 %

100 %

%1

3.1 General

RX/HC has a reversible heat pump function that is controlled by the GOLD air handling unit’s control system

IQlogic via bus communication to the refrigerant circuit’s

control system iPro.

Operation and setting occurs via the GOLD air handling

unit’s hand-held micro terminal (see section 5. Settings).

The reversible heat pump circuit is controlled

with three signals:

• Stop/Start (0/1)

• Heating/Cooling (0/1)

• Speed level compressor in per cent (25-100%)

When operation is requested, a start signal is sent for the

production of heating or cooling.

Depending on the need in question, a signal is also sent

for the operating level, 25-100%. When operation is

not required, a stop signal is sent and 0 % signal for the

operating level.

3.2 Start of RX/HC air handling units

Start of the reversible heat pump occurs after the GOLD

air handling unit’s ordinary start sequence. Operation of

RX/HC is blocked during the GOLD air handling unit’s

ordinary start sequence.

GB.FUNKRXHC.180907

3.4 Temperature regulation

The heat pump has its own control sequence (HC) in the

GOLD air handling unit’s temperature sequence. The

sequence regulates the temperature requirement 0-100%,

for the heating and cooling sequence respectively.

The heat pump is enabled when the temperature requirement exceeds 3% for 60 seconds and is disabled when

the temperature requirement drops below 1% for 60

seconds (applies for Operating mode - Standard).

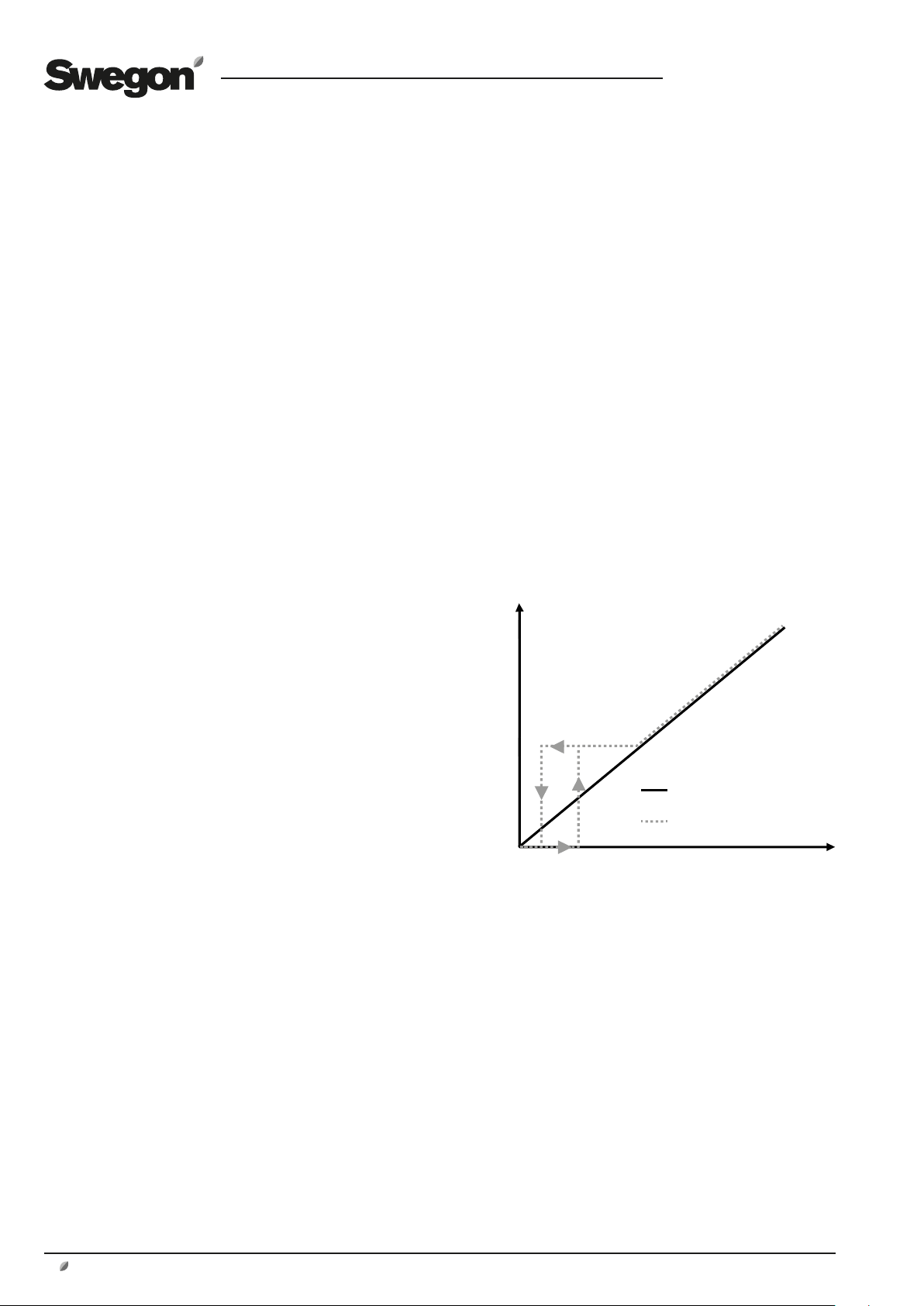

Size 011 - 035 (one compressor)

The refrigerant circuit contains a speed controlled compressor.

The compressor works between a MIN level (normal 25%)

and maximum speed.

At a temperature requirement below 25% the compressor

is run at 25% of max, at a need above 25% the compressor follows the temperature requirement. (see the diagram

below)

3.3 Stop of RX/HC air handling unit

When stopping the GOLD air handling unit, operation of

the reversible heat pump is shut down immediately.

Post-cooling of the refrigerant circuit and electric air

heater for defrosting (if fitted) is carried out. After cooling

is in progress two minutes after the last operation of the

compressor or electric air heater.

Compressor operation

Temperature requirement, GOLD

Operation level, HC

Temperature requirement

2 www.swegon.com

We reserve the right to alter specifications.

Page 3

Size 040 - 080 (two compressors)

0

20

100 % 908070605040302010

0

40

60

80

100%

100

100

0

20

100 % 908070605040302010

0

40

60

80

100%

0

20

100 % 908070605040302010

0

40

60

80

100%

100

The refrigerant circuit contains a speed controlled compressor and a compressor of the on/off type.

The speed controlled compressor works between a MIN

level (total 12.5% per compressor, corresponding to 25%

of the speed controlled compressor) and maximum speed.

Increasing temperature requirement

At a temperature requirement below 12.5% the speed

controlled compressor is run at 25% of max, speed.

GB.FUNKRXHC.180907

Compressor speed controlled

When the temperature requirement increases above

12.5%, the speed controlled compressor is regulated to

follow the temperature requirement.

At a temperature requirement above 50%, the speed

controlled compressor runs to max, speed.

When the temperature requirement increases above

62.5%, the on/off compressor and the speed controlled

compressor are regulated to follow the temperature requirement.

%

80

60

40

20

Compressor operation

0

0

100 % 908070605040302010

Temperature requirement

At a temperature requirement of 100%, both compressors

run at max, speed.

Decreasing temperature requirement

When the temperature requirement decreases below

100%, the on/off compressor is operational and the speed

controlled compressor is regulated to follow the temperature requirement.

At a temperature requirement below 62.5% the speed

controlled compressor is run at 25% of max, speed and

the on/off compressor is operational.

When the temperature requirement decreases below

50%, the on/off compressor shuts down and the speed

Compressor, on/off

%

80

60

40

20

Compressor operation

0

0

100 % 908070605040302010

Temperature requirement

controlled compressor is regulated to follow the temperature requirement.

At a temperature requirement below 12.5% the speed

controlled compressor runs at 25% of max, speed.

Total output

The diagram shows the total capacity in per cent, which is

the same as the control signal from the control system.

We reserve the right to alter specifications.

Total output

%

80

60

60

40

Total output

20

0

0

Temp. requirement, GOLD

Operation level, HC

100 % 908070605040302010

Temperature requirement

www.swegon.com 3

Page 4

GB.FUNKRXHC.180907

3.5 Stabilization

In certain circumstances, there is a need to stabilise operation of the refrigerant circuit and the temperature control

for GOLD.

During stabilization, operation of the refrigeration circuit

is forced to be between MIN-100% of the compressor

speed, regardless of the temperature control requirement.

The stabilisation time is normally 4 minutes + any time

between sending the start request of the refrigeration

circuit and the actual start of compressor operations. If the

cooling circuit is (or recently been in) in operating mode

Adapted operations, the stabilisation time is extended to 8

minutes.

Stabilization starts when one of the following occurs:

• The refrigerant circuit starts in stopped mode

• Defrosting is complete

• Oil return is terminated

• The number of compressors in operation is changed

(except when the number changes from one to zero).

Operations return to normal mode after stabilization is

complete and is controlled between MIN-100% according

to section 3.4 Temperature control.

Stabilization stops when one of the following occurs:

• Stop of the GOLD air handing unit

• Defrosting requirement occurs (see section 3.9)

• Oil return starts (see section 3.8)

3.6 Comfort function

The comfort function is possible to select for heating and/

or the cooling function.

When there is a need of low cooling/heating capacities,

the lowest compressor speed will be too high, the function prioritises comfort before economy.

If the comfort function is selected and the temperature

requirement is low (the corresponding compressor operation is lower than MIN level), comfort mode is enabled.

Operation of the reversible heat pump is then locked

to MIN level of the compressor speed. The rotary heat

exchanger is allowed to regulate to maintain the required

supply air temperature. If instead the temperature requirement exceeds MIN level, operations return to normal

mode.

If any of the following occurs the comfort function is cancelled and operation of the reversible heat pump stops:

• Stop of the GOLD air handing unit

• Time for comfort mode exceeds 30 minutes (factory

setting, can be set 5 – 30 minutes)

• Airflow limits for the supply air and/or extract air drop

below the permitted minimum limit (factory setting 40%

of the GOLD air handling unit’s maximum flow, can be set

0 – 100%)

• Outdoor temperature limits for heating or cooling function are not met (factory setting, heating -20°C, cooling

+15°C. Can be set, heating -50 – +50°C, cooling 0 –

50°C)

• The supply air temperature deviates from the set point to

such an extent that it is within 1 K from the limit value for

any of the alarms Supply air temperature above/below set

point.

• Reheating attempts to start when operations are in heating mode or reheating attempts to start when operations

are in cooling mode. This means that the rotor’s heating/

cooling capacity is not sufficient to balance the temperature and that there is an active regulation sequence after

the rotor.

3.7 Adapted operations

When the evaporation and condensation temperatures

are in a position outside of the optimal working range, the

speed of the compressor is adapted to attempt to reach

the optimal working range.

This is indicated on the hand-held micro terminal of the

GOLD unit.

3.8 Oil return

If the speed of the compressor has been below 28% for

more than 50 minutes, the speed is increased briefly to

extend the life of the compressor.

This results in a larger delivered supply air capacity than

requested. In order to avoid unnecessary system fluctuations, refrigeration circuit shut-off is prevented (independent of the temperature regulator’s requirement) after the

oil return is completed. This is done by starting the stabilization function.

4 www.swegon.com

We reserve the right to alter specifications.

Page 5

GB.FUNKRXHC.180907

3.9 Defrosting

Freezing occurs when operations are in heating mode and

the temperature across the exhaust coil is below 0 °C.

Depending on the temperature, compressor speed, airflow

as well as moisture content in the extract air and fresh air,

freezing occurs with varying speed and behaviour.

The pressure drop across the exhaust coil is measured

to detect the defrosting requirement or stop ongoing

defrosting. Defrosting starts when the pressure drop

exceeds a specific limit. When the pressure drop falls

below another lower limit defrosting stops.

At defrosting with recirculation, the recirculation damper

have a finishing sequence for protection against freezing.

Phases

Defrosting occurs by reversing the heat pump circuit. The

exhaust coil then works as a condenser (as with the cooling function) and heats.

Start delay

When the pressure drop across the exhaust air coil exceeds

the start limit, for a period longer than 60 seconds,

defrosting starts.

Initiation

When defrosting is detected the Initiation phase starts.

The recirculation damper then opens for recirculation, and

if there is an electric air heater this starts. For recirculation

the signal is sent with a delay of 60 seconds, if there is no

recirculation the signal is sent without a delay.

Pre-defrosting

When the defrosting process starts, a signal is sent to the

heating circuit which lowers the compressor speed and

turns the flow directions through the four-way valve.

Defrosting

The defrosting process continues through ramping up the

compressor speed and running until the control system

requests that defrosting stops or until the maximum

defrosting time has been reached.

When defrosting is completed, the outdoor air damper

and the exhaust air damper open, the recirculation

damper closes and stabilization operations are run.

In order to reduce the risk of freezing, a termination

sequence is started at the same time when the recirculation damper is opened and closed a number of times.

Electrical air heater RX/HC (accessory)

When there is a defrosting requirement, the electric air

heater is enabled immediately.

Overheating protection is installed. Post-cooling is carried out if the air handling unit stops during or just after

defrosting.

Critical defrosting

If the evaporation temperature in the heating circuit drops

below a critical limit, defrosting starts.

If the control system discovers ongoing ordinary defrosting, critical defrosting is adapted to the ordinary defrosting sequence, e.g. recirculation starts.

3.10 Limitations

For operations outside the outdoor temperature limits

and/or below air limits, the reversible heat pump function

stops and the air handling unit acts as a GOLD RX.

Outdoor temperature limit, cooling

Operation of the reversible heat pump in cooling mode

is only permitted at an outdoor temperature above 15°C

(adjustable value).

Outdoor temperature limit, heating

Operation of the reversible heat pump in heating mode

is only permitted at an outdoor temperature above -25°C

(adjustable value).

Air flow limits

Operation of the reversible heat pump is only permitted

when the extract airflow and supply airflow exceed a

minimum airflow limit. Values can be set for the extract air

and supply air.

Runoff

In the last part of the defrosting process, the compressor

speed drops and the flow directions through the four-way

valve are turned back.

Adaptive start and stop

Start and stop of the defrosting process is controlled by

calculations in the control system, which take a number

of different factors into consideration that are measured

continuously.

Adaptation is performed after each defrosting to optimise

the process.

Air recirculation section RX/HC (accessory)

When there is a defrosting requirement, the recirculation damper opens, and the outdoor air damper and the

exhaust air damper close.

Recirculation operation is ensured before defrosting starts.

We reserve the right to alter specifications.

www.swegon.com 5

Page 6

4. Wiring diagram

The following wiring diagram deals with connected components in addition to a standard air handling unit GOLD

RX. For the wiring diagram standard GOLD RX, see the

separate document.

Communication cable between connector COM4 on the air

handling unit’s IQlogic control unit and communication terminals 97, 98, 99 on the iPro cooling circuit control.

GB.FUNKRXHC.180907

1A2B3

GND4+5-6+7-8+9-

10+11-12+13

14+15-16+17-18+19

-

SA Te mpCom 5Com 4Com 3Com 2Com 1

Sensor 1 Sensor 2 Sensor 4Sensor 3 Com 6 Com 7 Com 8 Com 9 Com 10 Com 11

20C21NO22C23NO24C25NO26C27NO28P29G30G031G32

Heat Cool

-

SD

+33-34G35G036Y37U

38 39 40

24V AC In

18V AC In

41 42

WLAN

CPU 2

CPU 1

230V AC Ou t

230V AC In

45 46

G0

24V AC

4743 44

Control card

IQlogic

Communication cable between any connector

COM6-11 on the air handling unit’s

IQlogic control unit and pressure sensor.

Communication cable between connector SENSOR4

on the air handling unit’s IQlogic control unit and

temperature sensor.

Communication cable between connector SENSOR3

on the air handling unit’s IQlogic control unit and

temperature sensor.

97

98

99

-

+

GND

Control card iPro,

cooling circuit

control

Pressure sensor for pressure drop

measurement over the cooling circuit’s

exhaust air coil (function selector

switch in D position).

Temperature sensor for density correction of the airflow. The sensor is

placed between the coil and fan in the

exhaust air/supply air.

Temperature sensor for density correction of the airflow. The sensor is

placed between the coil and fan in the

exhaust air/supply air.

Electric air heater for defrosting (accessory)

Control card

IQlogic

1A2B3

GND4+5-6+7-8+9-

6 www.swegon.com

10+11-12+13

14+15-16+17-18+19

-

SA Te mpCom 5Com 4Com 3Com 2Com 1

Sensor 1 Sensor 2Sensor 4Sensor 3 Com 6 Com 7 Com 8 Com 9 Com 10 Com 11

20C21NO22C23NO24C25NO26C27NO28P29G30G031G32

-

Heat Cool

SD

+33-34G35G036Y37U

38 39 40

24V AC In

Connect from any of connectors COM1 or COM2 on the

IQLogic+module to one of the connectors on the air handling unit's IQLogic control unit marked COM6-11.

G0

24V AC

The function

selector switch

WLAN

CPU 2

CPU 1

18V AC In

230V AC In

230V AC Ou t

41 42

45 46

must be set to

position 5.

4743 44

IQlogic+-module

1234 5678 9101112

++--S - S

-+-+ -

+

IQlogic

COM POWER

D

C

E

B

F

A

0

9

1

8

P1

2

7

3

6

5

4

Com 1Heat/Cool Com 2

+17-

C13NO14C15NO

16

18

+19-

G21G0

20

22

Connect from connector HEAT/COOL on the

+

IQlogic

-module to the

RJ45 connector on the

electric air heater.

Electric air

heater

We reserve the right to alter specifications.

Page 7

GB.FUNKRXHC.180907

5. Electrical connection of the air recirculation section RX/HC (accessory)

The electrical connections are to be wired by a qualified

electrician in accordance with local electrical safety regulations.

Damper

-

actua

tor

The damper motor has a 0.9 metre long connection cable,

4 x 0.75 mm2 and is connected in the junction box, IP54.

IQlogic+

Requisite accessories

Outdoor air damper TBSA-X-xxx-xxx-x-1 or

TCSA-xxx, spring return

Exhaust air damper TBSA-X-xxx-xxx-x-1 or

TCSA-xxx spring return

Exhaust air

28

P

damper

G

30

G0

G0

Outdoor air

damper

G0

G

12

Air recirculation

damper

G0

G

1212 89

32

31

G0

G

U

Y

Function

In normal mode the recirculation damper must be fully

closed (deenergized state).

When defrosting is selected, the air recirculation damper

should be completely open (actuating time: 90 seconds).

1234 5678 9101112

-+-+ -

++--S - S

The IQlogic+ module is placed

in the electrical cabinet on the

GOLD air handling unit.

GOLD Control unit

Communication cable to the control unit of

the air handling unit, where it is connected

to one of the outlets for COM 6-11.

We reserve the right to alter specifications.

IQlogic

D

C

E

B

F

A

0

9

1

8

P1

2

7

3

6

5

4

C13NO14C15NO

16

+

COM POWER

Com 1Heat/Cool Com 2

+19-

+17-

18

The function

selector switch

must be set to

position 5.

G21G0

20

22

www.swegon.com 7

Page 8

6. Settings

For basic details on how to use the hand-held terminal,

see the Operation and Maintenance Instructions for the

GOLD Air Handling Unit.

The functions for the reversible heat pump are activated

manually under Functions/HC. This is only possible for

GOLD RX (rotary heat exchanger).

GB.FUNKRXHC.180907

HC

HC is activated by setting Position HC in On. Other possible settings are shown when HC is activated.

If any of the accessories electric air heater HC or air

recirculation section HC are fi tted, these are activated

by selecting the required accessory from the menu HC

defrosting accessory.

Set the required heating and cooling function, standard or

comfort.

Set the required values for outdoor temperature limits for

heating and cooling.

Set the required values for airfl ow limits for supply air and

extract air.

Calibration is carried out at the factory. If recalibration is

required, this can be carried out by pressing the calibration button. Remaining time is shown when calibration is

in progress. Calibration date and lowest/highest air fl ow/

pressure drop are shown when calibration is performed.

Function

Outdoor temperature limits

Air fl ow limits

Calibration

Regulation sequence for heating and cooling can be set,

see the separate Function manual installation.

8

www.swegon.com

Temperature

Regulation sequence

We reserve the right to alter specifi cations.

Loading...

Loading...